Shark SGP-3030,SGP-3530,SGP-3530E,SGP-4035E Operator's Manual

SGP

OPERATOR’S MANUAL

■ SGP-3030 ■ SGP-3530 ■ SGP-3530E ■ SGP-4035E

L

D

I

S

E

®

T

SHARK PRESSURE WASHERS ■ 4275 N.W. PACIFIC RIM BLVD. ■ CAMAS, WA 98607 ■ USA

For technical assistance or the Shark Dealer nearest you, call 1-800-771-1881.

CONTENTS

Introduction ................................................................................................................................... 4

Important Safety Instructions .................................................................................................... 4, 6

Component Identification .............................................................................................................. 5

Pre-Operation Checklist ................................................................................................................ 6

Set-Up Procedures ....................................................................................................................... 7

Operating Instructions................................................................................................................... 7

General Washing Techniques........................................................................................................ 7

Shut-Down Procedures ................................................................................................................. 7

How to Use the Detergent Injector ................................................................................................8

Preventative Maintenance ............................................................................................................. 9

Maintenance and Service ........................................................................................................ 9-11

Exploded View (All Models) ....................................................................................................12-13

Exploded View Parts List (All Models) ....................................................................................14-15

Control Panel .............................................................................................................................. 16

Hose & Spray Gun Assembly (All Models) .................................................................................. 17

Downstream Injector Assembly #4-011184 (All Models) .............................................................17

Preventative Maintenance Schedule ........................................................................................... 18

Oil Change Record ..................................................................................................................... 18

Troubleshooting ..................................................................................................................... 19-21

Warranty

3

SERIAL NUMBER:

DATE PURCHASED:

FOR SALES AND SERVICE, PLEASE CONTACT:

Shark SGP Manual • Form 97-6132 • Revised 3/02

4

SGP SERIES PRESSURE WASHER

OPERATOR’S MANUAL

INTRODUCTION

Thank you for purchasing a Shark Pressure Washer.

This manual covers the operation and maintenance of

the SGP washers. All information in this manual is based

on the latest product information available at the time of

printing.

Shark, Inc. reserves the right to make changes at any

time without incurring any obligation.

The SGP Series was designed for maximum

use of 4 hours per day, 5 days per week.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this Shark pressure washer. Warning information should be emphasized and understood. If the operator is not fluent in English, the manufacturer’s instructions and warnings shall be read to and discussed with

the operator in the operator’s native language by the purchaser/owner, making sure that the operator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

IMPORTANT SAFETY

INSTRUCTIONS

WARNING: When using this machine basic precautions should always be followed, including the following:

CAUTION

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

2. Know how to stop the machine and bleed pressures

quickly. Be thoroughly familiar with the controls.

3. Stay alert - watch what you are doing.

CAUTION: To reduce the risk of injury, read operating instructions

carefully before using.

1. Read the owner's manual thoroughly. Failure to follow instructions could cause malfunction

and result in death, serious

bodily injury and/or property

damage.

4. All installations must comply with local codes. Contact your electrician, plumber, utility company or the

selling distributor for specific details.

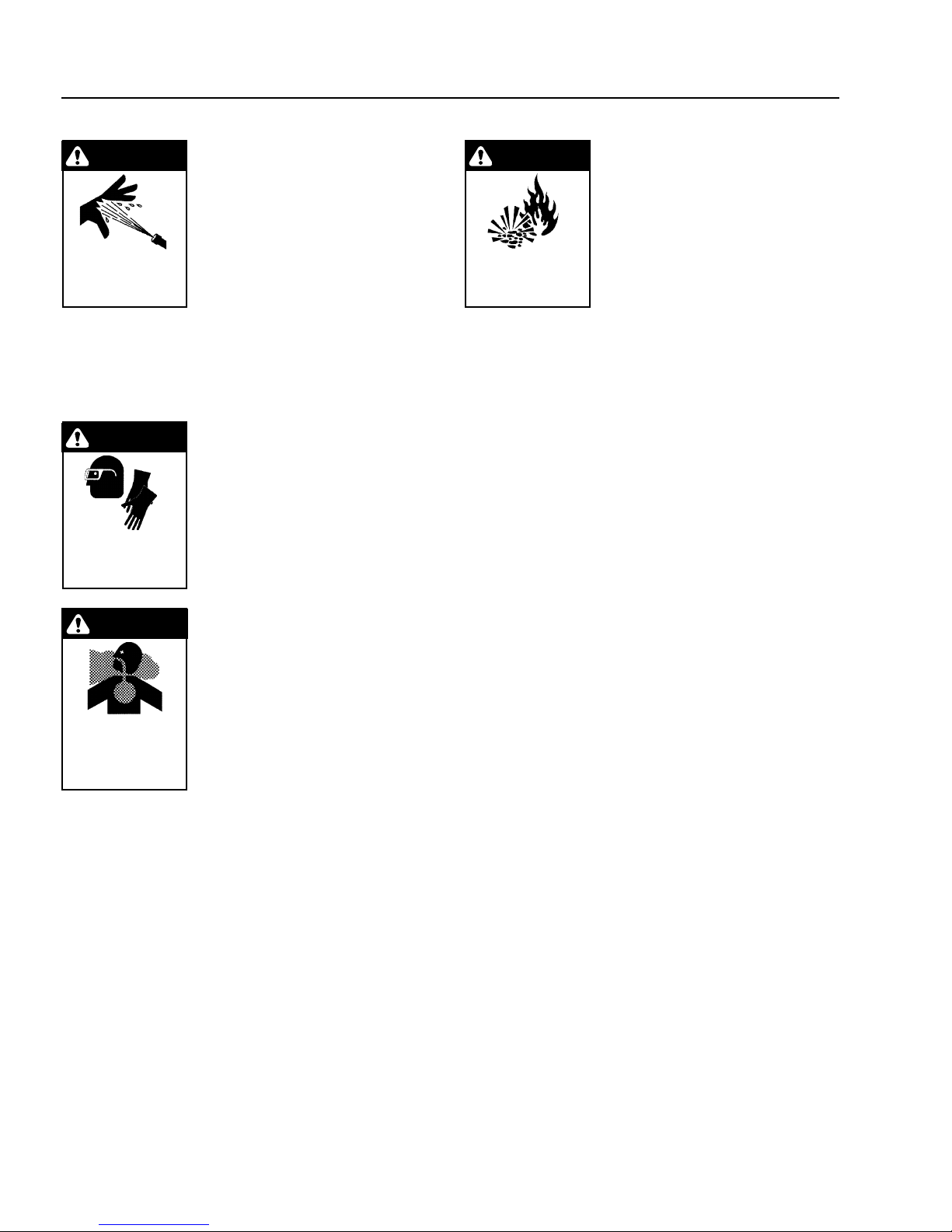

WARNING

WARNING: Flammable liquids

can create fumes which can ignite

causing property damage or severe injury.

5. Risk of explosion - do not spray

flammable liquids or operate in

RISK OF EXPLOSION:

DO NOT SPRAY

FLAMMABLE LIQUIDS.

WARNING

an explosive location. Operate

only where open flame or torch

is permitted.

WARNING: Do not place machine

near flammable objects when the

engine is hot.

WARNING: Keep water spray

away from electrical wiring or fatal electric shock may result. Read

KEEP WATER SPRAY

AWAY FRO M

ELECTRICAL WIRING.

warning tag on electrical cord.

WARNING: Spray gun kicks back.

Hold with both hands.

6. Grip cleaning wand securely with both hands before

starting the cleaner. Failure to do this could result in

injury from a whipping wand.

WARNING

WARNING: Risk of fire. Do not add

fuel when the machine is operating.

7. Allow engine to cool for 2 minutes before refueling. If any fuel

is spilled, make sure area is dry

RISK OF EXPLOSION:

USE CAUTION WHEN

REFUELLING.

Gasoline engines on mobile or portable equipment

shall be refueled:

a. Outdoors;

b. With the engine on the equipment stopped;

c. With no source of ignition within 10 feet of the

dispensing point;

d. With an allowance made for expansion of the fuel

should the equipment be exposed to a higher ambient temperature.

In an overfilling situation, additional precautions are

necessary to ensure that the situation is handled in

a safe manner.

before testing spark plug or

starting the engine. (Fire and/

or explosion may occur if this

is not done.)

SGP SERIES PRESSURE WASHER

COMPONENT IDENTIFICATION

OPERATOR’S MANUAL

5

Discharge

Nipple

Detergent

Injector

Collar

Quick

Coupler

Gasoline

Tank

Pressure

Switch

Unloader

Water Supply

Hose

(not included)

Battery Box

Swivel

Connector

High Pressure

Hose

Spray

Gun

Trigger

Control Wand

Handle

Variable Pressure

Control wand

Wand Coupler

Nozzle Quick

Coupler

Brass

Soap

Nozzle

6

SGP SERIES PRESSURE WASHER

OPERATOR’S MANUAL

WARNING

WARNING: Risk of injection or severe injury to persons - Keep clear

of nozzle - Do not touch or direct

discharge stream at persons. This

machine is to be used only by

HIGH PRESSURE

STREAM CAN

PIERCE SKIN AND

TISSUES.

trained operators.

CAUTION: Hot discharge fluid. Do

not touch or direct discharge

stream at persons.

8. High pressure developed by these machines can

cause personal injury or equipment damage. Use

caution when operating. Do not direct discharge

stream at people, or severe injury and/ or death may

result.

WARNING

WARNING: High pressure can

cause paint chips or other particles to become airborne and fly

at high speeds.

9. Eye safety devices and foot protection must be worn when us-

USE PROTECTIVE

EYEWEAR WHEN

OPERATING.

ing this equipment.

10. Never make adjustments on

machine while in operation.

WARNING

WARNING: Use only in well ventilated areas. Failure to observe

this warning could cause a loss

of consciousness or death.

11. Avoid installing in small areas

RISK OF

ASPHYXIATION.

USE THIS PRODUCT

ONLY IN A WELL

VENTILATED AREA.

or near exhaust fans. Exhaust

contains poisonous carbon

monoxide gas; exposure may

cause loss of consciousness

and may lead to death. It also

contains chemicals known, in certain quantities, to

cause cancer, birth defects or other reproductive

harm.

12. Do not operate with the spray gun in the off position

for extensive periods of time as this may cause damage to the pump.

13. The best insurance against an accident is precaution and knowledge of the machine.

14. Shark will not be liable for any changes made to our

standard machines, or any components not purchased from Shark.

15. Read engine safety instructions provided.

16. Never run pump dry or leave spray gun closed longer

than 5 minutes.

17. Inlet water must be from a cold, clean fresh city water supply.

WARNING

WARNING: Only use recommended fuel. Using other fuels

may result in a serious explosion

causing personal injury, property

damage or loss of life.

18. Use No. 1 or No. 2 heating oil

RISK OF FIRE OR

EXPLOSION: USE

VAPOR FUEL ONLY.

(ASTM D306) only. NEVER use

gasoline in your fuel oil tank.

Gasoline is more combustible

than fuel oil and could result in a serious explosion.

NEVER use crankcase or waste oil in your burner

assembly. Fuel unit malfunction could result from contamination.

19. Do not confuse gasoline and fuel oil tanks. Keep

proper fuel in proper tank.

20. Protect machine from freezing.

21. Be certain all quick coupler fittings are secured before using pressure washer.

22. Do not allow acids, caustic or abrasive fluids to pass

through the pump.

23. To reduce the risk of injury, close supervision is necessary when a product is used near children. Do not

allow children to operate the pressure washer. This

machine must be attended during operation.

24. Do not operate this product when fatigued or under

the influence of alcohol or drugs. Keep operating area

clear of all persons.

25. Protect high pressure hose from vehicle traffic and

sharp objects.

26. Before disconnecting high pressure hose from water outlet, turn burner off and pull the trigger on the

spray gun allowing water to cool to below 100° F

before stopping machine. Then open the spray gun

to relieve pressure. Failure to properly cool down or

maintain the heating coil may result in a steam explosion.

27. Do not overreach or stand on unstable support. Keep

good footing and balance at all times.

28. This machine must be attended during operation.

29.

CAUTION: Risk of injury. Disconnect battery

ground terminal before servicing.

PRE-OPERATION CHECK

❑ Pump oil (SAE 30W non-detergent oil)

❑ Cold water supply (6 gpm • 5/8" • 20 psi)

❑ Hose, wand, nozzle (nozzle size per serial plate)

❑ Water filter (intact, nonrestrictive)

❑ Engine fuel (unleaded 86 or higher)

❑ Engine oil (SAE 10W40)

❑ Burner fuel (No. 1 home heating fuel or diesel)

SGP SERIES PRESSURE WASHER

OPERATOR’S MANUAL

7

SET-UP PROCEDURES

This machine is intended for outdoor use only.

Machine must be stored indoors when not in use.

1. Attach a 5/8" water supply hose to inlet connector.

Minimum flow should be 5 gpm.

2. Attach high pressure hose to discharge nipple using

quick coupler. Lock coupler securely into place by

pulling back coupler collar and inserting it onto discharge nipple and then pushing collar forward to lock

in place.

3. Attach variable pressure control wand to spray gun

using teflon tape on threads to prevent leakage.

4. Attach swivel connector on high pressure hose to

spray gun using teflon tape on threads.

5. Check oil level on sight glass on side of pump. Oil

should be visible one-half way up sight glass (SAE

30W non-detergent). The oil level can also be

checked by using the dipstick on the top of the pump.

6. Fill gasoline tank and check engine oil.

7. Fill fuel tank. Do not confuse gasoline and fuel oil

(diesel) tanks. Keep proper fuel in proper tanks.

8. Install proper battery making sure that the red cable

is attached to the positive terminal. Use only a group

24 marine type deep cell battery with a 90 amp hour

rating (battery not included). This is for electric start

models only.

9. These machines are intended to be protected from

outside environments.

switch to return to the ON position. If the engine is to

be started without the battery, turn switch to start

position and pull rope to start. Turn off choke.

CAUTION: Small engines may kick back. Do not hold

pull rope tightly in hand.

5. With spray nozzle pointed away from you or anyone

else, press trigger on spray gun to obtain pressurized cold water spray.

6. For hot water, turn the burner switch ON when a

steady stream of water flows out of the spray gun.

Burner will light automatically.

NOTE: Do not start machine with burner switch on.

7. To apply detergent, see “How to Use the Detergent

Injector” (page 8).

GENERAL WASHING

TECHNIQUES

1. Hold spray nozzle approximately one foot from the

surface being cleaned. Spray at an angle to get under the material being removed.

2. When washing large objects, use detergent injector to

apply detergent. Start washing from the bottom and

work up. Better detergent economy and faster results

will be obtained by allowing the detergent to set 5 - 10

minutes. After washing, rinse from the top down.

3. Cleaning heavy dirt or material away with a hard

stream of clear water is recommended before using

a cleaning agent.

OPERATING INSTRUCTIONS

(See Component Identification on page 5.)

1. STOP! Read operator’s manual before operating this

machine. Failure to read operation and warning instructions may result in personal injury or property

damage.

2. Turn on water at faucet and pull trigger on spray gun

allowing water to flow until all air has discharged from

system. Check for water leaks; tighten as needed.

3. Pull wand coupler collar back and insert desired pressure nozzle into coupler then secure by pushing collar forward.

NOTE: Variable pressure control wand handle must

be turned clockwise to enable water to flow out of

the high pressure nozzle.

4. Read engine manual, turn on gas valve and choke.

Turn the engine switch to the START position and

hold it there until the engine starts. NOTE: Do not

use the electric starter for more than five seconds at

a time. If the engine fails to start, release the switch

and wait ten seconds before operating the starter

again. When the engine starts, allow the engine

SHUT DOWN PROCEDURES

1. Rinse all lines (and injector) with clean water to remove any soap residue.

2. Turn burner switch off and continue spraying, allowing the water to cool below 100° F.

3. Turn engine off.

4. Turn off water supply.

5. Open spray gun to relieve remaining pressure.

6. Remove water supply hose.

7. In freezing conditions, disconnect water supply and

open spray gun to allow water to drain. Then turn off

the engine. See winterizing procedure under Maintenance and Service.

CAUTION: Do not allow pump to run longer than 5

minutes without water. Disconnect all hoses to allow water to drain.

CAUTION: With the machine off, open spray gun to

release pressure before removing discharge hose.

CAUTION: Burner switch must be turned off when

the engine is off or damage to the battery and the

12V DC burner will result.

8

SGP SERIES PRESSURE WASHER

OPERATOR’S MANUAL

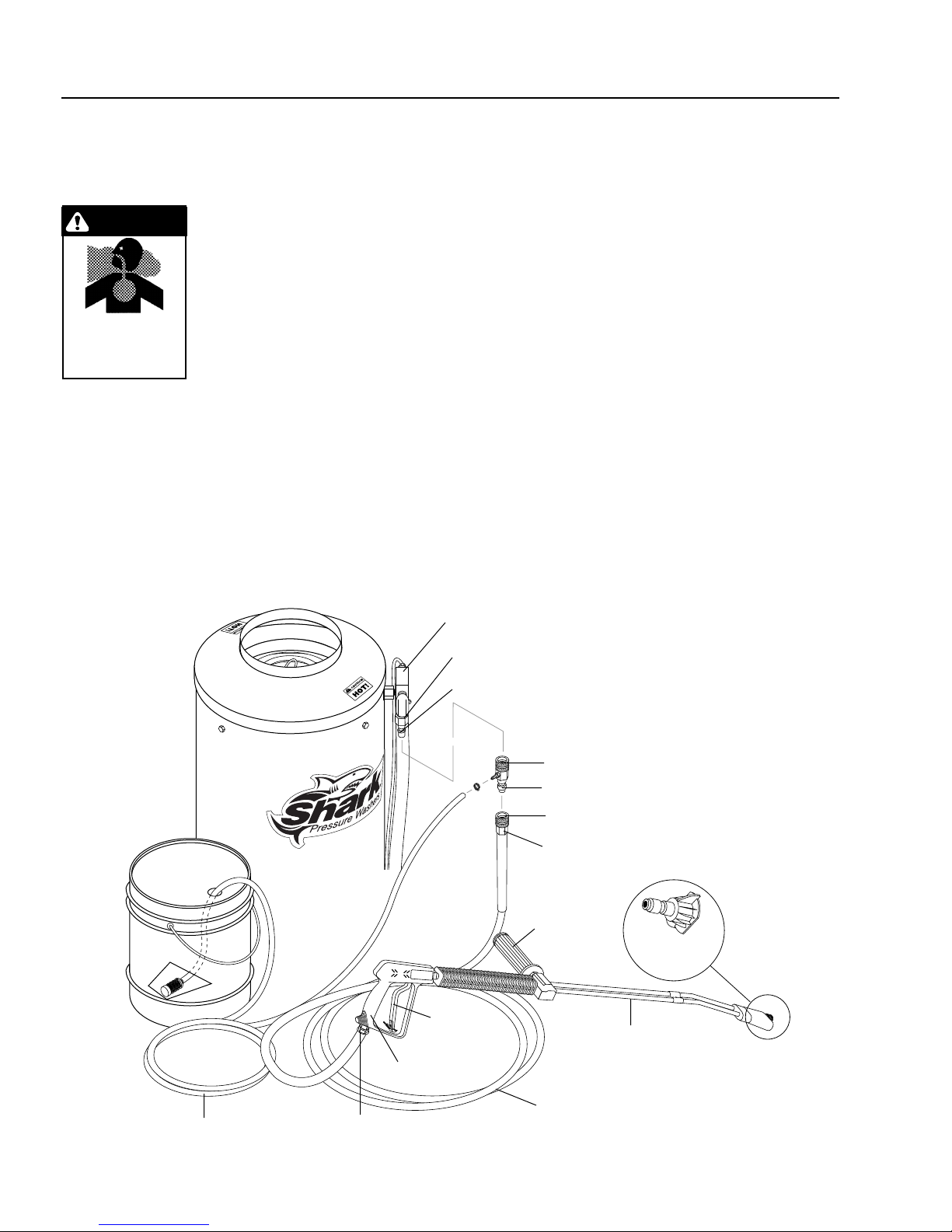

HOW TO USE THE

DETERGENT INJECTOR

WARNING

SOME DETERGENTS

MAY BE HARMFUL IF

INHALED OR

INGESTED.

1. Pull injector quick coupler collar back and secure on

discharge nipple. Injector valve body arrow should

point in direction of flow.

2. Connect high pressure hose to injector nipple securing quick coupler.

3. Start machine as outlined in Operating Instructions.

WARNING: Some detergents may

be harmful if inhaled or ingested

causing severe nausea, fainting

or poisoning. The harmful elements may cause property damage or severe injury.

The machine can siphon and mix detergents with the use of Shark's detergent injector kit.

4. Place detergent pick-up tube into container of detergent solution.

5. Turn pressure control handle counterclockwise on

the variable pressure wand. This lowers the pressure by directing the water flow through the soap

nozzle and allows the detergent injector to siphon

soap.

6. Open trigger spray gun. Water detergent ratio is approximately 15 to 1.

7. When you finish washing, rinse by simply turning

the variable pressure wand control handle clockwise

to increase pressure.

NOTE: The detergent injector will not siphon with

water flowing through the high pressure nozzle at

the end of the wand.

8. For clean up, place detergent pick-up tube into container of clear water and follow steps 5 and 8 to prevent detergent deposits from damaging the injector.

Spray Gun

Adjustable

Thermostat

Rupture Disk

Discharge Nipple

Trigger

Detergent Injector

Injector Discharge Nipple

Collar

Quick

Coupler

Variable

Pressure

Control

Handle

Variable Pressure

Brass Soap

Nozzle

Wand (VP)

Detergent

Pickup Tube

Nozzle Quick

Coupler

High Pressure

Hose

Loading...

Loading...