Page 1

SC

AUTOMATIC PARTS

WASHER

■ SC-2412A ■ SC-2412D

For technical assistance or the SHARK dealer nearest you, call 1-800-771-1881

or visit our website at www.shark-pw .com

97-6267

Page 2

Page 3

SECTION 1

Introduction and Safety

Using This Manual 5

General Safety Inf ormation 5

Component Identification 6-7

SECTION 2

Installation

Before you Begin 8

Step 1: Mak e Electrical Connections 8

Step 2: Connect a Compressed-Air Line and Accessories 8

Step 3: Connect a Water Line 8

Step 4: Fill the Machine with Water and Add Detergent 9

SECTION 3

Operation

CONTENTS

Main Operating Components 10

Control Panel 10

Thermostat 11

24-hour, 7-da y Heater Timer 11

Lid Safety Switch 11

Turntable Assembly 11

Debris Screen 12

Air Flow Valv e (Delux e Edition only) 12

Po wer Brush (Delux e Edition only) 12

Detail Brush and Flow Regulator (Deluxe Edition only) 12

Dual Oil Separator (DOS) System 13

Low W ater Shut-off System 13

Automatic W ater Fill 13

Detergents and Additives 14

Detergent 15

Rust Inhibitor Additive 16

Preparing the Machine for Use 17

3

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 4

CONTENTS

Washing P arts 19

Shutting Down the Machine 19

SECTION 4

Troubleshooting

Overview 20

Troubleshooting the Electrical System 20

T esting Individual Components 20

SECTION 5

Maintenance and Repair

Maintaining the Machine 21

Daily Maintenance 21

Weekly Maintenance 21

Monthly Maintenance 21

Using the DOS System 21

Cleaning and Aligning the Spray Nozzles 22

Cleaning out the Sump 22

Repairing the Machine 23

Heating Element 23

Thermostat 23

Timers and Switches on the Control Panel 23

T orque Limiter 23

T urntable Motor 24

WARRANTY

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal attached to

the parts washer. You should record both serial number and date of

purchase and keep in a safe place f or future ref erence .

4

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 5

WARNING

WARNING

WARNING

Section 1: Introduction

AUTOMATIC PARTS WASHER

This manual is intended as a guide for saf ely installing,

operating and maintaining your Automatic P arts Washer .

We reserve the right to make changes at any time without incurring any obligation.

Owner/User Responsibility:

The owner and/or user must hav e an understanding of

the manufacturer’ s operating instructions and warnings

before using this machine. Warning information should

be emphasized and understood. If the operator is not

fluent in English, the manufacturer’s instr uctions and

warnings shall be read to and discussed with the operator in the operator’s native language by the purchaser/owner, making sure that the operator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number .

GENERAL SAFETY

INFORMATION

WARNING

READ OPERATOR’S

MANUAL

THOROUGHLY

PRIOR TO USE.

2. Improper installation could cause serious injury to

the machine. All installations must comply with local codes. Contact your electrician, plumber, utility

company or the selling distributor for specific details.

3. The machine can only operate on the type of electrical power indicated on the electrical specifications

tag. Oper ating the machine on any other power supply will permanently damage the motors.

CAUTION: To reduce the risk of

injury, read operating instructions carefully before using.

1. Read the owner's manual thoroughly. Failure to follow instructions could cause a malfunction of the evaporator and

result in death, serious bodily

injury and/or property damage.

WARNING: Electrical shock

could cause serious injury or

death.

4. Install the machine in compliance with the National Electric

Code, connect it to a properly

KEEP WA TER SPRAY

AWAY FROM

ELECTRICAL WIRING.

sized lockable disconnect and

ground the machine using the

grounding stud inside the main

electrical panel.

5. While operating the machine, keep all electrical panels in place and securely fastened at all times.

6. Disconnect the machine completely from the outside power source before servicing.

WARNING: Hot, high pressure

cleaning solution could cause

serious injury .

7. Do not operate the machine

with the lid or door open and

do not override the safety

HIGH PRESSURE

SPRAY CAN PIERCE

SKIN AND TISSUES.

switch.

8. After the machine stops, wait

10 seconds before opening the

lid or door.

WARNING: Always wear approved eye protection and protective clothing while operating

machine.

9. Always wear rubber gloves

PROTECTIVE

EYEWEAR AND

CLOTHING MUST

BE WORN.

when loading and unloading

the machine or servicing components in the processing

chambers or sumps.

WARNING: Slips and falls could cause serious injury.

10. Maintain an unobstructed work area around the machine and keep the floor free of water , oil, grease or

other foreign substances.

This Automatic Parts Washer is designed to operate

safely and efficiently with a minimum of required maintenance. Before you begin to install and use the machine, please familiarize yourself with the major components.

OPERATOR’S MANUAL

5

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 6

AUTOMATIC PARTS WASHER

COMPONENT IDENTIFICATION

FRONT

Lid Handle

Control Panel

Optional Power

Brush

OPERATOR’S MANUAL

Sump Drain

Optional Air Flow

Valve w/Flow

Regulator

Optional Detail

Brush Pump

Power Cord

REAR

Lid Handle

Lid Support Strut

Low Water Shut-Off

System

Optional Automatic

Water Fill Assembly

6

DOS System™ w/

Optional Oil

Collection Container

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 7

COMPONENT IDENTIFICATION

AUTOMATIC PARTS WASHER

Spray Pipes

and Nozzles

Turntable Drive Arm

OPERATOR’S MANUAL

Turntable Assembly w/

Optional Removable

Containment Ring

Optional Detail

Brush

7

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 8

Section 2: Installation

BEFORE YOU BEGIN

To prepare to install the machine, choose an unobstructed, level site that allows convenient access for

operators and maintenance personnel. Sources for

water and electrical power should be located near the

installation site. If your machine is equipped with the

optional power brush and hand detail brush you must

also run a compressed air line to the installation site.

If you have any questions regarding the installation,

please contact your distributor or call a customer service representative. When contacting customer service

please refer to the machine identification tag inside the

AUTOMATIC PARTS WASHER

front cover of this manual for detailed machine specifications.

STEP 1: MAKE ELECTRICAL

CONNECTIONS

These machines are shipped with a factory-installed

power cord. To connect the machine to a power supply ,

plug the cord into a grounded outlet on a single-outlet

circuit. It is important that you connect the machine to

OPERATOR’S MANUAL

a single-outlet circuit to avoid possib le damage resulting from inadequate supply amperage.

STEP 2: CONNECT A

COMPRESSED-AIR LINE AND

ACCESSORIES

This step is required for machines equipped with the

optional power brush and hand detail brush.

If your machine does not have these options, skip the

following procedure.

Note: To ensure proper operation and to minimize the

possibility of premature component failure, make sure

the compressed air is supplied at 75 to 90 psi. W e also

recommend an in-line moisture trap and an in-line lubricator on the main air supply line. Refer to the documentation provided with the power brush for more information.

Step 1:

Remove the pow er brush from the bo x, install the wire

brush in the chuck, and connect the air hose.

Step 2:

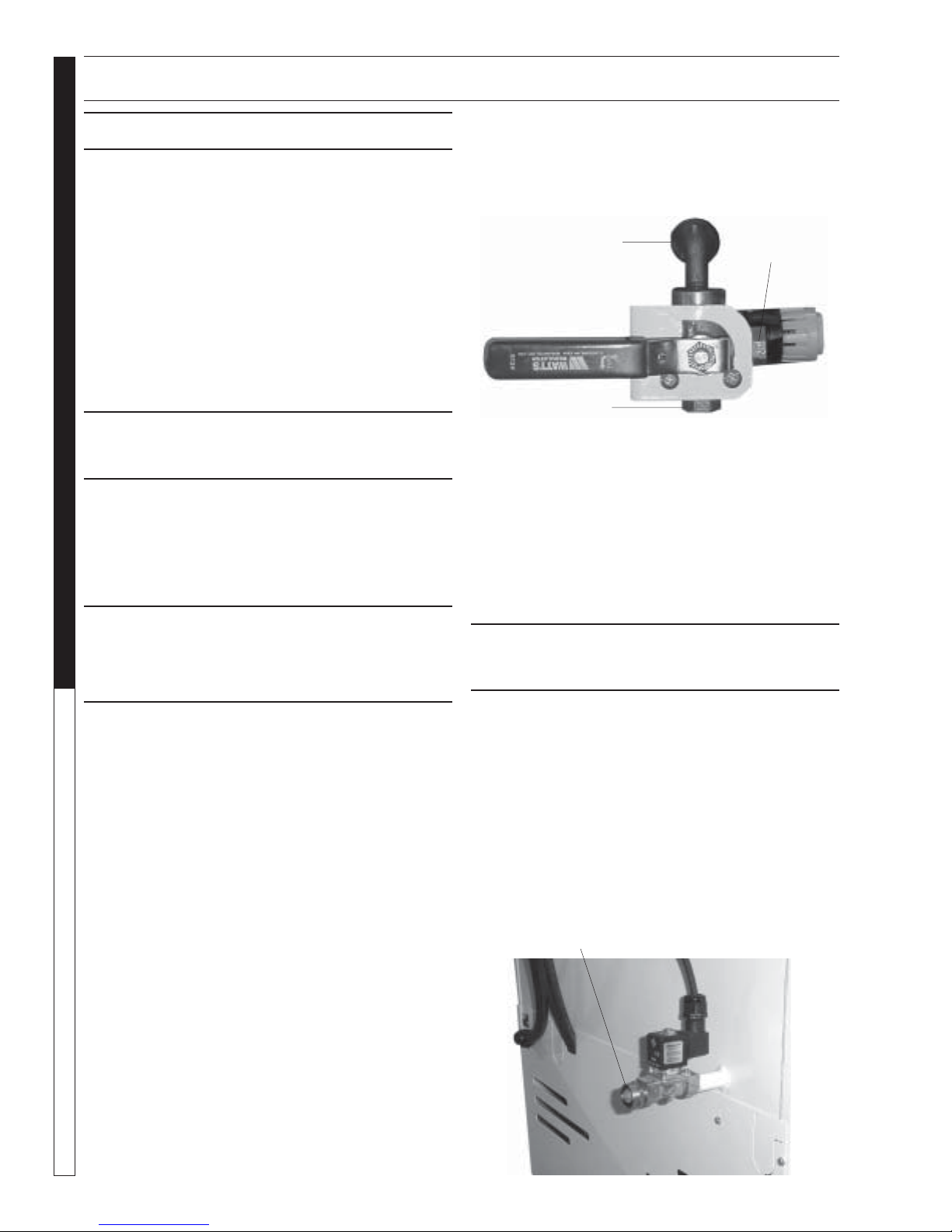

Familiarize yourself with the three-way air flow valve

(See Figure Below), then install a fitting (if necessary)

to accommodate a connection to your compressed-air

supply.

Line to Detail

Brush Pump

Power Brush

Connection

Step 3:

Connect the shop compressed-air line to the machine.

Step 4:

Connect the hose from the power brush to the air flow

valve.

Step 5:

Hang the power brush on the bracket mounted along

the right side of the machine.

Compressed Air

Connection

STEP 3: CONNECT A WATER

LINE

This step is required for machines equipped with the

optional automatic water fill feature. If your machine does

not have this option, skip this step .

The optional automatic water fill feature automatically

maintains the correct water lev el in the sump. The f eature requires that you connect the machine to a dedicated water supply line.

T o connect the machine to a w ater supply line, attach a

suitable burst-proof hose to the hose connection on the

rear of the machine (See Figure Below), then connect

the hose to a nearby water spigot.

Hose Connection

8

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 9

Section 2: Installation

AUTOMATIC PARTS WASHER

Note: The machine is designed for portability, and some

maintenance tasks require that you mov e the machine.

DO NOT make a permanent connection from your shop

water supply to the machine.

STEP 4: FILL THE MACHINE

WITH WATER AND ADD

DETERGENT

Step 1:

Familiarize y ourself with the lo w water shut-off system

on the left side of the machine (See Figures Below).

Target Aligned w/

Lower Switch

Target Aligned w/

Upper Switch

Step 3:

Close the lid.

Step 4:

Flip the heater switch to the ON position.

The sump water will reach operating temperature (160°-

180°F) in approximately f our hours.

To avoid having to wait f or the wash solution to heat up

before you use the machine each day, install an optional 24-hour 7-day heater timer. Refer to 24-hour, 7day Heater Timer” for more information.

IMPORTANT: Allow the sump water to reach operating

temperature before adding detergent and running the

machine. If y ou add detergent and run the machine when

the sump water is cool, the detergent will foam excessively and could ov erflow the machine .

Step 5:

Add appropriate amount of detergent

ber. To ensure that the detergent dissolves properly,

spread it evenly throughout the w ash chamber.

Note: The manufacturers detergents are the only de-

tergents approved for use with this automatic parts

washer. They are specially formulated with rust inhibitors and anti-foaming agents to optimize performance

and minimize maintenance. The use of an y other detergent during the warranty period will void the warranty.

Step 6:

Turn the wash cycle timer and allow the machine to

complete the cycle to dissolve the detergent into the

water . When the machine stops, it is ready f or use . Refer to

Section 3: Operation

structions.

for complete operating in-

to the wash cham-

OPERATOR’S MANUAL

Step 2:

Fill the sump with water .

If your machine is equipped with the optional automatic

water fill feature, simply turn the water on; the automatic

water fill feature will automatically turn off the water when

the sump is full.

If your machine is not equipped with optional automatic

water fill feature, add w ater through the wash chamber

until the low water shut-off system indicates that the

sump is full. The sump capacity is 25 gallons.

SHARK SC-2412 • 97-6267 • REV. 3/04

9

Page 10

Section 3: Operation

MAIN OPERATING

COMPONENTS

Familiarize yourself with the main oper ating components

before operating the machine.

CONTROL PANEL

The control panel is located on the front center of the

lid. It contains the heater, wash cycle, turntable controls, and low water indicator (See Figure Below).

AUTOMATIC PARTS WASHER

OPERATOR’S MANUAL

Low Water

Indicator

Low Water

Indicator

Wash Cycle

Timer w/Knob

Heater Switch

Wash Cycle Control

The wash cycle control is a timer switch. When set, the

timer automatically shuts off the pump and turntable

when the wash cycle is complete.

Thermostat

The thermostat is located inside pump enclosure. The

thermostat is factory-set to heat the wash solution to a

maximum temperature of 180 °F.

Adjusting the Thermostat

To adjust the thermostat, rotate the adjustment screw

or knob clockwise to increase the temperature, or counterclockwise to decrease the temperature (See Figure

Below).

Decrease

Temperature

Increase

Temperature

Low Water Indicator

The low water indicator light illuminates if the wash solution in the sump is low. For more information refer to

Low W ater Shut-off System

.

Turntable Switch

The turntable switch is an illuminated rocker s witch that

enables you to disconnect pow er to the turntable motor.

Set to ON, the turntable rotates during the wash cycle.

Set to OFF, the turntable does not rotate during the wash

cycle. The switch is useful for washing large parts that

would otherwise impede turntable rotation.

Heater Control

The heater control is an illuminated rocker switch. It

controls the heating element in the sump chamber. The

heater control illuminates when the heating system is

on. The heating system is ther mostatically set at the

factory to reach a high temperature of 180 °F. The temperature is adjustable using the thermostat (See

mostat

).

Note: The machines contain an internal power relay that

automatically disconnects power to the heater when the

pump turns on; the heater and pump cannot run simultaneously (120V only). After long w ash cycles it may be

necessary to let the machine sit idle for a period of time

to allow the wash solution to reheat to operating temperature.

Ther-

Adjustment

Screw

24-hour, 7-day Heater Timer

A 24-hour, 7-da y heater timer is a vailable as an option

on these machines. The timer plugs directly into a 15amp outlet and automatically cycles the heating system on and off each day. To configure the timer, ref er to

the instructions printed on the back of the timer housing.

To order a 24-hour, 7-day heater timer, contact your

distributor or call customer service.

Lid Safety Switch

10

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 11

Section 3: Operation

AUTOMATIC PARTS WASHER

The lid safety s witch is located behind the front left lip of

the lid, just below the control panel (See Figure Below).

The safety switch disconnects po wer to the water pump

and the turntable motor if the lid is raised during operation.

Lid Safety Switch

Turntable Assembly

The turntable assembly uses a torque arm mounted on

the underside of the lid to rotate the turntable (See Figure Below). The torque arm includes a torque limiter

which prevents the turntable motor from b urning out in

case a part falls off the turntable and obstructs rotation.

For information on adjusting the torque limiter, refer to

Torque Limiter

table motor , refer to

. For information on replacing the turn-

Turntable Motor

Torque Limiter

.

Removing the Turntable

To remove the turntable, grasp it evenly on opposite

sides and lift it free of the spindle.

Important: The turntable rotates on a thrust bearing

inside of the hub. As you lift the turntable free of the

spindle, take care not to jar the thrust bearing loose. If

the thrust bearing drops out of the hub, inspect it for

wear then either replace it or re-install it (See Previous

Figure).

Debris Screen

The debris screen is located below the turntable inside

of the wash chamber (See Figure Below). The debris

screen continuously filters debris particles from the

cleaning solution to ensure blockage free spra y nozzle

operation, and also provides a safeguard against small

parts that might accidentally be washed through from

the wash chamber .

The frequency at which you must clean the debris

screen depends on machine usage. In general, you

should clean the screen before operating the machine

each day. To access and remove the screen you must

remove the turntable (see

Note: Never operate the machine without the debris

screen in place. The screen is specially sized to filter

particles that could clog the spray nozzles or damage

the water pump. Operating the machine without the

debris screen in place could cause spray nozzle clogging or water pump failure.

Removing the Turntable

).

OPERATOR’S MANUAL

Torque Arm

Turntable

Thrust Bearing

Air Flow Valve (

Deluxe Edition

only)

The air flow valve is located on the right rear corner of

the machine. It is a three-way ball valve that controls

the flow of compressed air to the power brush and the

hand detail brush (See Figure Below).

Detail Brush

Power Brush

Detail Brush

Pump

Air In

Power Brush

11

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 12

Section 3: Operation

Power Brush (

Deluxe Edition only

)

The power brush is located on the right front corner of

the machine (See Figure Below). Refer to

nect a Compressed-Air Line and Accessories

Step 2: Con-

for de-

tailed installation information.

Throttle

Lever

AUTOMATIC PARTS WASHER

Throttle

Note: The power brush is available as an option on this

machine. For ordering information, contact your distributor or call customer service.

Using the Power Brush

Warning: P articles dislodged by the power brush could

OPERATOR’S MANUAL

cause serious injury to your eyes. Always wear appro ved

eye protection when using the pow er brush.

With stiff stainless steel bristles turning at 1800 RPM,

the power brush easily removes carbon deposits, old

gasket material, or other tightly-adhered materials from

parts before washing.

To turn on the power brush, position the air flow select

valve appropriately, then push the power brush lever

lock forward with your thumb and squeeze the throttle

lever to control the speed of the brush.

Detail Brush and Flow Regulator (

Edition only

The detail brush is located on the front inside wall of the

wash chamber . The flow regulator is located on the right

rear corner of the machine (See Following Figure). The

detail brush uses a continuous flow of hot cleaning solution through its nylon bristles to help you clean delicate or lightly soiled parts. The flow regulator controls

the flow of cleaning solution through the detail brush.

Warning: Hot, high-pressured cleaning solution could

cause serious injury. Always wear rubber gloves and

approved eye protection when handling hot cleaning

solution.

Lever Lock

Deluxe

)

Adjusting the Flow of Cleaning Solution

The flow of cleaning solution through the detail brush is

pre-set at the factory . If you need to adjust the flo w , pull

out the flow regulator knob, then rotate it clockwise to

decrease the flow or counter-clockwise to increase the

flow . After adjusting, push the knob back in to lock it.

Flow Regulator,

Behind

Machine

Detail Brush

Note: The detail brush is available as an option on this

machine. For ordering information, contact your distributor or call customer service.

Dual Oil Separator (DOS) System

The DOS System™ is located on the lower left side of

the machine (See Figure Below). It is made up of an oil

decant valve, a removable oil collection container, and

a water decant valve . The DOS System removes oil from

the cleaning solution to prolong its useful life. Refer to

Using the DOS System

tions.

for detailed operating instruc-

Oil Decant Valve

Optional Oil

Collection

Container

12

Water Decant

Valve

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 13

Section 3: Operation

AUTOMATIC PARTS WASHER

Low Water Shut-off System

The low water shut-off system shuts down the machine

if the wash solution in the sump chamber drops below a

safe lev el. The system uses two pro ximity switches and

a float rod mounted on the right outer wall of the sump

chamber to control the water lev el (See Figure Below).

Target Aligned w/

Lower Switch

Target Aligned w/

Upper Switch

If the wash solution drops below the lower proximity

switch, the low water indicator light on the control panel

turns on and the system disconnects power to the heating element, the pump, and the turntable motor. T o reset the system, add water to the sump until the low water

indicator light turns off.

WATER LEVEL OK:

Both switches OPEN, Automatic

Water Fill Valve (if installed) CLOSED,

Heating Element ON.

CLOSED, Automatic Water Fill Valve (if

installed) OPEN, Heating Element OFF.

LOW W ATER LEVEL:

Top switch CLOSED, Bottom Switch

Automatic W ater Fill

The automatic water fill system automatically maintains

a proper water level in the sump. It is available as on

option on these machines.

The automatic water fill system uses the low water shutoff proximity switches to open and close a water solenoid valve, which automatically maintains a proper water level in the sump. The figure below describes the

operation of the automatic water fill system.

DETERGENTS AND

ADDITIVES

Detergent

Factory approved detergents are the only detergents

approved f or use with the manufacturers automatic parts

washers. They are specially formulated with rust inhibitors and anti-foaming agents to optimize performance

and minimize maintenance. The use of an y other detergent during the warranty period will void the warranty.

T o monitor the relativ e concentration of the detergent in

the wash solution, periodically examine the wash solution in the sump chamber for the follo wing indicators:

• Rust inside the machine: not enough detergent

• Excessive foaming: not enough detergent

• Thick, white residue on parts after washing:

too much detergent

Note: To maintain proper detergent concentration under normal operating conditions follow factory directions.

SUMP FILLING:

Top switch CLOSED, Bottom Switch

OPEN, Automatic Water Fill Valve (if

installed) OPEN, Heating Element OFF.

OPERATOR’S MANUAL

13

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 14

Section 3: Operation

Rust Inhibitor Additive

Factory detergents protects the entire inside of your machine against the degenerative effects of w ater e v aporation. It actually evaporates with the water and continuously coats and protects metal surfaces, e ven while

your machine is sitting idle. F or more inf ormation, contact your distributor or call customer service.

PREP ARING THE MACHINE

FOR USE

Before you begin to wash parts, it is important that you

properly prepare the machine. Bef ore y ou begin to use

AUTOMATIC PARTS WASHER

the machine each day:

• check the water level and add water to the sump

tank if necessary;

• heat the water to operating temperature

• add detergent if necessary (see “Detergents and

Additives”);

• verify that none of the spray nozzles are clogged;

and

• clean the debris screen.

OPERATOR’S MANUAL

WASHING PARTS

The following procedure assumes that the heater is on

and the sump water is at operating temperature.

To wash parts, perform the following procedure.

Warning: Hot, high-pressured cleaning solution could

cause serious injury. Always wear rubber gloves and

approved eye protection when loading and unloading

the machine.

Step 1:

Load large, heavy parts directly onto the turntable. Load

small, light parts in the optional small par ts basket, if

available. Make sure none of the parts extend beyond

the edge of the turntable and make sure large, light parts

(valve cov ers, for e xample) are secured to the turntable.

Note: For optimum cleaning performance, provide a

slight clearance between parts to allow adequate flow

of cleaning solution around and between them.

Step 2:

Close the lid.

Note: If you are washing large parts that might impede

turntable rotation, flip the turntable switch OFF.

Step 3:

Set the wash cycle timer.

Step 4:

When the machine stops, lift the lid and wait a fe w moments to allow the parts to cool and dry before removing them. Most parts flash-dry in seconds.

SHUTTING DO WN THE

MA CHINE

To shut down the machine at the end of the day:

• set the wash cycle control to OFF;

• set the heater control to ON to enable automatic

turn-on the following day;

• shut off the compressed air at the supply line (if

installed).

WARNING

• For periods of extended shut-down (w eekends and

holidays, f or example), disconnect power to the machine.

• If your machine is equipped with an optional pro-

grammable heater timer , periodically verify the settings to prevent inadv ertent unattended operation.

14

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 15

Section 4: Troubleshooting

MELBORPESUACELBISSOPNOITULOS

AUTOMATIC PARTS WASHER Troubleshooting Guide

GNINAELCROOP

ECNAMROFREP

rehto

detaeh

ylreporp

NOITULOSHSAW

GNITAEHTON

esufnwolBotrefeR

sihctiwselbatnruT FFO sihctiwselbatnrutehttahtyfireV NO eeS( elbatnruT

hctiwS .)

hcaegnitcurtsboerastraP

.meht

pmusnilevelretawwoL .yrassecenfiretawdda;levelretawpmuskcehC

ylreporpmirodeggolC

selzzonyarpsdengila

noitartnecnoctnegretedwoL gninaelcevresbodnatnegretedfospoocs2-1ddA

ylreporptonsinoituloshsaW

gnitarepotonsipmuP

pmusnilevelretawwoL firetawdda;pmusehtnilevelretawehtkcehC

tesyltcerrocnisitatsomrehTeeS(°081ottes;gnittestatsomrehtkcehC gnitsujdA

eeS

eeS

eeS(yrassecen ffO-tuhSretaWwoL .)

tatsomrehTeht .)

selzzoNyarpSehtgningilA .)

eeS(yrassecenfingiladnanaelc dnagninaelC

gnitaehtonsinoituloshsaw

.

ylreporpetarepotonseodpmup

.

strapnoitisop;elbatnrutnostrapfonoitisopehtkcehC

neewtebdnadnuoranoitulosgninaelcfowolfwollaot

;tnemngiladnasnoitcurtsborofselzzonyarpskcehC

.yrassecenfieromspoocs2-1dda;ecnamrofrep

metsySlacirtcelEehtgnitoohselbuorT

.

putliubsisirbedssecxE

tnemelegnitaehdnuora

wolootsiegatloveniL ehttahtyfirevotnaicirtceledesnecilatcatnoC

remitretaehdeliaF eeS(yrassecenfiecalper;remittaehehttseT hsaW

tatsomrehtdeliaF eeS(yrassecenfiecalper;tatsomrehtehttseT elgniS

tnemelegnitaehdeliaF eeS(yrassecenfiecalper;tnemelegnitaehehttseT

eeS(yrassecenfituonaelc )pmuSehttuogninaelC .

.stnemeriuqersteemegatlovenilgnimocni

)sremiTretaeHdnaelcyC .

,tatsomrehTesahP otecivresremotsuctcatnocro

.)tatsomrehtesahp-eerhtatset

,tnemelEgnitaeHelgniS ecivresremotsuctcatnocro

.)tnemelegnitaehesahp-eerhtatsetot

;tnemelegnitaehdnuorapudliubsirbedrofkcehC

15

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 16

Section 4: Troubleshooting

MELBORPESUACELBISSOPNOITULOS

OTSLIAFENIHCAM

NEHWTRATS

"STRAPGNIHSAW"

SIERUDECORP

DEWOLLOF

ylreporp

SEODELBATNRUT

ETAREPOTON

YLREPORP

sihctiwselbatnruT FFO ehtnisihctiwselbatnrutehttahterusnE no noitisop

gnitcurtsboerastraP

noitatorelbatnrut

gniraebtsurhtnroW yrassecenfiecalper;gniraebtsurhtehttcepsnI

ffositcennocsidrewopniaM ehtnodemrofrepgniebsiecivresontahtyfireV

ylreporpgnisolctonsirooD fitsujda;hctiwsytefasrooddnahctalroodehtkcehC

hctiwsytefasrooddeliaF fiecalper;hctiwsytefaserusolcroodehttseT

remitelcycrehsawdeliaF eeS(yrassecenfiecalper;remitelcychsawehttseT

gnitarepotonsipmuP

tesylreporpmiretimileuqroT fitsujda;retimileuqrotehtnognittesehtyfireV

remitelcychsawdeliaF eeS(yrassecenfiecalper;remitelcychsawehttseT

eeS(yassecen hctiwSytefaSehtgnitsujdA .)

eeS(yrassecen hctiwSytefaSrooD .)

eeS

eeS( hctiwSelbatnruT .)

yrassecen

.notcennocsidrewopniamehtnrutneht,enihcam

sremiTremmikSdnaretaeH,elcyChsaW .)

lreporpetarepotonseodpmup

y .noitces

;elbatnrutehtfonoitatorgnitcurtsbostraprofkcehC

.yrassecenfiegnarraer

)sremiTremmikSdna,retaeH,elcyChsaW .

AUTOMATIC PARTS WASHER Troubleshooting Guide

TONSEODPMUP

ETAREPO

YLREPORP

roticapactratsdeliaF eeS(yrassecenfiecalper;roticapactratsehttseT

rotomelbatnrutdeliaF ;rotomehttsetotnaicirtceledesnecilatcatnoC

pmusnilevelretawwoL firetawdda;pmusehtnilevelretawehtkcehC

deggulpsiekatnipmuP fituonaelc;snoitcurtsborofekatnipmupkcehC

siyalerdaolrevopmuP

deppirt

esufnwolB fiecalper;esufnwolbaroflenaplacirtcelekcehC

wolootsiegatloveniL ehttahtyfirevotnaicirtceledesnecilatcatnoC

deliafsipmuP ecalper;pmupehttsetotnaicirtceledesnecilatcatnoC

roticapaCtratS ).

eeS(yrassecenfiecalper

eeS(yrassecen metsySffO-tuhSretaWwoL .)

.yrassecen

.yalerdaolrevorotomehtteseR

.yrassecen

.gatDIenihcamehtno

.yrassecenfi

rotoMelbatnruT

.)

deificepssastnemeriuqersteemegatlovenilgnimocni

16

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 17

Section 4: Troubleshooting

AUTOMATIC PARTS WASHER Troubleshooting Guide

TROUBLESHOOTING THE

ELECTRICAL SYSTEM

WARNING

KEEP WA TER SPRAY

AWAY FROM

ELECTRICAL WIRING.

Troubleshooting the Electrical Panel

Heater and Pump

To troubleshoot the electrical system use the following diagrams to

eliminate the possibility of a blown

fuse or a bad connection, then refer to Testing Individual Components to determine which component is causing the problem.

Warning: Electrical shock could

cause serious injury or death.

Relays

Heater Fuse

• Electrical troubleshooting should be performed

by qualified personnel only.

• Avoid contact with power leads, terminals, and

fuses when power is connected.

• Disconnect power to machine before removing

fuses or other electrical components.

Power

ON

Power

OFF

Measure Voltage Across

L1 and N Terminals on

Junction Box

110 to 120V

▲▲

▲

▲▲

Visibly Inspect Heater

Relay

OK

▲▲

▲

▲▲

Electrical Panel is OK,

▲

▲▲

▲▲

Check Main Power

Disconnect

None

▲

▲▲

▲▲

Heater Relay is Blown;

Replace the Relay

Black or

Deformed

Junction Block

Terminal Block -

Blue

Terminal Block -

Grey

Power

OFF

Power

OFF

Visibly Inspect Pump

Relay

OK

▲▲

▲

▲▲

Check the Blue and

Grey T erminal Blocks for

Loose Connections

OK

▲▲

▲

▲▲

Electrical Panel is OK,

Refer to Testing

Individual Components

▲

▲▲

▲▲

Pump Relay is Blown;

Replace the Relay

Black or

Deformed

Tighten Loose

▲

▲▲

▲▲

Connections

Loose

17

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 18

Section 4: Troubleshooting

TESTING INDIVIDU AL

COMPONENTS

Note: The following troubleshooting procedures require

the use of a volt/ohm meter . If you are not familiar with

using a volt/ohm meter do not attempt to perform the

following troubleshooting procedures. If you need assistance please contact your distributor or a customer

service representative.

Wash Cycle Timers

Step 1:

Disconnect power to the machine.

Step 2:

Disconnect all wires and remove the timer from the control panel and (See

Panel

).

Step 3:

With the timer in the OFF position, test for continuity

using an ohm meter.

If there is continuity the timer is no longer functional;

replace the timer.

Step 4:

With the timer in the ON position, test f or continuity using an ohm meter.

AUTOMATIC PARTS WASHER Troubleshooting Guide

If there is not continuity the timer is no longer functional; replace the timer .

Heating Element

Step 1:

Disconnect power to the machine.

Step 2:

Remove the rear panel from the machine (ten screws;

use a 5/16" wrench or socket – See Figure Below).

Timers and Switches on the Control

Screws

Step 3:

Detach the power leads from the heating element (See

Figure Below).

Power Leads

Heating

Element

Step 4:

Use an ohm meter to measure the resistance of the

heating element. The resistance should be approximately 10 Ohms if not, replace the heating element (See

Heating Element

).

Thermostat

Thermostat

Step 1:

Disconnect power to the machine.

Step 2:

Remove the rear panel from the machine (ten screws;

use a 5/16" wrench or socket ).

Step 3:

Detach the power leads from the thermostat.

Step 4:

Using a large flat-head screwdriver , pry the thermostat

out of the mounting bracket, then remove it from the

machine.

Step 5:

Set the thermostat to 120 °F, warm it to just above 120

°F, then test for continuity.

If there is continuity the thermostat is no longer functional; replace the thermostat.

Step 6:

Allow the thermostat to cool to room temperature, then

test for continuity.

If there is not continuity the thermostat is no longer

functional; replace the thermostat.

18

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 19

Section 5: Maintenance and Repair

AUTOMATIC PARTS WASHER Maintenance Guide

MAINT AINING THE MACHINE

To ensure optimum performance and trouble-free operation, observe the following maintenance schedule

consistently.

Daily Maintenance

• Check the water lev el; add water if necessary.

• Clean the debris screen.

Weekly Maintenance

• Remove oil and grease from the wash solution

using the DOS System (See

tem

).

• Examine spray nozzles; clean and align if necessary (See

Nozzles

• Wipe down the e xterior of the machine using spray

degreaser and a soft, damp cloth. TO PREVENT

ELECTRICAL COMPONENT FAILURE, DO NOT

SPRA Y THE MACHINE WITH WA TER.

Note: Spray degreaser and a damp cloth will usually

remove all dirt and grime from the machine. For particularly stubborn soap deposits, use a soft cloth dampened with warm solution from the wash chamber.

Cleaning and Aligning the Spray

).

Monthly Maintenance

• Drain and clean out the sump chamber (See

Cleaning out the Sump

Using the DOS System

The DOS System is most effective if used when the

cleaning solution in the sump is low and cool, and after

it has been sitting for at least 30 minutes. It is best to

remove oil before you begin to use the machine each

week.

To remove oil from the cleaning solution, perform the

following procedure:

Step 1:

Check the water lev el indicator to ensure that the water

level in the sump is low. If the water level is not low,

drain excess water using the oil decant valve.

Step 2:

Slowly add cool water to the sump through the wash

chamber. Use a hose that reaches to the bottom of the

sump.

Note: When adding w ater f or the purpose of removing

oil and grease, it is important that you add it slowly to

the bottom of the sump so as not to disturb the oil and

grease sitting on the top of the wash solution.

Using the DOS Sys-

).

Step 3:

Open the oil decant valve and allow the fluid to run out

of the valve until there are no traces of oil, then close

the valve (See Figure Belo w).

Oil Decant Valve

Optional Oil

Collection

Container

Water Decant

Valve

Step 4:

Turn off the water flowing into the sump.

Step 5:

Allow the fluid in the oil collection container to settle for

approximately 30 minutes to allow the water and oil to

separate completely .

Step 6:

Place the container over the wash chamber and open

the water decant valve to dr ain the w ater from the bottom of the container into sump.

Step 7:

Allow the fluid to run until traces of oil begin to appear,

then close the valve.

Step 8:

Dispose of the oil appropriately, then replace the container.

19

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 20

Section 5: Maintenance and Repair

TOP NOZZLES

Lid

Rotate each nozzle

3°

approximately 3°

from the centerline of

the pipe

3°

SIDE NOZZLES

SIDE NOZZLES

Turntable

Cleaning and Aligning the Spray Nozzles

AUTOMATIC PARTS WASHER Maintenance Guide

BOTTOM NOZZLES

Align the notch in

each spray nozzle

with the center of the

turntable

To ensure optimum cleaning performance, it is important that you examine the spra y nozzles periodically and

clean and align them if necessary .

To clean a plugged nozzle, remove it from the spray

pipe and use a small wire brush to free the nozzle of

any obstructions. When you replace the nozzle on the

spray pipe, make sure you align it according to Figure

Above to maintain a proper spra y pattern.

Note: The spray nozzles are sized and positioned to

optimize the distribution of cleaning solution in the wash

chamber. If you remove the nozzles make sure you replace them in the correct position on the appropriate

pipe. Spray nozzle specifications are stamped on the

face of each nozzle, as shown abo v e .

Cleaning out the Sump

Step 1:

Remove oil from the cleaning solution using the DOS

System (See

Step 2:

Remove the debris screen.

Step 3:

Drain the wash solution from the sump chamber . T o drain

the solution either use the sump drain or a small submersible pump.

Using the DOS System

).

Note: Manufacturer recommends that you reuse the

wash solution. To do so, transfer it to a suitable holding

container (such as a 55-gallon drum) while you clean

out the sump chamber.

Step 4:

Remove sand and other debris from the bottom of the

sump chamber. To remove the debris either flush it out

through the sump drain, or vacuum it out using a wet/

dry vac. Dispose of the debris in accordance with applicable local, state, and feder al regulations.

Note: Take special care to ensure that the heating element and the low-water float are free of debris. A build

up of debris around the heating element will decrease

heating performance and may cause the element to

overheat and fail. A build up of debris around the float

may cause the low water shut-off system to malfunction (See

Low Water Shutoff System

)

Step 5:

Transfer the wash solution back to the sump chamber ,

and add fresh water if necessary .

Step 6:

Replace the debris screen.

Step 7:

Heat the wash water to operating temperature, then add

appropriate amount of factory detergent.

Step 8:

Run the machine through a 15-minute wash cycle.

20

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 21

Section 5: Maintenance and Repair

AUTOMATIC PARTS WASHER Maintenance Guide

REP AIRING THE MACHINE

The following procedures outline the steps necessary

to replace specific items on the machine that could wear

out or otherwise fail.

Heating Element

Required Tools and Equipment

• 5/16" wrench or socket

• 1-1/2" socket and breaker bar

• sealing tape or compound

• medium phillips-head screwdriver

Replacement Procedure

Step 1:

Disconnect power to the machine.

Step 2:

Drain the wash solution from the sump .

Step 3:

Remove the rear panel from the machine (ten screws;

use a 5/16" wrench or socket – See Figure Below).

Screws

Step 4:

Detach the power leads from the heating element (See

Figure Below).

Power Leads

Thermostat

Step 5:

Using a 1-1/2" socket and breaker bar, unscrew the

heating element from the machine.

Note: Since the heating element is in continuous contact with the cleaning solution the threads may corrode

slightly. The element may be difficult to remove. When

you install a new heating element, use sealing tape or

compound on the threads to deter corrosion, and be

sure to install the rubber gasket to prevent leak.

Step 6:

Install the new heating element. Installation is the reverse of remov al.

Thermostat

Required Tools and Equipment

• 5/16" wrench or socket

• medium phillips-head screwdriver

• large flat-head screwdriver

Replacement Procedure

Step 1:

Disconnect power to the machine.

Step 2:

Remove the rear panel from the machine (ten screws;

use a 5/16" wrench or socket).

Step 3:

Detach the power leads from the heating element.

Step 4:

Using a large flat-head screwdriver , pry the thermostat

out of the mounting bracket, then remove it from the

machine.

Step 5:

Install the new thermostat. Installation is the re v erse of

removal.

Note: When you install the thermostat make sure you

press it firmly into the mounting bracket. In order to operate correctly , the thermostat must be in direct contact

with the rear wall of the sump chamber.

Timers and Switches on the Control

Panel

Required Tools and Equipment

• 5/16" wrench or socket

• 1/2" wrench or deep socket

• small phillips-head screwdriver

• small flat-head screwdriver

Replacement Procedure

Step 1:

Disconnect power to the machine.

Heating

Element

21

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 22

Section 5: Maintenance and Repair

Step 2:

Close the lid.

Step 3:

Remove the lid cov er (four screws use a 5/16" wrench

or socket – See Figure Below).

Front

Rear

Step 4:

AUTOMATIC PARTS WASHER Maintenance Guide

From the rear of the control panel, remove the power

Screws

Screws

leads from the component you wish to replace, then

remove the component (See Figure Below).

Step 2:

Loosen the torque limiter set screw (use a 1/8" allen

wrench – See Figure Below).

Set Screw

Adjusting Bolt

Step 3:

Rotate the torque arm 180°

Step 4:

Clamp the hub against the top spray arm with a pair of

locking pliers, then use a spring scale on the end of the

torque arm to measure the torque setting (See Figure

Below).

The torque arm should begin to slip at 7 pounds. If it

slips at less than 7 pounds, tighten the adjusting bolt. If

it slips at greater than 7 pounds, loosen the adjusting

bolt.

Locking Pliers

Wash Cycle Timer

Heater and

Turntable

Switches

Low Water

Indicator

Step 5:

Replace the component, then reassemble the lid cover .

Torque Limiter

The torque limiter prevents the turntable motor from

burning out in case a part falls off the turntable and

obstructs rotation. The torque limiter is pre-set at the

factory, but you may need to adjust it if the turntable

begins to slip or bind.

Adjusting the Torque Limiter

To adjust the torque limiter, perform the following procedure;

Step 1:

Raise the lid.

22

SHARK SC-2412 • 97-6267 • REV. 3/04

Step 5:

Remove the locking pliers from the hub, then tighten

the set screw.

Turntable Motor

The turntable motor is located near the main electrical

panel beneath the lid cover. To replace the turntable

motor, perf orm the following procedure:

Step 1:

Disconnect power to the machine.

Page 23

Section 5: Maintenance and Repair

AUTOMATIC PARTS WASHER Maintenance Guide

Step 2:

Close the lid.

Step 3:

Remove the lid cov er (four screws use a 5/16" wrench

or socket – See Figure Below).

Front

Rear

Screws

Screws

Step 7:

Close the lid.

Step 8:

Disconnect the power leads from the motor, then remove the motor from the lid (See Figure Below).

Power Leads

Step 4:

Raise the lid.

Step 5:

Loosen the retaining screw to remove the torque arm

assembly from the drive shaft (use a 1/8" allen wrench

– See Figure Below).

Retaining

Screw

Adjusting Bolt

Step 6:

Remove the three turntable mounting screws (See Figure Above).

23

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 24

Page 25

SC-2412 PARTS WASHER

WARRANTY

SHARK LIMITED NEW PRODUCT WARRANTY

ATUMATIC PARTS WASHER

WHA T THIS WARRANTY COVERS

All SHARK PRESSURE WASHERS are warranted by SHARK to the original purchaser to be free from defects in materials and

workmanship under normal use, for the periods specified below . This Limited W arranty is subject to the e xclusions sho wn below ,

is calculated from the date of the original purchase, and applies to the original components only. Any parts replaced under this

warranty will assume the remainder of the part’s warranty period. This warranty applies to the original purchaser and is not

transferable.

LIMITED LIFETIME PARTS WARRANTY:

Components manufactured by SHARK, such as frames, handles, coil wraps, float tanks, and belt guards. Forged brass pump

manifold. All heating coils will have a three year w arranty. Internal components on the oil-end of all pressure washer pumps will

have a seven year warranty.

ONE YEAR PARTS WARRANTY:

All other components, excluding normal wear items as described below, will be warranted for one year on parts. Warranty on

these parts will be for one year regardless of the duration of the original component manufacturer’s part warranty.

WARRANTY PROVIDED BY OTHER MANUFACTURERS:

Motors, generators, and engines, which are warranted by their respective manufacturers, are serviced through these manufacturers’ local authorized service centers. SHARK cannot provide warranty on these items.

WHAT THIS WARRANTY DOES NOT COVER

This warranty does not cover the following items:

1. Normal wear items, such as nozzles, guns, discharge hoses, wands, quick couplers, seals, filters, gaskets, O-rings,

packings, pistons, pump valve assemblies, strainers, belts, brushes, rupture disks, fuses, pump protectors.

2. Damage or malfunctions resulting from accidents, abuse, modifications, alterations, incorrect installation, improper

servicing, failure to follow manufacturer’s maintenance instructions, or use of the equipment beyond its stated usage

specifications as contained in the operator’s manual.

3. Damage due to freezing, chemical deterioration, scale buildup, rust, corrosion, or thermal expansion.

4. Damage to components from fluctuations in electrical or water supply.

5. Normal maintenance service, including adjustments, fuel system cleaning, and clearing of obstructions.

6. Transpor tation to ser vice center, shop labor charges, field labor charges, or freight damage.

WHAT YOU MUST DO TO OBTAIN WARRANTY SERVICE

While not required for warranty service, we request that you register your SHARK pressure washer by returning the completed

registration card. In order to obtain warranty service on items, you must return the product to an Authorized SHARK Dealer,

freight prepaid, with proof of purchase, within the applicable warranty period. If the product is permanently installed, you must

notify your Authorized SHARK Dealer of the defect. The Authorized Dealer will file a claim, which must subsequently verify the

defect. In most cases, the part must be returned to SHARK freight prepaid with the claim. For warranty service on components

warranted by other manufacturers, the Authorized Dealer can help you obtain warranty service through these manufacturers’

local authorized service centers.

LIMIT A TION OF LIABILITY

SHARK’S liability for special, incidental, or consequential damages is expressly disclaimed. In no event shall SHARK’S liability

exceed the purchase price of the product in question. SHARK makes every effort to ensure that all illustrations and specifications are correct, however, these do not imply a warranty that the product is merchantable or fit for a particular purpose, or that

the product will actually conform to the illustrations and specifications. THE WARRANTY CONTAINED HEREIN IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. SHARK does not authorize any other party , including authorized Dealers, to mak e any representation or

promise on behalf of SHARK, or to modify the terms, conditions, or limitations in any way. It is the buy er’ s responsibility to ensure

that the installation and use of SHARK products conforms to local codes. While SHARK attempts to assure that its products

meet national codes, it cannot be responsible for how the customer chooses to use or install the product.

SHARK PRESSURE WASHERS

1-360-833-9100 • 1-800-771-1881 • www.shark-pw.com

AUTOMATIC PARTS WASHER WARRANTY

SHARK SC-2412 • 97-6267 • REV. 3/04

Page 26

Form #97-6267 • Revised 3/04 • Printed in U .S.A.

Loading...

Loading...