.

SYNCHRONISATION CIRCUIT

.

ESD PROTECTED

.

PRECISION OSCILLATOR AND RAMP

GENERATOR

.

POWER OUTPUT AMPLIFIER WITH HIGH

CURRENT CAPABILITY

.

FLYBACK GENERATOR

.

VOLTAGE REGULATOR

.

PRECISION BLANKING PULSE GENERATOR

.

THERMAL SHUT DOWN PROTECTION

.

CRT SCREEN PROTECTION CIRCUIT

WHICH BLANKS THE BEAM CURRENT IN

THE EVENT OF LOSS OF VERTICAL DEFLECTION CURRENT

TDA1675A

VERTICAL DEFLECTION CIRC UIT

MULTIWATT 15

(Plastic Package)

DESCRIPTION

The TDA1675A is a monolithic integrated circ uit i n

15-lead Multiwatt

and very efficient vertical def lection circuit intended

for direct drive of the yoke of 1 10

tubes. It offers a wide range of applications also in

portable CTVs, B&W TVs, monitors and displays.

PIN CONNECTIONS (top view)

®

package. It is a full performance

o

colour TV picture

15

14

13

12

11

10

ORDER CODE : TDA1675A

FLYBACK

SUPPLY

BLANKING OUTPUT

AMPLIFIER INPUT (-)

AMPLIFIER INPUT (+)

RAMP OUTPUT

9

8

7

6

5

4

3

2

1

RAMP GENERATOR

GROUND

HEIGHT ADJUSTMENT

OSCILLATOR

SYNC. INPUT

OSCILLATOR

OSCILLATOR

AMPLIFIER SUPPLY

AMPLIFIER OUTPUT

September 1993

Tab connected to Pin 8

1675A-01.EPS

1/11

TDA1675A

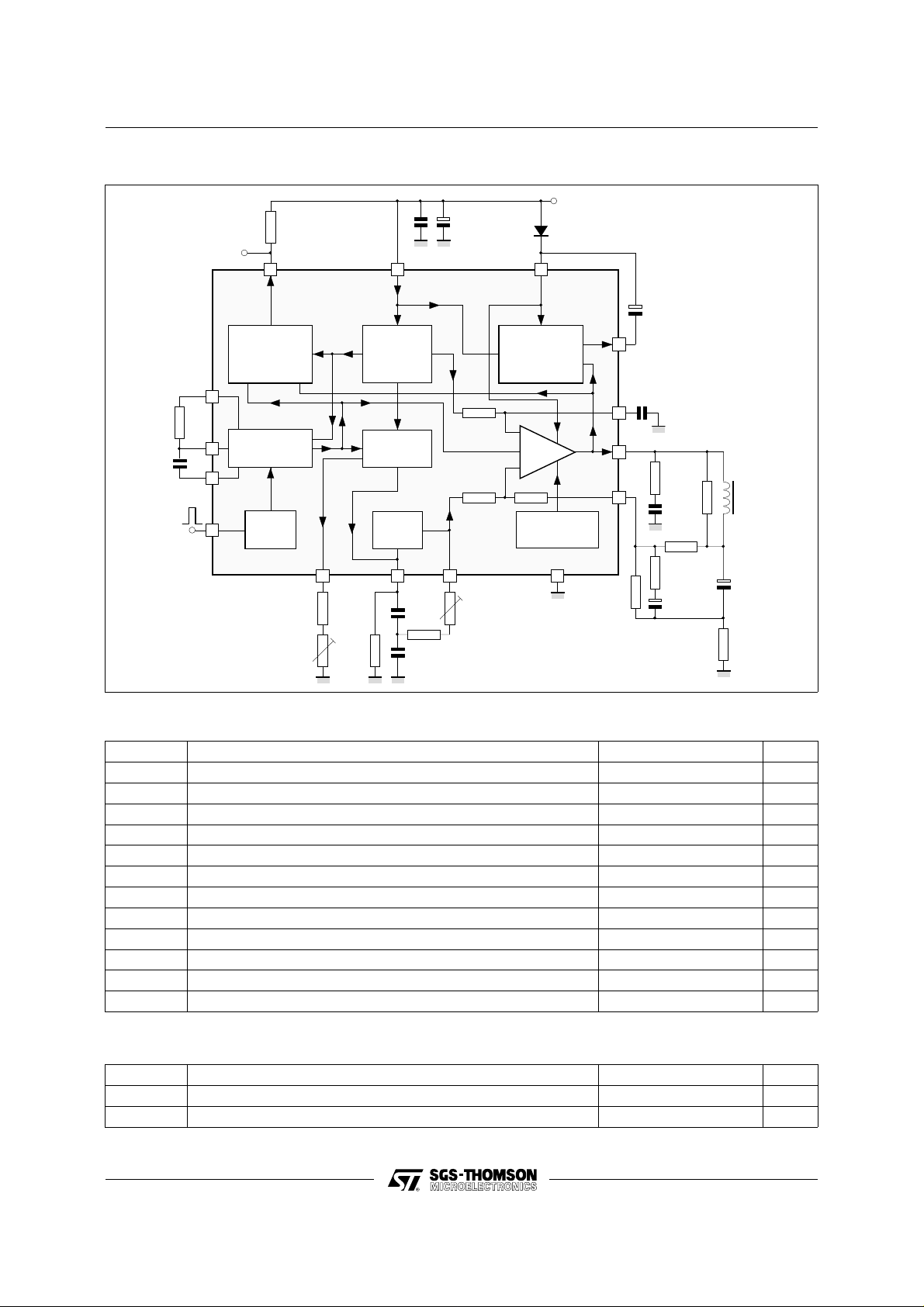

BLOCK DIAGRAM

BLANKING

OUT

6

R

o

4

C

o

3

7

SYNC.

+

13 2

BLANK

GENERATOR

AND CRT

PROTECTION

OSCILLATOR

SYNC.

14

VOLTAGE

REGULATOR

RAMP

GENERATOR

BUFFER

STAGE

R3

CLOCK

PULSE

R1 R2

FLYBACK

GENERATOR

+

POWER

AMP.

-

THERMAL

PROTECTION

+V

S

+

C

f

15

11

Ly

Ry

Iy

e

YOKE

12

1

R

R

a

+

R

f

HEIGHT

R

7

9

R

d

10

C

a

LIN

C

b

8

R

b

c

+

C

c

ABSOL UTE MAX IM UM RAT INGS

Symbol Parameter Value Unit

V

S

, V

V

1

V

5

, V

V

11

V

13

I

O

I

O

I

O

I

15

I

15

P

tot

, T

T

stg

Supply Voltage at Pin 14 35 V

Flyback Peak Voltage 65 V

2

Sync. Input Voltage 20 V

Power Amplifier Input Voltage VS - 10 V

12

Voltage at Pin 13 V

S

Output Current (non repetitive) at t = 2ms 3 A

Output Peak Current at f = 50Hz t > 10µs2A

Output Peak Current at f = 50Hz t ≤ 10 µs 3.5 A

Pin 15 Peak-to-peak Flyback Current at f = 50Hz, tfly ≤ 1.5ms 3 A

Pin 15 D.C. Current at V1 < V

Maximum Power Dissipation at T

Storage and Junction Temperature - 40, + 150

j

14

≤ 60oC30W

case

100 mA

1675A-02.EPS

o

C

1675A-01.TBL

THERMAL DATA

Symbol Parameter Value Unit

2/11

R

R

TH(j-c)

TH(j-a)

Thermal Resistance Junction-case

Thermal Resistance Junction-ambient

Max. 3

Max. 40

o

C/W

o

C/W

1675A-02.TBL

TDA1675A

DC ELECTRICAL CHARACTE RIS T ICS (VS = 35V, T

= 25oC, unless otherwise specified)

amb

Symbol Parameter Test conditions Min. Typ. Max. Unit Fig.

I

Pin 2 quiescent current I1 = 0 16 36 mA 1b

2

- I

- I

∆I

I

V

V

V

V

V

∆V

∆V

V

V

V

Ramp generator bias current V9 = 0 0.02 1 µA1b

9

Ramp generator current V9 = 0 ; - I7 = 20µA 18.5 20 21.5 µA1b

9

9

Ramp generator non linearity ∆V9 = 0 to 15V, - I7 = 20µA 0.2 1 % 1b

I

9

Pin 14 quiescent current 25 45 mA 1b

14

Quiescent output voltage VS = 35V, Ra = 2.2kΩ, Rb = 1kΩ

1

Output saturation voltage to ground I1 = 1.2A, 1 1.4 V 1c

1L

Output saturation voltage to supply - I1 = 1.2A 1.6 2.2 V 1d

1H

Oscillator virtual ground 0.45 V 1b

4

Regulated voltage at pin 7 - I7 = 20µA 6.3 6.6 7 V 1b

7

7

Regulated voltage drift with supply

voltage

S

Amplifier input (+) reference voltage 4.1 4.4 4.7 V 1b

11

Blanking output saturation voltage I13 = 10 mA 0.35 0.5 V 1a

13

Pin 15 saturation voltage to ground I15 = 20 mA 1 1.5 V 1a

15

VS = 15V, Ra = 390Ω, Rb = 1kΩ

∆VS = 15 to 35V 1 2

16.4

6.9

17.8

7.5

19.5

8.1VV

mV

V

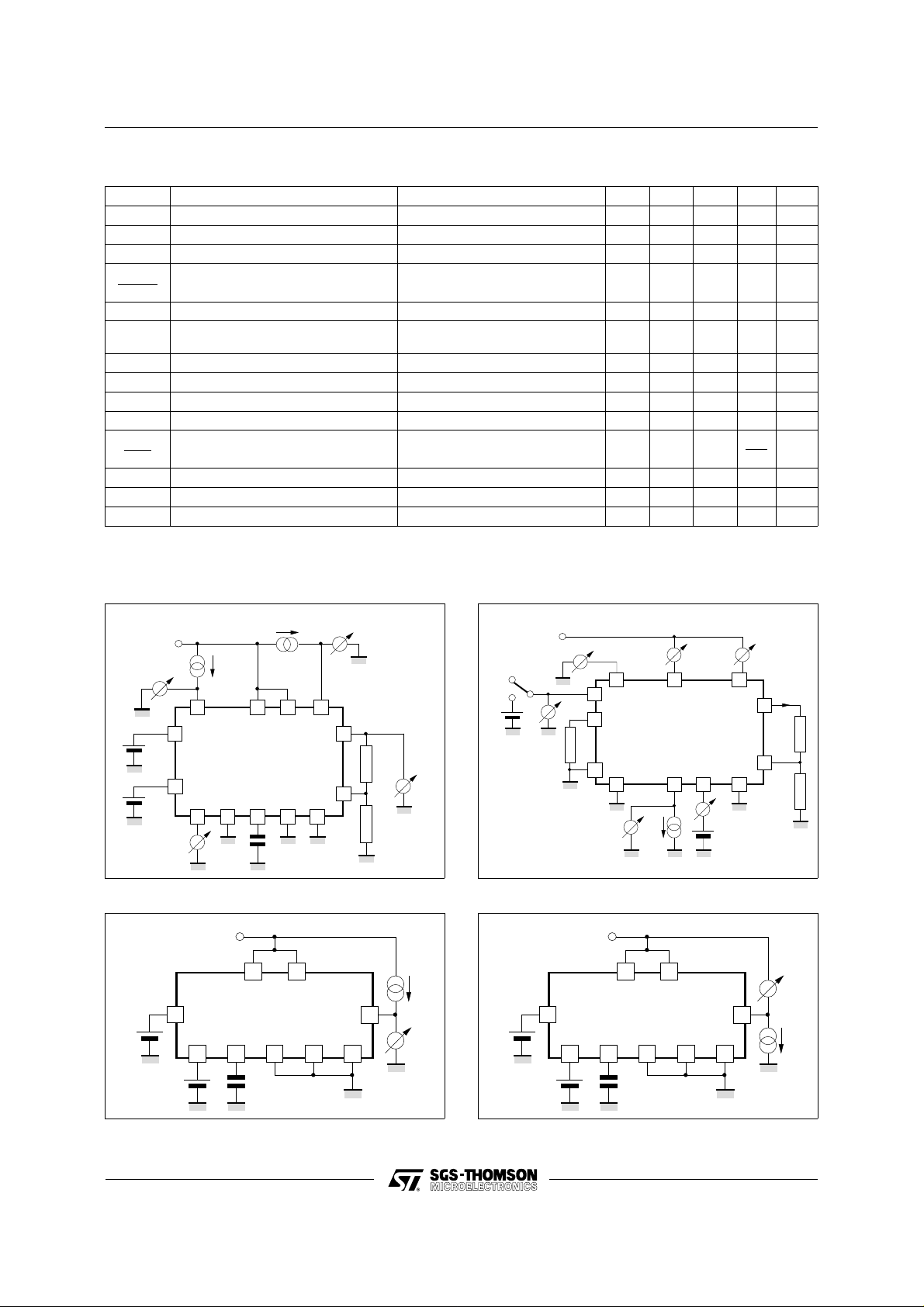

Figure 1 : DC Test Circuit.

Figure 1a

V

V

13

8V

1V

I

15

S

I

13

13

7

4

59 11 8 10

-I

9

0.1µF

2

14 15

V

15

1

R

a

V

12

R

1

b

Figure 1b

1675A-03.EPS

1V

V

S

V

11

A

B

V

4

75kΩ

I2+ I

1

11

4

4

3

5

V

7

2

97 810

-I

7

I

14

14

I

1

12

-I

9

V

9

1a

1b

1675A-03.TBL

1

22kΩ

47kΩ

1675A-04.EPS

Figure 1c

1V

V

4

12 5

8V

S

14

2

11 8

10

0.1µF

Figure 1d

V

S

14

2

+I

1

1

V

1L

1V

1675A-05.EPS

4

12 5

8V

11 8

10

0.1µF

V

1H

1

-I

1

1675A-06.EPS

3/11

TDA1675A

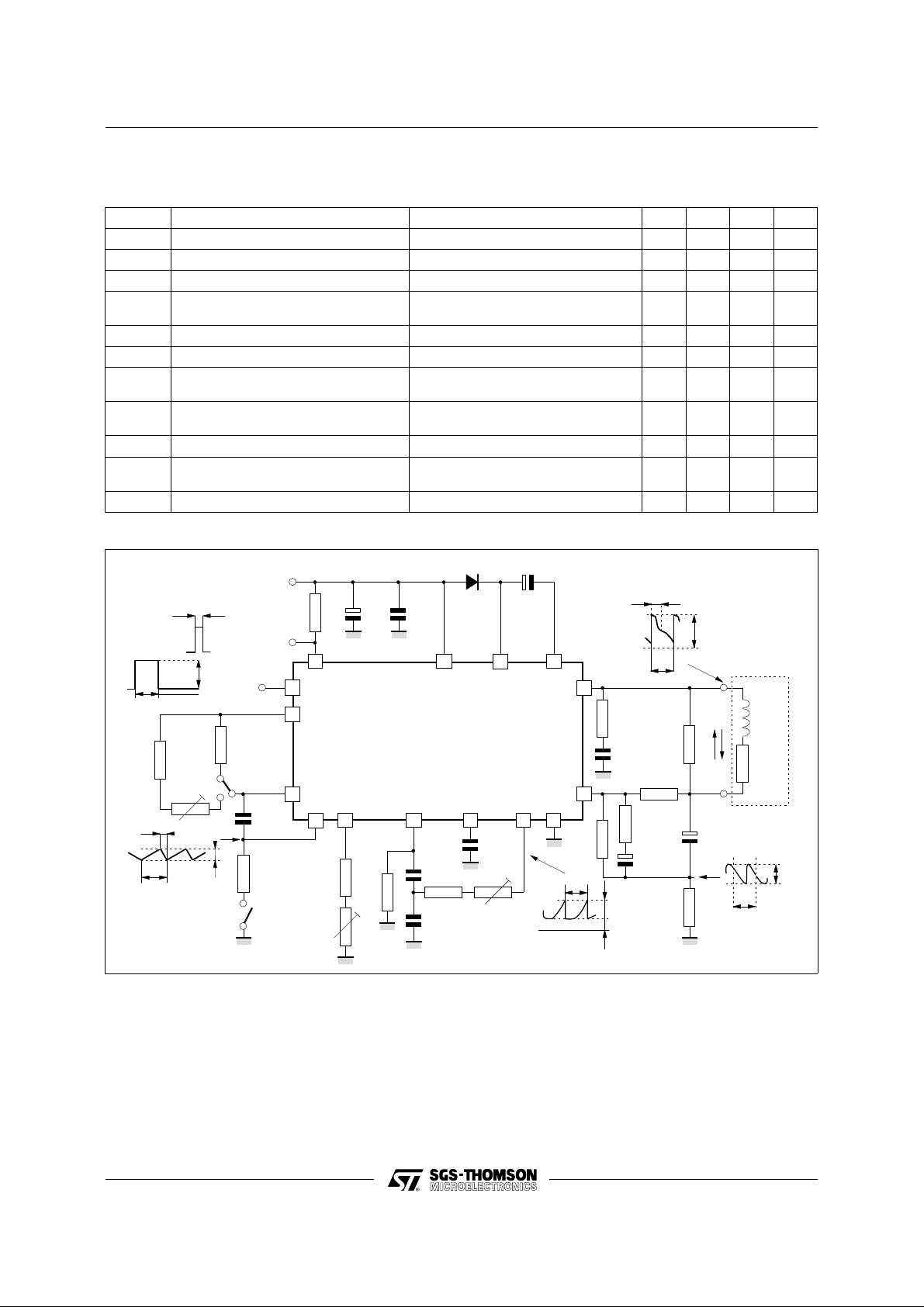

AC ELECTRICAL CHARACTE RIS TICS

(Refer to A.C. test circuit of fig. 2, T

Symbol Parameter Test conditions Min. Typ. Max. Unit

Supply Current IY = 2A

S

Sync Input Current Required to Sync 100 µA

I

5

Flyback Voltage Iy = 2App 50 V

1

Peak-to-peak Oscillator Sawtooth

3

Voltage

Start Scan Level of the Input Ramp 1.85 V

Flyback Time Iy = 2App 0.6 ms

Blanking Pulse Duration fo = 50Hz, Tj = 75oC

Free Running Frequency Ro = 7.5kΩ, Co = 330nF, Tj = 75oC

f

o

V

10TH(L)

t

t

BLANK

I

V

V

FLY

∆f Synchronization Range I

T

V

Junction Temperature for Thermal

j

Shut-down

Peak-to-peak Output Noise 35 mV

ON

Figure 2 : A C Test Circuit

+V

S

t

4.7k

(FREQ.)

t

blank

Ω

Ω

4.7k

1/fo

100µA

t

sync.

blank

SYNC. IN

Ω

7.5k

A

B

C

V

SERVICE

SWITCH

o

3

BLANKING

OUT

S1 (R )

o

0.33µF

15kΩ

S2

2.4kΩ

13

5

6

4

3

220kΩ

HEIGHT

= 25oC, VS = 24V, f = 50Hz, unless otherwise specified)

amb

PP

I5 = 0

= 100µA

I

5

1.33 1.4

fo = 60Hz, Tj = 75oC

42 43.5

Ro = 6.2kΩ, Co = 330nF, Tj = 75oC

= 100µA, Tj = 75oC1416Hz

5

1N4001 220µF

tfI

y

0.1µF

1000µF

1/fo

GND

1/fo

1

2.2Ω

0.22µF

Ω

V

V

2.4k

120Ω

47µF

10

10thL

12

1kΩ

14 15

2

TDA 1675A

7 8

Ω

180k

9

0.1µF

560kΩ

0.1µF

LINEARITY

1011

0.1µF

100kΩ56kΩ

GND

295 mA

3.6

3.4

1.47 ms

1.17

46 Hz

52.5

145

V

1

I

Y

270Ω

2200µF

Ω

0.82

1/fo

R

f

YOKE

10mH

5.9Ω

V

V

ms

Hz

o

C

PP

1675A-04.TBL

R

I

f

y

1675A-07.EPS

4/11

TDA1675A

Figure 3 : Application Circuit for Small Scree 90o CTV Set (Ry = 15Ω ; Ly = 30 mH ; Iy = 0.82 APP)

1N4001D1220µF - 35V

+V

S

R3

Ω

10k

BLANKING

OUT

SYNC.

PULSE

IN

0.1µF

C1

R1

4.7kΩ

R

7.5k

1%

330nF

5%

C

o

R2

15kΩ

SERVICE

SWITCH

* The value depends on the characteristics of the CRT. The value shown is indicative only.

S1

13

5

6

o

Ω

4

3

150kΩ

HEIGHT

C2

35V

470µF

7 8

*

R4

390kΩ

RT1

100kΩ

C3

0.1µF

TDA 1675A

9

C5 0.1µF

*

R5

14 15

Ω

RT2

56k

R6

*

C6

0.1µF

0.1µF

100k

2

1011

Ω

C4

LINEARITY

1

C7 0.22µF

12

R7

910Ω

2%

R9

2.2Ω

120

R8

C8

R11

330Ω

Ω

2.4k

*

R10

2%

Ω

47µF

10V

5%

C9

1000µF

25V

R12

Ω

2.2

YOKE

1675A-08.EPS

TYPICAL PERFORMANCE

Symbol Parameter Value Unit

V

S

I

S

t

FLY

t

BLKG

f

O

* P

TOT

* R

TH(heatsink)

* Worst case condition.

Minimum supply voltage 25 V

Supply current 140 mA

Flyback time 0.7 ms

Banking time 1.4 ms

Free running frequency 43.5 Hz

Power dissipation 2.4 W

Thermal resistance of the heatsink

for T

for T

= 60oC and T

amb

= 60oC and T

amb

j max

j max

= 110oC

= 120oC

13

16

o

C/W

o

C/W

1675A-05.TBL

5/11

TDA1675A

Figure 4 : Application Circuit for 11 0o CTV Set (Ry = 9.6Ω ; Ly = 24.6 mH ; Iy = 1.2 APP)

1N4001D1220µF - 25V

14 15

Ω

56k

R6

*

C6

0.1µF

2

0.1µF

RT2

100k

C4

1011

LINEARITY

Ω

SYNC.

PULSE

IN

0.1µF

C1

BLANKING

OUT

R1

4.7kΩ

C

SERVICE

SWITCH

+V

S

R3

Ω

10k

13

5

6

R

o

7.5k

Ω

1%

4

330nF

5%

o

R2

15kΩ

S1

3

180kΩ

HEIGHT

C2

35V

470µF

7 8

*

R4

470kΩ

RT1

220kΩ

C3

0.1µF

TDA 1675A

9

C5 0.1µF

*

R5

* The value depends on the characteristics of the CRT. The value shown is indicative only.

1

C7 0.22µF

12

R7

1.2kΩ

2%

R9

2.2Ω

120

R8

C8

YOKE

R11

330Ω

Ω

2.4k

*

R10

2%

Ω

47µF

10V

C9

5%

1500µF

16V

R12

Ω

1.2

1675A-09.EPS

TYPICAL PE RF O RMANC E

Symbol Parameter Value Unit

V

S

I

S

t

FLY

t

BLKG

f

O

* P

TOT

* R

TH(heatsink)

* Worst case condition.

Minimum supply voltage 22.5 V

Supply current 185 mA

Flyback time 1 ms

Banking time 1.4 ms

Free running frequency 43.5 Hz

Power dissipation 2.7 W

Thermal resistance of the heatsink

for T amb = 60oC and T

for T

= 60oC and T

amb

j max

j max

= 110oC

= 120oC

11.5

14.5

o

C/W

o

C/W

1675A-06.TBL

6/11

Figure 5 : Application Circuit for 11 0o CTV Set (Ry = 5.9Ω ; Ly = 10 mH ; Iy = 1.95 APP)

TDA1675A

1N4001D1220µF - 25V

14 15

Ω

56k

R6

*

C6

0.1µF

2

0.1µF

RT2

100k

C4

1011

LINEARITY

Ω

SYNC.

PULSE

IN

0.1µF

C1

BLANKING

OUT

R1

4.7kΩ

C

SERVICE

SWITCH

+V

S

R3

Ω

10k

13

5

6

R

o

7.5k

Ω

1%

4

330nF

5%

o

R2

15kΩ

S1

3

180kΩ

HEIGHT

C2

35V

1000µF

7 8

*

R4

560kΩ

RT1

220kΩ

C3

0.1µF

TDA 1675A

9

C5 0.1µF

*

R5

* The value depends on the characteristics of the CRT. The value shown is indicative only.

1

C7 0.22µF

12

R7

1kΩ

2%

R9

2.2Ω

120

R8

C8

YOKE

R11

330Ω

Ω

2.4k

*

R10

2%

Ω

47µF

10V

C9

5%

2200µF

16V

R12

Ω

0.82

1675A-10.EPS

TYPICAL PERFORMANCE

Symbol Parameter Value Unit

V

S

I

S

t

FLY

t

BLKG

f

O

* P

TOT

* R

TH(heatsink)

* Worst case condition.

Minimum supply voltage 24 V

Supply current 285 mA

Flyback time 0.6 ms

Banking time 1.4 ms

Free running frequency 43.5 Hz

Power dissipation 4.3 W

Thermal resistance of the heatsink

for Tamb = 60oC and T

for T

= 60oC and T

amb

j max

j max

= 110oC

= 120oC

6.5

8.5

o

C/W

o

C/W

1675A-07.TBL

7/11

TDA1675A

Figure 6 : PC Board and C omponents Layout for t he Application Circuits of Figures 3, 4 and 5 (1 : 1 s cale)

R

S1

o

C

R

o

2

TDA 1675A

R4

C3

R3

RT1

R9C6R1

R12

D1

C7

C1

GND SYNC.

C5

C4

C9

IN

Iy

TEST

R5 RT2

R6

R7

R11

YOKE

R8

C11

V

S

C8

BLANK

OUT

C2

R10

GND

1675A-11.EPS

APPLICATION INFORMATION (Refer to the

block diagram)

Oscillator and sync g ate (Clock generation)

The oscillator is obtained by means of an integrator

driven by a two threshold circuit that switches R

high or low so allowing the charge or the discharge

of C

under constant current conditions.

o

The Sync input pulse at the Sync gate lowers the

level of the upper thresh old and than it controls the

period duration. A clock pulse is generated.

Pin 4 is the inverting input of the amplifier used

as integrator.

8/11

Pin 6 is the output of the switch driven by the

internal clock pulse generated by the

threshold circuits.

Pin 3 is the output of the amplifier .

Pin 5 is the input for sync pulses (positive)

o

Ramp generator and buffer stage

A current mirror, the current intensity of which can

be externally adjusted, charges one capacitor

producing a linear voltage ramp.

The internal clock pulse s tops the increas ing r amp

by a very fast discharge of the capacitor a new

voltage ramp is immediately allowed.

TDA1675A

The required value of the capacitance is obtained

by means of the series of two capacitors Ca and

Cb, which allow the linearity control by applying a

feedback between the output of the buffer and the

tapping from C

and Cb.

a

Pin 7 The resistance between pin 7 and ground

defines the current mirror current and

than the height of the scanning.

Pin 9 is the output of the current mirror that

charges the series of C

and Cb. This

a

pin is also the input of the buffer stage.

Pin 10 is the output of the buffer stage and it is

internally coupled to the inverting input

of the power amplifier through R1.

Power amplifier

This amplifier is a voltage-to-current power

converter, the transconductance of which is

externally defined by means of a negative current

feedback.

The output stage of the power amplifier is supplied

by the main supply during the trace period, and by

the flyback generator circuit during the m ost of the

duration of the flyback time. The internal clock turns

off the lower power output stage to start the flyback.

The power output stage is thermally protected by

sensing the junction temperature and then by

putting off the current sources of the pow er stage.

Pin 12 is the inverting input of the amplifier.

An external network, R

the DClevel across C

and Rb, defines

a

so allowing a cor-

y

rect centering of the output voltage. The

series network R

with R

input I

and Rb, applies at the feedback

a

2 a small part of the parabola,

available across C

voltage, taken across R

components R

and Cc, in conjunction

c

, and AC feedback

y

. The external

f

, Ra and Rd, produce the

c

linearity correction on the output scanning currentIy and their values must be

optimized for each type of CRT.

Pin 11 is the non-inverting input. At this pin the

non-inverting input reference voltage

supplied by the voltage regulator can be

measured. A capacit or mus t be co nnected to increase the performances

from the noise point of view.

Pin 1 is the output of the power amplifier and it

drives the yoke by a negative slope cur-

rent ramply. R

and the Boucherot cell

e

are used to stabilize the power amplifier.

Pin 2 The supply of the power output stage is

forced at this pin. During the trace time

the supply voltage is obtained from the

main supply voltage V

by a diode,

S

while during the retrace time this pin is

supplied from the flyback generator.

Flyback generator

This circuit supplies bot h the power amplifier output

stage and the yoke during the most of the duration

of the flyback time (retrac e).

The internal clock opens the loop of the amplifier

and lets pin 1 floating so allowing the rising of the

flyback. Crossi ng the main supply voltage at pin 14,

the flyback pulse front end drives the flyback

generator in such a way allowing its output to reach

and overcome the main supply voltage, starting

from a low condition forced during the trace period.

An integrated diode stops the rising of this output

increase and the voltage jump is transferred by

means of capacitor C

at the supply voltage pin of

f

the power stage (pin 2).

When the current across the yoke changes its

direction, the output of the flyback generator falls

down to the main supp ly voltage and it is stopped

by means of the saturated output darlington at a

high level. At this time the flyback generator starts

to supply the power output amplifier output stage

by a diode inside the device. The flyback generator

supplies the yoke too.

Later, the increasing flyback current reaches the

peak value and then the flyback time is completed:

the trace period restarts. The output of the power

amplifier (pin 1) falls under the main supply v oltage

and the output of the flyback generator is driven for

a low state so allowing the flyback capacitor Cf to

restore the energy lost during the retrace.

Pin 15 is the output of the flyback generator that,

when driven, jumps from low to high

condition. An exter nal capacitor C

trans-

f

fers the jump to pin 2 (see pin 2).

Blanking generator an d CRT protect ion

This circuit is a pulse shaper and its output goes

high during the blanking period or for CRT

protection. The input is inter nally driven by the clock

pulse that defines the width of the blanking time

9/11

TDA1675A

when a flyback pulse has been generated. If the

flyback pulse is absent (short cirucit or open ciruc it

of the yoke), the blanking output remains high so

allowing the CRT protection.

Pin 13 is an open collector output where the

blanking pulse is available.

V o ltage r eg u lato r

The main supply voltage V

, is lowered and

S

regulated internally to allow the required reference

voltages for all the above described blocks.

Pin 14 is the main supply voltage input V

S

(positive).

Pin 8 is the GND pin or the negative input of V

Figure 7 : Output Saturation V olt age to Ground

vs. Peak Output Current

V1L(V)

1.5

VS= 35V

1

0.5

IY(App)

0

0.5 1 1.5 2

Figure 8 : Output Saturation Voltage to Supply

versus Output Peak Curren t

(V)

V

1H

2

VS= 35V

1.5

1

IY(App)

0.5

S

0 0.5 1 1.5 2

Figure 9 : Maximum allowable Power Dissipation

vs. Ambient Temperature

P

(W)

tot

32

R

t

24

16

8

0

1675A-12.EPS

-50 50 1501000

h

R

t

h

=

8

˚

R

=

C

th

4

˚

C

/

W

/

W

I

N

F

=

T

amb

I

NI

2

T

˚

C

E

/

W

HE

A

T

S

I

N

(˚C)

1675A-13.EPS

K

1675A-14.EPS

MOUNTING INSTRUCTIONS

The power dissipated in the circuit must be

removed by adding an external heatsink. Thanks

to the MULTIWATT ® package attaching the

heatsink is very simple, a screw or a compression

Figure 10 : Mounting Examples

10/11

spring (clip) being suf fic ient. Between the heats ink

and the package, it is better to insert a layer of

silicon grease, to optimize the thermal contact; no

electrical isolation is needed between the two

surfaces.

1675A-15.IMG

TDA1675A

PACKAGE MECHANICAL DATA : 15 PINS - PLASTIC MULTIWA TT

Dimensions

Min. Typ. Max. Min. Typ. Max.

A 5 0.197

B 2.65 0.104

C 1.6 0.063

D 1 0.039

E 0.49 0.55 0.019 0.022

F 0.66 0.75 0.026 0.030

G 1.14 1.27 1.4 0.045 0.050 0.055

G1 17.57 17.78 17.91 0.692 0.700 0.705

H1 19.6 0.772

H2 20.2 0.795

L 22.1 22.6 0.870 0.890

L1 22 22.5 0.866 0.886

L2 17.65 18.1 0.695 0.713

L3 17.25 17.5 17.75 0.679 0.689 0.699

L4 10.3 10.7 10.9 0.406 0.421 0.429

L7 2.65 2.9 0.104 0.114

M 4.2 4.3 4.6 0.165 0.169 0.181

M1 4.5 5.08 5.3 0.177 0.200 0.209

S 1.9 2.6 0.075 0.102

S1 1.9 2.6 0.075 0.102

Dia. 1 3.65 3.85 0.144 0.152

Information furnished i s believed to be accurate and rel iabl e. However, S GS-THOMSON Microel ectroni cs assumes no responsibil ity

for the consequences of use of such information nor for any infringement of patents or other rights of third parties which may result

from its use. No licence is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics.

Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all

information previously supplied. SGS-THOMSON Microelectronics products are not authorized for use as critical components in life

support devices or systems without express written approval of SGS-THOMSON Microelectronics.

Millimeters Inches

PMMUL15V.EPS

MUL15V.TBL

© 1994 SGS-THOMSON Microelectronics - All Rights Reserved

2

Purchase of I

2

C Patent. Rights to use these components in a I2C system, is granted provided that the system conforms to

I

Australia - Brazil - China - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco

The Netherlands - Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

C Components of SGS-THOMSON Microelectronics, conveys a license under the Philips

2

C Standard Specifications as defined by Philips.

the I

SGS-THOMSON Microelectronics GROUP OF COMPANIES

11/11

Loading...

Loading...