SGS Thomson Microelectronics ST7FLITE29F2M6, ST7FLITE29F2B6, ST7FLITE29, ST7FLITE25F2M6, ST7FLITE25F2B6 Datasheet

...

August 2003 1/131

Rev. 2.0

ST7LITE2

8-BIT MCU WITH SINGLE VOLTAGE FLASH MEMORY,

DATA EEPROM, ADC, TIMERS, SPI

■ Memories

– 8 Kbytes single voltag e Flas h Pro gram mem-

ory with read-out protection, In-Circuit Programming and In-Application programming

(ICP and IAP). 10K write/erase cycles guar-

anteed, data retention: 20 years at 55°C.

– 384 bytes RAM

– 256 bytes data EEPROM with read-out pro-

tection. 300K write/erase cycles guarant eed,

data retention: 20 years at 55°C.

■ Clock , Res et and Supp ly Managem e n t

– Enhanced reset system

– Enhanced low voltage supervisor (LVD) for

main supply and an auxiliary voltage detector

(AVD) with interrupt capability for implement-

ing safe power-down procedures

– Clock sources: Internal 1% RC oscillator,

crystal/ceramic resonator or external clock

– Internal 32-MHz input clock for Auto-reload

timer

– Optional x4 or x8 PLL for 4 or 8 MHz internal

clock

– Five Power Saving Modes: Halt, Active-Halt,

Wait and Slow, Auto Wake Up From Halt

■ I/O Ports

– Up to 15 multifunctional bidirectional I/O lines

–7 high sink outputs

■ 4 Timers

– Configurable Watchdog Timer

– Two 8-bit Lite Timers with prescaler,

1 realtime base and 1 input capture

– One 12-bit Auto-reload Timer with 4 PWM

outputs, input capture and output compare

functions

■ 1 Communication Interface

– SPI synchronous serial interface

■ Interrupt M ana g em e n t

– 10 inter r u pt vecto r s plu s TRAP an d RESET

– 15 external interrupt lines (on 4 vectors)

■ A/D Converter

– 7 input channels

– Fixed gain Op-amp

– 13-bit resolution for 0 to 430 mV (@ 5V V

DD

)

– 10-bit resolution for 430 mV to 5V (@ 5V V

DD

)

■ Instruction Set

– 8-bit data manipulation

– 63 basic instruct ions

– 17 main addressing modes

– 8 x 8 unsigned multiply instructions

■ Development Tools

– Full hardware/software development package

– DM (Debug Module)

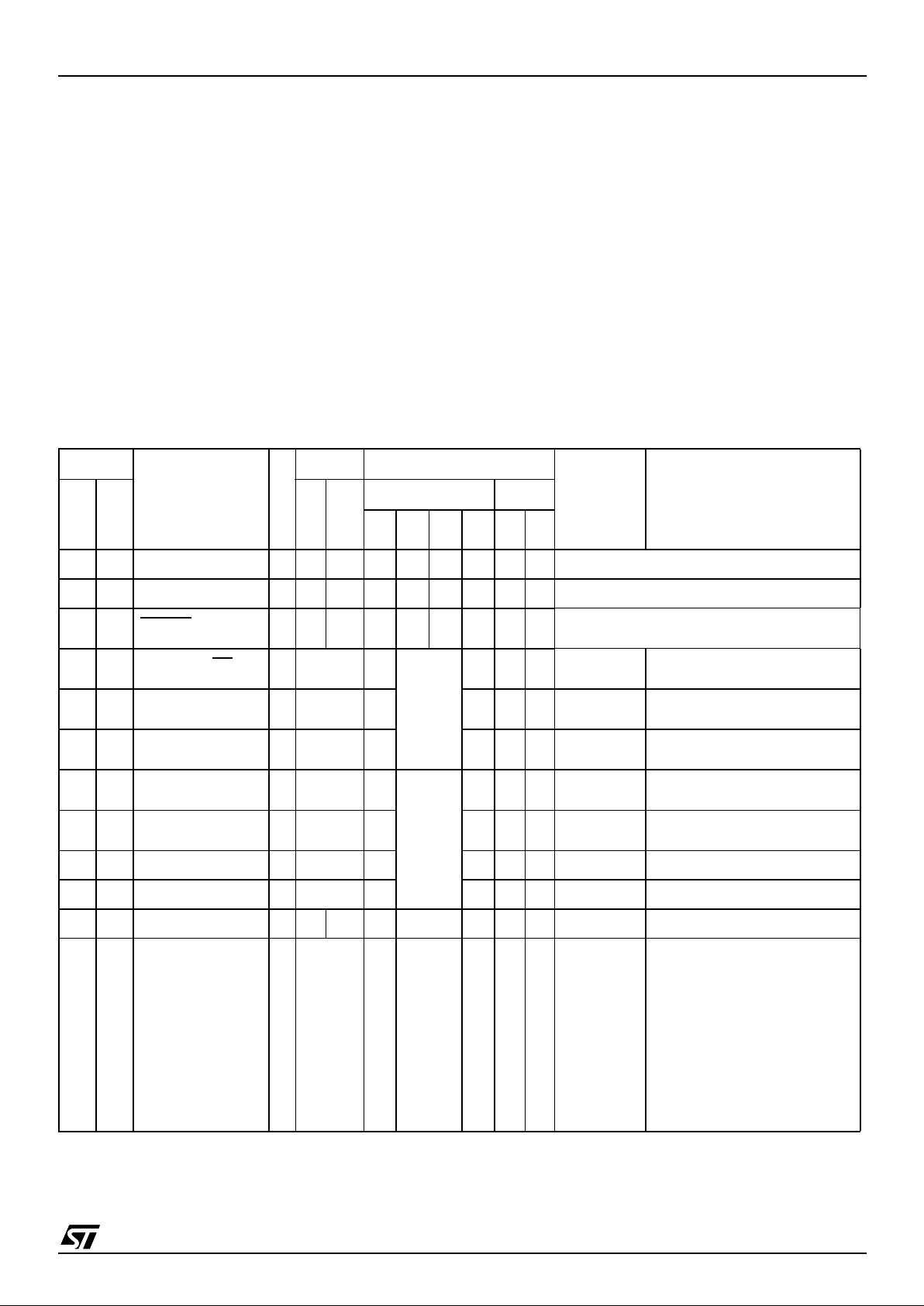

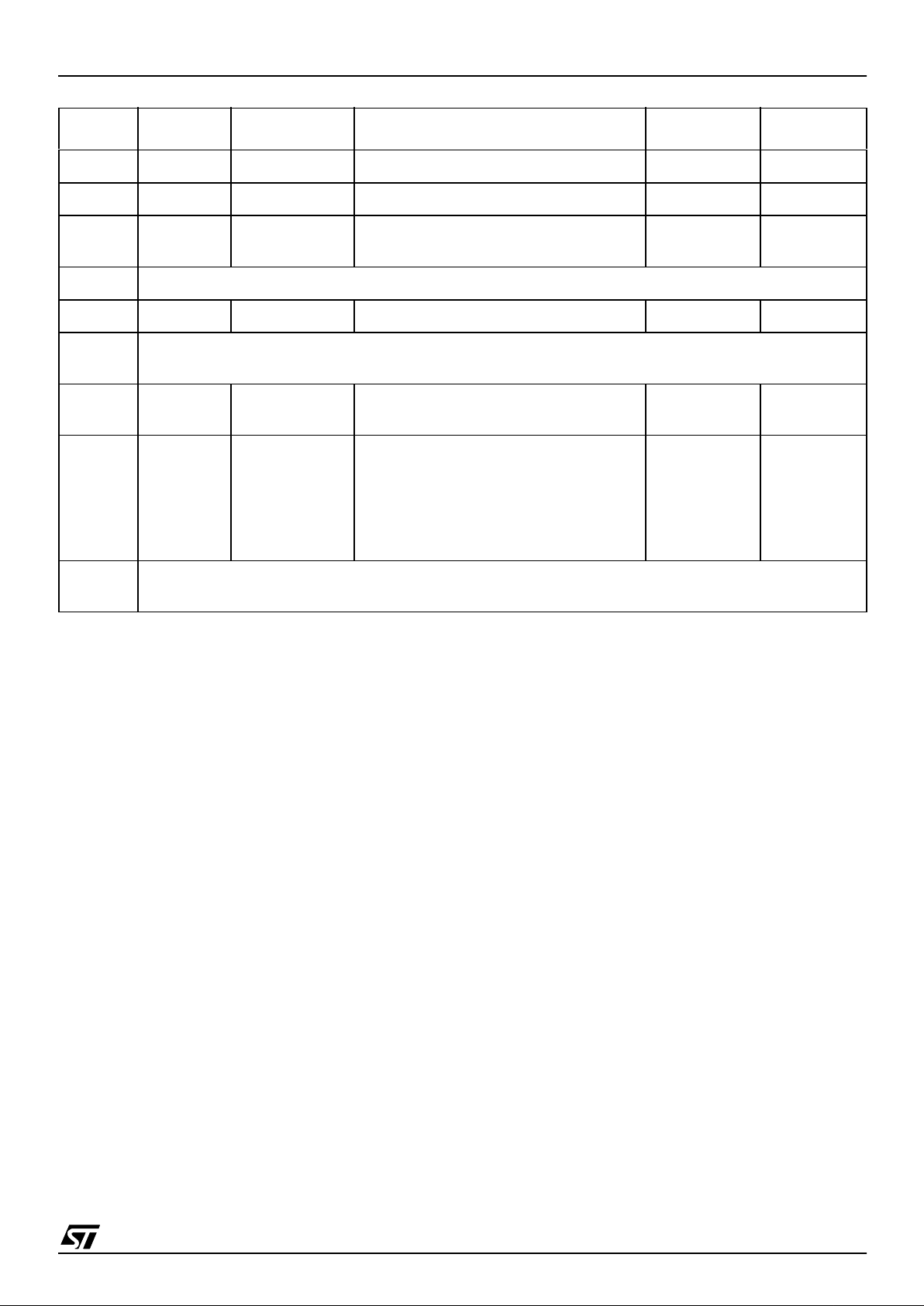

Device Summary

DIP20

SO20

300”

Features ST7LITE20 ST7LITE25 ST7LITE29

Program memory - bytes 8K

RAM (stack) - byte s 384 (128)

Data EEPROM - bytes - - 256

Peripherals

Lite Timer with Watchdog,

Autoreload Timer, SPI,

10-bit ADC with Op-Amp

Lite Timer with Watchdog,

Autoreload Timer with 32-MHz input clock,

SPI, 10-bit ADC with Op-Amp

Operat ing Supply 2.4V to 5.5V

CPU Frequency

Up to 8Mhz

(w/ ext OS C up to 16 MHz)

Up to 8Mhz (w/ ext OSC up to 16MHz

and int 1MHz RC 1% PLLx 8/4MHz)

Operat i ng T em perature -40°C to +85°C

Packages SO20 300”, DIP20

1

Table of Cont ents

131

2/131

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 REGISTER & MEMORY MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 FLASH PROGRAM MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 PROGRAMMING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 ICC INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5 MEMORY PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.6 RELATED DOCUMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.7 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 DATA EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 MEMORY ACCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5 ACCESS ERROR HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.6 DATA EEPROM READ-OUT PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.7 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2 MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 SUPPLY, RESET AND CLOCK MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 INTERNAL RC OSCILLATOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 PHASE LOCKED LOOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.3 REGISTER DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.4 MULTI-OSCILLATOR (MO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.5 RESET SEQUENCE MANAGER (RSM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.6 SYSTEM INTEGRITY MANAGEMENT (SI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.1 NON MASKABLE SOFTWARE INTERRUPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2 EXTERNAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3 PERIPHERAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.2 SLOW MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.3 WAIT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.4 HALT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.5 ACTIVE-HALT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.6 AUTO WAKE UP FROM HALT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1

Table of Cont ents

3/131

10 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.2 FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10.3 I/O PORT IMPLEMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.4 UNUSED I/O PINS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.5 LOW POWER MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.6 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10.7 DEVICE-SPECIFIC I/O PORT CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.1 WATCHDOG TIMER (WDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.2 12-BIT AUTORELOAD TIMER 2 (AT2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

11.3 LITE TIMER 2 (LT2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.4 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

11.5 10-BIT A/D CONVERTER (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12.1 ST7 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

13.1 PARAMETER CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

13.2 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

13.3 OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

13.4 SUPPLY CURRENT CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

13.5 CLOCK AND TIMING CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

13.6 MEMORY CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

13.7 EMC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

13.8 I/O PORT PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

13.9 CONTROL PIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.10 COMMUNICATION INTERFACE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . 114

13.11 10-BIT ADC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

14 PACKAGE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

14.1 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

14.2 SOLDERING AND GLUEABILITY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

15 DEVICE CONFIGURATION AND ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . 123

15.1 OPTION BYTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

15.2 DEVICE ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

15.3 DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

15.4 ST7 APPLICATION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

16 IMPORTANT NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

16.1 EXECUTION OF BTJX INSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

16.2 ADC CONVERSION SPURIOUS RESULTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

16.3 A/ D CONVERTER ACCURACY FOR FIRST CONVERSION . . . . . . . . . . . . . . . . . . . 129

ST7LITE2

4/131

17 SUMMARY OF CHANGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

To obtain the most recent version of this datasheet,

please check at www.st.com>products>technical literature>datasheet

Please also pay special attention to the Section “IMPORTANT NOTES” on page 129.

ST7LITE2

5/131

1 INTRODUCTION

The ST7LITE2 is a member of the ST7 m icrocontroller family. All ST7 devices are based on a common industry-standard 8-bit core, feat uring an enhanced instruction set.

The ST7LITE2 features FLASH memory with

byte-by-byte In-Circuit Programming (ICP) and InApplication Programming (IAP) capability.

Under software control, the ST 7LITE2 device can

be placed in WAIT, SLOW, or HALT mode, reducing power consumption when the application is in

idle or standby state.

The enhanced instruction set and addressing

modes of the ST7 offer both power and flexibility to

software developers, enabling the design of highly

efficient and compact application code. In addition

to standard 8-bit data management, all ST7 microcontrollers feature true bit manipulation, 8x8 unsigned multiplication and indirect addressing

modes.

For easy reference, all parametric data are located

in section 13 on page 91.

The devices feature an on-chip Debug Module

(DM) to support in-circuit debugging (ICD). F or a

description of the DM registers, refer to the ST7

ICC Protocol Reference Manual.

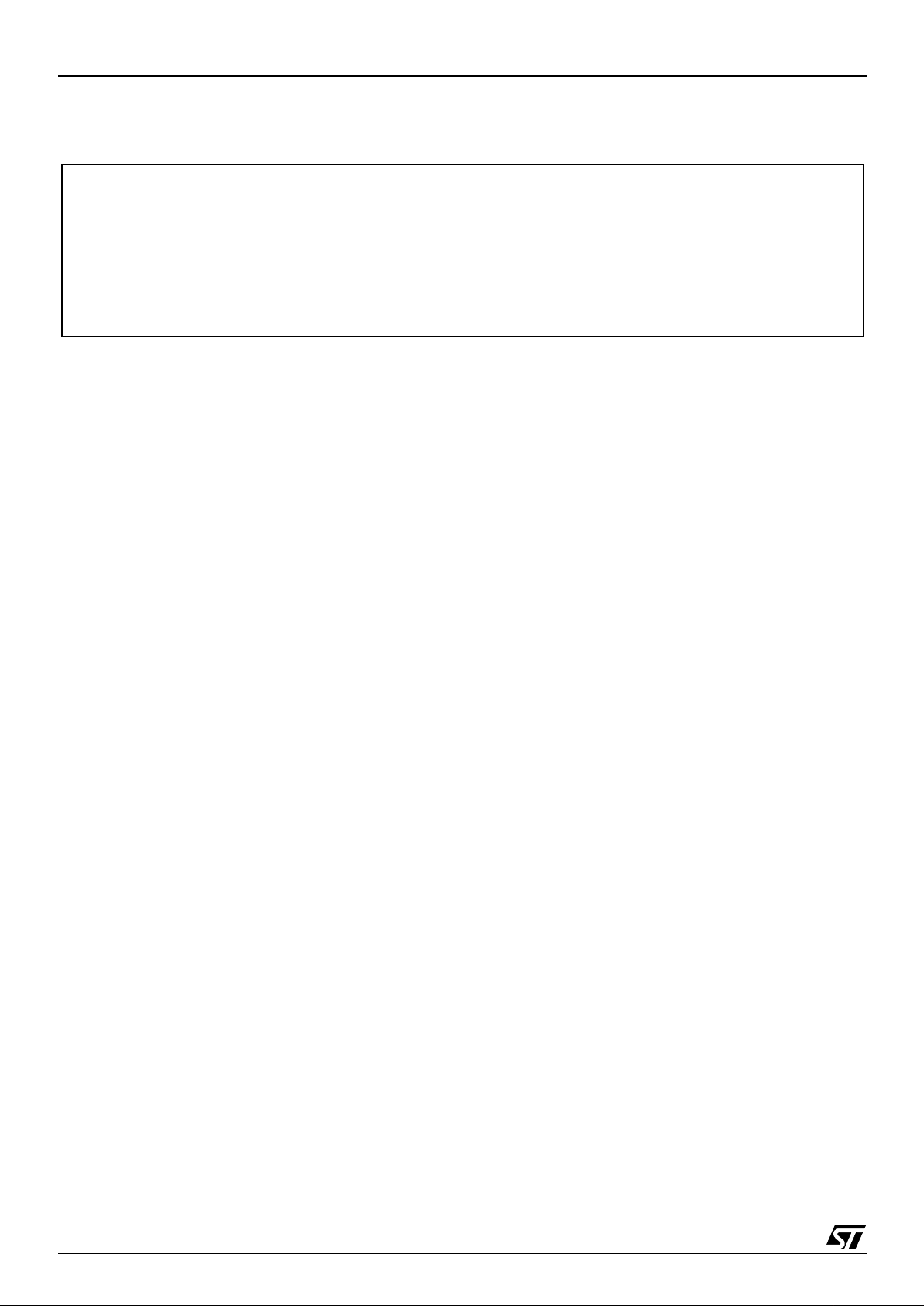

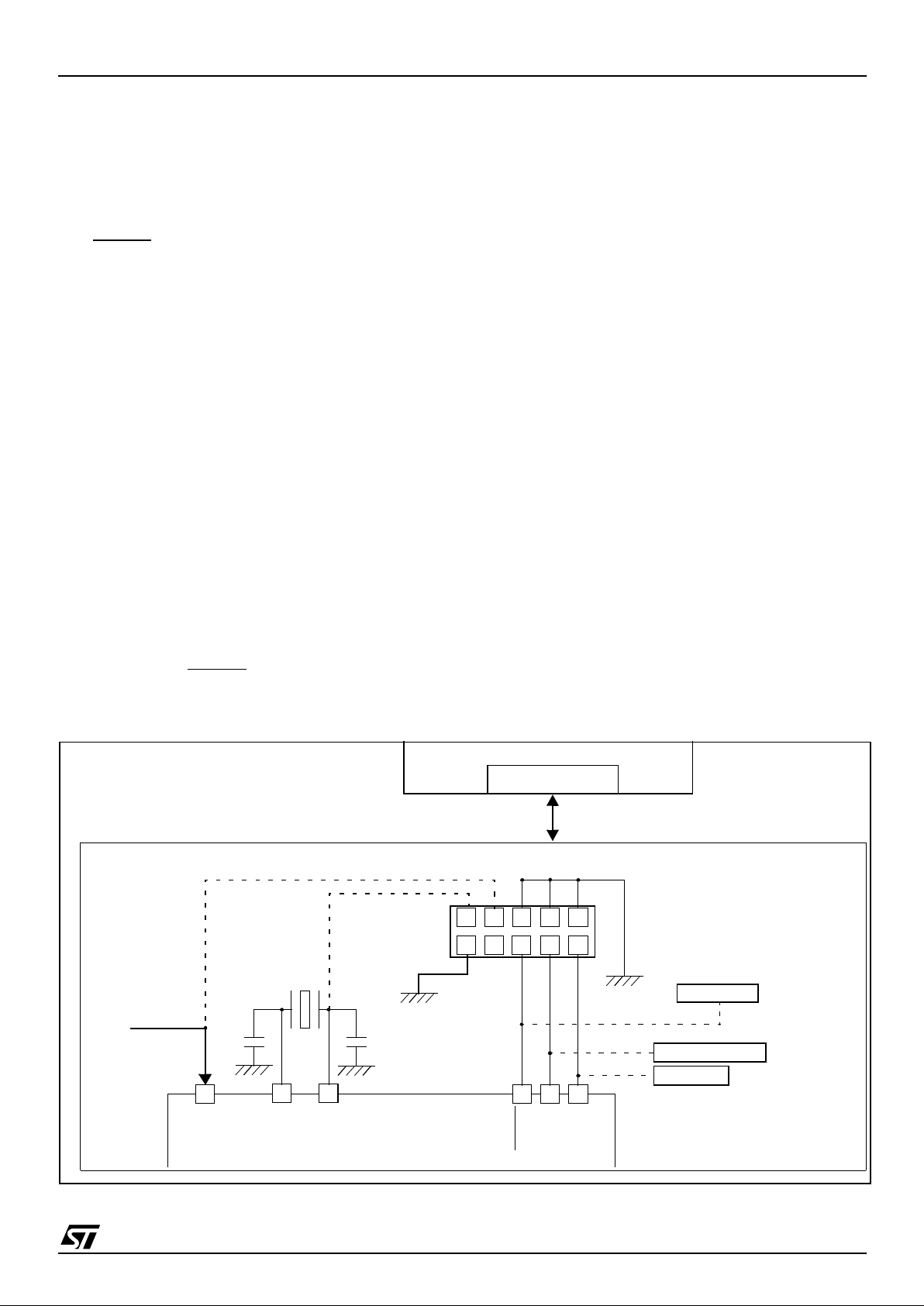

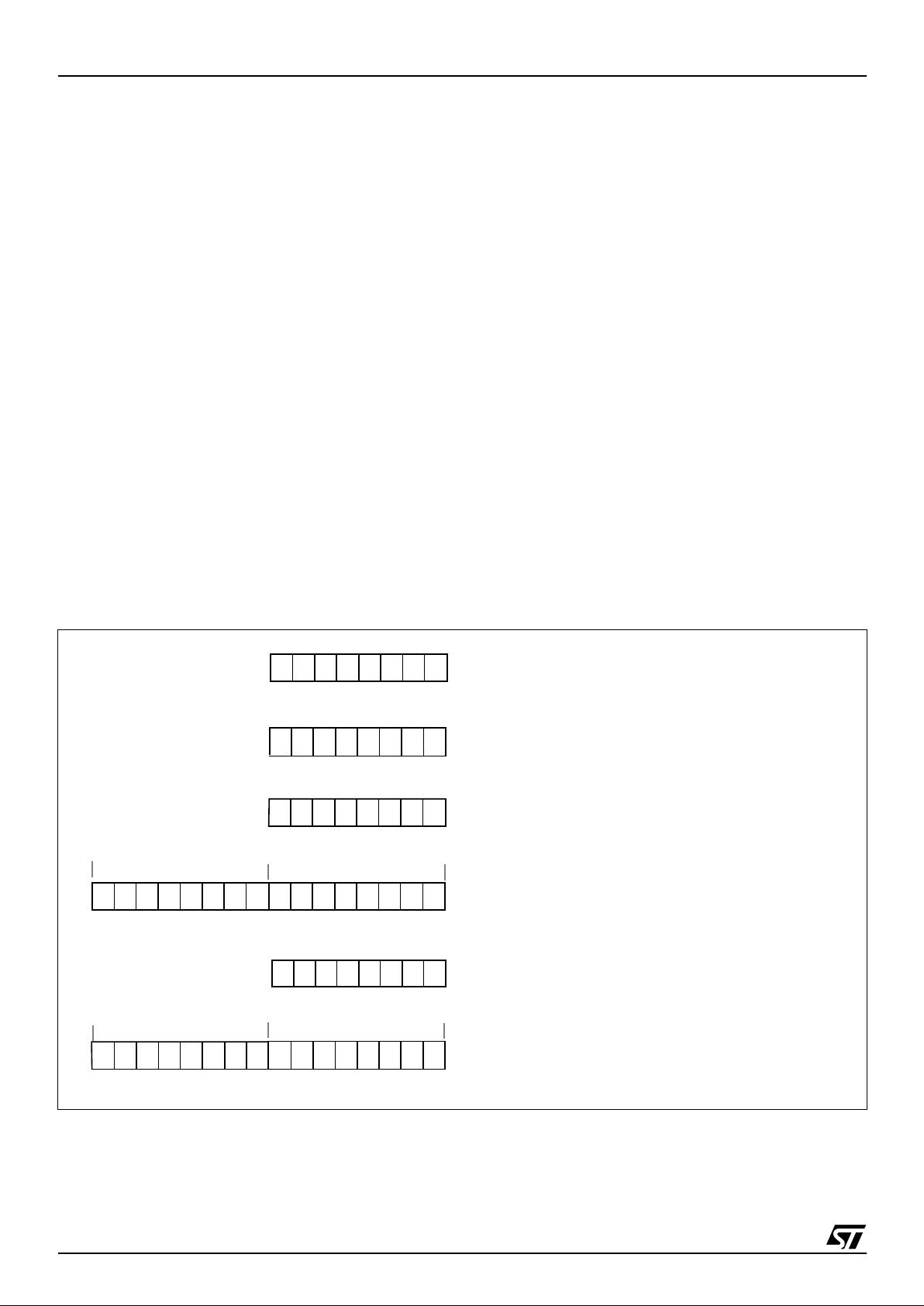

Figure 1. General B lock Diag ram

8-BIT CORE

ALU

ADDRESS AND DATA BUS

OSC1

OSC2

RESET

PORT A

Internal

CLOCK

CONTROL

RAM

(384 Bytes)

PA7:0

(8 bits)

V

SS

V

DD

POWER

SUPPLY

PROGRAM

(8K Bytes)

LVD

MEMORY

PLL x 8

Ext.

1MHz

PLL

Int.

1MHz

8-Bit

LITE TIMER 2

PORT B

SPI

PB6:0

(7 bits)

DATA EEPROM

(256 Bytes)

1% RC

OSC

to

16MHz

ADC

+ OpAmp

12-Bit

Auto-Reload

TIM E R 2

CLKIN

/ 2

or PLL X4

8MHz -> 32MHz

WATCHDOG

Debug Modul e

1

ST7LITE2

6/131

2 PIN DESCRIPTION

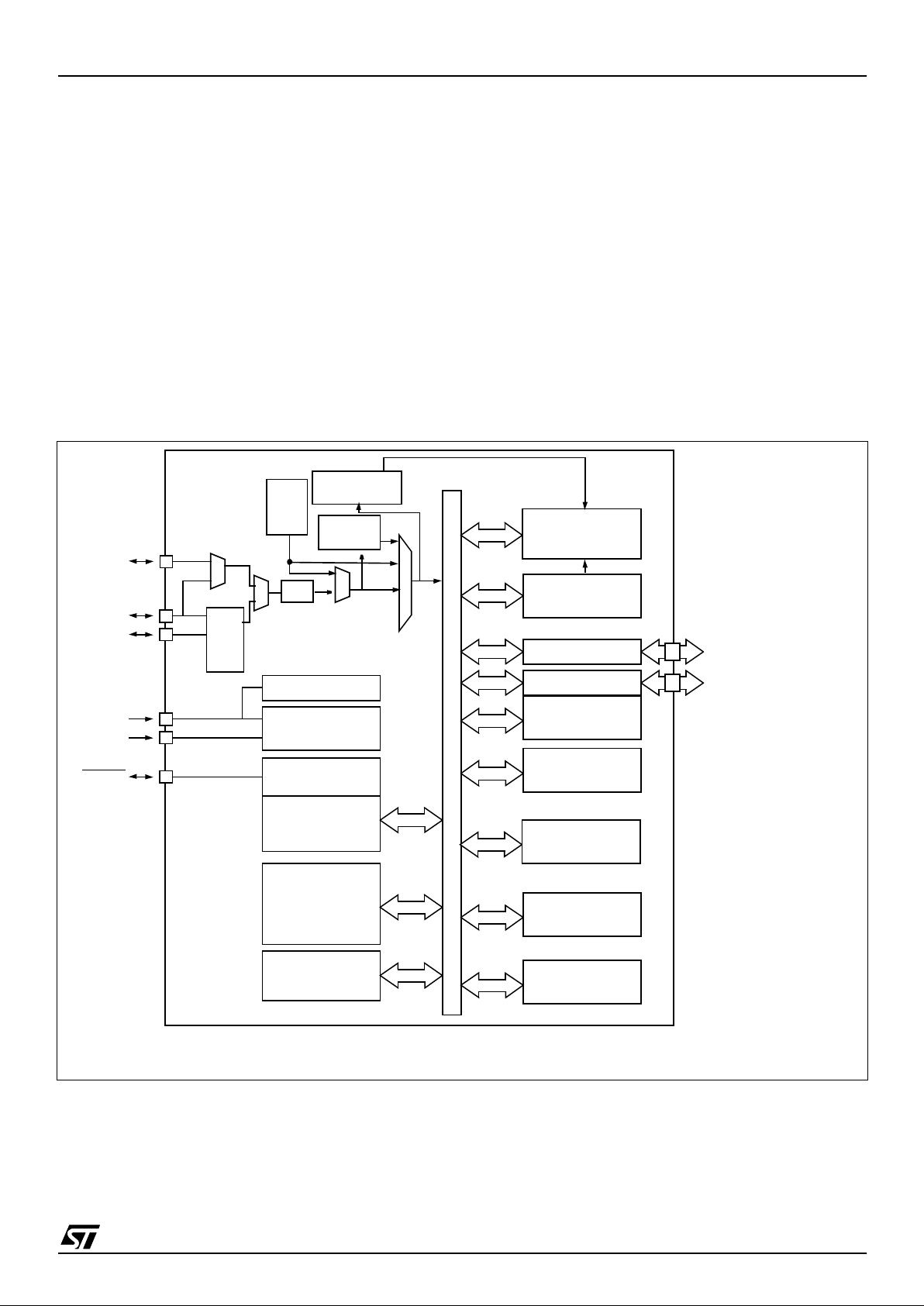

Figure 2. 20-Pin SO Package Pinout

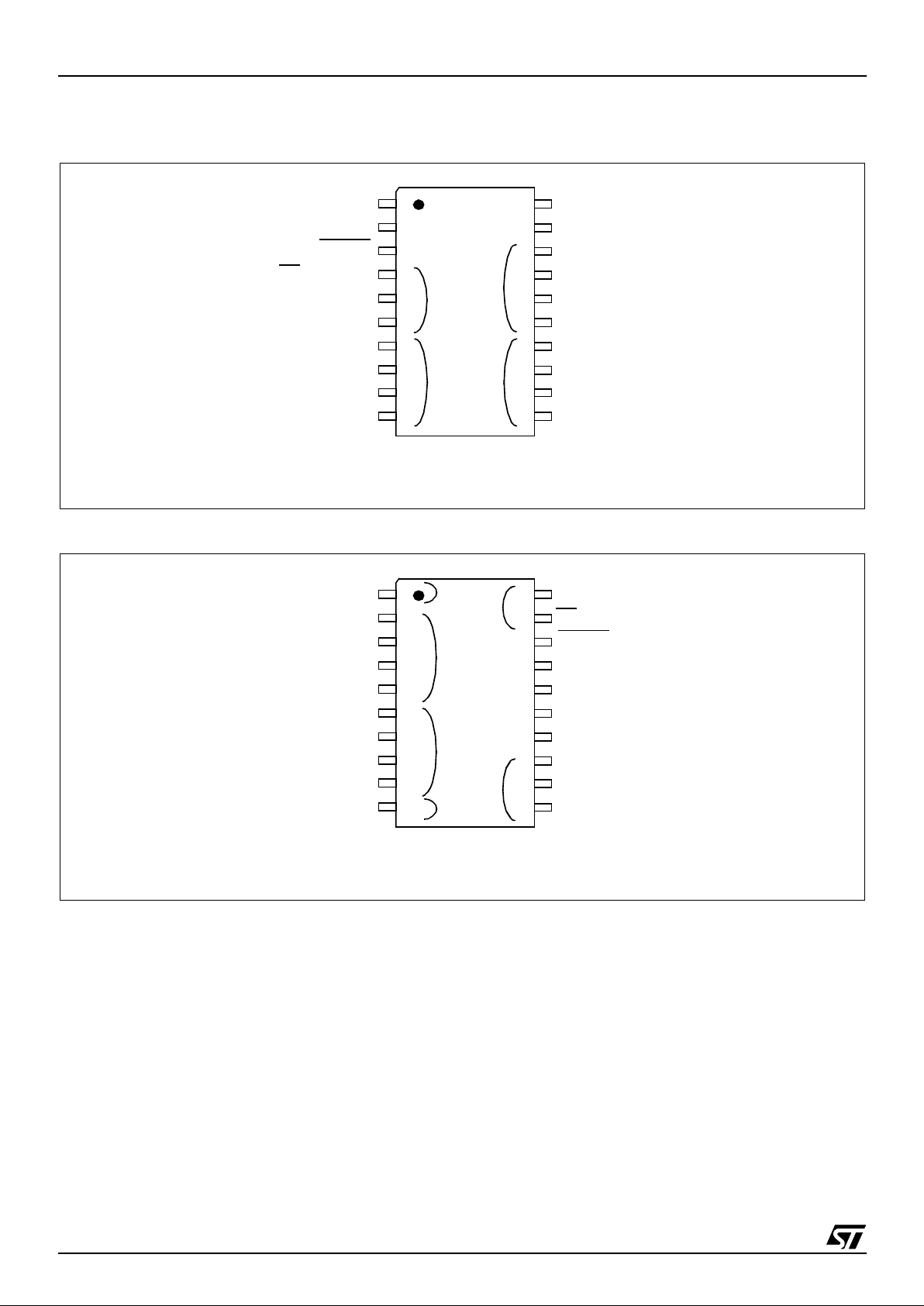

Figure 3. 20-Pin DIP Package Pinout

20

19

18

17

16

15

14

13

1

2

3

4

5

6

7

8

V

SS

V

DD

AIN5/PB5

CLKIN/AIN4/PB4

MOSI/AIN3/PB3

MISO/AIN2/PB2

SCK/AIN1/PB1

SS

/AIN0/PB0

OSC1/CLKIN

OSC2

PA5

(HS)/ATPWM3/ICCDATA

PA4

(HS)/ATPWM2

PA3

(HS)/ATPWM1

PA2

(HS)/ATPWM0

PA1

(HS)/ATIC

PA0

(HS)/LTIC

(HS) 20mA high sink capability

eix associated external interrupt vector

12

11

9

10

AIN6/PB6

PA7(HS)

PA6/MCO/ICCCLK/BREAK

RESET

ei3

ei2

ei0

ei1

20

19

18

17

16

15

14

13

1

2

3

4

5

6

7

8

MISO/AIN2/PB2

MOSI/AIN3/PB3

ATPWM2/PA4(HS)

ATPWM3/ICCDATA/PA5(HS)

MCO/ICCCLK/BREAK/PA6

PA7(HS)

AIN6/PB6

AIN5/PB5

SCK/AIN1/PB1

SS

/AIN0/PB0

PA0(HS)/LTIC

OSC2

OSC1/CLKIN

V

SS

V

DD

RESET

(HS) 20mA high sink capability

eix associated external interrupt vector

12

11

9

10

ATPWM1/PA3(HS)

PA2(HS)/ATPWM0

PA1(HS)/ATIC

CLKIN/AIN4/PB4

ei3

ei3

ei2

ei1

ei0

ei0

1

ST7LITE2

7/131

PIN DESCRIPTION (Cont’d)

Legend / Abbreviations for Table 1 :

Type: I = input, O = output, S = supply

In/Output le v el: C

T

= CMOS 0.3VDD/0.7VDD with input trigger

Output level: HS = 20mA high sink (on N-buffer only)

Port and control configuration:

– Input: float = floating, wpu = weak pull-up, int = interrupt, ana = analog

– Output : OD = open drain, PP = push-pull

The RESET co nf igurati on of eac h pin i s shown in b old whic h is va lid as l ong as the d evice is i n rese t sta te .

Table 1. Device Pin Description

Pin No.

Pin Name

Type

Level Port / Control

Main

Function

(after reset)

Alternate Function

SO20

DIP20

Input

Output

Input Output

float

wpu

int

ana

OD

PP

116V

SS

S Ground

217V

DD

S Main power supply

3 18 RESET

I/O C

T

XX

Top priority non maskable interrupt (active

low)

4 19 PB0/AIN0/SS

I/O C

T

X

ei3

XXXPort B0

ADC Analog Input 0 or SPI

Slave Select (active low)

5 20 PB1/AIN1/SCK I/O C

T

X XXXPort B1

ADC Analog Input 1 or SPI Serial Clock

6 1 PB2/AIN2/MISO I/O C

T

X XXXPort B2

ADC Analog Input 2 or SPI

Master In/ Slave Out Data

7 2 PB3/AIN3/MOSI I/O C

T

X

ei2

XXXPort B3

ADC Analog Input 3 or SPI

Master Out / Slave In Data

8 3 PB4/AIN4/CLKIN I/O C

T

X XXXPort B4

ADC Analog Input 4 or External clock input

9 4 PB5/AIN5 I/O C

T

X XXXPort B5 ADC Analog Input 5

10 5 PB6/AIN6 I/O C

T

X XXXPort B6 ADC Analog Input 6

11 6 PA7 I/O C

T

HS X ei1 X X Port A7

12 7

PA6 /MCO/

ICCCLK/BREAK

I/O C

T

X ei1 XXPort A6

Main Clock Output or In Circuit

Communication Clock or External BREAK

Caution: During reset, this pin

must be held at high level to

avoid entering ICC mode unexpectedly (this is guaranteed

by the internal pull-up if the application leaves the pin floating).

1

ST7LITE2

8/131

13 8

PA5 /ATPWM3/

ICCDATA

I/O CTHS X

ei1

XXPort A5

Auto-Reload Timer PWM3 or

In Circuit Communication Data

14 9 PA4/ATPWM2 I/O C

T

HS X XXPort A4 Auto-Reload Timer PWM2

15 10 PA3/ATPWM1 I/O C

T

HS X

ei0

XXPort A3 Auto-Reload Timer PWM1

16 11 PA2/ATPWM0 I/O C

T

HS X XXPort A2 Auto-Reload Timer PWM0

17 12 PA1/ATIC I/O C

T

HS X XXPort A1

Auto-Reload Timer Input Capture

18 13 PA0/LTIC I/O C

T

HS X XXPort A0 Lite Timer Input Capture

19 14 OSC2 O Resonator oscillator inverter output

20 15 OSC1/CLKIN I

Resonator oscillator inverter input or External clock input

Pin No.

Pin Name

Type

Level Port / Control

Main

Function

(after reset)

Alternate Function

SO20

DIP20

Input

Output

Input Output

float

wpu

int

ana

OD

PP

1

ST7LITE2

9/131

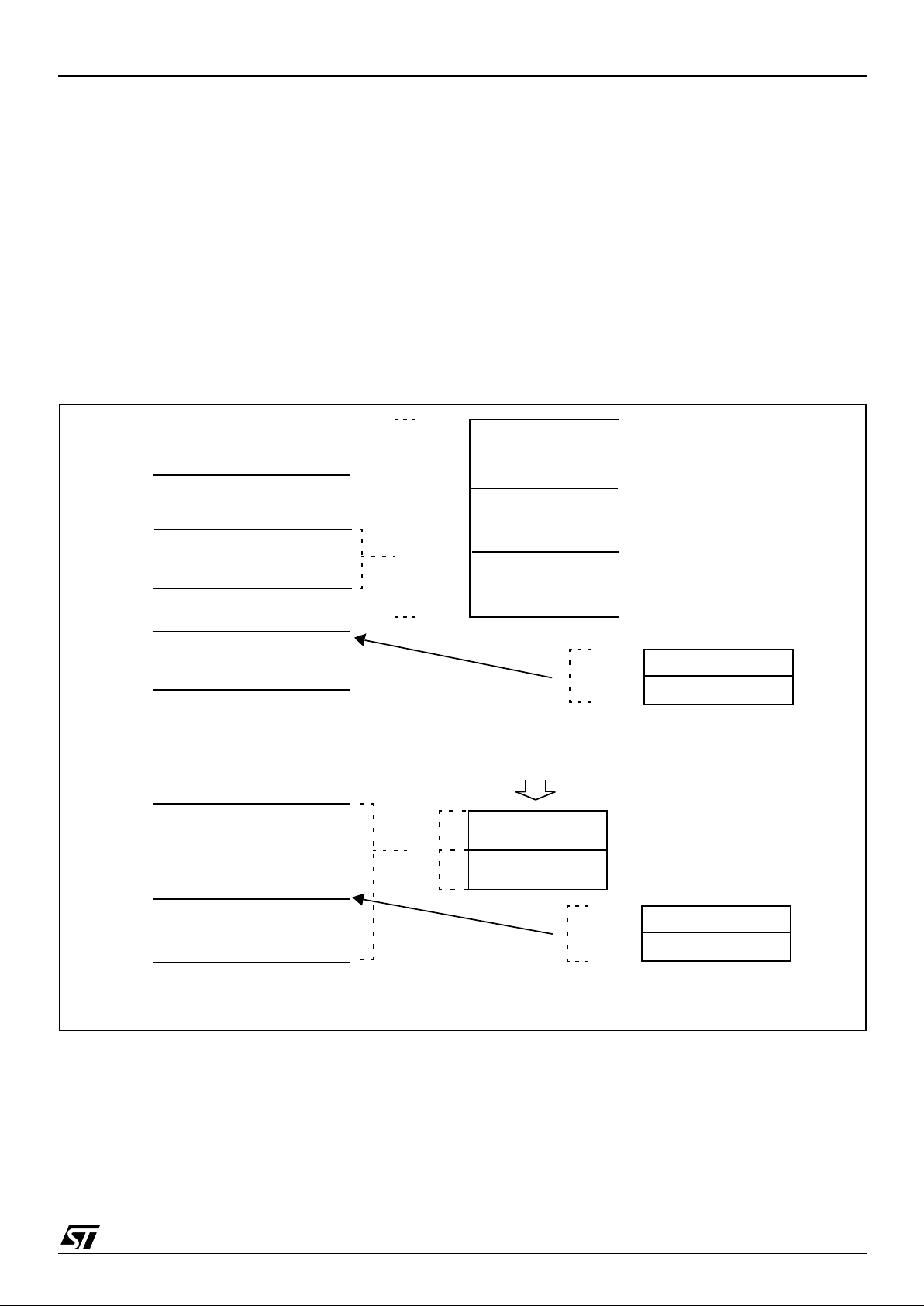

3 REGISTER & MEMORY MAP

As sho wn i n Figure 4, the MCU is capable of ad-

dressing 64K bytes of memories and I/O registers.

The available memory locations consist of 128

bytes of register locations, 384 bytes of RAM, 256

bytes of data EEPROM and 8 Kbytes of user program memory. The RAM space includes up to 128

bytes for the stack from 180h to 1FFh.

The highest address b ytes contain the user res et

and interrupt vectors.

The Flash mem ory contains two sectors (see Fig -

ure 4) mapped in the upper part of the ST7 ad-

dressing space so the res et and interrupt vectors

are located in Sector 0 (F000h-FFFFh).

The size of Flash Sector 0 and other device options are configurable by Option byte (refer to sec-

tion 15.1 on page 123).

IMPORTANT: Memory locations marked as “Reserved” must ne ver be accessed. Ac cessing a reseved area can have u npredict able effects on t he

device.l

Figure 4. Me m ory M a p

0000h

RAM

Flash Memory

(8K)

Interrupt & Reset Vectors

HW Registers

0080h

007Fh

0FFFh

(see Table 2)

1000h

10FFh

FFE0h

FFFFh

(see Table 5)

0200h

Reserved

01FFh

Short Addressing

RAM (zero page)

128 Bytes Stack

0180h

01FFh

0080h

00FFh

(384 Bytes)

Data EEPROM

(256 Bytes)

E000h

1100h

DFFFh

Reserved

FFDFh

16-bit Addressing

RAM

0100h

017Fh

1 Kbyte

7 Kbytes

SECTOR 1

SECTOR 0

8K FLASH

FFFFh

FC00h

FBFFh

E000h

PROGRAM MEMORY

1000h

1001h

RCCR0

RCCR1

see section 7.1 on page 23

FFDEh

FFDFh

RCCR0

RCCR1

see section 7.1 on page 23

1

ST7LITE2

10/131

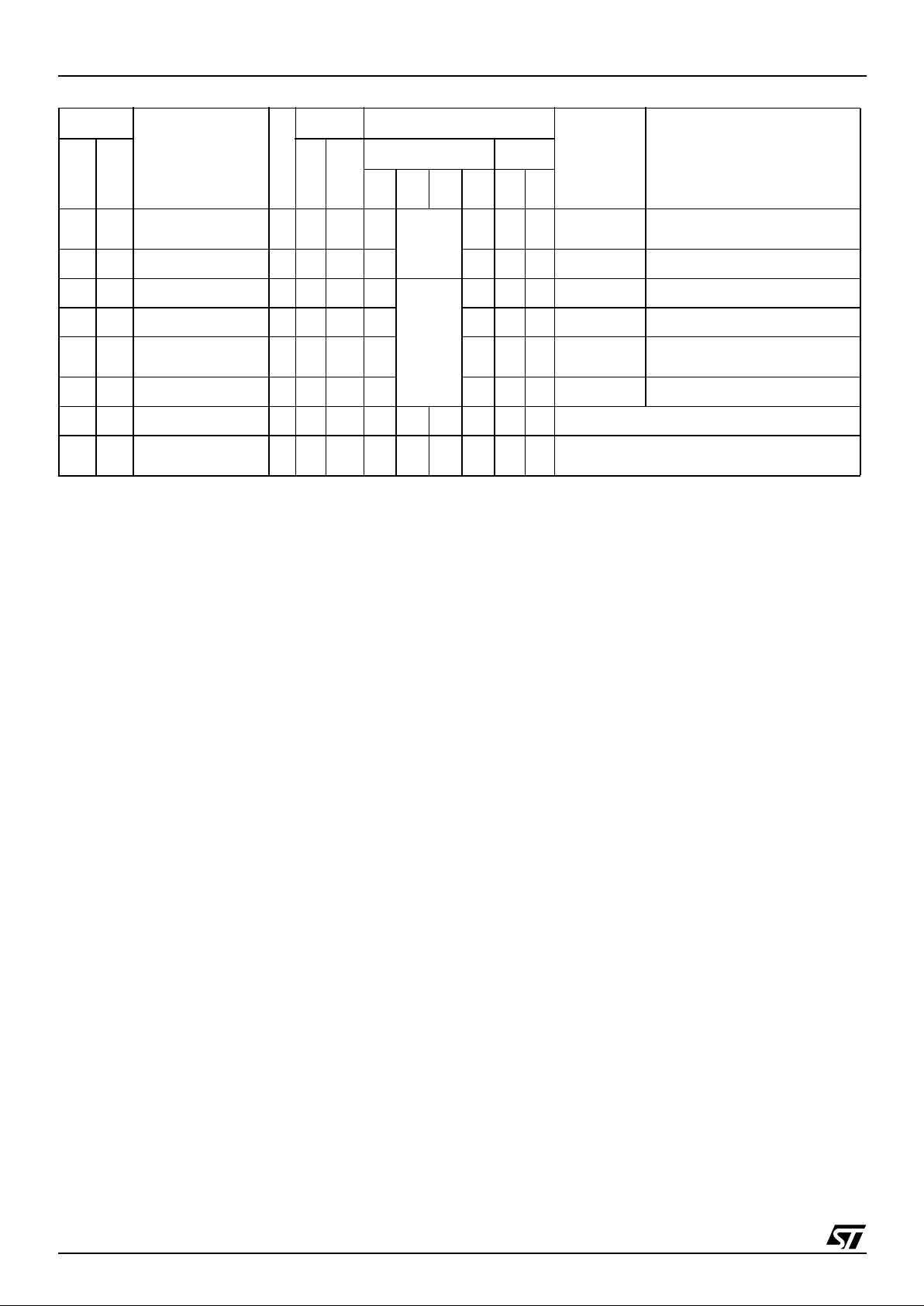

Table 2. Hardware Register M ap

Address Block Register Label Register Name Reset Status Remarks

0000h

0001h

0002h

Port A

PADR

PADDR

PAOR

Port A Data Register

Port A Data Direction Register

Port A Option Register

FFh

1)

00h

40h

R/W

R/W

R/W

0003h

0004h

0005h

Port B

PBDR

PBDDR

PBOR

Port B Data Register

Port B Data Direction Register

Port B Option Register

FFh

1)

00h

00h

R/W

R/W

R/W

2)

0006h

0007h

Reserved Area (2 bytes)

0008h

0009h

000Ah

000Bh

000Ch

LITE

TIMER 2

LTCSR2

LTARR

LTCNTR

LTCSR1

LTICR

Lite Timer Control/Status Register 2

Lite Timer Auto-reload Register

Lite Timer Counter Register

Lite Timer Control/Status Register 1

Lite Timer Input Capture Register

0Fh

00h

00h

0X00 0000h

xxh

R/W

R/W

Read Only

R/W

Read Only

000Dh

000Eh

000Fh

0010h

0011h

0012h

0013h

0014h

0015h

0016h

0017h

0018h

0019h

001Ah

001Bh

001Ch

001Dh

001Eh

001Fh

0020h

0021h

0022h

AUTO-

RELOAD

TIMER 2

ATCSR

CNTRH

CNTRL

ATRH

ATRL

PWMCR

PWM0CSR

PWM1CSR

PWM2CSR

PWM3CSR

DCR0H

DCR0L

DCR1H

DCR1L

DCR2H

DCR2L

DCR3H

DCR3L

ATICRH

ATICRL

TRANCR

BREAKCR

Timer Control/Status Register

Counter Register High

Counter Register Low

Auto-Reload Register High

Auto-Reload Register Low

PWM Output Control Register

PWM 0 Control/Status Register

PWM 1 Control/Status Register

PWM 2 Control/Status Register

PWM 3 Control/Status Register

PWM 0 Duty Cycle Register High

PWM 0 Duty Cycle Register Low

PWM 1 Duty Cycle Register High

PWM 1 Duty Cycle Register Low

PWM 2 Duty Cycle Register High

PWM 2 Duty Cycle Register Low

PWM 3 Duty Cycle Register High

PWM 3 Duty Cycle Register Low

Input Capture Register High

Input Capture Register Low

Transfer Control Register

Break Control Register

0X00 0000h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

00h

01h

00h

R/W

Read Only

Read Only

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Read Only

Read Only

R/W

R/W

0023h to

002Dh

Reserved area (11 bytes)

002Eh WDG WD GCR Watchdog Control Register 7Fh R/W

0002Fh FLASH FCSR Flash Control/Status Register 00h R/W

00030h EEPROM EECSR Data EEPROM Control/Status Register 00h R/W

0031h

0032h

0033h

SPI

SPIDR

SPICR

SPICSR

SPI Data I/O Register

SPI Control Register

SPI Control Status Register

xxh

0xh

00h

R/W

R/W

R/W

0034h

0035h

0036h

ADC

ADCCSR

ADCDRH

ADCDRL

A/D Control Status Register

A/D Data Register High

A/D Amplifier Control/Data Low Register

00h

xxh

0xh

R/W

Read Only

R/W

1

ST7LITE2

11/131

Legend: x=undefined, R/W=read/write

Notes:

1. The contents of the I/O port DR regist ers are readable only in out put c onfigurat ion. I n i nput c onfiguration, the values of the I/O pins are returned instead of the DR register contents.

2. The bits associated with unavailable pins must always keep their reset value.

3. For a description of the Debug Module registers, see ICC reference manual.

0037h ITC EICR External Interrupt Control Register 00h R/W

0038h MCC MCCSR Main Clock Control/Status Register 00h R/W

0039h

003Ah

Clock and

Reset

RCCR

SICSR

RC oscillator Control Register

System Integrity Control/Status Register

FFh

0000 0XX0h

R/W

R/W

003Bh Reserved area (1 byte)

003Ch ITC EISR External Interrupt Selection Register 0Ch R/W

003Dh to

0048h

Reserved area (12 bytes)

0049h

004Ah

AWU

AWUPR

AWUCSR

AWU Prescaler Register

AWU Control/Status Register

FFh

00h

R/W

R/W

004Bh

004Ch

004Dh

004Eh

004Fh

0050h

DM

3)

DMCR

DMSR

DMBK1H

DMBK1L

DMBK2H

DMBK2L

DM Control Register

DM Status Register

DM Breakpoint Register 1 High

DM Breakpoint Register 1 Low

DM Breakpoint Register 2 High

DM Breakpoint Register 2 Low

00h

00h

00h

00h

00h

00h

R/W

R/W

R/W

R/W

R/W

R/W

0051h to

007Fh

Reserved area (47 bytes)

Address Block Register Label Register Name Reset Status Remarks

1

ST7LITE2

12/131

4 FLASH PROGRAM MEMORY

4.1 Introduction

The ST7 single voltage extended Flash (XFlash) is

a non-volatile memory that can be electrically

erased and programmed either on a byte-by-byte

basis or up to 32 bytes in parallel.

The XFlash devices can be programmed off-board

(plugged in a programming tool) or on-board using

In-Circuit Programming or In-Application Programming.

The array matrix organ isation allows each sector

to be erased and reprogramm ed without affecting

other sectors.

4.2 Main Features

■ ICP (In-Circuit Programming)

■ IAP (In-Application Programming)

■ ICT (In-Circuit Testing) for downloading and

executing user application test patterns in RAM

■ Sector 0 size configurable by option byte

■ Read-out and write protection against piracy

4.3 PROGRAMMING MODES

The ST7 can be programmed in three different

ways:

– Insertion in a programming tool. In this m ode,

FLASH sectors 0 and 1, option byte row and

data EEPROM (if present) can be programmed or erased.

– In-Circuit Programming. In this mode, FLA SH

sectors 0 and 1, option byte row and data

EEPROM (if present) can be programme d or

erased without removing the device from the

application board.

– In-Application Programming. In this mode,

sector 1 and data EEPROM (if present) can

be programmed or erased without removing

the device from the application board and

while the application is running.

4.3.1 In-Circuit Programming (ICP)

ICP us es a pr otoco l c al l e d IC C ( I n- Ci r c ui t C om mu nication) which allows an ST7 plugged on a printed circuit board (PCB) to communicate with an external programming device connected via cable.

ICP is performed in three steps:

Switch the ST7 to ICC mode (In-Circuit Communications). This is done by driving a specific signal

sequence on the ICCCLK/DATA pins while the

RESET pin is pulled low. When the ST7 enters

ICC mode, it fetches a specific RESET vector

which points to the ST7 System Memory containing the ICC protocol routine. This routine enables

the ST7 to receive bytes from the ICC interface.

– Download ICP Driver c ode in RAM from the

ICCDATA pin

– Execute ICP Driver code in RAM to program

the FLASH memory

Depending on the IC P Driver c ode downl oaded in

RAM, FLASH m emory programming can be fully

customized (number of bytes to program, program

locations, or selection of the serial communication

interface for downloading).

4.3.2 In Application Programming (IAP)

This mode uses an IAP Driver program previously

programmed in Sector 0 by the user (in ICP

mode).

This mode is fully controlled by user software. This

allows it to be adapted to the user application, (user-defined strategy for entering programming

mode, choice of communications protocol us ed to

fetch the data to be stored etc.)

IAP mode can be used to program any memory areas except Sector 0, which is write/erase prot ected to allow recovery in case errors occur during

the programming operation.

1

ST7LITE2

13/131

FLASH PROGRAM MEMORY (Cont’d)

4.4 ICC interface

ICP needs a minimum of 4 and u p to 6 pins to be

connected to the programming tool. These pins

are:

– RESET

: device reset

–V

SS

: device power supply ground

– ICCCLK: ICC output serial clock pin

– ICCDATA: ICC input serial data pin

– OSC1: main clock input for external source

(not required on devices without OSC1/OSC2

pins)

–V

DD

: application board power supply (option-

al, see Note 3)

Notes:

1. If the ICCCLK or ICCDATA pins are only u sed

as outputs in t he ap plication, n o s ign al iso lation is

necessary. As soon as the Programming Tool is

plugged to the board, even if an ICC session is not

in progress, the ICCCLK and ICCDATA pins are

not available for the application. If they are used as

inputs by the application, isolation such as a serial

resistor has to be implemented in case another device forces the signal. Refer to the Programming

Tool documentation for recommended resistor values.

2. During the ICP session, the programming tool

must control the RESET

pin. This can lead to con-

flicts between the programming tool and the appli-

cation reset circuit if it drives more than 5mA at

high level (push pull output or pull-up resistor<1K).

A schottky diode can be u sed to isolat e the application RESET circuit in this case. When using a

classical RC network with R>1K or a reset management IC with open drain ou tput and pu ll-up resistor>1K, no additional com ponents are needed.

In all cases the user must ensure that no external

reset is generated by the application during the

ICC session.

3. The use of Pin 7 of the ICC con nector de pends

on the Programming Tool architecture. This pin

must be connected when using most ST Programming Tools (it is used to monitor the application

power supply). Please refer to the Programming

Tool manual.

4. Pin 9 has to be connected t o the OSC1 pin of

the ST7 when the clock is n ot available in the application or if the selected clock option is no t programmed in the option byte. ST7 devices with multi-oscillator capability need to have OSC2 grounded in this case.

5. During reset, this pin must be held at high level

to avoid entering ICC mode unexpec tedly (this is

guaranteed by the internal pull-up if the application

leaves the pin floating).

Figure 5. Typical ICC Interface

ICC CONNECTOR

ICCDATA

ICCCLK

RESET

VDD

HE10 CONNECTORTYPE

APPLICATION

POWER SUPPLY

1

246810

975 3

PROGRAMMING TOOL

ICC CONNECTOR

APPLICAT ION BOARD

ICC C a ble

OPTIONAL

(See No te 3)

ST7

C

L2

C

L1

OSC1

OSC2

OPTIONAL

See Note 1

See Notes 1 and 5

See Note 2

APPLICATION

RESET SOURCE

APPLICATION

I/O

(See No te 4)

1

ST7LITE2

14/131

FLASH PROGRAM MEMORY (Cont’d)

4.5 Memory Protection

There are two different types of memory protection: Read Out Protection and Write/Erase Protection which can be applied individually.

4.5.1 Read out Protection

Read out protection, when select ed, makes it impossible to extract the memory content from the

microcontroller, thus preventing piracy. Both program and data E

2

memory are protected.

In flash devices, this protection is removed by reprogramming the option. In this case, both program and data E

2

memory are automatically

erased and the device can be reprogrammed .

Read-out protection selection depends on the de-

vice type:

– In Flash dev ices it is enabled and remo ved

through the FMP_R bit in the option byte.

– In ROM devices it is enabled by mask option

specified in the Option List.

4.5.2 Flash Write/Erase Protection

Write/erase protection, when set, makes it impossible to both overwrite and erase program mem ory. It does not apply to E

2

data. Its purpose is to

provide advanced security to applications and prevent any change bei ng made to the m emory content.

Warning: Once set, Write/erase protection can

never be removed. A write-protected flash device

is no longer reprogrammable.

Write/erase protection is enabled through the

FMP_W bit in the option byte.

4.6 Related Documentation

For details on Flash program ming and ICC protocol, refer to the ST7 Flash Programming Reference Manual and to the ST7 ICC Protocol Re ference Manual

.

4.7 Register Description

FLASH CONTROL/STATUS REGISTER (FCSR)

Read/Write

Reset Value: 000 0000 (00h)

1st RASS Key: 0101 0110 (56h)

2nd RASS Key: 1010 1110 (AEh)

Note: This register is reserved for programming

using ICP, IAP or oth er programming methods. It

controls the XFlash programming and eras ing operations.

When an EPB or another programming tool is

used (in socket or ICP m ode), the RASS key s are

sent automatically.

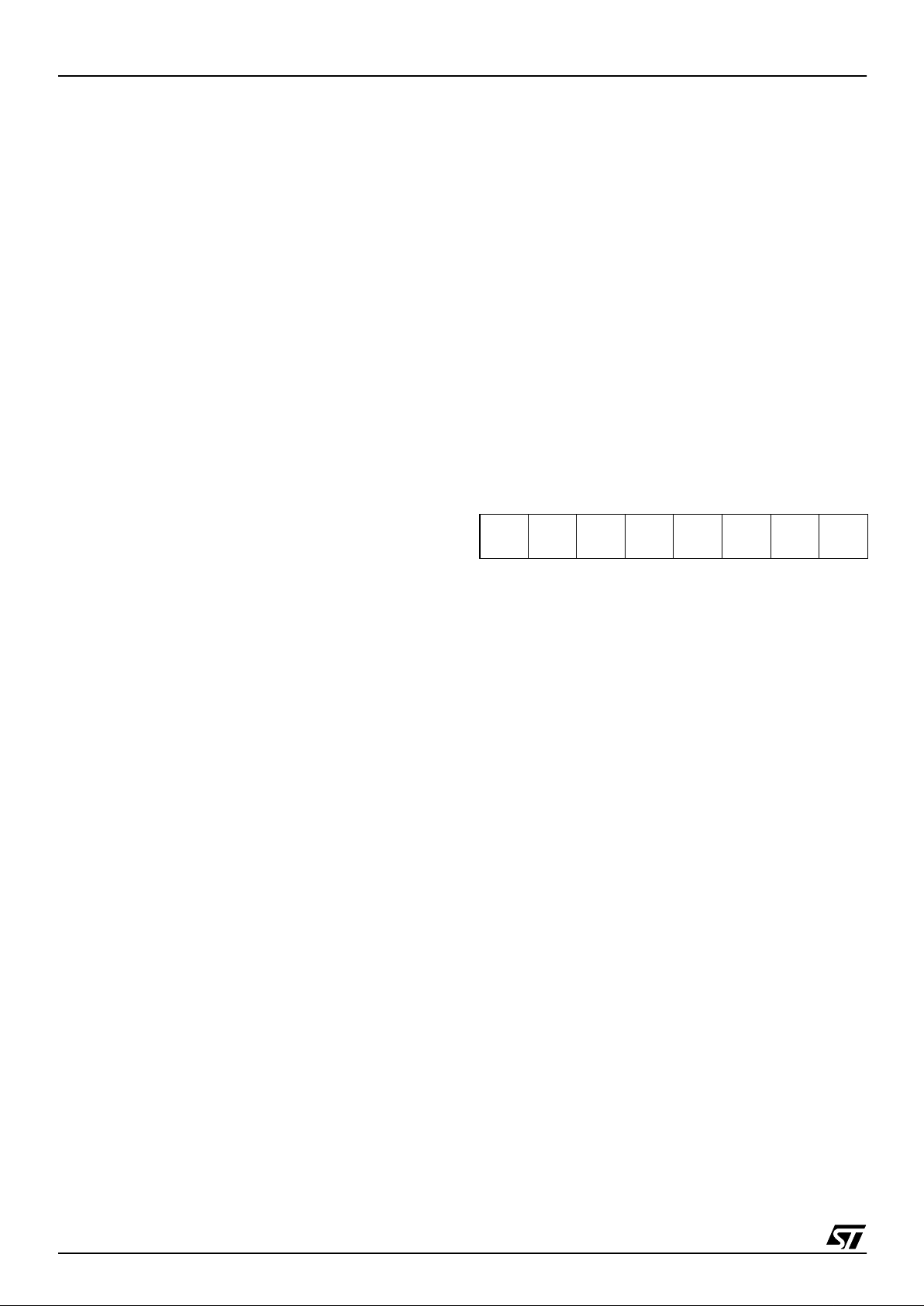

70

00000OPTLATPGM

1

ST7LITE2

15/131

5 DATA EEPROM

5.1 INTRODUCTION

The Electrically Erasable Programmable Read

Only Memory can be used as a non volatile backup for storing data. Using the EEPROM requires a

basic access protocol described in this chapter.

5.2 MAIN FEATURES

■ Up to 32 Bytes programmed in the same cycle

■ EEPROM mono-voltage (charge pump)

■ Chained er ase and progr ammi ng cycle s

■ Intern a l c ont rol of the global programming cycl e

duration

■ WAIT mode management

■ Readout protection against piracy

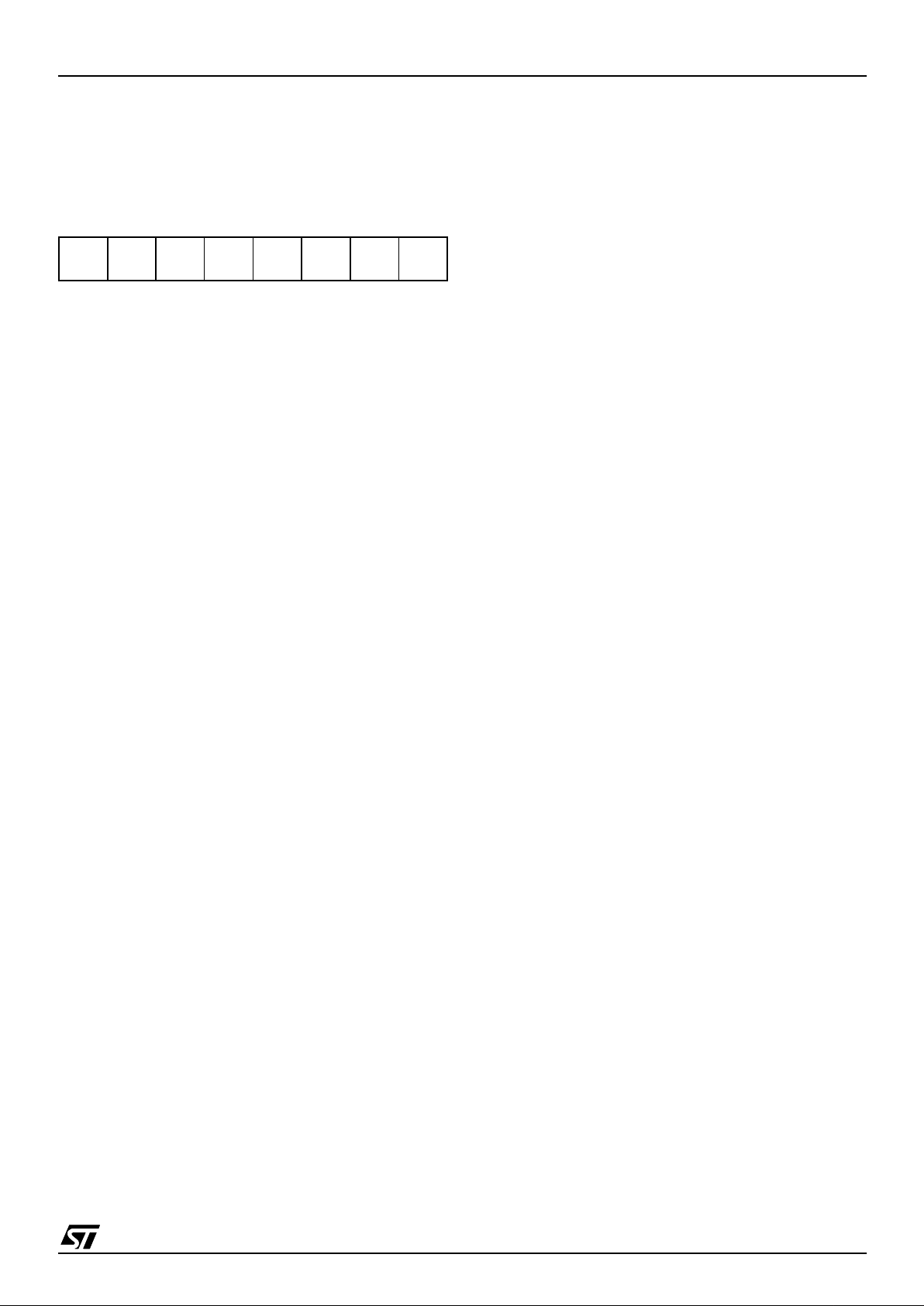

Figure 6. EEP ROM Block D ia gram

EECSR

HIGH VOLTAGE

PUMP

0 E2LAT00 0 0 0 E2PGM

EEPRO M

MEMORY MA TRIX

(1 ROW = 32 x 8 BITS)

ADDR ESS

DECODER

DATA

MULTIPLEXER

32 x 8 BITS

DATA LATCHES

ROW

DECODE R

DATA BUS

4

4

4

128128

ADDRESS BU S

1

ST7LITE2

16/131

DATA EEPROM (Cont’d)

5.3 MEMORY ACCESS

The Data EEPROM memory read/write access

modes are co ntr olle d by th e E2LAT b it of t he EEPROM Control/Status register (EECSR). The flowchart in Figure 7 describes these different memory

access modes.

Read Operation (E2L AT=0 )

The EEPROM can be read as a normal ROM location when the E2LAT bit of the EEC SR register is

cleared. In a read cycle, the byte to be accessed is

put on the data bus in less t han 1 CPU clock cycl e.

This means that reading data from EEPROM

takes the same time as reading data from

EPROM, but this memory canno t be used to execute machine code.

Write Operation (E2LAT=1)

To access the write mode, the E2LAT bit has to be

set by software (the E2PGM bit remains cleared).

When a write access to the EEPROM area occurs,

the value is latched inside the 32 dat a latches according to its address.

When PGM bit is set by the software, all the previous bytes written in the data latches (up to 32) are

programmed in the EEP ROM cells. The effective

high address (row) is determined by the last E EPROM write sequence. To avoid wrong programming, the user must take care that all the bytes

written between two programming sequences

have the same high address: only the five Least

Significant Bits of the address can change.

At the end of the programming cycle, the PGM and

LAT bits are cleared simultaneously.

Note: Care should be taken during the programming cycle. Writing to the same memory location

will over-program the memory (logical AND between the two w rite ac cess d ata result) because

the data latches are on ly cleared at t he end of the

programming cycle and by the fall ing edge of the

E2LAT bit.

It is not possible to read the latched data.

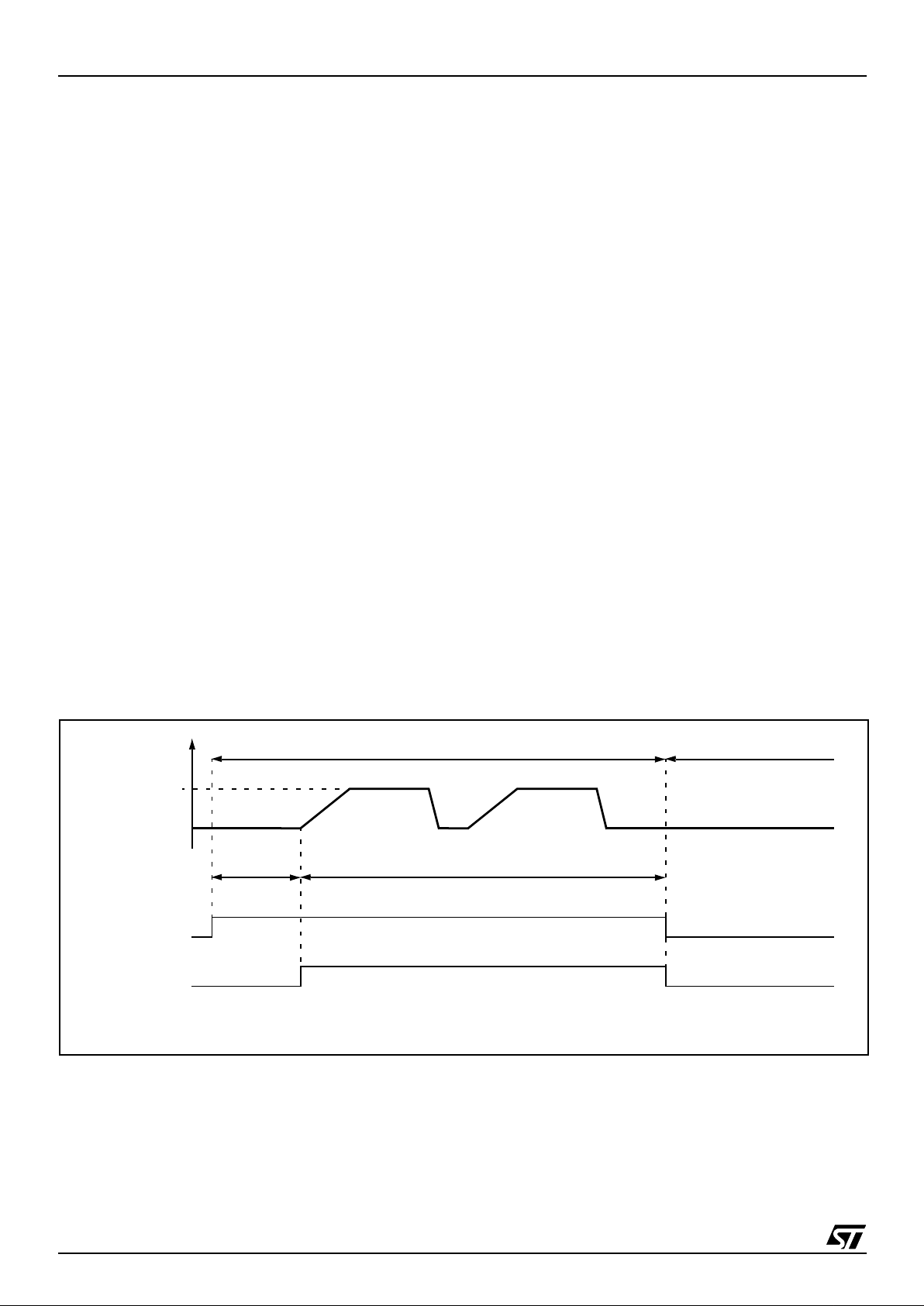

This note is ilustrated by the Figure 9.

Figure 7. Dat a EEP R OM Program m i ng Fl owchart

READ MODE

E2LAT=0

E2PGM=0

WRITE M ODE

E2LAT=1

E2PGM = 0

REA D BYTES

IN EEPROM AREA

WRITEUPTO32BYTES

IN EEPROM AREA

(with the same 11 MSB of the address)

START PROGR AMM I NG CY CL E

E2LAT=1

E2PGM=1 (set by software)

E2LAT

01

CLEARED BY HARDWARE

1

ST7LITE2

17/131

DATA EEPROM (Cont’d)

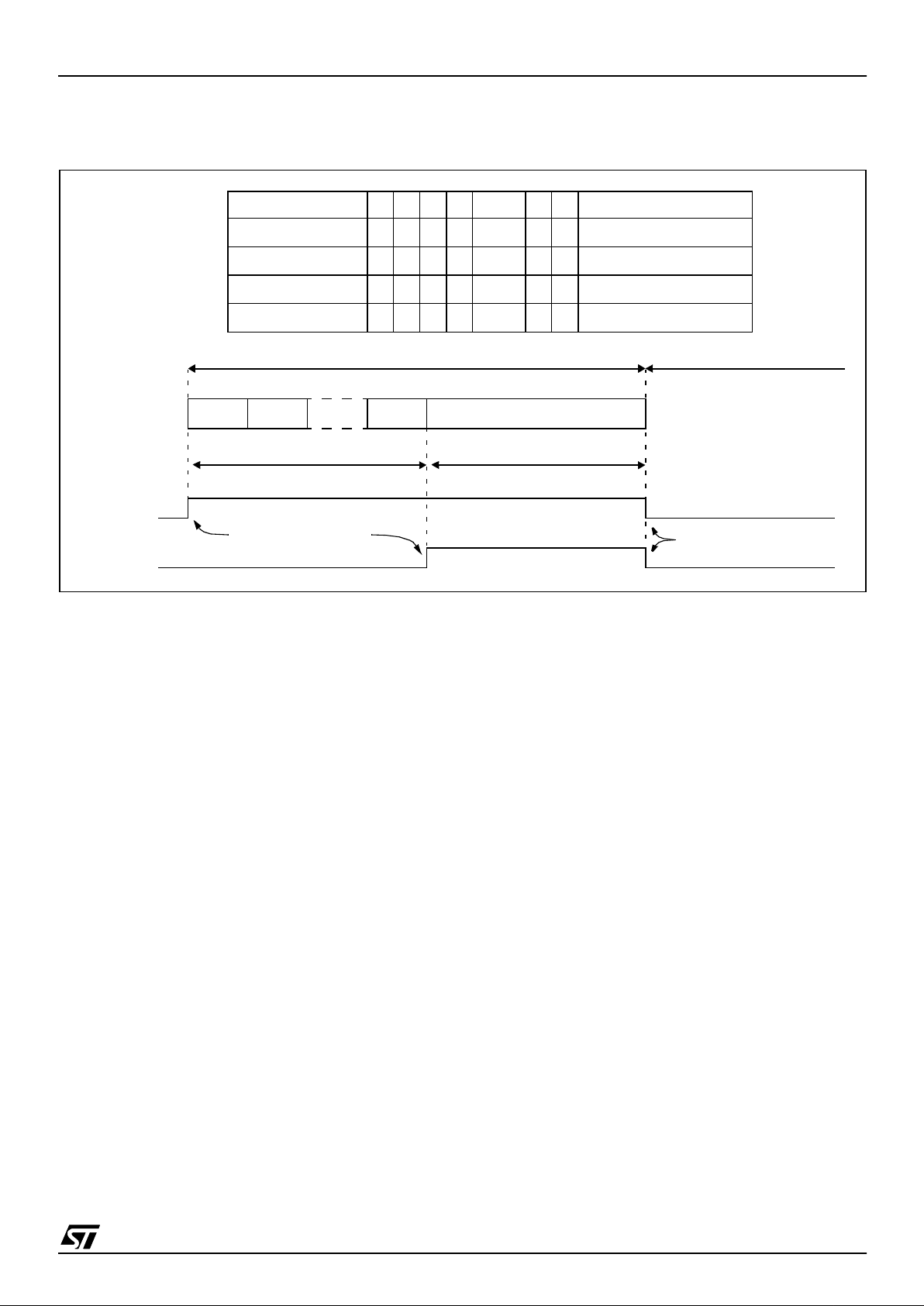

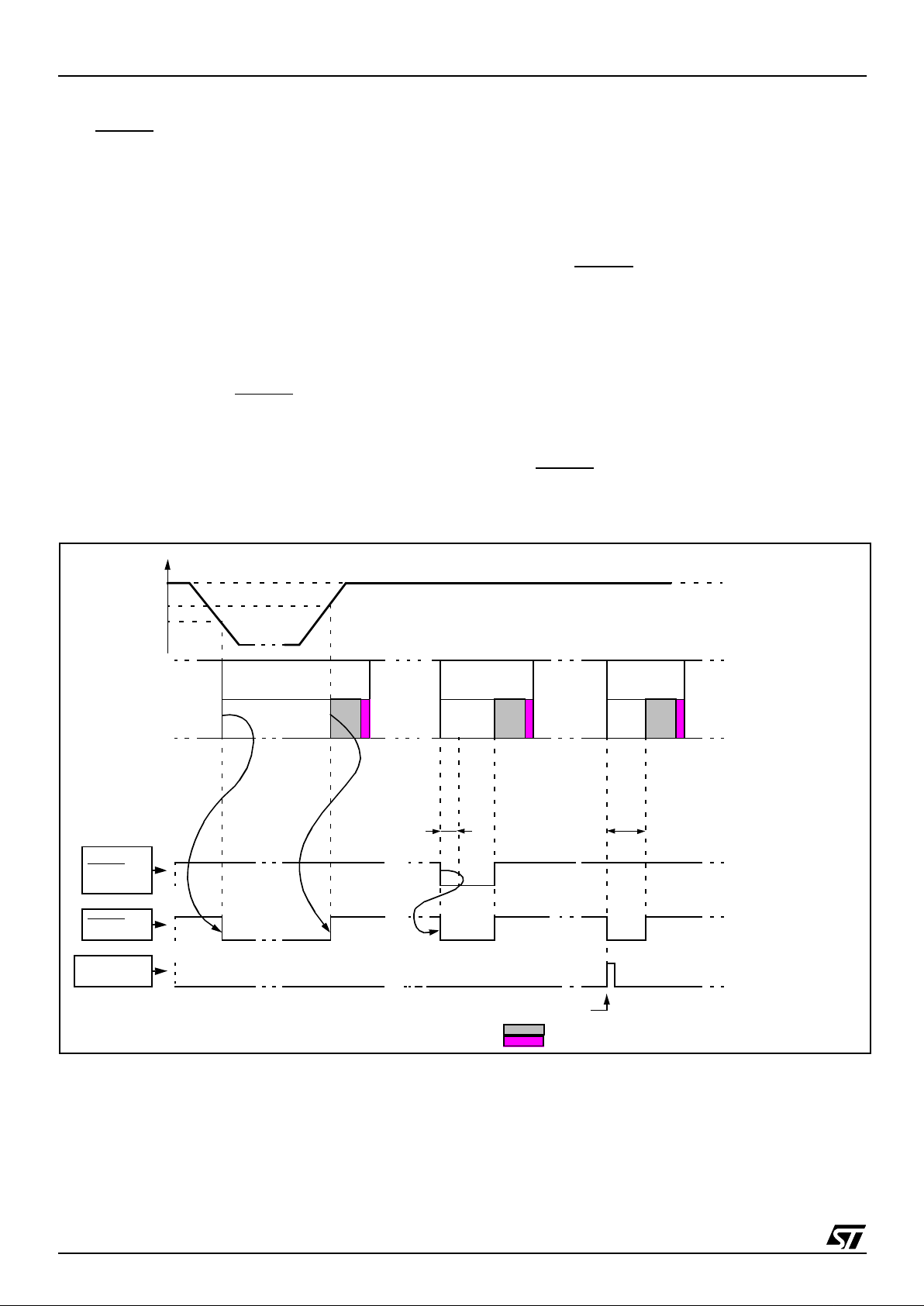

Figure 8. Dat a E

2

PROM Write Operation

Note: If a programming cycle is interrupted (by software or a reset action), the integrity of the data in mem-

ory is not guaranteed.

Byte 1 Byte 2 Byte 32

PHASE 1

Programming cycle

Read operation impossible

PHASE 2

Read operation possible

E2LAT bit

E2PGM bit

Writing data latches Waiting E2PGM and E2LAT to fall

Set by USER applicatio n

Cleared by hardware

⇓

Row / Byte

⇒

0 1 2 3 ... 30 31 Physical Address

0

00h...1Fh

1

20h...3Fh

...

N

Nx20h...Nx20h+1Fh

ROW

DEFINITION

1

ST7LITE2

18/131

DATA EEPROM (Cont’d)

5.4 POWER SAVI N G MO DES

Wait mode

The DATA EEPROM can enter WAIT mode on execution of the WFI instruction of the m icrocontroller or when the microcontroller enters Active-HALT

mode.The DATA EEPROM will immediately enter

this mode if there is no programming i n progress,

otherwise the DATA EEPROM will finish the c ycle

and then enter WAIT mode.

Active-Halt mode

Refer to Wait mode.

Halt mode

The DATA EEPROM immediately enters HALT

mode if the microcontroller ex ecutes the HALT i nstruction. Therefore the EEPROM will stop the

function in progress, and data may be corrupted.

5.5 ACCESS ERROR HANDLING

If a read access occurs while E2LAT=1, then the

data bus will not be driven.

If a write access occurs while E2LAT=0, t hen the

data on the b us w ill n ot b e latc hed.

If a programming cycl e is interrupted (by software/

RESET action), the memory data will not be guaranteed.

5.6 Data EEPROM Read-out Protection

The read-out protection is enabled through an option bit (see section 15.1 on page 123).

When this option is selected, the programs and

data stored in the EEPROM memory are protected

against read-out piracy (including a re-write protection). In Flash devices, when this protection is

removed by reprogram ming t he Option Byte, the

entire Program memeory a nd EEPROM is fi rst automatically erased.

Note: Both Pr ogram Me mory and da ta EEPROM

are protected using the same option bit.

Figure 9. Dat a EEP R OM Program m i ng C yc l e

LAT

ERASE CYCLE WRITE CYCLE

PGM

t

PROG

READ OPERATION NOT POSSIBLE

WRITEOF

DATA LATCHES

READ OPERATION POSSIBLE

INTERNAL

PROGRAMMING

VOLTAGE

1

ST7LITE2

19/131

DATA EEPROM (Cont’d)

5.7 REGISTER DESCRIPTION

EEPROM CONTROL/STATUS REGISTER (EEC-

SR)

Read/Write

Reset Value: 0000 0000 (00h)

Bits 7:2 = Reserved, forced by hardware to 0.

Bit 1 = E2LAT

Latch Access Transfe r

This bit is set by software. It is cleared by hardware at the end of the programming cycle. It can

only be cleared by software if the E2PGM bit is

cleared.

0: Read mode

1: Write mode

Bit 0 = E2PGM

Programming control and status

This bit is set by software to begin the programming

cycle. At the end of the programming cycle, this bit

is cleared by hardware.

0: Programming finished or not yet started

1: Programming cycle is in progress

Note: if the E2PGM bit is cleared during the programming cycle, the m emory data is not guaranteed

Table 3. DATA EEPROM Register M ap and Reset Values

70

000000E2LATE2PGM

Address

(Hex.)

Register

Label

76543210

0030h

EECSR

Reset Value

000000

E2LAT0E2PGM

0

1

ST7LITE2

20/131

6 CENTRAL PRO CESSING UNIT

6.1 INTRODUCTION

This CPU has a full 8-bit architecture and contains

six internal registers allowing efficient 8-bit data

manipulation.

6.2 MAIN FEATURES

■ 63 basic instructions

■ Fast 8-bit by 8-bit multiply

■ 17 main addressing modes

■ Two 8-bit index registers

■ 16-bit stack pointer

■ Low po wer modes

■ Maskable hardware interrupts

■ Non-maskable software interrupt

6.3 CPU REGISTERS

The 6 CPU registers shown in Figure 10 are not

present in the memory mapping and are accessed

by specific instructions.

Accumulator (A)

The Accumulator is an 8-bit general purpose register used to hold operands and the res ults of the

arithmetic and logic calculations and to manipulate

data.

Index Registers (X and Y)

In indexed addressing modes, these 8-bit registers

are used to create either effective addresses or

temporary storage areas for data manipulation.

(The Cross-Assembler generates a precede instruction (PRE) to indicate that the following instruction refers to the Y register.)

The Y register is not affected by the interrupt automatic procedures (not pushed to and popped from

the stack).

Program Counter (PC)

The program counter is a 16-bit register containing

the address of the next instruction to be executed

by the CPU. It is made of two 8-bit registers PCL

(Program Counter Low which is the LSB) and PCH

(Program Counter High which is the MSB).

Figure 10. CPU Registers

ACCUMULATOR

X INDEX REGISTER

Y INDEX REGISTER

STACK POINTER

CONDITION CODE REGISTER

PROGRAM COUNTER

70

1C11HI NZ

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

70

70

70

0

7

15 8

PCH

PCL

15

8

70

RESET VALUE = STACK HIGHER ADDRESS

RESET VALUE =

1X11X1XX

RESET VALUE = XXh

RESET VALUE = XXh

RESET VALUE = XXh

X = Undefined Value

1

ST7LITE2

21/131

CPU REGISTERS (Cont’d)

CONDITION CODE REGISTER (CC)

Read/Write

Reset Value: 111x1xxx

The 8-bit Condition Code regist er contains the i nterrupt mask and four flags repres entative of the

result of the instruction just executed. This register

can also be handled by the PUSH and POP instructions.

These bits can be individually tested and/or controlled by specific instructions.

Bit 4 = H

Half carry

.

This bit is set by hardware when a carry occurs between bits 3 and 4 of t he ALU during an ADD or

ADC instruction. It is reset by hardware during the

same instructions.

0: No half carry has occurred.

1: A half carry has occurred.

This bit is tested using the JRH or JRNH instruction. The H bit is useful in BCD arithmetic subroutine s .

Bit 3 = I

Interrupt mask

.

This bit is set by hardware when entering in interrupt or by software to disable all inte rrupts except

the TRAP software interrupt. This bit is cleared by

software.

0: Interrupts are enabled.

1: Interrupts are disabled.

This bit is controlled by the RIM, SIM and IRET instructions and is tested by the JRM and JR NM instructions.

Note: Interrupts requested while I is set are

latched and can be process ed when I is cleared.

By default an interrupt routine is not in terruptable

because the I bi t is set by h ardware at the start of

the routine and reset by the IRET instruction at the

end of the routine. If the I bit is cleared by software

in the interrupt routine, pending interrupts are

serviced regardless of the priority level of the current interrupt routine.

Bit 2 = N

Negative

.

This bit is set and cleared by hardware. It is representative of the result sign of the last arithm etic,

logical or data manipulation. It is a copy of the 7

th

bit of the result.

0: The result of the last operation is positive or null.

1: The result of the last operation is negative

(i.e. the most significant bit is a logic 1).

This bit is accessed by the JRMI and JRPL instructions.

Bit 1 = Z

Zero

.

This bit is set and cleared by hardware. This bit indicates that the result of the last arithmetic, logical

or data manipulation is zero.

0: The result of the last operation is different from

zero.

1: The result of the last operation is zero.

This bit is accessed by the JREQ and JRNE test

instructions.

Bit 0 = C

Carry/borrow.

This bit is set and cleared b y hardware and software. It indicates an overflow or an un derflow has

occurred during the last arithmetic operation.

0: No overflow or underflow has occurred.

1: An overflow or underflow has occurred.

This bit is driven by the SCF and RCF instructions

and tested by the JRC and JRNC instructions. It i s

also affected by the “bit test and branch”, shift and

rotate instructions.

70

111HINZC

1

ST7LITE2

22/131

CPU REGISTERS (Cont’d)

STACK POINTER (SP)

Read/Write

Reset Value: 01FFh

The Stack Pointer is a 16-bit register which is always pointing to the next free location in the stack.

It is then decremented after data has been pushed

onto the stack and incremented before data is

popped from the stack (see Figure 11).

Since the stack is 128 bytes deep, the 9 most significant bits are forced by hard ware. Following a n

MCU Reset, or after a Reset Stack Pointer instruction (RSP), the Stack Pointer contains its reset value (the SP6 to SP0 bits are set) which is the stack

higher address.

The least significant byte of the Stack Pointer

(called S) can be directly accessed by a LD instruction.

Note: When the lower limit is exceeded, the Stack

Pointer wraps around to the stack upper limit, without indicating the stack overflow. The previously

stored information is then o verwritten and therefore lost. The stack also wraps in case of an underflow.

The stack is used to sav e the return address during a subroutine call and the CPU context during

an interrupt. The user may also directly manipulate

the stack by means of the PUSH and POP instructions. In the case of an interrupt, the PCL is stored

at the first location po inted t o by t he SP. Th en t he

other registers are stored in the next locations as

shown in Figure 11.

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from the stack.

A subroutine call occupies two locations and an interrupt five locat ion s i n the stack ar ea.

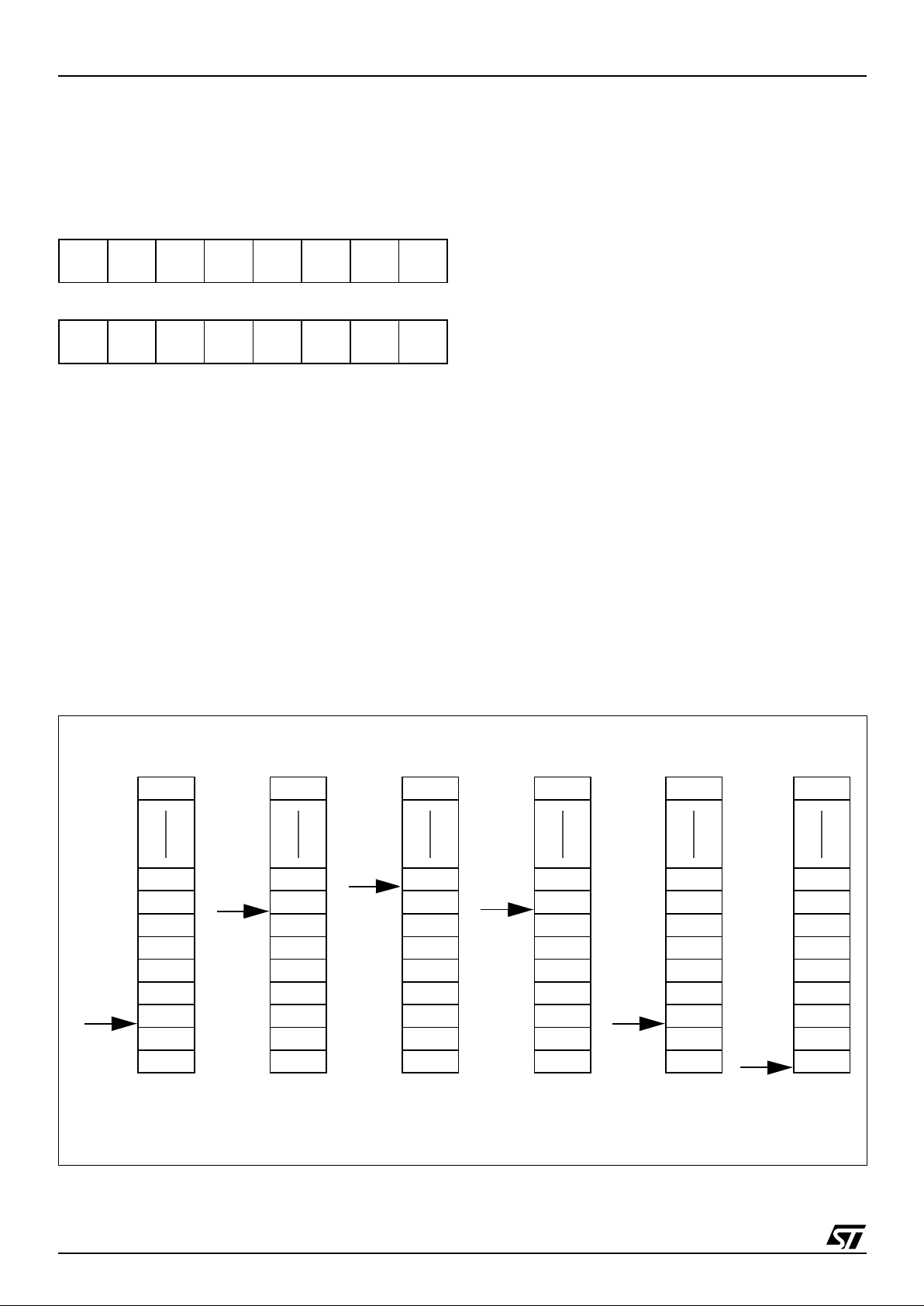

Figure 11. Stack Manipulation Examp le

15 8

00000001

70

1 SP6 SP5 SP4 SP3 SP2 S P1 SP0

PCH

PCL

SP

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

PCL

PCH

X

A

CC

PCH

PCL

SP

SP

Y

CALL

Subroutine

Interrupt

Event

PUSH Y POP Y IRET

RET

or RSP

@ 01FFh

@ 0180h

Stack Higher Address = 01FFh

Stack Lower Address =

0180h

1

ST7LITE2

23/131

7 SUPPLY, RESET AND CLOCK MANAGEMENT

The device includes a range of utility features for

securing the application in critical situations (for

example in case of a power brown-out), and reducing the number of external components.

Main features

■ Clock Management

– 1 MHz internal RC oscillator (enabled by op-

tion byte, available on ST7LITE25 and

ST7LITE29 devices only)

– 1 to 16 MHz or 32kHz External crystal/ceramic

resonator (selected by option byte)

– External Clock Input (enabled by option byte)

– PLL for multiplying the frequency by 8 or 4

(enabled by option byte)

– For clock ART counter on ly: PLL32 for multi-

plying the 8 MHz f requency by 4 (enabled by

option byte). The 8 MHz input frequency is

mandatory and can be obtained in the following ways:

–1 MHz RC + PLLx8

–16 MHz external clock (internally divided

by 2)

–2 MHz. external clock (internally divided by

2) + PLLx8

–Crystal oscillator with 16 MHz output fre-

quency (internally divided by 2)

■ Reset Sequence Manager (RSM)

■ System Integrity Management (SI)

– Main supply Low voltage detection (LVD) with

reset generation (enabled by option byte)

– Auxiliary Voltage detector (AVD) with interrupt

capability for monitoring the main suppl y (enabled by option byte)

7.1 INTERNAL RC OSCILLATOR ADJUSTMENT

The device contains an internal RC oscillator with

an accuracy of 1% for a given device, temperature

and voltage range (4.5V-5.5V). It must be calibrated to obtain the frequency required in the appl ication. This is done by software writing a calibration

value in the RCCR (RC Control Register).

Whenever the microcontroller i s reset, the RCCR

returns to its def ault value (F F h), i.e. each time the

device is reset, the calibration value must be loaded in the RCCR. Predefined calibration values are

stored in EEPROM for 3 and 5V V

DD

supply volt-

ages at 25°C, as shown in the following table.

Note:

– See “ELECTRICAL CHARACTERISTICS” on

page 91. for more information on the frequency

and accuracy of the RC oscillator.

– To improve clock stability, it is recommended to

place a decoupling capacitor between the V

DD

and V

SS

pins.

– These two byte s are syst ematicall y programmed

by ST, including on FASTROM devices. Consequently, customers intending to use FASTROM

service must not use these two bytes.

– RCCR0 and RCCR1 calibration values will be

erased if the read-out protection bit is reset after

it has been set. See “Read out Protection” on

page 14.

Caution: If the voltage or temperature conditions

change in the application, the frequency may need

to be recalibrated.

Refer to application note AN1324 f or information

on how to calibrate the RC frequency using an external reference signal.

7.2 PHASE LOCKED LOOP

The PLL can be used to multiply a 1MHz frequency from the RC oscillator or the external clock by 4

or 8 to obtain f

OSC

of 4 or 8 MHz. The PLL is enabled and the multiplication factor of 4 or 8 is selected by 2 option bits.

– The x4 PLL is intended for operation with V

DD

in

the 2.4V to 3.3V range

– The x8 PLL is intended for operation with V

DD

in

the 3.3V to 5.5V range

Refer to Section 15.1 for the option byte descrip-

tion.

If the PLL is disabled and the RC oscillator is enabled, then f

OSC =

1MHz.

If both the RC oscillator and the PLL are disabled,

f

OSC

is driven by the external clock.

RCCR Conditions

ST7LITE29

Address

ST7LITE25

Address

RCCR0

V

DD

=5V

T

A

=25°C

f

RC

=1MHz

1000h

and FFDEh

FFDEh

RCCR1

V

DD

=3V

T

A

=25°C

f

RC

=700KHz

1001h

and FFDFh

FFDFh

1

ST7LITE2

24/131

PHASE LOCKED LOOP (Cont’d)

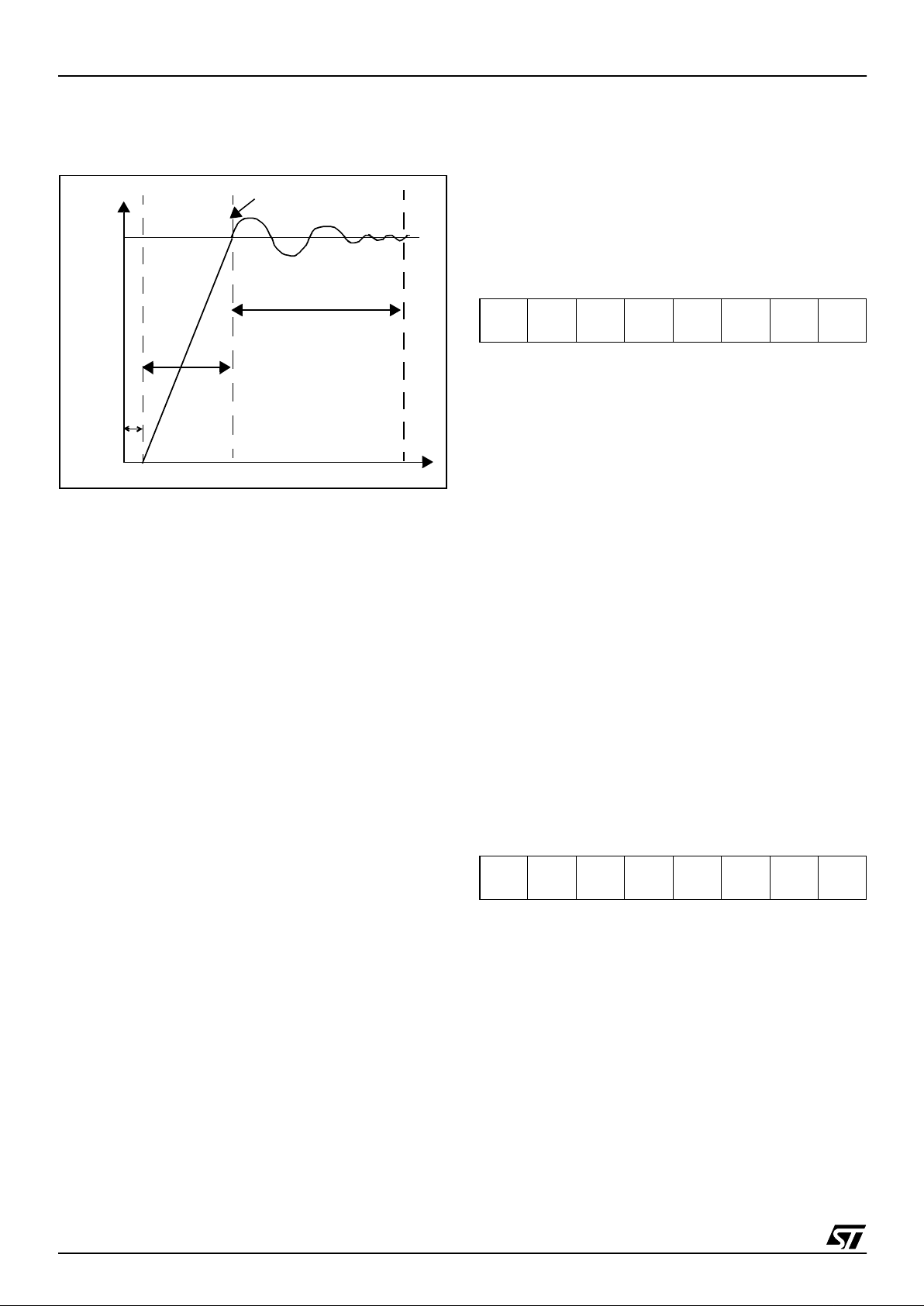

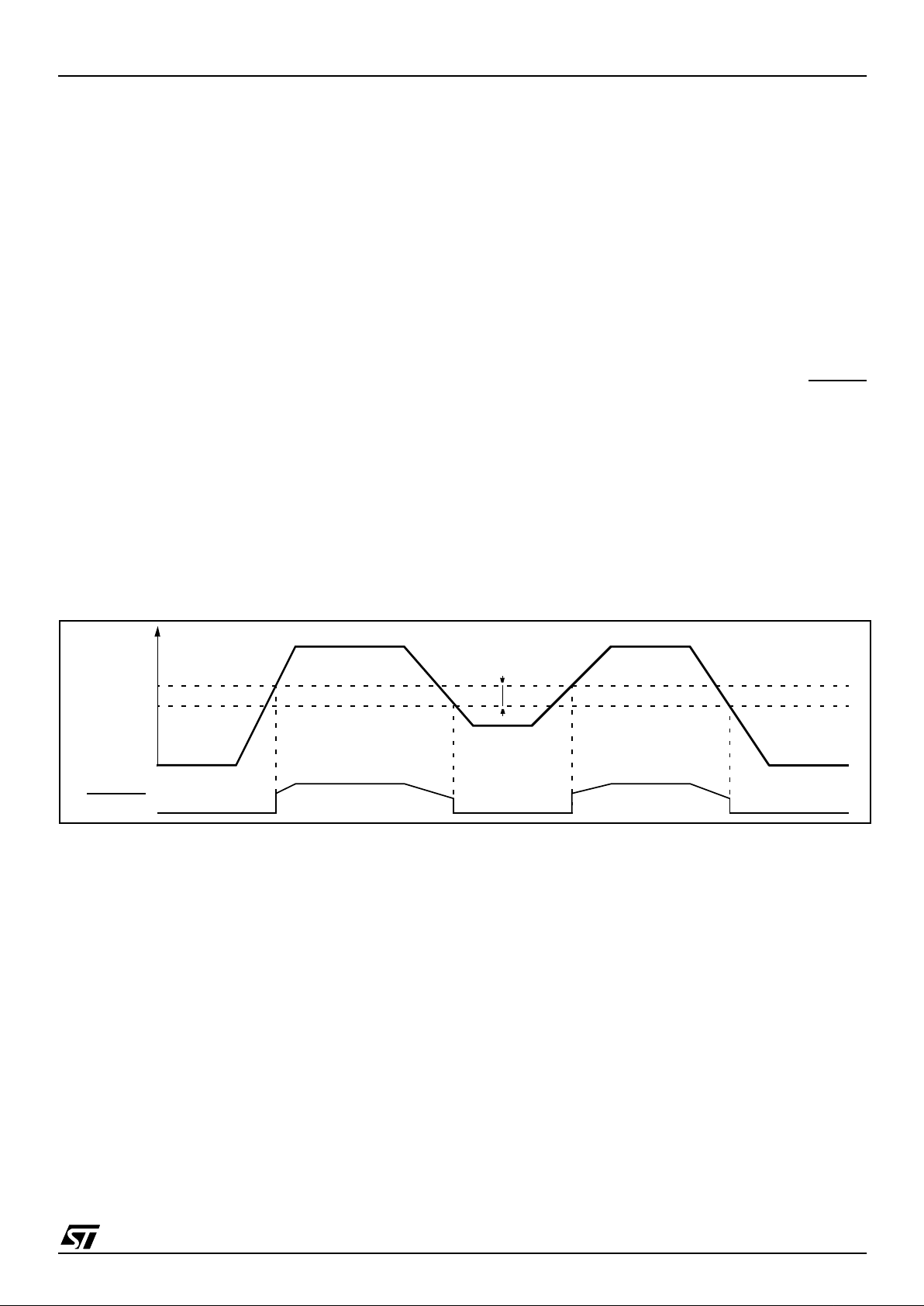

Figure 12. PLL Output Frequency Timing

Diagram

When the PLL is started, after reset or wakeup

from Halt mode or AWUFH mode, it outputs the

clock after a delay of t

STARTUP

.

When the PLL output signal reaches the operating

frequency, the LOCKED bit in the SICSCR register

is set. Full PLL accuracy (ACC

PLL

) is reached after

a stabilization time of t

STAB

(see Figure 12 and

13.3.4 Internal RC Oscillator and PLL)

Refe r to section 7.6.4 on page 33 for a description

of the LOCKED bit in the SICSR register.

7.3 REGISTER DESCRIPTION

MAIN CLOCK CONTROL/STATUS REGISTER

(MCCSR)

Read / Write

Reset Value: 0000 0000 (00h)

Bits 7:2 = Reserved, must be kept cleared.

Bit 1 = MCO

Main Clock Out enable

This bit is read /write by software and cleared by

hardware after a reset. This bit allows to enable

the MCO output clock.

0: MCO clock disabled, I/O port free for general

purpose I/O.

1: MCO clock enabled.

Bit 0 = SMS

Slow Mode select

This bit is read /write by software and cleared by

hardware after a reset. This bit selects the input

clock f

OSC

or f

OSC

/32.

0: Normal mode (f

CPU = fOSC

1: Slow mode (f

CPU = fOSC

/32)

RC CONTROL REGISTER (RCCR)

Read / Write

Reset Value: 1111 1111 (FFh)

Bits 7:0 = CR[7:0]

RC Oscillator Frequency Ad-

justment Bits

These bits must be written immediately after reset

to adjust the RC oscillator frequency and to obtain

an accuracy of 1%. The applica tion can store the

correct value for each voltage range in EEPROM

and write it to this register at start-up.

00h = maximum available frequency

FFh = lowest available frequency

Note: To tune the oscillator, write a series of different values in the register until the correct frequency is reached. The fastest method is to use a dichotomy starting with 80h.

4/8 x

freq.

LOCKED bit set

t

STAB

t

LOCK

input

Output freq.

t

STARTUP

t

70

000000

MCO SMS

70

CR70 CR60 CR50 CR40 CR30 CR20 CR10

CR

0

1

ST7LITE2

25/131

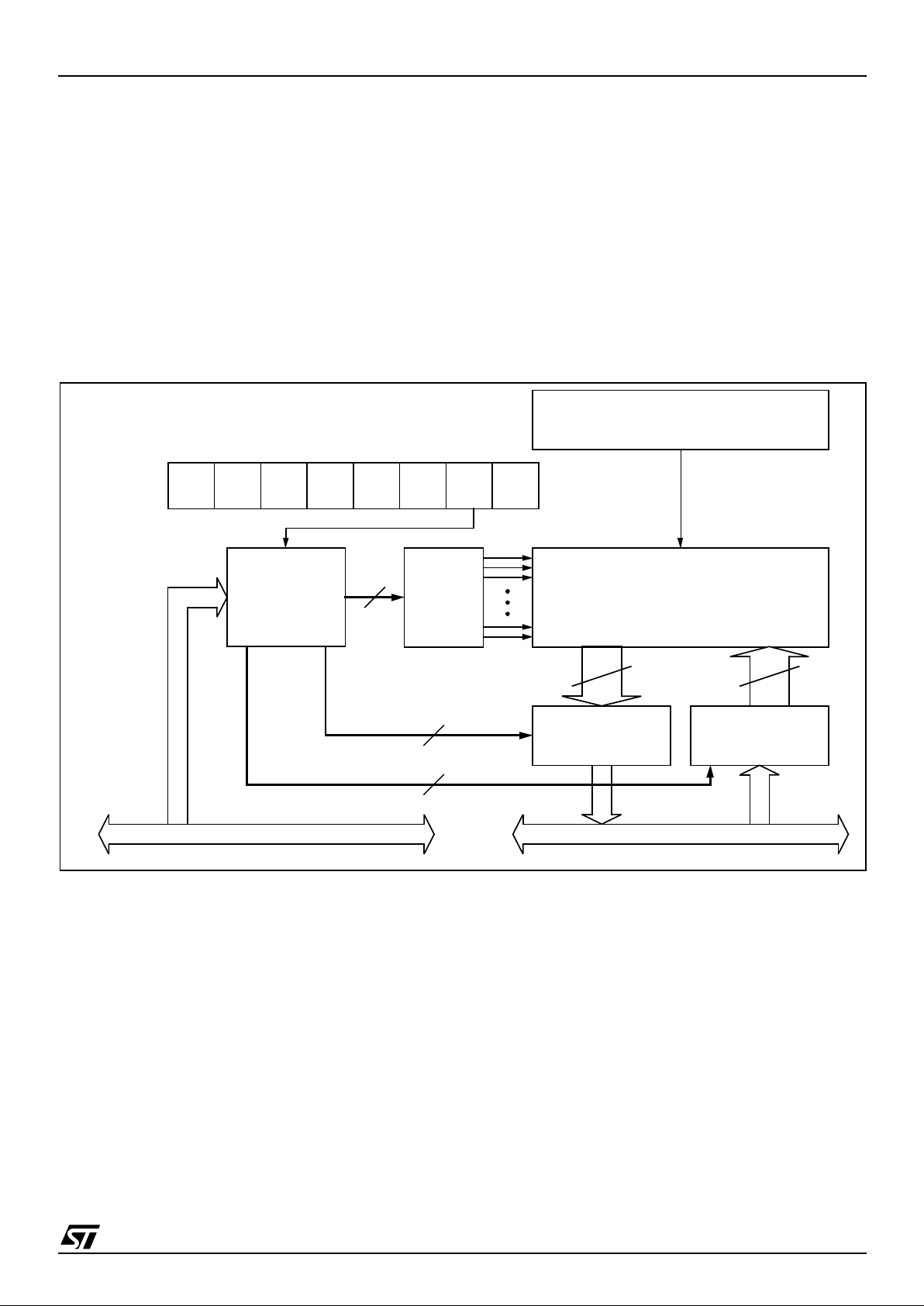

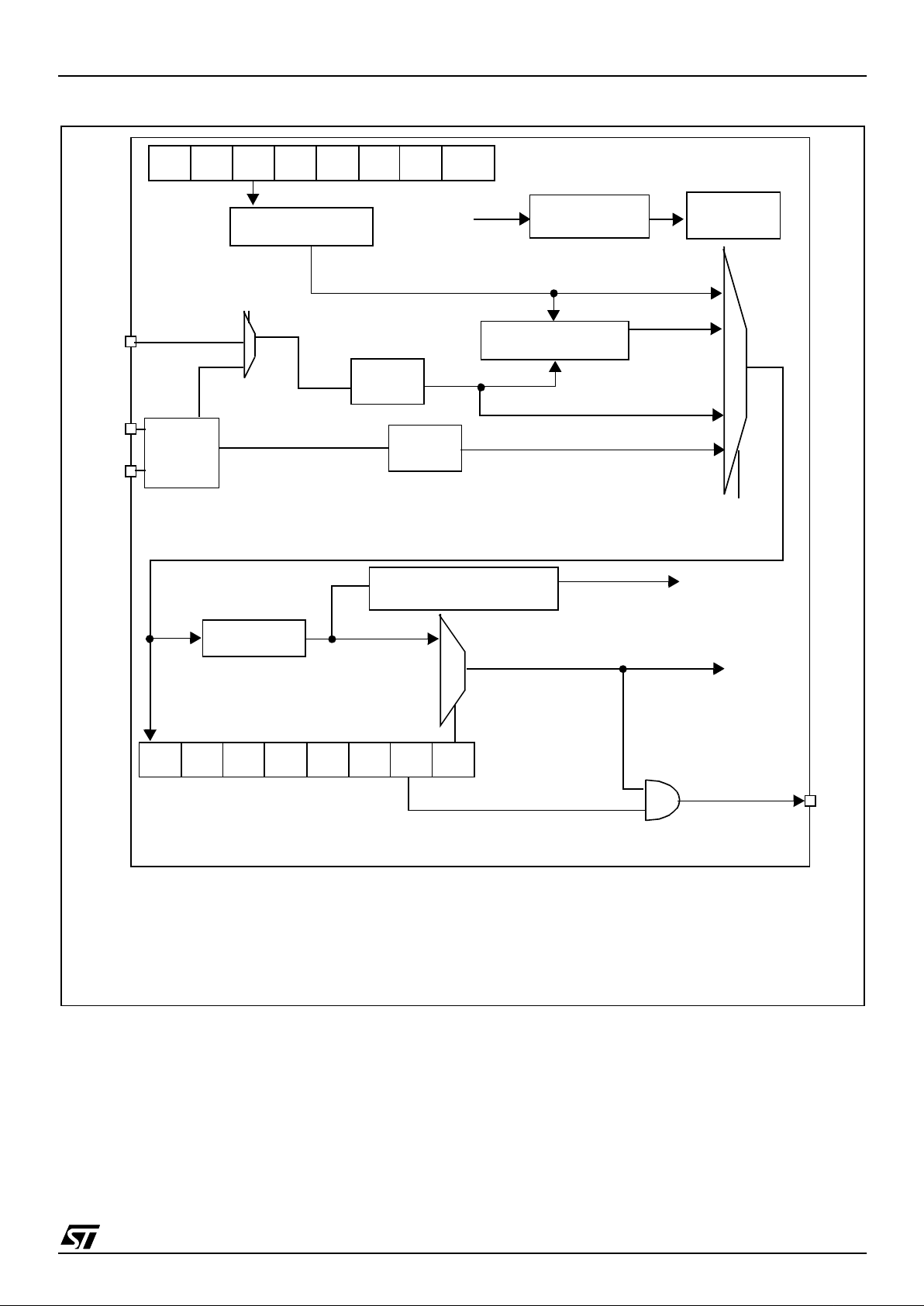

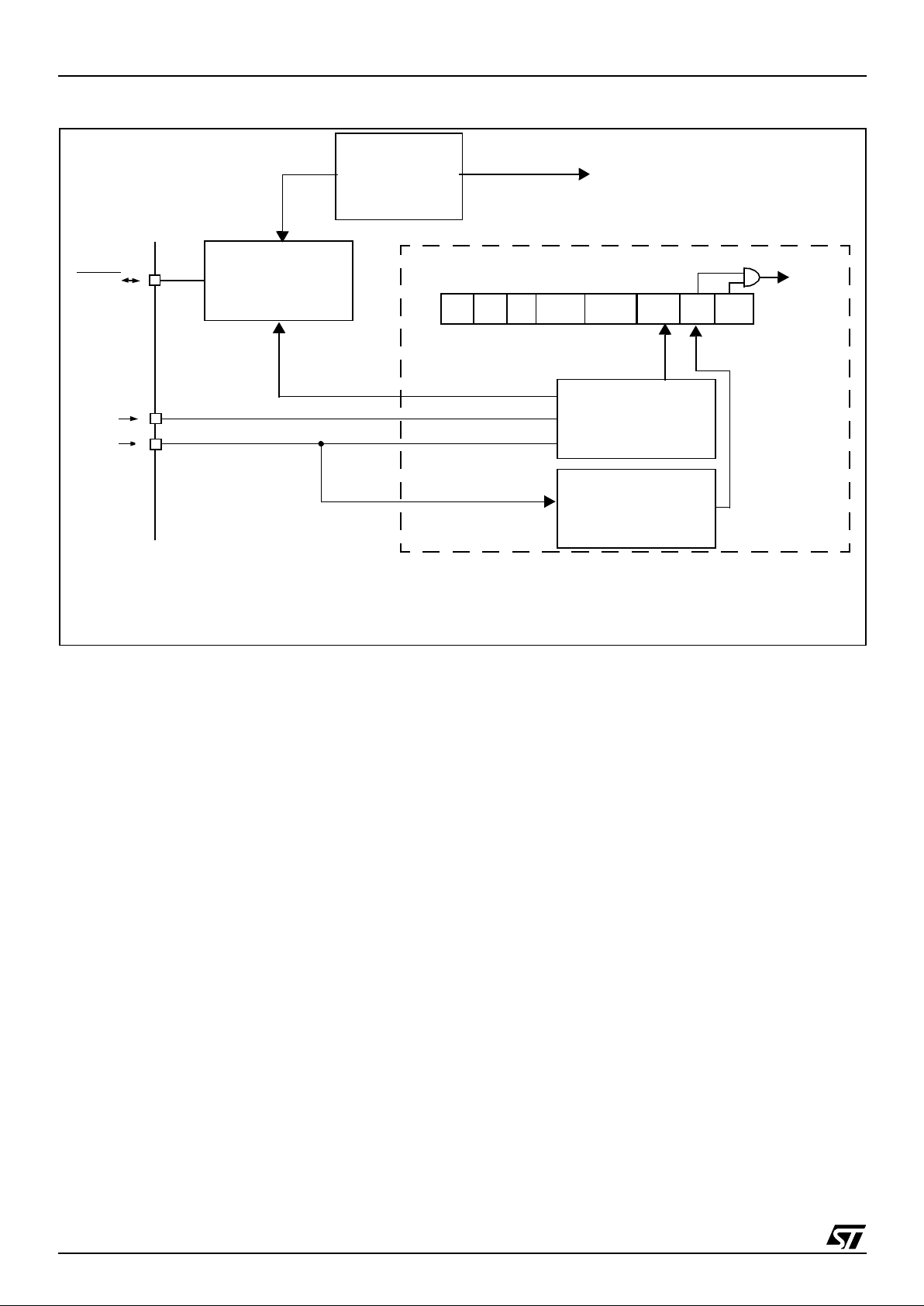

Figure 13. Clock Management Block Diagram

CR4CR7 CR0CR1CR2CR3CR6 CR5 RCCR

f

OSC

MCCSR

SMS

MCO

MCO

f

CPU

f

CPU

TO CPU AND

PERIPHERALS

(1ms timebase @ 8 MHz f

OSC

)

/32 DIVIDER

f

OSC

f

OSC

/32

f

OSC

f

LTIMER

1

0

LITE TIMER 2 COUNTER

8-BIT

AT TIMER 2

12-BIT

PLL

8MHz -> 32MHz

f

CPU

CLKIN

OSC2

CLKIN

Tunable

Oscillator1% RC

PLL 1MHz -> 8MHz

PLL 1MHz -> 4MHz

RC OSC

PLLx4x8

/2

DIVIDER

Option bits

OSC,PLLOFF,

OSCRANGE[2:0]

OSC

1-16 MHZ

or 32kHz

CLKIN

CLKIN

/OSC1

OSC

/2

DIVIDER

OSC/2

CLKIN/2

CLKIN/2

Option bits

OSC,PLLOFF,

OSCRANGE[2:0]

1

ST7LITE2

26/131

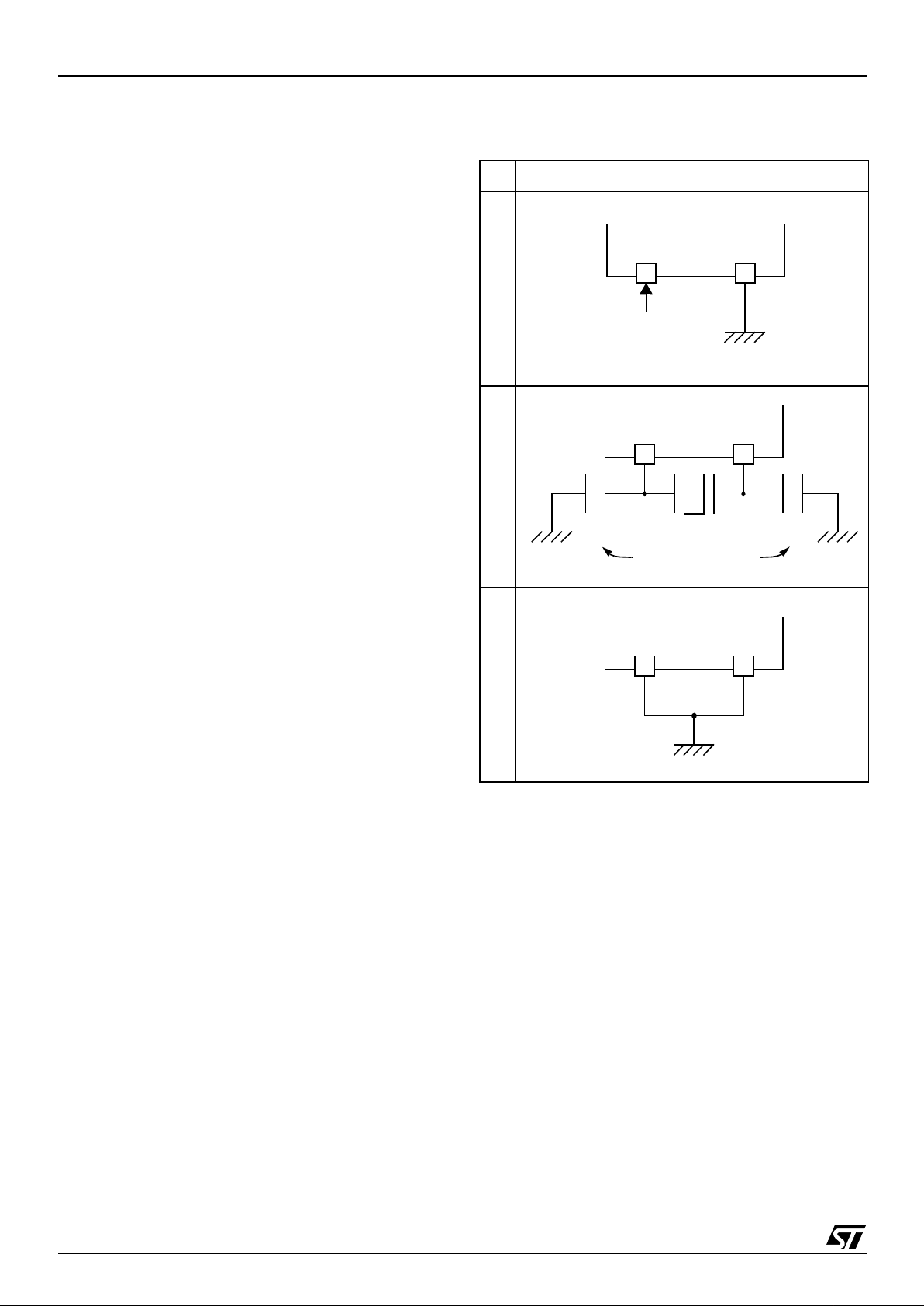

7.4 MULTI-OSCILLATOR (MO)

The main clock of the ST7 can be generated by

four different source types coming from the multioscillator block (1 to 16MHz or 32kHz):

■ an external source

■ 5 crystal or ceramic resonator oscillators

■ an internal high frequency RC oscillator

Each oscillator is optimized for a given freq uency

range in terms of consumption and is selectable

through the option byte. The assoc iated hardware

configurations are shown in Table 4. Refer to the

electrical characteristics section for more details.

External Clock Source

In this external clock mode, a clock signal (square,

sinus or triangle) with ~50% duty cycle has to drive

the OSC1 pin while the OSC2 pin is tied to ground.

Note: when the Multi-Oscillator is not used, PB4 is

selected by default as external clock.

Crystal/Ceramic Oscillators

This family of oscillators has the advantage of producing a very accurate rate on the main clock of

the ST7. The s election within a list of 4 os cillators

with different frequency ran ges has to be done by

option byte in order to redu ce consumption (refer

to section 15.1 on page 123 for more details on the

frequency ranges). In this mode of the multi-oscillator, the resonator and the load c apacitors have

to be placed as close as possible to t he oscillator

pins in order to minimize output distortion and

start-up stabilization time. The loading capacitance values must be adjusted according to the

selected osci lla tor .

These oscillators are not stopped during the

RESET phase to avoid losing time in the oscillator

start-up phase.

Internal RC Oscillator

In this mode, the tunable 1%RC oscilla tor is use d

as main clock source. The two oscillator pins have

to be tied to ground.

Table 4. ST7 Clock Sources

Hardware Configuration

External ClockCrystal/Ceramic ResonatorsInternal RC Oscillator

OSC1 OSC2

EXTERNAL

ST7

SOURCE

OSC1 OSC2

LOAD

CAPACITORS

ST7

C

L2

C

L1

OSC1 OSC2

ST7

1

ST7LITE2

27/131

7.5 RESET SEQUENCE MANAGER (RSM)

7.5.1 Introd uc tion

The reset sequence manager in cludes three RESET sources as shown in Figure 15:

■ External RESET source pulse

■ Internal LVD RESET (Low Voltage Detection)

■ Internal WATCHDOG RESET

These sources act on the RESET

pin and it is al-

ways kept low during the delay phase.

The RESET service routine vector is fixed at ad-

dresses FFFEh-FFFFh in the ST7 memory map.

The basic RE SET sequence consists of 3 phases

as shown in Figure 14:

■ Active Phase depending on the RESET source

■ 256 or 40 96 CPU clock cy cle delay (see table

below)

■ RESET vector fetch

The 256 or 4096 CPU clock cycle delay allows the

oscillator to stabilise and ensures that recovery

has taken place from t he Reset st ate. T he short er

or longer clock cycle delay is automatically selected dependi ng on the clock source chosen by option byte:

The RESET vector fetch phase duration is 2 clock

cycles.

If the PLL is en abled by opt ion by te, it ou tpu ts the

clock after an additional delay of t

STARTUP

(see

Figure 12).

Figure 14. RESET Sequence Phases

7.5.2 Async hr onous External RESET

pin

The RESET

pin is both an input and an open-drain

output with integrated R

ON

weak pull-up resistor.

This pull-up has no fixed value but varies in accordance with the input voltage. It

can be pulled

low by external circuitry to reset the device. See

Electrical Characteristic section for more details.

A RESET signal originating from an external

source must have a duration of at least t

h(RSTL)in

in

order to be recognized (see Figure 16). This detection is asynchronous and therefore the MCU

can enter reset state even in HALT mode.

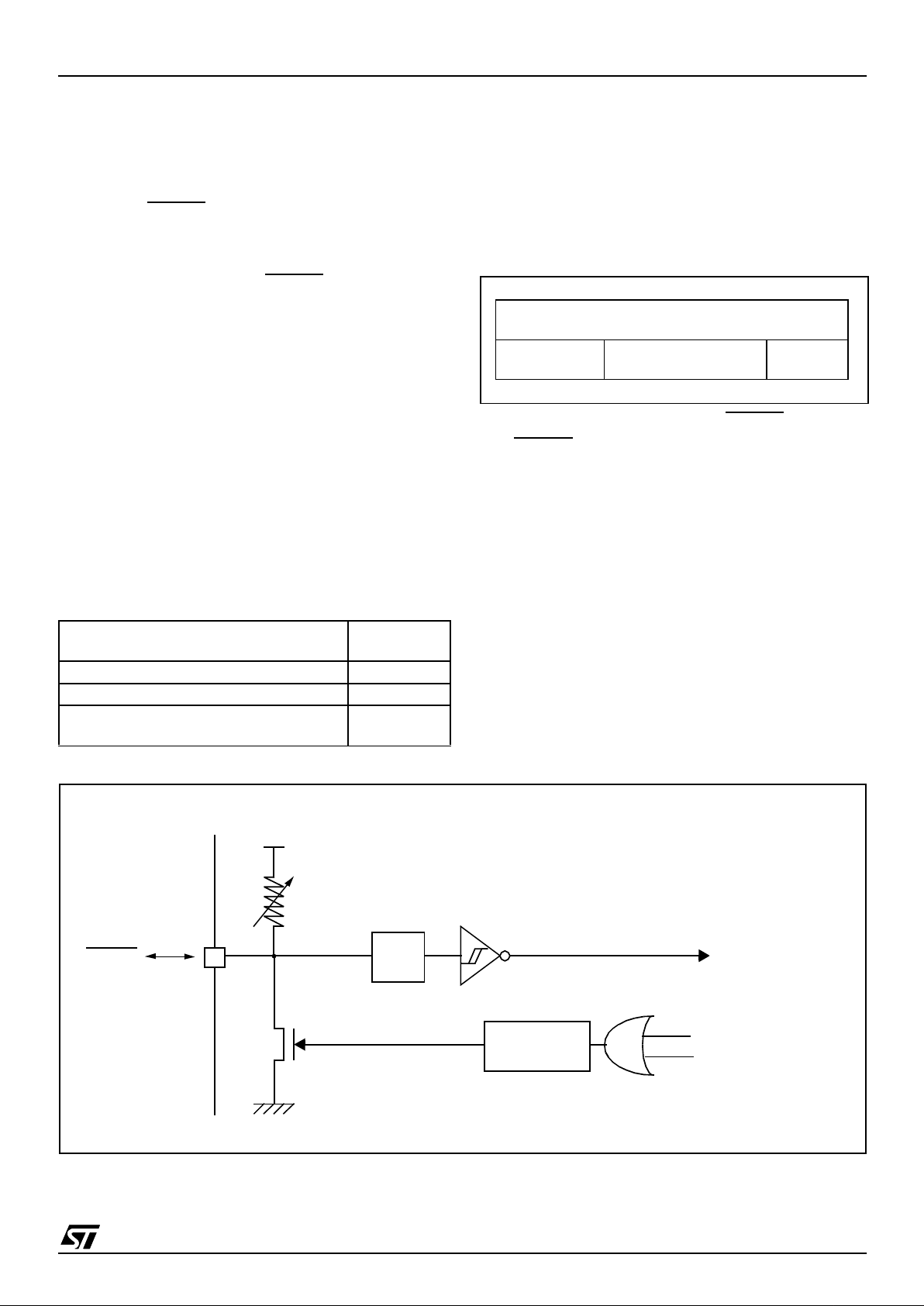

Figure 15. Reset Block Diagram

Clock Source

CPU clock

cycle delay

Internal RC Oscillator 256

External clock (connected to CLKIN pin) 256

External Crystal/Ceramic Oscillator

(connected to OSC1/OSC2 pins)

4096

RESET

Active Phase

INTERNAL RESET

256 or 4096 CLOCK CYCLES

FETCH

VECTOR

RESET

R

ON

V

DD

WATCHDOG RESET

LVD RESET

INTERNAL

RESET

PULSE

GENERATOR

Filter

1

ST7LITE2

28/131

RESET SEQUENCE MANAGER (Cont’d)

The RESET

pin is an asynchronous signal which

plays a major role in EMS performance. In a noisy

environment, it is recommended to follow the

guidelines mentioned in the elect rical characteristics section.

7.5.3 External Power-On RESET

If the LVD is disabled by option byte, to start up the

microcontroller correctly, the user must ensure by

means of an external reset circuit that the reset

signal is held low until V

DD

is over the minimum

level specified for the selected f

OSC

frequency.

A proper reset signal for a slow rising V

DD

supply

can generally be provide d by a n external R C network connected to the RESET

pin.

7.5.4 Internal Low Voltage Detector (LVD)

RESET

Two differe nt RESET sequences caused by the internal LVD circuitry can be distinguished:

■ Power-On RESET

■ Voltage Drop RESET

The device RESET

pin acts as an output that is

pulled low when V

DD<VIT+

(rising edge) or

V

DD<VIT-

(falling edge) as shown in Figure 16.

The LVD filters spikes on V

DD

larger than t

g(VDD)

to

avoid parasitic resets.

7.5.5 Internal Watchdog RESET

The RESET sequence generated by a internal

Watchdog counter overflow is shown in Figure 16.

Starting from the Watchdog counter underflow, the

device RESET

pin acts as an output that is pulled

low during at least t

w(RSTL)out

.

Figure 16. RESET Sequences

V

DD

RUN

RESET PIN

EXTERNAL

WATCHDOG

ACTIVE PHASE

V

IT+(LVD)

V

IT-(LVD)

t

h(RSTL)in

RUN

WATCHDOG UNDERFLOW

t

w(RSTL)out

RUN RUN

RESET

RESET

SOURCE

EXTERNAL

RESET

LVD

RESET

WATCHD O G

RESET

INTERNAL RESET (256 or 4096 T

CPU

)

VECTOR FETCH

ACTIVE

PHASE

ACTIVE

PHASE

1

ST7LITE2

29/131

7.6 SYSTEM INTEGRITY MANAGEMENT (SI)

The System Integrity Mana gement block co ntains

the Low voltage Detector (LVD) and Auxiliary Voltage Detector (AVD) functions. It is managed by

the SICSR register.

7.6.1 Low Voltage Detector (LVD)

The Low Voltage Dete ctor function (LVD ) generates a static reset when the V

DD

supply voltage is

below a V

IT-(LVD)

reference value. This means that

it secures the power-up as well as the power-down

keeping the ST7 in reset.

The V

IT-(LVD)

reference value for a voltage drop is

lower than the V

IT+(LVD)

reference value for poweron in order to avoid a parasitic reset when the

MCU starts running and sinks current on the supply (hysteresis).

The LVD Reset circuitry generat es a reset when

V

DD

is below:

–V

IT+(LVD)

when VDD is rising

–V

IT-(LVD)

when VDD is falling

The LVD func t io n is illustrat ed in F igure 17.

The voltage threshold can be configured by option

byte to be low, medium or high.

Provided the minimum V

DD

value (guaranteed for

the oscillator frequency) is above V

IT-(LVD)

, the

MCU can only be in two modes:

– under full software control

– in static safe reset

In these conditions, secure operation is always ensured for the application without the need for external reset hardware.

During a Low Voltage Detector Reset, the RESET

pin is held low, thus p ermitting the MCU to reset

other devices.

Notes:

The LVD allows the device to be used without any

external RESET circuitry.

The LVD is an optional func tion which can be se-

lected by option byte.

Figure 17. Low Voltage Detector vs Reset

V

DD

V

IT+

(LVD)

RESET

V

IT-

(LVD)

V

hys

1

ST7LITE2

30/131

Figure 18. Reset and Supply Management Block Diagram

LOW VOLTA G E

DETECTOR

(LVD)

AUXILIARY VOLTAGE

DETECTOR

(AVD)

RESET

V

SS

V

DD

RESET SEQUENCE

MANAGER

(RSM)

AVD Interrupt Reque st

SYSTEM INTEGRITY MANAGEMENT

WATCHDOG

SICSR

TIMER (WDG)

AVDIEAVDF

STATUS FLAG

00 LVDRFLOCKEDWDGRF0

1

ST7LITE2

31/131

SYSTEM INTEGRITY MANAGEMENT (Cont’d)

7.6.2 Auxiliary Voltage Detector (AVD)

The Voltage Detector function (AVD) is based on

an analog comparison between a V

IT-(AVD)

and

V

IT+(AVD)

reference value and the VDD main sup-

ply voltage (V

AVD

). The V

IT-(AVD)

reference value

for falling voltage is lower than the V

IT+(AVD)

reference value for rising voltage in order to avoid parasitic detection (hysteresis).

The output of the AVD comparator is directly readable by the application software through a real

time status bit (AVDF) in t he S ICS R regi ster. This

bit is read only.

Caution: The AVD functions only if the LVD is en-

abled through the option byte.

7.6.2.1 Monitoring the V

DD

Main Supply

The AVD vol tage thres hold value is relative to t he

selected LVD threshold configured by option b yte

(see section 15.1 on page 123).

If the AVD interrupt is enabled, an interrupt is generated when the vol tage crosses the V

IT+(LVD)

or

V

IT-(AVD)

threshold (AVDF bit is set).

In the case of a drop i n v oltage, t he A V D i nterrupt

acts as an early warning, allowing software to shut

down safely before the LV D resets the microcontroller. See Figure 19.

Figure 19. Using the AVD to Monitor V

DD

V

DD

V

IT+(AVD)

V

IT-(AVD)

AVDF bit

01

RESET

IF AVDIE bit = 1

V

hyst

AVD INTERRUPT

REQUEST

INTERRUPT C leared by

V

IT+(LVD)

V

IT-(LVD)

LVD RESET

Early Warning Interrupt

(Power has dropped, MCU not

not yet in reset)

01

hardware

INTERRUPT Cleared by

reset

1

ST7LITE2

32/131

SYSTEM INTEGRITY MANAGEMENT (Cont’d)

7.6.3 Low Power Modes

7.6.3.1 Interrupts

The AVD interrupt event generates an interrupt if

the corresponding Enable Control Bit (AVDIE) is

set and the interrupt mask in the CC register is reset (RIM instruction).

Mode Description

WAIT

No effect on SI. AVD interrupts cause the

device to exit from Wait mode.

HALT

The CRSR register is frozen.

The AVD remains active.

Interrupt Event

Event

Flag

Enable

Control

Bit

Exit

from

Wait

Exit

from

Halt

AVD event AVDF AVDIE Yes No

1

ST7LITE2

33/131

SYSTEM INTEGRITY MANAGEMENT (Cont’d)

7.6.4 Register Description

SYSTEM INTE GRITY (SI) CONTROL/STAT U S REGISTER (SICSR)

Read/Write

Reset Value: 0000 0xx0 (0xh)

Bit 7:5 = Reserved, must be kept cleared.

Bit 4 = WDGRF

Watchdog reset flag

This bit indicates that the last Reset was generated by the Watchd og peripheral. It is set by hardware (watchdog reset) and cleared by software

(writing zero) or an LVD Reset (to ensure a stable

cleared state of the WDGRF flag when CPU

starts).

Combined with the LVDRF flag information, the

flag description is given by the following table.

Bit 3 = L OCKED

PLL Locked Flag

This bit is set and cleared by hardware. It is set automatically when the PLL reaches its operating frequency.

0: PLL not locked

1: PLL locked

Bit 2 = LVDRF

LVD reset flag

This bit indicates that the last Reset was generated by the LVD block. It is set by hardware (LVD reset) and cleared by software (by reading). When

the LVD is disabled by OPTION BYTE, the LVDRF

bit value is undefined.

Bit 1 = AVDF

Voltage Detector flag

This read-only bit is set and cleared by hardware.

If the AVDIE bit is set, an interrupt reques t is generated when the AV DF bit is set. Refer to Figure

19 and to Section 7.6.2.1 for additional details.

0: V

DD

over AVD threshold

1: V

DD

under AVD threshold

Bit 0 = AVDIE

Voltage Detector interrupt enable

This bit is set and cleared by software. It enables

an interrupt to be generated when the AVDF flag is

set. The pending interrupt information is automatically cleared when sof tware ent ers t he A V D in terrup t rout ine.

0: AVD interrupt disabled

1: AVD interrupt enabled

Applicatio n notes

The LVDRF flag i s not cleared when another RE SET type occurs (external or watchdog), the

LVDRF flag remains set to ke ep trace of the original failure.

In this case, a watchdog res et can be detected by

software while an external reset can not.

70

000

WDG

RF

LOCKED LVDRF AVDF AVDIE

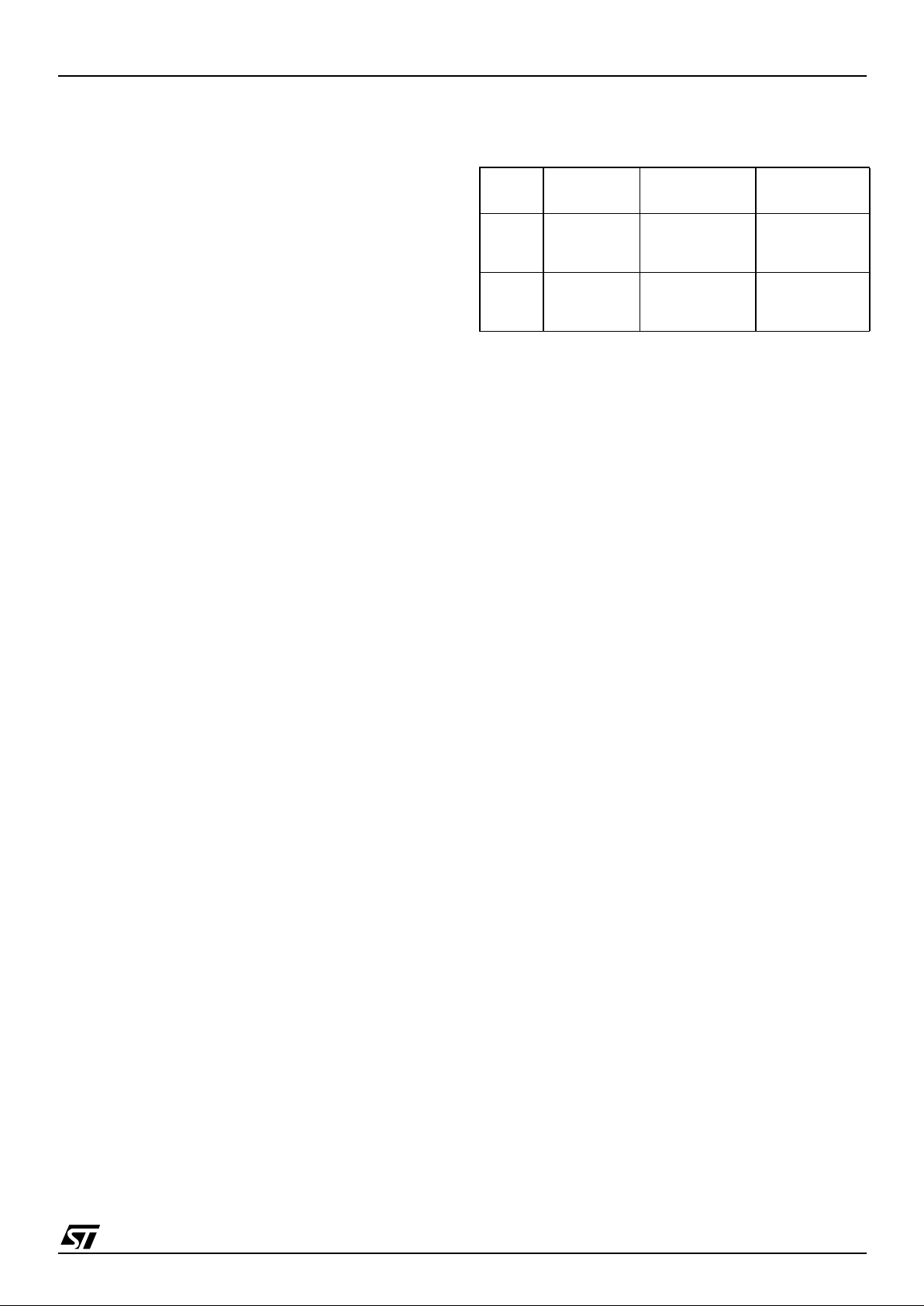

RESET Sources LVDRF WDGRF

External RESE T

pin 0 0

Watchdog 0 1

LVD 1 X

1

ST7LITE2

34/131

8 INTERRUP T S

The ST7 core may be interrupted by one of two different methods: maskable hardware interrupts as

listed in the Interrupt Mapping Table and a nonmaskable software interrupt (TRAP). The Interrupt

processing flowchart is shown in Figure 20.

The maskable interrupts must be enabled by

clearing the I bit in order to be serviced. However,

disabled interrupts may be latched and processed

when they are enabled (see external interrupts

subsection).

Note: After reset, all interrupts are disabled.

When an interrupt has to be serviced:

– Normal processing is susp ended at the end of

the current instruction execution.

– The PC, X, A and CC registers are saved onto

the stack.

– The I bit of the CC register is set to prevent addi-

tional interrupts.

– The PC is then loaded with the interrupt vector of

the interrupt to service and the first instruction of

the interrupt service routine is fetched (refer to

the Interrupt Mapping Table for vector addresses).

The interrupt service routine should finish with the

IRET instruction w hich causes the contents of the

saved registers to be recovered from the stack.

Note: As a consequence of the IRET instruction,

the I bit will be cl eared and the main p rogram will

resume.

Priority Management

By default, a servicing interrupt cannot be interrupted because the I bi t is set by hardware ent ering in interrupt routine.

In the case when several int e rrupts a re simultaneously pending, an hardware priority defines which

one will be serviced first (see the Interrupt Mapping Table).

Interrupts and Low Power Mode

All interrupts allow the processor to leave the

WAIT low power mode. Only external and specifically mentioned interrupts allow the proces sor to

leave the HALT low power mode (refer to the “Exit

from HALT“ column in th e Interrupt Mapping Table).

8.1 NON MASKABLE SOFTWARE INTERRUPT

This interrupt is entered when the TRAP instruction is executed regardless of the state of the I bit.

It will be serviced according to the flowchart on

Figure 20.

8.2 EXTERNAL INTERRUPTS

External interrupt vectors can be loaded into the

PC register if the corresponding ex ternal interrupt

occurred and if the I bit is cleared. These interrupts

allow the processor to leave the Halt low power

mode.

The external interru pt polarity is selected thro ugh

the miscellaneous register or interrupt register (if

available).

An external interrupt triggered on edge will be

latched and the interrupt request automatically

cleared upon entering the interrupt service routine.

If several input pins, connected to the same interrupt vector, are configured as interrupts, their signals are logically NANDed before entering the

edge/level detection block.

Caution: The type of sensitivity defined in the Miscellaneous or Interrupt register (if available) applies to the ei source. In case of a NANDed source

(as described on the I/O ports section), a low level

on an I/O pin configured as input with interrupt,

masks the interrupt request even in case of risingedge sensitivity.

8.3 PERIPHERAL INTERRUPTS

Different peripheral interrupt flags in the status

register are able to cause an interrupt when they

are active if both:

– The I bit of the CC register is cleared.

– The corresponding enable bit is set in the control

register.

If any of these two conditions is false, the interrupt

is latched and thus remains pending.

Clearing an interrupt request is done by:

– Writing “0” to the corresponding bit in the status

register or

– Access to the status register while t he flag is set

followed by a read or write of an associated register.

Note: the clearing sequence resets the internal

latch. A pending interrupt (i.e. waiting for being enabled) will therefore be lost if the clear sequence is

executed.

1

ST7LITE2

35/131

INTERRUPTS (Cont’d)

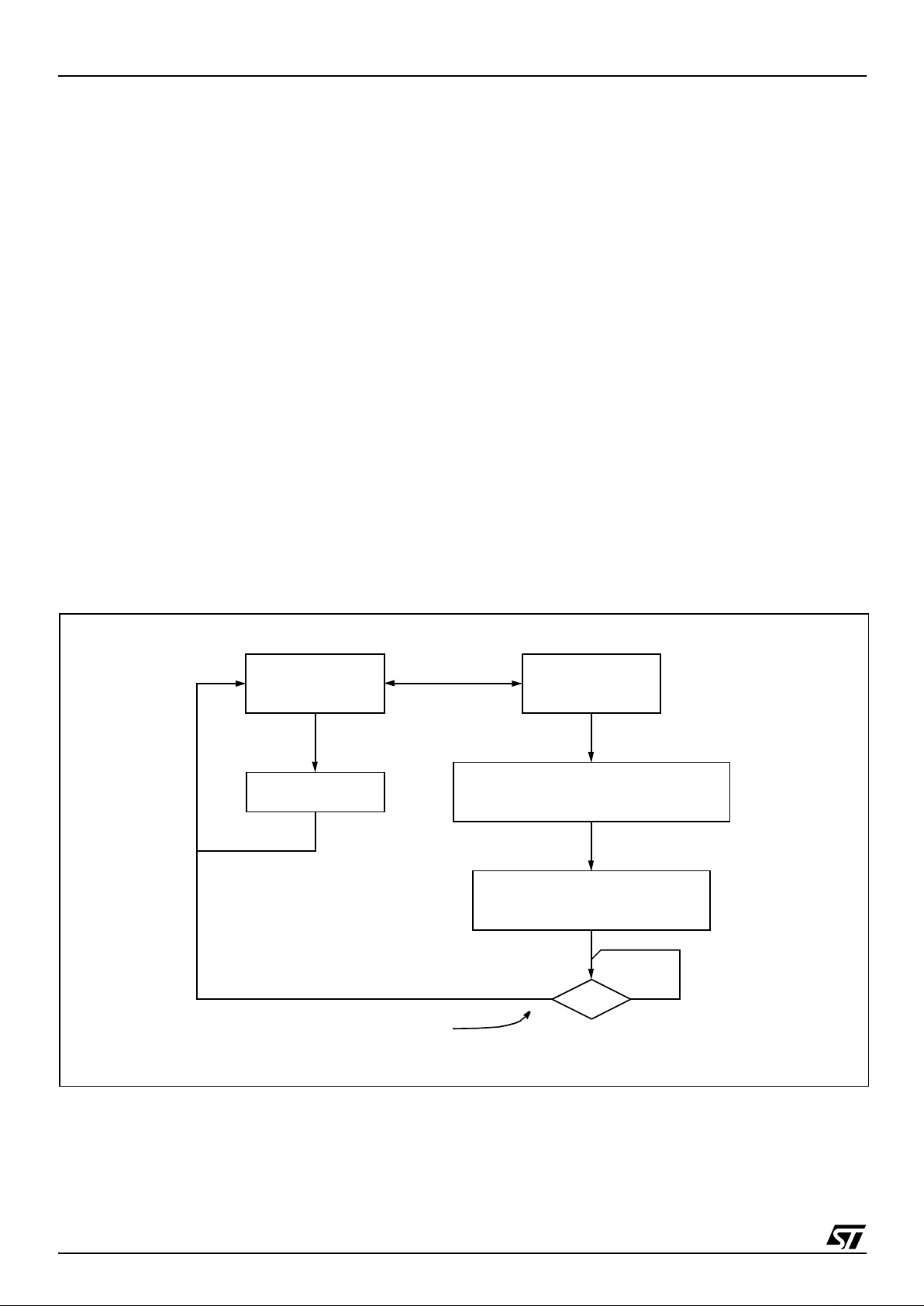

Figure 20. Int errupt Processing Flowchart

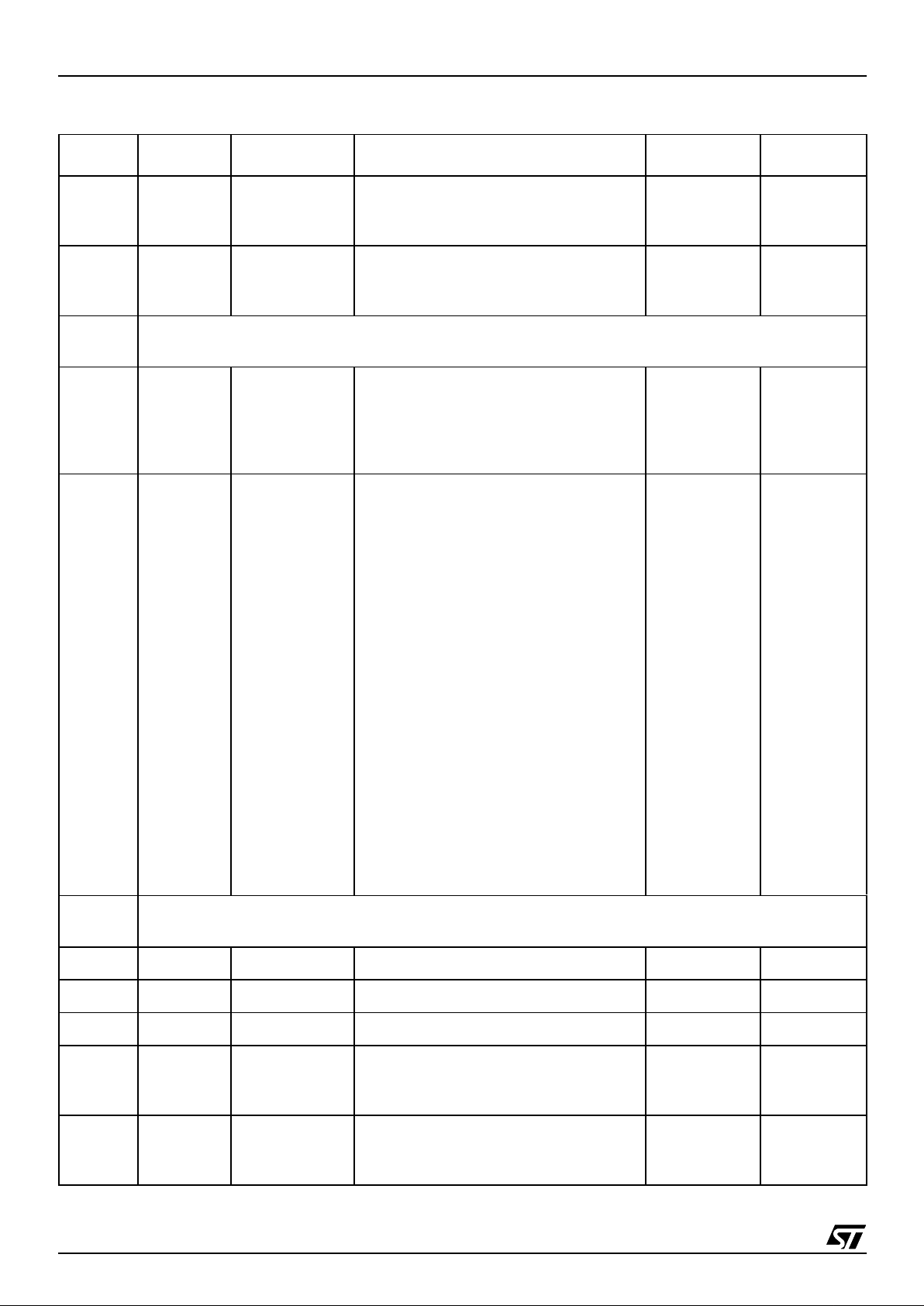

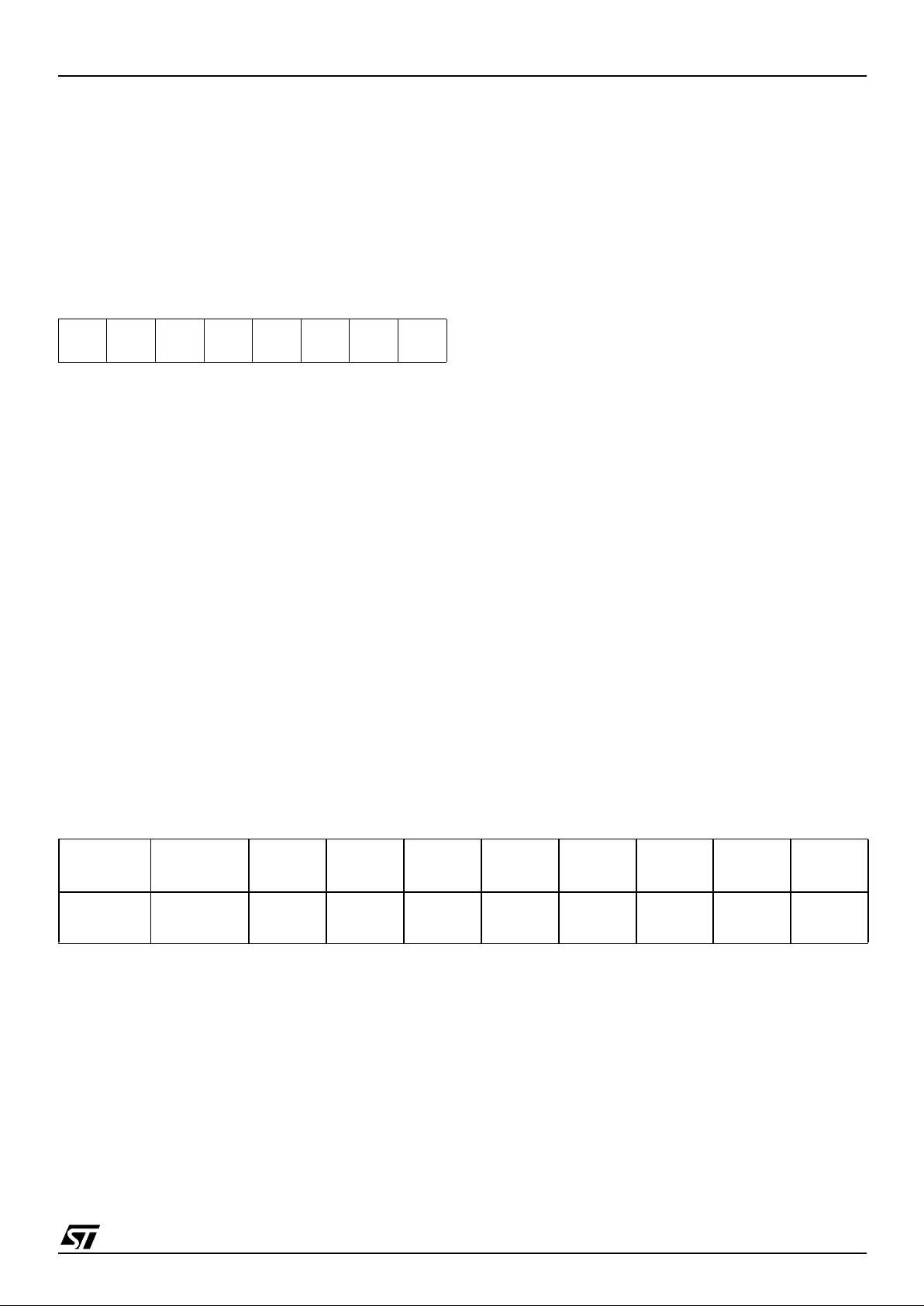

Table 5. I nte rrupt Mapping

Note 1: This interrupt exits the MCU from “Auto Wake-up from Halt” mode only.

N°

Source

Block

Description

Register

Label

Priority

Order

Exit

from

HALT or

AWUFH

Exit

from

ACTIVE

-HALT

Address

Vector

RESET Reset

N/A

Highest

Priority

Lowest

Priority

yes yes FFFEh-FFFFh

TRAP Software Interrupt no

no

FFFCh-FFFDh

0 AWU Auto Wake Up Interrupt AWUCSR yes

1)

FFFAh-FFFBh

1 ei0 External Interrupt 0

N/A

yes

FFF8h-FFF9h

2 ei1 External Interrupt 1 FFF6h-FFF7h

3 ei2 External Interrupt 2 FFF4h-FFF5h