SGS Thomson Microelectronics M40Z111W, M40Z111VMH1, M40Z111MH1, M40Z111 Datasheet

M40Z111

M40Z111W

NVRAM CO NTROLLER for up to TWO LPSRAM

February 1999 1/12

CONVERT LOW POWE R SRAMs into

NVRAMs

PRECISION POWER MONITORING and

POWER SWITCHING CIRCUITRY

AUTOMATIC WRITE-PROTECTION when V

CC

is OUT-OF-TOLERANCE

CHOICE of SUPPLY VOL TAGES and

POWER-FAIL DESELECT VOLTAGES:

– M40Z111:

V

CC

= 4.5V to 5.5V

THS = V

SS

4.5V ≤ V

PFD

≤ 4.75V

THS = V

OUT

4.2V ≤ V

PFD

≤ 4.5V

– M40Z111W:

V

CC

= 3.0V to 3.6V

THS = V

SS

2.8V ≤ V

PFD

≤ 3.0V

V

CC

= 2.7V to 3.3V

THS = V

OUT

2.5 ≤ V

PFD

≤ 2.7V

LESS THAN 15ns CHIP E NAB LE AC CESS

PROPAGATION DELAY (for 5.0V device)

PACKAGING INCLUDES a 28-LEAD SOIC

and SNAPHAT

®

TOP

(to be Ordered Separately)

SOIC PACKAGE PROVIDES DIRECT

CONNECTION for a SNAPHAT TOP which

CONTAINS the BATTERY

DESCRIPTION

The M40Z111/111W NVRAM Controller is a selfcontained device which converts a standard lowpower SRAM into a non-volatile memory.

A precision voltage reference and comparator

monitors the V

CC

input for an out-of-tolerance con-

dition.

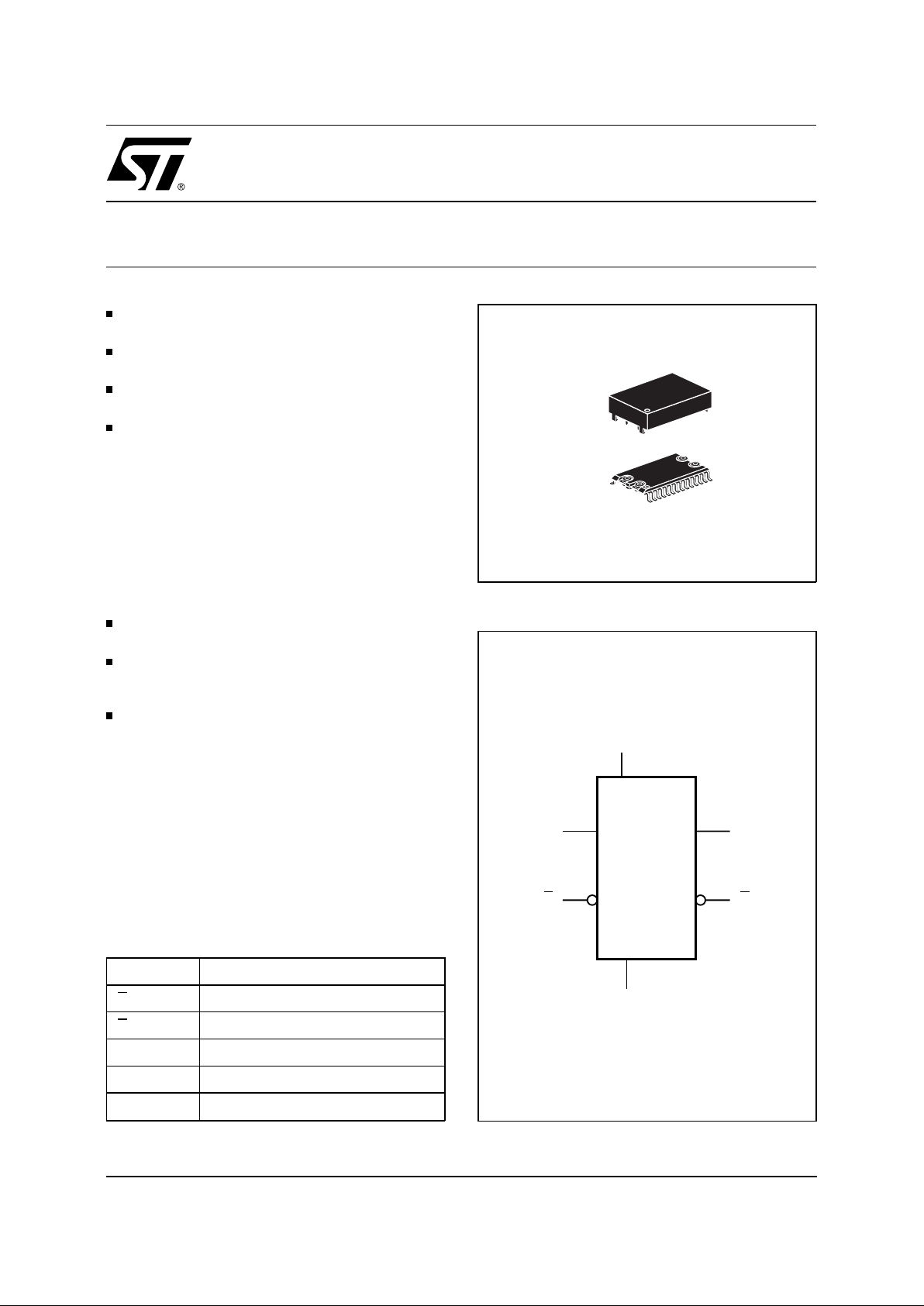

AI02238B

THS

V

CC

M40Z111

M40Z111W

E

CON

V

SS

E

V

OUT

Figure 1. Logic Diagram

THS Threshold Select Input

E Chip Enable Input

E

CON

Conditioned Chip Enable Output

V

OUT

Supply Voltage Output

V

CC

Supply Voltage

V

SS

Ground

Table 1. Signal Names

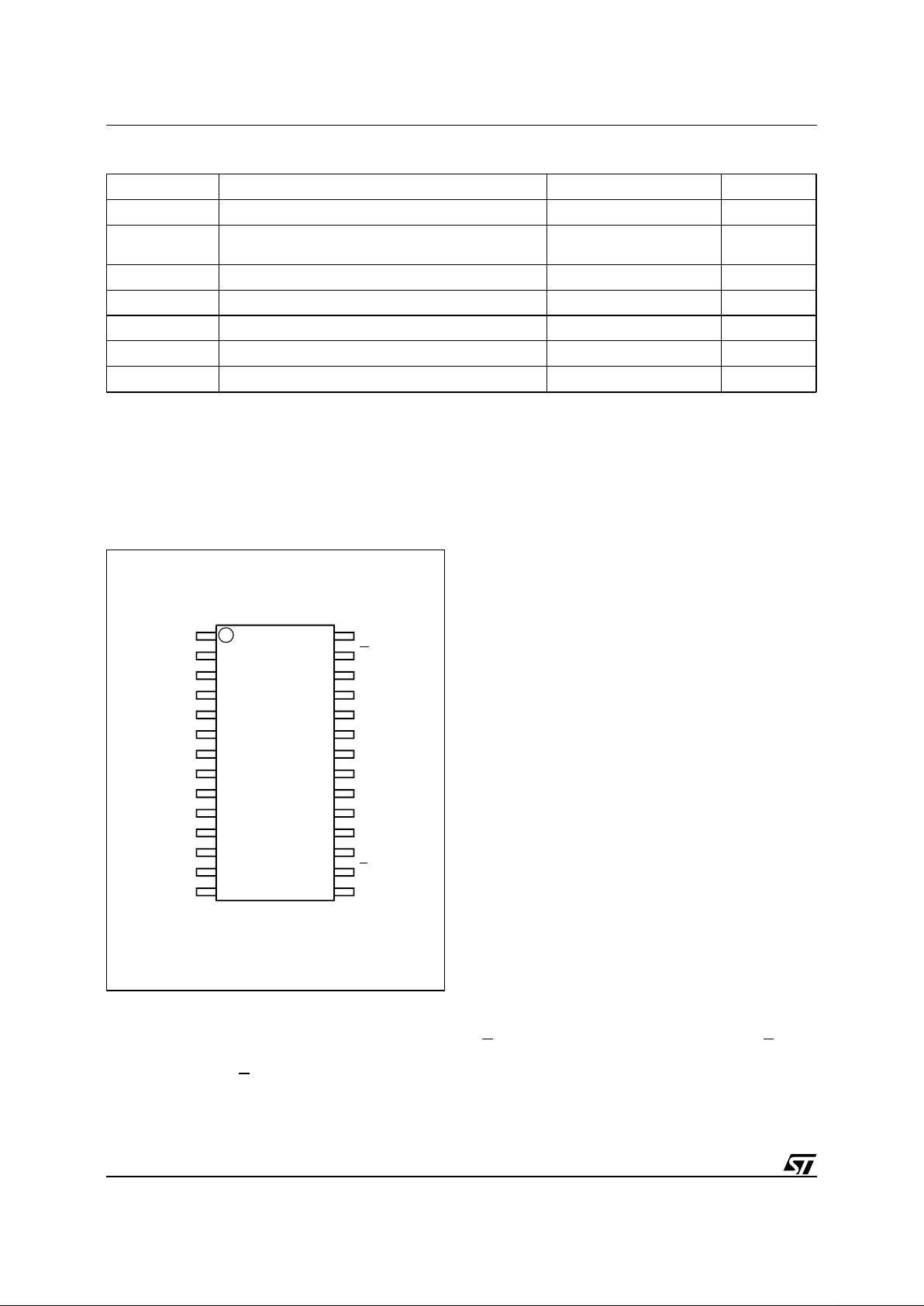

SNAPHAT (SH)

Battery

28

1

SOH28 (MH)

AI02239B

8

2

3

4

5

6

7

9

10

11

12

13

14

22

21

20

19

18

17

16

15

28

27

26

25

24

23

1

NC

NC

NC

NC

V

CC

NC

V

CC

NC

NC

NC

NC

NC

NC

NC

E

NC

NC

NC

NCNC

THS

NCV

SS

E

CON

NC

NC

V

OUT

V

CC

M40Z111

M40Z111W

Figure 2. SOIC Pin Connections

Warning:

NC = Not Connected.

Symbol Parameter Value Unit

T

A

Ambient Operating Temperature 0 to 70 °C

T

STG

Storage T emper ature (VCC Off) SNAPHAT

SOIC

–40 to 85

–55 to 125

°C

T

SLD

(2)

Lead Solder Temperature for 10 seconds 260 °C

V

IO

Input or Output Voltages –0.3 to VCC +0.3 V

V

CC

Supply Voltage –0.3 to 7 V

I

O

Output Current 20 mA

P

D

Power Dissipation 1 W

Notes:

1. Stresses greater than those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. This is a

stress rating only and functional operation of the device at these or any other conditions above those indi cat ed in the operati onal

section of this specification is not implied. Exposure to the absolute maximum rating conditions for extended periods of time may

affect reliability.

2. Soldering temperature not to exceed 260°C for 10 seconds (total thermal budget not to exceed 150°C for longer than 30 seconds).

CAUTION: Negat i ve undershoots below –0.3 volts are not allowed on any pin while in the Battery Back-up mode.

CAUTION: Do NOT wave solder SOIC to avoid damaging SNAPHAT sockets.

T ab le 2. Absolute Maximum Ratings

(1)

When an invalid VCC condition occurs, the conditioned chip enable (

E

CON

) output is forced inactive

to write-protect the stored data in the SRAM.

During a power failure, the SRAM is switched from

the V

CC

pin to the lithium cell within the SNAPHAT

to provide the energy required for data retention.

On a subsequent power-up, the SRAM remains

write protected until a valid power condition returns.

The 28 pin 330mil SOIC provides sockets with gold

plated contacts at both ends for direct connection

to a separate SNAPHAT housing containing the

battery. The unique design allows the SNAPHAT

battery package to be mounted on top of the SOIC

package after the completion of the surface mount

process. Insertion of the SNAPHAT housing after

reflow prevents potential battery damage due to the

high temperatures required for device surfacemounting. The SNAPHAT housing is keyed t o prevent reverse insertion. The SOIC and battery

packages are shipped separately in plastic antistatic tubes or in Tape & Reel form. For the 28 lead

SOIC, the battery package (i.e. SNAPHAT) part

number is "M4Z28-BR00SH1" or "M4Z32BR00SH1" (See Table 7).

OPERATION

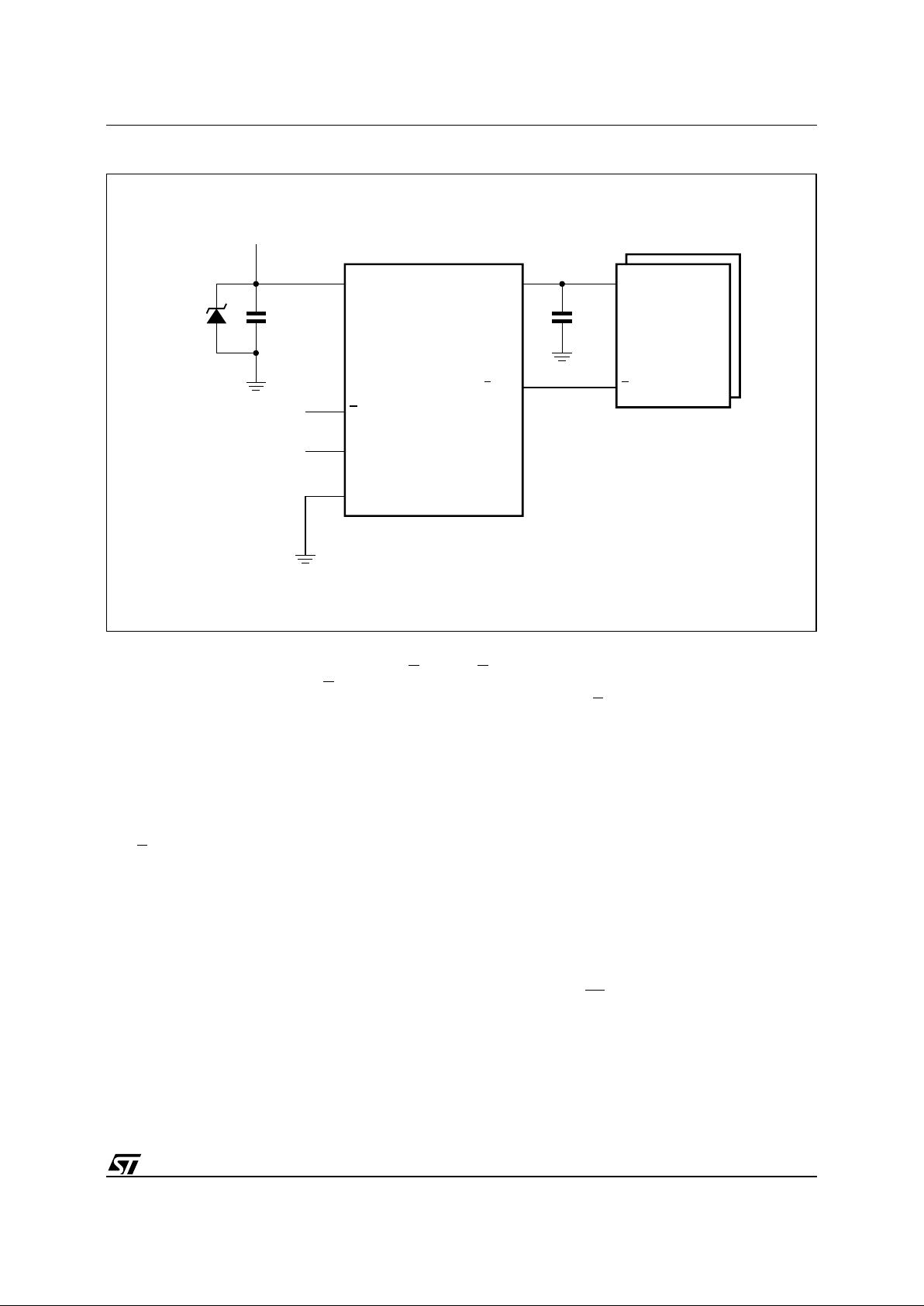

The M40Z111/111W, as shown in Figure 4, can

control up to two standard low-power SRAMs.

These SRAMs must be configured to have the chip

enable input disable all other input signals. Most

slow, low-power SRAMs are configured like this,

however many fast SRAMs are not. During normal

operating conditions, the conditioned c hip enable

(

E

CON

) output pin follows the chip enable (E) input

pin with timing shown in Table 6. A n internal switch

connects V

CC

to V

OUT

. This switch has a voltage

drop of less than 0.3V (I

OUT1

).

DESCRIPTION

(cont’d)

2/12

M40Z1 11, M40Z111W

When VCC degrades during a power failure,E

CON

is forced inactive independent of E. In this situation,

the SRAM is unconditionally write protected as V

CC

falls below an out-of-tolerance threshold (V

PFD

).

The power fail detection value associated with V

PFD

is selected by the THS pin and is shown in Table 5.

(Note: THS pin must be connected to either V

SS

or

V

OUT

). If chip enable access is in progress during

a power fail detection, that memory cycle continues

to completion before the memory is write protected.

If the memory cycle is not terminated within time

t

WP

, E

CON

is unconditionally driven high, write pro-

tecting the SRAM.

A power failure during a write cycle may corrupt

data at the currently addressed location, but does

not jeopardize the rest of the SRAM’s contents. At

voltages below V

PFD

(min), the user can be assured

the memory will be write protected provided the

V

CC

fall time exceeds tF.

As V

CC

continues to degrade, the internal switch

disconnects V

CC

and connects the internal battery

to V

OUT

. This occurs at the switchover voltage

(V

SO

). Below the VSO, the battery provides a volt-

age V

OHB

to the SRAM and can supply current

I

OUT2

(see Table 5). When VCC rises above VSO,

V

OUT

is switched back to the s upply voltage. Output

E

CON

is held inactive for tER (200ms maximum)

after the power supply has reached V

PFD

, inde-

pendent of the

E input, to allow for processor

stabilization (see Figure 6).

DATA RETENTION LIFETIME CALCULATION

Most low power SRAMs on the market today can

be used with the M40Z1 11/11 1W NVRAM Controller. Ther e are, however some criteria which should

be used in making the final choice of which SRAM

to use. The SRAM must be designed in a way

where the chip enable input disables all other inputs to the SRAM. This allows inputs to the

M40Z1 1 1/1 1 1W and SRAMs to be Don’t Care once

V

CC

falls below V

PFD

(min). The SRAM s hould also

guarantee data retention down to V

CC

=2.0V. The

chip enable access time must be sufficient to meet

the system needs with the chip enable propagation

delays included. If the SRAM includes a second

chip enable pin (

E2), this pin should be tied to V

OUT

.

If data retention lifetime is a critical parameter for

the system, it is important to review the data retention current specifications for the particular SRAMs

being evaluated. Most SRAMs specify a data retention current at 3.0V.

AI02394

V

CC

EE

CON

V

SS

V

OUT

V

CC

CMOS

SRAM

x8 or x16

3.3V or 5V

THS

E

0.1µF0.1µF

M40Z111

Thereshold

1N5817 or

MBR5120T3

Figure 3. Hardware Hookup

3/12

M40Z111, M40Z111W

Manufacturers generally specify a typical condition

for room temperature along with a worst case

condition (generally at elevated temperatures). The

system level requirements will determine the

choice of which value to use. The data retention

current value of the SRAMs can then be added to

the I

CCDR

value of the M40Z1 1 1/1 1 1W to det ermine

the total current requirements for data retention.

The available battery capacity for the SNAPHAT of

your choice can then be divided by this current to

determine the amount of dat a retention available

(see Table 7). For more information on Battery

Storage Life refer to the Application Note AN1012.

V

CC

NOISE AND NEGATIVE-GOING TRAN-

SIENTS

I

CC

transients, including those produced by output

switching, can produce voltage fluctuations, resulting in spikes on the V

CC

bus. These transients can

be reduced if capacitors are used to store energy,

which stabilizes the V

CC

bus. The energy stored in

the bypass capacitors will be released as low going

spikes are generated or energy will be absorbed

when overshoots occur.

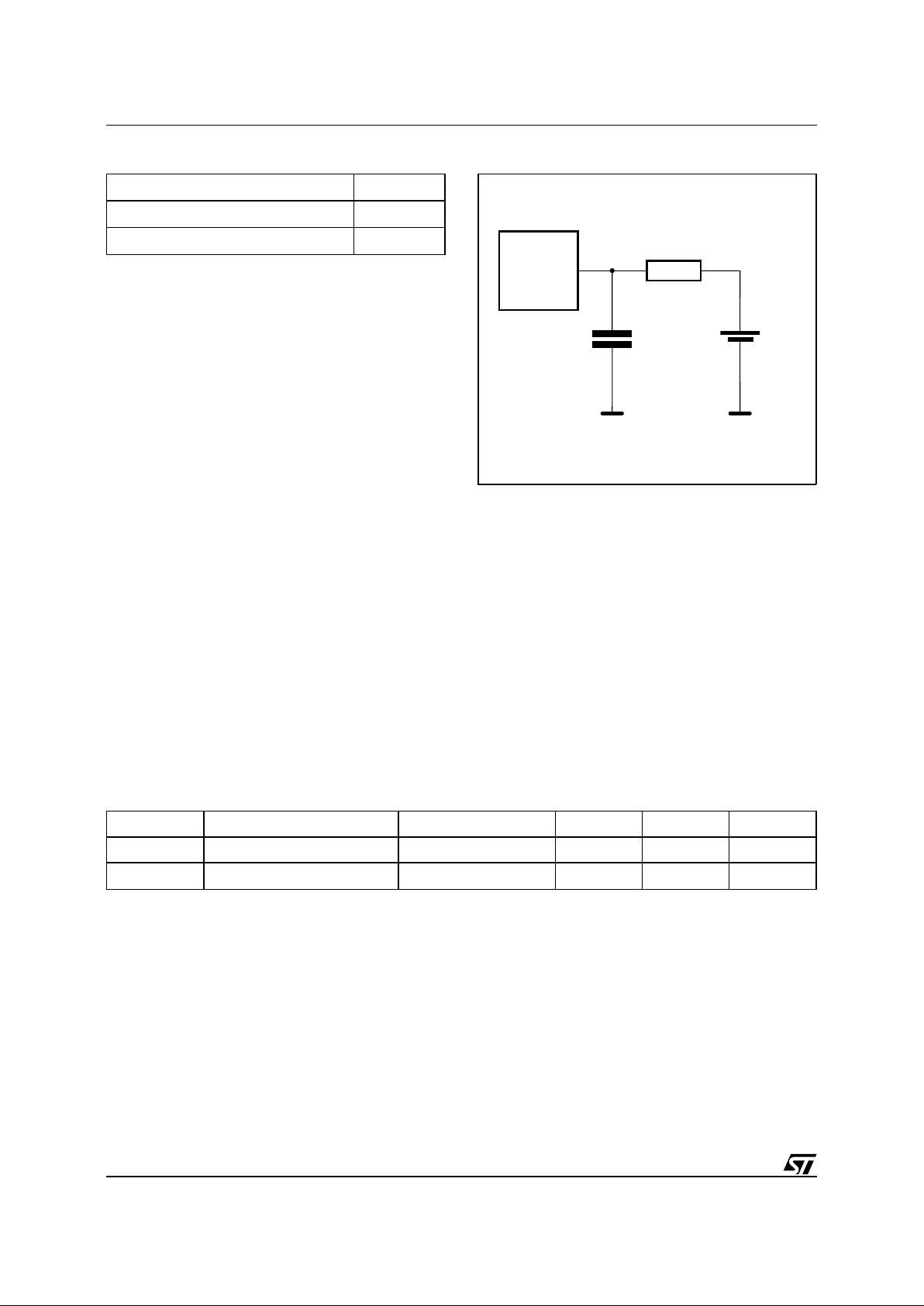

Input Rise and Fall Times ≤ 5ns

Input Pulse Voltages 0 to 3V

Input and Output Timing Ref. Voltages 1.5V

Note that Output Hi-Z is defined as the point where data is no

longer driven.

T ab le 3. AC Measurement Condition

AI02326

CL = 100pF

or 5pF

CL includes JIG capacitance

645Ω

DEVICE

UNDER

TEST

1.75V

Figure 4. AC Testing Load Circuit

Symbol Parameter T est Condition Min Max Unit

C

IN

Input Capacitance VIN = 0V 8 pF

C

OUT

(2)

Output Capacitance V

OUT

= 0V 10 pF

Note:

1. Sampled only, not 100% tested.

2. Outputs deselected.

T ab le 4. Capacitance

(1)

(TA = 25°C; f = 1MHz)

A ceramic bypass capacitor value of 0.1µF (as

shown in Figure 4) is recommended in order to

provide the needed filtering. In addition to transients that are caused by normal SRAM operation,

power cycling can generate negative voltage

spikes on V

CC

that drive it to values below VSS by

as much as one volt. These neg ative spikes can

cause data corruption in the SRAM while in battery

backup mode. To protect from these voltage

spikes, ST recommends connecting a schottky diode from V

CC

to VSS (cathode connected to VCC,

anode to V

SS

).

4/12

M40Z1 11, M40Z111W

Loading...

Loading...