5V or 3V NVRAM SUPERVISOR FOR LPSRAM

FEATURES SUMMARY

■ CONVERT LOW POWER SRAMs INTO

NVRAMs

■ 5V OR 3V OPERATING VOLTAGE

■ PRECISION POWER MONITORING and

POWER SWITCHING CIRCUITRY

■ AUTOMATIC WRITE-PROTECTION WHEN

V

IS OUT - OF-TOLERANC E

CC

■ CHOICE OF SUPPLY VOLTAGES and

POWER-FAIL DESELECT VOLTAGES:

– M40SZ100Y : V

4.20V ≤ V

PFD

– M40SZ100W: V

2.55V ≤ V

■ RESET OUTPUT (RST) FOR POWER ON

PFD

RESET

■ 1.25V REFERENCE (for PFI/PFO)

■ LESS THAN 10ns CHIP ENABLE ACCESS

PROPAGATION DELAY (at 5V)

■ OPTIONAL PACKA GING INCLUDES A 28-

LEAD SOIC and SNAPHAT

ordered separately)

■ 28-LEAD SOIC PAC KAG E PROVIDES

DIRECT CONNECTION FOR A SNAPHAT

TOP WHICH CONTAINS THE BATTERY

■ BATTERY LOW PIN (BL)

= 4.5 to 5.5V;

CC

≤ 4.50V

= 2.7 to 3.6V;

CC

≤ 2.70V

®

TOP (to be

M40SZ100Y

M40SZ100W

Figure 1. 16-pi n S O I C Package

16

1

SO16 (MQ)

Figure 2. 28-pi n S O I C Package*

SNAPHAT (SH)

Battery

28

1

SOH28 (MH)

* Contact Local Sales Office

Rev. 1.3

1/19September 2003

M40SZ100Y, M40SZ100W

TABLE OF CONTENTS

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Logic Diagram (Figure 3.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Signal Names (Table 1.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SOIC16 Connections (Figure 4.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SOIC28 Connections (Figure 5.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Block Diagram (Figure 6.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hardware Hookup (Figure 7.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Absolute Maximum Ratings (Table 2.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

DC AND AC PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DC and AC Measurement Conditions (Table 3.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AC Testing Load Circuit (Figure 8.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AC Testing Input/Output Waveforms (Figure 9.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Capacitance (Table 4.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

DC Characteristics (Table 5.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Retention Lifetime Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Power Down Timing (Figure 10.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Up Timing (Figure 11.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Down/Up AC Characteristics (Table 6.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power-on Reset Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Reset Input (RSTIN). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

RSTIN Timing Waveform (Figure 12.). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Reset AC Characteristics (Table 7.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Low Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power-fail Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

V

Noise And Negative Going Transients. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CC

Supply Voltage Protection (Figure 13.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PACKAGE MECHANICAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SNAPHAT® Battery Table (Table 13.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2/19

SUMMARY DESCRIPTION

The M40SZ100Y/W NVRAM Controller is a selfcontained device which converts a standard lowpower SRAM into a non-volatile mem ory. A prec ision voltage reference and comparator monitors

the V

When an invalid V

tioned chip enable output (E

input for an out-of-tolerance condition.

CC

condition occurs, t he condi-

CC

) is forced inactive

CON

to write protect the stored data in the SRAM. During a power failure, the SRAM is switched from the

pin to the lithium cell within the SNAPHAT (or

V

CC

external battery for the 16-lead S OIC) to provide

the energy required for data retention. On a subsequent power-up, the SRAM remains write protected until a valid power condition returns.

The 28-pin, 330 mil SOIC provides soc kets with

gold plated contacts for direct connection to a separate SNAPHAT

®

housing containing the battery.

The SNAPHAT housing has gold plated pins

which mate with the sockets, ensuring reliable

connection. The housing is keyed to prevent improper insertion. This unique design allows the

SNAPHAT battery p acka ge t o be m ount ed o n t op

M40SZ100Y, M40SZ100W

of the SOIC package after the c ompletion of the

surface mount process which greatly reduces the

board manufacturing process complexity of either

directly soldering or inserting a battery into a soldered holder. Providing non-volatility becomes a

“SNAP.” This feature is also a vailable in the “topless” 16-pin SOIC package (MQ).

Insertion of the SNAPHAT housing after reflow

prevents potential battery damage due to the high

temperatures required for device surface-moun ting. The SNAPHA T housing is also k eyed to prevent reverse insertion.

The 28-pin SOIC and battery packages are

shipped separately in plastic anti-static tubes or in

Tape & Reel form. For the 2 8-lead SOIC, t he ba ttery/crystal package (e.g., SNAPHAT) part number is “M4ZXX-BR00SH” (see Table 13, page 17).

Caution: Do not place the SNAPHAT battery top

in conductive foam, as this will drain the lithium

button-cell battery.

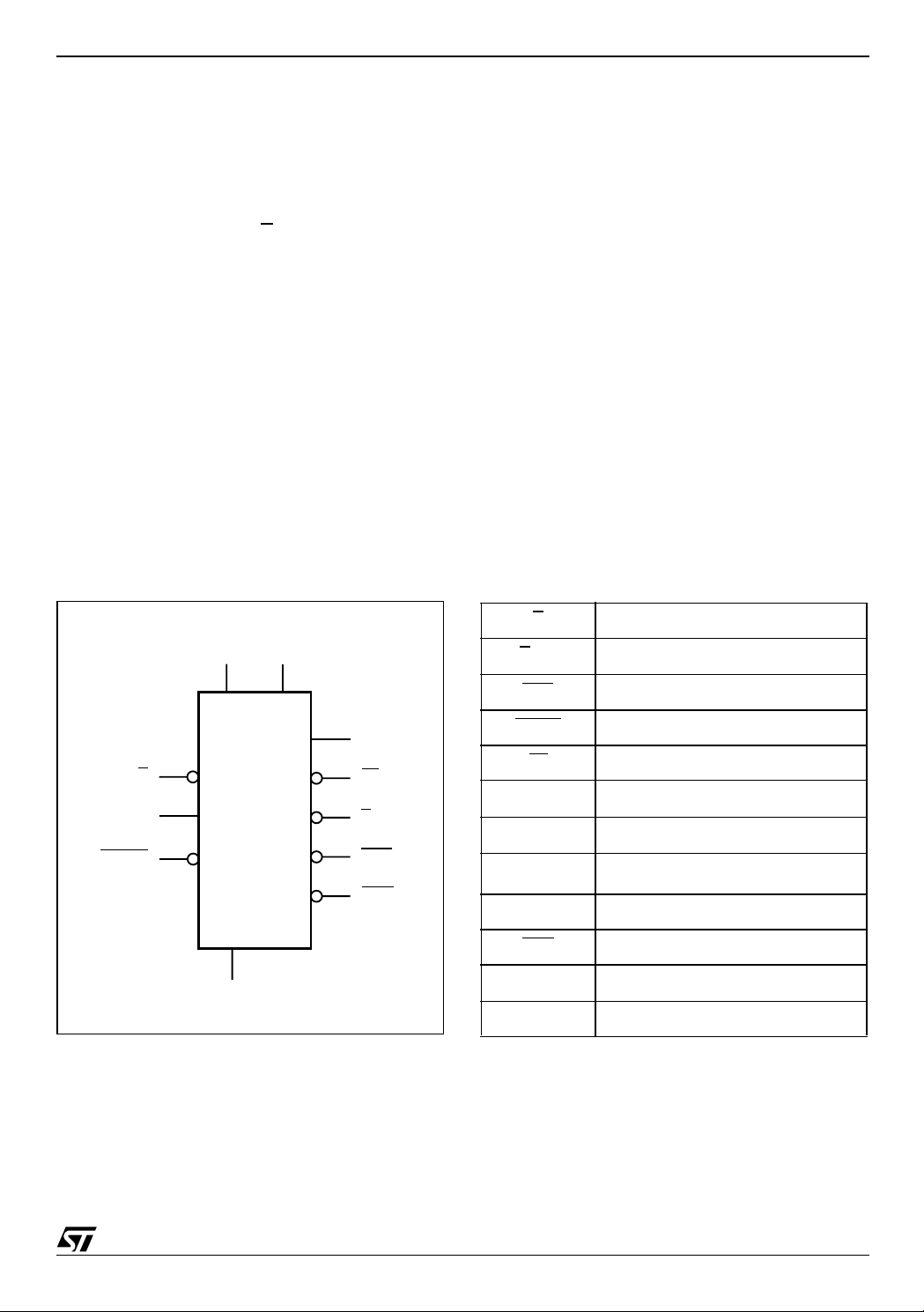

Figure 3. Logic Diagram

V

V

E

PFI

RSTIN

Note: 1. For 16-pin SOIC pac kage only.

M40SZ100Y

M40SZ100W

V

CC

SS

BAT

(1)

V

OUT

BL

E

CON

PFO

RST

AI03933

Table 1. Signal Names

E Chip Enable Input

E

CON

RST

RSTIN

BL

V

OUT

V

CC

(1)

V

BAT

PFI Power Fail Input

PFO

V

SS

NC Not Connected Internally

Note: 1. For SO1 6 onl y.

Conditioned Chip Enable Output

Reset Output (Open Drain)

Reset Input

Battery Low Output (Open Drain)

Supply Voltage Output

Supply Voltage

Back-up Supply Voltage

Power Fail Output

Ground

3/19

M40SZ100Y, M40SZ100W

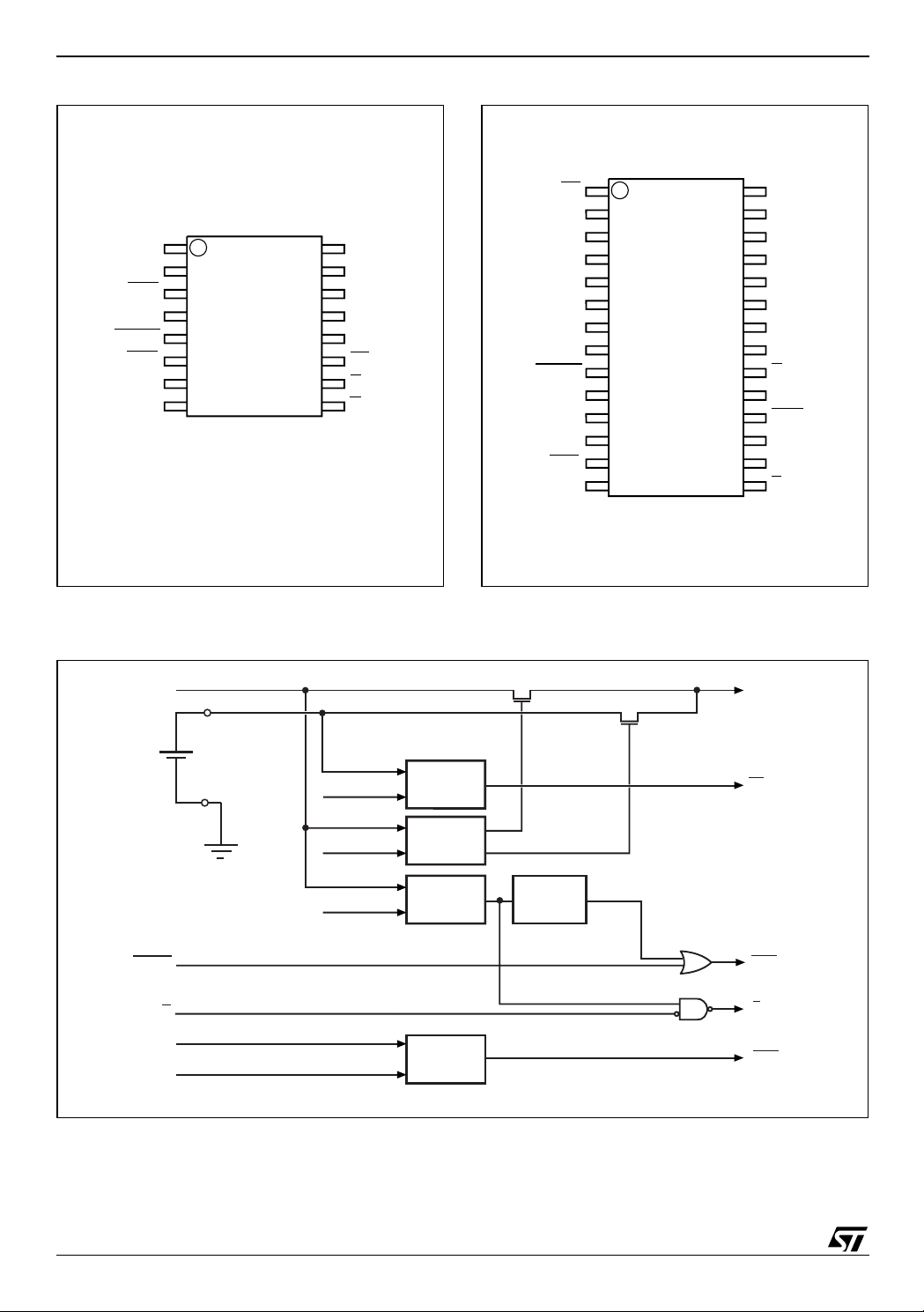

Figure 4. SOI C 16 Connection s

NC

NC

RST

NC

RSTIN

PFO

V

BAT

V

SS

Note: 1. DU = Do Not Use

1

2

3

4

M40SZ100Y

M40SZ100W

5

6

710

8

16

15

14

13

12

11

Figure 5. SOI C 28 Connection s

1

BL

NC

V

CC

NC

V

OUT

NC

PFI

BL

E

E

9

CON

AI03935

NC

NC

NC

NC

NC

NC

RSTIN

NC

NC

PFO

V

SS

2

3

4

5

6

7

M40SZ100Y

M40SZ100W

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AI03934

V

CC

NC

NC

V

OUT

NC

NC

PFI

NC

E

NC

RST

NCNC

NC

E

CON

Figure 6. Block Diagram

V

CC

V

BAT

RSTIN

E

PFI

1.25V

Note: Open dra i n output

VBL= 2.5V

V

= 2.5V

SO

V

= 4.4V

PFD

COMPARE

COMPARE

COMP ARE

(2.65V for SZ100W)

COMPARE

POR

V

OUT

(1)

BL

RST

E

CON

PFO

AI04766

(1)

4/19

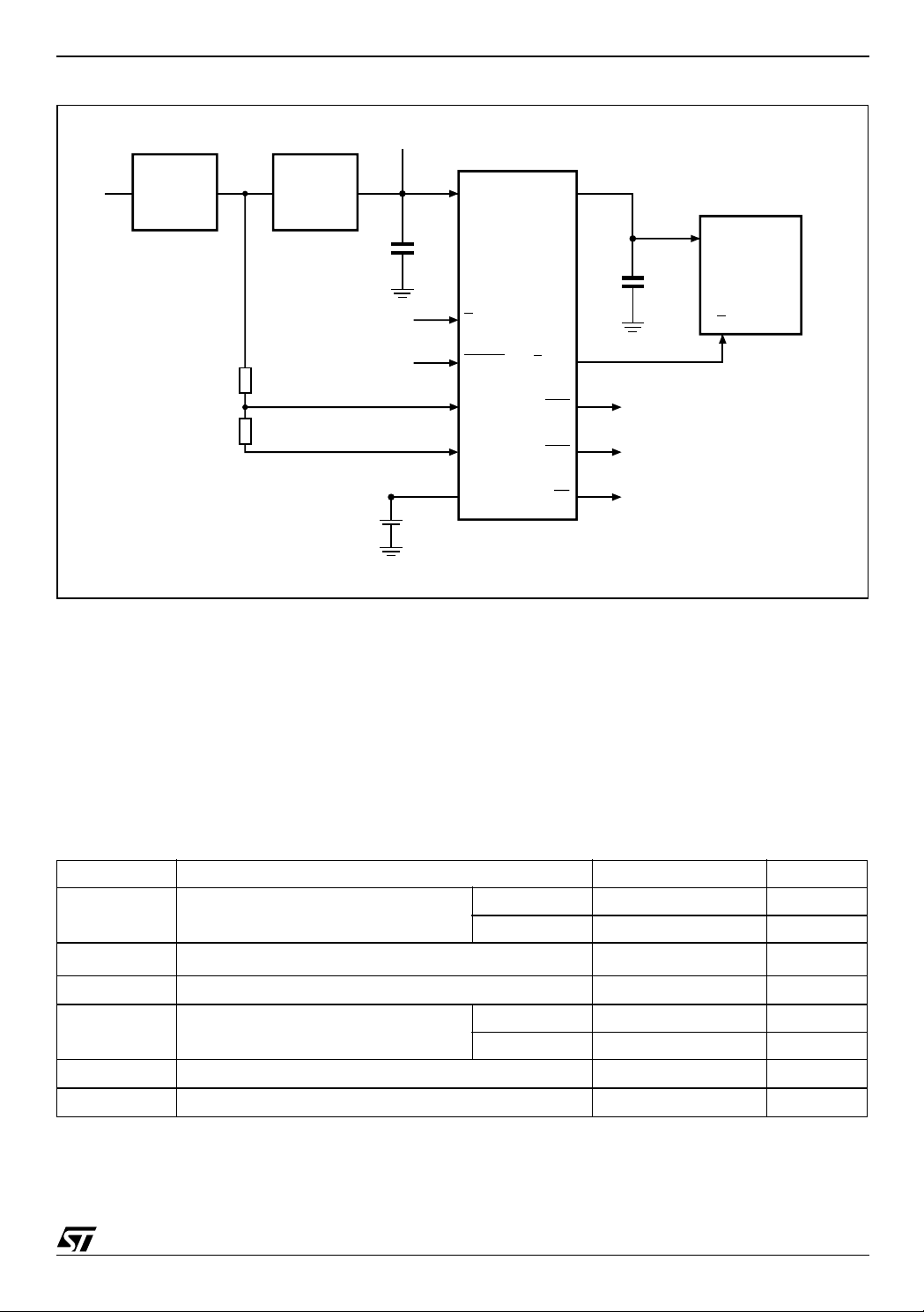

Figure 7. Hardware Hookup

M40SZ100Y, M40SZ100W

3.0V, 3.3V or 5V

Unregulated

Voltage

R1

R2

Note: 1. User supplied for the 16-pin pa ck age

Regulator

V

IN

From Microprocessor

V

CC

0.1µF

V

CC

E

RSTIN

PFI

V

SS

V

BAT

V

OUT

M40SZ100Y

M40SZ100W

E

CON

PFO

(1)

RST

BL

V

CC

0.1µF

To Microprocessor NMI

To Microprocessor Reset

To Battery Monitor Circuit

1Mb or 4Mb

LPSRAM

E

AI04767

MAXIMUM RATI N G

Stressing the device ab ove the rating listed in t he

“Absolute Maximum Ratings” table may cause

permanent damage to the device. These are

stress ratings only and operation of the dev ice at

these or any other conditions above those indicat-

not implied. Exposure to Absol ute Maxim um Ra ting conditions for extended periods may affect device reliability. Refer also to the

STMicroelectronics SURE Program and other relevant quality documents.

ed in the Operating sections of this specification is

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

STG

(1)

T

SLD

V

IO

V

CC

I

O

P

D

Note: 1. Reflow at peak temperature of 215°C to 225°C for < 60 seconds (total thermal budget not to ex ceed 180°C for between 90 to 120

secon ds).

CAUTION: Negative und ershoots below –0.3V are not allowed on any pin while in the Battery Ba ck-up mod e.

CAUTION: Do NOT wave solder SOIC to avoid damaging SNAP HAT sock ets.

Storage Temperature (VCC Off)

Lead Solder Temperature for 10 seconds 260 °C

Input or Output Voltages

Supply Voltage

Output Current 20 mA

Power Dissipation 1 W

SNAPHAT –40 to 85 °C

SOIC –55 to 125 °C

–0.3 to V

CC

+0.3

M40SZ100Y –0.3 to 7 V

M40SZ100W –0.3 to 4.6 V

V

5/19

M40SZ100Y, M40SZ100W

DC AND AC PARAMETERS

This section summarizes the operat ing and measurement conditions, as well as the DC and AC

characteristics of the device. The parameters in

the following DC and AC Characteristic tables are

derived from tests performed under the M easure-

Table 3. DC and AC Measurement Conditions

Parameter M40SZ100Y M40SZ100W

Supply Voltage

V

CC

Ambient Operating Temperature –40 to 85°C –40 to 85°C

ment Conditions listed in the rel evant tables. Designers should check that the operating conditions

in their projects match the measurement conditions when using the quoted parameters.

4.5 to 5.5V 2.7 to 3.6V

Load Capacitance (C

)

L

100pF 50pF

Input Rise and Fall Times ≤ 5ns ≤ 5ns

Input Pulse Voltages

Input and Output Timing Ref. Voltages

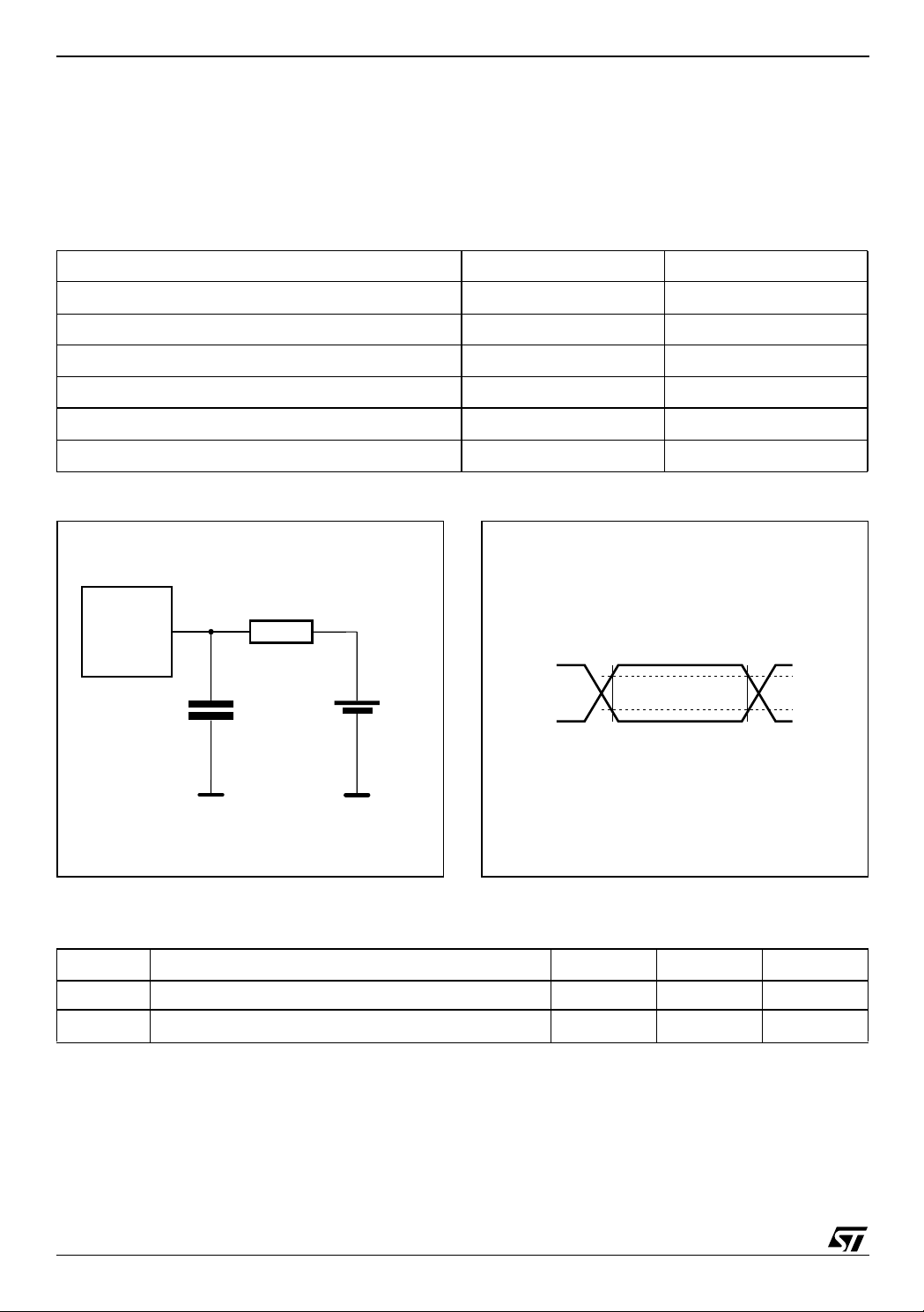

Figure 8. AC Testing Load Circuit

DEVICE

UNDER

TEST

CL includes JIG capacitance

333Ω

CL = 100pF

or 50pF

1.73V

AI02393

0.2 to 0.8V

0.3 to 0.7V

CC

CC

Figure 9. AC Testing Input/Output Waveforms

0.8V

CC

0.2V

CC

0.2 to 0.8V

0.3 to 0.7V

CC

CC

0.7V

0.3V

AI02568

CC

CC

Note: 1. CL = 100pF for M40SZ100Y and 50pF for M40SZ100W.

Table 4. Capacitance

Symbol

C

IN

C

OUT

Note: 1. Sampled only, not 100% tested.

2. At 25°C, f = 1MHz.

3. Outpu ts deselected

Input Capacitance 7 pF

(3)

Output Capacitance 10 pF

6/19

Parameter

(1,2)

Min Max Unit

M40SZ100Y, M40SZ100W

Table 5. DC Characteristics

Sym Parameter

I

Supply Current Outputs open 1 0.5 mA

CC

I

CCDR

Data Retention Mode

(2)

Current

Input Leakage

Current

(3)

I

LI

Input Leakage

Test Condition

0V ≤ V

(1)

≤ V

IN

CC

Current (PFI)

I

LO

I

OUT1

I

OUT2

V

V

V

V

V

V

(4)

Current

V

Current

OUT

(5)

(Active)

V

Current

OUT

(Battery Back-up)

Battery Voltage 2.5 3.0

BAT

V

Input High Voltage

IH

V

Input Low Voltage –0.3

IL

Output High

OH

OHB

(7)

Voltage

VOH Battery Back-

(8)

up

Output Low Voltage

OL

Output Low Voltage

(open drain)

Power-fail Deselect

PFD

Voltage

(9)

PFI Input Threshold

PFI

0V ≤ V

V

OUT

V

OUT

IOH = –1.0mA

I

OUT2

I

V

V

≤ V

OUT

> VCC – 0.3

> V

– 0.3

BAT

= –1.0µA

= 3.0mA

OL

IOL = 10mA

= 5V(Y)

CC

= 3V(V)

CC

CC

Output Leakage

PFI Hysteresis PFI Rising 20 70 20 70 mV

V

Note: 1. Valid fo r Ambient Op erating Temperature: TA = –40 to 85°C ; VCC = 2.7 to 3.6V or 4. 5 to 5.5V(exc ept where not ed).

Battery Back-up

SO

Switchover Voltage

2. Measured with V

3. RSTIN

4. Outpu ts deselected.

5. External SRAM must match SUPERVISOR chip V

6. For rechargeabl e back-up, V

7. For PFO

8. Chip Enable output (E

9. For RST

internally pulled-up to VCC through 100kΩ resis tor.

pin (CMOS).

duce batter y li fe.

& BL pins (Open Drain).

OUT

and E

CON

open.

CON

(max) may be considered VCC – 0.5V.

BAT

) can only sust ai n CMOS leakage currents i n the battery back-up mode. Higher leakag e currents wi ll re-

specification (3V or 5V).

CC

M40SZ100Y M40SZ100W

Min Typ Max Min Typ Max

50 200 50 200 nA

±1 ±1 µA

–25 2 25 –25 2 25 nA

±1 ±1 µA

175 100 mA

100 100 µA

0.7V

CC

(6)

3.5

VCC + 0.3 0.7V

0.3V

CC

2.5 3.0

CC

–0.3

3.5

VCC + 0.3

0.3V

2.4 2.4 V

2.5 2.9 3.5 2.5 2.9 3.5 V

0.4 0.4 V

0.4 0.4 V

4.20 4.40 4.50 2.55 2.60 2.70 V

1.225 1.250 1.275 1.225 1.250 1.275 V

2.5 2.5 V

(6)

CC

Unit

V

V

V

7/19

M40SZ100Y, M40SZ100W

OPERATION

The M40SZ100Y/W, as shown in Figure 7, page 5,

can control one (two, if placed in parallel) standard

low-power SRAM. This SRAM must be configured

to have the chip enable input disable all other input

signals. Most slow, low-power SRAM s are c onfigured like this, however many fast SRAM s are not.

During normal operating conditions, the conditioned chip enable (E

chip enable (E

) input pin with timing shown in Table 6, page 10. An internal switch connects V

V

. This switch has a voltage drop of less than

OUT

0.3V (I

When V

).

OUT1

degrades during a power failure, E

CC

is forced inactive independe nt of E. In t his situa tion, the SRAM is unconditionally write protected

as V

(V

falls below an out-of-tolerance threshold

CC

). For the M40SZ100Y/W the power fail de-

PFD

tection value associated with V

ble 5, page 7.

If chip enable access is in progress during a power

fail detection, that memory cycle continues to completion before the memory is write protected. I f the

memory cycle is not terminated within time t

E

is unconditionally driven high, write protect-

CON

ing the SRAM. A power failure during a WRITE cycle may corrupt data at the currently addressed

location, but does not jeopardize the rest of the

SRAM's contents. At voltage s below V

the user can be as sured the me mor y will be writ e

protected within the Write Protect Time (t

vided the V

fall time does not exceed tF (see Ta-

CC

ble 6, page 10).

As V

disconnects V

to V

(V

age V

I

OUT2

When V

continues to degrade, the internal switch

CC

. This occurs at the switchover voltage

OUT

). Below the VSO, the battery provides a volt-

SO

OHB

and connects the internal battery

CC

to the SRAM and can supply current

(see Table 5, page 7).

rises above VSO, V

CC

back to the supply voltage. Output E

active for t

(120ms maxim um ) af ter t he power

CER

) output pin follows the

CON

is shown in Ta-

PFD

PFD

is switched

OUT

CON

to

CC

CON

WPT

(min),

) pro-

WPT

is held in-

supply has reached V

, independent of the E in-

PFD

put, to allow for processor stabilization (see Figure

11, page 10).

Data Retention Lifetime Calculation

Most low power SRAMs on the market today can

be used with the M40SZ100Y/W NVRAM Controller. There are, however some criteria which should

be used in making the final choice of which SRAM

to use. The SRAM must be designed in a way

where the chip enable input disables all other inputs to the SRAM. This allows inputs to the

M40SZ100Y/W and SRAMs to be “Don't care”

once V

falls below V

CC

(min) (see Figure 10,

PFD

page 9). The SR AM should also guarantee data

retention down to V

= 2.0V. The chip enable ac-

CC

cess time must be sufficient to meet the system

needs with the chip enable propagation delays included.

If data retention lifetime is a critical parameter f or

the system, it is importa nt to re view the dat a retention current specifications for the particular

SRAMs being evaluated. M ost SRAMs specify a

,

data retention current at 3.0V. Manufacturers generally specify a typical condition for room temperature along with a worst case condition (generally

at elevated temperatures). The system level requirements will determine the choice of which value to use. The data retent ion current val ue of the

SRAMs can then be added to t he I

CCDR

the M40SZ100Y/W to determine the to tal current

requirements for data retention. The available battery capacity for the SNAPHAT

®

of your choice

(see Table 13, page 17) can then be divided by

this current to determine the amount of data retention available.

CAUTION: Take care to avoid inadvertent discharge through V

OUT

and E

after battery has

CON

been attached.

For a further more detailed review of lifetime calcu-

lations, please see Application Note AN1012.

value of

8/19

Figure 10. Power Down Timing

V

CC

V

(max)

PFD

V

PFD

V

(min)

PFD

VSO

tF

E

E

CON

RST

tWPT

tFB

V

M40SZ100Y, M40SZ100W

OHB

PFO

VALID

AI03936

9/19

M40SZ100Y, M40SZ100W

Figure 11. Power Up Timing

V

CC

V

(max)

PFD

V

PFD

V

(min)

PFD

VSO

tR

E

E

CON

RST

PFO

tRB

V

OHB

tCER

tREC

VALID

Table 6. Power Down/Up AC Characteristics

Symbol

(2)

t

F

(3)

t

FB

t

PFD

t

R

t

EPD

t

RB

t

CER

t

REC

t

WPT

Note: 1. Valid fo r Ambient Op erating Temperature: TA = –40 to 85°C ; VCC = 2.7 to 3.6V or 4. 5 to 5.5V(exc ept where not ed).

2. V

3. V

V

(max) to V

PFD

V

(min) to VSS VCC Fall Time

PFD

PFD

PFI to PFO Propagation Delay 15 25 µs

V

(min) to V

PFD

PFD

Chip Enable Propagation Delay (Low or High)

VSS to V

(min) VCC Rise Time

PFD

Chip Enable Recovery 40 120 ms

V

(max) to RST High

PFD

Write Protect Time 40 200 µs

(max) to V

PFD

passes V

PFD

(min) to VSS fall time of le ss than tFB may cause corruption of RAM d at a.

PFD

(min) fall ti me of less th an tF may result in deselect ion/writ e protec tion not oc currin g until 20 0 µs after V

PFD

(min).

Parameter

(min) VCC Fall Time

(max) VCC Rise Time

(1)

Min Max Unit

300 µs

10 µs

10 µs

M40SZ100Y 10 ns

M40SZ100W 15 ns

1µs

40 200 ms

tEPDtEPD

AI03937

CC

10/19

M40SZ100Y, M40SZ100W

Power-on Reset Output

All microprocessors have a reset input which forces them to a known state when starting. The

M40SZ100Y/W has a reset output (RST

is guaranteed to be low by V

PFD

) pin which

(see Table 5,

page 7). This signal is an open drain configuration.

An appropriate pull-up resistor to V

should be

CC

chosen to control the rise time. This signal will be

valid for all voltage conditions, even when V

CC

equals VSS (with valid battery voltage).

Once V

age V

t

REC

Figure 12. RSTIN

Note: With pul l -up resi stor

exceeds the power failure detect volt-

CC

, an internal timer keeps RST low for

PFD

to allow the power supply to stabilize.

Timing Waveform

RSTIN

tRLRH

(1)

RST

tR1HRH

Reset Input (RSTIN

)

The M40SZ100Y/W provides one indep endent input which can generate an output reset. The duration and function of this reset is identical to a reset

generated by a power cycle. Table 7 and Figure 12

illustrat e the AC rese t ch ara cterist ics of t his f unction. Pulses shorter than t

reset condition. RSTIN

V

through a 100kΩ resistor.

CC

is internally pulled up to

will not generate a

RLRH

AI04768

Table 7. Reset AC Characteristics

Symbol

(2)

t

RLRH

(3)

t

R1HRH

Note: 1. Valid fo r Ambient Op erating Temperature: TA = –40 to 85°C ; VCC = 2.7 to 3.6V or 4. 5 to 5.5V (exce pt where not ed).

2. Pulse width less than 50ns will result in no RESET (for noise immunity).

= 5pF (see Figure 8, page 6).

3. C

L

RSTIN Low to RSTIN High 200 ns

RSTIN High to RST High 40 200 ms

Parameter

(1)

Min Ma x Unit

11/19

M40SZ100Y, M40SZ100W

Battery Low Pin

The M40SZ100Y/W automatically performs battery voltage monitoring upon power-up, and at factory-programmed time intervals of at least 24

hours. The Battery Low (BL

the battery voltage is found to be less than approximately 2.5V. The BL

completion of battery replacement and subsequent battery low monitoring tests, either during

the next power-up sequence or the next scheduled

24-hour interval.

If a battery low is generated during a power-up sequence, this indicates that the battery is below

2.5V and may not be able to maintain data integrity

in the SRAM. Data should be considered suspect,

and verified as correct. A fresh battery should be

installed.

If a battery low indication is generated during the

24-hour interval check, this indicates that the battery is near end of life. However, data is not compromised due to the fact that a nominal V

supplied. In order to insure data integrity during

subsequent periods of bat tery back-up m ode, the

battery should be replaced.

The M40SZ100Y/W only monitors the battery

when a nominal V

is applied to the device. Thus

CC

applications which require extensive d urations in

the battery back-up mode sho uld be pow ered-up

periodically (at least once every few months) in order for this technique to be beneficial. Additionally,

if a battery low is indicated, data integrity should

be verified upon power-up via a checksum or other

technique. The BL

pin is an open drain output and

an appropriate pull-up resistor to V

chosen to control the rise time.

Power-fail Input/Output

The Power-Fail Input (PFI) is compared to an internal reference voltage (independent from the

comparator). If PFI is less than the power-fail

V

PFD

threshold (V

), the Power-Fail Output (PFO) will

PFI

go low. This function is intended for use as an under-voltage detector to signal a failing power supply. Typically PFI is connected through an external

voltage divider (see Figure 7, page 5) to either the

unregulated DC input (if it is a va ilable) or the regulated output of the V

vider can be set up such that t he voltage at PFI

falls below V

regulated V

several milliseconds before the

PFI

input to the M40SZ100Y /W or the

CC

microprocessor drops below the minimum operating voltage.

During battery back-up, the power-fail comparator

turns off and PFO

goes (or remains) low. This oc-

) pin will be asserted if

pin will remain asserted until

is

CC

should be

CC

regulator. The voltage di-

CC

curs after V

er returns, PFO

for the write protect time (t

from V

PFD

drops below V

CC

is forced high, irrespective of V

(min). When pow-

PFD

), which is the time

REC

PFI

(max) until the inputs are recognized. At

the end of this time, the power-fail comparator is

enabled and PFO

unused, PFI should be connected to V

follows PFI. If the comparator is

and PFO

SS

left unconnected.

Noise And Negative Going Transients

V

CC

transients, including those produced by output

I

CC

switching, can produce voltage fluctuations, resulting in spikes on the V

bus. These transients

CC

can be reduced if capacitors are used to store energy which stabilizes the V

bus. The energy

CC

stored in the bypass capacitors will be released as

low going spikes are generated or energy will be

absorbed when overshoots occur. A ceramic bypass capacitor value of 0.1µF (as shown in Figure

13) is recommended in order to provide the needed filtering.

In addition to transients that are caused by normal

SRAM operation, power cycling can generate negative voltage spikes on V

below V

by as much as one volt. These negative

SS

that drive it to values

CC

spikes can cause data corruption in the SRAM

while in battery backup mode. To protect from

these voltage spikes, STMicroelectronics recommends connecting a schottky diode from V

V

(cathode connected to VCC, anode to VSS).

SS

CC

to

Schottky diode 1N5817 is recommended for

through hole and MBRS120T3 is recommended

for surface mount.

Figure 13. Supply Voltage Protection

V

CC

V

CC

0.1µF DEVICE

V

SS

AI00622

12/19

PACKAGE MECHANICAL INFORMATION

Figure 14. SO16 – 16-lead Plastic Small Package Outline

M40SZ100Y, M40SZ100W

A2

A

B

e

CP

D

N

E

H

1

SO-b

Note: Drawing is not to scale.

Table 8. SO16 – 16-lead Plastic Small Plastic Package Mechanical Data

Symbol

T yp. Min. Max. Typ. Min. Max.

A 1.75 0.069

mm inches

C

LA1 α

A1 0.10 0.25 0.004 0.010

A2 1.60 0.063

B 0.35 0.46 0.014 0.018

C 0.19 0.25 0.007 0.010

D 9.80 10.00 0.386 0.394

E 3.80 4.00 0.150 0.158

e 1.27 – – 0.050 – –

H 5.80 6.20 0.228 0.244

L 0.40 1.27 0.016 0.050

a0°8°0°8°

N16 16

CP 0.10 0.004

13/19

M40SZ100Y, M40SZ100W

Figure 15. SOH28 – 28-lead Plastic Small Outline, 4-socket battery SNAPHAT, Package Outline

A2

A

C

Be

eB

CP

D

N

E

H

LA1 α

1

SOH-A

Note: Drawing is not to scale.

Table 9. SOH28 – 28-lead Plastic Sm al l Outl ine, bat tery SNAP HAT, Pac kage Mech an ical Data

Symbol

T yp Min Max Typ Min Max

A 3.05 0.120

A1 0.05 0.36 0.002 0.014

mm inches

A2 2.34 2.69 0.092 0.106

B 0.36 0.51 0.014 0.020

C 0.15 0.32 0.006 0.012

D 17.71 18.49 0.697 0.728

E 8.23 8.89 0.324 0.350

e 1.27 – – 0.050 – –

eB 3.20 3.61 0.126 0.142

H 1 1.51 12.70 0.453 0.500

L 0.41 1.27 0.016 0.050

α 0° 8° 0° 8°

N 28 28

CP 0.10 0.004

14/19

M40SZ100Y, M40SZ100W

Figure 16. SH – 4-pin S NAPHAT Ho using fo r 48mAh Ba ttery , Package Outline

A1

A

eA

D

B

eB

E

SHZP-A

Note: Drawing is not to scale.

Table 10. SH – 4-pin SNAPHAT Housing for 48mAh Battery, Package Mechanical Data

Symbol

Typ Min Max Typ Min Max

A 9.78 0.385

A1 6.73 7.24 0.265 0 .285

mm inches

A2

A3

L

A2 6.48 6.99 0.255 0 .275

A3 0.38 0.015

B 0.46 0.56 0.018 0.022

D 21.21 21.84 0.835 0 .860

E 14.22 14.99 0.560 0.590

eA 15.55 15.9 5 0.612 0.628

eB 3.20 3.61 0.126 0 .142

L 2.03 2.29 0.080 0 .090

15/19

M40SZ100Y, M40SZ100W

Figure 17. SH – 4-pi n SNAP HAT Housing for 12 0mAh B attery , Package Outline

A1

A

eA

D

B

eB

E

SHZP-A

Note: Drawing is not to scale.

Table 11. SH – 4-pin SNAPHAT Housing for 120mAh Battery, Package Mechanical Data

Symbol

Typ Min Max Typ Min Max

A 10.54 0.415

A1 8.00 8.51 0.315 0 .335

mm inches

A2

A3

L

A2 7.24 8.00 0.285 0 .315

A3 0.38 0.015

B 0.46 0.56 0.018 0.022

D 21.21 21.84 0.835 0 .860

E 17.27 18.03 0.680 0.710

eA 15.55 15.9 5 0.612 0.628

eB 3.20 3.61 0.126 0 .142

L 2.03 2.29 0.080 0 .090

16/19

M40SZ100Y, M40SZ100W

PART NUMBERING

Table 12. Ordering Information Scheme

Example: M40SZ 100Y MQ 6 TR

Device Type

M40SZ

Supply Voltage and Write Protect Voltage

100Y = V

100W = V

Package

MQ = SO16

(1,2)

MH

= 4.5 to 5.5V; V

CC

= 2.7 to 3.6V; V

CC

= SOH28

= 4.2 to 4.5V

PFD

= 2.6 to 2.7V

PFD

Temperature Rang e

6 = –40 to 85°C

Shipping Method for SOIC

blank = Tubes

TR = Tape & Reel

Note: 1. The SOIC packa ge (SOH28) require s the battery pack age (SNAPHAT®) which is o rdered separately under the part numbe r

“M4ZXX-BR00SHX” in plastic tube or “M4ZXX-BR00SHXTR” in Tape & Reel form.

2. Contact Local Sal es Off ice

Caution: Do not place the SNAPHAT battery package “M4Zxx-BR00SH” in conductive foam as it will drain the lithium button-cell bat-

tery.

For a list of available options (e.g., Speed, Package) or for further information on any aspect of this device,

please contact the ST Sales Office nearest to you.

®

Table 13. SNAPHAT

Part Number Description Package

M4Z28-BR00SH SNAPHAT Housing for 48mAh Battery SH

M4Z32-BR00SH SNAPHAT Housing for 120mAh Battery SH

Battery Ta bl e

17/19

M40SZ100Y, M40SZ100W

REVISION HIST ORY

Table 14. Document Revision History

Date Rev. # Revision Details

December 2001 1.0 First Issue

13-May-02 1.1 Modify reflow time and temperature footnote (Table 2)

01-Aug-02 1.2 Add marketing status (Figure 2; Table 12)

15-Sep-03 1.3 Remove reference to M68xxx (obsolete) part (Figure 7); update disclaimer

18/19

M40SZ100Y, M40SZ100W

M40SZ100, M40SZ100Y, M40SZ100W, 40SZ100, 40SZ100Y, 40SZ100W, ZEROPOWER, ZEROPOWER, ZEROPOWER, ZEROPOWER, ZEROPOWER, ZEROPOWER, ZEROPOWER, ZEROPOWER, ZEROPOWER, ZEROPOWER,

ZEROPOWER, ZEROPOWER, ZEROPOWER, ZEROPOWER, ZEROPOWER, SUPERVISOR, SUPER VISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, SUPERVISOR, NVRAM, NVRAM, NVRAM,

NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM,

NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM,

NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM, NVRAM,

NVRAM, NVRAM, NVR AM, NVRAM, NVRAM, NVR AM, NVRAM, NVRAM, NVR AM, NVRAM, NVRAM, I2C , I2C, I2C,

I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C,

I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, I2C, RTC, RTC, RTC, RTC, RTC, RTC, RTC,

RTC, RTC, RTC, RTC, RTC , RTC, RTC, RTC, RT C, RTC, RTC, RTC , RTC, RTC, RTC, RTC , RTC, RTC, RTC, RTC,

RTC, RTC, RTC, RTC, RTC , RTC, RTC, RTC, RT C, RTC, RTC, RTC , RTC, RTC, RTC, RTC , RTC, RTC, RTC, RTC,

RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, RTC, Oscillator, Oscillator, Oscillator, Osc illator, Oscillat or, Oscillator, Os cillator, Oscilla tor, Oscillator , Oscillator, Oscil lator, Oscillato r, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator, Oscillator,

Oscillator, Oscilla tor, Oscillator, Oscillator , Oscillator, Oscillator, O scillator, Oscillator, Osci llator, Oscillator, Oscillator,

Oscillator, Micropr ocessor, Microprocessor, Microp rocessor, Microprocessor, Micro processor, Microprocessor, Mic roprocessor, Micropro cessor, Microprocessor, Mic roprocessor, Microproce ssor, Microprocessor, Microproce ssor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor, Microprocessor,

LPSRAM, LPSRAM, LPSRAM, LPSRAM, LPSRAM, LPSRAM, LPSRAM, LPSRAM, LPSRAM, LPSRAM, LPSRAM,

LPSRAM, LPSR AM, LPSR AM, LPSR AM, P FI, P FI, P FI, PFI, PF I, PF I, PF I, PFI , PFI, PFI, PFI, PFI, PFI, P FI, P FI, P FI,

PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFI, PFO, PFO, PFO, PFO, PFO,

PFO, PFO, P FO, PFO , PFO, PFO, PF O, PFO, PFO, P FO, PFO , PFO, PFO, PF O, PFO, Reset, Reset, Re set, Res et,

Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset,

Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset,

Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset,

Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset,

Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset, Reset,

Reset, Reset, Reset, Reset, Reset, Reset, Write Protect, Write Protect, Write Protect, Write Protect, Write Protect, Write

Protect, Write Protect, Writ e Protect , Write Prote ct, Write Pro tect, Writ e Protect , Write Protect, Write Pro tect, Writ e Protect, Write Protect, Write Prote ct, Write Pro tect, Writ e Protec t, Write Prote ct, Write Pro tect, Writ e Protect, Write Prote ct,

Write Protect, Write Pro tect, Writ e Pr otect , Ba ttery, Batt ery, Batte ry, Batter y, B attery , Ba ttery, Bat tery, Batt ery, Batte ry,

Battery, Battery, Batte ry, Battery, Battery, Batte ry, Battery, Battery, Battery, Batte ry, Battery, Battery, Batte ry, Battery,

Battery, Battery, Batte ry, Battery, Battery, Batte ry, Battery, Battery, Battery, Batte ry, Battery, Battery, Batte ry, Battery,

Battery, Battery, Batte ry, Battery, Battery, Batte ry, Battery, Battery, Battery, Batte ry, Battery, Battery, Batte ry, Battery,

Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Battery, Switchover, Switchover, Switchover,

Switchover, Switchover, Switchover, Switchover, Switchover, Switchover, Switchover, Power-fail, Power-fail, Power-fail,

Power-fail, Powe r-fail, Pow er-fail, Pow er-fail, Pow er-fail, Pow er-fail, Pow er-fail, Com parator, C omparator , Comparat or,

Comparator, C omparator, Compara tor, Comp arator, Co mparator, Compara tor, Comp arator, Co mparator, Comparat or,

Comparator, C omparator, Compara tor, Comp arator, Co mparator, Compara tor, Comp arator, Co mparator, Comparat or,

Comparator, C omparator, Compara tor, Comp arator, Co mparator, Compara tor, Comp arator, Co mparator, Comparat or,

Comparator, C omparator, Compara tor, Comp arator, Co mparator, Compara tor, Comp arator, Co mparator, Comparat or,

Comparator, Comparator, Comparator, Comparator, Comparator, Comparator, SNAPHAT, SNAPHAT, SNAPHAT,

SNAPHAT, SNA PHAT , SNA PHAT , SNA PHAT , SNA PHAT , SNA PHAT, SNA PHA T, SNA PHA T, SN APHA T, SN APHA T,

SNAPHAT, SNA PHAT , SNA PHAT , SNA PHAT , SNA PHAT , SNA PHAT, SNA PHA T, SNA PHA T, SN APHA T, SN APHA T,

SNAPHAT, SNA PHAT , SNA PHAT , SNA PHAT , SNA PHAT , SNA PHAT, SNA PHA T, SNA PHA T, SN APHA T, SN APHA T,

SNAPHAT, SNA PHA T, SO IC, S OIC, SOIC , SO IC, S OIC, SOIC , SOI C, SO IC, S OIC, SOIC , SO IC, S OIC, SOIC , SO IC,

SOIC, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V,

5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 5V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V, 3V,

3V, 3V

Information furnished is believed to be accurate an d rel i able. However, STMicroelectro ni cs assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent ri ghts of STM i croelectr onics. Specifications menti oned in thi s publicati on are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics product s are not

authorized for use as cri tical comp onents in lif e support devi ces or systems without express written approv al of STMicroel ectronics.

The ST logo is a registered trademark of STMicroelectron ic s.

All other nam es are the pro perty of their respectiv e owners

© 2003 STMi croelectronics - All rights reser ved

STMicroelectron ics GROUP OF COMPANIES

Australi a - Belgium - B razil - Canada - China - Czech Republi c - Finland - F rance - Germ any - Hong Ko ng - India - Israel - Italy - Japan -

Malaysia - M al ta - Morocco - Singapore - Spain - Sweden - Swit zerland - Un i ted Kingdom - United Sta tes

www.st.c o m

19/19

Loading...

Loading...