SGS Thomson Microelectronics M29W641DL, M29W641DH, M29W641D Datasheet

1/42

PRODUCT PREVIEW

April 2003

This is preliminary information on a new product now in development. Details are subject to change without notice.

M29W641DH, M29W641DL

M29W641DU

64 Mbit (4Mb x16, Uniform Block)

3V Supply F l ash Me m ory

FEATURES SUMMARY

■ SUPPLY VOLTAGE

–V

CC =

2.7V to 3.6V Core Power Supply

–V

CCQ

= 1.8V to 3.6V for Input/Output

–V

PP

=12 V for Fast Program (optional)

■ ACCESS TIME: 70, 90, 100 and 120ns

■ PROGRAMMING TIME

– 10 µs typica l

– Double Word Program option

■ 128 UNIFORM, 32-KWord MEMORY BLOCKS

■ PROGRAM/ERASE CONTROLLER

– Embedded Program and Erase algorithms

■ ERASE SUSPEND and RESUME MODES

– Read and Program another Block during

Erase Suspend

■ UNLOCK BYPASS PROGRAM COMMAND

– Faster Production/Batch Progra mming

■ WRITE PROTECT OPTIONS

– M29W641DH: WP

Pin for Write Protection of

Highest Address Block

– M29W641DL: WP

Pin for Write Protection of

Lowest Address Block

– M29W64 1DU: No Write Protection

■ TEMPORARY BLOCK UNPROTECTION

MODE

■ COMMON FLASH INTERFACE

■ EXTENDED MEMORY BLOCK

– Extra block used as security block or to store

additional information

■ LOW POWER CONSUMPTION

– Standby and Automatic Standby

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 0020h

– Device Code M29W641D: 22C7h

Figure 1. Packages

TSOP48 (N)

12 x 20mm

FBGA

TFBGA63 (ZA)

7 x 11mm

M29W641DH, M29W641DL, M29W641DU

2/42

TABLE OF CONTENTS

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

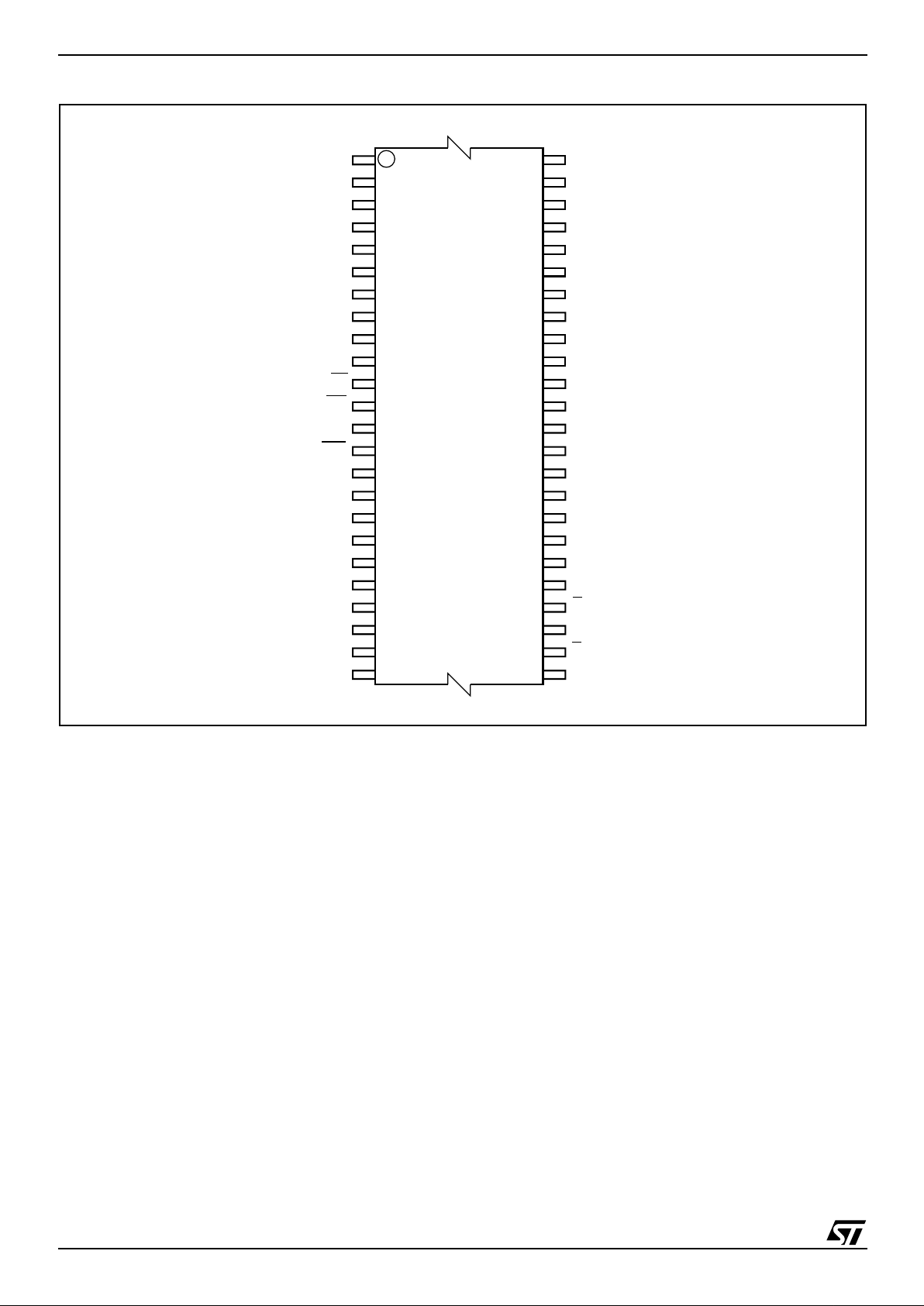

Figure 3. TSOP Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

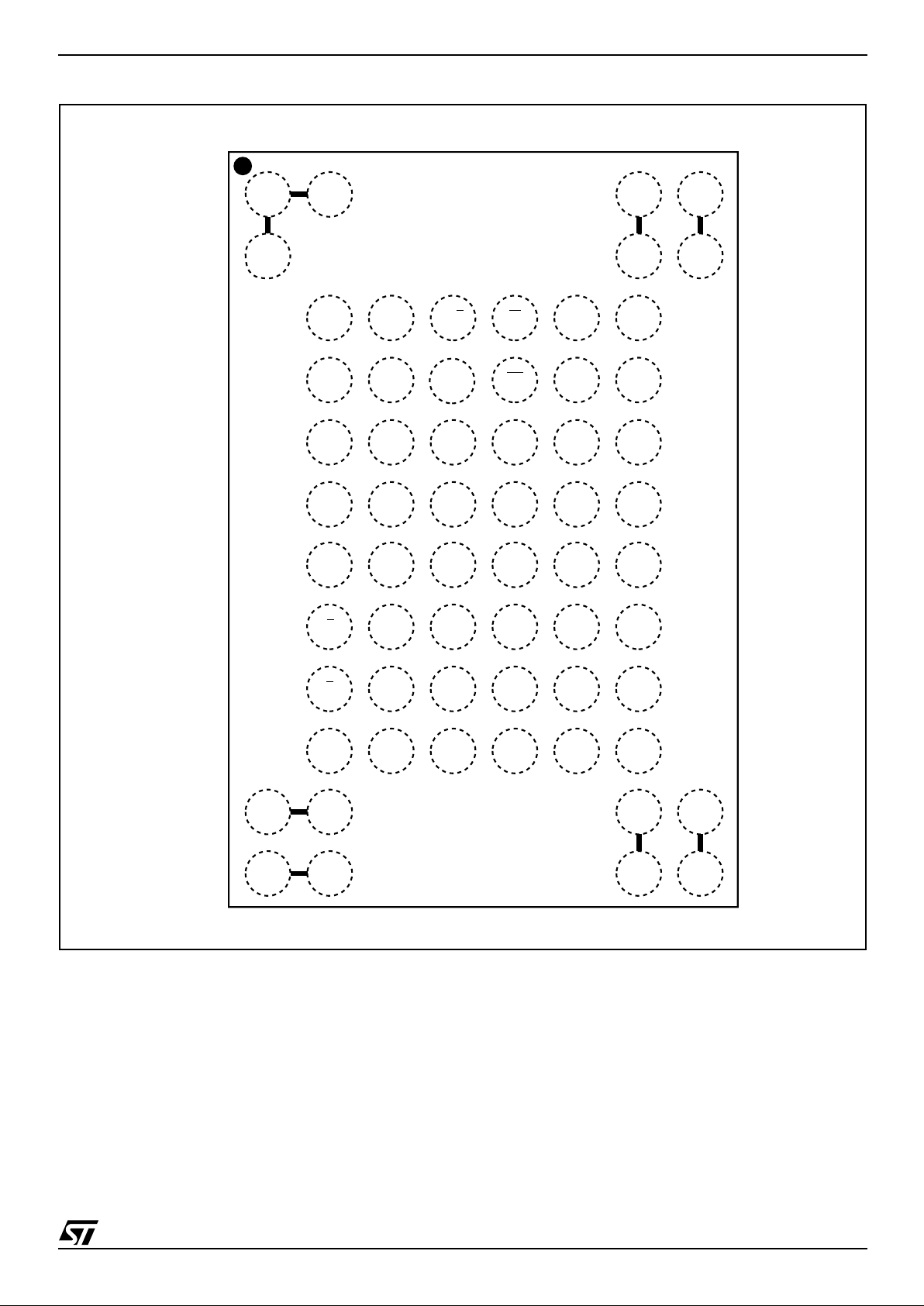

Figure 4. TFGBA Connections (Top view through package). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SIGNAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Address Inputs (A0-A21). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Inputs/Outputs (DQ0-DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Inputs/Outputs (DQ8-DQ15 ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chip Enable (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Output Enable (G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Write Enable (W). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Write Protect (WP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Reset/Block Temporary Unprotect (RP).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

V

PP

(VPP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

CC

Supply Voltage (2.7V to 3.6V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

CCQ

Supply Voltage (1.8V to 3.6V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

SS

Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 2. Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bus Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bus Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Automatic Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Special Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0

Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Block Protect and Chip Unprotect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Block Protect and Chip Unprotect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

COMMAND INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Read/Reset Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Auto Select Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unlock Bypass Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Unlock Bypass Program Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Unlock Bypass Reset Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Chip Erase Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2

Block Erase Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Erase Suspend Comma nd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Erase Resume Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3/42

M29W641DH, M29W641DL, M29W641DU

Enter Extended Block Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Exit Extended Block Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 3. Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 4. Program, Erase Times and Program, Erase E ndurance Cy cles . . . . . . . . . . . . . . . . . . . . 14

STATUS REGISTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Data Polling Bit (DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Toggle Bit (DQ6).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5

Error Bit (DQ5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Erase Timer Bit (DQ3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Alternative Toggle Bit (DQ2).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5

Table 5. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 5. Data Polling Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 6. Data Toggle Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 6. Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 9

Table 7. Operating and AC Measurement Condition s. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 7. AC Measurement I/O Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 8. AC Measurement Load Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 8. Device Capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 9

Table 9. DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 0

Figure 9. Read Mode AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 10. Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 10. Write AC Waveforms, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 11. Write AC Characteristics, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 11. Write AC Waveforms, Chip Enable Controlled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 12. Write AC Characteristics, Chip Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 12. Reset/Block Temporary Unprotect AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 13. Reset/Block Temporary Unprotect AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 13. Accelerated Program Timing Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 14. TSOP48 – 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Outline . . . . . . . . 25

Table 14. TSOP48 – 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Mechanical Data . 25

Figure 15. TFBGA63 - 7x11mm, 6x8 active ball array, 0.8mm pitch, Bottom view packag e outline26

Table 15. TFBGA63 - 7x11mm, 6x8 active ball array, 0.8mm pitch, Package Mech anical Data . . 26

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 16. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

APPENDIX A. BLOCK ADDRESSES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 17. Block Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

M29W641DH, M29W641DL, M29W641DU

4/42

APPENDIX B. COMMON FLASH INTERFACE (CFI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 18. Query Structure Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Table 19. CFI Query Identification String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Table 20. CFI Query System Interface Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 21. Device Geometry Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 22. Primary Algorithm-Spe cific Extended Query Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 23. Security Code Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 4

APPENDIX C. EXTENDED MEMORY BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Factory Locked Extended Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Customer Lockable Extended Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 24. Extended Block Address and Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

APPENDIX D. BLOCK PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Programmer Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

In-System Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 25. Programmer Technique Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 16. Programmer Equipment Group Protect Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 17. Programmer Equipment Chip Unprotect Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 18. In-System Equipment Group Protect Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 19. In-System Equipment Chip Unprotect Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 26. Document Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5/42

M29W641DH, M29W641DL, M29W641DU

SUMMARY DESCRIPTION

The M29W641D is a 64 M bit (4Mb x16 ) non-v olatile memory that can be read, erased and reprogrammed. These operations can be performed

using a single, low voltage, 2.7V to 3.6V V

CC

sup-

ply for the circuitry and a 1.8V to 3.6V V

CCQ

supply

for the Input/Output pins. An optional 12 V V

PP

power supply is provided to speed up customer

programming.

On power-up the memory defaults to its Read

mode where it can be read in the same way as a

ROM or EPROM.

The highest address blo ck of t he M 29W6 41DH or

the lowest address block of the M29W641 DL can

be protected from accidental programming or erasure using the WP

pin (if WP = VIL). The

M29W641DU doe s not feature the WP

pin.

Each block can be erase d independently so it is

possible to preserve valid data while old data is

erased. The blocks can be protected to prevent

accidental Program or Erase commands from

modifying the me mory. Program an d Erase commands are written to the Command Interface of

the memory. An on-chip Program/Erase Controller

simplifies the process of programming or e rasing

the memory by taking care of all of the special operations that are required to update the memory

contents. The end of a program or erase operation

can be detected and any error conditions identified. The command set required to control the

memory is consistent with JEDEC standards.

The M29W641D has an extra block, the Extended

Block, (of 32 KWords) that can be accessed using

a dedicated command. The Extended Block can

be protected and s o is useful for storing security

information. However the prot ection i s not reversible, once protected the protection cannot be undone.

Chip Enable, Output Enable and Write Enable signals control the bus operation of the memory.

They allow simple connection to most microprocessors, often without additional logic.

The memory is offered in a 48-pin TSOP package

(M29W641DL and M29W641DH) or i n a 63-ball TFBGA pack age (M29W64 1DU). All de vices a re del ivered with all the bits e ras ed (set to 1).

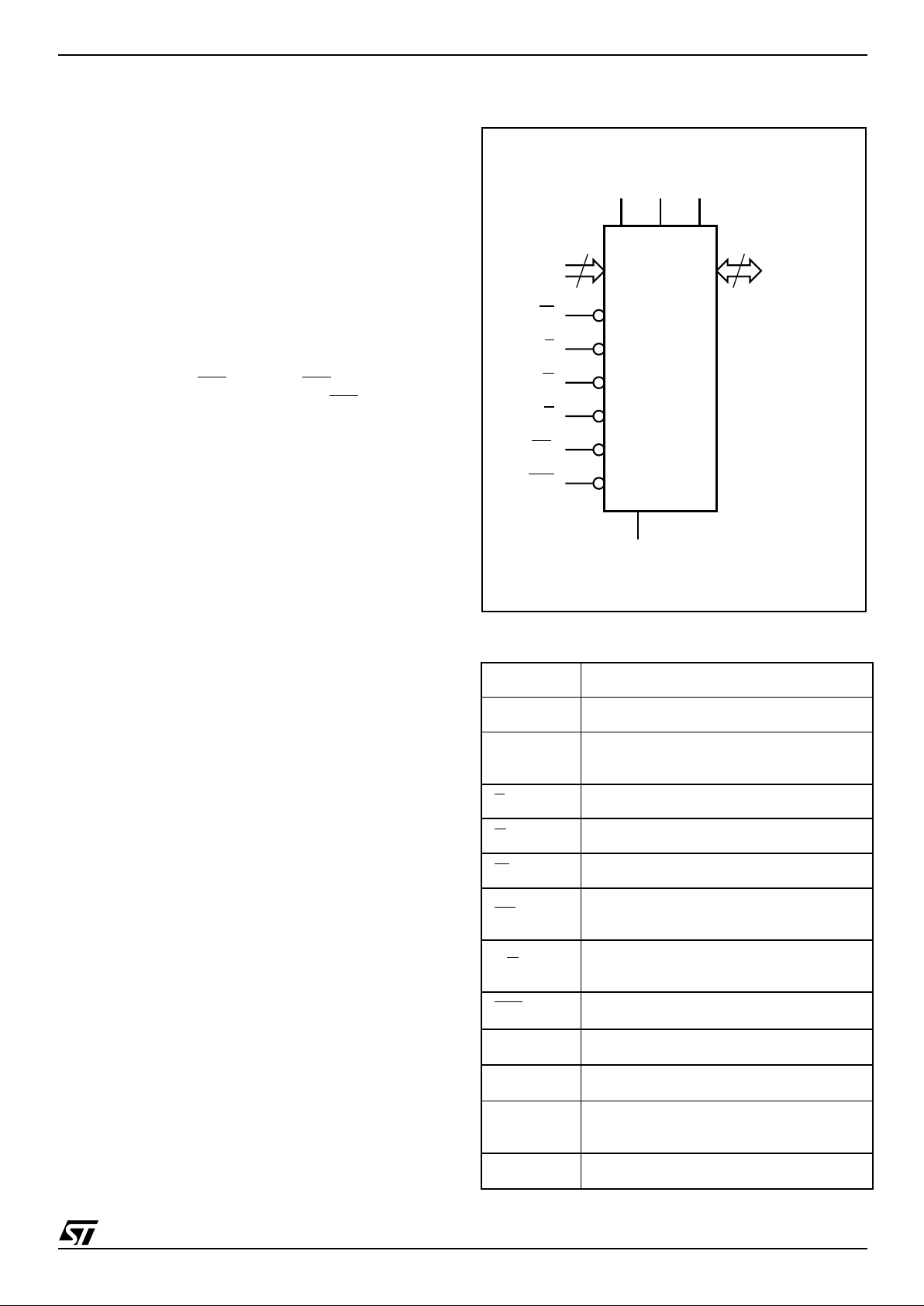

Figure 2. L o gi c D iagram

Table 1. Signal Names

A0-A21 Address Inputs

DQ0-DQ7 Data Inputs/Outputs

DQ8-

DQ15

Data Inputs/Outputs

E

Chip Enable

G

Output Enable

W

Write Enable

RP

Reset/Block Temporary Unprotect

(M29W641DH and M29W641DL only)

RB

Ready/Busy Output (M29W641DU

only)

WP

Write Protect

V

CC

Supply Voltage

V

CCQ

Supply Voltage for Input/Output

V

PP

Supply Voltage for Fast Program

(optional)

V

SS

Ground

AI06697b

22

A0-A21

W

DQ0-DQ15

V

CC

M29W641D

E

V

SS

16

G

RP

V

PP

WP

V

CCQ

RB

M29W641DH, M29W641DL, M29W641DU

6/42

Figure 3. TSOP C on ne cti ons

DQ3

DQ9

DQ2

A6

DQ0

W

A3

A19

DQ6

A8

A9

DQ13

A17

A10 DQ14

A2

DQ12

DQ10

DQ15

V

CC

DQ4

DQ5

A7

DQ7

WP

V

PP

M29W641D

12

1

13

24 25

36

37

48

DQ8

A20

A21

A1

A18

A4

A5

DQ1

DQ11

G

A12

A13

A16

A11

V

CCQ

A15

A14

V

SS

E

A0

RP

V

SS

AI06698

7/42

M29W641DH, M29W641DL, M29W641DU

Figure 4. TFGBA Connections (Top view through package)

Note: 1. Bal l s are shorte d to gether via the substrat e but not connec te d to the die.

654321

V

SS

A15

A14

A12

A13

DQ3

DQ11

DQ10

A18

V

PP

RB

DQ1

DQ9

DQ8

DQ0

A6

A17

A7

G

E

A0

A4

A3

DQ2

DQ6

DQ13

DQ14

A10

A8

A9

DQ4

V

CC

DQ12

DQ5

A19

A21

RP

W

A11

DQ7

A1

A2

V

SS

A5 A20

A16

C

B

A

E

D

F

G

H

DQ15

NC

(1)

NC

(1)

NC

(1)

NC

(1)

NC

(1)

NC

(1)

NC

(1)

NC

(1)

NC

(1)

NC

(1)

NC

(1)

J

K

L

M

87

NC

(1)

NC

(1)

NC

(1)

NC

(1)

AI06879

V

CCQ

M29W641DH, M29W641DL, M29W641DU

8/42

SIGNAL DESCRIPTIONS

See Figure 2, Logic Diagram, and T able 1, Signal

Names, for a brief overview of the signals connected to this device.

Address Inputs (A0-A21). The Address Inputs

select the cell s in the memory arra y to access during Bus Read operations. During Bus Write operations they control the commands sent to the

Command Interface of the Program/Erase Controller.

Data Inputs/Outputs (DQ0-DQ7). The Data I/O

outputs the data stored at the selected address

during a Bus Read operation. During Bus Write

operations they represent the commands sent to

the Command Interface of the Program/Erase

Controller.

Data Inputs/Outputs (DQ8-DQ15). The Data I/O

outputs the data stored at the selected address

during a Bus Read operation. During Bus Write

operations the Command Register does not use

these bits. When reading the Status Register

these bits should be ignored.

Chip Enable (E

). The Chip Enable, E, activates

the memory, allowing Bus Read and Bus Write operations to be performed. When Chip Enable is

High, V

IH

, all other pins are ignored.

Output Enable (G

). The Output Enable, G, con-

trols the Bus Read operation of the memory.

Write Enable (W

). The Write Enable, W, controls

the Bus Write operation of the memory’s Command Interface.

Write Protect (W

P). The Write Protect pin is

available in the M29W641DH and M29W641DL

only. I t provid es a hard war e metho d of pro tecting

the highest address block for the M29W641DH

and the lowest address block for the

M29W 641DL. The Write Protect pin must not be

left floating or unconnected.

When Write Protect is Low, V

IL

, the memory protects either the highest or lowest address block;

Program and Erase operations in this block are ignored while Write Protect is Low.

When Write P rotect

is High, VIH, the memory reverts to the previous protection status for this

block. Program and Erase operations can now

modify the data in this block unless the block is

protected using Block Protection.

Ready/Busy Output (RB

). The Ready/Busy pin

is an open-drain output that can be used to identify

when the device is performing a Program or Erase

operation. During Program or Erase operations

Ready/Busy is Low, V

OL

. Ready/Busy is high-impedance during Read mode, Auto Select mode

and Erase Suspend mode.

After a Hardware Reset, Bus Read and Bus Write

operations cannot begin until Ready/Busy be-

comes high-impedanc e. See Tabl e 13 a nd Fi gure

12, Reset/Block Temporary Unprotect AC Characteristics.

The use of an open-drain output allows the Ready/

Busy pins from several memories to be connected

to a single pull-up resistor. A Low will then indicate

that one, or more, of the memories is busy.

Reset/Block Temporary Unprotect (RP

). The

Reset/Block Temporary Unprotect pin can be

used to apply a Hardware Reset to the memory or

to temporarily unprotect all Blocks that have been

protected.

Note that if Write Protect

(WP) is at VIL, then one

of the two ou termost blocks will remain p rotected

even if RP is at V

ID

.

A Hardware Reset is achieved by holding Reset/

Block Temporary Unprotect Low, V

IL

, for at least

t

PLPX

. After Reset/Block Temporary Unprotect

goes High, V

IH

, the memory will be ready for Bus

Read and Bus Write operations after t

PHEL

or

t

RHEL

, whichever occurs last. See Table 13 and

Figure 12, Reset/Block T emporary Unprotect AC

Characteristics, for more details.

Holding RP

at VID will temporarily unprotect the

protected Blocks in the memory. Program and

Erase operations on all blocks will be possible.

The transition from V

IH

to VID must be slower than

t

PHPHH

.

V

PP

(VPP). When the VPP pin is raised to V

PPH

the memory automatically enters the Unlock Bypass mode. When the pin is returned to V

IH

or V

IL

normal operation resumes. During Unlock Bypass

Program operations the memory draws I

PP

from

the pin to supply the programming circuits. See the

description of the Unlock Bypas s c ommand in the

Command Interface section. The transitions from

V

IH

to VPP and from VPP to VIH must be slower

than t

VHVPP

, see Figure 13.

Never raise the pin to V

PP

from any mode except

Read mode, otherwise the memory may be left in

an indeterminate state.

V

CC

Supply Voltage (2.7V to 3.6V). VCC pro-

vides the power supply for all operations (Read,

Program and Erase).

The Command Interface is disabled when the V

CC

Supply Voltage is less than the L ockout Voltage,

V

LKO

. This prevents Bus Write operations from accidentally damaging the data during power up,

power down and power surges. If the Program/

Erase Controller is programming or erasing during

this time then the operation aborts and the memory contents being altered will be invalid.

V

CCQ

Supply Voltage (1.8V to 3.6V). V

CCQ

provides the power supply to the I/O pins and enables

all Outputs to be powered i ndependently of V

CC

.

9/42

M29W641DH, M29W641DL, M29W641DU

V

CCQ

can be tied to VCC or can use a separate

supply.

V

SS

Ground. VSS is the reference for all voltage

measurements. The device f eatures two V

SS

pins

which must be both connected to the system

ground.

Note: Each device in a system should have

V

CC, VCCQ

and VPP decoupled from V

SS

with a

0.1µF ceramic capacitor close to the pin for

current surge protection (high frequency, inherently low inductan ce capacitors should b e

as close as possible to the device). See Figure

8, AC Measurement Load Circuit. The PCB

trace widths should be sufficient to carry the

required V

PP

program and erase currents. See

Table 9, DC Characteristics.

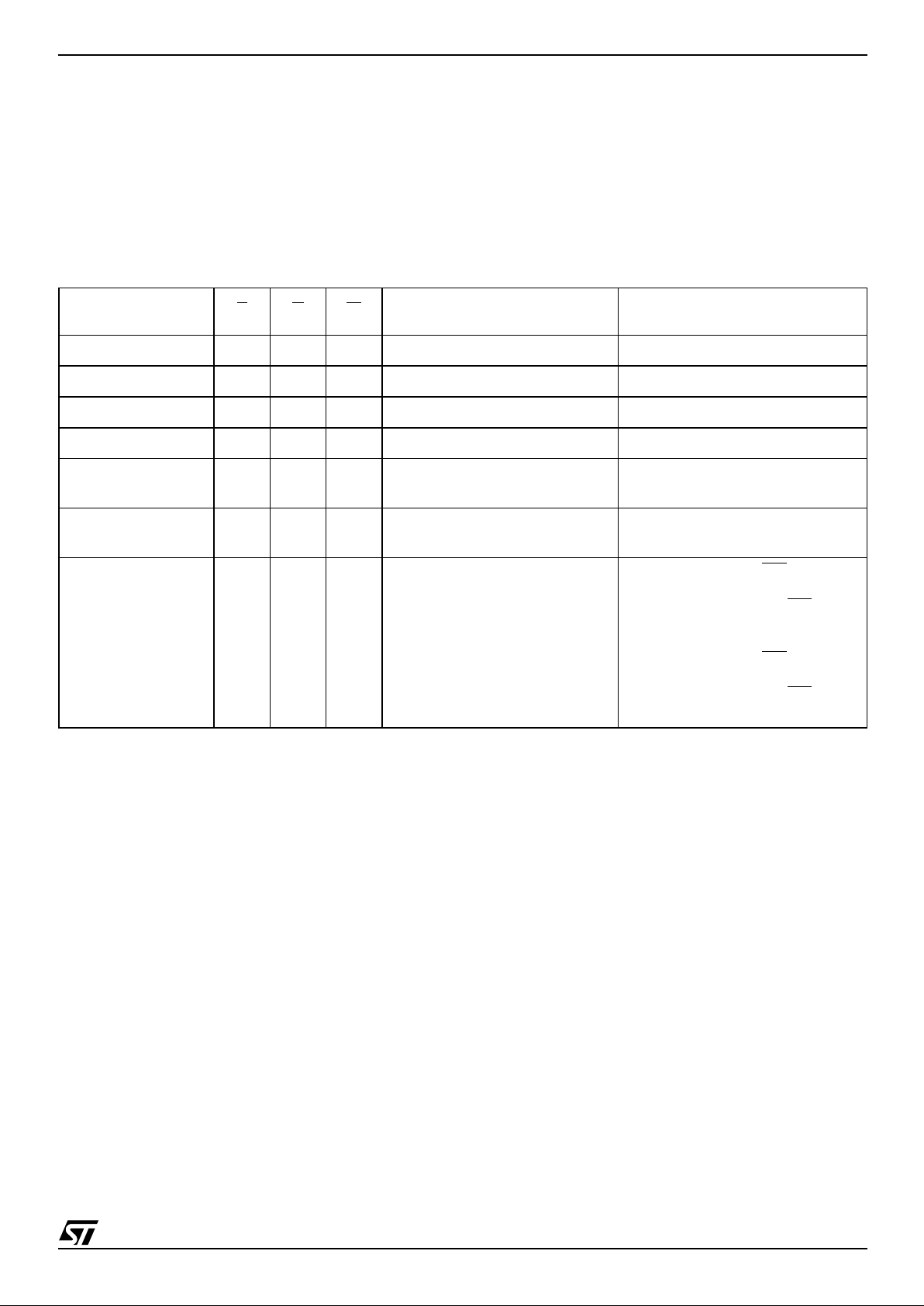

Table 2. Bus Operations

Note: X = VIL or VIH.

Operation E G W

Address Inputs

A0-A21

Data Inputs/Outputs

DQ15-DQ0

Bus Read

V

IL

V

IL

V

IH

Cell Address Data Output

Bus Write

V

IL

V

IH

V

IL

Command Address Data Input

Output Disable X

V

IH

V

IH

X Hi-Z

Standby

V

IH

X X X Hi-Z

Read Manufacturer

Code

V

IL

V

IL

V

IH

A0 = VIL, A1 = VIL, A9 = VID,

Others V

IL

or V

IH

0020h

Read Device Code

V

IL

V

IL

V

IH

A0 = VIH, A1 = VIL, A9 = VID,

Others V

IL

or V

IH

22C7h

Extended Memory

Block Verify Code

V

IL

V

IL

V

IH

A0 = VIH, A1 = VIH, A6 = VIL,

A9 = V

ID

, Others VIL or V

IH

98h (factory locked, WP protects

highest address block)

18h (not factory locked, WP

protects highest address

block)

88h (factory locked, WP

protects

lowest block)

08h (not factory locked, WP

protects lowest block)

M29W641DH, M29W641DL, M29W641DU

10/42

BUS OPERATIONS

There are five standard bus operations that control

the device. These are B us Read, Bus Wri te, Output Disable, Standby and Automatic Standby. See

Table 2, Bus Operations, for a summary. Typically

glitches of less t han 5ns on Chip E nable o r Write

Enable are ignored by the memory and do not a ffect bus operations.

Bus Read. Bus Read operations read from the

memory cells, or specific registers in the Command Interface. A valid Bus Read operation involves setting the desired address on the Address

Inputs, applying a Low signal, V

IL

, to Chip Enable

and Output Enable and keeping Write Enable

High, V

IH

. The Data Inputs/Outputs will outp ut the

value, see Figure 9 , Read Mode AC Waveforms,

and Table 10, Read AC Characteristics, for details

of when the output becomes valid.

Bus Write. Bus Write operations write to the

Command Interface. A valid Bus Write operation

begins by setting th e desired address o n the Address Inputs. The Address Input s are latched by

the Command Interface on the falling edge of Chip

Enable or Write Enable, whichever occurs last.

The Data Inputs/Outputs a re latc hed by the Com mand Interface on the rising edge of Chip Enable

or Write Enable, whichever occurs first. Output Enable must remain High, V

IH

, during the whole Bus

Write operation. See Figure 10 and Figure 11,

Write AC Waveforms, and Table 11 and Table 12,

Write AC Characteristics, for details of the timing

requirements.

Output Disable. T he Data Inputs/Outputs are in

the high impedanc e state when Out put Enable is

High, V

IH

.

Standby. When Chip Enable is High, V

IH

, the

memory enters Standby mode and the Data Inputs/Outputs pins are placed in the high-impedance state. To reduce t he Supply Current to the

Standby Supply Current, I

CC2

, Chip Enable should

be held within V

CC

± 0.2V. For the Standby current

level see Table 9, DC Characteristics.

During program or erase operations the memory

will continue to use the Program/Erase Supply

Current, I

CC3

, for Program or Erase operations un-

til the operation completes.

Automatic Standby. If CMOS levels (V

CC

± 0.2V)

are used to drive the bus and the bus is inactive for

300ns or more the memory enters Automatic

Standby where the internal Supply Current is reduced to the Standby Supply Current, I

CC2

. The

Data Inputs/Outputs will still output data if a Bus

Read operation is in progress.

Special Bus Operations

Additional bus operations can be performed to

read the Electronic Signature and also to apply

and remove Block Protection. These bus operations are intended for use by programming equipment and are not usually used in applications.

They require V

ID

to be applied to some pins.

Electronic Signature. The memory has two

codes, the manufacturer code and the device

code, that can be read to identify the memory.

These codes can be read by app lying the signals

listed in Table 2, Bus Operations.

Block Protect and Chip Unprotect.

Groups of

blocks can be protected against accidental Program or Erase. The whole chip can be unprotected

to allow the data inside the blocks to be changed.

Write Protect

(WP) can be used to protect one of

the outermost blocks. When Write Protect

(WP) is

at V

IL

one of the two outer m os t blocks i s prot e cted and r emai ns prot ect ed r eg ardle s s of the Bl ock

Protection Status or the Reset/Block Temporary

Unprotect pin stat us. For th e M29W641D H, it is

the highest addressed block that can be protected. For the M29 W641DL, i t i s the lowest.

Block Protect and Chip Un protect operations are

described in Appendix D.

11/42

M29W641DH, M29W641DL, M29W641DU

COMMAND INTERFACE

All Bus Write operations to the memory are in terpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. Failure to observe a valid sequence of Bus

Write operations will result in the memory returning to Read mode. The long command sequences

are imposed to maximize data security.

See Table 3 for a summary of the commands.

Read/Reset Command

The Read/Reset command returns the memory to

its Read mode where it behaves like a ROM or

EPROM. It also resets the errors in the Status

Register. Either one or three Bus Write operations

can be used to issue the Read/Reset command.

The Read/Reset command can be issued, between Bus Write cycles before the start of a program or erase operation, to return the device to

read mode. If the Read/Reset command is issued

during the timeout of a Block erase operation then

the memory will take up to 10µs to abort. During

the abort period no valid data can be read from the

memory. The Read/Reset command will not abort

an Erase operation when issued while in Erase

Suspend.

Auto Select Command

The Auto Select command is used to read the

Manufacturer Code, the Device Code, the Block

Protection Status and the Extended Memory Block

Verify Code. Three consecut ive Bus W rite operations are required to issue the Auto Select command. Once the Auto Select command is issued

the memory remains in Auto S elect mode until a

Read/Reset command is issued. Read CFI Query

and Read/Reset com ma nds are accepted in Aut o

Select mode, all other commands are ignored.

In Auto Select mode the Manuf acturer Code can

be read using a Bus Read operation with A0 = V

IL

and A1 = VIL. The other address bits may be set to

either V

IL

or VIH. The Manufacturer Co de for ST-

Microelectronics is 0020h.

The Device Code can be read using a Bus Read

operation with A0 = V

IH

and A1 = VIL. The other

address bits may be set to e ither V

IL

or VIH. The

Device Code for the M29W641D is 22C7h.

The B l ock Protecti on Sta tus of each block can be

read using a Bus Read operation with A0 = V

IL

,

A1 = V

IH

, and A 12-A21 sp ecifyin g t h e addres s of

the b lock. T he oth er addr ess bi ts may b e set t o either V

IL

or VIH. If th e addr ess ed bloc k is p rot ecte d

then 01h is output on Data Inputs/Outputs DQ0DQ7, otherwise 00h is output.

Read CFI Query Command

The Read CFI Query Command is used to read

data from the Common Flash Interface (CFI)

Memory Area. This command is valid when the de-

vice is in the Read Array mode, or when the device

is in Autos ele c t e d mo de.

One Bus Write cycle is required to issue the Read

CFI Query Command. Once the command is issued subsequent Bus Read ope rations read from

the Common Flash Interface Memory Area.

The Read/Reset comm and must be issued to return the device to the previous mode (the Read Array mode or Autoselected mode). A second Read/

Reset command would be needed if the device is

to be put in the Read Array mode from Autoselected mode.

See Appendix B, Ta ble 18 to Table 23 for details

on the information contained in the Common Flash

Interface (CFI) memory area.

Program Command

The Program command can be used to program a

value to one address in the memory array at a

time. The command requires four Bus Write operations, the final write operation latches the address and data, and starts the Program/Erase

Controller.

If the address falls in a protected block then the

Program command is ignored, the data remains

unchanged. The Status Register is never read and

no error condition is given.

During the program operat ion the me mory will ignore all commands. I t is not possible to issue any

command to abort or pause the operation. Typical

program times are given in Table 4. Bus Read operations during the program o peration will output

the Status Register on the Data Inputs/Outputs.

See the section on t he Status Register for more

details.

After the program operation has completed the

memory will return to the Read mode, unless an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

Note that the Program command cannot change a

bit set at ’0’ back to ’1’. One of the Erase Commands must be used to set all the bits in a block or

in the whole memory from ’0’ to ’1’.

Fast Program Commands

There is a Fast Program command available to improve the programming throughput, by writing several adjacent words or bytes in parallel: the Double

Word Program command.

Double Word Program Command. The Doub l e

Word Program comm and is used to write a page

of two adjacent words in paral lel. The two words

must differ only for the address A0.

Three bus write cycles are necessary to issue the

Double Word Program command.

M29W641DH, M29W641DL, M29W641DU

12/42

■ The first bus cycle sets up the Double Word

Program Command.

■ The second bus cycle latches the Address and

the Data of the first word to be written.

■ The third bus cycle latches the Address and the

Data of the second word to be written and starts

the Program/Erase Controller.

Only one bank can be programmed at any one

time. The other b ank must be in Read mode or

Erase Suspend.

Programming should not be attempted when V

PP

is not at V

PPH

.

After programming has started, Bus Read operations in the Bank being programmed output the

Status Register content, while Bus Read operations to the oth er Bank o utput the c ontents of t he

memory a r ra y.

After the program operation has completed the

memory will return to the Read mode, unless an

error has occurred. When an error occurs Bus

Read operations to the Bank where the command

was issued will continue to output the Status Register. A Read/Reset command must be issued to

reset the error condition and return to Read mode.

Note that the Fast Program commands cannot

change a bit set at ’0’ back to ’1’. One of the Erase

Commands must be used to set all the bits in a

block or in the whole memory from ’0’ to ’1’.

Typical Program time s are given in Tab le 4, Program, Erase Times and Program, Erase Endurance Cycles.

Unlock Bypass Command

The Unlock Bypass command is used in conjunction with the Unlock Bypass Program command to

program the memory faster than with the standard

program commands. Whe n the cycle time to the

device is long (as with some EPROM programmers) considerable time saving can be made by

using these commands. Three Bus Write operations are required to issue the Unlock Bypass

command.

Once the Unlock By pass command has been issued the memory enters Unlock Bypass mode.

When in this mode the memory can be read as if

in Read mode.

When V

PPH

is applied to the VPP pin the memory

automatically enters the Unlock Bypass mode and

the Unlock Bypass Program command can be issued immediately.

Unlock Bypass Program Command

The Unlock Bypass Program command can be

used to program one address in the memory array

at a time. The command requires t wo Bus Write

operations, the final write operation latches the ad-

dress and data, and starts the Program/Erase

Controller.

A Program operation initiated by issuing the Unlock Bypass Program command is identical to a

Program operation initiated by issuing the Program command. It cannot be aborted and a B us

Read operation will output the Status Register.

See the Program Comma nd paragraph for further

details.

Unlock Bypass Reset Command

The Unlock Bypass R eset com m and c an b e us ed

to return to Read/Reset mode from Unlock Bypass

Mode. Two Bus Write operations are required to

issue the Unlock Bypass Reset command. Read/

Reset command does not exit from Unlock Bypass

Mode.

Chip Erase Command

The Chip Erase command can be used to erase

the entire chip. Six Bus Write operations a re required to issue the Chip Erase Command and start

the Program/Erase Controller.

If any blocks are protected then these are ignored

and all the other blocks are erased. If all of the

blocks are protected the Chip Erase operat i on appears to start but will terminate within about 100µs,

leaving the data unchanged. No error condition is

given when protected blocks are ignored.

During the erase operation the memory will ignore

all commands, including the Erase Suspen d command. It is not possible t o issue any comm and to

abort the operation. Typical chip erase t imes are

given in Table 4. All Bus Read operations during

the Chip Erase operation will output the Status

Register on the Data Inputs/Outputs. See the section on the Status Register for more details.

After the Chip Erase operation has com pleted the

memory will return to the Read Mode, unless an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read Mode.

The Chip Erase Command sets all of the bits in unprotected blocks of the memory to ’1’. All previous

data is lost.

Block Erase Command

The Block Erase c ommand can be used to erase

a list of one or more blocks. Six Bus Write operations are required to select the first block i n the list.

Each additional block in the list can be selected by

repeating the sixth Bus Write operat ion using the

address of the additional block. The Block Erase

operation starts the Program/Erase Controller

about 50µs after the last Bus Write operation.

Once the P rogram /Erase Controller starts it is not

possible to select any more blocks. Each additional block must therefore be selected within 50µ s of

13/42

M29W641DH, M29W641DL, M29W641DU

the lowest address block. The 50µs time r restarts

when an additional block is selected. The Status

Register can be read after the sixth Bus Write operation. See the Status Register section for details

on how to identify if the P rogram /Erase Cont roller

has started the Block Erase operation.

If any selected blocks are protected then these are

ignored and all the other selected blocks are

erased. If all of the selected blocks are p rotected

the Block Erase operation appears to start but will

terminate within about 100µs, leaving the data unchanged. No error condition is given when protected blocks are ignored.

During the Block Erase operation th e memory wi ll

ignore all commands except the Erase Suspend

command. Typical block era se t imes a re given in

Table 4. All Bus Read operations during the Block

Erase operation w ill ou t pu t the S t a tus R eg i st er on

the Data Inputs/Outputs. See the section on the

Status Register for more details.

After the Block Erase operation has completed the

memory will return to the Read Mode, unless an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

The Block Erase Command sets all of the bits in

the unprotected selected blocks to ’1’. All previous

data in the selected blocks is lost.

Erase Suspend Command

The Erase Suspend Command may be used to

temporarily suspend a Block Erase o peration and

return the memory to Read mode. The com mand

requires one Bus Write operation.

The Program/Erase Controlle r will suspend within

the Erase Suspend Latency time of the Erase Suspend Command being issued. Once the Program/

Erase Controller has stopped the mem ory will be

set to Read mode and t he E rase wi ll be suspended. If the Erase Suspend c ommand is issued during the period when the memory is waiting for an

additional block (before the Program/E rase Controller starts) then the Erase is suspended immediately and will start immediately when the Erase

Resume Command is issued. It is not poss ible to

select any further blocks to erase after the Erase

Resume.

During Erase Suspend it is possible to Read and

Program cells in blocks that are not being erased;

both Read and Program operations behave as

normal on these blocks. If any attempt is made to

program in a protected block or in the suspen ded

block then the Program co mmand is ignored and

the data remains unchanged. The Status Register

is not read and no error condi tion is given. Reading from blocks that are being erased will output

the Status Register.

It is also possible to issue the Auto Select, Read

CFI Query and Unlock Bypass commands du ring

an Erase Suspend. The Read/Reset command

must be issued to return the device to Read Array

mode before the Resume command will be accepted.

Erase Resume Command

The Erase Resume command must be used to restart the Program/Erase Controller after an Erase

Suspend. The device must be in Read Array mode

before the Resume command will be accepted. An

erase can be suspended and resumed mo re than

once.

Enter Extended Block Command

The device has an extra 32 KWord block (Extended Block) that can only be accessed using the Enter Extended Block command. Three Bus write

cycles are required to issue the Extended Block

command. Once the command has been issued

the device enters Extende d Block mo de where a ll

Bus Read or Write operations to the Boot Block

addresses access the Extended Block. The Extended Block (with the same address as the Boot

Blocks) cannot be erased, and c an be treated as

one-time programmable (OTP) memory. In Extended Block mode the Boot Blocks are not accessible.

To exit from the Extended Block mode the Exit Extended Block command must be issued.

The Extended Block can be protected, however

once protected the protection cannot be undone.

Exit Exte nded Block Com m and

The Exit Extended Block command is used to exit

from the Extended Block mod e and return t he device to Read mode. Four Bus Write operations are

required to issue the command.

Block Protect and Chip Unprotect Commands

Groups of blocks can be protected against acci-

dental Program or Erase. The whole chip can be

unprotected to allow the dat a inside the blocks to

be changed.

Block Protect and Chip Un protect operations are

described in Appendix D.

Loading...

Loading...