FEATURES SUMMARY

■ SUPPLY VOLTAGE

–V

–V

■ ACCESS TIME: 90, 110ns

■ PROGRAMMING TIME

2.7V to 3.6V for Read

CC =

11.4V to 12.6V for Program and Erase

PP =

– 9µs per Word typical

– Multiple Word Programming Option (2s

typical Chip Program)

■ ERASE TIME

– 11s typical factory Chip Erase

■ UNIFORM BLOCKS

– 8 blocks of 2 Mbits

■ PROGRAM/ERA SE CONTROLLER

– Embedded Word Program algorithms

■ 10,000 PROGRAM/ERASE CYCLES per

BLOCK

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 0020h

– Device Code : 88ABh

M29KW016E

16 Mbit (1Mb x16, Uniform Block)

3V Supply LightFlash™ Memory

PRELIMINARY DATA

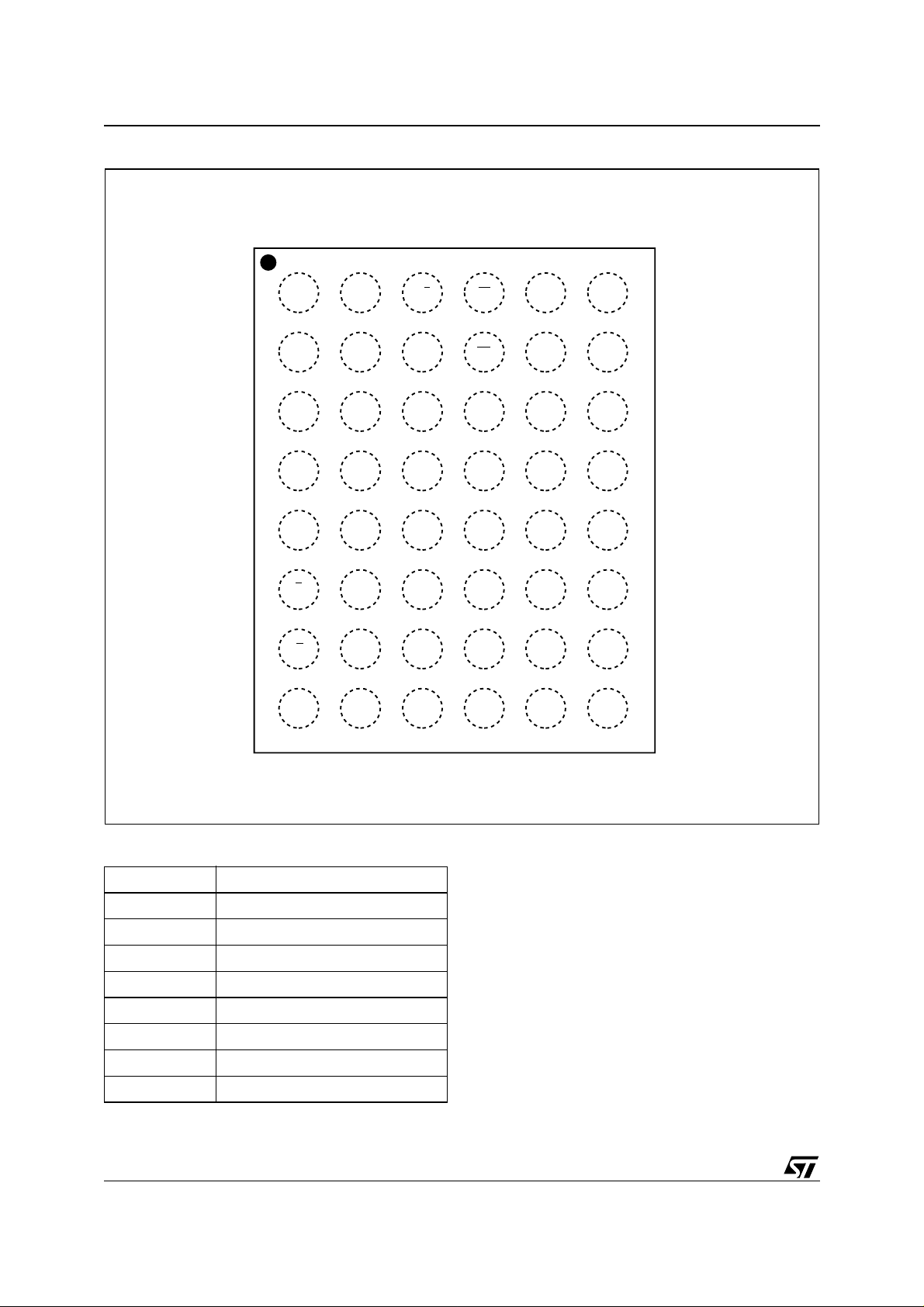

Figure 1. Packages

SO44 (M)

TSOP48 (N)

12 x 20mm

FBGA

TFBGA48 (ZA)

6 x 9mm

July 2002

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

1/31

M29KW016E

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1. Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. SO Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. TSOP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

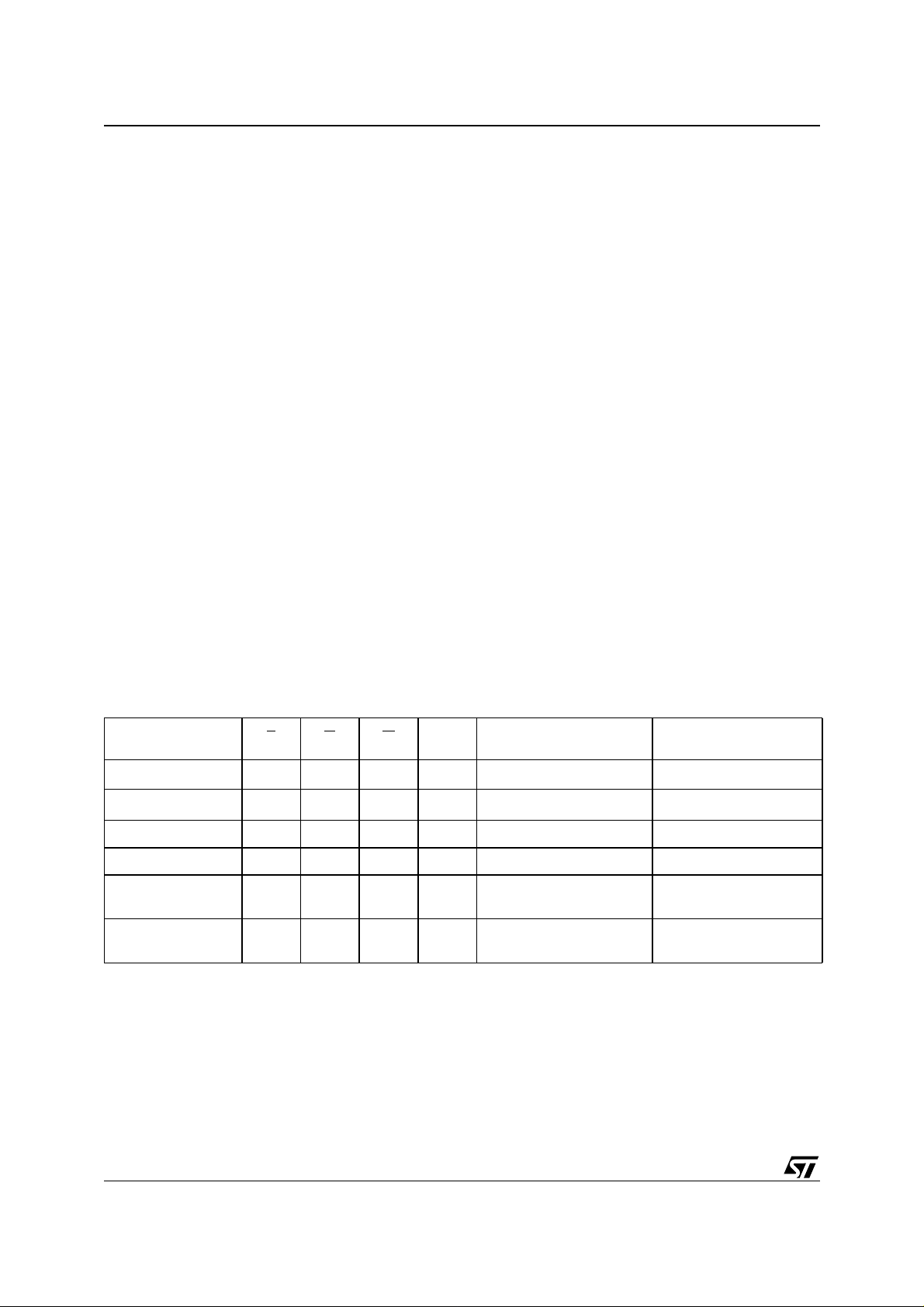

Figure 5. TFBGA Connections (Top view through package). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. Block Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SIGNAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Address Inputs (A0-A19). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Data Inputs/Outputs (DQ0-DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Data Inputs/Outputs (DQ8-DQ15 ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chip Enable (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Output Enable (G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Write Enable (W). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Reset (RP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ready/Busy Output (RB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

V

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CC

V

Program Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PP

Vss Ground.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bus Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bus Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Output Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Automatic Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3. Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

COMMAND INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Read/Reset Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Auto Select Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Word Program Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Multiple Word Program Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Setup Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Program Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Verify Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Exit Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Block Erase Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chip Erase Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 4. Standard Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 5. Multiple Word Program Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 6. Program, Erase Times and Program, Erase Endurance Cycles . . . . . . . . . . . . . . . . . . . . 11

Figure 6. Multiple Word Program Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2/31

M29KW016E

STATUS REGISTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Data Polling Bit (DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Toggle Bit (DQ6).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Error Bit (DQ5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

VPP Status Bit (DQ4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Erase Timer Bit (DQ3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Alternative Toggle Bit (DQ2).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Multiple Word Program Bit (DQ0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 7. Multiple Word Program Timings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 8. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 7. Data Polling Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 4

Figure 8. Data Toggle Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 9. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 10. Operating and AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. AC Measurement I/O Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 10. AC Measurement Load Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 11. Device Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 12. DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 11. Read AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 13. Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 12. Write AC Waveforms, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 14. Write AC Characteristics, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 13. Write AC Waveforms, Chip Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 15. Write AC Characteristics, Chip Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 14. Reset AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 16. Reset AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 15. SO44 - 44 lead Plastic Small Outline, 525 mils body width, Package Outline . . . . . . . . 24

Table 17. SO44 - 44 lead Plastic Small Outline, 525 mils body width, Package Mechanical Data . 24

Figure 16. TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Outline . . . . . . . . 25

Table 18. TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Mechanical Data . 25

Figure 17. TFBGA48 6x9mm - 8x6 ball array, 0.80 mm pitch, Bottom View Package Out line . . . . 26

Table 19. TFBGA48 6x9mm - 8x6 ball array, 0.80 mm pitch, Package Mechanical Data. . . . . . . . 26

Figure 18. TFBGA48 Daisy Chain - Package Connections (Top view through package) . . . . . . . . 27

Figure 19. TFBGA48 Daisy Chain - PCB Connections (Top view through package) . . . . . . . . . . . 28

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 20. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Table 21. Daisy Chain Ordering Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 22. Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3/31

M29KW016E

SUMMARY DESCRIPTION

The M29KW016E L ightFlash™ is a 16 Mbit (1Mb

x16) non-volatile memory that can be read, erased

and reprogrammed. Read op erations can b e performed using a single low voltage (2.7 to 3.6V)

supply. Program an d Er ase operations require an

additional V

power-up the memory defaults to its Read mode

where it can be read in the same way as a ROM or

EPROM.

The memory is divide d into 8 uniform bl ocks that

can be erased i ndependently so it is poss ible to

preserve valid data whi le old data is erased (see

Figures 2, Block Address es). Program a nd Erase

commands are written to the Command Interface

of the memory. An on-chip Program/Erase Controller (P/E.C.) simplifies the process of programming or erasing the memory by taking care of all of

the special operations that are required to update

the memory contents.

The M29KW016E LightFlash™ features a new

command, Multiple Word Program, used to program large streams of dat a. I t g reatly reduc es t he

total programming time when a large number of

Words are written to the memory at any one time.

Using this command the entire memory can be

programmed in 2s, compared to 9s using the standard Word Program.

The end of a program or erase operation can be

detected and any error conditions identified. The

command set required to control the memory is

consistent with JEDEC standards.

Chip Enable, Output Enable and Write Enable signals control the bus operation of the memory.

They allow simple conne ction to most m icroprocessors, often without additional logic.

The memory is offered in SO44, TSOP48 (12 x

20mm) and TFBGA48 (6 x 9mm, 0.8mm pitch)

packages. The memory is supplied with all the bits

erased (set to ’1’).

(11.4 to 12.6) power supply. On

PP

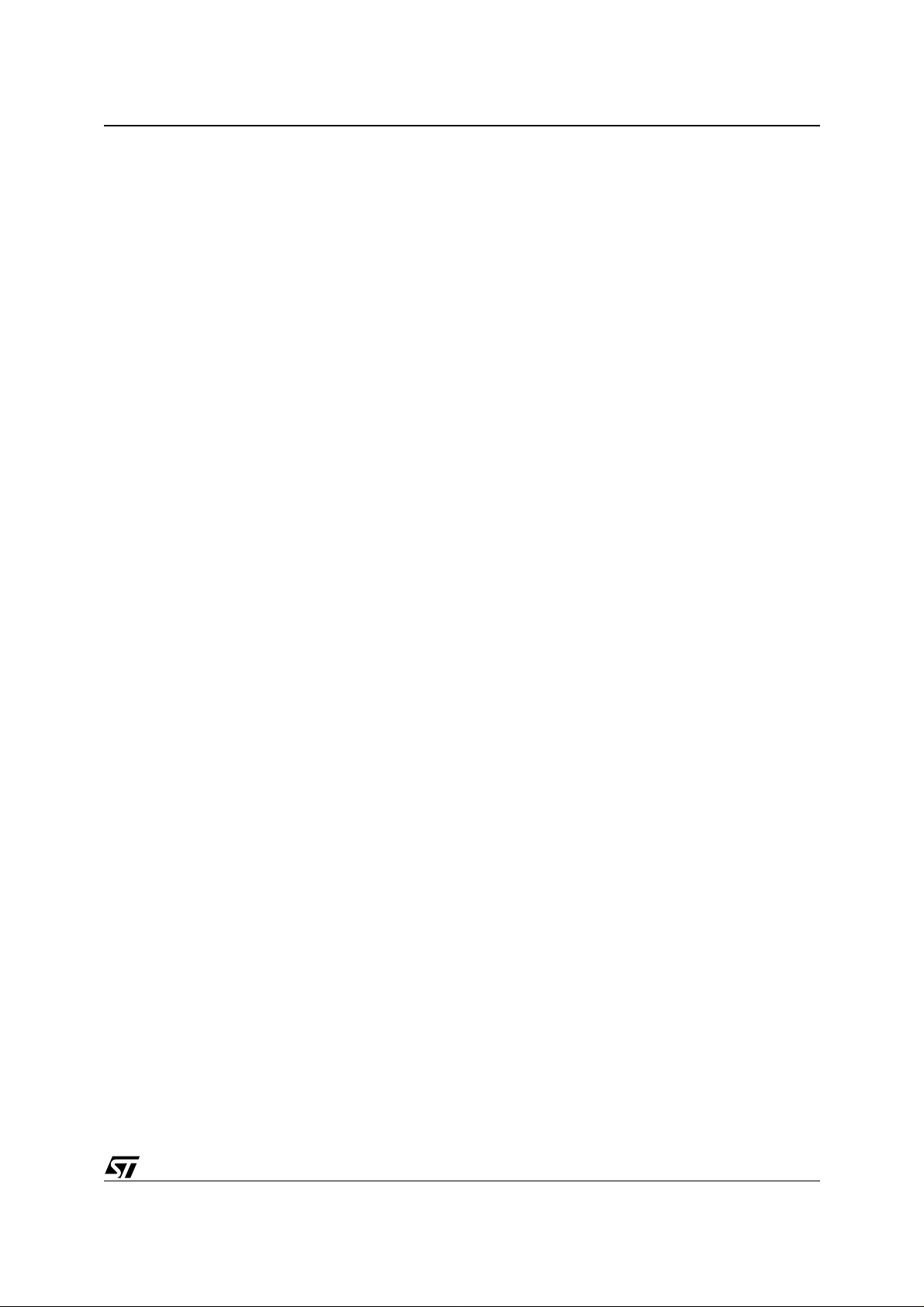

Figure 2. Logic Diagram

V

V

20

A0-A19 DQ0-DQ15

W

E

G

RP

Note: RB not availab l e on SO44 pa ckage.

M29KW016E

V

CC

SS

PP

16

RB

Table 1. Signal Names

A0-A19 Address Inputs

DQ0-DQ15 Data Inputs/Outputs

E

G

W

RP

RB

Chip Enable

Output Enable

Write Enable

Reset

Ready/Busy Output

(not available on SO44 package)

AI04371

4/31

V

CC

V

PP

V

SS

NC Not Connected Internally

Supply Voltage read

Supply Voltage program erase

Ground

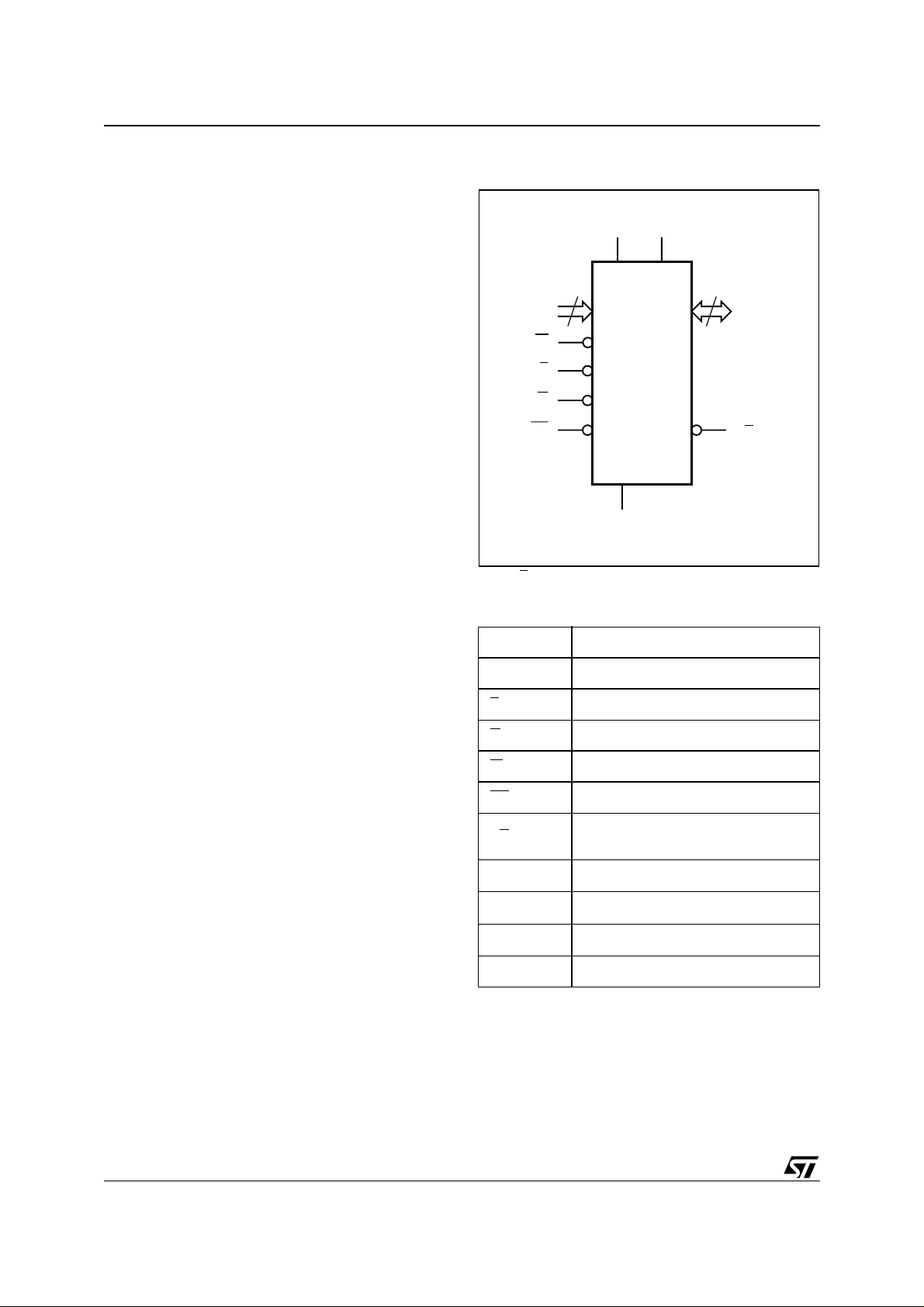

Figure 3. SO Connections Figure 4. TSOP Connections

M29KW016E

A7

A6

A5

A4

A3

A2

A1

A0

1

2

3

4

5

6

7

8

9

10

11

M29KW016E

12

E

13

14

G

15

16

RP

A18

A17 A8

V

SS

DQ0

DQ8

17DQ1

DQ9

18

19

DQ10

DQ3

20

21

DQ11

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

2322

W

A19

A9

A10

A11

A12

A13

A14

A15

A16

V

PP

V

SS

DQ15

DQ7

DQ14

DQ6

DQ13

DQ5DQ2

DQ12

DQ4

V

CC

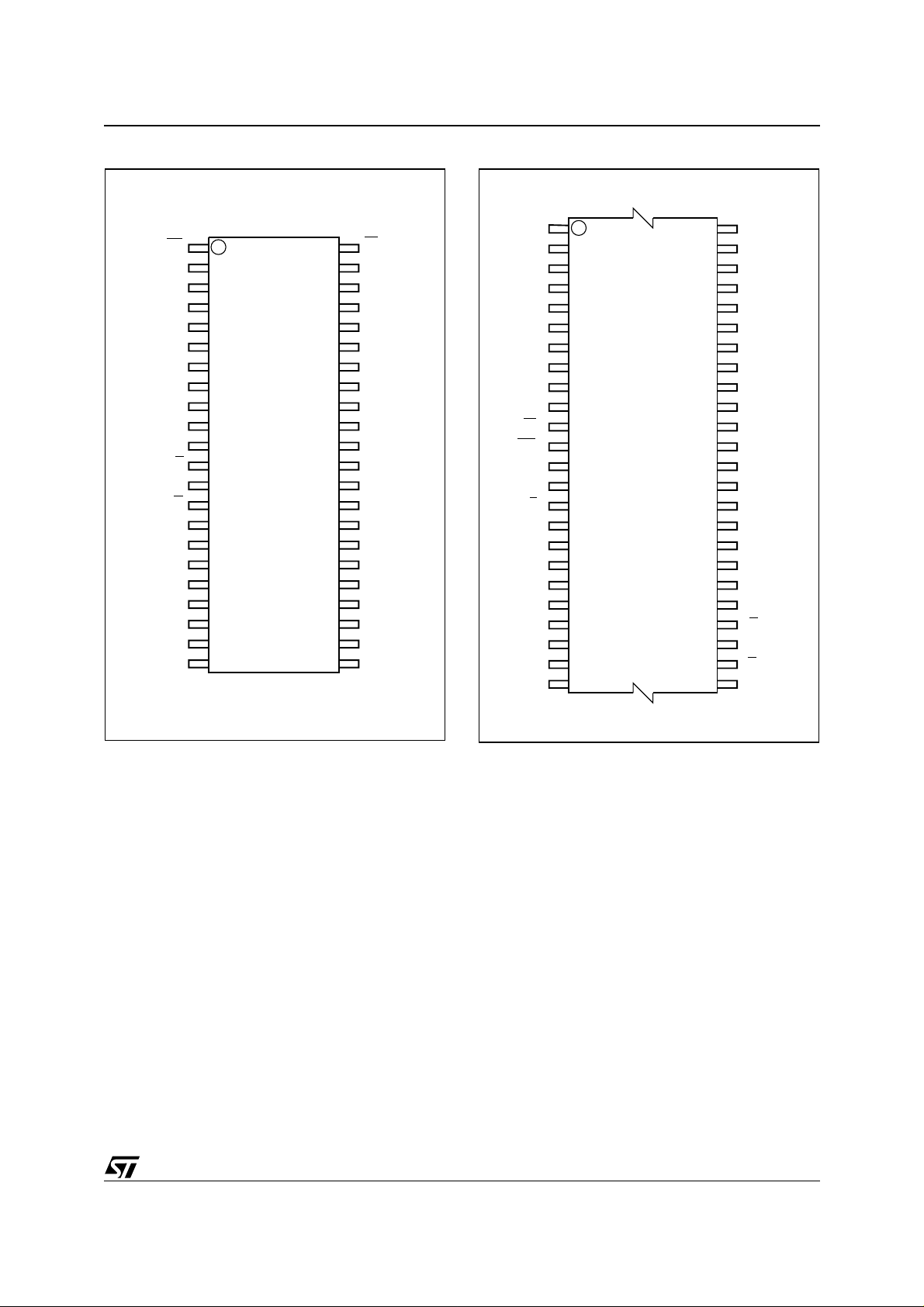

A15

A14

A13

A12

A11

1

48

A16

NC

V

SS

DQ15

DQ7

A10 DQ14

A9

A8

A19

NC

W

RP

NC

V

PP

RB

A18

A17

A7

A6

A5

A4

A3

A2

A1

12

M29KW016E

13

37

36

24 25

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

G

V

SS

E

A0

AI04377

AI04376b

5/31

M29KW016E

Figure 5. TFBGA Connections (Top view through package)

654321

A

B

C

D

E

F

G

H

A3

A4

A2

A1

A0

E

G

V

SS

A7

A17

A6

A5

DQ0

DQ8

DQ9

DQ1

RB

V

PP

A18

NC

DQ2

DQ10

DQ11

DQ3

W

RP

NC

A19

DQ5

DQ12

V

CC

DQ4

A9

A8

A10

A11

DQ7

DQ14

DQ13

DQ6

A13

A12

A14

A15

A16

NC

DQ15

V

SS

Table 2. Block Addresses

Block Number Address Range

8 E0000h-FFFFFh

7 C0000h-DFFFFh

6 A0000h-BFFFFh

5 80000h-9FFFFh

4 60000h-7FFFFh

3 40000h-5FFFFh

2 20000h-3FFFFh

1 00000h-1FFFFh

6/31

AI04373

SIGNAL DESCRIPTIONS

See Figure 2, Logic Diagram, and Table 1, Sign al

Names, for a brief overview of the signals connected to this device.

Address Inputs (A0-A19). The Address Inputs

select the cells i n the memory array to a ccess during Bus Read operations. During Bus Write operations they control the commands sent to the

Command Interface of the Program/Erase Controller.

Data Inputs/Outputs (DQ0-DQ7). The Data Inputs/Outputs outputs the data stored at the selected address during a Bus Rea d operation. Du ring

Bus Write operations they represent the commands sent to the Command Interface of the Program/Erase Controller.

Data Inputs/Outputs (DQ8-DQ15). The Data Inputs/Outputs output the data stored at the selected

address during a Bus Read operation. During Bus

Write operations the Command Register does not

use these bits. When reading t he Status Register

these bits should be ignored.

Chip Enable (E

). The Chip Enable, E, activates

the memory, allowing Bus Read and Bus Write operations to be performed. When Chip Enable is

High, V

Output Enable (G

, all other pins are ignored.

IH

). The Output Enable, G, con-

trols the Bus Read operation of the memory.

Write Enable (W

). The Write Enable, W, controls

the Bus Write operation of the memory’s Command Interf a c e .

Reset (RP

). The Reset pin can be used to apply

a Hardware Reset to the memory.

A Hardware Reset is achieved by holding Reset

Low, V

V

IH

Bus Write operations after t

, fo r at least t

IL

. After Reset goes High,

PLPX

, the memory will be ready for B us Read and

PHEL

or t

RHEL

, which ever occurs last. See the Ready/Busy Output section, Table 16 and Figure 14, Reset AC

Characteristics for more details.

Ready/Busy Output (RB

). The Ready/Busy pin

is an open-drain output that can be used to identify

when the memory array can be read. Ready/Busy

is high-impedance during Read mode and Auto

Select mode. After a Hardware Reset, Bus Read

and Bus Write operations cannot begin until

M29KW016E

Ready/Busy becomes high-impedance. See Table

16 and Figure 14, Reset AC Characteristics.

During Program or Erase operations Ready/Busy

is Low, V

Read/Reset commands or Hardw are Resets until

the memory is ready to enter Read mode.

The use of an open-drain output allows the Ready/

Busy pins from several memories to be connected

to a single pull-up resistor. A Low will then indicate

that one, or more, of the memories is busy.

Supply Voltage. The VCC Supply Voltage

V

CC

supplies the power for Read operations.

The Command Interface is disabled when the V

Supply Voltage is less than the L ockout Voltage,

V

. This prevents Bus Write operations from ac-

LKO

cidentally damaging the data during power up,

power down and power surges. If the Program/

Erase Controller is programming or erasing during

this time then the operation aborts and the memory contents being altered will be invalid.

A 0.1µF capacitor should be connected between

the V

pin to decouple the current surges from the power

supply. The PCB track widths must be sufficient to

carry the currents required during program and

erase operations, I

Program Supply Voltage. VPP is both a

V

PP

power supply and Write Protect pin. The two functions are selected by t he voltage range a pplied t o

the pin. The Supply Voltage V

before the Program Supply Voltage V

If V

PP

power supply pin for program and erase operations. V

algorithm is completed.

If V

PP

V

is seen as a Write Protect pin. In this case a

PP

voltage lower than V

tion against program or erase, while V

range of V

12, DC Characteristics for the relevant values).

Note that V

nected as the device may become unreliable.

Vss Ground. The V

for all voltage measurements.

. Ready/Busy will remain Low during

OL

Supply Voltage pin and the VSS Ground

CC

.

CC3

must be applied

CC

PP

.

is in the range 11.4V to 12.6V it acts as a

must be stable until the Program/Erase

PP

is kept in a low voltage range (0V to 3.6V)

gives an absolute p rotec-

HH

enables these functions (se e Table

HH

must not be left floating o r uncon-

PP

Ground is the reference

SS

in the

PP

CC

7/31

M29KW016E

BUS OPERATIONS

There are six standard bus operations that control

the device. These are Bus Read, Bus Wri te, Output Disable, Standby, Automatic Standby and

Electronic Signature. See Tables 3, Bus Operations, for a summary. Typically glitches of less

than 5ns on Chip Enable or Write Enable are ignored by the memory and do not affect bus operations.

Bus Read. Bus Read operations read from the

memory cells, or specific registers in the Command Interface. A valid Bus Read operation involves setting the desired address on the Address

Inputs, applying a Low sig nal, V

and Output Enable and keeping Write Enable

High, V

. The Data Inputs/Outputs will output the

IH

value, see Figure 11, Read Mode AC Waveforms,

and Table 13, Read AC Characteristics, for details

of when the output becomes valid.

Bus Write. Bus Write operations write to the

Command Interface. A valid Bus Write operation

begins by setting the desire d address on t he Address Inputs. The Address Inputs are latched by

the Command Interface on the falling edge of Chip

Enable or Write Enable, whichever occurs last.

The Data Inputs/Outputs a re latched by the Command Interface on the rising edge of Chip Enable

or Write Enable, whichever occurs first. Output Enable must remain High, V

IH

Write operation. See Figures 12 and 13, Write AC

Waveforms, and Tables 14 and 15, Write AC

, to Chip Enable

IL

, during the whole Bus

Characteristics, for details of the timing requirements.

Output Disa bl e . The Data Inputs/Outputs are in

the high impedance s tate when Output Enable is

High, V

Standby. When Chip Enable is High, V

.

IH

, the

IH

memory enters Standby mode and the Data Inputs/Outputs pins are placed in the high-impedance state. To reduce the S upply Current to the

Standby Supply Current, I

be held within V

± 0.2V. For the Standby current

CC

, Chip Enable should

CC2

level see Table 12, DC Characteristics.

During program or erase operations the memory

will continue to use the Program/Erase Supply

Current, I

, for Program or Erase operations un-

CC3

til the operation completes.

Automatic Standby. If CMOS levels (V

± 0.2V)

CC

are used to drive the bus and the bus is inactive for

150ns or more the memory enters Automatic

Standby where the internal Supply Current is reduced to the Standby Supply Current, I

CC2

. The

Data Inputs/Outputs will still output data if a Bus

Read operation is in progress.

Electronic Signature. The memory has two

codes, the manufacturer code and the device

code, that can be read to identify the memory.

These codes can be read by applying t he signals

listed in Tables 3, Bus Operations.

Table 3. Bus Operations

V

V

XX

PP

HH

X

XX

XX

Operation E G W

V

IL

V

IH

V

IH

X X X X Hi-Z

V

IL

V

IL

or V

HH

V

IL

V

IL

V

IH

V

IL

V

IL

Bus Read

Bus Write

Output Disable X

Standby

Read Manufacturer

Code

Read Device Code

Note: 1. X = VIL or VIH.

2. XX = V

3. Not necessary for A uto Select or Read/Res et command s.

4. When re adi ng the Status Register during Program or Eras e operations, V

, V

IL

IH

V

IH

V

IL

V

IH

V

IH

V

IH

Address Inputs

A0-A19

(4)

Cell Address Data Output

(3)

Command Address Data Input

X Hi-Z

A0 = V

Others V

A0 = V

Others V

, A1 = VIL,

IL

or V

IL

IH

, A1 = VIL,

IH

or V

IL

IH

must be kept at VHH.

PP

Data Inputs/Outputs

DQ15-DQ0

0020h

88ABh

8/31

COMMAND INTERFACE

All Bus Write operations t o the me mory are in terpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. Failure to observe a valid sequence of Bus

Write operations will result in the memory returning to Read mode. The long command sequences

are imposed to maximize data security.

Refer to Tables 4 and 5, for a summary of the commands.

Read/Reset Command.

The Read/Reset command returns the memory to

its Read mode where it behaves like a ROM or

EPROM, unless otherwise stated. It also resets

the errors in the Status Register. Either one or

three Bus Write operations can be u sed to issue

the Read/Reset command.

The Read/Reset Command can be issued, between Bus Write cycles before the start of a program or erase operation, to return the device to

read mode. Once the program or erase operation

has started the Read/Reset command is no longer

accepted. The Read/Res et co mmand is executed

regardless of the value of V

(VIL, VIH or VHH).

PP

Auto Select Command.

The Auto Select command is used to read the

Manufacturer Code and the Device Code. Three

consecutive Bus Write operations are re quired to

issue the Auto Selec t command. Onc e the Auto

Select command is issued the memory remains in

Auto Select mode until a Read/Reset command is

issued, all other commands are ignored. The Auto

Select command is executed regardless of the value of V

(VIL, VIH or VHH).

PP

From the Auto Select mode the Manufacturer

Code can be read using a Bus Read operation

with A0 = V

may be set to either V

and A1 = VIL. The other address bits

IL

or VIH.

IL

The Device Code can be read using a B us Read

operation with A0 = V

address bits may be set to either V

and A1 = VIL. The other

IH

or VIH.

IL

Word Progr a m Com m a n d.

The Word Program command can be used to program a Word to the memory array. V

set to V

ther V

during Word Program. If VPP is set to ei-

HH

or VIH the command will be ignored, the

IL

must be

PP

data will remain unchanged and the device will revert to Read/Reset mode. The command requires

four Bus Write operations, the final write operation

latches the address and data in the internal state

machine and starts the Program/Erase Controller.

During the program operat ion the memo ry will ignore all commands. I t is n ot poss ible t o iss ue any

command to abort or pause the operation. Typical

program times are given in Table 6. Bus Read operations during the program o peration will output

M29KW016E

the Status Register on the Data Inputs/Outputs.

See the section on the S tatus Register for more

details.

After the program operation has completed the

memory will return to the Read mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

Note that the Program command cannot change a

bit set at ’0’ bac k to ’1’. One of the E rase Commands must be used to set all the bits in a block or

in the whole memory from ’0’ to ’1’.

Multiple Word Program Command

The Multiple Word Program command can be

used to program large streams of data. It greatly

reduces the total programming time when a l arge

number of Words are written to the memory at any

one time. V

Word Progr am. If V

command will be ignored, the data will remain unchanged and the device will revert to Read/Reset

mode.

It has four phases : the Set up P ha se to initiate t he

command, the Program Phase to program the

data to the memory, the Verify Phase to check that

the data has been correctly programmed and reprogram if necessary and the Exit Phase.

Setup Phase. The M ultiple Word Program command requires three Bus Write operations to initiate the command (refer to Table 5, Multiple Word

Program Command and Figure 6, Multiple Word

Program Flowchart). The Status Register Toggle

bit (DQ6) should be checked to verify that the operation has started and the Multiple Word Program

bit (DQ0) checked to verify that the P/E.C. is ready

for the first Word.

Program Phase. The Program Phase requires

n+1 cycles, where n is the number of Words, to execute the programming phase (refer to Table 5,

Multiple Word Program Command and Figure 6,

Multiple Word Program Flowchart).

Three successive steps are required to issue and

execute the Program Phase of the command.

1. The fourth Bus Write operation of the command

latches the Start Address and the first Word to

be programmed. The Status Register Multiple

Word Program bit (DQ0) should be read to

check that the P/E.C. is ready for the next Word.

2. Each subsequent Word to be programmed is

latched with a new Bus Write operation. The

address can remain the Start Address, be

incremented or be any address in the same

block, as the device automatically increments

the address with each sucssesive Bus Write

must be set to VHH during Multiple

PP

is set to e ither V

PP

or VIH the

IL

9/31

M29KW016E

cycle. If the command is used to program in

more than one block then the address must

remain in the starting block as any address that

is not in the same block as the Start Address

terminates the Program operation. The Status

Register Multiple Word Program bit (DQ0) must

be read between each Bus Write cycle to check

that the P/E.C. is ready for the next Word.

3. Finally, after all Words have been programmed,

write one Bus Write operat ion to any address

outside the block containing the Sta rt Address,

to terminate the programming phase.

The memory is now set to enter the Verify Phase.

Verify Phase. Th e Verify Phase is s imilar to the

Program Phase in that all Words must be resent to

the memory for them to be che cked against the

programmed data. If the ch eck fails the P /E.C wi ll

try to reprogram the correct data. The P/E.C will

remain busy until the correct data has been successfully programmed. The Verify Phase is mandatory. If the Verify Phase is not executed the

programmed data cannot be guaranteed.

Three successive steps are required to execute

the Verify Phase of the command.

1. Us e one Bus Write operation to latch the Start

Address and the first Word, to be verified. The

Status Register Multiple Word Program bit

(DQ0) should be read to check that the P/E.C. is

ready for the next Word.

2. Each subsequent Word to be verified is latched

with a new Bus Write operation. If any address

that is not in the same block as the Start

Address is given, the Verify operation

terminates. The Status Register Multiple Word

Program (DQ0) must be read to check that the

P/E.C. is ready for the next Word.

3. Finally, after all Words have been verified, write

one Bus Write operation to any address outside

the block containing the Start Address, to

terminate the Verify Phase.

Exit Phase . Read the Status Register to verify

that DQ6 has stopped toggling. If the Verify Phase

is successfully completed the memory returns to

the Read mode. If the P/E.C. fails to reprogram a

given location, the Verify Phase will terminate and

Error bit DQ5 will be set in the Status Register. If

the error is due to a V

failure DQ4 w ill als o be

PP

set. If the operation fails a R ead/Res et comm and

must be issued to return the device to Read mode.

It is not possible to issue any command to abort or

pause the operation. Typical program times are

given in Table 6. Bus Read operations du ring the

program operatio n will outpu t the Sta tus Regi ster

on the Data Inputs/Outputs. See the section on the

Status Register for more details.

Note that the Multiple Word Program command

cannot change a bit set at ’0’ back to ’1’. One of the

Erase Commands must be used to set all the bits

in a block or in the whole memory from ’0’ to ’1’.

Block Erase Command.

The Block Erase com mand can be used to erase

a block. It sets all of the bits in the block to ’1’. All

previous data in the block is lost.

must be set to VHH during Block Erase. If V

V

PP

is set to either V

or VIH the command will be ig-

IL

PP

nored, the data will remain unchanged and the device will revert to Read/Reset mode.

Six Bus Write operations are required to select the

block . The Block Erase operation starts the Program/Erase Controller after the last Bus Write operation. The Status Register can be read after the

sixth Bus Write operation. See the Status Register

for details on how to identify if the P rogram /Erase

Controller has started the Block Erase operation.

During the Block Erase operation the me mory wi ll

ignore all commands. Typical block erase times

are given in Table 6. All Bus Read operations during the Block Erase operation will output the Status Register on the Data Inputs/Outputs. See the

section on the Status Register for more details.

After the Block Erase operation has completed the

memory will return to the Read Mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

Chip Erase Command.

The Chip Erase command can be used to erase

the entire memory. It sets all of the bits in the memory to ’1’. All previous data in the memory is lost.

must be set to VHH during Chip Erase. If V

V

PP

is set to either V

or VIH the command will be ig-

IL

PP

nored, the data will remain unchanged and the device will revert to Read/Reset mode. Six Bus Write

operations are required to issue the Chip Erase

Command and start the Program/Erase Controller.

During the erase operation the memory will ignore

all commands. It is not possible to issue any command to abort the operation. Typical chip erase

times are given in Table 6. All Bus Read operations during the Chip E rase operation will output

the Status Register on the Data Inputs/Outputs.

See the section on the S tatus Register for more

details.

After the Chip Erase operation has completed t he

memory will return to the Read Mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read Mode.

10/31

Loading...

Loading...