®

LCP02-150M

A.S.D.™

PROGRAMMABLE TRANSIENT VOLTAGE

FEATURES

Protection IC recommended for ringing SLICs.

■

Wide firing voltage range: from -110V to +95V.

■

Low gate triggering current

■

Peak pulse current: IPP= 100A (10/1000µs) .

■

Holding current: IH= 150mA min.

■

High power dissipation capability

■

UL497B approved (file E136224)

■

MAIN APPLICATIONS

Dual battery supply voltage SLICs

■

- negative battery supply configuration

-negative &positive batterysupply configuration

Central Office (CO)

■

Private Branch Exchange (PBX)

■

■ Digital Loop Carrier (DLC)

■ Asymmetrical Digital Subscriber Line (ADSL)

■ Fiber in the Loop (FITL)

■

Wireless Local Loop (WLL)

■

Hybrid Fiber Coax (HFC)

■

ISDN Terminal Adapter

■

Cable modem

DESCRIPTION

The LCP02-150M has been developed to protect

SLICs operating on both negative and positive

supplies, as well as on high voltage SLICs. It

providescrowbarmodeprotection forboth TIPand

RING lines. Surge suppression is assumed for

each wire by two thyristor structures, one

dedicated to positive surges, the second one to

negative surges. Both positive and negative

threshold levels are programmable by two gates

(Gn and Gp).The use of transistors decreases the

battery currents during surge suppression.

The LCP02-150M has high Bellcore Core, ITU-T

and FCC Part 68 lightning surge ratings, ensuring

rugged performance in the field.

The choice of the PowerSo-10

TM

package is

driven by its high power dissipation capability.

In addition, the LCP02-150M is also specified to

assist a designer to comply with UL1950, IEC950

and CSA C22.2. It is UL 497B approved (file

E136224), and has UL94-V0 resin approved

TM: ASD is trademarks of STMicroelectronics.

May 2003 - Ed: 4B

SUPPRESSOR FOR RINGING SLICS

PowerS0-10™

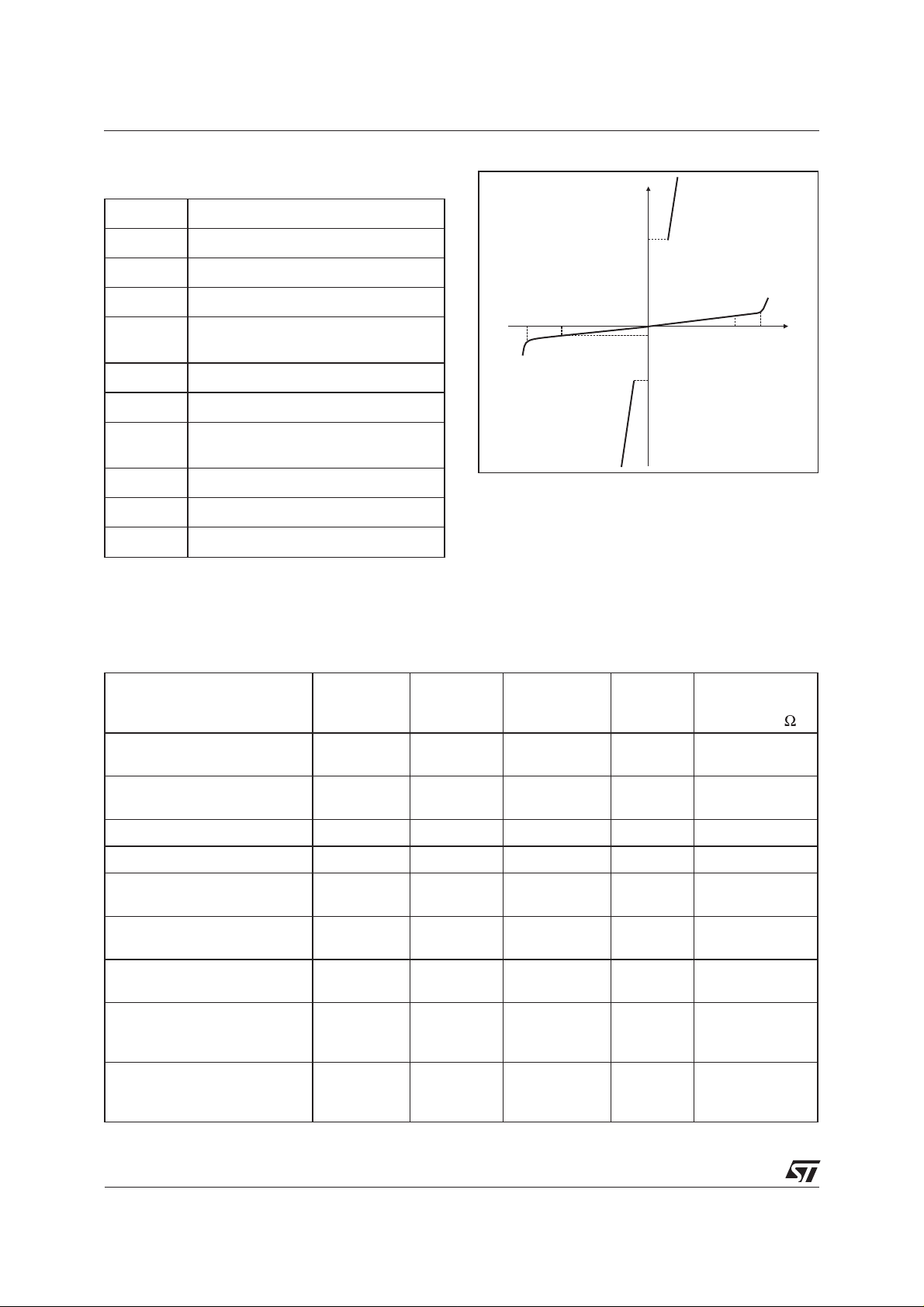

FUNCTIONAL DIAGRAM

TIP

Gn

GND

RING

PIN-OUT CONFIGURATION

GND

Gp

TIP

TIP

TIP

TIP

GND

Gn

RING

RING

RING

RING

Gp

1/9

LCP02-150M

ELECTRICAL CHARACTERISTICS (Tamb = 25°C)

Symbol Parameter

I

GP

Positive gate triggering current

I

H

I

I

GN

I

H

RG

Negative gate triggering current

Holding current

Reverse leakage current GATE /

LINE

Reverse leakage current

Reverse voltage LINE/ GND

Dynamic switching voltage GATE

V

V

I

RM

RM

DGL

/ LINE

V

V

GATE

RG

C

GATE / GND voltage

Reverse voltage GATE / LINE

Capacitance LINE / GND

COMPLIES WITH FOLLOWING STANDARDS

Peak surge

voltage

(V)

Voltage

waveform

(µs)

V

V

RM

GN

Required

peak current

(A)

I

RM

I

RM

I

H

Current

waveform

(µs)

VRMV

GP

Minimum serial

resistor to meet

standard (

)

ITU-T K20

ITU-T K21

VDE0433

VDE0878

IEC61000-4-5

FCC Part 68

lightning surge type A

FCC Part 68

lightning surge type B

BELLCORE

GR-1089-CORE

First level

BELLCORE

GR-1089-CORE

Second level

2/9

6000

1500

6000

1500

10/700

10/700

10/700

10/700

150

37.5

150

37.5

5/310

5/310

5/310

5/310

2000 10/700 50 5/310 2000 1.2/50 50 1/20 -

level 4

level 4

1500

800

10/700

1.2/50

10/160

10/560

100

100

200

100

5/310

8/20

10/160

10/560

1000 9/720 25 5/320 -

2500

1000

2/10

10/1000

500

100

2/10

10/1000

5000 2/10 500 2/10 -

-

-

-

-

-

-

-

-

-

-

LCP02-150M

ABSOLUTE RATINGS (T

amb

=25°C)

Symbol Parameter Value Unit

I

PP

I

TSM

max

V

GN

max

V

GP

∆ V

bat

T

op

T

stg

T

L

Note 1: Within the Top range, the LCP02-150M keeps onoperating. The impacts of the ambient temperature are given by derating curves.

Peak pulse current

Non repetitive surge peak on-state current

(sinusoidal)

Maximum negative battery voltage range

Maximum positive battery voltage range

Total battery supply voltage

max

Operating temperature range (see note 1)

Storage temperature range

Maximum lead temperature for soldering during 10s

10/1000µs

8/20µs

10/560µs

5/310µs

10/160µs

1/20µs

2/10µs

t = 0.2 s

t=1s

t=15min

100

250

120

150

200

250

500

13

10

3.5

See fig.1 -110to 0

0to+95

190

-20 to +85 °C

-55to+150 °C

260 °C

A

A

V

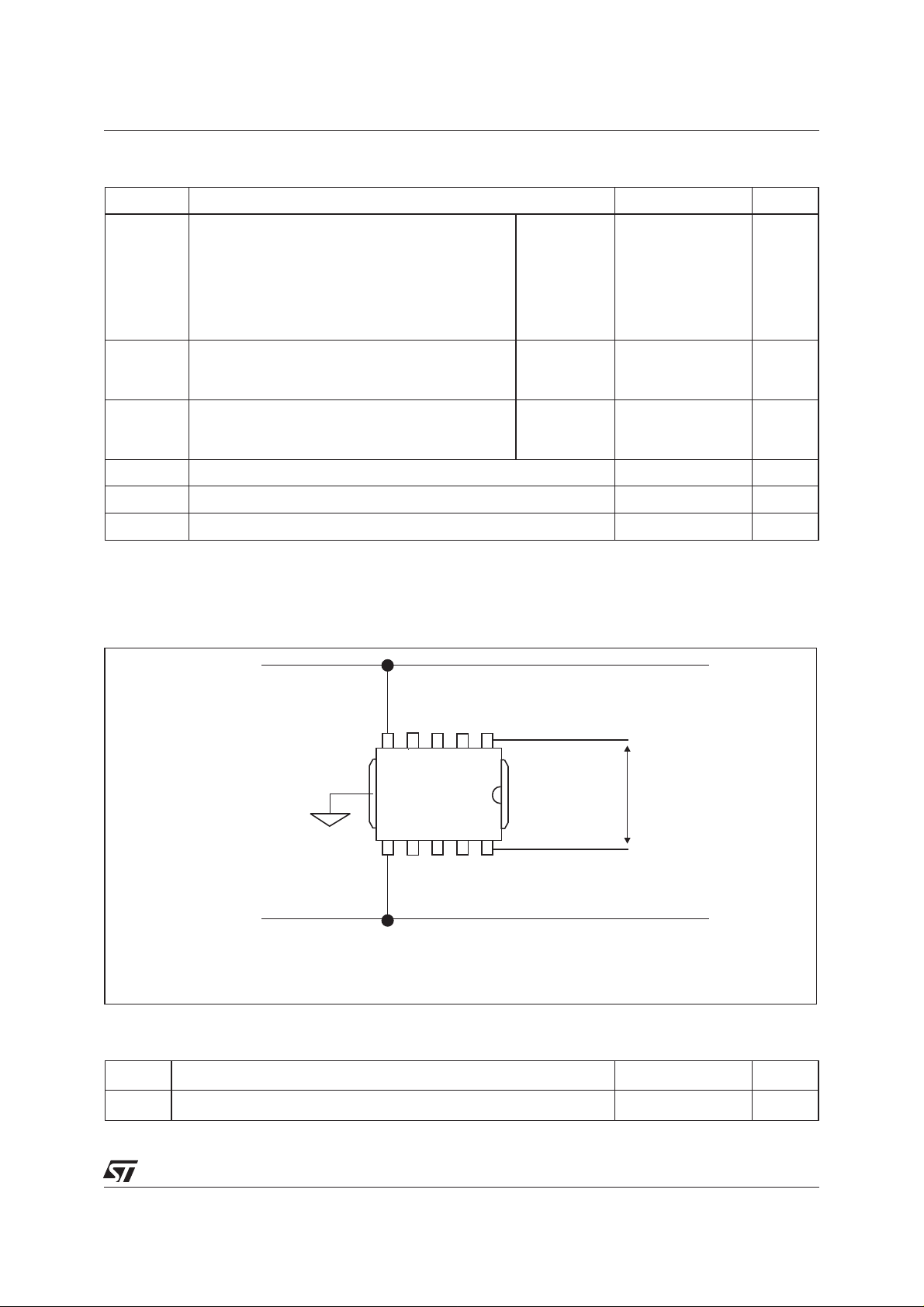

Fig. 1: Test circuit

TIP

Gp from +0V to +95V

Gp

TIP

TIP

TIP

TIP

GND

RING

RING

RING

RING

GND

Gn

Gn from -110V to +0V

∆≤Vbat 190V

RING

Gn connected to negative supply voltage

Gp connected to positive supply voltage

V t: differential voltage betweenV and V∆

ba GpGn

THERMAL RESISTANCE

Symbol Parameter Value Unit

R

th (j-a)

Junction to ambient

60 °C/W

3/9

LCP02-150M

ELECTRICAL CHARACTERISTICS (T

amb

= 25°C)

1 - PARAMETERS RELATED TO THE NEGATIVE SUPPRESSOR

Symbol Test conditions Min. Max. Unit

I

Gn

V

Gn/GND

= -60V

5mA

Measured at 50Hz

I

H-

I

RGL-

V

DGL-

Go-No Go test, VGn= -60V 150

Tj = 25°C, V

V

Gn/GND

= -60V

10/1000µs 1kV R

10/700µs 2kV R

1.2/50µs 2kV R

= -190V

Gn/line

=25ΩIPP= 30A

P

=25ΩIPP= 30A

P

=25ΩIPP= 30A

P

5µA

10

6

12

2 - PARAMETERS RELATED TO THE POSITIVE SUPPRESSOR

Symbol Test conditions Min. Max. Unit

I

Gp

V

Gp/GND

= 60V

10 mA

Measured at 50Hz

I

RGL+

V

DGL+

Tj = 25°C, V

V

Gp/GND

Gp/line

= +60V

10/1000µs 1kV R

10/700µs 2kV R

1.2/50µs 2kV R

= +190V

=25ΩIPP= 30A

P

=25ΩIPP= 30A

P

=25ΩIPP= 30A

P

5µA

12

8

18

mA

V

V

3 - PARAMETERS RELATED TO LINE/GND

Symbol Test conditions Typ. Max. Unit

4/9

I

R

Tj = 25°C, V

Tj = 25°C, V

C

off

VR= -3V, F =1MHz, VGp= 60V, VGn= -60V

= +90V, V

LINE

= -105V, V

LINE

GP/LINE

GN/LINE

= +1V

= -1V

5

5

150 pF

µA

LCP02-150M

Fig. 2: Non repetitive surge peak on state current

versus overload duration (Tj initial = 25°C).

I (A)

TSM

25

20

15

10

5

0

0.01 0.1 1 10 100 1000

t(s)

F=50Hz

Tj initial=25C

Fig. 4:Variation of junction capacitanceversus reverse voltage applied (typical calues) with:

= -90V and VGP= +90V.

V

GN

Fig. 3: Relative variation of holding current versus

junction temperature.

I (T)/I [T =25°C]

HjHj

2

1.5

1

0.5

0

-20 0 20 40 60 80 100

T(°C)

C(pF)

200

180

160

140

120

100

80

1 10 100

Vline (V)

Line - Line +Line - Line +

5/9

LCP02-150M

TECHNICAL INFORMATION

Fig. 5: LCP02 concept behavior.

Rs1

L 1

GND

-Vbat

TIP

VTip

Ign Igp

Gn

T1

Th1

Th2

T2

Gp

+Vb

Cp

Rs2

Cn

RING

GND

L 2

V Ring

Figure 5 showsthe classical protection circuit using theLCP02-150M crowbar concept. This topology has

been developped to protect the new two-battery voltage SLICs. It allows both positive and negative firing

thresholds to be programmed. The LCP02-150M has two gates (Gn and Gp). Gn is biased to negative battery voltage -Vbat, while Gp is biased to the positive battery voltage +Vb.

When a negative surge occurs on one wire (L1 for example), a current Ign flows through the base of the

transistor T1and then injects a current in the gate of the thyristor Th1 which fires. The entiresurge current

flows through the ground. After the surge, when the current flowing through Th1 becomes less negative

than the negative holding current, Th1 switches off. This holding current I

per figure 2.

When a positive surge occurs on one wire (L1 for example), a current Igp flows through the base of the

transistor T2and then injects a current in the gate of the thyristor Th2 which fires. The entiresurge current

flows through the ground. After the surge, when the current flowing through Th2 becomes less positive

than the positive holding current Ih+, Th2 switches off. This holding current I

and is equal to 30mA at 25°C.

The capacitors Cn and Cp are used to speed up the crowbar structure firing during the fast surge rise or

fallingedges. Thisallows tominimize thedynamical breakovervoltageat theSLIC Tipand Ringinputs during fast surges. Please notethat these capacitors are generally available around the SLIC. To be efficient

they have to be as close as possible to the LCP02-150M gate pins (Gn and Gp) and to the reference

ground track (or plan). The optimized value for Cn and Cp is 220nF.

The seriesresistors Rs1 and Rs2represent the fuse, fuseresistors or the PTCswhich are needed towithstand the power contactor the power induction tests imposed by the country standards. Taking this factor

into account, the actual lightning surge current flowing through the LCP02-150M is equal to :

I surge = Vsurge / (Rg + Rs)

is temperature dependant as

H-

is temperature dependant

H+

With V surge = peak surge voltage imposed by the standard.

Rg = series resistor of the surge generator

Rs = series resistor of the line card (e.g. PTC)

The LCP02-150M topology is particularly optimized for the new telecom applications such as cable modem,fiber in theloop, WLLsystems, and decentralized central officefor example.Theschematics offigures

6 and 7 give the 2 most frequent topologies used for these emergent applications.

6/9

Fig. 6: Protection of SLIC with positive and negative battery voltages.

Line card

Rs (*)

LCP02-150M

-Vbat

TIP

GND

220nF

Line

Rs (*)

Rs (*) = PTC or Resistor fuse

Fig. 7: Protection of high voltage SLIC

Line card

Rs (*)

GND

220nF

Line

Rs (*)

Gn

Gn

LCP02

TIP

LCP02

RING

TIP

RING

Gp

Gp

220nF

SLIC

RING

+Vb

-Vbat

TIP

SLIC

RING

Rs (*) = PTC or Resistor fuse

Figure 6 shows the classical protection topology for SLIC using both positive and negative battery voltages. With such a protection the SLIC is protected against surge over +Vb and lower than -Vbat. In this

case, +Vb can be programmed up to +95V while -Vbat can be programmed down to -110V. Please note

that the differential voltage does not exceed ∆V

Figure 7 gives the protection topology for the new SLIC using high negative voltage down to -110V.

max at 190V.

bat

7/9

LCP02-150M

PACKAGE MECHANICAL DATA

PowerSO-10™ (Plastic)

10

6

E

H

1

eB

0.25 M

h

A

F

A1

E4

D

D1

E2

5

DETAIL "A"

DETAIL "A"

DIMENSIONS

B

0.10 A B

REF.

Millimeters Inches

Min. Max. Min. Max.

A 3.35 3.65 0.131 0.143

E1

E3

A1 0.00 0.10 0.00 0.0039

B 0.40 0.60 0.0157 0.0236

SEATING

PLANE

A

C

Q

C 0.35 0.55 0.0137 0.0217

D 9.40 9.60 0.370 0.378

D1 7.40 7.60 0.291 0.299

E 9.30 9.50 0.366 0.374

E1 7.20 7.40 0.283 0.291

E2 7.20 7.60 0.283 0.299

SEATING

PLANE

A1

L

a

E3 6.10 6.35 0.240 0.250

E4 5.90 6.10 0.232 0.240

e 1.27 Typ. 0.05 Typ.

F 1.25 1.35 0.0492 0.0531

H 13.80 14.40 0.543 0.567

h 0.5 Typ. 0.019 Typ.

L 1.20 1.80 0.0472 0.0708

Q 1.70 Typ 0.067 Typ.

a0°8°0°8°

FOOTPRINT DIMENSIONS (in millimeters)

0.54 - 0.60

14.6 - 14.9

6.30

1.27

0.67 - 0.73

9.5

10.8 - 11.0

8/9

LCP02-150M

ORDER CODE

Ordering Type Marking Package Weight Base qty Delivery mode

LCP02-150M LCP02-150M PowerSO-10 1.02 g 50 Tube

LCP02-150M-TR 600 Tape & Reel

Informationfurnishedis believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility forthe consequences of

useof such information nor for any infringement of patents orother rights ofthird parties which mayresult from its use.No license isgranted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replacesall information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written

approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

9/9

Loading...

Loading...