D10, D15, D20, D22, C20, C30

MICROMODULES

Memory Micromodules

General Information for D1, D2 and C Packaging

■ Micromodules were developed specifically for

embedding in Smartcards and Memory Cards

■ The Micromodule provides:

– Support for the chip

– Electrical contacts

– Suitable embedding interface for gluing the

module to the plastic package

■ Physical dimensionsand contact positions

compliant to the ISO 7816 standard

■ Micromodules delivered asa continuousSuper

35 mm tape. (This differsfrom the standard

35 mm tape in the spacing distance between

the indexing holes.)

DESCRIPTION

Memory Cards consist of two main parts: the

plastic card, and the embedded Micromodule

(which, in turn, carries the silicon chip).

The plastic card is made of PVC, ABS or similar

material, and can be over-printed with graphics,

text, and magnetic strips. The Micromodule is

embedded in a cavity in the plastic card.

The Micromodules are mounted on Super 35 mm

metallized epoxy tape, and are delivered on reels.

These contain all of the chips from a number of

wafers, including thosechips that were found to be

non-functioning during testing. Traceability is

ensured by a label fixed on the reel.

potting side contact side

D15

11

D10

D20

D22

C30 C20

1

11

1

1

1

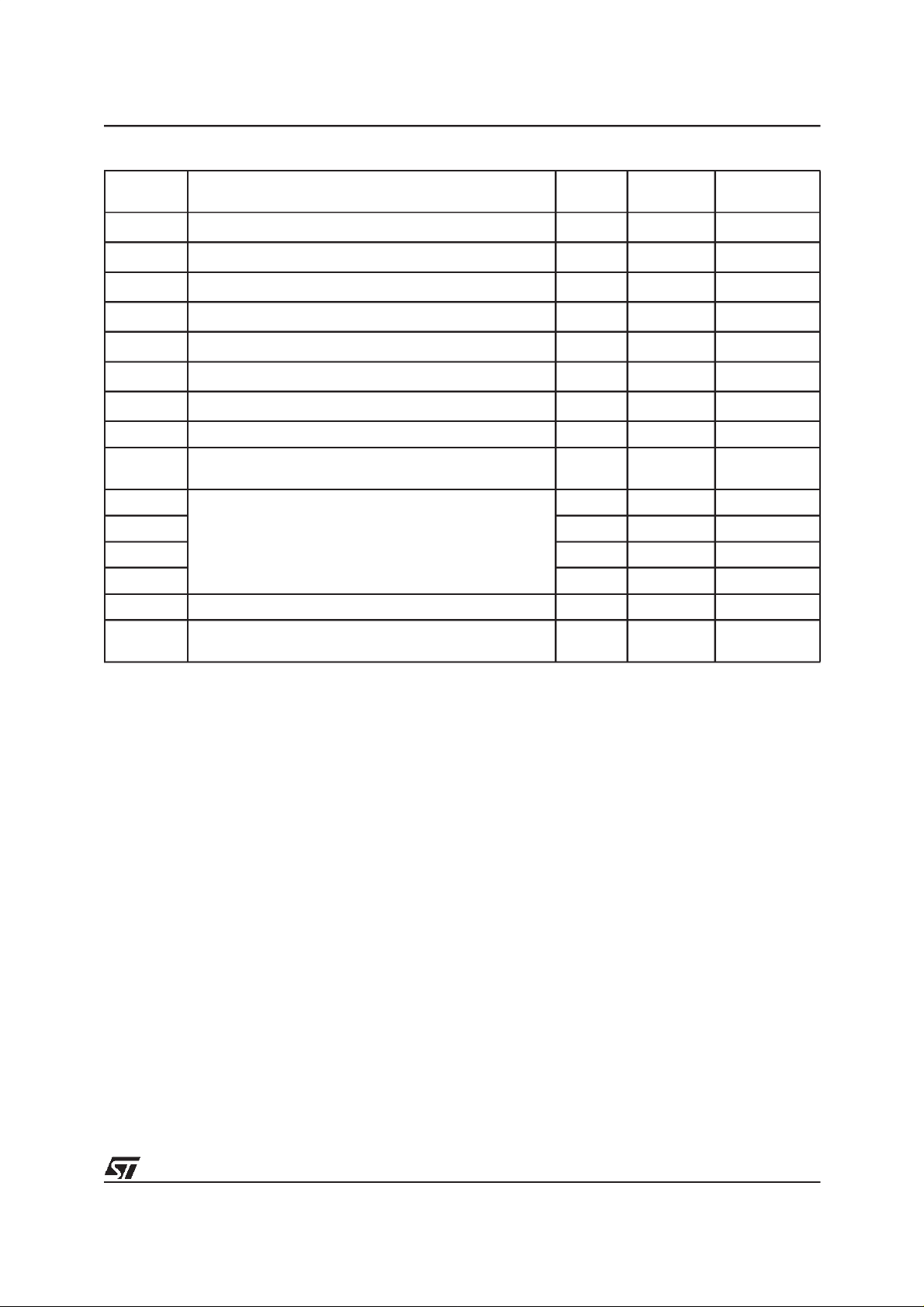

Table 1. Memory Card and Memory Tag Integrated Circuits

Module

D10 ST1200, ST1305B, ST1331, ST1333, ST1335, ST1336, ST1353, ST1355

D15 ST14C02, ST1305B, ST1335, ST1336, ST1355

D20 ST14C02, M14C04, M14C16, M14C32

D22 M14C64, M14128, M14256

C30 M35101, M35102

C20 M35101, M35102

Please see the data briefing sheets of these products for example illustrations of these

micromodules

1/13December 1999

MICROMODULES

Table 2. Memory Card Products

Type

ST14C02C

M14C04

M14C16

M14C32

M14C64

M14128

M14256

ST1200 Memory Card IC, 256 bitOTP EPROM with Lock-Out 3.5 µm NMOS D10

ST1305B

Description (please see the individual product data

sheets for full specifications)

2

Memory Card IC, 2 Kbit (256 x 8) Serial I

2

Memory Card IC, 4 Kbit Serial I

Memory Card IC, 16 Kbit Serial I

Memory Card IC, 32 Kbit Serial I

Memory Card IC, 64 Kbit Serial I

Memory Card IC, 128 Kbit Serial I

Memory Card IC, 256 Kbit Serial I

Memory Card IC, 192 bitHigh Endurance EEPROM

with Secure Logic Access Control

C Bus EEPROM

2

C Bus EEPROM

2

C Bus EEPROM

2

C Bus EEPROM

2

2

C Bus EEPROM

C Bus EEPROM

C Bus EEPROM

Process Technology Module Style

1.2 µm CMOS D15, D20

0.6 µm CMOS D20

0.6 µm CMOS D20

0.6 µm CMOS D20

0.6 µm CMOS D22

0.6 µm CMOS D22

0.6 µm CMOS D22

1.5 µm CMOS D10, D15

ST1331

ST1333 1.2 µm CMOS D10

ST1335 1.2 µm CMOS D10, D15

ST1336 1.2 µm CMOS D10, D15

M35101 Contactless Memory Chip, 13.56 MHz, 2048 bit EEPROM 0.6 µm CMOS C20, C30

M35102

The assembly flows is as follows:

1. Dice sawing

2. Dice attach

3. Wire bonding

4. Potting

5. Milling (depending on product)

The range of products and types of Micromodule

are summarizedin Table 1 and Table 2. For large

volumes, ST is able to offer customized module

tape.

DELIVERY

The Super 35mm metallized epoxy tape is

delivered on reels, as shown in Figure 1. These

contain all of the chips from a number of wafers,

including those chips that were found to be nonfunctioning during testing. Traceability is ensured

by alabel fixed on the reel.

The typical quantity is 10,000 modules per reel,

with priority given to lot integrity on the reel. The

maximum quantity is 15,000 per reel.

Parts which are faulty (mechanically or electrically

defective) are identified by punch holes. The

specification for the reject punch holes is shown in

Memory Card IC, 272 bitHigh Endurance EEPROM

with Advanced Security Mechanisms

Contactless Memory Chip with 64-bit Unique ID,

13.56 MHz, 2048 bit EEPROM

Figure 4 for the D10 micromodule, in Figure 5 for

the D15 micromodule, in Figure 6 for the D20

micromodule, and in Figure 7 for the D22

micromodule.

Tape joins (tape splicing) are never more than 10

per 10 metre length, as shown in Figure 2 and

Figure 3.

At least 2.1 m of leader, and 2.1 m of trailer is

included oneach reel. Eachis made ofPVC Super

35 mm tape, without metalisation, and is opaque

to infrared and white light.

A “failure”marking of reject holes is included at the

beginning and end of the tape of a minimum of 5

consecutive module pitches (double positions).

Modules should be stored within the temperature

range -40 °Cto+85°C, for no more than 1 year.

Each reel ispacked in an antistatic bag, alongwith

a desiccant bag, and a humidity indicator card.

This cardindicates the level ofhumidity as follows:

30 - Blue: protection assured

40 - Pink: renew the desiccant bag

50 - Pink: protection no longer ensured

Three selfadhesive plastic identification labelsare

attached: one to the reel, one to the antistatic bag,

1.2 µm CMOS D10

0.6 µm CMOS C20, C30

2/13

MICROMODULES

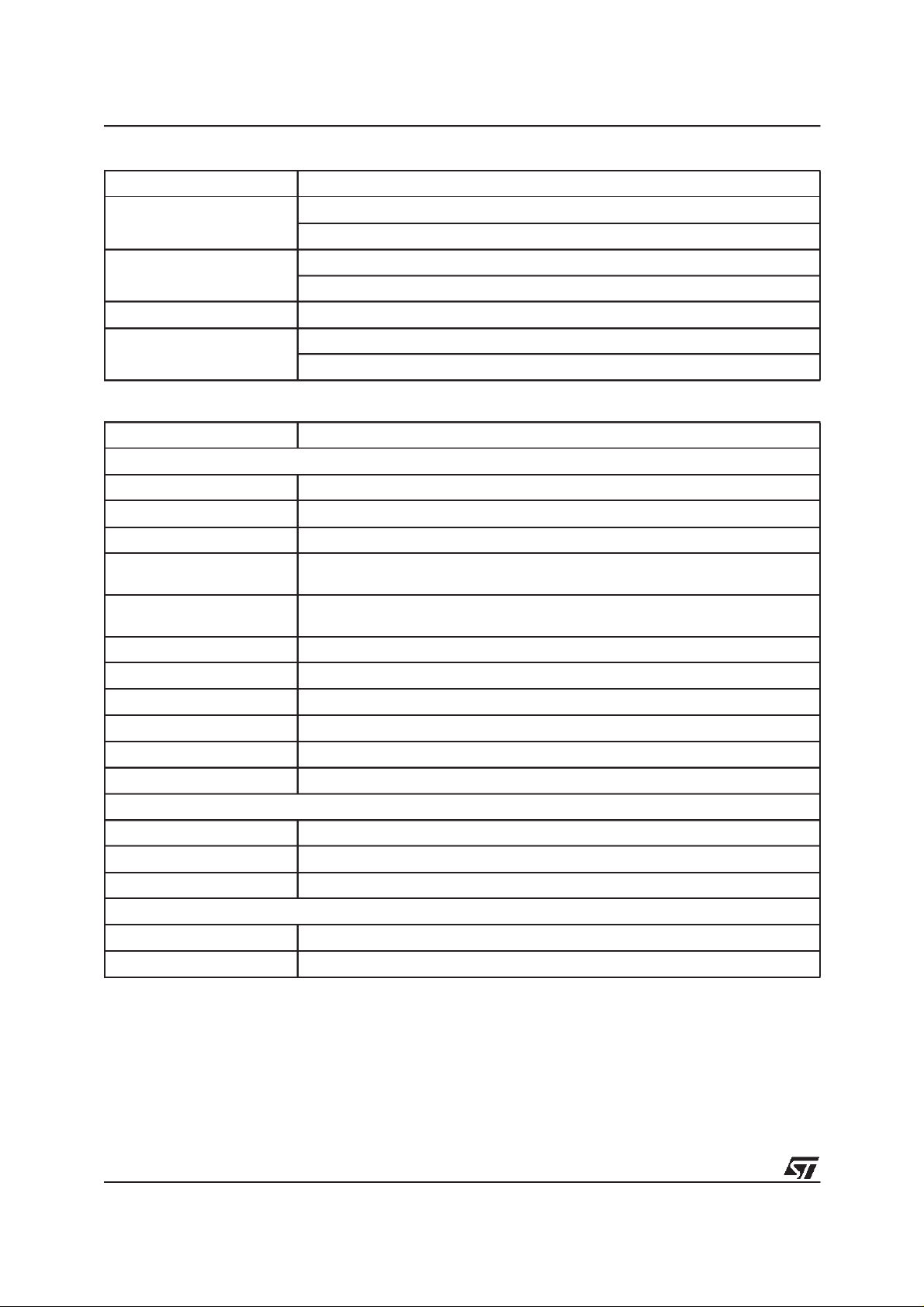

Table 3. Manufacturing Flow and Manufacturing Facility Locations

Operation Location and Facility

Wafer Diffusion

Electrical WaferTest

Assembly Casablanca, Morocco.

Final Test

Table 4. Material Specification

Material Description

Basic material MCTS T2 or IBIDEN rough, typical thickness 120 µm

Adhesive Modified epoxy, typical thickness 18 µm

Laminated copper foil Typical thickness 35 µm

Adhesive strength

Tape Surface

Surface roughness Typically Rz: 3-12 µm at first accepted delivery

Contact surface Nickel-gold, galvanised treatment

Nickel thickness 2 µm (min.)

Gold thickness contact side, 0.1 µm (min.)

Totaltape thickness 160 ± 30 µm

Rousset, France.6” wafer fab.

Agrate, Italy.6” wafer fab.: standard EEPROM only

Rousset, France.

Agrate, Italy: standard EEPROM only

Rousset, France.

Casablanca, Morocco.

Tape

> 0.8 N/mm at room temperature. Monitored by the tape manufacturer using

appropriate test methods

The whole epoxy adhesive surface is controlled to be free of dirt, grease,cleaning

compounds and parting compounds

Control, Palmer “Special flat” diameter 3 mm, F = 1.5 N

Chip Interconnect

Dice bonding Silver epoxy

Bonding wire Gold 25 µm

Ring (D22 only) Bronze

Protective coating

Material UV epoxy,Black epoxy

Assembly Casablanca, Morocco.

3/13

MICROMODULES

and one to the reel box. Each label carries the

following information:

– PRODUCT: sales type

– LOT NUMBER: reel number

– POS: total number of positions

– GOOD: number of good positions

– FAIL: number of fail positions

– DATE: date of sealing

In addition, the antistatic bag and the delivery box

carry a self adhesive plastic “ESD” warning label,

85 x38 mm in size, indicating “Electrostatic

sensitive devices”.

Each reelis packed ina reel box,made ofrecycled

cardboard. The size of the reel boxdepends on its

origin. Several reel boxes arepacked in a delivery

box, which is also made of recycled cardboard.

A delivery note is provided, listing the following

information:

– Date of sealing

– Reel numbers

– Total number of positions, with the details of

positions per reel

– Order number and customer name

– Sales type

– Tape type

RECOMMENDED ACCEPTANCECRITERIA

The product identity should be checked against

the delivery documentation, and the quantity of

good positions on the reel recorded. The product

may be tested in accordance with the appropriate

data sheet, the conditions depending on the

product type, and the ISSUERor USER mode (for

ST13xx products).

For delivery acceptance, ST recommends

sampling the Micromodules from the beginning of

the reel. The sampling AQL should be applied, to

the ISO 2859 standard (test level II, normal test).

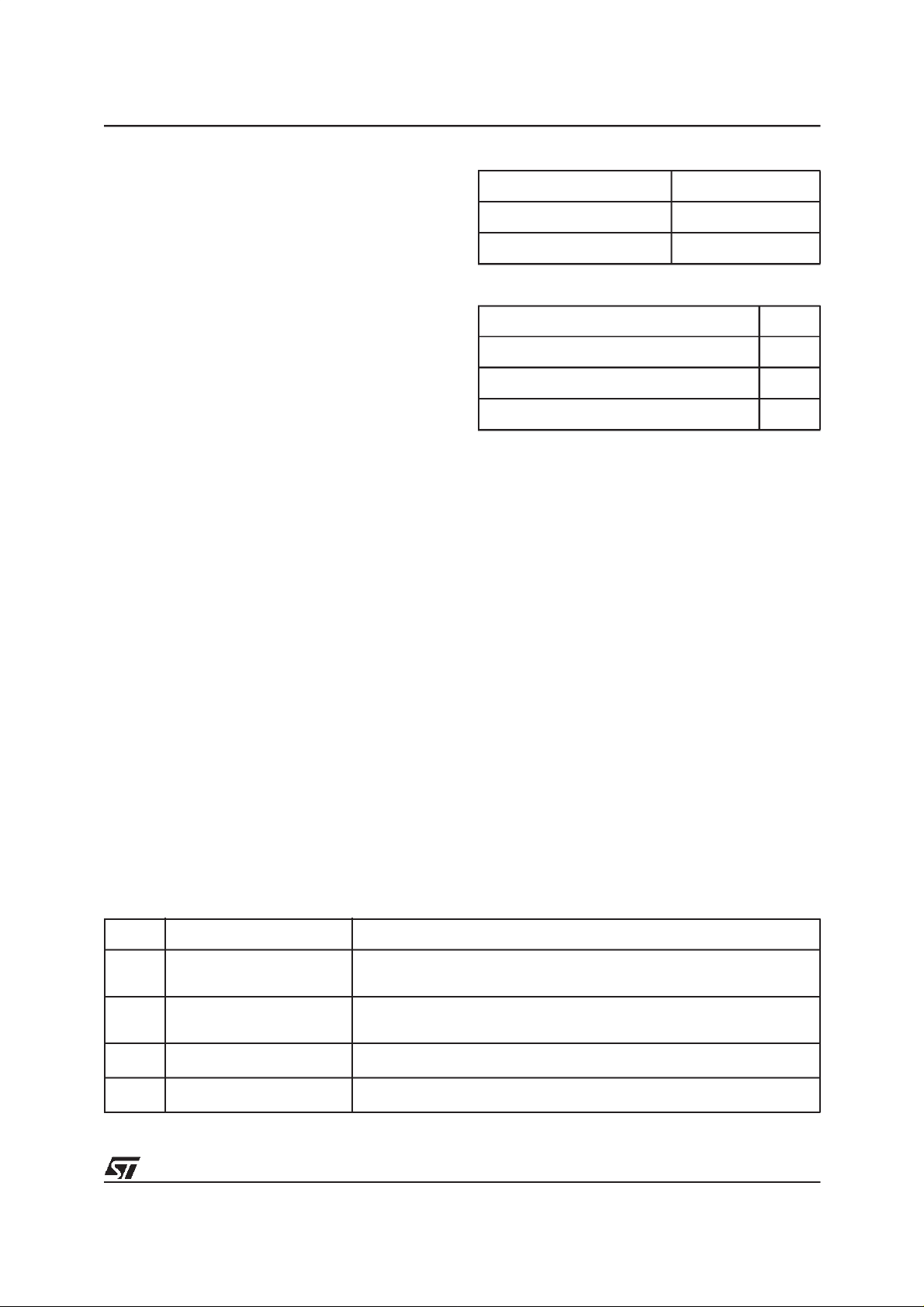

Table 5. Size of the Reel Box

Manufacturing Location Size of Reel Box

Rousset 370 x 390 x 80 mm

Casablanca 373 x 370 x 78 mm

Table 6. AQL Levels

Defect AQL

Totaldefects - mechanical and electrical 0.65

Mechanical defects 0.65

Electrical defects 0.65

Any observed discrepancies should bereported in

writing to the ST quality department. Table 6

shows the recommendedAQL levels.

The visual and mechanical test specification and

test conditions are described in Table 7.

Defect Acceptance Rate

Each reel contains the stated number of defective

devices, distributed so that no more than 20% of

them are found in a contiguous block on the tape.

ST’s own quality acceptance standard guarantees

that the customer will be informed when the

electrical yield is less than 90%.

The part numbers and re-ordering information will

be set according to ST’s current product coding

policy, as shown on the individual product data

sheets, or asagreed with the customer.

Reels that do not pass inspection should be

returned to ST within 15 working days after

delivery.

Table 7. Visual and Mechanical Specification and Test Conditions

Test Description and Method Reject Criteria

1 Contact area

2 Chip covering

1

3

1

4

Note: 1. Test 3 and 4 are conducted in accordance with MIL-STD-833.

Die bond strength Die shear force < 10 N

Wire bonding Wire lift or broken at pull test with < 4 g

Glue or particles, scratches print, severdefects on contact area

damaging the gold layer. Visual test distance 30 cm, naked eye.

Thickness and external dimension measurement exceeding total

thickness, or other dimensions not complying to the drawings

4/13

MICROMODULES

RELIABILITY

Product qualification and on-going reliability

monitoring is performed by ST. The principal steps

are listed in Table 8 and Table 9.

Table 8. Package Related Tests

Test Description Method Condition LPTD

1 Geometry ST Specification Monitoring/Lot 5 0/45

2 Visual inspection ST Specification Outgoing/Lot AQL= 0.040 0/315

3 Temperature cycling

Salt atmosphere

4

corrosion of contacts

5 Moisture resistance

Vibration with electrical

6

measurement

7 Bending properties ISO/IEC 7816-1

8 Torsionproperties ISO/IEC 7816-1

Note: 1. The notation

sample of 45devices taken from a lot, with the whole lot only accepted if every one of the 45 sample devices passed the test.

m/n

means: reject the whole lot if more thanmdevices fail from a sample ofndevices. For instance, 0/45 means a

MIL-STD-883

Method 1010

MIL-STD-883

Method 1009

MIL-STD-883

Method 1004

ISO/IEC 10373

-40 °Cto150°C,100 cycles 5 0/45

35 °C, 5% NaCl, 24 hour 15 0/15

85 °C, 85% HR Biased 5.5 V,

168 hour

1 octave/minute, acceleration up to

10 G (repeated 20 times)

measurement memory check at 25 °C

Long side: deflection 2 cm

Short side: deflection 1 cm

30 bendings per minute

Maximum displacement 15°±1°

1000 torsions, 30 torsions per minute

applied on long side only

7 0/32

20 0/11

20 0/11

20 0/11

Criteria

(note 1)

Table 9. Product Related Tests

Test Description Method Condition LPTD Criteria

1 Life test MIL-STD-883

Method 1005

2 Electrostatic discharge MIL-STD-883

Electrostatic discharge MIL-STD-883

3 Data retention,

Temperature storage

4 Write/Erase cycles ST Specification 100,000 Cycles 200 ppm/

5 Magnetic field, memory

check

6 X-rays, memory check ISO IEC 10373 70 kV,0.1 Grey 15 1/25

7 UV light,memory check ISO IEC 10373

Method 3015

Method 3015

MIL-STD-883

Method 1005

ISO IEC 10373 79,500 A/m 15 1/25

140 °C, 6 V,504 hours measurement

memory check at 25 °C

Human body model:

1.5 kΩ,100 pF,± 5000 V

Machine model: 0 Ω, 200 pF,± 200 V

measurement memory check at 25 °C

150 °C, 1000 hours, no bias

measurement memory check at 25 °C

2

15 W.s/cm

, 30 minutes maximum

3 0/76

n/a 0/9

n/a 0/9

5 0/45

0/32

1024 byte/

1000 cycle

15 1/25

5/13

Figure 1. Reel and Winding Direction

MICROMODULES

6/13

MICROMODULES

Figure 2. D10, D20, D22 Tape Join Specification

7/13

Figure 3. D15 Tape Join Specification

MICROMODULES

I

21

654 3

H

G

F

E

D

C

B

DATUM

06/1998

SCALE

A

DRAWN BY:

STEFFEN.F

CONTROLED BY:

ROYER.G

A

21

GRAPHICS REV.

JOIN

( Sproket holes axis straightness)

SUPER 35 6 CONTACTS MICROMODULE:

Z.I. de Rousset

Fax (33) 42.53.22.88

Tel. (33) 42.25.88.00

0.2/16

Copyright SGS-THOMSON Microelectronics. Unauthorized reproduction and communication is stricly proh

GRAPHIC TITLE:

B.P. 2 - 13106 ROUSSET CEDEX

654 3

12 11 10 9 8 7

I

H

G

F

E

7

area

98

* Measurements are subject to change without notice.

DIMENSIONS ARE IN MILIMETERS

10

11

NOTES:

-Total thickness in splice area is 0.300 Typical

-Reject hole and sproket holes are punched free in splice

-Assy reject holes (M) may be punched in splice area ( see (M) in POA for location )

-Joint is on contact side only

D

C

B

12

A

8/13

MICROMODULES

Figure 4. D10 Micromodule Outline

1

1

11

CONTACT SIDE

1

1

X

11

Y

9/13

CROSS SECTION

O

POTTING SIDE

Figure 5. D15 Micromodule Outline

DIE SIDE

CROSS SECTION

0.58 max

R1.3

max

7

10.8

7.62

0.16

0.1

NOTE:

- (P) is reject identification hole ø2.2

- (M) may be punched with (P): center positioning ±0.2

- Sproket holes may be with or without metalisation

- Recommended punching contour for the customer: 8.32*11 R1.4

- Minimal contact area according to ISO 7816-1

GENERAL TOLERANCE IS ±0.1 mm

ALL DIMENSIONS ARE IN MILLIMETERS

Measurements are subject

CONTACT SIDE

8.12

2.6min

2.2min

2.54

to change without notice

9.5

1.422

R0.15

1.422

(P)ø2.2

35

31.83

27±0.2

23.015

12.8±0.2

8.815

4.75

(M)ø1.5

Copyright SGS-THOMSON Microelectronics. Unauthorized reproduction and communication is stricly

GRAPHIC TITLE:

Z.I. de Rousset

B.P. 2 - 13106 ROUSSET CEDEX

Tel. (33) 42.25.88.00

Fax (33) 42.53.22.88

POA FOR MICROMODULE D15

3±0.2

5.2±0.2

PACKAGE CODE

FU

SCALE

none

GRAPHICS REV.

A

DATUM

06/1998

DRAWN BY:

ROYER.G

CONTROLED BY:

STEFFEN.F

MICROMODULES

10/13

MICROMODULES

Figure 6. D20 Micromodule Outline

1

1

11

CONTACT SIDE

1

1

X

11

Y

11/13

CROSS SECTION

O

POTTING SIDE

Figure 7. D22 Micromodule Outline

O

CONTACT SIDE

MICROMODULES

CROSS SECTION

POTTING SIDE

O

12/13

MICROMODULES

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of useof such information norforany infringement of patents orotherrights of third parties which mayresult from itsuse. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products arenot

authorized for use as critical components in life support devices or systems without express writtenapproval of STMicroelectronics.

1999 STMicroelectronics - All Rights Reserved

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong -India - Italy - Japan -Malaysia - Malta - Morocco - Singapore - Spain -

Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

13/13

Loading...

Loading...