Page 1

Fastening Solutions

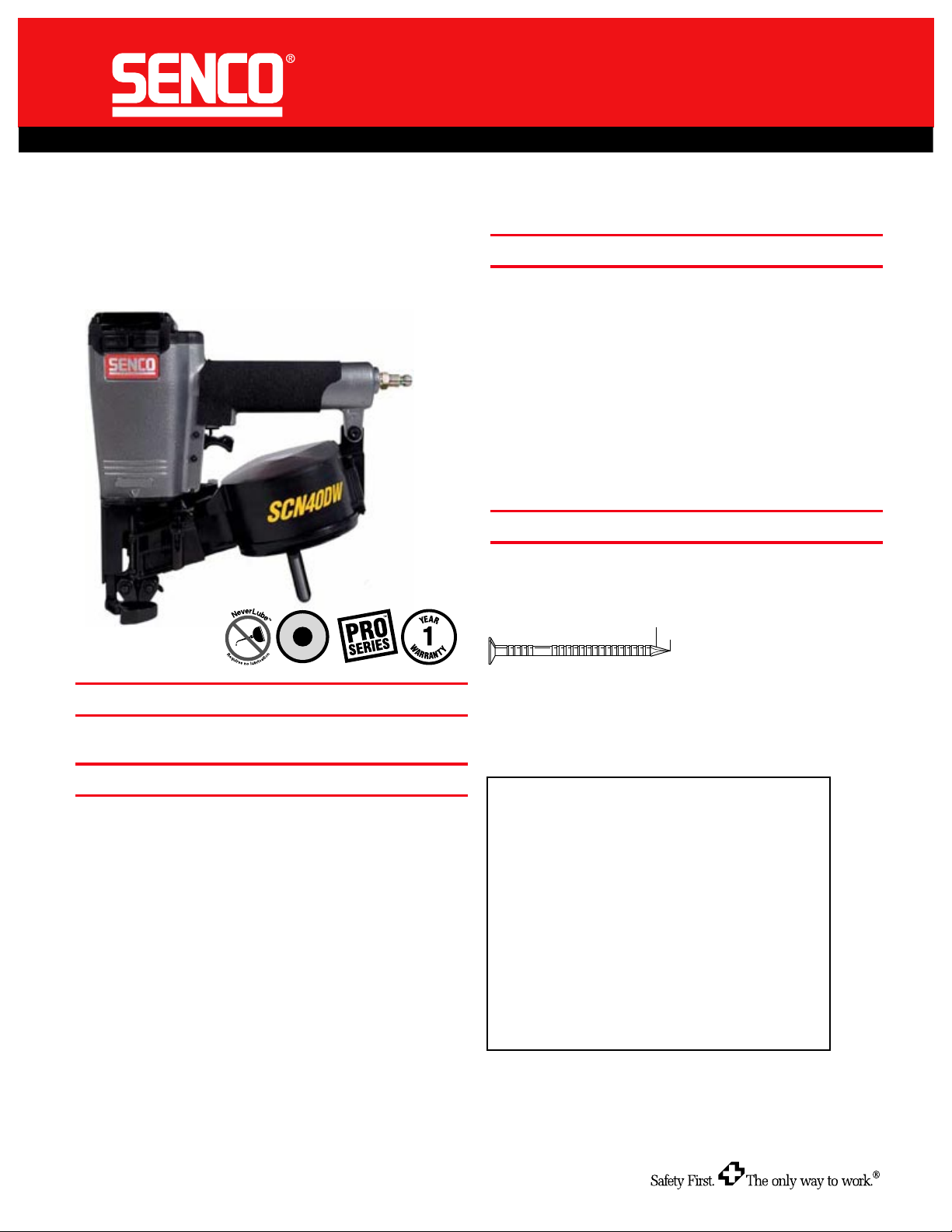

SCN40DW

Coil Drywall Nailer

™

The SCN40DW Drywall Coil Nailer eliminates crooked nails and

shattered drywall. It's loaded with features that cut application time and

increase reliability. Has an 120 nail capacity for less down time in your

drywall installatons.

�

�

�

�

�

�

�

�

�

�

�

�

�

Tool Specifications:

Item #: 650003N: Contact Actuation (Dual Action)

650003N: Sequential Actuation (Restrictive)

Weight: 4.7 lbs. ( 2.1 kg)

Height: 10-3/8" (264 mm)

Length: 9-3/4" (248 mm)

Nail Capacity: 120

Collation: Wire weld coil wire

Operating Pressure: 70-120 psig (4.8-8.3 bar)

Mode of Operation: TContact or Sequential Actuation

Hose Fitting: 1 ⁄4 " NPT

Fastener Specifications:

Drives 12.5 gauge (shank .099) , Full Round Bugle-Head Nails

1-1/2” – 1-5/8" 4d-5d ring shank. Capacity 120.

11/

2

15/

BG (.099)

8

Applications:

For drywall installation.

Features and Benefits:

• Lightweight - 4.7 lb for easy one-handed operation, improving

productivity

• Adjustable depth-of-drive control on the tool means no compressor

adjustments or additional tools for adjustments are required

• Neverlube Design - requires no lubrication

For additional information on how SENCO Power Fastening Systems will save you time,

reduce costs, and increase quality, call our toll-free Action Line: 1-800-543-4596 to

find your nearest Authorized Senco Dealer or Distributor.

Visit our web site at: www.senco.com

Seq uen tial Actua tion Trigg er (also known as restricti ve trig ger o r

trigger fire) op erates in th e followin g a sequ ence - d epress the safety

element at the n ose of too l again st the work surface th en pull the trigger.

After each fastener is driven, release the trigg er and li ft th e to ol o ff th e

work surface before starting th e sequ ence ag ain . Th is trigg er is

recommend ed and acceptable fo r most appl ication s.

Con tact Actua tion Trigg er (also kn ow n as du al action , bo un ce or

bo ttom fire) operates i n the follo wi ng sequence- pul l the trigg er first and

keep th e trig ger p ul led whi le moving th e to ol al on g the work surface

with a bo uncing motion , d epressing th e safety element at the nose of

the too l again st the work surface w here the fastener is to be d riven. T his

trigger is recommend ed for use by trained professionals on ly in hig h

prod uction or volume appl icati on s.

Alw ays read the Operators Manual and Safety Instructi on s wi th all to ol s

to ensure prop er use and safety precautio ns or l og o n to

www .senco.co m or call 1-800-54 3-459 6 for more info rmation o n

SENCO’s trigg er systems. Choose the righ t trig ger system for your

specific n eeds!

©2005 by Senco Products, Inc. www.senco.com

Loading...

Loading...