Page 1

Verpa Senco BV

Pascallaan 88

8218 NJ Lelystad

The Netherlands

EMEA: www.senco.eu

© 2016 by Senco Brands, Inc.

Operating Instructions

(Original Instructions)

Käyttöohjeet

(Alkuperäisten Ohjeiden Käännös)

Bruksvisning

(Översättning av de Ursprungliga Undervisningarna)

Mode d’Emploi

(Traduction des Instructions Originales)

S45CNR

Roofing Coilnailer

VPRC01M • 2/2/2016

Page 2

English 3

Deutsch 19

Nederlands 35

Suomi 13

Norsk

Svenska 23

Dansk 83

Français 33

Español 115

Italiano

Polskie 131

GB

D

NL

F

FIN

N

S

DK

E

I

PL

2

Page 3

English

Suomi

Svensk

IMPORTANT

TÄRKEÄÄ

VIKTIGT

Please make certain that the

person who is to use this

equipment

carefully reads and

understands these instructions

before starting operations.

Varmista, että tätä naulainta

käyttävä henkilö lukee tarkasti

ja ymmärtää nämä ohjeet

ennen käytön aloittamista.

Personen som ska använda

verktyget bör noga läsa

igenom

dessa instruktioner och förstå

dem innan arbetet påbörjas.

Français

IMPORTANT

Veuillez vous assurer que la

personne qui utilise

l'équipement

lit attentivement et comprend

les présentes instructions avant

toute utilisation.

TÄRKEÄÄ

VIKTIGT

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using pneumatic tools, basic safety precautions should always be followed to

reduce the risk of personal injury, including the following:

READ AND FOLLOW ALL INSTRUCTIONS.

1.KEEP WORKING AREA CLEAN. Cluttered areas invite injuries.

2.DON'T ALLOW CHILDREN AT THE WORKING AREA. Don't let them

handle the tool.

3.USE SAFETY GLASSES. To prevent eye injuries, the tool operator

and all persons in the working area must wear safety glasses with

permanently attached, rigid, plastic side shields. These safety

glasses must conform to ANSI Z87.1 requirements (approved

glasses have“Z87”printed or stamped on them) dessus)

4.USE EAR PROTECTION. The working area may be exposed to high

noise levels that can lead to hearing damage

5.DRESS SAFELY. Protective gloves and non-skid footwear or safety

shoes are recommended when working with and operating this tool.

Don't wear loose clothing or jewellery. They can get caught in

moving parts. Also, wear a protective hair covering to prevent long

hair from getting caught in the tool.

6.ONLY USE CLEAN, DRY AND REGULATED compressed air at 4.8 to

8.3 bar

7.NEVER USE OXYGEN, CARBON DIOXIDE, combustible gases or any

other bottled gas as a power source for this tool

8. DO NOT CONNECT TOOL to pressure that potentially exceeds

9,13 bar.

9. ONLY USE AIR HOSE THAT IS RATED for 150% of the maximum

system pressure. Please try to use a hose of ID 3/8”connecting

nailer with compressor.compresseur.

10.DON'T OPERATE TOOL NEAR ANY COMBUSTIBLE, or any other

easy explosive material and don't operate the tool under easy

producing corrosion, rust and having heavy powder

GB

3

Page 4

11. DISCONNECT TOOL FROM AIR SUPPLY HOSE before doing tool

maintenance, clearing a jammed fastener, leaving work area,

moving tool to another location, or handing the tool

to another person.

12.ONLY DISCONNECT QUICK CONNECTOR with the body tail

portion of the air inlet, no compressed air can be guaranteed when

disconnecting. If operating is not correct, the tool can remain

charged with air after being disconnected and still be able to drive a

fastener causing personal injury.

13.REPLACE PARTS AND ACCESSORIES. Only use same replacement

parts while servicing. Approved accessories and replacement parts

are available

14. BEFORE USING TOOL, carefully check if there is any part

damaged to obtain ideal results. Do not use the tool if the tool has

any air leaks, uncompleted, damaged parts or needs repairing.

15. NEVER USE TOOL if safety, trigger or spring is inoperable,

missing or damaged. Do not alter or remove safety, trigger or

springs. Make daily inspections for free movement of trigger

repairing.

16. ONLY USE PARTS AND FASTENERS, recommended by the seller.

17. CONNECT TOOL TO AIR SUPPLY BEFORE loading fasteners to

prevent a fastener from being fired during connection. The tool

driving mechanism may cycle when tool is connected to the air

supply. When not in use remove all fasteners from the nail housing.

18. ALWAYS ASSUME THE TOOL CONTAINS FASTENERS. Keep the

tool pointed away from yourself and others at all times. No

horseplay. Respect the tool as a working implement.

19. DO NOT LOAD FASTENERS with trigger or safety depressed to

prevent unintentional firing of a fastener.

20. REMOVE FINGER FROM TRIGGER when not driving fasteners.

Never carry tool with finger on trigger: tool will fire a fastener if

safety is bumped while trigger is depressed.

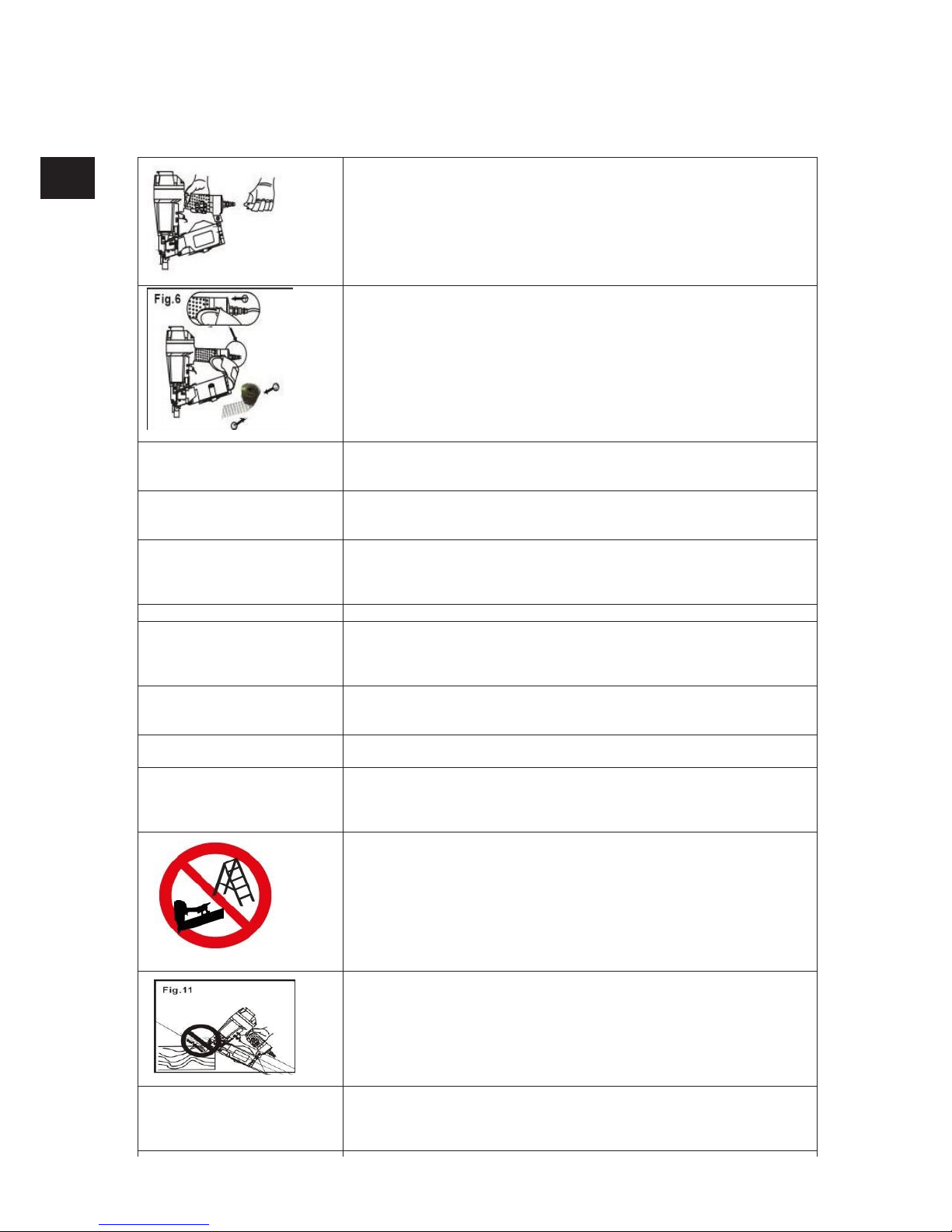

21. DO NOT USE ON SCAFFOLDINGS, LADDERS Tools equipped with

“contact actuation

” shall not be used:

-

if a change of driving locations is affected via stairs, ladders or

scaffolding.

–

for closing boxes or crates.

– for fitting transportation safety systems.

22.FIRE FASTENERS INTO WORK SURFACE ONLY: NEVER into

materials too hard to penetrate

23. GRIP TOOL FIRMLY TO MAINTAIN CONTROL while allowing tool

to recoil away from work surface as fastener is driven. If safety

bracket is allowed to contact work surface again before trigger is

released, an unwanted fastener will be fired.

GB

4

Page 5

24.DO NOT DRIVE FASTENERS on top of other fasteners, or with the

tool at too steep an angle: the fasteners can ricochet causing

personal injury.

25.DO NOT DRIVE FASTENERS CLOSE to the edge of the work piece.

The work piece is likely to split allowing the fastener to fly free or

ricochet causing personal injury.

26.KEEP ALERT. Watch what you are doing. Use common sense. Do

not operate any tool when you are tired.

27.KEEP HANDS AND BODY PARTS away from area shown in Fig. 13,

to avoid injury.

supply and rotate the knob of the adjuster by hand until it is

satisfactory.

29.WHEN NOT IN USE, tool should be cleaned and put it back into

the packing box. For safety, keep out of reach of children.

EMPLOYER’S RESPONSIBILITIES

Employer must enforce compliance with the safety warnings and all other instructions contained in

this manual.

Keep this manual available for use by all people assigned to use this tool. For personal safety and

proper operation of this tool, read and follow a of these instructions carefully.

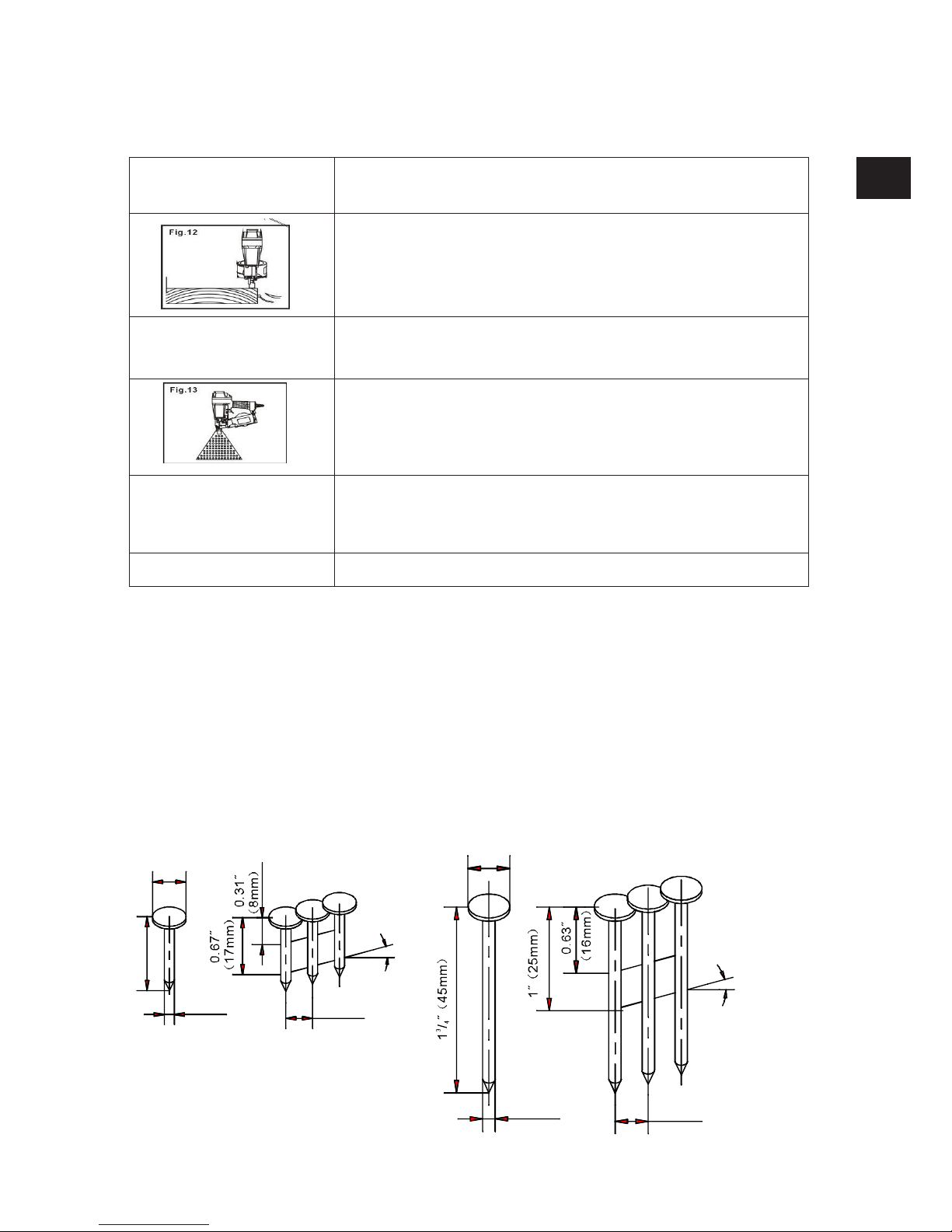

FASTENERS SPECIFICATIONS

Min.

φ0.39˝

(φ10mm)

( φ3.1mm)

φ0.12˝

0.31˝

(8mm)

15o-16

o

Max.

φ0.39˝

(φ10mm)

15o-16

o

( φ3.1mm)

φ0.12˝

0.31˝

(8mm)

7/8" (22mm)

28.THIS TOOL IS EQUIPPED WITH ADJUSTER that can adjust driving

depth. When adjusting the driving depth, first disconnect from air

GB

5

Page 6

TECHNICAL PARAMETER

Characteristic

Value

Compressed Air pressure

4.8-8.3 bar

Outline Dimension (L×H×W)

300 × 310 × 110 mm

Nail Length Range

22-45 mm

Tool Weight

2.75Kg

Air Inlet

1/4"NPT

Air Consumption

68 l/min at 5.52 bar

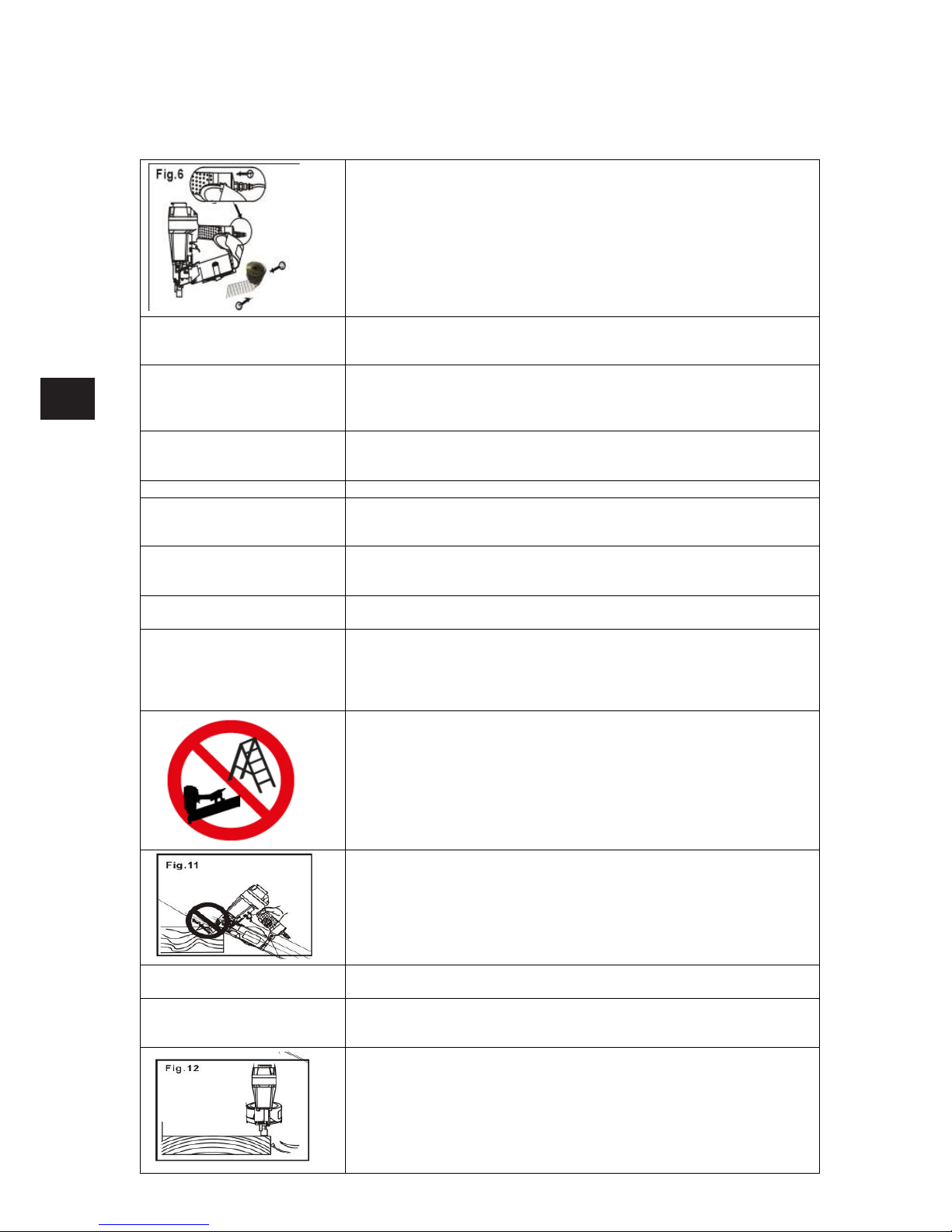

PACKING LIST

Description

Q'ty

S45CNR coilnailer

1

S5 Hex Key

1

S4 Hex Key

1

S3 Hex Key

1

Air Tool Oil

1

Operating instruction

1

NOISE INFORMATION

These noise characteristic values are in accordance with EN 12549:1999

LpA, 1s, d=84dB

LwA, 1s, d=97dB

These values are tool-related characteristic values and do not represent noise developed at the

point of use. Workplace design can also serve to reduce noise levels, for example placing work

piece on sound-damping supports.

VIBRATION INFORMATION

These values are in accordance with ISO 8662-11:1999

Vibration characteristic value ( m/s2 ) = 8,22

This value is a tool-related characteristic value and does not represent the influence to the

hand-arm-system when using the tool.

Safety glasses

1

GB

6

Page 7

OPERATING INSTRUCTIONS

FOREWORD

S45CNR is a heavy duty, coil fed, pneumatic nailer using compressed air as a power source. It is

designed to install 22-45mm or 3,1mm diameter nails of various lengths. It is widely used for

connection of roofing frame and connection of roofing frame and felt.

POWER SOURCE

This tool is designed to operate on clean, dry, compressed air at regulated pressures 4.8 and 8.3

bar. The preferred system would include a filter, a pressure regulator, and automatic oiler

located as close to the tool as possible (within15 feet is ideal).

All compressed air contains moisture and other contaminates that are detrimental to internal

components of the tool. An air-line filter will remove most of these contaminates and

significantly prolong the life of the tool. If an in-line oiler is not available: place five or six drops

of tool oil into the tool’s air inlet at the beginning of each workday.

Only disconnect the quick connector with the body tail portion of the air inlet. No compressed air

can be guaranteed when disconnecting. If operation is not correct, the tool can remain charged

with air after being disconnected and still be able to drive a fastener causing personal injury.

CAUTION: All line components (hoses, connectors, filters, regulators, etc.) must meet

150% of the maximum system pressure. Please try to use a hose of ID 9,5mm

connecting the nailer with compressor when disconnecting.

Do not connect this tool to a system with maximum potential. Only disconnect quick connector

being connected with the connector of the body tail portion air inlet, no compressed air can be

guaranteed when disconnecting.

Disconnect tool from air supply before performing maintenance, c

learing a jammed fastener,

leaving work area, moving tool to another location, or handing the tool to another person.

GB

7

Page 8

PREPARING THE TOOL BEFORE DRIVING

After reading and understanding this entire manual, connect tool to air supply.

CAUTION: Keep tool pointed away from yourself and others at all times.

Always connect tool to air supply before loading fasteners. Do not load fasteners with

trigger or safety depressed. Always wear approved safety glasses, and hearing

protection when preparing or operating the tool. Never use a tool that leaks air or needs

repair.

Depress Handle (See A Fig. 14) and open the Latch. Rotate the Upper Nail Housing to the side of

the Body.

The Adjuster Plate can be moved up and down when twisting the Adjuster Nut (see B Fig.15) .

According to the length of nail, the Adjuster Plate should be adjusted correctly to the position

indicated inside Lower Nail Housing.

Place a coil of nails over the Lower Nail Housing. Uncoil enough nails to reach the Feed Hook and

place the second nail between the teeth on the Feed Hook. (see Fig. 16).

Close the Upper Nail Housing and depress the Latch (see Fig. 17).

Adjust directional EXHAUST deflector (see Fig. 18), so that the exhaust air blast will be directed

away from the operator. Grasp the deflector and rotate it to the desired position for the current

application.

GB

8

Page 9

USING THE TOOL

Complete all steps of PREPARING THE TOOL before using the tool.

Trigger firing: Put the nose on the working surface, lightly push the tool toward the working

surface until the safety element is depressed, then, depress the trigger to drive the fasteners. This

‘trigger fire’ method provides the most accurate fastener placement. In this method, the safety

element can be adjust downwards with knob to avoid striking two nails at one time.

Manufacturer assumes no responsibility for any injuries and loss caused by any improper use of

this tool.

CAUTION: Remove finger from trigger when not driving fasteners. Never carry tool with

finger on trigger: tool will fire a fastener if safety is bumped. Keep tool pointed in a safe

direction at all times.

Never attempt to drive a fastener into material that is too hard, or at too steep an angle, or near

the edge of the work piece. The fastener can ricochet causing personal injury.

Disconnect tool from air supply before performing maintenance, clearing a jammed fastener,

leaving working area, moving tool to another location, or handing the tool to another person. Clean

and inspect tool daily. Carefully check for proper operation of trigger and safety mechanism.

Stands for mounting the fastener driving tools shall be safely designed. Do not disassemble or

modify parts such as the safety yoke.

Do not use the tool unless both the trigger and the safety mechanism are functional, or if the tool

is leaking air or needs any other repair.

3. Driving depth will be increased or decreased by rotating the depth of drive knob or adjuster (A)

fig. 19. Test fire a fastener and check depth. If the nail is driven too deep, rotate the adjuster

clockwise to make the safety element push downward. Whereas, rotate the adjuster counter

clockwise to make the safety element push upward. Repeat this step to achieve desired results

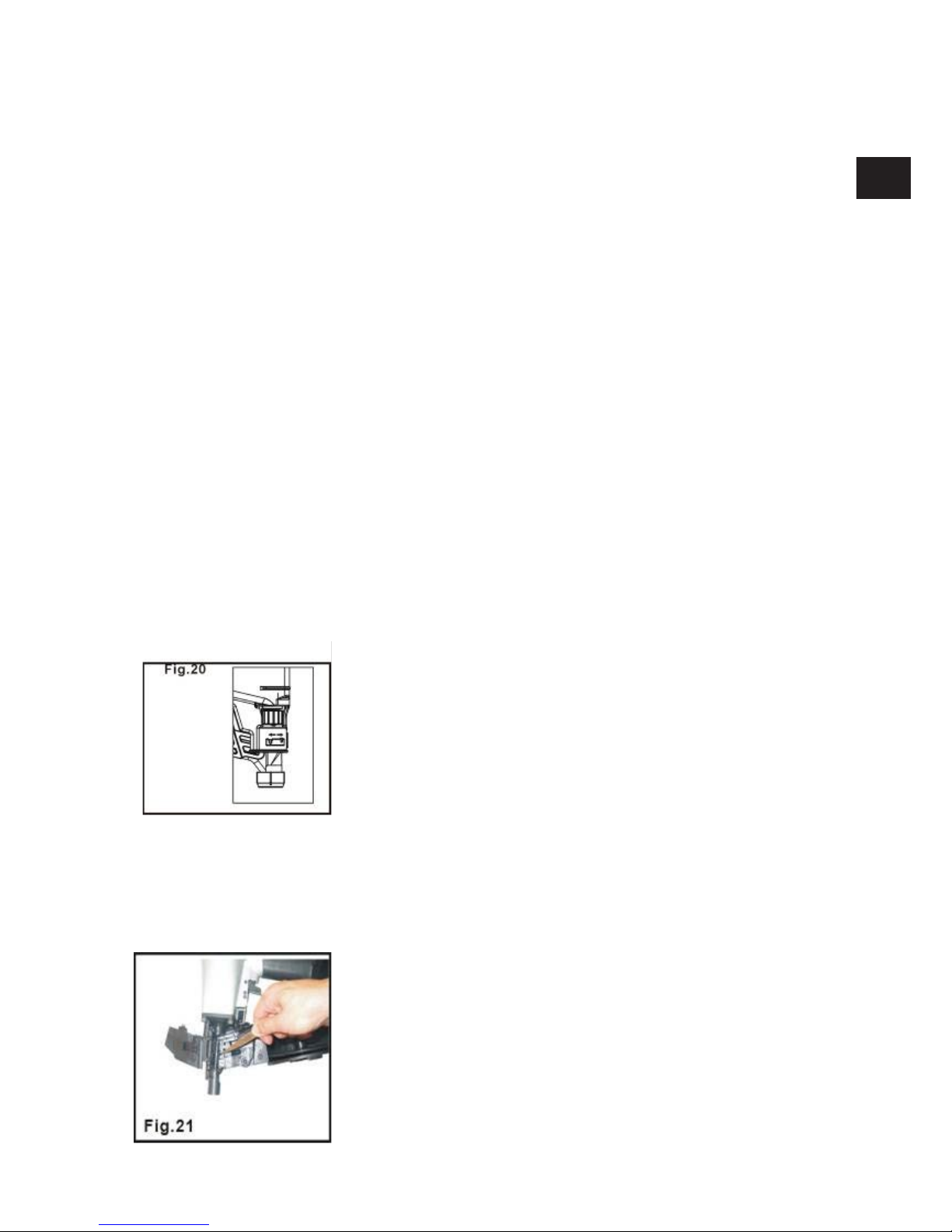

(See Fig. 20).

CLEARING A JAMMED FASTENER

1.CAUTION: Disconnect tool from air supply .

2.Open latch, rotate lower housing and remove the nails of the lower housing.

3.Use a slender, soft steel rod to drive the drive blade to its uppermost position. Use needle nose

pliers to remove the jammed fastener (see Fig.21).

4.Follow instructions in PREPARING THE TOOL BEFORE DRIVING to reload fasteners.

GB

9

Page 10

MAINTENANCE

CLEAN AND INSPECT DAILY

CAUTION: Disconnect tool from air supply before cleaning and

inspection. Correct all problems before operating.

Check the filter of the compressor weekly and switch off manual valve to drain water and

contaminations out.

Do not soak tool with cleaning solutions. Such solutions can damage internal parts. The exposed

portion of the small piston rod and feed hook must be kept clean.

Inspect trigger and safety mechanism to assure system is complete and functional: no loose or

missing parts, no binding or sticking parts shall be found.

Keep all screws tight. Loose screws can cause personal injury or damage tool.

Check if there are worn and damaged parts. If any, please replace immediately.

If tool is used without an in-line oiler: place 5 or 6 drops of air tool oil into the air inlet of the tool

at the beginning of each workday.

SERVICE AND REPAIRS

All quality tool eventually require servicing of replacement parts due to wear from normal use.

Some user serviceable components are described in the TROUBLESHOOTING section. All repairs

made by local agencies are fully guaranteed against defective material and workmanship. We

cannot guarantee repairs made or attempted by anyone other than these agencies.

Should you have any questions about your tool, please contact your seller at any time. In any

communications, please give all information shown on the nameplate of your tool (model number,

type, serial number, etc.)

TROUBLESHOOTING

CAUTION: Disconnect tool from air supply before performing any Service Procedure.

PROBLEM

CAUSE

SOLUTION

Air leaking at trigger area

1. O-ring in trigger valve stem

is worn and damaged.

2. O-ring in trigger valve head

is worn and damaged.

3. Having foreign matters.

1.Check/replace O-

ring/lubricate.

2.Check/replace Oring/lubricate

3.Clean the tool/lubricate

Air leaking at the lower body

portion and nose

1.Screw is loose at connecting

portion of the nose and body.

2.O-ring is damaged between

body and nose.

3.Bumper is damaged.

4.Having foreign matters at

the contacting portion of the

bumper and body.

1. Tighten screw/recheck

2. Check/replace Oring/lubricate

3. Replace the bumper.

4. Disassemble and clean

Air leaking at the body

portion and cylinder cap

1.Screw is loose at the

connecting portion of the

cylinder and body.

2.Gasket is damaged.

1. Tighten the screw and

recheck.

2. Replace the gasket.

Failure to start tool.

1.Tool dry, lacks lubrication.

2.The spring in the cylinder

cap is damaged.

1. Use pneumatic tool oil

2.Replace the spring in the

cylinder cap.

Blade driving fasteners

too deeply

1.Safety element poison is not

correct.

2.Air pressure is too high.

1.Rotate knob of the adjuster

to move safety element down.

2.Decrease air pressure.

Skipping

fasteners/feeding

intermittently

1.Having foreign matters

between the small piston and

small cylinder.

2.O-ring on the small piston is

worn and damaged.

1.Disassemble/ clean/lubricate.

2.Check/replace O-ring /

lubricate

GB

10

Page 11

3.Tool dry and lacks

lubrication.

4.The spring on the small

piston is damaged.

5.Air pressure is low.

6.Connecting screw of nose

and body is loose.

7.Stopped hook can't stop the

fasteners.

8.Bent fasteners.

9.Wrong size fasteners.

10.Small piston bumper is

worn and damaged.

11.Feed hook is binding.

12.Nail length is not correct

with loading space of nail

housing.

13.Weld wires in nail coil are

broken.

3.Use pneumatic tool oil.

4.Replace small piston spring.

5.Increase the air pressure,

but don't exceed 8.3 bar.

6.Tighten all screws.

7.Replace taper spring of the

stopped hook.

8.Use recommended fasteners.

9.Use recommended fasteners

10.Replace bumper and

lubricate small piston.

11.Clean feed hook and torsion

spring.

12.Adjust adjuster plate at the

nail housing tail portion

according to the recommended

nail length to make arrow on

the nail housing tail point to

correct direction.

13.Stop using.

Runs slowly or has power loss

1. Tool dry, lacks lubrication

2. The spring in the cylinder

cap is damaged.

3.Having foreign matters

between piston assembly and

cylinder.

4.Have not assembled the

cylinder to home position.

5.O-ring on the valve is dry

after disassembly.

6.Air pressure is too low.

7.Driver is worn (sort)

8.Inner diameter of used hose

is small

1.Use pneumatic tool oil.

2.Replace the spring in the

cylinder cap.

3.Disassemble/clean/lubricate.

4.Reassemble after

disassembling.

5.Reassemble after lubricating

6.Increase the air pressure,

but don't exceed 8.3 bar.

7.Replace piston assembly.

8.Use bigger inner diameter of

the hose.

Fasteners are jammed

1.Fasteners are wrong size.

2.Weld wires in nail coil are

broken.

1.Use recommended fasteners.

2.Stop using.

GB

11

Page 12

12

Page 13

TÄRKEITÄ TURVALLISUUSTIETOJA

VAROITUS: Pneumaattisia työkaluja käytettäessä tulee aina noudattaa perusturvatoimia

henkilövahinkojen riskin vähentämiseksi. Näihin lukeutuvat seuraavat:

LUE KAIKKI OHJEET JA NOUDATA NIITÄ.

Tämä työkalu on suunniteltu tiettyihin toimiin. Suosittelemme tiukasti, että tätä työkalua EI

muunnella ja/tai käytetä mihinkään muuhun toimeen kuin mihin se on suunniteltu. Jos sinulla on

mitään kysymyksiä liittyen työkalun käyttöön, ota yhteys myyjääsi.

1. PIDÄ TYÖALUE PUHTAANA. Epäsiistit alueet aiheuttavat vammoja.

2. ÄLÄ PÄÄSTÄ LAPSIA TYÖALUEELLE.

Älä anna lasten käsitellä

yökalua.

3. ÄYTÄ SUOJALASEJA. Silmävahinkojen

välttämiseksi työkalun käyttäjän ja kaikkien työalueella

olevien henkilöiden tulee käyttää turvalaseja, joissa on

pysyvät, jäykät, muoviset sivusuojat. Näiden turvalasien tulee

noudattaa standardin ANSI Z87.1 vaatimuksia (hyväksytyissä

laseissa on merkintä Z87 tulosteena tai leimana).

4. KÄYTÄ KUULOSUOJAIMIA. Työalue voi altistua korkeille

äänitasoille, jotka voivat johtaa kuulon vahingoittumiseen.

5. PUKEUDU TURVALLISESTI. Suojahansikkaita ja liukumattomia

kenkiä tai turvajalkineita suositellaan käytettävän tätä työkalua

käytettäessä. Älä käytä löysiä vaatteita tai koruja. Ne voivat tarttua

liikkuviin osiin. Käytä myös suojaavaa hiuspeitettä, jotta pitkät

hiukset eivät jää kiinni työkaluun.

6. KÄYTÄ VAIN PUHDASTA, KUIVAA JA SÄÄNNELTYÄ

paineilmaa 4,8‐8,3 baarin

7. ÄLÄ KOSKAAN KÄYTÄ HAPPEA TAI HIILI

‐

DIOKSIDIA, räjähtäviä kaasuja tai muita pullotettuja kaasuja tämän

työkalun voimanlähteenä.

8. ÄLÄ LIITÄ TYÖKALUA paineistukseen, joka saattaa ylittää arvon

12.3

BAR.

9. KÄYTÄ VAIN ILMALETKUA, JOKA ON MÄÄRITELTY 150 %

järjestelmän enimmäispaineesta. Pyri käyttämään letkua, jonka Ø on

3/8” liitettäessä naulain kompressoriin.

10. ÄLÄ KÄYTÄ TYÖKALUA MINKÄÄN RÄJÄHTÄVÄN AINEEN

LÄHEISYYDESSÄ tai minkään helposti räjähtävän materiaalin

yhteydessä, äläkä käytä työkalua olosuhteissa, jotka tuottavat

helposti korroosiota, ruostetta tai erittäin pölyisessä ympäristössä.

11. IRROTA TYÖKALU ILMA‐LETKUSTA ennen sen huoltamista,

jumittuneen naulan poistamista, työalueelta lähtiessäsi, työkalua

siirrettäessä tai kun ojennat työkalun toiselle henkilölle.

FIN

13

Page 14

12. IRROTA PIKALIITIN

niin, että irrottamisen yhteydessä työkaluun

ei jää paineilmaa. Jos irrottamista ei tehdä oikein,

työkalussa voi yhä olla ilmaa sen jälkeen, kun se on irrotettu, jolloin

se pystyy yhä toimimaan ja saattaa aiheuttaa henkilövahingon.

13. KÄYTÄ VAIN alkuperäisiä varaosia ja

kiinnittimiä.

14. ENNEN TYÖKALUN KÄYT TÖÄ, tarkista varovaisesti, että mikään

osa ei ole vahingoittunut parhaan tuloksen aikaan saamiseksi. Älä

käytä työkalua,

jos siinä on ilmavuotoja, keskeneräisiä tai

vahingoittuneita osia tai jos se vaatii huoltoa.

15. ÄLÄ KOSKAAN KÄYTÄ TYÖKALUA,

jos osia puuttuu tai ne ovat

vaurioituneita. Tarkista varmistimen liikkuvuus päivittäin

siltä varalta,

että se kaipaa huoltoa

16. KÄYTÄ VAIN OSIA JA

KIINNITTIMIÄ,

joita myyjä suosittelee.

17. LIITÄ TYÖKALU ILMANLÄHTEESEEN ENNEN, kiinnittimien

lataamista, jotta työkalu ei voi laueta ennen liitäntää. Kun työkalua

ei käytetä, poista kaikki kiinnittimet.

18. OLETA AINA, ETTÄ TYÖKALUSSA

ON KIINNITTIMIÄ. Pidä

työkalua niin, että se osoittaa poispäin sinusta ja muista

kaikkina aikoina. Älä leiki työkalulla. Kunnioita sitä työkaluna

19. ÄLÄ LATAA KIINNITTIMIÄ,

jos liipaisin on painettuna

tahattoman kiinnittimen laukaisun estämiseksi

20. POISTA SORMESI LIIPAISIMELTA,

kun et laukaise kiinnittimiä.

Älä koskaan kanna työkalua niin, että sormesi on

liipaisimella; työkalu ampuu naulan, jos

varmistimeen osuu isku

liipaisimen ollessa painettuna

21. ÄLÄ KÄYTÄ telineillä, tikkailla Työkalut varustettu "contact

toiminta" ei saa käyttää:

- Jos muutos ajo paikoissa vaikuttaa portaita, tikkaita tai telineitä.

- Sulkemiseen laatikkojen.

- For kuljetuksen turvajärjestelmien kiinnittämiseen.

22. LAUKAISE KIINNITTIMIÄ VAIN TYÖPINTAAN: EI KOSKAAN

materiaaliin, joka on liian kovaa

23. PIDÄ TYÖKALUSTA HYVIN KIINNI JA SÄILYTÄHALLINTA

samalla,

kun kiinnittimen laukaisua seuraa rekyyli

24. ÄLÄ LAUKAISE KIINNITTIMIÄ, toisten kiinnittimien päälle tai niin,

että työkalun kulma on liian suuri. Kiinnittimet voivat kimmota ja

aiheuttaa henkilö‐ vahingon

25. ÄLÄ LAUKAISE KIINNITTIMIÄ, työstettävän kappaleen reunan

lähellä. Kappale saattaa haljeta, mikä saa kiinnittimet irtoamaan tai

kimpoamaan, aiheuttaen henkilövahingon.

FIN

14

Page 15

26. OLE TARKKAAVAINEN. Pidä silmällä tekemisiäsi. Käytä

maalaisjärkeä. Älä käytä työkalua väsyneenä.

27. PIDÄ KÄDET JA KEHON OSAT

kuvassa 13 näytetyn alueen ulkopuolella

28. TÄMÄ TYÖKALU ON VARUSTETTU SYVYYDENSÄÄDÖLLÄ,

jolla voi säätää iskunsyvyyttä. Syvyyttä säädettäessä irrota ensin

ilmanlähde ja käännä syvyydensäädön nuppia kunnes syvyys on

haluttu.

29. KUN TYÖKALU EI OLE KÄYTÖSSÄ, työkalu tulee puhdistaa ja

asettaa säilytyslaatikkoon. Turvasyistä säilytä lasten

ulottumattomissa.

TYÖANTAJA

N VASTUUT

Ty

önantajan tulee ylläpitä ä

tur v

allisuusvaroitusten ja mu iden

täm

än oppaan ohjeiden

nouda

tt

amist a . Pidä

täm

ä op a s k a i kkien

tät

ä

työk

alu a

käyttävie

n ulottuvissa .

Tu

rv

allisuuden ja

työk

alun oi kean

käyt

ön varmista

misek

s i,

lue

tark

asti ja noudata

näitä ohjeita.

KIINNIT T IMIEN MÄÄRITYKSET

Käytä vain suositeltuja kiinnittimiä:

Min.

φ0.39˝

(φ10mm)

( φ3.1mm)

φ0.12˝

0.31˝

(8mm)

15o-16

o

Max.

φ0.39˝

(φ10mm)

15o-16

o

( φ3.1mm)

φ0.12˝

0.31˝

(8mm)

7/8" (22mm)

FIN

15

Page 16

TEKNISETTIEDOT

Ominaispiirre

Arvo

Paineilman paine

4.8-8.3 bar

Koko (PxKxL)

300 × 310 × 110 mm

Naulan pituusalue

22-45 mm

Työkalun paino

2.75Kg

Ilman sisäänotto

1/4"NPT

Ilman käyttö

68 l/min at 5.52 bar

PAKKAUSLISTA

KUVAUS

Määrä

S45CNR naulain

1

S5 kuusioavain

1

S4 kuusioavain

1

S3 kuusioavain

1

Voiteluöljy

1

Käyttöohjeet

1

MELUTIEDOT

Nämä kohinaa arvot ovat standardin EN 12549:1999

LpA, 1s, d = 84dB

LwA, 1s, d = 97dB

Nämä arvot ovat työkaluja liittyviä arvoja eivätkä edusta melua kehitetty pisteen käyttöä.

Työpaikka suunnittelu voi myös vähentää melua, esimerkiksi asettamalla työn pala

äänenvaimennusmassaa tukee.

TIETOA TÄRINÄSTÄ

Nämä arvot ovat standardin ISO 8662-11:1999

Tärinä ominaisarvo (m/s2) = 8,22

Tämä arvo on työkalu-liittyvä arvo ei edusta vaikutusvaltaansa käsi-käsivarsijärjestelmää käytettäessä työkalua.

Tur valasit

1

FIN

16

Page 17

KÄYTTÖOHJEET

JOHDANTO

S45CNR on vaativaan harrastekäyttöön tarkoitettu pneumaattinen rullanaulain, joka

käyttää paineilmaa. Sitä käytetään paljon ulkoverhousten ja vastaavien kiinnittämiseen. Työkalun

runkomateriaalina käytetään magnesiumseosta.

VOIMANLÄHDE

Työkalu on suunniteltu käytettäväksi puhtaalla, kuivalla paineilmalla painealueiden

4,8 ‐ 8,3 bar välillä. Suositeltava järjestelmä käsittää suodattimen (C) kuva 2,

painesäätimen (A) kuva 2 ja automaattisen öljyäjän (B) kuva 2, joka sijaitsee niin

lähellä työkalua kuin mahdollista (n. 6 m päässä on paras).

Kaikki paineilma sisältää kosteutta ja muita materiaaleja, jotka vahingoittavat työkalun

sisäosia. Ilmaletkun suodatin poistaa näistä suurimman osan ja kasvattaa työkalun käyttöikää

huomattavasti. Jos öljyäjää ei ole saatavissa: lisää 5‐6 tippaa työkaluöljyä työkalun ilmanottoon

jokaisen työpäivän alussa. Irrota letkun pikaliitin rungon nipasta.

VAROITUS: Kaikkien linjan osien (letkut, liittimet, suodattimet, säätimet jne.) tulee

kestää 150 % järjestelmän enimmäispaineesta. Pyri käyttämään letkua kooltaan Ø 3/8”

liitettäessä naulain kompressoriin.

Irrota työkalu ilmanlähteestä ennen huoltoa, jumittuneen kiinnittimen irrottamista, työalueelta

poistumista, työk

alun siirtämistä.

FIN

17

Page 18

Liitä työkalu ilmanlähteeseen, kun olet lukenut ja ymmärtänyt koko käyttöohjeen.

VAROITUS: Osoita työkalu aina poispäin itsestäsi ja muista.

Liitä työkalu aina ilmanlähteeseen ennen kiinnittimen lataamista. Älä lataa kiinnittimiä

liipaisimen tai varmistimen ollessa painettuna. Käytä aina hyväksyttyjä turvalaseja ja

kuulo‐

suojaimia työkalua valmistellessa tai käytettäessä. Älä koskaan käytä työkalua,

joka vuotaa ilmaa tai vaatii huoltoa.

Paina lukitusvipua (katso A kuva 14) ja avaa luukku. Käännä makasiinin kansi rungon sivulle.

Pohjalevyä voidaan siirtää ylös ja alas säädinnupin avulla (katso B kuva 15). Naulan pituudesta

riippuen levy voidaan säätää oikeaan asentoon, joka on merkitty alemman naulakennon

sisäpuolelle.

Aseta naulat makasiinin pohjalle. Aseta rullanpää syöttäjän hampaisiin

(katso kuva 16).

Sulje makasiinin kansi ja paina luukku kiinni (katso kuva 17).

Käännä säädettävää POISTOILMAN ohjainta (katso kuva 18) niin, että ilmavirta on poispäin

käyttäjästä.

FIN

18

Page 19

TYÖKALUN KÄYT TÖ

Suorita kaikki kohdan TYÖKALUN VALMISTELU toimet ennen työkalun käyttöä.

Laukaisu: Aseta varmistin kappaletta vasten ja paina sitten liipaisinta.

Valmistaja ei ota vastuuta vammoista tai menetyksistä, jotka johtuvat työkalun väärästä käytöstä.

VAROITUS:

Poista sormi laukaisimelta, kun et käytä työkalua. Älä koskaan kanna työkalua

niin, että sormesi on liipaisimella. Se laukaisee kiinnittimen, jos varmistimeen osuu

isku.Osoita työkalu aina turvalliseen suuntaan.

Älä koskaan laukaise kiinnitintä liian kovaan pintaan tai

liian tiukassa kulmassa tai lähelle

työkappaleen reunaa. Kiinnittimet voivat kimmota ja aiheuttaa henkilövahingon.

Telineet asennus

Naulaimet on turvallisesti suunniteltu. Älä pura tai muokkaa osia kuten turvallisuus ikeestä.

Irrota työkalu ilmanlähteestä ennen puhdistamista,

jumittuneen kiinnittimen poistamista,

työalueelta poistumista, työkalun siirtämistä tai kun ojennat työkalun toiselle henkilölle. Puhdista ja

tarkista työkalu päivittäin. Tarkista laukaisimen ja turvamekanismin toiminta varovaisesti. Älä käytä

työkalua, elleivät sekä laukaisin että turvamekanismi toimi oikein tai jos työkalu vuotaa ilmaa tai

vaatii muuta huoltoa.

Iskusyvyys kasvaa tai vähenee säätönuppia kääntämällä (A), kuva 19. Testaa ja tarkista syvyys.

Jos naula on liian syvällä, käännä säädintä myötäpäivään työntääksesi varmistinta alaspäin.

Säätimen kääntäminen vastapäi

vään työntää varmistinta ylöspäin. Toista, kunnes lopputulos on

haluttu (katso kuva 20).

JUMIT

T UNEEN

KIINNIT

T IMEN

POIST A MINEN

1. VAROITUS: Irrota työkalu ilmanlähteestä.

2. Avaa salpa ja poista tukos.

3. Noudata kohdan

TYÖKALUN VALMISTELU ohjeita ladataksesi kiinnittimet uudelleen.

FIN

19

Page 20

YLLÄPITO

PUHDISTA JA TARKISTA PÄIVITTÄIN

VAROITUS: Irrota työkalu ilmanlähteestä ennen puhdistamista ja tarkistamista. Korjaa

kaikki ongelmat ennen käyttöä.

Tarkista kompressorin suodatin viikoittain ja poista kondenssiovesi säiliöstä. Älä liota työkalua

puhdistusaineissa. Ne voivat vahingoittaa sisäosia.

Tarkista laukaisin‐ ja turvamekanismit sen varmistamiseksi, että järjestelmä on kokonainen ja

käyttökunnossa: ei irtonaisia tai puuttuvia osia, eikä jumissa olevia tai juuttuvia osia.

Varmista, että kaikki ruuvit ovat tiukassa. Löysät ruuvit voivat aiheuttaa

henkilövahingon tai vahingoittaa työkalua.

Tarkista kuluneiden tai vaurioituneiden osien varalta. Vaihda tarvittaessa heti. Jos työkalua

käytetään ilman linjaöljyäjää: lisää 5‐6 tippaa työkaluöljyä työkalun

ilmanottoon jokaisen työpäivän alussa.

HUOLTO JA YLLÄPITO

Kaikki laatutyökalut vaativat vaihto‐osien huoltoa normaalin käytön aiheuttaman

kulumisen takia. Jotkin käyttäjän huollettavissa olevat osat on kuvattu kohdassa.

ONGELMANRATKAISU. Kaikki paikallisten edustajien tekemät korjaustoimenpiteet

on taattu kokonaisuudessaan viallisten materiaalien ja työn laadun varalta. Emme

voi taata korjaustoimia, jotka on tehnyt kukaan muu kuin nämä edustajat

Jos sinulla on kysyttävää työkalustasi, ota yhteys myyjääsi milloin vain. Anna työkalusi

tyyppikilvessä olevat tiedot (mallinumero, tyyppi, sarjanumero jne.) aina, kun

otat yhteyttä.

ONGELMANRATKAISU

VAROITUS: Irrota työkalu ilmanlähteestä ennen huoltotoimenpiteiden suorittamista

ONGELMA

SYY

RATKAISU

Liipaisin vuotaa.

1. Liipaisinventtiilin O‐rengas

kulunut ja vahingoittunut.

2. Liipaisinventtiilin pään

O‐rengas kulunut ja

vahingoittunut.

3. Laitteessa on

epäpuhtauksia.

1. Tarkista/vaihda

O‐rengas/voitele.

2. Tarkista/vaihda

O‐rengas/voitele.

3. Puhdista/voitele työkalu.

Työkalun rungon alaosasta

vuotaa ilmaa.

1. Rungon ja suuttimen

yhdistävän osan

ruuvi on irti.

2. Rungon ja suukappaleen

välinen O‐rengas on

vioittunut.

3. Männän pysäytin on

vioittunut.

4. Männän pysäyttimen ja

rungon yhdistävässä osassa

on epäpuhtauksia.

1. Tiukenna ruuvi ja tarkista

uudelleen.

2. Tarkista/vaihda

O‐rengas/voitele.

3. Vaihda puskuri.

4. Pura ja puhdista.

Työkalun rungon ja

kannen välisestä osasta

vuotaa

ilmaa.

1. Kannen ja rungon

yhdistävät ruuvit

ovat löysällä.

2.T iiviste on

vioittunut.

1. T iukenna ruuvi ja

tarkista uudelleen.

2. Vaihda tiiviste.

Työkalu ei toimi. 1. Työkalu on kuiva ja

vaatii voitelua.

1. Käytä

pneumaattista

työkaluöljyä.

FIN

20

Page 21

ONGELMA

SYY

RATKAISU

Kiinnittimet iskeytyvät liian

syvään.

1. Varmistimen säätö ei ole

oikea.

2. Ilmanpaine on liian korkea.

1. Käännä

syvyydensäädintä

säätääksesi

naulaussyvyyttä.

2. Vähennä ilmanpainetta.

Kiinnittimiä

jää väliin/syöttö

on katkonaista.

1. Työkalu on kuiva ja

vaatii voitelua.

2. Ilmanpaine on liian matala.

3. Kiinnittimet vääntyvät.

4. Kiinnittimet ovat

väärän kokoisia.

5. Naulojen pituus ei vastaa

makasiinin pohjalevyn

asetuksia.

1. Käytä

pneumaattista

työkaluöljyä.

2. Nosta ilmanpainetta,

mutta älä ylitä arvoa 120

PSI (8,3 bar).

3. Käytä suositeltuja

kiinnittimiä.

4. Käytä suositeltuja

kiinnittimiä.

5. Säädä asetusta

suositeltuun

naulapituuteen, jotta

makasiinin takaosan nuoli

osoittaa oikeaan suuntaan.

Työkalu toimii

tehottomasti.

1. Työkalu on kuiva ja

vaatii voitelua.

2. Ilmanpaine on liian matala.

3. Käytössä olevan

letkun sisähalkaisija

on pieni.

1. Käytä

pneumaattista

työkaluöljyä.

2. Nosta ilmanpainetta,

mutta älä ylitä arvoa 120

PSI (8,3 bar).

3. Käytä letkua, jonka

sisäläpimitta on

suurempi.

Kiinnittimet ovat jumissa. 1. Väärän kokoiset

kiinnittimet.

1. Käytä suositeltuja

kiinnittimiä.

FIN

21

Page 22

22

Page 23

VIKTIGA

SÄKERHETSINSTRUKTIONER

VA RNING: Vid användning av tryckluftsverktyg bör man alltid följa allmänna

säkerhetsanvisningar för att minska risken för personskada, bl a följande:

LÄS IGENOM OCH FÖLJ ALLA INSTRUKTIONER.

Detta verktyg är avsett för vissa ändamål. Vi uppmanar Dig strängt att INTE modifiera verktyget

och/eller använda det för anda ändamål än de avsedda. Om Du har några frågor om användning av

verktyget, var god kontakta Din återförsäljare.

1. HÅLL ARBETSOMRÅDET RENT.

Belamrade arbetsområden inbjuder till personskada

2.

BARN FÅR INTE VISTAS I ARBETSOMRÅDET.

Låt aldrig barn hantera verktyget.

3. ANVÄND SKYDDSGLASÖGON. För att undvika ögonskador bör

användaren och alla andra personer i arbetsområdet använda

skyddsglasögon med permanenta styva sidoskydd av plast. Dessa

skyddsglasögon bör uppfylla kraven enligt ANSI Z87.1

(godkändaskyddsglasögon har en påtryckt eller präglad märkning

“Z87”)

4. ANVÄND HÖRSELSKYDD. Höga ljudnivåer som kan leda till

hörselskada kan förekomma i arbetsområdet.

5. ANVÄND SÄKER KLÄDSEL Skyddshandskar och halkfria skor eller

säkerhetsskor rekommenderas vid

arbete med och hantering av verktyget. Ha inte på Dig löst sittande

kläder eller smycken. Dessa kan fastna i

rörliga detaljer. Täck även över håret för att undvika

att långt hår fastnar i verktyget.

6.

ANVÄND ENDAST REN, TORR OCH REGLERBAR

tryckluft med tryck på 4,8 till 8,3 BAR.

7. ANVÄND ALDRIG SYRE, KOLDIOXID,

brännbara gaser eller någon annan gas i flaska för att driva

verktyget

8. ANSLUT INTE VERKTYGET till tryck som eventuellt kan överskrida

12,3 BAR.

9. ANVÄND ENDAST LUFTSLANG SOM ÄR GODKÄND för 150% av

systemets maxtryck. Använd helst en slang ID 3/8”

för att ansluta spikpistolen till kompressorn.

10. VERKTYGET FÅR INTE ANVÄNDAS NÄRA ETT LÄTTANTÄNDLIGT

eller explosivt material eller i korrosiva eller

mycket dammiga miljöer.

11. KOPPLA LOSS VERKTYGET FRÅN LUFTSLANGEN innan Du utför

underhåll, tar ut en fastnad spik, lämnar arbetsområdet, flyttar

verktyget eller räcker över den

till någon annan.

S

23

Page 24

12. KOPPLA LOSS SNABBKOPPLINGEN BAKTILL PÅ

VERKTYGSKROPPEN

för att göra verktyget trycklöst.

Om verktyget inte fungerar korrekt kan det förbli trycksatt efter

frånkoppling, skjuta ut ett fästmedel och orsaka personskada.

13. RESERVDELAR OCH TILLBEHÖR. Använd endast

originalreservdelar vid service. Godkända tillbehör och reservdelar

är tillgängliga.

14. INNAN VERKTYGET ANVÄNDS, kontrollera noga att alla detaljer

är oskadade för att uppnå bästa resultat. Verktyget får

inte användas om det läcker luft, är ofullständigt monterat, har

skadade detaljer eller behöver reparation.

15. VERKTYGET FÅR INTE ANVÄNDAS om säkerhetsbygeln,

avtryckaren eller fjädern inte fungerar, saknas eller är skadade.

Säkerhetsbygeln, avtryckaren eller fjädrar

får inte modifieras eller avlägsnas. Kontrollera dagligen att

avtryckaren rör sig fritt.

16. ANVÄND ENDAST DETALJER OCH FÄSTMEDEL rekommenderade

av återförsäljaren.

17. VERKTYGET FÅR INTE ANSLUTAS TILL LUFTKÄLLAN INNAN

fästmedel laddas för att undvika oavsiktlig avfyrning

av fästmedel.

Verktygets drivmekanism kan

aktiveras medan verktyget ansluts till

luftkällan. Ta ut alla fästmedel ur magasinet när verktyget inte

används.

18. FÖRUTSÄTT ALLTID ATT VERKTYGET INNEHÅLLER FÄSTMEDEL.

Rikta alltid verktyget bort från Dig själv och andra.

Lek aldrig med verktyget. Respektera produkten som ett

arbetsredskap.

19. LADDA INTE FÄSTMEDEL med avtryckaren eller säkerhetsbygeln

nedtryckt för att undvika oavsiktlig avfyrning.

20. HÅLL FINGRET BORTA FRÅN AVTRYCKAREN medan Du inte

spikar. Håll aldrig fingret på avtryckaren medan Du bär verktyget:

verktyget kan skjuta ut en spik om säkerhetsbygeln stöter mot

något medan avtryckaren är nedtryckt.

21. ANVÄND INTE på ställningar, skall YRKESTRAPPSTEGAR Verktyg

försedda med "kontaktutlösare" inte användas:

- Om en förändring av kör platser påverkas via trappor, stegar eller

byggnadsställningar.

- För att stänga lådor eller lådor.

- För montering av transportsäkerhetssystem system.

22. SPIKA ENDAST I ARBETSYTAN: SPIKA ALDRIG i material som är

för hårda för spikar att tränga igenom.

23. HÅLL STADIGT I VERKTYGET FÖR ATT BEHÅLLA KONTROLLEN

vid rekyl av verktyget från arbetsytan under spikningen. Om

säkerhetsbygeln på

nytt stötet mot arbetsytan innan avtryckaren släpps skjuts en spik

ut oavsiktligt.

24. SPIKA ALDRIG ovanpå andra spikar eller med verktyget på en

S

24

Page 25

för stor vinkel: spiken kan rikoschettera och orsaka personskada.

25. SPIKA ALDRIG NÄRA arbetsstyckets kant. Arbetsstycket kan

spricka och spiken kan flyga iväg eller rikoschettera och orsaka

personskada.

26. SPIKA ALDRIG NÄRA arbetsstyckets kant. Arbetsstycket kan

spricka och spiken kan flyga iväg eller rikoschettera och orsaka

personskada.

27. HÅLL HÄNDERNA OCH ANDRA KROPPSDELAR borta från området

som visas på fig. 13 för att undvika personskada

28. VERKTYGET HAR ETT REGLAGE för justering av spikningsdjupet.

För att justera spikningsdjupet bör man först frånkoppla

luftförsörjningen och sedan vrida justeringsknappen manuellt till

lämpligt läge.

29. VERKTYGET HAR ETT REGLAGE för justering av spikningsdjupet.

För att justera spikningsdjupet bör man först frånkoppla

luftförsörjningen och sedan vrida justeringsknappen manuellt till

lämpligt läge.

ARBETSGIVARENS ANSVAR

Arbetsgivaren bör säkerställa efterlevnad av alla säkerhet sanvisningar och alla andra

instruktioner i denna bruksanvisning.

Förvara bruksanvisningen tillgänglig för alla som använder verktyget.

Läs noga igenom och följ alla här angivna instruktioner för att försäkra personsäkerhet och

korrekt funktion av verktyget.

TILLÅTNA

FÄSTMEDEL

Använd endast följande fästmedel.

Min.

φ0.39˝

(φ10mm)

( φ3.1mm)

φ0.12˝

0.31˝

(8mm)

15o-16

o

Max.

φ0.39˝

(φ10mm)

15o-16

o

( φ3.1mm)

φ0.12˝

0.31˝

(8mm)

7/8" (22mm)

S

25

Page 26

TEKNISKA SPECIFIKATIONER

Parameter

Värde

Lufttryck

4.8-8.3 bar

Yttermått (L×H×B)

300 × 310 × 110 mm

Spikmått

22-45 mm

Verktygets vikt

2.75Kg

Luftintag

1/4"NPT

Luftförbrukning

68 l/min at 5.52 bar

FÖRPACKNINGENS INNEHÅLL

BENÄMNING

ANTAL

Spikpistol S45CNR

1

Insexnyckel S5

1

Insexnyckel S4

1

Insexnyckel S3

1

Olja för tryckluftsverktyg

1

Bruksanvisning

1

BULLERINFORMATION

Dessa buller karakteristiska värden är i enlighet med EN 12549:1999

LpA, 1s, d = 84dB

LWA, 1s, d = 97dB

Dessa värden är verktyg-relaterade karakteristiska värden och representerar inte buller

utvecklats vid tidpunkten för utnyttjandet. Arbetsplatsens utformning kan också bidra till att

minska bullernivåerna, till exempel att placera arbetsstycket på ljuddämpande stöd.

VIBRATIONSINFORMATION

Dessa värden är i enlighet med ISO 8662-11:1999

Vibration karakteristiskt värde (m/s2) = 8,22

Detta värde är ett verktyg egenskapsvärde och representerar inte inflytandet på hand-armsystemet när verktyget används.

Skyddsglasögon

1

S

26

Page 27

BRUKSINSTRUKTIONER

FÖRORD

S45CNR är en hållbar rundbandad tryckluftsdriven spikpistol. Den är avsedd för spikning av spikar

med olika längder och diameter på 22-45 mm eller 3,1mm. Spikpistolen används främst för

remmontering och ihopmontering av ram och beklädnadsmaterial. Verktyget har en kropp av

magnesiumlegering och en lätt cylinderkåpa som försäkrar hög specifik hållfasthet och styvhet.

DRIVKÄLLA

Verktyget är avsett för ren och torr tryckluft med reglerbart tryck mellan 4,8 och 8,3 bar.

Systemet borde helst inkludera ett filter (C) fig. 2, ett tryckreglage (A) fig. 2 och en automatisk

smörjenhet (B) fig. 2 som är belägen så nära verktyget som möjligt (helst inom 15 fot).

Tryckluft innehåller alltid fukt och andra föroreningar som kan skada verktygets invändiga delar.

Ett filter på luftledningen avlägsnar de flesta föroreningar och ökar verktygets livslängd betydligt.

Om luftledningen inte har dimsmörjare bör man applicera fem-sex droppar olja i verktygets

tryckluftsintag i början av varje arbetsdag.

Luftförsörjningen bryts genom att lossa snabbkopplingen på luftintaget baktill på verktyget.

Frånkoppling av tryckluft gör verktyget trycklöst. Om verktyget inte fungerar korrekt kan det

dock hända att verktyget förblir trycksatt efter att tryckluften har frånkopplats, i så fall kan det

skjuta ut en spik och orsaka personskada.

VAR FÖRSIKTIG: Alla ledningskomponenter (slangar, kopplingar, filter, reglagen osv.) ska kunna

tåla 150% av systemets maxtryck. Använd helst en slang ID 3/8” för

anslutning av spikpistolen till

kompressorn.

Verktyget får inte anslutas till ett system vars tryck motsvarar verktygets maximala tillåtna tryck.

Luftförsörjningen bryts genom att lossa snabbkopplingen på luftintaget baktill på verktyget för att

göra verktyget trycklöst.

Koppla bort tryckluftsförsörjningen innan Du utför underhåll på verktyget, avlägsnar en fastnad

spik, lämnar arbetsområdet, flyttar verktyget eller räcker det över det till någon annan.

S

27

Page 28

FÖRBEREDELSE FÖRE ARBETET

När Du har läst igenom och förstått hela bruksanvisningen, anslut verktyget till luftkällan.

VAR FÖRSIKTIG: Rikta aldrig verktyget mot Dig själv eller någon annan.

Anslut aldrig verktyget till tryckluftsförsörjningen innan Du laddar spikar. Ladda

aldrig spikar med avtryckaren eller säkerhetsmekanismen nedtryckt. Använd alltid

märkta skyddsglasögon och hörselskydd medan Du förbereder eller använder

verktyget. Verktyget får inte användas om det läcker luft eller behöver reparation.

Tryck ned handtaget (se A på fig. 14) och öppna spärren. Vrid spikmagasinets överdel till sidan av

verktygets kropp.

Justeringsplattan kan flyttas uppåt eller nedåt genom att vrida justeringsmuttern (se B på fig. 15).

Ställ in justeringsplattan korrekt enligt spiklängden, så att dess position i spikmagasinets nederdel

motsvarar den angivna.

Placera en spikrulle i spikmagasinets nederdel. Dra ut spikrullens ände så att den når matarklon

och placera den andra spiken mellan matarklons tänder (se fig. 16).

Stäng spikmagasinets överdel och tryck ned spärren (se fig. 17).

Justera utblåsdeflektorn (se fig. 18) så att det utgående luftflödet riktas bort från användaren. Ta

tag i deflektorn och vrid den till det önskade läget.

S

28

Page 29

ANVÄNDNING AV VERKTYGET

Utför alla steg i avsnittet FÖRBEREDELSE FÖRE ARBETET innan verktyget används.

Verktyget kan avfyras på två olika sätt:

Avtryckarfunktion (singelskott): Vrid det vridbara skaftet så att dess ände hamnar uppåt (se

figur 18A).

Medan säkerhetsbygeln är tryckt mot arbetsstycket, tryck på avtryckaren upprepade gånger för att

avfyra spikar.

1. Serieskott: Placera munstycket på arbetsytan, tryck verktyget lätt mot arbetsytan tills

säkerhetsbygeln är nedtryckt, tryck sedan ner avtryckaren för att avfyra spikar. Denna

avfyringsmetod

möjliggör precisare spikning. I detta läge kan säkerhetsbygeln justeras nedåt med hjälp av

vridknappen för att undvika avfyrning av två spikar samtidigt.

1. Fabriksinställningen avser läget för singelskott.

2. Tillverkaren åtar sig inget ansvar för skada eller förlust pga felaktig användning av verktyget.

VAR FÖRSIKTIG: Håll aldrig fingret på avtryckaren medan Du inte spikar.

Bär aldrig verktyget med fingret på avtryckaren: en spik skjuts ut om säkerhetsbygeln stöter mot

någonting.

Rikta aldrig verktyget mot Dig själv eller någon annan.

Försök aldrig att skjuta fästmedel i för hårda material, med verktyget på en för stor vinkel eller

nära arbetsstyckets kant. Fästmedlet kan rikoschettera och orsaka personskada.

Koppla bort tryckluftsförsörjningen innan Du utför underhåll på verktyget, avlägsnar en fastnad

spik, lämnar arbetsområdet, flyttar verktyget eller räcker det över det till någon annan.

Rengör och granska verktyget dagligen. Kontrollera noga korrekt funktion av avtryckaren och

säkerhetsmekanismen.

Hållare för montering av verktyg för indrivning av fästanordningar skall

vara säkert utformade. Plocka inte isär eller modifiera delar såsom säkerhet oket. Verktyget får

inte användas om avtryckaren eller säkerhetsmekanismen inte fungerar korrekt, luftläckage

förekommer eller verktyget annars behöver reparation.

3. Spikningsdjupet ökas eller minskas genom att vrida justeringsknappen (A) på fig. 19.

Provspika och kontrollera djupet. Om spiken sitter för djupt, vrid knappen medurs för att

justera säkerhetsbygeln nedåt. Eller vrid knappen moturs för att justera säkerhetsbygeln uppåt.

Upprepa tills önskade resultat uppnås (se fig. 20).

ATT TA BORT EN FASTNAD SPIK

1.VAR FÖRSIKTIG: Koppla loss verktyget från luftkällan.

2.Öppna spärren, vrid spikmagasinets nederdel och ta ut spikarna ur spikmagasinets nederdel.

3.Använd en smal, mjuk stålpinne för att trycka drivbladet till dess översta läge. Använd spetstång

för att ta ut det fastnade

fästmedlet (se fig.21).

4.Följ instruktionerna i avsnittet FÖRBEREDELSE FÖRE ARBETET för att ladda spikarna i magasinet

igen.

S

29

Page 30

UNDERHÅLL

RENGÖR OCH KONTROLLERA DAGLIGEN

VAR FÖRSIKTIG: Koppla loss verktyget från luftkällan före rengöring och kontroll. Åtgärda alla

problem innan verktyget används igen.

Kontrollera kompressorns filter varje vecka och stäng av den manuella ventilen för att tömma ut

vatten och föroreningar.

Verktyget får inte vätas ner med rengöringslösningar. Dessa kan skada de invändiga detaljerna.

Den synliga delen av den lilla kolvpinnen och matarklon bör hållas rena.

Kontrollera avtryckaren och säkerhetsmekanismen för att försäkra att systemet är komplett och

funktionsdugligt: inga detaljer är lösa eller saknas, detaljer får inte fastna eller kärva.

Se till att alla skruvar är väl åtdragna. Lösa skruvar kan leda till personskada eller skada på

verktyget.

Kontrollera att inga detaljer är nötta eller skadade. Nötta eller skadade detaljer bör bytas ut

omgående.

Om verktyget används utan en dimsmörjare på luftledningen: applicera 5 eller 6 droppar

olja för tryckluftsverktyg i verktygets luftintag vid början av varje arbetsdag.

SERVICE OCH REPARATION

Alla verktyg med hög kvalitet kräver eventuellt byte av reservdelar pga normalt slitage. Vissa

komponenter som kan bytas av användaren beskrivs i avsnittet

FELSÖKNING. Alla reparationer utförda av lokala representanter har full garanti mot

materialfel- och arbetsfel. Vi kan dock inte lämna garanti på reparationer eller reparationsförsök

som utförs av andra än dessa representanter.

Om Du har några frågor om Ditt verktyg, var god kontakta Din återförsäljare. Var god ange all

information på maskinskylten av Ditt verktyg (modellnummer, typ, serienummer osv.)

FELSÖKNING

VAR FÖRSIKTIG: Koppla loss verktyget från luftkällan före varje serviceåtgärd.

PROBLEM

CAUSE

SOLUTION

Luftläckage vid avtryckaren

1. O-ringen i avtryckarens

ventilskaft är nött eller

skadad.

2. O-ringen i avtryckarens

ventilhuvud är nött eller

skadad.

3. Främmande partiklar.

1.Kontrollera/byt ut

O-ringen/smörj.

2.Kontrollera/byt ut

O-ringen/smörj.

3.Rengör/smörj verktyget.

Luftläckage vid kroppens

nederdel och mynningen

1.Lös skruv mellan

munstycket och

verktygskroppen.

2.Skadad O-ring mellan

kroppen och munstycket.

1.Dra åt skruven och

kontrollera på nytt

2.Kontrollera/byt ut

O-ringen/smörj.

S

30

Page 31

3.Skadad buffert.

4.Främmande partiklar

mellan bufferten och

verktygskroppen.

3. Byt ut bufferten.

4. Ta isär och rengör.

Luftläckage vid kroppen och

cylinderkåpan

1.Lös skruv mellan cylindern

och kroppen.

2.Skadad packning.

1. Dra åt skruven och

kontrollera på nytt.

2. Byt ut packningen.

Verktyget startar inte.

1.Verktyget är torrt,

otillräckligt smort.

2.Skadad fjäder i

cylinderkåpan.

1.Använd olja för

tryckluftsverktyg.

2.Byt ut fjädern i

cylinderkåpan.

Drivbladet skjuter in

fästmedel för djupt.

1.Fel läge av säkerhetsbygeln.

2.För högt lufttryck.

1.Vrid justeringsknappen

för att justera

säkerhetsbygeln nedåt.

2.Minska lufttrycket.

Verktyget hoppar över

fästmedel / avbruten

matning

1.Främmande partiklar mellan

den lilla kolven och den

lilla cylindern.

2.O-ringen på den lilla kolven

är nött eller skadad.

3. Ve rktyget är torrt,

otillräckligt smort.

4.Skadad fjäder på den

lilla kolven.

5.För lågt lufttryck.

6.Fästskruven mellan

munstycket och kroppen är

lös.

7.Stoppklon kan inte hindra

fästmedel.

8.Böjda fästmedel.

9.Fästmedel med fel storlek.

10.Den lilla kolvens buffert

är nött eller skadad.

11.Matarklon fastnar.

12.Fel spiklängd för

spikmagasinet.

13.Brustna svetstrådar i

spikrullen.

1.Ta isär / rengör /

smörj.

2.Kontrollera /byt ut Oringen / smörj.

3.Använd olja för

tryckluftsverktyg.

4.Byt ut fjädern på den lilla

kolven.

5.Öka lufttrycket men inte

över 8,3 bar.

6.Dra åt alla skruvar.

7.Byt ut fjädern på

stoppklon.

8.Använd rekommenderade

fästmedel.

9.Använd rekommenderade

fästmedel.

10.Byt ut bufferten och

smörj kolven.

11.Rengör matarklon och

torsionsfjädern.

12.Justera justeringsplattan i

spikmagasinets bakre del till

den rekommenderade

spiklängden så att pilen på

spikmagasinet pekar i rätt

riktning.

13.Avbryt användning av

verktyget.

Trög funktion eller

effektförlust

1. Ve rktyget är torrt,

otillräckligt smort.

2.Skadad fjäder i

cylinderkåpan.

3.Främmande partiklar

mellan kolvenheten och

cylindern.

4.Fel monterad cylinder.

5.O-ringen på ventilen är

torr efter isärmontering.

6.För lågt lufttryck.

7.Nött drivenhet

8.Slangens innerdiameter är

för liten.

1.Använd olja för

tryckluftsverktyg.

2.Byt ut fjädern i

cylinderkåpan.

3.Ta isär / rengör / smörj.

4.Montera ihop korrekt

efter isärmontering.

5.Montera ihop efter

smörjning.

6.Öka lufttrycket men inte

över 8,3 bar.

7.Byt ut kolvenheten.

8.Använd en slang med

större innerdiameter.

S

31

Page 32

32

Page 33

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ

AVERTISSEMENT: Lors de l'utilisation d'outils pneumatiques, des précautions basiques de sécurité

doivent toujours être respectées pour réduire le risque de blessures physiques. Il faut notamment

respecter ce qui suit:

LIRE ET RESPECTER TOUTES LES INSTRUCTIONS.

1.GARDER UN ESPACE DE TRAVAIL PROPRE. Les zones encombrées

sont propices aux blessures.

2.NE PAS PERMETTRE AUX ENFANTS DE PÉNÉTRER DANS LA ZONE

DE TRAVAIL. Ne les laisser pas manipuler l'outil.

3.UTILISER LES LUNETTES DE SÉCURITÉ. Pour éviter les lésions

oculaires, l'opérateur de l'outil et toutes les personnes de la zone de

travail doivent porter des lunettes de sécurité avec des protections

latérales fixes, rigides, en plastique. Ces lunettes de sécurité doivent

être conformes aux exigences ANSI Z87.1 (les lunettes homologuées

doivent voir "Z87" imprimé ou étiqueté dessus)

4. UTILISER LA PROTECTION AUDITIVE. La zone de travail peut être

exposée à des niveaux sonores forts pouvant entraîner une perte

d'audition.

5. PORTER DES VÊTEMENTS DE SÉCURITÉ Les gants de protection

et les chaussures antidérapantes ou de sécurité sont recommandés

lors du travail avec et la commande de cet outil. Ne pas porter des

vêtements amples ou des bijoux. Ils peuvent être happés dans les

pièces mobiles. Porter également une protection de cheveux pour

éviter que les longs cheveux ne soient happés dans l'outil.

6. UTILISER UNIQUEMENT DE L'air comprimé PROPRE, SEC ET

RÉGULÉ de 4,8 à 8,3 bar

7. NE JAMAIS UTILISER DE L'OXYGÈNE, DU DIOXYDE DE CARBONE,

des gaz combustibles ou un autre gaz en bouteille comme source

d'énergie pour l'outil

8. NE PAS CONNECTER L'OUTIL à une pression pouvant dépasser

9,13 bar.

9. UTILISER UNIQUEMENT UN TUYAU D'AIR QUI EST HOMOLOGUÉ

pour 150 % de la pression maximale du système. Essayez d'utiliser

un tuyau d'ID 3/8" qui connecte la cloueuse à un compresseur.

10. NE PAS UTILISER L'OUTIL PRÈS D'UN COMBUSTIBLE, ou de

tout autre matériau facilement explosif et ne pas utiliser l'outil

dans un environnement produisant facilement de la corrosion, de

la rouille et très poussiéreux.

11. DÉCONNECTER L'OUTIL DU TUYAU D'AIR avant d'effectuer

une maintenance, de nettoyer une fixation bloquée, de quitter la

zone de travail, de déplacer l'outil dans un autre endroit ou de

remettre l'outil à une autre personne.

F

33

Page 34

12. DÉCONNECTER SEULEMENT LE CONNECTEUR RAPIDE avec la

portion arrière du carter de l'entrée d'air, aucun air comprimé ne

peut être garanti lors de la déconnexion. Si l'opération n'est pas

correcte, l'outil reste chargé en air après avoir été déconnecté et il

peut toujours entraîner une fixation et causer une blessure

corporelle.

13. REMPLACER LES PIÈCES ET LES ACCESSOIRES. Utiliser

uniquement les mêmes pièces de remplacement pour la

maintenance. Les accessoires et pièces de rechange homologués

sont disponibles

14. AVANT D'UTILISER L'OUTIL, vérifier prudemment s'il y a des

pièces endommagées pour obtenir des résultats parfaits. Ne pas

utiliser l'outil si celui entraîne des fuites, si des pièces sont

incomplètes, endommagées ou ont besoin d'être réparées.

15. NE JAMAIS UTILISER L'OUTIL si la sécurité, le déclencheur ou le

ressort sont inactifs, manquants ou endommagés. Ne pas modifier ou

retirer la sécurité, le déclencheur ou les ressorts. Effectuer des inspections

quotidiennes des mouvements libres de la réparation du déclencheur.

17. CONNECTER L'OUTIL À L'ALIMENTATION EN AIR AVANT de

charger les fixations pour éviter qu'une fixation ne soit éjectée

pendant la connexion: Le mécanisme d'entraînement de l'outil peut

tourner lorsque l'outil est connecté à l'alimentation en air. Lorsqu'il

n'est pas utilisé, retirer toutes les fixations du carter à clou.

18. TOUJOURS SUPPORTER QUE L'OUTIL CONTIENT DES FIXATIONS :

Toujours tenir l'outil éloigné de vous et des autres personnes en

permanence. Ne pas chahuter. Respecter l'outil comme un outil de

travail.

19. NE PAS CHARGER LES FIXATIONS avec le déclencheur ou la

sécurité enfoncée pour éviter l'éjection non intentionnelle d'une

fixation.

20. ÉLOIGNER LES DOIGTS DU DÉCLENCHEUR lorsqu'aucune

fixation n'est entraînée. Ne jamais porter l'outil avec un doigt sur

le déclencheur : l'outil éjectera une fixation si la sécurité est

déclenchée pendant que le déclencheur est enfoncé.

21. NE PAS UTILISER SUR LES ÉCHAFAUDAGES, les outils

D'ÉCHELLE équipées

d'une "activation par contact" ne doivent pas être utilisés :

- si un changement des emplacements d'entraînement est affecté

par des escaliers, des échelles ou des échafaudages.

- pour fermer les boîtes ou les caisses.

- pour fixer les systèmes de sécurité de transport.

22. ÉJECTER UNIQUEMENT LES FIXATIONS SUR UNE SURFACE DE

TRAVAIL : JAMAIS dans les matériaux trop durs

23. PRENDRE L'OUTIL FERMEMENT EN MAIN POUR GARDER LE

CONTRÔLE tout en permettant à l'outil de reculer de la surface de

travail lorsqu'une fixation est entraînée. Si le collier de sécurité est

autorisé à entrer en contact à nouveau avec la surface de travail

avant que le déclencheur ne soit relâché, une fixation indésirable sera

éjectée.

24.NE PAS ÉJECTER DES FIXATIONS par dessus d'autres fixations

ou avec l'outil à un angle trop abrupt : les fixations peuvent ricocher

et entraîner des blessures physiques.

25. NE PAS ÉJECTER DES FIXATIONS PRÈS DU bord de la pièce à

usiner. La pièce à usiner peut se rompre et faire voler la fixation ou

la faire ricocher et entraîner une blessure physique.

16. UTILISER UNIQUEMENT DES PIÈCES ET DES FIXATIONS

F

34

Page 35

26. RESTER ALERTE. Regardez ce que vous faites. Utiliser

votre bon sens. Ne pas utiliser un outil lorsque vous êtes

fatigué, évitez les blessures.

27. GARDER LES MAINS ET LES PARTIES DU CORPS éloignées de la

zone indiquée à l'ill. 13.

28. CET OUTIL EST ÉQUIPÉ D'UN AJUSTEUR qui peut être ajuster à la

profondeur d'entraînement. Lors de l'ajustement de la profondeur

d'entraînement, commencer par déconnecter l'alimentation d'air et

tourner le bouton de l'ajusteur manuellement.

29.LORSQU'IL N'EST PAS UTILISÉ, l'outil doit être nettoyé et replacé

dans l'emballage. Pour des raisons de sécurité, tenir hors de portée

des enfants.

RESPONSABILITÉS DE L'EMPLOYEUR

L'employeur doit garantir la conformité aux avertissements de sécurité et à toutes les autres

instructions de ce manuel.

Garder ce manuel disponible pour une utilisation par toutes les personnes autorisées à utiliser

cet outil. Pour la sécurité du personnel et une utilisation correcte de cet outil, lire et suivre

attentivement les présentes instructions.

SPÉCIFICATIONS DES FIXATIONS

Utiliser uniquement les fixations recommandées :

Min.

φ0.39˝

(φ10mm)

( φ3.1mm)

φ0.12˝

0.31˝

(8mm)

15o-16

o

Max.

φ0.39˝

(φ10mm)

15o-16

o

( φ3.1mm)

φ0.12˝

0.31˝

(8mm)

7/8" (22mm)

F

35

Page 36

PARAMÈTRES TECHNIQUES

Caractéristique Valeur

Pression de l'air comprimé 4.8-8.3 bar

Dimensions extérieures (Lxhxl) 300 × 310 × 110 mm

Plage de longueur des clous 22-45 mm

Poids de l'outil 2.75Kg

Entrée d'air

1/4"NPT

Consommation d'air 68 l/min à 5.52 bar

Description Qté

S45CNR Cloueuse à bobine

1

S5 Clé hexagonale

1

S4 Clé hexagonale

1

S3 Clé hexagonale

1

Huile pneumatique

1

Instructions d'utilisation 1

INFORMATIONS SONORES

Ces valeurs sonores caractéristiques sont conformes à la norme EN 12549:1999

LpA, 1s, d = 84dB

LwA, 1s, d = 97dB

Ces valeurs sont caractéristiques à l'outil et ne représentent pas le bruit développé sur

le point d'utilisation. Le design du poste de travail peut également servir à réduire les

niveaux sonores, par exemple en plaçant la pièce à usiner sur des supports isolants.

INFORMATIONS DE VIBRATION

Ces valeurs sont conformes à la norme ISO 8662-11:1999.

Valeur caractéristique de vibration ( m/s2 ) = 8,22

Cette valeur est une valeur caractéristique à l'outil et ne représente pas l'influence sur le

système main-bras lors de l'utilisation de l'outil.

CONTENU DE L'EMBALLAGE

Lunettes de sécurité

1

F

36

Page 37

PRÉAMBULE INSTRUCTIONS

D'UTILISATION

S45CNR est une cloueuse pneumatique solide, alimentée par une bobine qui utilise l'air

comprimé comme source d'énergie. Elle est conçue pour installer des clous de différentes

longueurs et de 22-45 mm ou 3,1 mm de diamètre. Elle est largement utilisée pour connecter

les cadres et connecter les cadres et le feutre. L'outil possède un corps en alliage de

magnésium et le capuchon cylindrique est léger et fournit une force et une rigidité spécifique.

SOURCE ÉLECTRIQUE

Cet outil est concu pour fonctionner avec de l'air comprimé propre, sec à des pressions régulées

de 4,8 et 8,3 bar. Le système privilégié inclut un filtre, un régulateur de pression et un huileur

automatique situé aussi près que possible de l'outil (idéalement à 15 pieds).

Tout air comprimé contient de l'humidité et d'autres contaminants pouvant nuire aux

composants internes de l'outil. Un filtre à air intégré éliminera la plupart de ces contaminants et

augmentera de manière significative la durée de vie de l'outil. Si un huileur intégré n'est pas

disponible: placer cinq ou six gouttes d'huile dans l'entrée d'air de l'outil au début de chaque

journée de travail.

Déconnecter uniquement le connecteur rapide de la portion arrière de l'entrée d'air. L'absence

d'air comprimé ne peut être garantie lors de la déconnexion. Si l'opération n'est pas correcte,

l'outil reste chargé en air après avoir été déconnecté et il peut toujours entraîner une fixation et

causer une blessure corporelle.

PRUDENCE : Tous les composants intégrés (tuyaux, connecteurs, filtres, régulateurs

etc.) doivent satisfaire 150 % de la pression maximale du système. Essayez d'utiliser

un tuyau d'ID 9,5 mm qui connecte la cloueuse à un compresseur lors de la

déconnexion.

Ne pas connecter cet outil à un système avec un potentiel maximum. Déconnecter uniquement

le connecteur rapide connecté au connecteur de l'entrée d'air arrière, l'absence d'air comprimée

ne peut pas être garantie lors du déplacement dans un autre endroit ou de la remise de l'outil à

une autre personne.

Déconnecter l'outil à l'alimentation d'air avant d'effectuer une maintenance, de nettoyer une

fixation bloquée, de quitter la zone de travail, de déplacer l'outil dans un autre endroit.

F

37

Page 38

PRÉPARER L'OUTIL AVANT L'ENTRAÎNEMENT

Après avoir lu et compris tout le manuel, connecter l'outil à l'alimentation d'air.

PRUDENCE: Toujours tenir l'outil éloigné de vous et des autres personnes.

Toujours connecter l'outil à l'alimentation d'air avant de charger les fixations. Ne pas

charger les fixations lorsque le déclencheur ou la sécurité sont activés. Toujours porter

des lunettes de sécurité homologuées et une protection auditive lors de la préparation ou

de l'utilisation de l'outil. Ne jamais utiliser un outil qui a une fuite d'air ou doit être

réparé.

Abaisser le levier (voir A, ill. 14) et ouvrir la languette. Faire pivoter le carter supérieur du clou vers

le côté du corps.

La plaque de l'ajusteur peut être déplacé de haut en bas lorsque l'écrou de l'ajusteur est tourné

(voir B ill. 15). En fonction de la longueur du clou, la plaque de l'ajusteur doit être ajustée

correctement sur la position indiquée à l'intérieur du carter inférieur du clou.

Placer une bobine de clous sur le carter inférieur du clou. Dérouler suffisamment de clous pour

atteindre le crochet d'alimentation et placer le second clou entre les dents sur le crochet

d'alimentation (voir illustration 16)

Fermer le carter inférieur du clou et abaisser la languette (voir ill. 17).

Ajuster le déflecteur directionnel de SORTIE (voir ill. 18) de sorte à ce que l'air expiré soit dirigé

loin de l'opérateur. Attraper le déflecteur et le faire tourner dans la position désirée pour

l'application en cours.

F

38

Page 39

34

UTILISER L'OUTIL

Effectuer toutes les étapes de PRÉPARATION DE L'OUTIL avant d'utiliser l'outil.

Déclencher l'outil : placer le nez sur la surface de travail, pousser légèrement l'outil vers la surface

de travail jusqu'à ce que l'élément de sécurité soit abaissé, ensuite, appuyer sur le déclencheur

pour éjecter les fixations. Cette méthode "de déclenchement" fournit le placement le plus précis

des fixations. Avec cette méthode, l'élément de sécurité peut être ajusté vers le bas avec le bouton

pour éviter de déclencher deux clous à la fois.

Le fabricant décline toute responsabilité pour les blessures et les pertes causées par une utilisation

incorrecte de cet outil.

PRUDENCE: Éloigner les doigts du déclencheur lorsque vous ne souhaitez pas éjecter de

fixations. Ne jamais porter l'outil avec un doigt sur le déclencheur : l'outil éjectera une

fixation si la sécurité est déclenchée. Toujours orienter l'outil dans une direction sûre.

Ne jamais essayer d'enfoncer une fixation dans un matériau qui est trop dur, à un angle trop

abrupt ou près du bord de la pièce à usiner. La fixation peut ricocher et entraîner une blessure

physique.

Déconnecter l'outil de l'alimentation d'air avant d'effectuer une maintenance, de nettoyer une

fixation bloquée, de quitter la zone de travail, de déplacer l'outil dans un autre endroit ou de

remettre l'outil à une autre personne. Nettoyer et inspecter l'outil chaque jour. Vérifier

prudemment que le déclencheur et le mécanisme de sécurité fonctionnent correctement.

Les supports pour le montage des outils de cloutage doivent être conçus de manière sûre. Ne pas

démonter ou modifier les pièces comme étrier de sécurité.

Ne pas utiliser l'outil à moins que le déclencheur et le mécanisme de sécurité soient fonctionnels ou

si l'outil a une fuite d'air ou a besoin de réparation.

3. La profondeur d'entraînement peut être augmentée ou diminuée en faisant tourner le bouton ou

l'ajusteur (A) ill. 19. Faites un test avec une fixation et vérifier la profondeur. Si le clou est enfoncé

trop profondément, faire tourner l'ajusteur dans le sens horaire pour que l'élément de sécurité soit

poussé vers le bas. Pendant ce temps, faire tourner le compteur de l'ajusteur dans le sens horaire

pour s'assurer que l'élément de sécurité est poussé vers le bas. Répéter cette étape pour atteindre

les résultats désirés (voir ill. 20).

NETTOYER UNE FIXATION BLOQUÉE

1. PRUDENCE: Déconnecter l'outil de l'alimentation d'air.

2. Ouvrir la languette, faire pivoter le carter inférieur et retirer les clous du carter inférieur.

3. Utiliser une corde en acier doux fuselée pour entraîner la lame dans sa position supérieure.

Utiliser une pince fine pour retirer la fixation bloquée (voir ill. 21).

4. Respecter les instructions de PRÉPARATION DE L'OUTIL AVANT ENTRAÎNEMENT pour recharger

les fixations.

F

39

Page 40

MAINTENANCE

NETTOYER ET INSPECTER CHAQUE JOUR

PRUDENCE: Déconnecter l'outil de l'alimentation d'air avant le nettoyage et

l'inspection. Corriger tous les problèmes avant utilisation.

Vérifier chaque semaine le filtre du compresseur et éteindre la valve manuelle pour drainer

l'eau et les contaminations.

Ne pas mouiller l'outil avec des solutions nettoyantes. Ces solutions peuvent endommager les

pièces internes. La portion exposée de la petite tige à piston et du crochet d'alimentation doit

être toujours propre.

Inspecter le déclencheur et le mécanisme de sécurité pour s'assurer que le système est

complet et fonctionnel: aucune pièce en vrac ou manquante, aucune pièce colmatée ou

collante.

Bien visser les vis. Les vis mal serrées peuvent entraîner des blessures corporelles ou des

dommages matériels. Vérifier s'il y a des pièces usées ou endommagées. Le cas échéant, les

remplacer immédiatement.

Si l'outil est utilisé sans un huileur intégré: placer 5 ou 6 gouttes d'huile dans l'entrée d'air de

l'outil au début de chaque jour de travail.

ENTRETIEN ET RÉPARATIONS

Tout outil de qualité a besoin de pièces de rechange en raison de l'usure due à une utilisation

normale. Certains composants pouvant être entretenus par l'utilisateur sont décrits dans le

paragraphe RÉSOLUTION DES DÉFAUTS. Toutes les réparations effectuées par des centres

locaux sont garanties du point de vue des vices matériels et de fabrication. Nous ne pouvons

pas garantir les réparations faites ou tentées par des personnes autres que ces centres.

Si vous avez des questions sur votre outil, veuillez contacter votre revendeur. Dans toute

communication, donnez toutes les informations indiquées sur la plaque signalétique de votre

outil (numéro de modèle, type, numéro de série etc.)

RÉSOLUTION DES DÉFAUTS

PRUDENCE : Déconnecter l'outil de l'alimentation d'air avant toute procédure de

maintenance.

PROBLÈME CAUSE SOLUTION

Fuite d'air dans la zone de

déclenchement

1. Le joint torique dans la tige

de vanne du déclencheur est

usée et endommagée.

2. Le joint torique dans la tête

de vanne du déclencheur est

usée et endommagée.

3. Autres problèmes.

1. Vérifier/remplacer le

joint torique/le lubrifiant.

2. Vérifier/remplacer le

joint torique/le lubrifiant.

3. Vérifier l'outil/le

lubrifiant

Fuite d'air sur la partie

inférieure du carter et le

nez

1. La vis est mal serrée sur la

portion de connexion du nez

et du carter.

2. Le joint torique est

endommagé entre le carter et

le nez.

3. Le tampon est endommagé.

4. Autres problèmes sur la

portion de contact du tampon

et du corps.

1. Visser la vis/revérifier

2. Vérifier/remplacer le joint

torique/le lubrifiant.

3. Remplacer le tampon.

4. Démonter et nettoyer

Fuite d'air sur la partie du

carter et le capuchon du

cylindre

1. Outil sec, manque de

lubrifiant.

2. Le ressort du capuchon du

cylindre est endommagé.

1. Utiliser de l'huile

pneumatique

2. Remplacer le ressort

dans le capuchon du cylindre.

L'outil ne démarre pas.

1. Outil sec, manque de

lubrifiant.

2. Le ressort du capuchon du

cylindre est endommagé.

1. Utiliser de l'huile pneumatique

2. Remplacer le ressort

dans le capuchon du cylindre.

F

40

Page 41

PROBLÈME CAUSE SOLUTION

La lame entraîne les

fixations trop

profondément

1. La position de l'élément de

sécurité n'est pas correcte.

2. La pression d'air est trop

élevée.

1. Faire tourner le bouton de

l'ajusteur pour déplacer l'élément

de sécurité vers le bas.

2. Faire baisser la pression de

l'air.

Des fixations/l'alimentation

sont passées par

intermittence

1. Autres problèmes

entre le petit piston et le petit

cylindre.

2. Le joint torique sur le petit

piston est usé et endommagé.

3. Outil sec, manque de

lubrifiant.

4. Le ressort du petit piston est

endommagé.

5. La pression d'air est trop

faible.

6. La vis de connexion du nez et

du carter n'est pas assez serrée.

7. Le crochet d'arrêt ne peut pas

arrêter les fixations.

8. Fixations pliées.

9. Mauvaise taille de fixations.

10. Le tampon du petit piston est

usé et endommagé.

11. Le crochet d'alimentation

colmate.

12. La longueur de clou n'est pas

correcte avec un espace de

chargement du carter du clou.

13. Les câbles soudés dans la

bobine de clous sont cassés.

1. Démonter/nettoyer/lubrifier.

2. Vérifier/remplacer le joint

torique/lubrifier

3. Utiliser de l'huile pneumatique.

4. Remplacer le ressort du petit

piston.

5. Augmenter la pression de l'air

mais ne pas dépasser 8,3 bar.

6. Serrer toutes les vis.

7. Remplacer le ressort du

crochet d'arrêt.

8. Utiliser les fixations

recommandées.

9. Utiliser les fixations

recommandées.

10. Remplacer le tampon et

lubrifier le petit piston.

11. Nettoyer le crochet

d'alimentation et le ressort de

torsion.

12. Ajuster la plaque de

l'ajusteur sur la portion arrière

du carter du clou en fonction de

la longueur de clou

recommandée pour que la flèche

de la partie arrière du carter du

clou pointe dans la bonne

direction.

13. Arrêter l'utilisation

Fonctionne plus lentement

ou a une perte de puissance

1. Outil sec, manque de

lubrifiant.