Page 1

OWNERS MANUAL FOR

PERMANENTLY LUBRICATED AIR COMPRESSOR

Accuset

MODEL NO.

PC2053-1

*A circuit breaker is preferred. Use only a fuse or circuit breaker that is the same rating as

the branch circuit the air compressor is operated on.

D23708 Rev. 0 3/20/01

Page 2

TABLE OF CONTENTS

Page

SAFETY GUIDELINES ........................... 2

WARNING CHART ............................ 3-5

GLOSSARY............................................ 6

SPECIFICATION CHART ......................6

DUTY CYCLE ........................................6

STORAGE ..............................................6

DESCRIPTION OF OPERATION...........7

INSTALLATION AND BREAK-IN

PROCEDURES .................................. 8-9

Location of Air Compressor ........... 8

Page

Voltage and Circuit Protection ......... 8

Extension Cords ...............................8

Grounding Instructions ..................... 8

Additional Regulators and

Controls ............................................8

Break-In Procedures .........................9

OPERATING PROCEDURES ................ 9

TROUBLESHOOTING GUIDE ....... 10-11

COMPRESSOR PARTS LIST ........ 12-15

WARRANTY ......................... Back Cover

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols

to the right. Please read the manual and pay attention to these sections.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death of serious injury.

D23708

CAUTION indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result

in property damage.

2-ENG

Page 3

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS INJURY AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS

EQUIPMENT. SAVE THESE INSTRUCTIONS. OWNER’S MANUAL SHOULD REMAIN WITH UNIT AT ALL TIMES.

HAZARD

RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN

IT IS NORMAL FOR ELECTRICAL CONTACTS WITHIN THE

MOTOR AND PRESSURE SWITCH TO SPARK.

IF ELECTRICAL SPARKS FROM COMPRESSOR COME INTO

CONTACT WITH FLAMMABLE VAPORS, THEY MAY IGNITE,

CAUSING FIRE OR EXPLOSION.

RESTRICTING ANY OF THE COMPRESSOR VENTILATION

OPENINGS WILL CAUSE SERIOUS OVERHEATING AND

COULD CAUSE FIRE.

UNATTENDED OPERATION OF THIS PRODUCT COULD

RESULT IN PERSONAL INJURY OR PROPERTY DAMAGE.

ALWAYS OPERATE THE COMPRESSOR IN A WELL VENTILATED AREA FREE OF COMBUSTIBLE MATERIALS,

GASOLINE OR SOLVENT VAPORS.

IF SPRAYING FLAMMABLE MATERIALS, LOCATE COMPRESSOR AT LEAST 20 FEET AWAY FROM SPRAY AREA. AN

ADDITIONAL LENGTH OF HOSE MAY BE REQUIRED.

STORE FLAMMABLE MATERIALS IN A SECURE LOCATION

AWAY FROM COMPRESSOR.

NEVER PLACE OBJECTS AGAINST OR ON TOP OF COMPRESSOR. OPERATE COMPRESSOR IN AN OPEN AREA AT

LEAST 12 INCHES AWAY FROM ANY WALL OR OBSTRUCTION THAT WOULD RESTRICT THE FLOW OF FRESH AIR TO

THE VENTILATION OPENINGS.

OPERATE COMPRESSOR IN A CLEAN, DRY, WELL VENTILATED

AREA. DO NOT OPERATE UNIT INDOORS OR IN ANY CON-

FINED AREA.

ALWAYS REMAIN IN ATTENDANCE WITH THE PRODUCT

WHEN IT IS OPERATING.

HOW TO PREVENT IT

RISK OF BURSTING

AIR TANK: THE FOLLOWING CONDITIONS COULD LEAD TO A WEAKENING OF THE TANK, AND RESULT IN A

VIOLENT TANK EXPLOSION AND COULD CAUSE PROPERTY DAMAGE OR SERIOUS INJURY.

WHAT CAN HAPPEN

1. FAILURE TO PROPERLY DRAIN CONDENSED WATER

FROM THE TANK, CAUSING RUST AND THINNING OF THE

STEEL TANK.

2. MODIFICATIONS OR ATTEMPTED REPAIRS TO THE TANK.

3. UNAUTHORIZED MODIFICATIONS TO THE UNLOADER

VALVE, SAFETY VALVE, OR ANY OTHER COMPONENTS

WHICH CONTROL TANK PRESSURE.

4. EXCESSIVE VIBRATION CAN WEAKEN THE AIR TANK

AND CAUSE RUPTURE OR EXPLOSION.

ATTACHMENTS & ACCESSORIES:

EXCEEDING THE PRESSURE RATING OF AIR TOOLS, SPRAY

GUNS, AIR OPERATED ACCESSORIES, TIRES AND OTHER

INFLATABLES CAN CAUSE THEM TO EXPLODE OR FLY

APART, AND COULD RESULT IN SERIOUS INJURY.

HOW TO PREVENT IT

DRAIN TANK DAILY OR AFTER EACH USE. IF TANK DEVELOPS A LEAK, REPLACE IT IMMEDIATELY WITH A NEW TANK OR

REPLACE THE ENTIRE COMPRESSOR.

NEVER DRILL INTO, WELD, OR MAKE ANY MODIFICATIONS

TO THE TANK OR ITS ATTACHMENTS.

THE TANK IS DESIGNED TO WITHSTAND SPECIFIC OPERATING

PRESSURES. NEVER MAKE ADJUSTMENTS OR PARTS

SUBSTITUTIONS TO ALTER THE FACTORY SET OPERATING

PRESSURES.

FOR ESSENTIAL CONTROL OF AIR PRESSURE, YOU MUST

INSTALL A PRESSURE REGULATOR AND PRESSURE GAUGE

TO THE AIR OUTLET OF YOUR COMPRESSOR. FOLLOW THE

EQUIPMENT MANUFACTURERS RECOMMENDATION AND

NEVER EXCEED THE MAXIMUM ALLOWABLE PRESSURE

RATING OF ATTACHMENTS. NEVER USE COMPRESSOR TO

INFLATE SMALL LOW-PRESSURE OBJECTS SUCH AS

CHILDREN’S TOYS, FOOTBALLS, BASKETBALLS. ETC.

3-ENG

D23708

Page 4

HAZARD

RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN HOW TO PREVENT IT

THE COMPRESSED AIR STREAM CAN CAUSE SOFT TISSUE

DAMAGE TO EXPOSED SKIN AND CAN PROPEL DIRT, CHIPS,

LOOSE PARTICLES AND SMALL OBJECTS AT HIGH SPEED,

RESULTING IN PROPERTY DAMAGE OR PERSONAL INJURY.

RISK TO BREATHING

WHAT CAN HAPPEN

THE COMPRESSED AIR FROM YOUR COMPRESSOR IS NOT

SAFE FOR BREATHING! THE AIR STREAM MAY CONTAIN

CARBON MONOXIDE, TOXIC VAPORS OR SOLID PARTICLES

FROM THE TANK.

ALWAYS WEAR ANSI Z87.1 APPROVED SAFETY GLASSES

WITH SIDE SHIELDS WHEN USING THE COMPRESSOR.

NEVER POINT ANY NOZZLE OR SPRAYER TOWARD ANY

PART OF THE BODY OR AT OTHER PEOPLE OR ANIMALS.

ALWAYS TURN THE COMPRESSOR OFF AND BLEED PRESSURE FROM THE AIR HOSE AND TANK BEFORE ATTEMPTING

MAINTENANCE, ATTACHING TOOLS OR ACCESSORIES.

HOW TO PREVENT IT

ALWAYS OPERATE AIR COMPRESSOR OUTSIDE IN A CLEAN,

WELL VENTILATED AREA. AVOID ENCLOSED AREAS SUCH AS

GARAGES, BASEMENTS, STORAGE SHEDS, WHICH LACK A

STEADY EXCHANGE OF AIR. KEEP CHILDREN, PETS AND

OTHERS AWAY FROM AREA OF OPERATION.

NEVER INHALE AIR FROM THE COMPRESSOR EITHER

DIRECTLY OR FROM A BREATHING DEVICE CONNECTED TO

THE COMPRESSOR.

SPRAYED MATERIALS SUCH AS PAINT, PAINT SOLVENTS,

PAINT REMOVER, INSECTICIDES, WEED KILLERS, CONTAIN

HARMFUL VAPORS AND POISONS.

RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN

YOUR AIR COMPRESSOR IS POWERED BY ELECTRICITY.

LIKE ANY OTHER ELECTRICALLY POWERED DEVICE, IF IT IS

NOT USED PROPERLY IT MAY CAUSE ELECTRIC SHOCK.

REPAIRS ATTEMPTED BY UNQUALIFIED PERSONNEL CAN

RESULT IN SERIOUS INJURY OR DEATH BY ELECTROCUTION.

ELECTRICAL GROUNDING: FAILURE TO PROVIDE ADEQUATE

GROUNDING TO THIS PRODUCT COULD RESULT IN SERIOUS

INJURY OR DEATH FROM ELECTROCUTION. SEE GROUND-

ING INSTRUCTIONS.

WORK IN AN AREA WITH GOOD CROSS-VENTILATION. READ

AND FOLLOW THE SAFETY INSTRUCTIONS PROVIDED ON

THE LABEL OR SAFETY DATA SHEETS FOR THE MATERIAL

YOU ARE SPRAYING. USE A NIOSH/MSHA APPROVED

RESPIRATOR DESIGNED FOR USE WITH YOUR SPECIFIC

APPLICATION.

HOW TO PREVENT IT

NEVER OPERATE THE COMPRESSOR OUTDOORS WHEN IT IS

RAINING OR IN WET CONDITIONS.

NEVER OPERATE COMPRESSOR WITH COVER COMPONENTS

REMOVED OR DAMAGED.

ANY ELECTRICAL WIRING OR REPAIRS REQUIRED ON THIS

PRODUCT SHOULD BE PERFORMED BY AUTHORIZED

SERVICE CENTER PERSONNEL IN ACCORDANCE WITH

NATIONAL AND LOCAL ELECTRICAL CODES.

MAKE CERTAIN THAT THE ELECTRICAL CIRCUIT TO WHICH

THE COMPRESSOR IS CONNECTED PROVIDES PROPER

ELECTRICAL GROUNDING, CORRECT VOLTAGE AND

ADEQUATE FUSE PROTECTION.

D23708

4-ENG

Page 5

HAZARD

RISK FROM MOVING PARTS

WHAT CAN HAPPEN

MOVING PARTS SUCH AS THE PULLEY, FLYWHEEL AND BELT

CAN CAUSE SERIOUS INJURY IF THEY COME INTO CONTACT

WITH YOU OR YOUR CLOTHING.

ATTEMPTING TO OPERATE COMPRESSOR WITH DAMAGED

OR MISSING PARTS OR ATTEMPTING TO REPAIR COMPRESSOR WITH PROTECTIVE SHROUDS REMOVED CAN

EXPOSE YOU TO MOVING PARTS AND CAN RESULT IN

SERIOUS INJURY.

RISK OF BURNS

WHAT CAN HAPPEN

TOUCHING EXPOSED METAL SUCH AS THE COMPRESSOR

HEAD OR OUTLET TUBES, CAN RESULT IN SERIOUS BURNS.

HOW TO PREVENT IT

NEVER OPERATE THE COMPRESSOR WITH GUARDS OR

COVERS WHICH ARE DAMAGED OR REMOVED.

ANY REPAIRS REQUIRED ON THIS PRODUCT SHOULD BE

PERFORMED BY AUTHORIZED SERVICE CENTER PERSONNEL.

HOW TO PREVENT IT

NEVER TOUCH ANY EXPOSED METAL PARTS ON COMPRESSOR DURING OR IMMEDIATELY AFTER OPERATION. COMPRESSOR WILL REMAIN HOT FOR SEVERAL MINUTES AFTER

OPERATION.

DO NOT REACH AROUND PROTECTIVE SHROUDS OR ATTEMPT

MAINTENANCE UNTIL UNIT HAS BEEN ALLOWED TO COOL.

RISK OF FALLING

WHAT CAN HAPPEN

A PORTABLE COMPRESSOR CAN FALL FROM A TABLE,

WORKBENCH OR ROOF CAUSING DAMAGE TO THE COM-

PRESSOR AND COULD RESULT IN SERIOUS INJURY OR

DEATH TO THE OPERATOR.

RISK OF PROPERTY DAMAGE WHEN TRANSPORTING

COMPRESSOR

(Fire, Inhalation, Damage to Vehicle Surfaces)

WHAT CAN HAPPEN

OIL CAN LEAK OR SPILL AND COULD RESULT IN FIRE OR

BREATHING HAZARD, SERIOUS INJURY OR DEATH CAN RESULT.

OIL LEAKS WILL DAMAGE CARPET, PAINT OR OTHER SURFACES

IN VEHICLES OR TRAILERS.

ESW-99 9/26/99

HOW TO PREVENT IT

ALWAYS OPERATE COMPRESSOR IN A STABLE SECURE

POSITION TO PREVENT ACCIDENTAL MOVEMENT OF THE

UNIT. NEVER OPERATE COMPRESSOR ON A ROOF OR

OTHER ELEVATED POSITION. USE ADDITIONAL AIR HOSE

TO REACH HIGH LOCATIONS.

HOW TO PREVENT IT

ALWAYS PLACE COMPRESSOR ON A PROTECTIVE MAT WHEN

TRANSPORTING TO PROTECT AGAINST DAMAGE TO VEHICLE

FROM LEAKS. REMOVE COMPRESSOR FROM VEHICLE IMMEDIATELY UPON ARRIVAL AT YOUR DESTINATION.

5-ENG

D23708

Page 6

SPECIFICATIONS

Model No.

Horsepower

SCFM @ 40 psig

SCFM @ 90 psig

Cut-In

Cut-Out

Voltage-Single Phase

Minimum Branch Circuit Requirement

*Fuse Type

Amperage at Max. Pressure

GLOSSARY

SCFM or CFM: Standard Cubic Feet per Minute; a unit

of measurement of air delivery.

PSIG or PSI: Pounds per square inch gauge.

CUT-IN PRESSURE: While the motor is off, air tank

pressure drops as you continue to use your accessory.

When the tank pressure drops to approximately 100 PSI

the motor will restart automatically. The low pressure at

PC2053-1

2

3.6

2.5

100 PSI

125 PSI

120/60/1

15 AMPS

Time Delay

10 AMPS

which the motor automatically re-starts is called "cut-in

pressure."

CUT-OUT PRESSURE: When you turn on your air compressor and it begins to run, air pressure in the air tank

begins to build. It builds to to approximately 125 PSI before

the motor automatically shuts off .The high pressure at

which the motor shuts off is called "cut-out pressure."

DUTY CYCLE

This air compressor's optimum life may be achieved by operating the unit at a 50 % duty cycle, or less.

A 50% duty cycle is considered to be 30 minutes of 'run time' in any 1 hour time period.

Should the unit operate at a greater than a 50% duty cycle, then the compressor may be undersized for the

required job demand and continued operation above a 50% duty cycle may constitute misuse of the product.

This air compressor is specifically designed for use in lighter duty

contractor finishing applications. Use in any other application requiring

higher performance or longer duty cycle operation may cause premature

failure.

STORAGE

When you have finished using the air compressor:

1. Set the "ON/OFF" switch to "OFF" and unplug the

cord.

3. Protect the electrical cord and air hose from damage

by winding them loosely around the air compressor.

2. Relieve all pressure from the air compressor head and

air hose by opening the regulator.

D23708

4. Store the air compressor in a clean and dry location.

6-ENG

Page 7

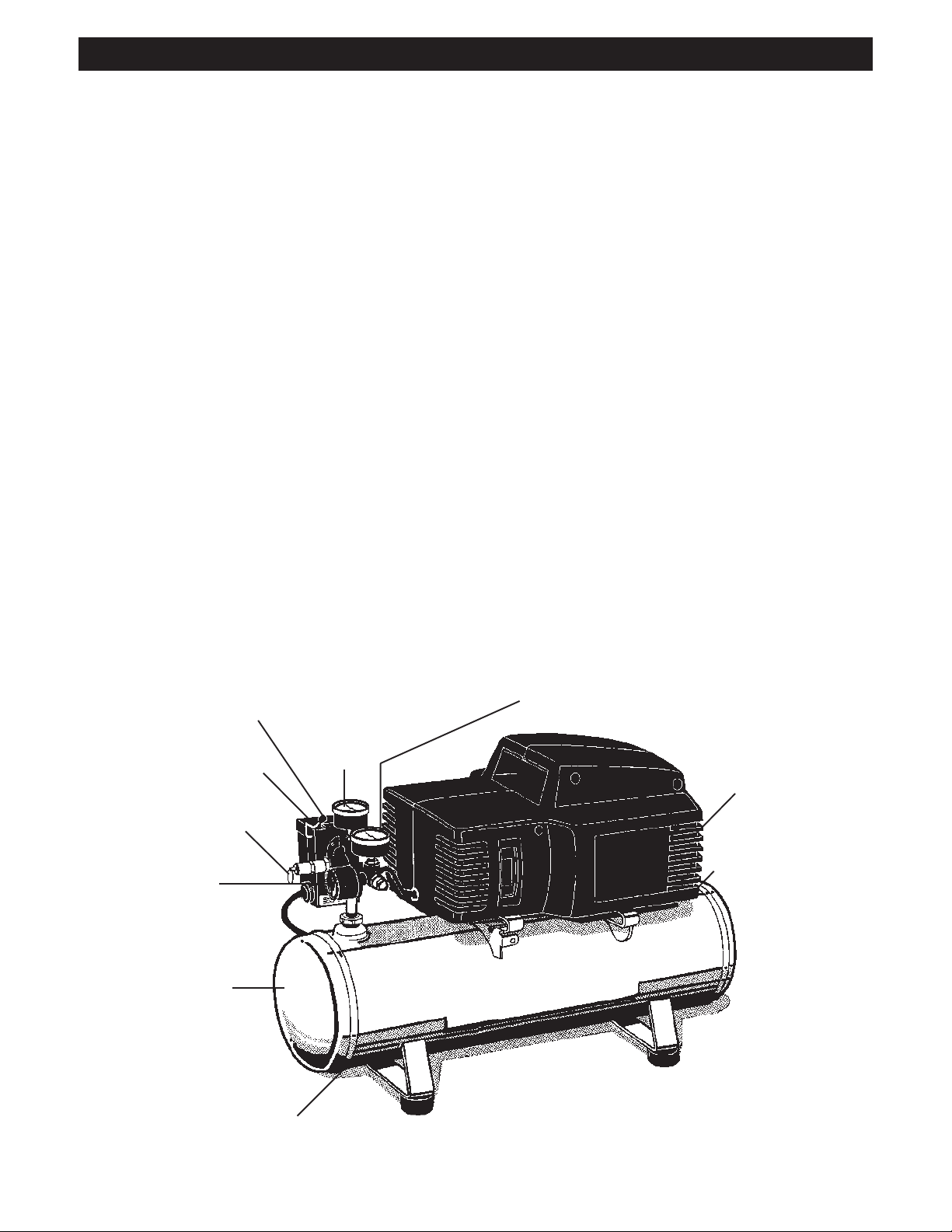

DESCRIPTION OF OPERATION

Air Compressor Pump (Included in compressor assembly): To compress air, the piston moves up and down

in the cylinder. On the downstroke, air is drawn in through

the air intake valves. The exhaust valves remain closed.

On the upstroke of the piston, air is compressed. The

intake valves close and compressed air is forced out

through the exhaust valves, through the outlet tubes,

through the check valve and into the air tank. Working air

is not available until the compressor has raised the air tank

pressure above that required at the air outlet.

Cooling System (Included in compressor assembly):

This compressor contains an advanced design cooling

system. At the heart of this cooling system is an engineered fan. It is perfectly normal for this fan to blow air

through the vent holes in large amounts. You know that the

cooling system is working when air is being expelled.

Air Intake Filter (Included in compressor assembly):

The unit requires no air filter due to the unique design of the

air intake system.

Check Valve (Not Shown): When the air compressor is

operating, the check valve is “open”, allowing compressed air to enter the air tank. When the air compressor

reaches “cut-out” pressure, the check valve “closes”,

allowing air pressure to remain inside the air tank.

Pressure Switch: The pressure switch automatically

starts the motor when the air tank pressure drops below

the factory set “cut-in” pressure. It stops the motor when

the air tank pressure reaches the factory set “cut-out”

pressure.

Regulator: The air pressure coming from the air tank is

controlled by the regulator. Turn the regulator knob

clockwise to increase pressure and counter-clockwise to

decrease pressure. To avoid minor readjustment after

making a change in pressure setting, always approach the

desired pressure from a lower pressure. When reducing

from a higher to a lower setting, first reduce to some

pressure less than that desired, then bring up to the

desiredpressure. Depending on the air requirements of

each particular accessory, the outlet regulated air pressure may have to be adjusted while operating the accessory.

Outlet Pressure Gauge: The outlet pressure gauge

indicates the air pressure available at the outlet side of the

regulator. This pressure is controlled by the regulator and

is always less or equal to the tank pressure. See

“Operating Procedures”.

Tank Pressure Gauge: The tank pressure gauge indicates the reserve air pressure in the tank.

Drain Valve (Not Shown): The drain valve is located at the

base of the air tank and is used to drain condensation at

the end of each use.

On/Auto-Off Switch: Turn this switch ON to provide

automatic power to the pressure switch and OFF to

remove power at the end of each use.

ON/AUTO-OFF

PRESSURE

SWITCH

SAFETY VALVE

REGULATOR

AIR TANK

(NOT ILLUSTRATED)

SWITCH

TANK PRESSURE

DRAIN VALVE

GAUGE

OUTLET PRESSURE GAUGE

COMPRESSOR

ASSEMBLY

CHECK VALVE

(Not Shown)

7-ENG

D23708

Page 8

INSTALLATION AND BREAK-IN PROCEDURES

Location of the Air Compressor

Your compressor comes to you completely assembled

and ready for use. Operate the air compressor in a dry,

clean, cool and well ventilated area. The air compressor

pump and case are designed to allow for proper cooling.

Clean or blow off dust or dirt that collects on the air

compressor. A clean air compressor runs cooler and

provides longer service. The ventilation openings on your

air compressor are necessary to maintain proper operating temperature. Do not place rags or other containers on

or near these openings.

Voltage and Circuit Protection

See specification chart on page 5.

Extension Cords

Use extra air hose instead of an extension cord to avoid

voltage drop and power loss to the motor.

If an extension cord must be used, be sure it is:

• a 3-wire extension cord that has a 3-blade grounding

plug, and a 3-slot receptacle that will accept the plug

on the compressor

• in good condition

• no longer than 50 feet

• 14 gauge (AWG) or larger. (Wire size increases as

gauge number decreases.) 12 AWG, 10 AWG and 8

AWG may also be used. DO NOT USE 16 OR 18

AWG.

Do not modify the plug that has been provided. If it does

not fit the available outlet, the correct outlet should be

installed by a qualified electrician.

If repairing or replacing cord or plug, the grounding wire

must be kept separate from the current-carrying wires.

Never connect the grounding wire to a flat blade plug

terminal. The grounding wire has insulation with an outer

surface that is green - with or without yellow stripes.

If these grounding instructions are not completely understood, or if in doubt as to whether the compressor is

properly grounded, have the installation checked by a

qualified electrician.

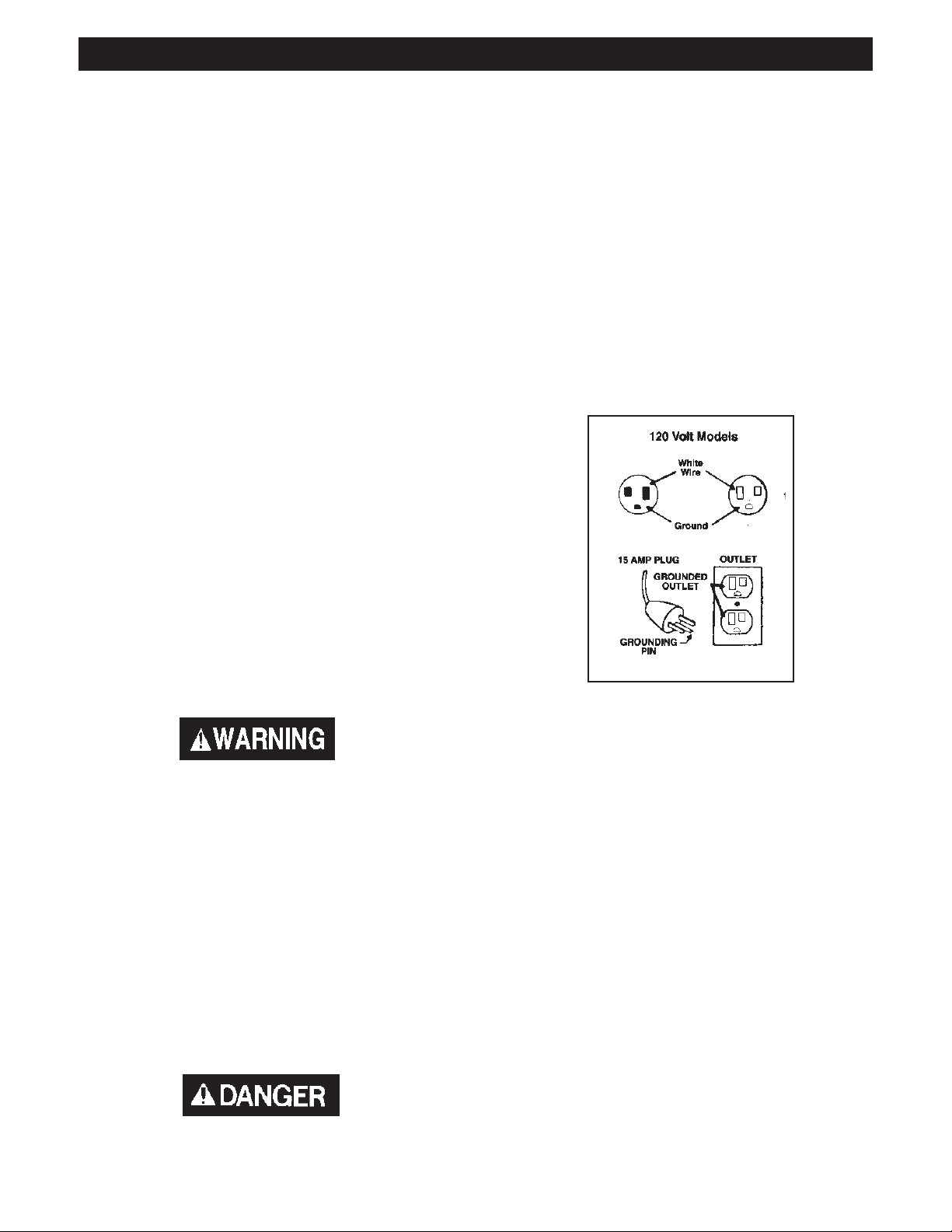

Grounding Instructions

RISK OF ELECTRICAL SHOCK! IN THE EVENT

OF A SHORT CIRCUIT, GROUNDING REDUCES

THE RISK OF SHOCK BY PROVIDING AN ESCAPE WIRE FOR THE ELECTRIC CURRENT.

THIS AIR COMPRESSOR MUST BE PROPERLY

GROUNDED.

The air compressor is equipped with a cord having a

grounding wire with an appropriate grounding plug. The

plug must be used with an outlet that has been installed

and grounded in accordance with all local codes and

ordinances. The outlet must have the same configuration

as the plug. See illustration. DO NOT USE AN ADAPT-

ER.

Inspect the plug and cord before each use. Do not use if

there are signs of damage.

IMPROPER GROUNDING CAN RESULT IN

ELECTRICAL SHOCK.

Additional Regulators and

Controls

Since the air tank pressure is usually greater than that

which is needed, a separate regulator is usually employed

to control the air pressure ahead of any individual air driven

device.

Separate air transformers which combine the function of air

regulation, moisture and dirt removal should be used

where applicable.

NOTE

It is not uncommon for the air tank

to contain some water from the

testing of the tank at the factory.

D23708

8-ENG

Page 9

INSTALLATION AND BREAK-IN PROCEDURES

Break-in Procedures

Serious damage may result if the following break-in instructions are not

closely followed.

This procedure is required:

1. Before the air compressor is put into service.

2. When the check valve is replaced.

a. Set the pressure switch lever to the "OFF"

position.

OPERATING PROCEDURES

1. Before attaching air hose or accessories, make sure

the OFF/AUTO lever is set to “OFF” and the air

regulator or shut-off valve is closed.

2. Attach hose and accessories.

b. Plug the power cord into the correct branch

circuit receptacle.

c. Turn the drain valve clockwise, opening it fully, to

prevent air pressure build-up in the tank.

d. Move the pressure switch lever to "ON/AUTO".

The compressor will start.

e. Run the compressor for 15 minutes. Make sure

the drain valve is open and there is little tank

pressure build-up.

f. After 15 minutes, close the drain valve by turning

counterclockwise. The air receiver will fill to cutout pressure and the motor will stop. The

compressor is now ready for use.

When you are finished:

6. Set the “OFF/AUTO” lever to “OFF”.

7. Turn the regulator counterclockwise and set the

outlet pressure to zero.

TOO MUCH AIR PRESSURE CAUSES A HAZARDOUS RISK OF BURSTING. CHECK THE MANUFACTURER'S MAXIMUM PRESSURE RATING

FOR AIR TOOLS AND ACCESSORIES. THE REGULATOR OUTLET PRESSURE MUST NEVER EXCEED THE MAXIMUM PRESSURE RATING. ON

MODELS HAVING ONLY A SHUT-OFF VALVE,

YOU MUST INSTALL A REGULATOR BEFORE

USING ACCESSORIES RATED AT LESS THAN

125 PSIG.

3. Turn the OFF/AUTO lever to “AUTO” and allow tank

pressure to build. Motor will stop when tank pressure

reaches “cut-out” pressure.

4. Open the regulator by turning it clockwise. Adjust the

regulator to the correct pressure setting. Your compressor is ready for use.

5. Always operate the air compressor in well-ventilated

areas; free of gasoline or other solvent vapors. Do not

operate the compressor near a paint spray area.

8. Remove the air tool or accessory.

9. Open the regulator and allow the air to slowly bleed

from the tank. Close the regulator when tank pressure is approximately 20 psi.

10. Drain water from air tank by opening drain valve

underneath the tank.

WATER WILL CONDENSE IN THE AIR TANK.

IF NOT DRAINED, WATER WILL CORRODE

AND WEAKEN THE AIR TANK CAUSING A

RISK OF AIR TANK RUPTURE.

NOTE

If drain valve is plugged, release all air

pressure. The valve can then be removed,

cleaned, then reinstalled.

11. After the water has been drained, close the drain

valve. The air compressor can now be stored.

9-ENG

D23708

Page 10

TROUBLESHOOTING GUIDE

PERFORMING REPAIRS MAY EXPOSE VOLTAGE SOURCES, MOVING PARTS OR COMPRESSED

AIR SOURCES. PERSONAL INJURY MAY OCCUR. PRIOR TO ATTEMPTING ANY REPAIRS,

UNPLUG THE COMPRESSOR AND BLEED OFF TANK AIR PRESSURE.

PROBLEM

Excessive tank pressure - safety

valve pops off.

Air leaks at fittings.

Air leaks at or inside check valve.

Air leaks at pressure switch

release valve.

CAUSE CORRECTION

Pressure switch does not shut off motor

when compressor reaches “cut-out”

pressure.

Pressure switch “cut-out” too high.

Tube fittings are not tight enough.

Defective or dirty check valve.

Defective pressure switch release valve.

Defective check valve.

Move the pressure switch lever to the “OFF” position.

If the unit doesn’t shut off, and the electrical contacts

are welded together, replace the pressure switch.

If the contacts are good, check to see if the pin in the

bottom of the pressure release valve is stuck. If it does

not move freely, replace the valve.

Return the unit to an authorized dealer to check and

adjust, or replace switch.

Tighten fittings where air can be heard escaping.

Check fittings with soapy water solution. DO NOT

OVER-TIGHTEN.

A defective check valve results in a constant air leak at

the pressure release valve where there is pressure in

the tank and the compressor is shut off. Remove and

clean or replace check valve. DO NOT OVER-TIGHTEN.

Remove and replace the release valve..

A defective check valve results in a constant air leak at

the pressure release valve when there is pressure in the

tank and the compressor is shut off. DO NOT OVERTIGHTEN.

Air leaks in air tank or at air tank

welds.

Pressure reading on the regulated pressure gauge drops

when an accessory is used.

D23708

Defective air tank.

It is normal for “some” pressure drop to

occur.

10-ENG

Air tank must be replaced. Do not repair the leak.

DO NOT DRILL INTO, WELD OR OTHERWISE

MODIFY AIR TANK OR IT WILL WEAKEN. THE

TANK CAN RUPTURE OR EXPLODE.

If there is an excessive amount of pressure drop when

the accessory is used, adjust the regulator following

the instructions on page 8.

NOTE

Adjust the regulated pressure under flow

conditions (while accessory is being used).

Page 11

TROUBLESHOOTING GUIDE

Air leak from safety valve.

Knocking Noise

Compressor is not supplying

enough air to operate accessories.

Motor will not run.

CAUSEPROBLEM

Possible defect in safety valve.

Defective check valve.

Prolonged excessive use of air.

Compressor is not large enough for air

requirement.

Hole in hose.

Air leaks. Tighten fittings. (See Air Leaks Section of

Tank pressure exceeds pressure switch

“cut-in” pressure.

Wrong gauge wire or length of extension cord.

Operate safety valve manually by pulling on ring. If

valve still leaks, it should be replaced.

Remove and clean, or replace.

Decrease amount of air usage.

Check the accessory air requirement. If it is higher than

the SCFM or pressure supplied by your air compressor, you need a larger compressor.

Check and replace if required.

Remove and clean, or replace.Check valve restricted.

Troubleshooting Guide.)

Motor will start automatically when tank pressure

drops below “cut-in” pressure of pressure switch.

Check for proper gauge wire and cord length.

CORRECTION

Check valve stuck open.

Loose electrical connections.

Paint spray on internal motor parts.

Possible defective motor.

Fuse blown, circuit breaker tripped.

Pressure release valve on pressure

switch has not unloaded head pressure.

Remove and clean, or replace.

Check wiring connection inside pressure switch and

terminal box area.

Have checked at an Authorized Warranty Service

Center. Do not operate the compressor in the paint

spray area. See flammable vapor warning.

Have checked at an Authorized Warranty Service

Center.

1. Check fuse box for blown fuse and replace, if

necessary. Reset circuit breaker. Do not use a

fuse or circuit breaker with higher rating than that

specified for your particular branch circuit.

2. Check for proper fuse. You should be using a

time delay fuse.

3. Check for low voltage conditions and/or proper

extension cord.

4. Disconnect the other electrical appliances from

circuit or operate the compressor in its own

branch circuit.

Bleed the line by pushing the lever on the pressure

switch to the “off” position; if the valve does not open,

replace it.

Regulator knob continuous air

leak. Regulator will not shut off

at air outlet.

Dirty or damaged regulator internal

parts.

11-ENG

Replace regulator.

D23708

Page 12

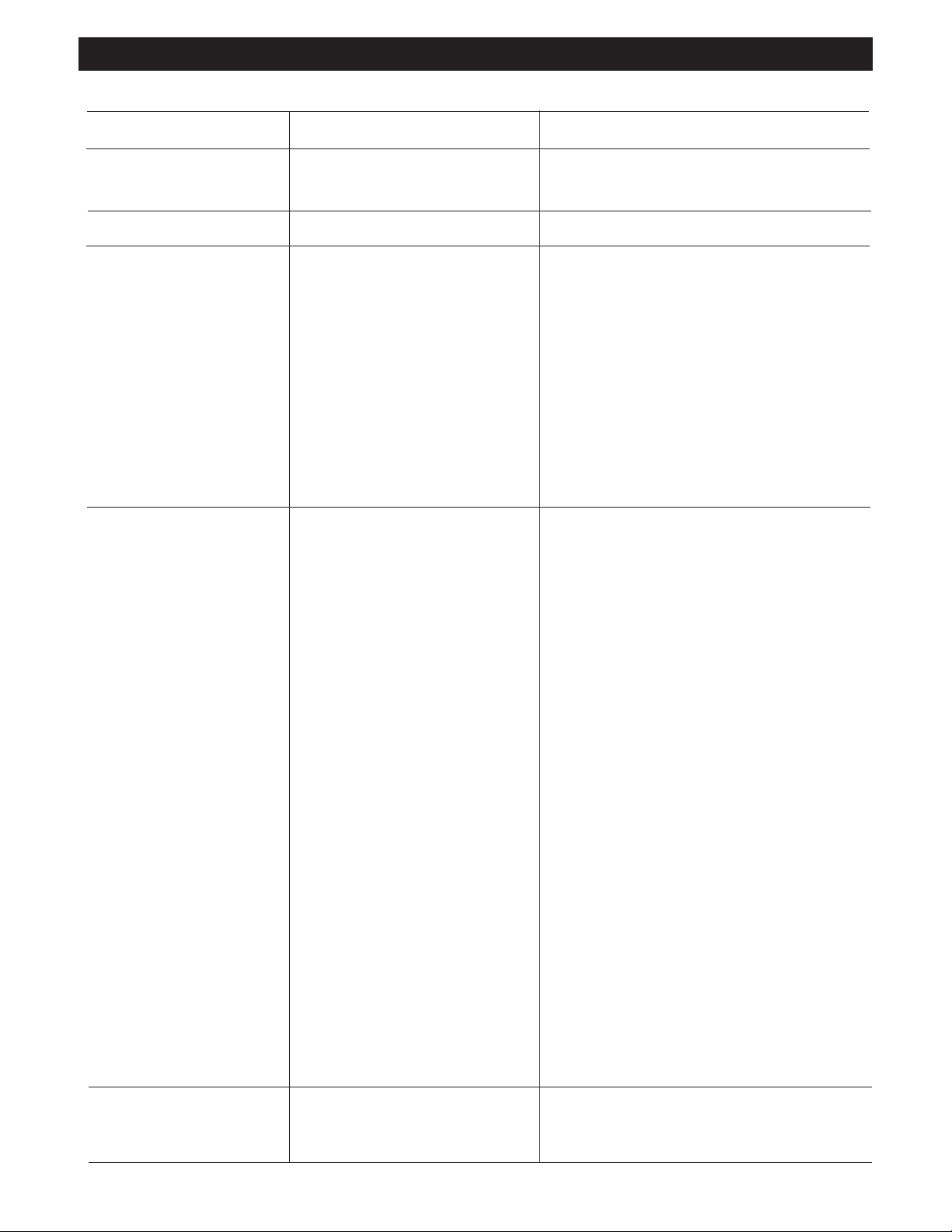

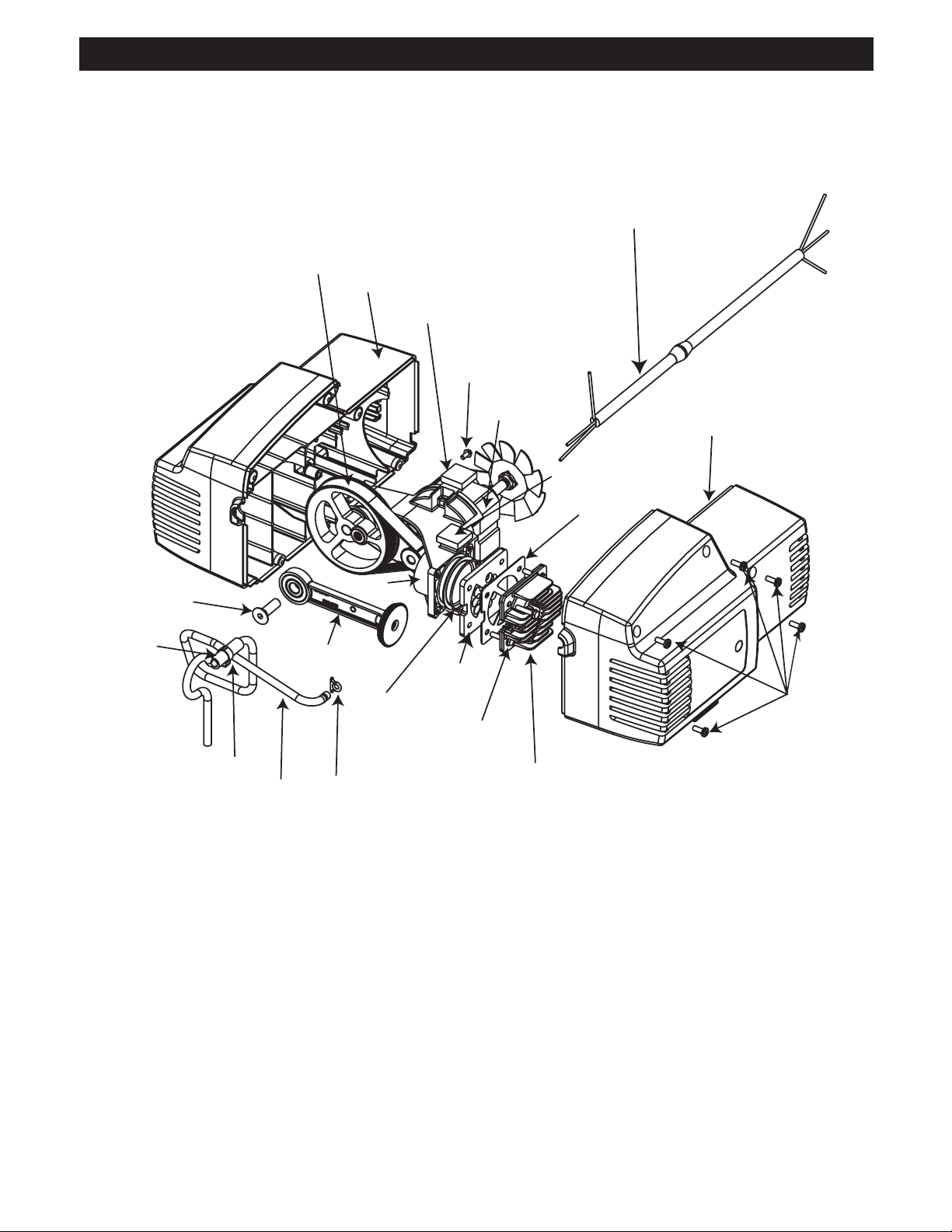

PARTS DIAGRAM

SSP-473

CAC-1275

SST-5314-1

SSF-607

CAC-1254

AC-0430

SSP-6021

DAC-4105-2

SSW-7367

SUDL-9-1

SSP-480

SSF-621

GA-352

AC81-B

CAC-4296-1

SS-1286

TIA-4150

SSW-7480

SUDL-403-1

D23708

12-ENG

Page 13

PARTS AVAILABLE FOR THIS UNIT

Part Number Description

* SSF-607 Screw (4 used)

* SST-5314-1 Bumper, Rubber (4 used)

* SSF-621 Screw, ¼-14 x .625

DAC-4105-2 Pressure Switch

* CAC-1254 Isolator Pump (4 used)

SSW-7480 Bushing Strain Relief

CAC-1275 Check Valve

SSP-473 Nut Sleeve

● Only Availiable with Pressure Switch

DAC-4105-2

SUDL-9-1 Screw, 8-32 x .375/.344 (2 used)

SSP-480 Nipple

SSW-7367 Bushing, Strain Relief

SUDL-403-1 Cord Assembly

AC-0430 Drain Valve

TIA-4150 Safety Valve

SS-1286 Nipple, ¼-18 NPT

CAC-4296-1 Regulator

AC81-B Quick Connect

GA-352 Gauge (2 used)

SSP-6021 Bushing, Reducer 1/8-1/4 NPT

13-ENG

D23708

Page 14

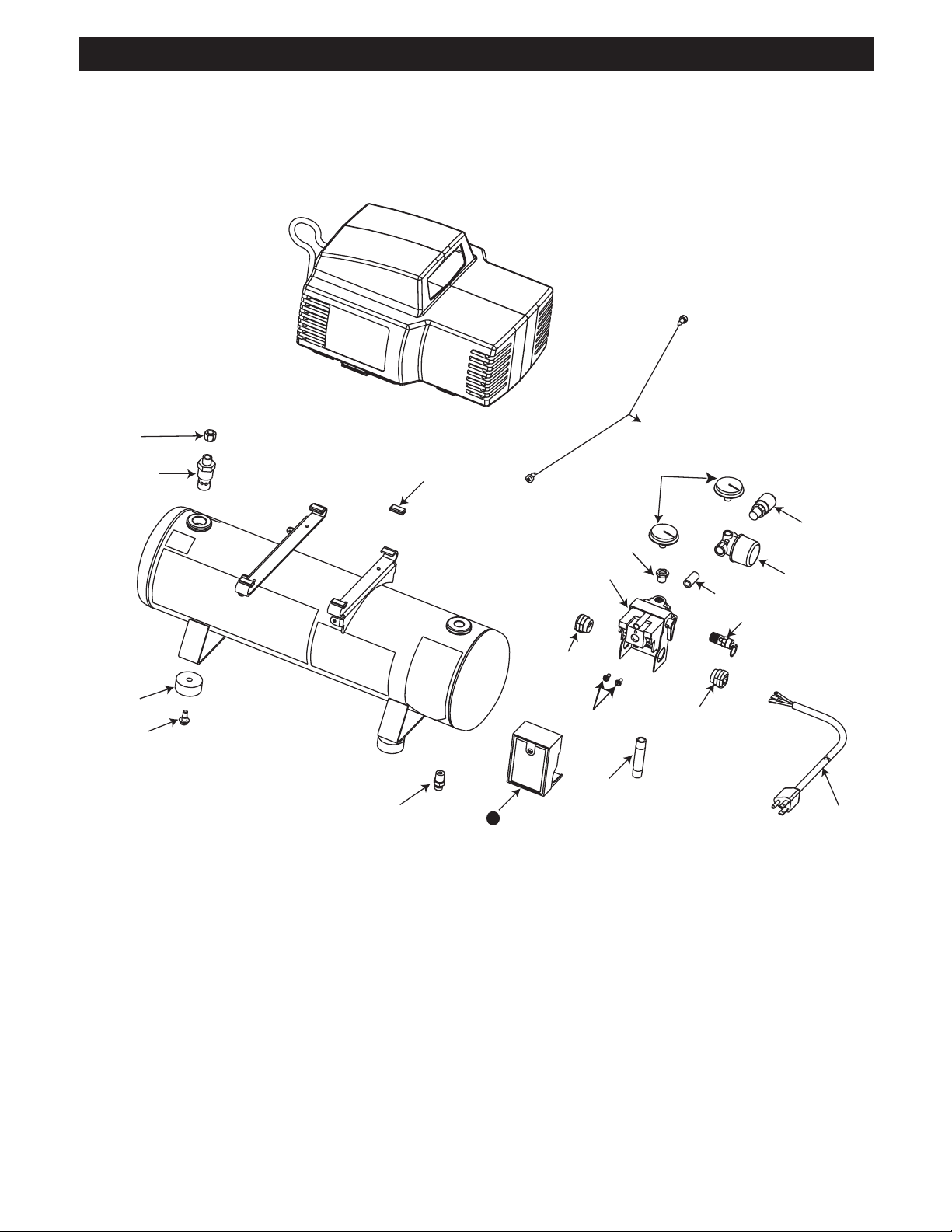

AIR COMPRESSOR DIAGRAM

D21919

AC-0815

AC-0470

CAC-1213

SUDL-9-1

D23584

CAC-1213

CAC-1199

AC-0471

SSF-3147

AC-0206

CAC-1206-1

DAC-269

+

+

SSG-8169

CAC-1212

CAC-4323

SSF-3156

SSF-995

CAC-1196

D23708

14-ENG

Page 15

PARTS LIST

Part Number Description

x SSF-995 Screw #10-24 x 7/8 LG. Hex head thd forming (4 used)

CAC-1196 Cylinder Head

* CAC-1212 Tube Seal

* CAC-1199 Gasket Head

CAC-4323 Valve Plate Assembly

* SSG-8169 O-ring

+ ————— Rod Assembly

x SSF-3147 Screw, 3/8-16 socket head

+ ————— Cylinder Sleeve

D23584 Endbell Assembly

AC-0815 Timing Belt

* CAC-1213 Pump Isolator (5 used)

x SUDL-9-1 Screw, 8-32x .375/.344

AC-0471 Shroud, Left

AC-0470 Shroud, Right

D21919 Motor Cord

DAC-269 Outlet Tube

CAC-1206-1 Clamp

AC-0206 Tube Isolator

x SSF-3156 Screw,10-90 x.50

* K-0387 – Isolator Kit

+ KK-4964 – Connecting Rod Kit

x KK-4929 – Fastener Kit

15-ENG

D23708

Page 16

ACCUSET COMPRESSOR AND PARTS WARRANTY

This compressor has been designed and constructed using the highest standards of material and workmanship.

COMPRESSOR WARRANTY:

Products, Inc., will repair or replace at Senco’s option, any original part or parts for the original retail purchaser. This will be done free of

charge, provided the parts are determined defective in materials or workmanship upon examination by a Senco/Accuset Authorized Warranty

Service Center, with the exceptions and exclusions described below. Any replacement part provided will carry a warranty for the balance

of the period of warranty applicable to the part it replaces. When repair or replacement of parts or compressor is necessary, the original retail

purchaser returns the complete compressor or part, with transportation prepaid, to the nearest Senco/Accuset Authorized Warranty Service

Center, with purchase receipt or other positive proof that the part or compressor is within the warranty period.

Accuset warrants all parts (except those listed below) of your Accuset air compressor to be free from defects in materials and workmanship

during the following periods:

Defective parts not subject to normal wear and tear will be repaired or replaced, at our (Senco’s) option, during warranty period. In any

event, reimbursement is limited to the purchase price paid.

EXCLUSIONS:

1. Engine/Motor is covered under separate warranty by its respective manufacturer and is subject to the terms set forth therein.

2. Normal wear parts not covered under warranty:

3. This warranty does not cover parts damaged due to normal wear, misapplication, misuse, accidents, operation at other

than recommended speeds or voltage (electric units only), improper storage, or damages resulting during shipping.

4. Deviation from operating instructions, specifications, and maintenance schedules.

5. Labor charges, loss or damage resulting from improper operation, maintenance or repairs made by person(s) other than a

Senco/Accuset Authorized Warranty Service Center.

6. The use of other than genuine Accuset Repair Parts will void warranty.

The length of this guarantee is one year from date of purchase by the original retail purchaser. During this period, Senco

1. For 1 year from date of original purchase:

Compressor Pump Pilot Valve

Tank Assembly Plumbing

Flywheel Throttle Control

Power Cord

2. For 90 days from date of original purchase:

Pressure Gauge Pressure Relief Valve

Draincocks

Isolators Drive Belt

Air Filter

This warranty is contingent upon proper use of the compressor by purchaser and does not cover:

WRITTEN, EXPRESS, OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, ARE EXCLUDED. BUYER’S OR USER’S REMEDIES ARE SOLELY AND EXCLUSIVELY AS STATED ABOVE.

SENCO PRODUCTS, INC. SHALL IN NO EVENT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, INDIRECT, OR SPECIAL DAMAGES.

IN NO EVENT, WHETHER AS A RESULT OF A BREACH OF CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE) OR OTHERWISE,

SHALL SENCO’S LIABILITY EXCEED THE PRICE OF THE COMPRESSOR WHICH HAS GIVEN RISE TO THE CLAIM OR LIABILITY. ANY

LIABILITY CONNECTED WITH THE USE OF THIS COMPRESSOR SHALL TERMINATE UPON THE EXPIRATION OF THE WARRANTY

PERIOD SPECIFIED ABOVE.

(A) Abnormal conditions, accident, neglect, misuse or improper storage of the unit.

(B) Deviation from operating or maintenance instructions.

(C) Modifications not authorized by Senco.

(D) Repairs or maintenance (other than routine air tank draining and oil filter changes required by your operating and

maintenance manual) made by persons other than Senco or its authorized agents.

(E) Freight damage.

THIS WARRANTY IS THE ONLY WARRANTY ON THIS COMPRESSOR, AND ALL OTHER WARRANTIES, WHETHER ORAL,

Replacement of Compressor Due to Natural Disaster

Senco will also replace any compressor destroyed by an Act of God such as flood, earthquake, hurricane or other disaster resulting only

from the forces of nature. Such a claim will be honored provided that such original retail purchaser had previously submitted a completed

warranty registration card, and then submits proof of ownership and an acceptable statement describing such Act of God documented

by an insurance carrier, police department, or other official governmental source. To obtain instructions for filing a claim call 1-888-222-

8144.

SENCO PRODUCTS, INC.

CINCINNATI, OHIO 45244-1611 USA

Page 17

MANUAL DEL OPERADOR PARA

COMPRESOR DE AIRE PERMANTEMENTE LUBRICADO

Accuset

MODELO NO.

PC2053-1

*Es preferible un interruptor de circuito. Usar sólo un fusible o interruptor de circuito del mismo

amperaje que el circuito en el cual está operando el compresor de aire.

D23708 Rev. 0 3/20/01

Page 18

TABLA DE CONTENIDOS

Página

PAUTAS DE SEGURIDAD.......................

2

CARTILLA DE ADVERTENCIAS ............ 3-5

TABLA DE SPECIFICACIONS .......... 5

GLOSARIO................................................ 6

CICLO DE USO ........................................ 6

ALMACENAJE ........................................... 6

DESCRIPCIÓN DE LA OPERACIÓN...... 7

INSTALACIÓN Y ASENTAMIENTO ... 8-9

Ubicación del Compresor de Aire ... 8

Voltaje y Protección del Circuito ..... 8

Página

Longitud de los cordones ................ 8

Instrucciones para

Conexión a Tierra ........................... 8

Reguladores y Controles

Adicionales ................................. 8

Procedimiento para el

Asentamiento .............................. 9

PROCEDIMIENTOS PARA OPERAR ... 9

GUÍA PARA DETECCIÓN DE

PROBLEMAS ........................ 10-11

LISTA DE REPUESTOS

PARA EL COMPRESOR ...... 12-15

GARANTÍA................. Cubierta Superior

DEFINICIONES DE NORMAS DE SEGURIDAD

Este manual contiene información que es importante que usted conozca y comprenda. Dicha información se relaciona con la protección

de SU SEGURIDAD PERSONAL y LA PREVENCIÓN DE PROBLEMAS PARA SU EQUIPO. A fin de ayudarlo a reconocer dicha información

usamos los símbolos que se muestran a la derecha. Sírvase leer este manual y prestar atención a

PELIGRO

PELIGRO indica una situación de inminente riesgo, la cual, si no

evitada, causará la muerte o lesiones serias.!

ADVERTENCIA

ADVERTENCIA indica una situación potencialmente riesgosa,

que si no es evitada, podría resultar en la muerte o lesiones serias.

D23708

PRECAUCION indica una situación potencialmente peligrosa, la

cual, si no es evitada, podría resultar en lesiones menores.

PRECAUCION usado sin el símbolo de seguridad de alerta indica

una situación potencialmente riesgosa la que, si no es evitada,

podría causar daños en la propiedad.

2-SP

PRECAUCION

PRECAUCION

Page 19

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

GUARDE ESTAS INSTRUCCIONES

LA OPERACIÓN O EL MANTENIMIENTO INADECUADOS DE ESTE PRODUCTO PODRÍAN OCASIONAR SERIAS LESIONES Y DAÑOS

A LA PROPIEDAD. LEA Y COMPRENDA TODAS LAS ADVERTENCIAS E INSTRUCCIONES DE FUNCIONAMIENTO ANTES DE UTILIZAR

ESTE EQUIPO. EL MANUAL DEL PROPIETARIO DEBERÍA PERMANECER TODO EL TIEMPO JUNTO A LA UNIDAD.

PELIGRO

RIESGO DE EXPLOSIÓN O INCENDIO

¿QUÉ PUEDE OCURRIR?

PARA LOS CONTACTOS ELÉCTRICOS ES NORMAL LA EXISTENCIA DE CHISPAS

ENTRE EL MOTOR Y EL INTERRUPTOR A PRESIÓN.

SI LAS CHISPAS ELÉCTRICAS PROVENIENTES DEL COMPRESOR TOMARAN

CONTACTO CON EMANACIONES DE MATERIALES INFLAMABLES, ELLOS

PODRÍAN ARDER ORIGINANDO INCENDIO O EXPLOSIÓN.

RESTRINGIR CUALQUIERA DE LAS ABERTURAS DE VENTILACIÓN CAUSARÁ UN

SERIO RECALENTAMIENTO Y PODRÍA PRODUCIR UN INCENDIO.

DEJAR DESATENDIDO ESTE PRODUCTO MIENTRAS EL MISMO ESTÁ EN

FUNCIONAMIENTO PUEDE RESULTAR EN LESIONES PERSONALES O DAÑOS

A LA PROPIEDAD.

RIESGO DE EXPLOSIÓN

¿CÓMO PREVENIRLO?

OPERE SIEMPRE EL COMPRESOR EN UN SECTOR BIEN VENTILADO Y LIBRE DE

MATERIALES COMBUSTIBLES, GASOLINA O EMANACIONES DE SOLVENTE.

EN UN ÁREA DE ROCIADO DE MATERIALES INFLAMABLES, UBIQUE AL COMPRESOR

POR LO MENOS A 6,1M (20 PIES) DE DISTANCIA DEL ÁREA DE ROCIADO.

PODRÍA REQUERIRSE UNA EXTENSIÓN DE LA MANGUERA.

ALMACENE LOS MATERIALES INFLAMABLES EN UNA UBICACIÓN SEGURA,

ALEJADOS DEL COMPRESOR.

JAMÁS COLOQUE OBJETOS APOYADOS O SOBRE EL COMPRESOR. OPERE

EL COMPRESOR EN UN SECTOR ABIERTO, POR LO MENOS A 30 CM (12

PULGADAS) ALEJADOS DE CUALQUIER PARED U OBSTRUCCIÓN QUE RESTRINJA

EL FLUJO DE AIRE FRESCO A LAS ABERTURAS DE VENTILACIÓN.

OPERE EL COMPRESOR EN UN SECTOR LIMPIO, SECO, Y BIEN VENTILADO,. NO

OPERE LA UNIDAD EN ESPACIOS CERRADOS O CUALQUIER ÁREA

CONFINADA.

MANTÉNGASE SIEMPRE ALERTA CADA VEZ QUE EL PRODUCTO ESTE

FUNCIONANDO.

TANQUE DE AIRE: LAS SIGUIENTES CONDICIONES PUEDEN DETERMINAR EL DEBILITAMIENTO DEL TANQUE, Y ORIGINAR

UNA VIOLENTA EXPLOSIÓN DEL MISMO, SIENDO CAUSA DE DAÑOS A LA PROPIEDAD O LESIONES SERIAS.

¿QUÉ PUEDE OCURRIR?

1. DRENAJE INADECUADO DEL AGUA CONDENSADA EN EL TANQUE,

SIENDO LA CAUSA DEL ÓXIDO QUE REDUCE EL ESPESOR DEL TANQUE

DE ACERO.

2. MODIFICACIONES O INTENTO DE REPARACIONES AL TANQUE.

3. MODIFICACIONES NO AUTORIZADAS A LA VÁLVULA DE DESCARGA,

VÁLVULA DE SEGURIDAD O CUALQUIER OTRO COMPONENTE QUE

CONTROLE LA PRESIÓN DEL TANQUE.

4. LA VIBRACIÓN EXCESIVA PUEDE DEBILITAR EL TANQUE DE AIRE Y

CAUSAR SU RUPTURA O EXPLOSIÓN. DICHA VIBRACIÓN EXCESIVA

OCURRIRÁ SI EL COMPRESOR NO ESTÁ ADECUADAMENTE MONTADO.

AGREGADOS Y ACCESORIOS

EL EXCESO A LOS VALORES DE PRESIÓN ESTABLECIDOS PARA LA

HERRAMIENTAS NEUMÁTICAS, PISTOLAS ROCIADORAS, ACCESORIOS

ACTIVADOS POR AIRE, CUBIERTAS Y OTROS OBJETOS INFLABLES, PUEDE

CAUSAR SU EXPLOSIÓN O SER ARROJADOS, PUDIENDO OCASIONAR

SERIAS LESIONES.

DRENE EL TANQUE DIARIAMENTE O DESPUÉS DE CADA USO. SI EL TANQUE

GENERA UNA PÉRDIDA, REEMPLÁCELO INMEDIATAMENTE CON UN NUEVO

TANQUE O REEMPLACE EL COMPRESOR COMPLETO.

JAMÁS PERFORE, SUELDE, O EFECTÚE MODIFICACIÓN ALGUNA AL TANQUE

O SUS ACCESORIOS.

EL TANQUE ESTÁ DISEÑADO PARA RESISTIR PRESIONES OPERATIVAS

ESPECÍFICAS. JAMÁS EFECTÚE AJUSTES O SUSTITUYA PARTES QUE ALTEREN

LAS REGULACIONES DE PRESIÓN ORIGINALES DE FÁBRICA.

PARA UN CONTROL ESENCIAL DE LA PRESIÓN, DEBE USTED INSTALAR UN

REGULADOR Y UN MEDIDOR DE PRESIÓN A LA SALIDA DEL AIRE DE SU

COMPRESOR. SIGA LAS RECOMENDACIONES DE LOS FABRICANTES DE SU

EQUIPO Y JAMÁS EXCEDA LOS VALORES MÁXIMOS DE PRESIÓN PERMITIDOS

PARA LOS ACCESORIOS. JAMÁS USE EL COMPRESOR PARA INFLAR OBJETOS

QUE REQUIEREN POCA O BAJA PRESIÓN, TALES COMO JUGUETES PARA

LOS NIÑOS, PELOTAS DE FÚTBOL, PELOTAS DE BASQUET, ETC.

3-SP

¿CÓMO PREVENIRLO?

D23708

Page 20

PELIGRO

RIESGO DE OBJETOS ARROJADOS POR EL AIRE.

¿QUÉ PUEDE OCURRIR?

EL CHORRO DE AIRE COMPRIMIDO PUEDE CAUSAR DAÑOS SOBRE LOS

TEJIDOS BLANDOS DE LA PIEL EXPUESTA, Y PUEDE PROPULSAR SUCIEDAD,

ASTILLAS, PARTÍCULAS SUELTAS Y PEQUEÑOS OBJETOS A ALTA VELOCIDAD,

OCASIONANDO DAÑOS A LA PROPIEDAD O LESIONES PERSONALES.

RIESGO DE INHALACIÓN

¿QUÉ PUEDE OCURRIR?

EL AIRE COMPRIMIDO DE SU COMPRESOR ¡NO ES SANO PARA SER INHALADO!

EL CHORRO DE AIRE PUEDE CONTENER MONÓXIDO DE CARBONO, EMANACIONES

TÓXICAS O PARTÍCULAS SÓLIDAS PROVENIENTES DEL TANQUE.

EL ROCIADO DE MATERIALES TALES COMO PINTURA, SOLVENTES,

REMOVEDORES DE PINTURA, INSECTICIDAS, MATA HIERBAS, CONTIENEN

EMANACIONES DAÑINAS Y VENENOSAS.

¿CÓMO PREVENIRLO?

AL UTILIZAR EL COMPRESOR, USE SIEMPRE ANTEOJOS DE SEGURIDAD

Z87.1 APROBADOS, CON PROTECCIÓN LATERAL.

JAMÁS APUNTE NINGUNA BOQUILLA O PULVERIZADOR HACIA PARTES DEL

CUERPO, A OTRAS PERSONAS O ANIMALES.

APAGUE SIEMPRE EL COMPRESOR Y PURGUE LA PRESIÓN DE LA MANGUERA

DEL AIRE Y DEL TANQUE, ANTES DE INTENTAR EL MANTENIMIENTO, EL ACOPLE

DE HERRAMIENTAS O ACCESORIOS.

¿CÓMO PREVENIRLO?

OPERE SIEMPRE EL COMPRESOR DE AIRE EN UNA ZONA EXTERNA, LIMPIA

Y BIEN VENTILADA. EVITE LAS ÁREAS CERRADAS TALES COMO GARAJES,

SÓTANOS, ÁREAS CUBIERTAS DE ALMACENAJE, QUE CARECEN DE CONTINUO

RECAMBIO DE AIRE. MANTENGA ALEJADOS A LO NIÑOS, ANIMALES DOMÉSTICOS

Y OTROS FUERA DEL SECTOR DE OPERACIONES.

JAMÁS INHALE EL AIRE PROVENIENTE DEL COMPRESOR TANTO

DIRECTAMENTE O DESDE UN RESPIRADOR INSTALADO AL COMPRESOR.

TRABAJE EN UN ÁREA CON BUENA VENTILACIÓN CRUZADA. LEA Y SIGA LAS

INSTRUCCIONES DE SEGURIDAD PROVISTAS EN EL RÓTULO O EN LOS DATOS

DE LAS HOJAS DE SEGURIDAD DEL MATERIAL QUE ESTÁ PULVERIZANDO. USE

EL RESPIRADOR APROBADO NIOSH/MSHA DESIGNADO PARA UTILIZARSE CON

SU APLICACIÓN ESPECÍFICA.

¿QUÉ PUEDE OCURRIR?

SU COMPRESOR DE AIRE ESTÁ ACCIONADO POR ELECTRICIDAD. COMO

CUALQUIER OTRO DISPOSITIVO ELÉCTRICO IMPULSADO ELÉCTRICAMENTE, SI

NO SE LO UTILIZA ADECUADAMENTE, PODRÍA CAUSARLE UNA DESCARGA

ELÉCTRICA.

LAS REPARACIONES INTENTADAS POR PERSONAL NO CALIFICADO PODRÍAN

OCASIONAR SERIAS LESIONES O LA MUERTE POR ELECTROCUCIÓN.

CONEXIÓN A TIERRA: DEJAR DE PROVEER UNA ADECUADA CONEXIÓN A

TIERRA A ESTE PRODUCTO PODRÍA OCASIONAR LESIONES SERIAS O LA

MUERTE POR ELECTROCUCIÓN. VER INSTRUCCIONES PARA LA PUESTA A

TIERRA.

D23708

¿CÓMO PREVENIRLO?

JAMÁS OPERE EL COMPRESOR A LA INTEMPERIE CUANDO ESTÁ LLOVIENDO O

EN CONDICIONES DE HUMEDAD.

NUNCA OPERE EL COMPRESOR SIN SUS DEFENSAS O SUS CUBIERTAS

REMOVIDAS O DAÑADAS.

CUALQUIER CONEXIÓN ELÉCTRICA O REPARACIÓN REQUERIDA POR ESTE

PRODUCTO DEBE SER EFECTUADA POR PERSONAL AUTORIZADO DE LOS

SERVICENTROS DE ACUERDO A LOS CÓDIGO ELÉCTRICOS NACIONALES Y

LOCALES.

ASEGÚRESE QUE EL CIRCUITO ELÉCTRICO AL CUAL ESTÁ CONECTADO EL

COMPRESOR, SUMINISTRA APROPIADA CONEXIÓN A TIERRA, TENSIÓN

CORRECTA Y UNA ADECUADA PROTECCIÓN DE FUSIBLES.

4-SP

Page 21

PELIGRO

RIESGO DE PARTES MÓVILES

¿QUÉ PUEDE OCURRIR? ¿CÓMO PREVENIRLO?

PARTES MOVIBLES TALES COMO LA POLEA, EL VOLANTE Y LA CORREA

PODRÍAN SER LA CAUSA DE SERIAS LESIONES SI ELLAS ENTRARAN EN

CONTACTO CON USTED O SUS ROPAS.

INTENTAR OPERAR EL COMPRESOR CON SUS PARTES DAÑADAS O

FALTANTES, O LA REPARACIÓN DEL COMPRESOR CON SUS PROTECCIONES

REMOVIDAS, PUEDE EXPONERLO A USTED A PARTES MOVIBLES, QUE

PODRÍAN RESULTAR EN LESIONES SERIAS.

RIESGO DE QUEMADURAS

NUNCA OPERE EL COMPRESOR SIN SUS DEFENSAS O SUS CUBIERTAS

REMOVIDAS O DAÑADAS.

CUALQUIER REPARACIÓN REQUERIDA POR ESTE PRODUCTO DEBE SER

EFECTUADA POR PERSONAL AUTORIZADO DE LOS SERVICENTROS.

¿QUÉ PUEDE OCURRIR?

TOCAR EL METAL EXPUESTO TAL COMO EL CABEZAL DEL COMPRESOR O LOS

TUBOS DE SALIDA DEL ESCAPE, PUEDEN OCASIONARLE SERIAS QUEMADURAS.

JAMÁS TOQUE PARTES DE METAL EXPUESTAS, EL COMPRESOR DURANTE

O INMEDIATAMENTE DESPUÉS DE LA OPERACIÓN. EL COMPRESOR

PERMANECERÁN CALIENTES POR VARIOS MINUTOS LUEGO DE LA OPERACIÓN.

NO LO CUBRA CON FUNDAS PROTECTORAS O INTENTE EL MANTENIMIENTO

HASTA QUE LA UNIDAD HAYA ALCANZADO SU ENFRIAMIENTO.

RIESGO DE CAIDAS

¿QUÉ PUEDE OCURRIR?

UN COMPRESOR PORTÁTIL PUEDE CAERSE DE LA MESA, EL BANCO DE

TRABAJO O DEL TECHO DAÑANDO AL COMPRESOR Y PUDIENDO RESULTAR

EN SERIAS LESIONES O LA MUERTE DEL OPERADOR.

OPERE SIEMPRE EL COMPRESOR EN UNA POSICIÓN ESTABLE Y SEGURA

A FIN DE PREVENIR EL MOVIMIENTO ACCIDENTAL DE LA UNIDAD. JAMÁS OPERE

EL COMPRESOR SOBRE UN TECHO U OTRA POSICIÓN ELEVADA. UTILICE

MANGUERAS ADICIONALES DE AIRE PARA ALCANZAR POSICIONES ALTAS.

RIESGO DE DAÑOS A LA PROPIEDAD AL TRANSPORTAR

EL COMPRESOR

¿CÓMO PREVENIRLO?

¿CÓMO PREVENIRLO?

(Fuego, inhalación, daño a la superficie de vehículos)

¿QUÉ PUEDE OCURRIR?

EL ACEITE PUEDE DERRAMARSE Y ELLO PODRÍA RESULTAR EN SERIAS

LESIONES O LA MUERTE DEBIDO AL RIESGO DE INCENDIO O INHALACIÓN. EL

DERRAME DE ACEITE DAÑA ALFOMBRAS, PINTURAS U OTRAS SUPERFICIES DE

VEHÍCULOS O REMOLQUES.

¿CÓMO PREVENIRLO?

DEPOSITE EL COMPRESOR SOBRE UNA ALFOMBRILLA PROTECTORA CUANDO

LO TRANSPORTE, A FIN DE PROTEGER AL VEHÍCULO DE PÉRDIDAS POR GOTEO.

RETIRE EL COMPRESOR DEL VEHÍCULO INMEDIATAMENTE DESPUÉS DE SU

ARRIBO AL DESTINO.

5-SP

D23708

Page 22

TABLA DE ESPECIFICACIONES

Modelo No. PC2053-1

Caballaje 2

SCFM @ 40 psig 3.6

SCFM @ 90 psig 2.5

Entra a operar 100 PSI

Deja de operar 125 PSI

Requerimiento de voltaje 120/60/1

Requerimiento Mínimo de Circuito 15 Amps

* Tipo de fusible Fusible de Retardo

Amperaje a máx. Presión 10 (Efectivo)

Tamaño de tanque 2.5 Galones

GLOSARIO

SCFM O CFM: Pies cúbicos estándar por minuto; una

medida para el aire producido.

PSIG o PSI: libras por pulgada cuadrada de calibre.

PRESIÓN DE ARRANQUE: Cuando el motor está apagado,

la presión de aire va disminuyendo conforme usted continua usando el accesorio. Cuando la presión del tanque

cae a aproximadamente 100 PSI, el motor arranca

automáticamente. Esa baja presión a la cual el motor

arranca automáticamente, se llama presión de arranque.

PRESIÓN DE CORTE: Cuando usted arranca el compresor

de aire y empieza a funcionar, el aire dentro del tanque

comienza a acumularse; cuando llegue a aproximadamente

125 PSI, el motor se apagará automáticamente. La presión

a la cual el motor se apaga se llama presión de corte.

CICLO DE TRABAJO

Para lograr la vida útil óptima de este compresor de aire, la unidad se debe operar a 50% de su ciclo de trabajo o

menos.

Se considera que el 50% de un ciclo de trabajo es 30 minutos de operación durante un periodo de 1 hora.

Si la unidad opera por más del 50% de un ciclo de trabajo, se considera que la unidad ha sido subdimensionada

para la demanda de esa aplicación, y la operación continuada por más del 50% del ciclo de trabaja constituye un

mal uso del producto.

Este compresor de aire esté especificamente diseñado para el uso de

contratistas en aplicacions ligeras de acabados. El uso operaciones que

requieren mayor rendimiento o un ciclo más prolongado de trabajo puede

hacer que falle prematuramente.

ALMACENAJE

Cuando termine usted de usar el compresor de aire:

1. Ponga el interruptor ON/OFF en posición de OFF

y desenchufe el cordón.

2. Descargar toda la presión del cabezal del compresor

de aire y manguera abriendo el regulador.

D23708

3. Proteger el cordón eléctrico y la manguera para que

no se dañen enrollándolos en forma suelta alrededor

del compresor de aire.

4. Almacenar el compresor de aire en un lugar limpio y

seco.

6-SP

Page 23

DESCRIPCIÓN DE LA OPERACIÓN

Bomba de Aire Comprimido (Incluido En El Conjunto

Del Compresseur): Para comprimir aire, el pistón se

mueve de arriba a abajo en el cilindro. En la carrera hacia

abajo, el aire ingresa por las válvulas de admisión. La

válvula de salida permanece cerrada. Cuando el pistón

corre hacia arriba, el aire se comprime. Las válvulas de

admisión se cierran y el aire comprimido es forzado a salir

por las válvulas de salida a través de los tubos, pasando por

la válvula de chequeo hacia el tanque de aire. El aire no está

disponible para trabajar hasta que la presión en el compresor

se haya acumulado por encima de lo requerido por la

boquilla de salida de aire.

Sistema de Enfriamiento (Incluido En El Conjunto Del

Compresseur): Este compresor tiene un sistema de

enfriamiento avanzado. En el centro de este sistema de

enfriamiento hay un ventilador especialmente diseñado.

Es perfectamente normal que el ventilador bote grandes

cantidades de aire por los orificios de ventilación. Se sabe

que el sistema de enfriamiento está funcionando cuando

expele aire.

Filtro de Entrada de Aire (Incluido En El Conjunto Del

Compresseur): El diseño avanzado de esta unidad hace

que no requiera filtro de aire.

arrancar el motor automáticamente cuando la presión del

tanque cae al nivel de la presión de arranque fijada en la

fábrica. También apaga el motor cuando la presión del

tanque de aire sube hasta el nivel de corte fijado en la

fábrica.

Regulador: La presión de aire proveniente del tanque de

aire está controlada por el regulador. Girar la perilla del

regulador en el sentido del reloj para aumentar la presión y

contra el sentido del reloj para reducir la presión.Para evitar

reajustes menores después de hacer cambios en la presión

fijada, siempre llegar a una presión superior a la deseada

salida deberá ajustarse mientras se opera el accesorio.

desde un nivel inferior de presión. Para reducir la presión,

siempre bajarla más abajo del nivel deseado y luego subirla

hasta el nivel que se desee. Dependiendo del requerimiento

de presión de cada accesorio en particular, la presión de

Medidor de Presión de Salida: El medidor de presión

indica la presión en la salida del regulador. Esta presión la

controla el regulador y siempre es menor o igual a la presión

del tanque. Ver los Procedimientos de Operación.

Medidor de Presión del Tanque: El medidor de presión

del tanque indica la presión dentro del tanque de reserva.

Válvula de Chequeo (No Se Muestra): Cuando el

compresor de aire está operando, la válvula está abierta,

permitiendo que el aire comprimido entre al tanque. Cuando

el compresor de aire llegue a la presión de corte, la válvula

de chequeo se cierra, haciendo que el aire se quede

dentro del tanque de aire.

Interruptor de Presión: El interruptor de presión hace

INTERRUPTOR

"ON/AUTO-OFF"

INTERRUPTOR

DE PRESIÓN

VÁLVULA DE

SEGURIDAD

REGULADOR

MEDIDOR DE

PRESIÓN DEL

TANQUE

Válvula de Drenaje (No Se Muestra): La válvula de

drenaje está ubicada en la base del tanque de aire y se

activa después de cada uso para drenar la condensación.

Interruptor ON/Auto-Off: Colocar este interruptor en la

posición de ON para proveer energía automáticamente al

interruptor de presión, y en OFF para quitarle la electricidad

después de cada uso.

MEDIDOR DE PRESIÓN DE SALIDA

COMPRESOR

ASAMBLEA

VÁLVULA DE

CHEQUEO

(No Se Muestra)

TANQUE DE AIRE

7-SP

D23708

Page 24

PROCEDIMIENTOS PARA LA INSTALACIÓN Y ASENTAMIENTO

Ubicación del Compresor de Aire

Su compresor viene completamente ensamblado y listo

para usar. Operar el compresor de aire en un área limpia,

fría y ventilada. El motor del compresor de aire y el casco

están diseñados para permitirles el enfriamiento adecuado.

Limpiar o soplar la tierra que se acumula en el compresor.

Un compresor limpio funciona más frío y tiene una vida útil

más larga. Las aberturas para ventilación en el compresor

de aire son necesarias para mantener la temperatura

adecuada durante su funcionamiento. No colocar trapos

ni otros contenedores sobre ni alrededor de estas aberturas.

Protección del Voltaje y Circuito

Ver la tableau de especificaciones en la página 5.

Cordones de Extensión

Para evitar la caída de voltaje y pérdida de potencia del

motor, usar manguera más larga en ves de cordón de

extensión. Un cable subdimensionado causará una

caída de voltaje a lo largo de la línea resultando en una

perdida de potencia y sobrecalentamiento.

Si se hace necesario usar un cordón de extensión:

Utilizar sólo cordones de extensión de 3 alambres,

enchufe con espiga para conexión a tierra, y un

tomacorriente compatible con el enchufe del

compresor.

Que esté en buenas condiciones.

Que no tenga más de 50 pies de largo.

Calibre 14 (AWG) o más grueso. (El grosor del cable

es mayor cuanto menor sea su número). También

pueden usarse cordones de calibre 12 AWG, 10

AWG y 8 AWG. (NO USAR CORDONES DE CALI

BRE 16 NI 18 AWG.)

Este compresor de aire está equipado con un cordón que

tiene un alambre para conectar a tierra y un enchufe

adecuado para tierra. El enchufe debe conectarse a un

tomacorriente instalado a tierra de acuerdo con los códigos

y ordenanzas locales. El tomacorriente debe tener la

misma configuración que el enchufe. Ver la ilustración. NO

USAR ADAPTADORES.

Inspeccionar el cordón y el enchufe antes de usarlo. No

usarlo si muestra señas de estar dañado.

LA CONEXIÓN INADECUADA A TIERRA PUEDE

RESULTAR EN CHOQUE ELÉCTRICO

No modificar el enchufe que se ha provisto. Si no encaja en

el tomacorriente, un electricista calificado debe instalar un

tomacorriente adecuado.

Si se va a reparar o reemplazar el cordón o enchufe, el

alambre para tierra debe mantenerse separado de los

alambres conductores de corriente. Nunca conectar el

alambre para tierra a una espiga plana del enchufe. El

alambre para tierra tiene aislamiento de color verde con

líneas amarillas.

Si no entiende estas instrucciones completamente, o si

tiene dudas en cuanto a que el compresor esté conectado

a tierra apropiadamente, haga verificar la instalación por un

electricista calificado.

INSTRUCCIONES PARA CONECTAR A

TIERRA

¡RIESGO DE CHOQUE ELÉCTRICO! EN CASO DE

CORTOCIRCUITO, LA CONEXIÓN A TIERRA REDUCE EL RIESGO DE CHOQUE ELÉCTRICO

FACILITANDO EL ESCAPE DE LA CORRIENTE.

ESTE COMPRESOR DE AIRE DEBE CONECTARSE

A TIERRA APROPIADAMENTE

¡RIESGO DE CHOQUE ELÉCTRICO! EN CASO DE

CORTOCIRCUITO, LA CONEXIÓN A TIERRA REDUCE EL RIESGO DE CHOQUE ELÉCTRICO

FACILITANDO EL ESCAPE DE LA CORRIENTE.

ESTE COMPRESOR DE AIRE DEBE CONECTARSE

A TIERRA APROPIADAMENTE

D23708

Controles y Reguladores Adicionales

Debido a que la presión en el tanque de aire normalmente

es mayor a la que se necesita, usualmente se usa un

regulador separado para controlar la presión de aire antes

de la entrada al dispositivo o herramienta que se conecte.

Donde el caso lo requiera, se debe utilizar transformador

que combine la función de regulador de aire, y removedor

de humedad y suciedad.

8-SP

Page 25

PROCEDIMIENTOS PARA LA INSTALACIÓN Y ASENTAMIENTO

NOTA

Es común que el tanque de aire contenga

un poco de agua de las pruebas realizadas en fábrica.

Procedimiento para el Asentamiento

Se puede causar serios daños si no se

observan las instrucciones para el

asentamiento abajo indicadas.

Se requiere seguir este procedimiento:

1. Antes de poner el compresor de aire en servicio.

2. Cuando se reemplace la válvula de chequeo.

a. Fijar la palanquita del interruptor de presión en la

posición de OFF.

PROCEDIMIENTO PARA OPERAR

1. Antes de conectar la manguera de aire o accesorios,

asegurarse que la palanquita OFF/AUTO esté en la

posición de OFF y que la válvula reguladora o

interruptora esté cerrada.

2. Conectar los accesoriosreaches cut-out pressure.

b. Conectar el cordón de extensión en el tomacorriente

adecuado.

c. Girar el válvula de drenaje en el sentido del reloj

abriéndolo completamente para evitar que se

acumule presión de aire dentro del tanque.

d. Mover la palanquita del interruptor de presión a la

posición de ON/AUTO. El compresor arrancará.

e. Dejar funcionar el compresor por 15 minutos.

Asegurarse que el válvula de drenaje esté

abierto y que no haya acumulación de presión

en el tanque.

f. Después de 15 minutos, cerrar el válvula de

drenaje girando la perilla contra el sentido del

reloj. El tanque de aire se llenará hasta que

alcance la presión de corte y el motor se apague.

Ahora el compresor está listo para usar.

Cuando usted termine:

6. Mover la palanquita de OFF/AUTO a la posición de

OFF.

7. Girar el regulador contra el sentido del reloj y fijar la

presión en cero.

8. Desconectar la herramienta neumática o accesorios.

EL EXCESO DE PRESIÓN DE AIRE GENERA EL

RIESGO DE EXPLOSIÓN. VERIFICAR LAS

ESPECIFICACIONES DE PRESIÓN MÁXIMA CON EL

FABRICANTE DE LAS HERRAMIENTAS Y

ACCESORIOS. EL REGULADOR DE LA PRESIÓN DE

SALIDA NUNCA DEBE EXCEDER LA CAPACIDAD

MÁXIMA ESTIPULADA. EN LOS MODELOS CON

SÓLO UNA VÁLVULA DE INTERRUPCIÓN, AL USAR

ACCESORIOS CON UNA CAPACIDAD MÁXIMA INFERIOR A 125 PSIG, ANTEPONER UN REGULADOR. EL AGUA DEL AIRE SE CONDENSARÁ

3. Colocar la palanquita de OFF/AUTO en AUTO y

9. Abrir el regulador y lentamente permitir que el aire del

tanque se drene. Cerrar el regulador cuando la

presión del tanque esté en aproximadamente 20 PSI.

10. Drenar el agua condensada en el tanque aire.

DENTRO DEL TANQUE DE AIRE, Y SI NO SE

DRENA, CORROERÁ Y DEBILITARÁ EL

TANQUE DE AIRE CAUSANDO UN RIESGO DE

RUPTURA.

permitir que el tanque acumule presión. El motor

parará cuando la presión llegue al nivel de corte.

4. Abrir el regulador girándolo en el sentido del reloj.

Ajustar el regulador a la presión correcta. El compresor

Si la válvula de paso se atraca, soltar toda

la presión de aire. Desmontar la válvula,

limpiarla y volverla a instalar.

NOTA

está listo usar.

11. Después de drenar el agua, cerrar el grifo o válvula

5. Siempre operar el compresor de aire en áreas bien

de drenaje. Ahora se puede guardar el compresor.

ventiladas, libres de vapores de gasolina y de vapores

de otros solventes. No operar el compresor cerca del

área del pulverizado de la pintura.

9-SP

D23708

Page 26

GUÍA PARA DETECCIÓN DE PROBLEMAS

AL HACER EL MANTENIMIENTO PUEDEN QUEDAR EXPUESTAS LAS FUENTES DE VOLTAJE,

PARTES MOVIBLES O FUENTES DE AIRE COMPRIMIDO QUE PUEDEN CAUSAR DAÑOS

PERSONALES. ANTES DE INTENTAR HACER REPARACIONES, DESCONECTAR EL

COMPRESOR Y DRENAR LA PRESIÓN DE AIRE DEL TANQUE.

PROBLEMA CAUSA SOLUCIÓN

Presión excesiva en el tanque.

La válvula de presión salta.

Fuga de aire por las uniones.

Fuga de aire en o alrededor de

la válvula de chequeo.

Fugas de aire por el interruptor

de presión de la válvula de

alivio o desfogue.

El interruptor de presión no apaga

el motor cuando la presión de éste

alcanza el nivel de corte.

El nivel de la presión de corte está

muy alto.

Los acoples no están lo

suficientemente ajustados.

Válvula de chequeo sucia o

defectuosa.

Interruptor de presión de la válvula

de alivio defectuoso.

Válvula de chequeo defectuosa.

Mover la palanquita del interruptor de presión a la

posición de OFF. Si esto no apaga el motor y

los contactos eléctricos se han fundido y pegado,

reemplazar el interruptor de presión.

Si los contactos están bien, ver si el pin en el

fondo de la válvula de salida de presión está

atracado. Si no se mueve libremente, reemplazar

la válvula.

Devolver la unidad a un distribuidor autorizado

para que verifique, regule o reemplace el interruptor.

Ajustar los acoples donde se escuche que el aire

escapa. Verificar las uniones con una solución

de agua jabonosa. NO SOBREAJUSTAR.

Una válvula de chequeo defectuosa produce fugas

de aire constantes por la válvula de alivio de

presión cuando hay presión en el tanque y el

compresor está apagado. Retirar y limpiar o

reemplazar la válvula de chequeo. NO

SOBREAJUSTAR.

Retirar y reparar la válvula de alivio.

Una válvula de chequeo defectuosa produce fugas

de aire constantes por la válvula de alivio de

presión cuando hay presión en el tanque y el

compresor está apagado. Retirar y limpiar o

reemplazar la válvula de chequeo. NO

SOBREAJUSTAR.

Fugas de aire por las costuras

del tanque de aire.

La presión en el medidor del

regulador cae cuando se usa

un accesorio.

D23708

Tanque de aire defectuoso.

Es normal que ocurra una ligera

caída de presión.

10-SP

Reemplazar el tanque de aire. No reparar la fuga.

NO HACER PERFORACIONES, NI SOLDAR,

NI MODIFICAR EL TANQUE DE AIRE EN

FORMA ALGUNA PORQUE SE DEBILITARÁ

Y PUEDE ROMPERSE O EXPLOSIONAR.

Si hay una caída de presión excesiva cuando se

conecta un accesorio, ajustar el regulador

siguiendo las instrucciones de la página 8.

NOTA

Ajustar la presión regulada bajo

condiciones de flujo (mientras se usa el

accesorio).

Page 27

GUÍA PARA DETECCIÓN DE PROBLEMAS

PROBLEMA CAUSA

Fuga de aire por la válvula de

seguridad

Sonido de golpes.

El compresor no provee

suficiente aire para operar los

accesorios.

El motor no funciona.

Posible defecto en la válvula de

seguridad.

Válvula de chequeo defectuosa.

Uso prolongado de aire excesivo.

El compresor no es lo

suficientemente grande para los

requerimientos de aire.

Hueco en la manguera.

Restricción en la válvula de

chequeo.

Fugas de aire.

La presión del tanque excede la

presión de corte del interruptor.

Calibre y largo del cordón de

extensión equivocado.

Verificar si la válvula se ha atascado

abierta.

SOLUCIÓN

Operar la válvula de seguridad manualmente

bajando el anillo. Si la fuga persiste, reemplazar

la válvula.

Desmontar, limpiar o reemplazar.

Disminuir la cantidad de aire en uso

Verificar el requerimiento de aire del accesorio.

Si es mayor que el SCFM o que la presión

suministrada por el compresor de aire, usted

necesita un compresor más grande.

Inspeccionar y reemplazar si es necesario

Desmontar, limpiar o reemplazar.

Ajustar las conexiones. (Ver la sección fugas de

aire en la guía para detección de problemas).

El motor arrancará automáticamente cuando la

presión del tanque caiga por debajo del nivel de

arranque del interruptor de presión.

Verificar que el calibre y longitud del cordón sean

los adecuados.

Desmontar, limpiar o reemplazar.

Conexiones eléctricas sueltas.

Pintura usada para rociar en las

partes internas del motor.

Motor eléctrico posiblemente

defectuoso.

Fusible quemado, interruptor de

circuito abierto.

Verificar la conexión del cable dentro del

interruptor de presión y área de la caja del

terminal.

Hacer revisar en un Centro de Servicio Autorizado.

No operar el compresor dentro del área de

pintado. Ver la advertencia sobre vapores

inflamables.

Hacer revisar en un Centro de Servicio Autorizado

1. Detectar fusibles volados en la caja de fusibles

y reemplazar si es necesario. Reposicionar el

interruptor de circuitos. No usar un fusible o

interruptor de circuito de mayor capacidad

que el especificado para su circuito.

2. Verificar que el fusible sea el adecuado. Debe

usar un fusible de acción retardada.

3. Verificar si existen condiciones de bajo voltaje

y/o si el cordón de extensión es el adecuado.

4. Desconectar los demás artefactos eléctricos

del circuito u operar el compresor en un

circuito propio.

Fuga continua de aire por la

perilla del regulador. El

regulador no cierra la salida

de aire.

La válvula de alivio de presión no ha

descargado la presión.

Partes internas del regulador sucias

o dañadas.

11-SP

Drenar la línea empujando la palanquita en el

interruptor de presión a la posición de OFF. Si

la válvula no se abre de nuevo, reemplazarla.

Reemplazar el regulador.

D23708

Page 28

LISTA DE REPUESTOS

SSP-473

CAC-1275

SST-5314-1

SSF-607

CAC-1254

AC-0430

SSP-6021

DAC-4105-2

SSW-7367

SUDL-9-1

SSP-480

SSF-621

GA-352

AC81-B

CAC-4296-1

SS-1286

TIA-4150

SSW-7480

SUDL-403-1

D23708

12-SP

Page 29

LISTA DE PARTES

DESCRIPCIÓN NÚMERO DE PARTE

* SSF-607 Tornillo (se usan 4))

* SST-5314-1 Aislador (se usan 4)

* SSF-621 Tornillo, ¼-14 x .624

DAC-4105-2 Juego del interruptor de pressión

* CAC-1254 Aislador de la bomba (se usan 4)

SSW-7480 Buje de Alivio de tensión

CAC-1275 Válvula de Chequeo

SSP-473 Manga de tuerca

● Pedir juego del interruptor de pressión

SUDL-9-1 Tornillo, 8-32 x .375/.344 (se usan 2)

SSP-480 Niple

SSW-7367 Vuje de alivio de tensión

SUDL-403-1 Cordón

AC-0430 Válvula de drenaje

TIA-4150 Válvula de Seguridad

SS-1286 Niple de ¼-18 NPT

CAC-4296-1 Reductor

AC81-B Acople hembra de conexión rápida

GA-352 Medidor

SSP-6021 Reductor de 1/8-1/4 NPT

13-SP

D23708

Page 30

DIAGRAMA DEL COMPRESOR

D21919

AC-0815

AC-0470

CAC-1213

SUDL-9-1

D23584

CAC-1213

CAC-1199

AC-0471

SSF-3147

AC-0206

CAC-1206-1

DAC-269

+

+

SSG-8169

CAC-1212

CAC-4323

SSF-3156

SSF-995

CAC-1196

D23708

14-SP

Page 31

LISTA DE PARTES

DESCRIPCIÓN NÚMERO DE PARTE

X SSF-995 Tornillo #10-24 x7/8 (se usan 4)

CAC-1196 Cebeza de cilindro

* CAC-1212 Sello de tubo

* CAC-1199 Junta o emaque de cabeza

CAC-4323 Conjunto de la placa de válvula

* SSSG-8169 Anillo en « O »

+ —————— Conjunto de biela

x SSF-3147 Tornillo, 3/8-16

+ —————— Camisa de cilindro

D23584 Conjunto de terminación de cable

AC-0815 Correa de sincronización

* CAC-1213 Aislador de la bomba (se usan 5)

x SUDL-9-1 Tornillo, 8-32 x .375/.344

AC-0471 Cubierta (izquierda)

AC-0470 Cubierta (derecha)

D21919 Cordón den motor

DAC-269 Tubo de salida

CAC-1206-1 Grapa

AC-0206 Buje de alivio tensión

x SSF-3156 Tornillo, 9-10 x .50

* K-0387 Cunjunto aislador

x KK-4929 Cunjunto de sujeción

+ KK-4964 Conjunto de biela

15-SP

D23708

Page 32

GARANTÍA DEL COMPRESOR ACCUSET Y SUS COMPONENTES

El presente compresor ha sido diseñado y construido utilizando la mano de obra y los materiales de más altos estándares.

GARANTÍA DEL COMPRESOR

La extensión de esta garantía es de un año a partir de la fecha de adquisición por su comprador original. Durante dicho período Senco

Products Inc. reparará o reemplazará a opción de Senco, cualquier parte original o partes para el comprador inicial. Ello será efectuado

libre de cargo, siempre que la partes sean halladas defectuosas en material o mano de obra por el servi-centro de garantía autorizado por

Senco/Accuset, con las excepciones y exclusiones descriptas mas abajo. Cualquier parte de reemplazo provista mantendrá una garantía

por la diferencia del tiempo de garantía aplicable a la parte que se está sustituyendo. Cuando se necesaria la reparación o el reemplazo de

partes o del compresor, el comprador original deberá reintegrar el compresor completo o la parte, con su transporte previamente pago al

servi-centro de garantía autorizado más cercano, adjuntando el recibo u otra prueba segura de que la parte o el compresor están dentro

del período de garantía.

Accuset garantiza todas las partes (excepto aquellas listadas más abajo) de que su compresor de aire Accuset está libre de defectos en

materiales y mano de obra durante los siguientes períodos:

1. 1 año a partir de la fecha de compra original:

Válvula piloto de la bomba del compresor

Plomería del armado del tanque

Control del volante de estrangulación

Cable eléctrico

2. Por 90 días a partir de la fecha de compra original:

Medidor de presión de la válvula liberadora

Llaves de desagote

Las partes defectuosas no sujetas a un desgaste normal pero rajadas, serán reparadas o reemplazadas a opción de Senco durante el período

de garantía. En cualquier circunstancia, el reembolso estará limitado al precio de compra pagado.

EXCLUSIONES:

1 La máquina/motor está cubierto, por su fabricante respectivo, bajo una garantía por separado, y estará sujeto a los términos en ella

establecidos.

2 Desgaste normal de partes no cubiertos bajo esta garantía:

Aislantes Correa de transmisión

Filtro de aire

3 Esta garantía no cubre las partes dañadas debido a su uso normal, utilización inadecuada, operación inadecuada, accidentes, forma

de operar la velocidad en forma diferente a la recomendada, o el uso de voltaje inadecuado (en unidades eléctricas únicamente), impropio

almacenaje, o daños resultantes durante su transporte.

4 Desviación de las instrucciones operativas, especificaciones, y programas de mantenimiento.

5 Costos de mano de obra, pérdida o daños resultantes de una operación inadecuada, mantenimiento o reparaciones hechas por

persona(s) ajenas al servi-centro de reparación por garantía de Senco/Accuset.

6 La utilización de partes de reparación diferentes a las genuinas Accuset anularán la garantía.

Esta garantía por contingencias, está basada en el uso adecuado del compresor por parte del comprador, y no cubre:

a Condiciones anormales, accidentes, negligencia, uso inadecuado, o almacenaje de la unidad en forma inapropiada.

b Desviación de las instrucciones operativas o de mantenimiento.

c Modificaciones no autorizadas por Senco.

d Reparaciones o mantenimiento (fuera de las rutinas del drenaje del tanque del aire o los cambios de aceite y filtro requeridos

por nuestro manual de operaciones y mantenimiento) realizado por personas diferentes a Senco o a sus agentes autorizados.

eDaño por transporte.

ESTA GARANTÍA ES LA ÚNICA PARA ESTE COMPRESOR, Y CUALQUIER OTRA GARANTÍA, SEA ORAL, ESCRITA, EXPRESA, O

IMPLÍCITA, INCLUYENDO, PERO NO LIMITADA A, LA GARANTÍA IMPLÍCITA DE COMERCIALIZACIÓN O USO PARA UN PROPÓSITO

EN PARTICULAR, QUEDAN EXCLUÍDAS. LOS UNICOS RECURSOS LEGALES DEL COMPRADOR O DEL USUARIO SON SOLA Y

EXCLUSIVAMENTE LOS MENCIONADOS MÁS ARRIBA. SENCO PRODUCTS INC. NO SERÁ PUNIBLE EN NINGUNA INSTANCIA

INCIDENTAL, CONSECUENTE, INDIRECTA, O POR DAÑOS ESPECIALES. EN NINGUN CASO, SEA COMO RESULTANTE DE UNA BRECHA

DEL CONTRATO, GARANTÍA, TRANSGRESIÓN (INCLUÍDA NEGLIGENCIA) U OTRA CIRCUNSTANCIA, HARÁ QUE LA RESPONSABILIDAD

DE SENCO EXCEDA EL PRECIO DEL COMPRESOR HASTA UN VALOR MAS ELEVADO POR CAUSA DEL RECLAMO O RESPONSABILIDAD.

CUALQUIER RESPONSABILIDAD CONECTADA CON EL USO DE ESTE COMPRESOR CADUCARÁ CON LA FECHA EN LA QUE EXPIRA

EL PERÍODO DE GARANTÍA ARRIBA ESPECIFICADO.

Reemplazo del compresor por causa de desastre natural.

Senco sustituirá cualquier compresor destruido por causas de desastre natural tales como inundación, terremoto, huracán, u otro desastre

resultante solamente de las fuerzas de la naturaleza. Tales reclamos serán atendidos si previamente se ha producido el sometimiento de

la tarjeta de registro de garantía por parte del comprador original, luego este suministrará prueba de su propiedad y una declaración aceptable

describiendo tales desastres naturales, documentados por un corredor de seguros, departamento de policía, o otra fuente oficial del

Gobierno. A fin de obtener instrucciones para el llenado del formulario de reclamo, sírvase llamar al 1-888-222-8144.

SENCO PRODUCTS INC.

CINCINATI, OHIO 45244-1611 USA

Page 33

GUIDE D’UTILISATION

COMPRESSEUR D'AIR À LUBRIFICATION PERMANENTE

Accuset

MODÈLE Nº

PC2053-1

* Un disjoncteur est recommandé. N’utiliser qu’un fusible ou disjoncteur qui a la même

valeur nominale que le circuit de dérivation du compresseur d’air.

D23708 Rev. 0 3/20/01

Page 34

TABLE DES MATIÈRES

MESURES DE SÉCURITÉ..................... 2

TABLEAU DE MISES EN GARDE ...... 3-5

TABLEAU DES SPÉCIFICATIONS........ 6

LEXIQUE ................................................ 6

FACTEUR D’UTILISATION ...................6

ENTREPOSAGE .................................... 6

DESCRIPTION DU FONCTIONNEMENT

DE L’APPAREIL..................................... 7

PROCÉDURES D’INSTALLATION ET

DE MISE EN ROUTE ......................... 8-9

Emplacement du compresseur

d’air ............................................. 8

Tension et protection du circuit ........8

Rallonges.......................................... 8

Directives de mise à la masse.......... 8

Commandes et régulateurs

supplémentaires ...........................8

Procédures de mise

en route .........................................9

PROCÉDURES D’EXPLOITATION .......9

GUIDE DE DÉPANNAGE .............. 10-11

LISTE DES PIÈCES DU

COMPRESSEUR ........................... 12-15

GARANTIE.................. Couverture arrière

MESURES DE SÉCURITÉ - DÉFINITIONS

Ce guide contient des renseignements importants que vous devez bien saisir. Cette information porte sur VOTRE SÉCURITÉ et sur LA

PRÉVENTION DE PROBLÈMES D’ÉQUIPEMENT. Afin de vous aider à identifier cette information, nous avons utilisé des signes de

danger plus bas. Veuillez lire attentivement ce guide en portant une attention particulière à ces sections. CONSERVEZ CES DÉFINITIONS/

INSTRUCTIONS.

DANGER

DANGER : Indique un danger imminent qui, s'il n'est

pas évité, causera de graves blessures ou la mort.

AVERTISSEMENT

AVERTISSEMENT : Indique la possibilité d’un danger qui, s’il

n’est pas évité, pourrait causer de graves blessures ou la

mort.

D23708

MISE EN GARDE : Indique la possibilité d’un danger qui, s’il

n’est pas évité peut causer des blessures mineures ou

moyennes.

MISE EN GARDE (sans le symbole d'attention) : Indique la

possibilité d'un danger qui, s'il n'est pas évité, peut causer des

dommages à la propriété.

2-FR

MISE EN GARDE

MISE EN GARDE

Page 35

MESURES DE SÉCURITÉ IMPORTANTES

CONSERVER CES DIRECTIVES

AVERTISSEMENT

UN EMPLOI OU UN ENTRETIEN NON APPROPRIÉS DE CE PRODUIT PEUT CAUSER DES BLESSURES GRAVES ET DES DOMMAGES

À LA PROPRIÉTÉ. LIRE ATTENTIVEMENT TOUS LES AVERTISSEMENTS ET LES DIRECTIVES D’UTILISATION AVANT D’UTILISER CET

APPAREIL.

DANGER

RISQUE D’EXPLOSION OU D’INCENDIE

RISQUE PRÉVENTION

LES ÉTINCELLES QUI PROVIENNENT DES CONTACTS ÉLECTRIQUES DU

MOTEUR ET DU MANOSTAT SONT CONSIDÉRÉES NORMALES.

SI DES ÉTINCELLES ÉLECTRIQUES DU COMPRESSEUR ENTRENT EN CONTACT

AVEC DES VAPEURS INFLAMMABLES, ELLES PEUVENT S’ENFLAMMER,

PROVOQUANT UN INCENDIE OU UNE EXPLOSION.

TOUTE OBSTRUCTION DES ORIFICES D’AÉRATION DU COMPRESSEUR

ENTRAÎNERA UNE SURCHAUFFE DANGEREUSE ET RISQUE DE CAUSER UN

INCENDIE.

.