Page 1

Questions? Comments? call SENCO's toll-free Action-line: 1-800-543-4596 or e-mail: toolprof@senco.com

PC0968

Electric Air Compressor

Senco Products, Inc.

8485 Broadwell Rd.

Cincinnati, OH 45244

Operating Instructions

Warnings for the safe use of this compressor are included in this manual.

Des mises en garde pour une utilisation en toute sécurité de ce compresseur

sont incluses dans ce manuel.

En este manual se incluyen avisos para el uso seguro de este compresor.

© 2003 by Senco Products, Inc.

PC0968 Revised July 31, 2003

(Replaces 6/30/03)

1

Page 2

TABLE OF CONTENTS

INTRODUCTION ................................................................... 3

SAFETY ALER

INSPECTION .........................................................................

SAFETY

ELECTRICAL ................................................................ 4

EXPLOSION OR FIRE..................................................

BURSTING ...................................................................

BREATHING .................................................................

BURNS .........................................................................

FLYING OBJECTS ........................................................

MOVING PARTS........................................................... 7

NEGLIGENCE ..............................................................

AIR COMPRESSOR DAMAGE..................................... 7

COMPRESSOR FEATURES .................................................

PREPARATION.................................................................... 10

INITIAL SET-UP ......................................................... 10

LOCATION .................................................................. 10

ELECTRICAL .............................................................. 10

OPERATION........................................................................ 11

PRE-ST

START-UP .................................................................. 11

SHUTDOWN .............................................................. 11

T..................................................................... 3

WARNINGS ............................................................ 4

ART CHECKLIST ........................................... 11

3

5

5

6

6

6

7

8

MAINTENANCE................................................................... 11

TROUBLESHOOTING ................................................... 12-14

SPECIFICATIONS ............................................................... 15

WARRANTY ........................................................................ 16

2

Page 3

3

INTRODUCTION

Congratulations on the purchase of your new SENCO® Air Compressor! You can be assured your SENCO Air

Compressor was constructed with the highest level of precision and accuracy. Each component has been rigorously

tested by technicians to ensure the quality, endurance and performance of this air compressor.

This operator’s manual was compiled for your benefit. By reading and following the simple safety, installation and

operation, and maintenance steps described in this manual, you will receive years of troublefree

operation

from your new SENCO Air Compressor. . The contents of this manual are based on the latest product

information available at the time of publication. The manufacturer reserves the right to make changes in price,

color, materials equipment, specifications or models at any time without notice.

SAFETY ALERT!

A ”

DANGER, WARNING or CAUTION

” safety warning will be surrounded by a ”SAFETY ALERT BOX”.

This box is used to designate and emphasize Safety Warnings that must be followed when operating this

air compressor. Accompanying the safety warnings are “Signal Words” which designate the degree or

level of hazard seriousness. The “Signal

Words” used in this manual are as follows:

DANGER:

Indicates an imminently hazardous situation which, if not avoided,

WILL result in

death or serious injury

.

WARNING:

Indicates a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation which, if not avoided

MAY result in

minor or moderate injury or damage to the air

compressor

.

The symbols set to the left of this paragraph are “Safety Alert Symbols”.

These symbols are used to call attention to items or procedures that could

be dangerous to you or other persons using this equipment.

ALWAYS PROVIDE A COPY OF THIS MANUAL

TO ANYONE USING THIS EQUIPMENT. READ ALL

INSTRUCTIONS IN THIS MANUAL AND ANY INSTRUCTIONS SUPPLIED BY MANUFACTURERS OF

SUPPORTING EQUIPMENT BEFORE OPERATING THIS AIR COMPRESSOR AND ESPECIALLY POINT OUT

THE “SAFETY

WARNINGS” TO PREVENT THE POSSIBILITY OF PERSONAL INJURY TO THE OPERATOR.

INSPECTION

Unbox the air compressor and write in the serial number in the space provided below. Inspect for signs of obvious

or concealed freight damage. Be sure that all damaged parts are replaced and any mechanical problems are

corrected prior to the operation of the air compressor.

SERIAL NUMBER__________________________________________

If you have Questions or Comments call SENCO’s

toll-free Action-line: 1-800-543-4596 or, e-mail:

toolprof@Senco.com

Please have the following information available for all service calls:

1. Model Number

2. Serial Number

3. Date and Place of Purchase

Senco, 8485 Broadwell Road, Cincinnati, OH 45244

Page 4

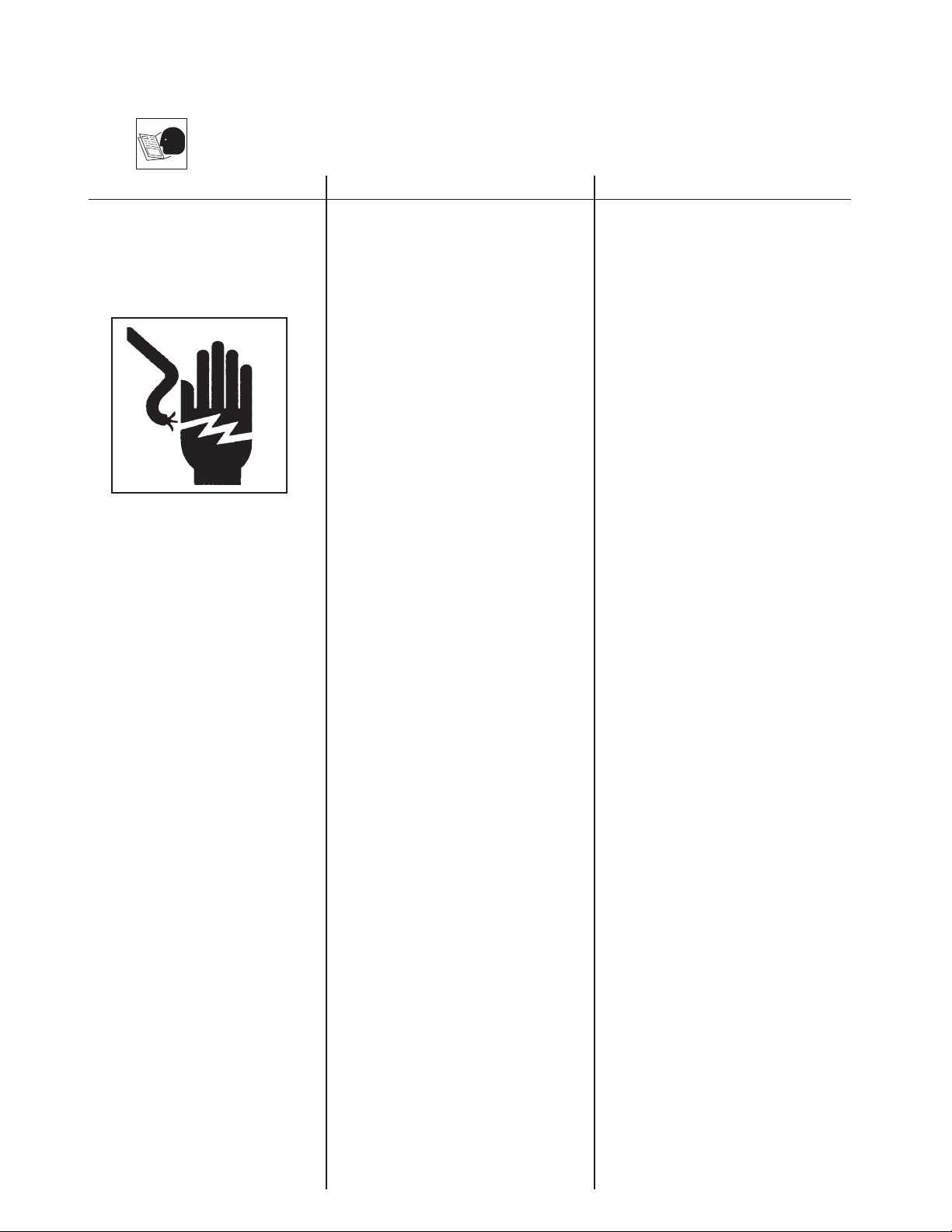

SAFETY WARNINGS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

HAZARD

RISK OF

ELECTRIC SHOCK

OR

ELECTROCUTION

POTENTIAL CONSEQUENCE

Serious injury or death could occur if

the air compressor is not properly

grounded.

powered by electricity and may cause

electric shock or electrocution if not

used properly

Electrical shock may occur from

electrical cord.

Electrical shock may occur if air

compressor is not operated properly.

Your air compressor is

.

PREVENTION

Make sure the air compressor is

plugged into a properly grounded

outlet which provides correct

voltage and adequate fuse

protection.

Check power cord for signs of

crushing, cutting or heat damage.

Replace faulty cord before use.

Keep all connections dry and off the

ground. Do not allow electrical

cords to lay in water or in such a

position where water could come in

contact with them. Do not touch

plug with wet hands.

Do not pull on the electrical cord to

disconnect from the outlet.

Never operate air compressor in

wet conditions or outdoors when it

is raining.

Serious injury or death may occur if

electrical repairs are attempted by

unqualified persons.

Never operate air compressor with

safety guards/covers removed or

damaged.

Any electrical wiring or repairs

performed on this air compressor

should be done by Authorized

Service Personnel in accordance

with National and Local electrical

codes.

Before opening any electrical

enclosure, always shut off the air

compressor, relieve pressure and

unplug the air compressor from the

power source. Allow air compressor

to cool down. Never assume the air

compressor is safe to work on just

because it is not operating. It could

restart at any time!

4

Page 5

5

SAFETY WARNINGS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

POTENTIAL CONSEQUENCE

Serious injury or death may occur from

normal electrical sparks in motor and

pressure switch.

Serious injury may occur if any air

compressor ventilation openings are

restricted, causing the air compressor

to overheat and start on fire.

Serious injury or death may occur from

an air tank explosion if air tanks are

not properly maintained.

Serious injury may occur from an air

compressor malfunction or exploding

accessories if incorrect system

components, attachments or

accessories are used.

HAZARD

RISK OF

EXPLOSION OR FIRE

RISK OF

BURSTING

PREVENTION

Always operate air compressor in a

well ventilated area free of

flammable vapors, combustible

dust, gases or other combustible

materials.

If spraying flammable material,

locate the air compressor at least

20 feet away from the spray area.

(An additional hose may be

required.)

Never place objects against or on

top of air compressor. Operate air

compressor at least 12 inches away

from any wall or obstruction that

would restrict proper ventilation.

Drain air tank daily or after each use

to prevent moisture buildup in the

air tank.

If air tank develops a leak, replace

the air tank immediately. Never

repair, weld or make modifications

to the air tank or its attachments.

Never make adjustments to the

factory set pressures.

Never exceed manufacturers

maximum allowable pressure rating

of attachments.

Because of extreme heat, do not

use plastic pipe or lead tin soldered

joints for a discharge line.

Never use air compressor to inflate

small, low pressure objects such as

toys.

Page 6

SAFETY WARNINGS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

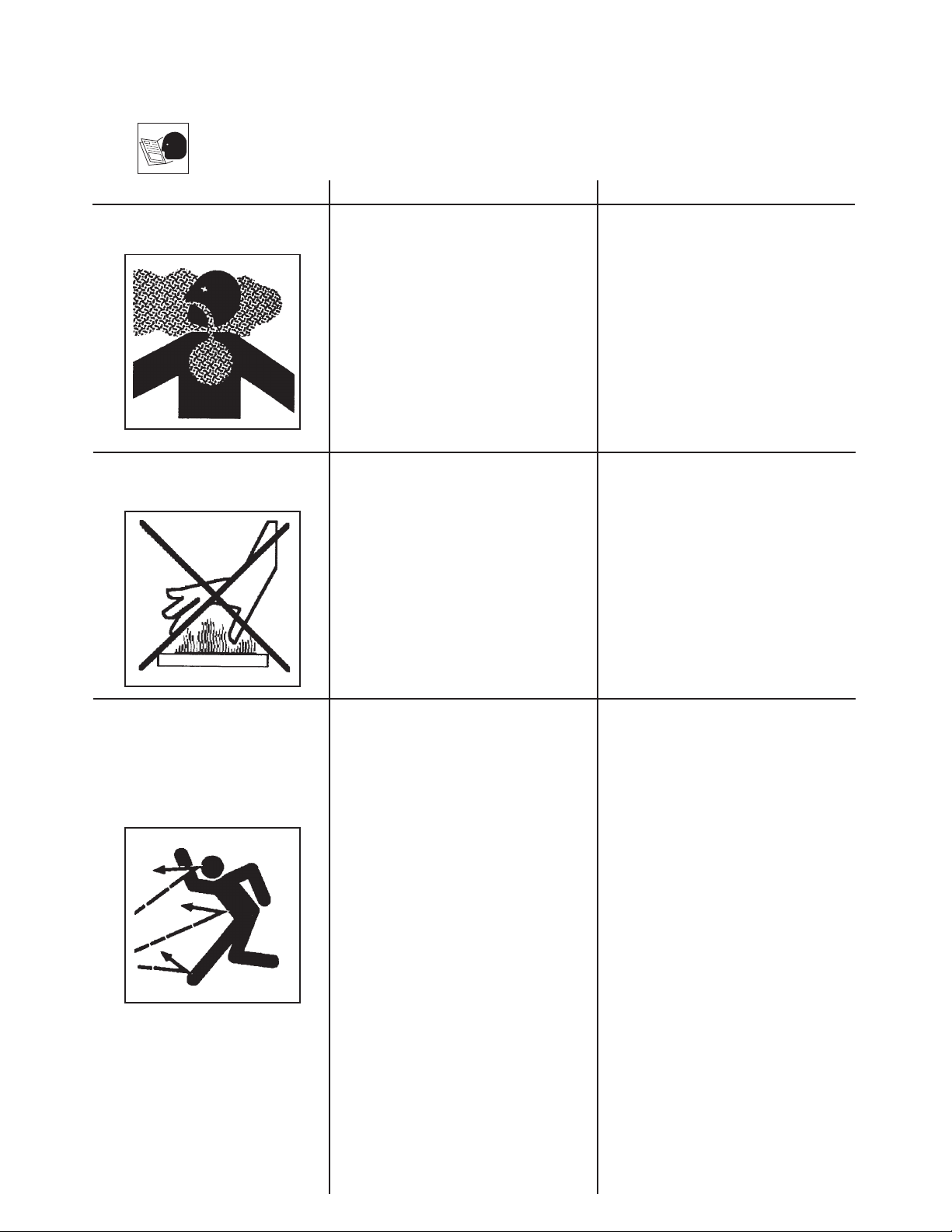

HAZARD

RISK TO

BREATHING

RISK OF

BURNS

POTENTIAL CONSEQUENCE

Serious injury or death could occur

from inhaling compressed air. The air

stream may contain carbon monoxide,

toxic vapors or solid particles.

Sprayed materials such as paint, paint

solvents, paint remover, insecticides,

weed killers, etc. contain harmful

vapors and poisons.

Serious injury could occur from

touching exposed metal parts.

These areas can remain hot for some

time after the air compressor is

shutdown.

PREVENTION

Never inhale air from the air

compressor either directly or from

breathing device connected to the air

compressor

Operate air compressor only in a well

ventilated area. Follow all safety

instructions provided with the

materials you are spraying. Use of a

respirator may be required when

working with some materials.

Never allow any part of your body or

other materials to make contact with

any exposed metal parts on the air

compressor

.

.

a

RISK

OF FLYING

OBJECTS

Soft tissue damage can occur from the

compressed air stream.

Serious injury can occur from loose

debris being propelled at a high speed

from the compressed air stream.

Always wear OSHA required “Z87”

safety glasses to shield the eyes

from flying debris.

Never point the air stream at any part

of your body, anyone else or animals.

Never leave pressurized air

compressor unattended. Shut off air

compressor and relieve pressure

before attempting maintenance,

attaching tools or accessories.

Always maintain a safe distance from

people and animals while operating

the air compressor.

Do not move the air compressor

while air tank is under pressure. Do

not attempt to move the air

compressor by pulling on the hose.

6

Page 7

7

POTENTIAL CONSEQUENCE

Risk of bodily injury from moving parts.

This air compressor cycles

automatically when the pressure

switch is in the “On/Auto” position.

Risk of injury from negligent use.

Risk of major repair

.

SAFETY WARNINGS

READ ALL SAFETY WARNINGS BEFORE USING AIR COMPRESSOR

RISK FROM

NEGLIGENCE

RISK

OF AIR COMPRESSOR

DAMAGE

HAZARD

RISK FROM

MOVING PARTS

PREVENTION

Always turn off air compressor when

not in use. Bleed pressure from the

air hose and unplug from electrical

outlet before performing

maintenance. All repairs to the air

compressor should be made by an

Authorized Service person. Never

assume the air compressor is safe

to work on just because it is not

operating. It could restart at any time!

Do not operate without protective

covers/guards. Replace damaged

covers/guards before using the air

compressor

.

Never allow children or adolescents

to operate this air compressor!

Stay alert-watch what you are doing.

Do not operate the air compressor

when fatigued or under the influence

of alcohol or drugs.

Know how to stop the air

compressor. Be thoroughly familiar

with controls.

Do not operate air compressor

without an air filter.

Do not operate air compressor in a

corrosive environment.

Always operate the air compressor

in a stable, secure position to prevent

air compressor from falling.

Follow all maintenance instructions

listed in this manual.

! SAVE THESE INSTRUCTIONS !

Page 8

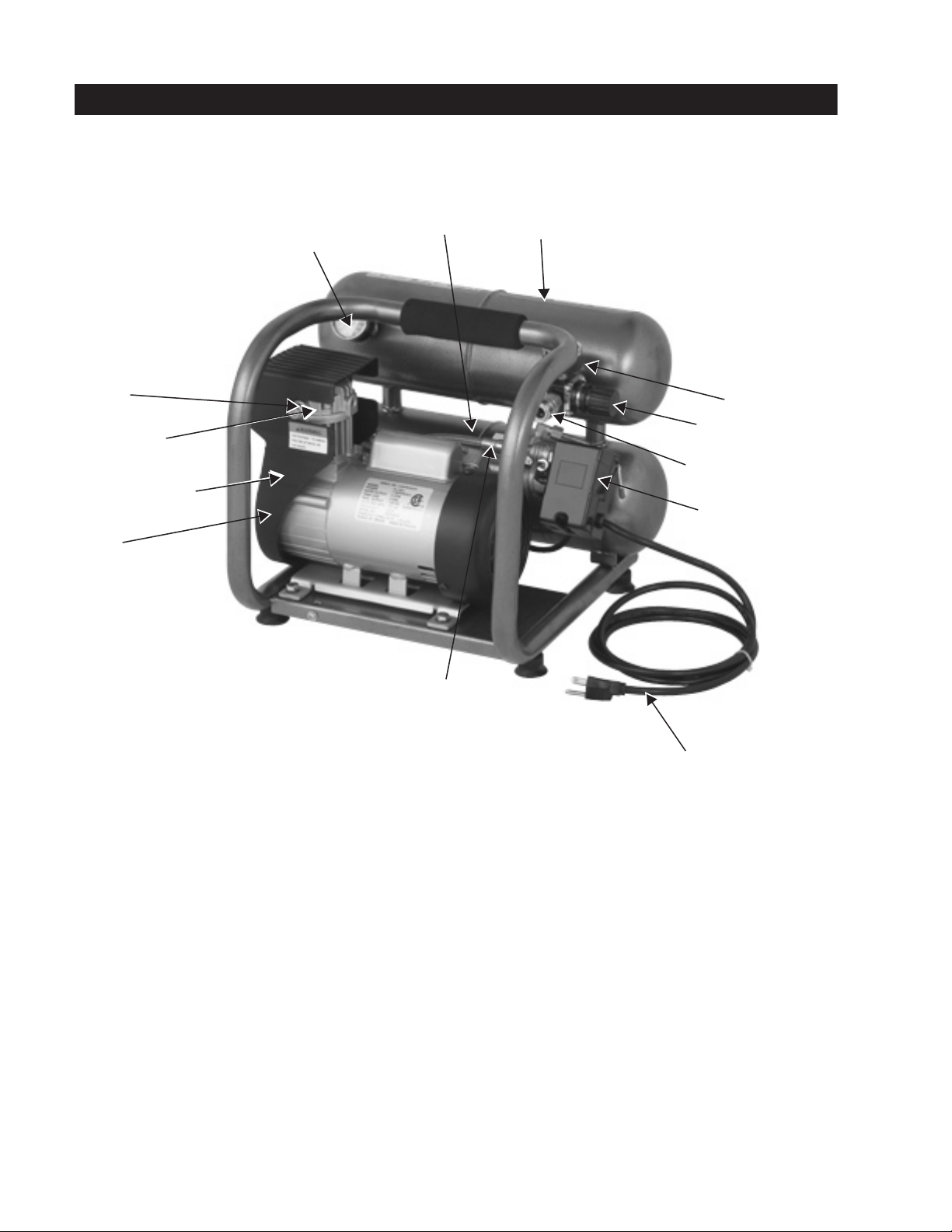

COMPRESSOR FEATURES

13

11

4

3

12

5

6

2

10

9

1

1 Motor/Pressure Switch

Air Compressor Pump

2

Safety Relief

3

Tank Pressure Gauge

4

5

Outlet Pressure Gauge

6

Pressure Regulator

7

Discharge Line

8

9

10

11

12

13

Volt Electric Power Cord

115

Ventilation Openings/Protective Shroud

Quick Disconnect

Air Filter

Tank Drain

Cold Start Valve

V

alve

7

8

8

Page 9

COMPRESSOR FEATURES

1) MOTOR/PRESSURE SWITCH: This switch is used to start or stop the air

compressor. Moving the switch to the Auto (On) position will provide automatic

power to the pressure switch which will allow the motor to start when the air tank

pressure is below the factory set cut-in pressure. When in the Start/ Stop Option,

the pressure switch stops the motor when the air tank pressure reaches the factor

set cut-out pressure. For safety purposes, this switch also has a pressure release

valve located on the side of the switch designed to automatically release compressed

air from the air compressor pump head and its discharge line when the air compressor

reaches cut-out pressure or is shut off.

the switch to the Off position will remove power from the pressure switch and stop

the air compressor.

2)

MOTOR THERMAL OVERLOAD: The electric motor has a thermal

overload protector. If the motor overheats for any reason, the thermal overload will

cut off power, thus preventing the motor from being damaged. Wait until the motor is

cool. Motor also has a magnetic breaker. Reset switch if it is tripped.

3) AIR INTAKE FILTER: This filter is designed to clean air coming into the pump. To

ensure the pump continually receives a clean, cool, dry air supply this filter must

always be clean and ventilation opening free from obstructions. The filter can be

removed for cleaning by using warm, soapy water. Rinse the filter and air dry.

4) AIR COMPRESSOR PUMP: To compress air, the piston moves up and down in

the cylinder. On the downstroke, air is drawn in through the air intake valve while

the exhaust valve remains closed. On the upstroke, air is compressed, the intake

valve closes and compressed air is forced out through the exhaust valve, into the

discharge line, through the check valve and into the air tank.

This allows the motor to restart freely. Moving

1

2

3

5) SAFETY RELIEF VA

relieving pressure from the system when the compressed air reaches a predetermined

level. The valve is preset by the manufacturer and must not be modified in any way

To

verify the valve is working properly, pull on the ring. Air pressure should escape.

When the ring is released, it will reseat.

6) AIR TANK DRAIN VALVE: The drain valve is used to remove moisture from the air

tank(s) after the air compressor is shut off.

when more than 10 PSI of air pressure is in the air tank! To open the drain valve,

turn the knob counterclockwise. Tilt tank to ensure that all condensation drains

through valve.

7) AIR TANK PRESSURE GAUGE: The air tank pressure gauge indicates the

reserve air pressure in the air tank (s).

8) OUTLET PRESSURE GAUGE: The outlet pressure gauge indicates the air

pressure available at the outlet side of the regulator. This pressure is controlled

by the regulator and is always less or equal to the air tank pressure.

9) PRESSURE REGULA

controlled by the regulator knob. Turn the pressure regulation knob clockwise to

increase discharge pressure, and counterclockwise to decrease discharge

pressure.

LVE: This valve is designed to prevent system failures by

NEVER attempt to open the drain valve

TOR: The air pressure coming from the air tank is

5

.

6

7

8

9

10

10) DISCHARGE LINE: Please note that the discharge line is very hot.

9

Page 10

10

PREPARATION

INITIAL SET-UP:

1.

Read safety warnings before setting-up air compressor

.

LOCATION:

CAUTION

In order to avoid damaging the air compressor, do not incline the air compressor

transversely or longitudinally more than 10°.

1. Place air compressor at least 12 inches away from obstacles that may prevent proper ventilation.

Do not place air compressor in an area:

-where there is evidence of oil or gas leaks.

-where flammable gas vapors or materials may be present.

WARNING

Serious injury or death may occur if electrical sparks from motor and pressure switch

come in contact with flammable vapors, combustible dust, gases or other

combustible materials. When using the air compressor for spray painting, place the

air compressor as far away I from the work area as possible, using extra air hoses instead of

extension cords.

-where air temperatures fall below 32°F or exceed 104°F.

-where extremely dirty air or water could be drawn into the air compressor.

ELECTRICAL:

DANGER

Improper connection of the equipment-grounding conductor can result in a risk

of shock or electrocution. Check with a qualified electrician or service personnel

if you are in doubt as to whether the outlet is properly grounded. Do not use any type of

adapter with this product. If repair or replacement of the cord or plug is necessary, do not

connect the grounding wire to either flat blade terminal. The wire with insulation having

an outer surface that is green with or without yellow stripes is the grounding wire.

WARNING

This product must be grounded. If there should be a malfunction or breakdown,

grounding

provides a path of least resistance for electric current to reduce the

risk of electric shock. This product is equipped with a cord having an equipmentgrounding conductor and a grounding type plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

1. SENCO® DOES NOT RECOMMEND THE USE OF EXTENSION CORDS as this can create power loss and

overheating of the motor. Use of an additional air hose is recommended rather than an extension cord. If use of an

extension cord is unavoidable, it should be plugged into a GFCI found in circuit boxes or protected receptacles.

When using an extension cord, observe the following:

Cable Length Wire Gauge

Up to 25 feet 12 AWG

Up to 100 feet 10 AWG

Up to 150 feet 8 AWG

Up to 250 feet 6 AWG

Use only 3-blade extension cords that have 3-blade grounding-type plugs and 3-slot cord connectors that will

accept the plug from the product. Use only extension cords having an electrical rating not less than the rating of

the product. Do not use damaged extension cords. Examine extension cord before using and replace if damaged.

Do not abuse extension cord and do not yank on any cord to disconnect. Keep cord away from heat and sharp

edges. Always shut off the air compressor switch before removing the plug from the receptacle.

Page 11

11

OPERATION

PRE-START CHECKLIST:

1. Remove any moisture in the air compressor air tank. Remove excessive pressure with an air tool, then open

the air tank drain valve in the bottom of the air tank. Close tightly when drained.

WARNING: Risk of bodily injury. NEVER attempt to open the drain valve when

more than 10 PSI of air pressure is in the air tank!

2. Make sure the air compressor Motor Switch is in the “OFF” position.

3.

Make sure all safety valves are working correctly.

4.

Make sure all guards and covers are in place and securely mounted.

START-UP:

1.

Ensure the lever on the pressure switch box is in the “OFF” position.

2.

Plug the power cord into a grounded outlet.

3. Move the lever on the pressure switch box to the “AUTO” position.

4. START/STOP OPTION:

Turn it to the ON

position.

This will allow the air compressor

to “START” building

up pressure in the air tanks and “STOP” when correct pressure is achieved. When pressure

drops with usage,

the air compressor will “START” building up pressure again.

5. Set pressure by adjusting the pressure regulator knob counterclockwise for less pressure and clockwise for

more pressure.

6.

If you notice any unusual noise or vibration, stop the air compressor and refer to “Troubleshooting”.

SHUTDOWN:

1. To stop the air compressor, move the lever on the pressure switch box to the “OFF” position. NEVER stop the

air compressor by unplugging it from the power source. This could result in risk of electrocution.

2. Drain air from the air tank by releasing air with an attached air tool or by pulling on the safety relief valve ring.

3. Once pressure in the air tanks register under 10 pounds, open the drain valve under each air tank to drain any

moisture.

4.

Allow the air compressor to cool down.

5.

Wipe air compressor clean and store in a safe, non-freezing area.

MAINTENANCE

Read the instruction manual before performing maintenance. The following procedures must be performed when

stopping the air compressor for maintenance or service.

1.

Turn off air compressor.

WARNING: Never assume the air compressor is safe to work on just because it is not

operating. It could restart at any time!

2. Disconnect cord from main power supply.

3.

Open all drains.

4.

Wait for the air compressor to cool before starting service.

MAINTENANCE CHART

PROCEDURE DAILY WEEKLY MONTHLY

Drain condensation in air tank(s) X

Check for unusual noise/vibration X

Check for air leaks X

Inspect air filter

X

Clean exterior of compressor

X

Check safety relief valve

X

Page 12

12

TROUBLESHOOTING

Symptom 1. Motor will not run or restart.

Power cord not plugged in.

Motor/Pressure switch in “OFF” position.

Motor thermal overload switch has

tripped.

Fuse blown or circuit breaker has tripped.

Wrong gauge wire or length of extension

cord.

Air tank pressure exceeds motor/

pressure switch “cut-in” pressure.

Pressure release valve on motor/

pressure switch has not unloaded pump

head pressure.

Defective motor, motor capacitor, motor/

pressure switch, or check valve.

Plug

cord into grounded outlet.

Move switch to “ON”

position.

Turn air compressor off, wait until motor is cool, then check

motor circuit breaker.

Replace

fuse or reset circuit breaker.

Check for proper fuse amperage.

Check

for low voltage conditions.

Disconnect any other electrical appliances from circuit or

operate air compressor on its own branch circuit.

Check chart on page #10 for proper gauge wire and cord length.

Motor

will start automatically when air tank pressure drops

below

“cut-in” pressure of motor/pressure switch.

Bleed

the line by moving the switch to the “Off” position.

Contact

Senco Customer Service.

PROBABLE CAUSE

Motor/Pressure switch does not shut off motor when

air compressor reaches “cut-out” pressure and safety

relief valve activates.

Air compressor is incorrectly sized.

PROBABLE CAUSE

Defective pilot valve, the check valve is stuck open.

REMEDY

Move the motor/pressure switch to the “Off” position. If

the motor doesn’t shut off, unplug the air compressor. If

the electrical contacts are welded together, replace the

pressure switch.

Limit the air pressure to the capacity of the air

compressor. Either use a smaller tool or a larger air

compressor

.

REMEDY

Remove, clean or replace.

Symptom 2. When in the Start/Stop option, motor runs continuously.

Symptom 3. Air continues to leak at motor/pressure switch release valve after motor stops.

Page 13

13

PROBABLE CAUSE

Defective motor/pressure switch.

PROBABLE CAUSE

Possible defective safety relief valve.

Excessive air tank pressure.

PROBABLE CAUSE

Fittings are not tight enough.

PROBABLE CAUSE

Defective or rusted air tank.

PROBABLE CAUSE

Damaged inlet (reed) valve.

TROUBLESHOOTING

REMEDY

Replace.

REMEDY

Operate safety relief valve manually by pulling on ring.

If it still leaks, it should be replaced.

Defective motor/pressure switch. Replace.

REMEDY

Tighten fittings where air can be heard escaping. Check

fittings with soapy water solution. Do not overtighten.

REMEDY

Air tank must be replaced. Do not attempt to repair

air tank!

REMEDY

Contact SENCO Customer Service 888-222-8144.

Symptom 4. Air continues to leak at motor/pressure switch release valve while motor is running.

Symptom 5. Air leaks from safety relief valve.

Symptom 6. Air leaks at fittings.

Symptom 7. Air leak in air tank.

Symptom 8. Air blowing from inlet filter

.

PROBABLE CAUSE

Pressure regulator knob not turned to high enough

pressure or defective pressure regulator.

Restricted air intake filter.

Air leaks.

Air compressor is not large enough for air

requirement.

REMEDY

Adjust pressure regulator knob to proper setting or

replace.

Clean.

Check for leaks and repair.

Check the accessory air requirement. If it is higher than

the CFM or pressure supply of the air compressor, you

need a larger air compressor.

Symptom 9. Insufficient pressure at air tool or accessory.

Page 14

TROUBLESHOOTING

Symptom 10. Air compressor not making enough air.

PROBABLE CAUSE

Restricted air intake filter.

Defective (reed) valve.

Symptom 11. Moisture in discharge air.

PROBABLE CAUSE

Condensation in air tank caused by high level

of atmospheric humidity or air compressor is

not run long enough.

REMEDY

Clean.

Drain air tank and measure pump up time. Compare to

specifications. If lower, remove pump head and inspect

valve plate, clean or replace.

REMEDY

Drain air tank after every use. Drain air tank more often

in humid weather and use an air line filter.

14

Page 15

15

SPECIFICATIONS

Model # PC0968

Motor

Horsepower 1.5 (Peak)

Voltage 115

Amperage 8

Hz. 60

Phase Single

RPM 3450

Compressor Pump

Number of Cylinders 1

Compression Stage 1

Lubrication Lubeless

Crankcase Aluminum

Bearings Ball

Cylinder Aluminum/Steel Sleeve

Valves Reed-Single

Head Aluminum

Filter Insert

Motor/Pressure Switch Setting

Cut-out 120 PSI

Cut-in 90 PSI

Controls On/Off

Air tank

Capacity 2 gallon

Performance

CFM Air Displacement

4

CFM @ 90 PSI 2.2

Maximum Pressure 120 PSI

Pump-up Time: 0-125 PSI 68 sec.

Recovery Time: 90-120 PSI 15 seconds

Weight

Net 38 Ibs.

Dimensions

Basic LxWxH 16"x15"x13.5"

Page 16

SENCO COMPRESSOR AND P

This compressor has been designed and constructed using the highest standards of material and workmanship.

ARTS W

ARRANTY

COMPRESSOR

The length of this guarantee is one year

Senco Products, Inc., will repair or replace at Sencoís option, any original part or parts for the original retail purchaser. This will

be done free of charge, provided the parts are determined defective in materials or workmanship upon examination by a Senco

Authorized

carry a warranty for the balance of the period of warranty applicable to the part it replaces. When repair or replacement of parts

or compressor is necessary, the original retail purchaser returns the complete compressor or part, with transportation prepaid,

to the nearest Senco Authorized

is within the warranty period.

Senco warrants all parts (except those listed below) of your Senco air compressor to be free from defects in materials and

workmanship during the following periods:

1. For 1 year from date of original purchase:

2. For 90 days from date of original purchase:

Defective parts not subject to normal wear and tear will be repaired or replaced, at our (Sencoís) option, during warranty period.

In any event, reimbursement is limited to the purchase price paid.

EXCLUSIONS:

1. Engine/Motor is covered under separate warranty by its respective manufacturer and is subject to the terms set forth

therein.

2. Normal wear parts not covered under warranty:

3. This warranty does not cover parts damaged due to normal wear,

than recommended speeds or voltage (electric units only), improper storage, or damages resulting during shipping.

4.

Deviation from operating instructions, specifications, and maintenance schedules.

5. Labor charges, loss or damage resulting from improper operation, maintenance or repairs made by person(s) other than

a Senco Authorized Warranty Service Center.

6. The use of other than genuine Senco Repair Parts will void warranty.

WARRANTY:

Warranty Service Center, with the exceptions and exclusions described below. Any replacement part provided will

Warranty Service Center, with purchase receipt or other positive proof that the part or compressor

Compressor Pump Pilot

Tank Assembly Plumbing

Flywheel Throttle Control

Power Cord

Pressure Gauge Pressure Relief

Valve Draincocks

Isolators Drive Belt

Air Filter

from date of purchase by the original retail purchaser. During this period,

Valve

misapplication, misuse, accidents, operation at other

This warranty is contingent upon proper use of the compressor by purchaser and does not cover:

THIS

ORAL, WRITTEN, EXPRESS, OR IMPLIED, INCLUDING, BUT NOT LIMITED

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE EXCLUDED. BUYERíS OR USERíS REMEDIES

ARE SOLELY AND EXCLUSIVELY AS STATED ABOVE. SENCO PRODUCTS, INC. SHALL IN NO EVENT BE LIABLE FOR

INCIDENTAL, CONSEQUENTIAL, INDIRECT, OR SPECIAL DAMAGES. IN NO EVENT, WHETHER AS A RESULT OF A

BREACH OF CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL SENCOíS LIABILITY

EXCEED THE PRICE OF THE COMPRESSOR WHICH HAS GIVEN RISE TO THE CLAIM OR LIABILITY. ANY LIABILITY

CONNECTED WITH THE USE OF THIS COMPRESSOR SHALL TERMINATE UPON THE EXPIRATION OF THE

PERIOD SPECIFIED ABOVE.

Senco will also replace any compressor destroyed by an Act of God such as flood, earthquake, hurricane or other disaster

resulting only from the forces of nature. Such a claim will be honored provided that such original retail purchaser had previously

submitted a completed warranty registration card, and then submits proof of ownership and an acceptable statement describing

such Act of God documented by an insurance carrier, police department, or other official governmental source. To

instructions for filing a claim call 1-800-543-4596.

(A) Abnormal conditions, accident, neglect, misuse or improper storage of the unit.

(B) Deviation from operating or maintenance instructions.

(C) Modifications not authorized by Senco.

(D) Repairs or maintenance (other than routine air tank draining and oil filter changes required by your operating

and maintenance manual) made by persons other than Senco or its authorized agents.

(E) Freight damage.

WARRANTY IS THE ONLY WARRANTY ON THIS COMPRESSOR, AND ALL OTHER WARRANTIES, WHETHER

TO, THE IMPLIED WARRANTY OF

Replacement of Compressor Due to Natural Disaster

SENCO PRODUCTS, INC.

CINCINNATI, OHIO 45244-1611 USA

16

WARRANTY

obtain

Page 17

Questions? Commentaires? appel gratuit de SENCO au 1-800-543-4596 ou courriel à toolprof@senco.com

Compresseur d'aire eléctrique PC0968

Senco Products, Inc.

8485 Broadwell Rd.

Cincinnati, OH 45244

Notice technique d'utilisation

© 2003 by Senco Products, Inc.

PC0968 Revised July 31, 2003

(Replaces 6/30/03)

Des mises en garde pour une utilisation en toute sécurité de ce compresseur

sont incluses dans ce manual.

Page 18

TABLE DES MATIÈRES

INTRODUCTION ................................................................... 3

ALERTES POUR LA SÉCURITÉ

INSPECTION .........................................................................

MISES EN GARDE DE SÉCURITÉ

ÉLECTRICITÉ ...............................................................

EXPLOSION OU INCENDIE

ÉCLATEMENT ...............................................................

INHALATION................................................................. 6

BRÛLURES

OBJETS PROJETÉS

PIÈCES EN MOUVEMENT

NÉGLIGENCE ..............................................................

DOMMAGES AU COMPRESSEUR ............................. 7

CARACTÉRISTIQUES DU COMPRESSEUR

PRÉPARATION

MISE EN ŒUVRE INITIALE

EMPLACEMENT

ALIMENTATION ÉLECTRIQUE

FONCTIONNEMENT ............................................................ 11

LISTE DE VÉRIFICATIONS PRÉLIMINAIRES . ............

DÉMARRAGE

COUPURE .............................................................. 11

..................................................................

...................................................

.................................................................... 10

.........................................................

.............................................................

................................ 3

..............................

.......................................

.........................................

........................ 8

.......................................

..................................

10

3

4

4

5

5

6

6

7

7

10

10

11

11

ENTRETIEN

DÉPANNAGE

SPÉCIFICATIONS ............................................................... 15

GARANTIE

.........................................................................

.................................................................

.......................................................................... 16

11

12-14

2

Page 19

INTRODUCTION

Félicitations pour votre achat de notre nouveau compresseur d’air SENCO® ! Vous pouvez

être assuré que votre compresseur d’air SENCO a été construit avec le plus haut niveau de

précision et d’exactitude. Chaque composant a été rigoureusement testé par des techniciens

pour constituer la qualité, l’endurance et la performance de ce compresseur d’air.

Ce manuel d’utilisation a été composé pour vous servir. En lisant puis en appliquant les étapes

simples décrites dans de manuel de sécurisation, installation et fonctionnement, et entretien,

vous aurez des années de service sans souci pour votre nouveau compresseur à air SENCO.

Le contenu de ce manuel est basé sur les dernières informations produit disponibles au moment

de sa publication. Le constructeur se réserve le droit d’opérer des changements sur prix, couleur,

matériel et équipement, spécifications ou modèles, à tout moment et sans préavis.

ALERTES POUR LA SÉCURITÉ !

Une signalisation pour DANGER, AVERTISSEMENT ou ATTENTION pour la sécurité sera entouré d’un

encadrement d’alerte. Ce cadre est utilisé pour montrer et renforcer les mesures de sécurité qui doivent

être respectées pour faire fonctionner ce compresseur d’air. En accompagnement des mises en garde de

sécurité il y a les mots clés d’alerte qui donnent le degré de danger du risque. Les mots utilisés dans ce

manuel sont :

DANGER:

AVERTISSEMENT : Indique une situation potentiellement dangereuse, qui si les

mesures ne sont pas prises ENTRAÎNERAIT une blessure sérieuse voire mortelle.

ATTENTION : Indique une situation potentiellement dangereuse, qui si les mesures

ne sont pas prises POURRAIT ENTRAÎNER une blessure légère ou endommager le

compresseur d’air.

FOURNISSEZ TOUJOURS UNE COPIE DE CE MANUEL À TOUTE PERSONNE QUI VA UTILISER CET ÉQUIPEMENT.

IL FAUT LIRE TOUTES LES INSTRUCTIONS DE CE MANUEL PLUS TOUTES LES INSTRUCTIONS FOURNIES PAR

LES FABRICANTS DES ÉQUIPEMENTS ANNEXES AVANT DE FAIRE FONCTIONNER LE COMPRESSEUR D’AIR, ET

PRÊTER UNE ATTENTION TOUTE PARTICULIÈRE AUX MISES EN GARDE DE SÉCURITÉ POUR ÉVITER LA

POSSIBILITÉ DE BLESSURES CORPORELLES POUR L’OPÉRATEUR.

Indique une situation très dangereuse, qui si les mesures ne sont pas

prises ENTRAÎNERA une blessure sérieuse voire mortelle.

Les symboles placés à la gauche de ce paragraphe sont les symboles d’alerte de

sécurité, ils sont utilisés pour attirer l’attention sur des articles ou procédures qui

pourraient présenter un danger pour vous ou d’autres personnes utilisant cet

équipement.

INSPECTION

Déballez le compresseur d’air et écrivez son numéro de série dans l’emplacement fourni plus bas. Inspectez pour

chercher des signes d’éventuels dommages évidents ou cachés venant du transport. Assurez-vous que toutes pièces

endommagées soient remplacées et que tout problème mécanique soit résolu avant de mettre le compresseur d’air en

marche.

NUMÉRO DE SÉRIE __________________________

Si vous avez des questions ou commentaires à transmettre, contactez SENCO par appel sans frais au 1-800-222-8144 ou

en envoyant un message électronique à toolproof@Senco.com

Veuillez avoir sous la main ces informations en cas d’appel pour n’importe quel service

1. Référence de modèle

2. Numéro de série

3. Date et lieu d’achat

Senco, 8485 Broadwell Road, Cincinnati, OH 45244, USA

:

3

Page 20

MISES EN GARDE DE SÉCURITÉ

LISEZ TOUTES LES MISES EN GARDE DE SÉCURITÉ AVANT D’UTILISER LE

COMPRESSEUR D’AIR

DANGER

CONSEQUENCES POTENTIELLES

PREVENTION

RISQUE DE

COMMOTION ÉLECTRIQUE

OU D’ÉLECTROCUTION

Des blessures graves ou

mortelles peuvent arriver si le

compresseur n’est pas mis à la

terre de façon convenable. Votre

compresseur d’air est alimenté de

l’électricité et cela peut provoquer

une commotion électrique ou une

électrocution si l’utilisation n’est

pas correcte.

Une commotion électrique peut

venir du cordon secteur.

Une commotion électrique peut

arriver si le compresseur n’est

pas utilisé correctement.

Assurez-vous que compresseur d’air est

bien branché sur une prise secteur

convenablement reliée à la terre, qui

fournit la tension correcte, et qui est

protégée en amont par fusible ou

disjoncteur.

Vérifiez le cordon secteur pour y déceler

des signes d’écrasement, de coupure ou

de brûlure. Remplacez le cordon s’il est

abîmé avant toute nouvelle utilisation.

Gardez toutes les connexions au sec et

ne reposant pas par terre. Ne laissez pas

le cordon secteur traîner dans l’eau ou

dans une position telle que de l’eau

puisse venir à son contact. Ne touchez

pas la fiche secteur avec des mains

mouillées.

Ne tirez pas sur le cordon secteur pour

débrancher la fiche de la prise murale.

Ne faites jamais fonctionner le

compresseur d’air dans des conditions

d’humidité ou à l’extérieur quand il pleut.

Des blessures graves ou

mortelles peuvent arriver si des

réparations électriques sont

tentées par des personnes non

qualifiées.

4

Ne faites jamais fonctionner le

compresseur d’air avec ses couvercles

et protections de sécurité enlevés.

Tout câblage ou dépannage électrique

effectué sur le compresseur d’air doit

être confié à un personnel de dépannage

agréé, en conformité avec les

réglementations électriques locales et

nationales.

Avant d’ouvrir toute partie électrique

fermée, arrêtez toujours le compresseur

d’air, faites chuter la pression et

débranchez l’appareil de sa prise

secteur. Laissez le compresseur d’air

refroidir. Ne présumez jamais que vous

pouvez intervenir en sécurité sur le

compresseur d’air juste parce qu’il ne

tourne pas. Il pourrait redémarrer

inopinément!

Page 21

LISEZ TOUTES LES MISES EN GARDE DE SÉCURITÉ AVANT D’UTILISER LE

DANGER

RISQUE D’EXPLOSION

OU D’INCENDIE

MISES EN GARDE DE SÉCURITÉ

COMPRESSEUR D’AIR

CONSÉQUENCES POTENTIELLES

Des blessures sérieuses voire

mortelles peuvent arriver à partir

d’étincelles électriques normales

au niveau du moteur ou du

manostat.

PRÉVENTION

Faites toujours fonctionner le

compresseur d’air dans une zone

bien ventilée exempte de vapeurs

inflammables, de poussière

combustible, de gaz ou autres

matières combustibles.

Si vous pulvérisez sous pression de

la matière inflammable, placez le

compresseur d’air au moins 6

mètres plus loin que la zone traitée

(vous pouvez avoir besoin d’un

flexible auxiliaire).

RISQUE

D’ÉCLATEMENT

Des blessures sérieuses peuvent

arriver si des ouvertures de

ventilation du compresseur d’air

sont obstruées, provoquant la

surchauffe de l’appareil et

l’amenant à prendre feu.

Des blessures sérieuses voire

mortelles peuvent arriver suite à

une explosion d’un réservoir d’air,

suite à un mauvais entretien.

Des blessures sérieuses peuvent

arriver par un dysfonctionnement

du compresseur d’air ou

l’explosion d’accessoires, si des

composants, annexes ou

accessoires du système qui

seraient de type incorrect sont

utilisés.

Ne placez jamais de objets contre ou

sur le compresseur d’air. Faites-le

fonctionner à au moins 30 cm à

l’écart de tout mur ou obstacle qui

pourrait empêcher une ventilation

convenable.

Purgez le réservoir d’air

quotidiennement, ou après chaque

utilisation, afin d’éviter une

accumulation d’humidité à

l’intérieur.

Si une fuite est constatée au

réservoir d’air, il faut immédiatement

le remplacer. Ne jamais chercher à

réparer, souder ou modifier le

réservoir d’air ni ses accessoires.

Ne jamais modifier les pression

réglées en usine.

Ne dépassez jamais la pression

correspondant au maximum

nominal admissible par les

accessoires reliés.

Du fait de la température très élevée,

n’utilisez pas de tuyauterie plastique

ou de jonctions soudées à l’étain

pour la conduite de sortie.

N’utilisez jamais le compresseur

pour gonfler des petits objets pour

basse pression, comme les jouets.

5

Page 22

LISEZ TOUTES LES MISES EN GARDE DE SÉCURITÉ AVANT D’UTILISER LE

DANGER

RISQUE

D’INHALATION

RISQUE DE BRÛLURE

MISES EN GARDE DE SÉCURITÉ

COMPRESSEUR D’AIR

CONSÉQUENCES POTENTIELLES

Des blessures sérieuses voire

mortelles peuvent arriver suite à

l’inhalation d’air comprimé. Le

courant d’air peut contenir du

monoxyde de carbone, des

vapeurs toxiques ou des particules

solides.

Des matières vaporisées comme

peinture, solvants pour peinture,

décapants, insecticides,

herbicides, etc. peuvent contenir

des vapeurs et poisons qui

présentent un danger.

Des blessures sérieuses peuvent

arriver en touchant des pièces

métalliques exposées.

Ces surfaces peuvent rester très

chaudes pendant un certain temps

après l’arrêt du compresseur d’air.

PRÉVENTION

Ne respirez jamais de l’air venant du

compresseur d’air, ni directement ni

par un appareil respiratoire branché

sur le compresseur d’air.

Ne faites fonctionner le compresseur

d’air que dans une zone bine

ventilée. Respectez toutes les

instructions fournies avec le produit

que vous vaporisez. L’utilisation d’un

masque respiratoire peut être

nécessaire pour appliquer certains

produits.

Ne laissez jamais une partie

quelconque de votre corps ou des

objets entrer en contact avec

n’importe quelle partie métallique

exposée du compresseur d’air.

RISQUE

D’OBJETS

PROJETÉS

Des dommages aux tissus fragiles

peuvent être provoqués par le jet

d’air comprimé.

Des blessures sérieuses peuvent

arriver par le fait que des débris

libérés peuvent être projetés à

grande vitesse par le jet d’air

comprimé.

Portez toujours des lunettes de

sécurité norme OSHA "Z87" pour

protéger vos yeux des débris

projetés.

Ne dirigez jamais le jet d’air

comprimé vers une quelconque

partie de votre corps, ni vers d’autres

personnes ou des animaux.

Ne laissez jamais le compresseur

d’air en marche sans surveillance.

Coupez le compresseur et libérez la

pression avant toute intervention sur

le compresseur, comme le

rattachement d’outils ou

accessoires.

Gardez toujours une distance de

sécurité par rapport aux personnes

et aux animaux en faisant

fonctionner le compresseur d’air.

Ne déplacez pas le compresseur

d’air pendant que son réservoir est

encore sous pression. Ne tentez pas

de déplacer le compresseur en le

tirant par sa conduite.

6

Page 23

LISEZ TOUTES LES MISES EN GARDE DE SÉCURITÉ AVANT D’UTILISER LE

DANGER

RISQUE PRÉSENTÉ

PAR LES PIÈCES

MOBILES

RISQUE PAR

NÉGLIGENCE

RISQUE DE

DOMMAGES

AU COMPRESSEUR

D’AIR

MISES EN GARDE DE SÉCURITÉ

COMPRESSEUR D’AIR

CONSÉQUENCES POTENTIELLES

Risque de blessure

corporelle venant des

pièces mobiles. Le

compresseur d’air se

relance automatiquement

quand son manostat est sur

la position "On,/Auto".

Risque de blessure par

utilisation négligente

.

Risque d’avoir à procéder à

des réparations lourdes.

PRÉVENTION

Coupez toujours le compresseur

d’air quand vous ne vous servez

pas de l’air comprimé. Purgez la

pression du flexible d’envoi d’air

et débranchez l’appareil de sa

prise secteur avant d’entamer

tout entretien. Toutes les

réparations sur le compresseur

d’air doivent être menées par un

agent de dépannage autorisé. Ne

présumez jamais que vous

pouvez intervenir en sécurité sur

le compresseur d’air juste parse

qu’il ne tourne pas. Il pourrait

redémarrer inopinément

!

Ne laissez jamais enfants ou

adolescents faire fonctionner ce

compresseur d’air

!

Restez attentif à ce que vous

faites. Ne faites pas fonctionner

le compresseur d’air si vous êtes

fatigué ou sous l’influence

d’alcool ou médicaments.

Sachez comment arrêter le

compresseur d’air. Familiarisezvous avec ses commandes.

Ne faites pas fonctionner le

compresseur d’air sans son filtre

à air.

Ne faites pas fonctionner le

compresseur d’air dans un

environnement corrosif.

Faites toujours fonctionner le

filtre à air en position stable et

sûre pour éviter qu’il ne tombe.

Suivez bien toutes les

instructions d’entretien données

dans ce manuel.

Remplir avec de l’huile jusqu’au

niveau marqué sur la jauge

(réservoir inférieur)

CONSERVEZ CES INSTRUCTIONS !

7

Page 24

CARACTÉRISTIQUES DU COMPRESSEUR

13

11

4

3

12

5

6

2

10

9

1

7

1. Moteur, manostat

2. Pompe du compresseur d’air

3. Soupape de sûreté

4. Manomètre de pression de réservoir

5. Manomètre de refoulement

6. Régulateur de pression

7. Conduite de refoulement

8. Cordon secteur 115 volts

9. Ouvertures de ventilation / coiffe de

protection

10. Déconnexion rapide

11. Filtre d'entrée d'air

12. Robinet de purge du réservoir d'air

13. Valve de démarrage à froid

8

8

Page 25

8

CARACTÉRISTIQUES DU COMPRESSEUR

1). MOTEUR / MANOSTAT : Ce commutateur est utilisé pour démarrer ou arrêter le

compresseur d’air. En le passant sur la position Auto, le manostat est alimenté et de

façon automatique commande le démarrage du moteur quand la pression dans le

réservoir d’air est en dessous du seuil de pression basse fixé en usine. Quand il est

sur la sélection Start / Stop, le manostat commande la coupure du moteur quand la

pression dans le réservoir d’air est au dessus du seuil de pression haute fixé en

usine. Pour des raisons de sécurité le manostat comporte également une soupape de

surpression située sur le côté, conçue pour relâcher automatiquement l’air comprimé

de la tête de pompe du compresseur d’air et de sa conduite de déchargement quand

l’appareil atteint sa pression de coupure ou est arrêté. Cela permet au moteur de

redémarrer librement. Le passage du manostat en position Off lui coupe son

alimentation et arrête le compresseur d’air.

2). RUPTEUR THERMIQUE DU MOTEUR : Le moteur possède une protection contre le

suréchauffement. Si le moteur chauffe trop pour une quelconque raison, le rupteur

thermique va couper son alimentation, ce qui empêchera qu’il soit endommagé.

Attendez jusqu’à ce que le moteur soit refroidi. Le moteur a également un coupecircuit magnétique. Restaurez le rupteur en cas de déclenchement.

3). FILTRE D’ENTRÉE D’AIR : Ce filtre est prévu pour nettoyer l’air qui arrive à la

pompe. Pour assurer une arrivée d'air frais à la pompe continuellement propre et sec,

ce filtre doit rester toujours propre et l’ouverture de ventilation libre de toute

obstruction. Le filtre peut être déposé pour un nettoyage utilisant de l’eau

savonneuse chaude. Rincez ensuite le filtre et faites-le sécher.

4). POMPE DU COMPRESSEUR D’AIR : Pour compresser l’air, le piston monte et

descend dans le cylindre. Dans le mouvement de descente, l’air est aspiré par la

soupape d’admission, tandis que la soupape d’échappement reste fermée. Dans le

mouvement de remontée, l’air est compressé, la soupape d’admission se ferme et

l’air comprimé est chassé par la soupape d’échappement dans la conduite

d’échappement, au travers du clapet anti-retour puis dans le réservoir d’air.

5). SOUPAPE DE SÛRETÉ : Cette soupape est conçue pour éviter des pannes de

système en relâchant sa pression quand l’air comprimé atteint un niveau

prédéterminé. La soupape est réglée à l’avance par le constructeur et ne doit être

retouchée en aucune manière. Pour vérifier le bon fonctionnement de cette soupape,

tirer sur l’anneau. De l’air sous pression doit s’échapper. Quand l’anneau est relâché

la soupape se remet en place.

6). ROBINET DE PURGE DU RÉSERVOIR D’AIR : Ce robinet de purge est utilisé pour

évacuer l’humidité du réservoir d’air après l’arrêt du compresseur. Ne JAMAIS

essayer d’ouvrir ce robinet quand il y a plus de 10 psi (0,68 bar) de pression

dans le réservoir d’air ! Pour ouvrir ce robinet de purge, tournez son bouton

dans le sens du dévissage. Penchez le réservoir pour vous assurer que toute

l’eau coule bien par le robinet.

1

2

3

5

6

7

7). MANOMÈTRE DE RÉSERVOIR D’AIR : Ce manomètre indique la pression de

l’air comprimé en réserve dans le réservoir d’air.

). MANOMÈTRE DE REFOULEMENT : Ce manomètre indique la pression d’air

disponible du côté de sortie du régulateur. Cette pression est contrôlée par le

régulateur et elle est toujours inférieure ou égale à celle de l’air du réservoir.

9). RÉGULATEUR DE PRESSION : L’air sous pression venant du réservoir d’air

est contrôlé par le bouton du régulateur. En tournant ce bouton dans le sens du

vissage on augmente la pression de sortie, et en sens contraire on la diminue.

10). CONDUITE DE REFOULEMENT : Veuillez garder en mémoire que cette conduite

est très chaude.

9

8

9

10

Page 26

PRÉPARATION

MISE EN ŒUVRE INITIALE :

1. Lisez les mises en garde de sécurité avant de mettre en œuvre le compresseur d’air.

EMPLACEMENT:

ATTENTION

De façon à éviter d’endommager le compresseur d’air, ne l’inclinez pas

transversalement ou longitudinalement de plus de 10°.

1. Placez le compresseur d’air au moins à 30 cm de tous les obstacles qui pourraient empêcher une bonne

ventilation. Ne le placez pas dans toute zone où :

- il y a une évidence de fuites de gaz ou d’huile.

- il y a des vapeurs ou des matériaux inflammables.

AVERTISSEMENT

Des blessures graves voire mortelles peuvent survenir si des étincelles électriques

du moteur ou du manostat entrent en contact avec de vapeurs inflammables, de la

poussière de combustible, des gaz ou d’autres matériaux combustibles. Quand vous

utilisez le compresseur d’air pour vaporiser de la peinture, placez-le le plus loin possible

de la zone de travail, utilisez une rallonge de flexible plutôt qu’une rallonge de cordon

secteur.

- où la température de l’air tombe en dessous de 0°C ou dépasse 40°C.

- où de l’air très pollué ou de l’eau peut entrer dans le compresseur

ALIMENTATION ÉLECTRIQUE :

DANGER

Une connexion incorrecte du conducteur de mise à la terre de l’équipement peut

entraîner un risque de commotion électrique ou d’électrocution. Faites vérifier par un

électricien qualifié ou un agent de dépannage si vous avez un doute quant à la bonne

mise à la terre de la prise secteur. N’utilisez aucun type d’adaptateur avec ce produit.

Si la réparation ou le remplacement du cordon secteur s’avère nécessaire, ne connectez

pas le fil de terre sur l’une ou l’autre des bornes à lame plate. Le fil avec isolant dont la

surface extérieure est verte avec ou sans rayures jaunes est le fil de terre.

AVERTISSEMENT

Ce produit doit être mis à la terre. En cas d’hypothétique dysfonctionnement ou panne, la

mise à la terre fournit un chemin de moindre résistance pour le courant électrique, ce qui

réduit le risque de commotion électrique ou d’électrocution. Ce produit est équipé d’un

cordon ayant un fil pour la mise à la terre de l’équipement et une fiche secteur de type mise

à la terre. Cette fiche doit être enfoncée dans une prise murale adéquate correctement

installée et reliée à la terre en conformité avec toutes les normes et réglementations

locales.

SENCO ne recommande pas l’utilisation de rallonges secteur, car cela provoque de la perte de puissance et une surchauffe

du moteur. Utilisez plutôt une rallonge de flexible de sortie d’air comprimé. Si vous étiez dans l’obligation d’utiliser une

rallonge secteur, elle doit être branchée sur boîte de raccordement protégée par disjoncteur différentiel ou sur des prises

protégées. Quand vous utilisez une rallonge secteur, observez ces règles

Longueur de câble Calibre AWG de fil

Jusqu’à 7,5 m

Jusqu’à 30 m 10

Jusqu’à 45 m 8

Jusqu’à 75 m 6

N’utilisez que des rallonges à trois broches munies de fiches secteur à trois broches pour mise à la terre, et des douilles

secteur trois broches qui pourront recevoir le fiche secteur du produit. N’utilisez que des rallonge secteur ayant au moins de

spécifications égales à celles du cordon du produit. N’utilisez pas de rallonge électrique usagée. Examinez la rallonge avant

de l’utiliser et rejetez-la si elle est endommagée. N’abusez pas des rallonges électriques et ne tirez pas sur le câble pour

débrancher. Gardez le cordon à l’écart de la chaleur et des angles vifs. Coupez toujours le compresseur d’air à son

interrupteur avant de débrancher sa prise secteur.

12

:

10

Page 27

FONCTIONNEMENT

LISTE DE VÉRIFICATIONS PRÉLIMINAIRES :

1. Enlevez toute humidité du réservoir d’air comprimé. Faites retomber la pression en activant un outil mu

par air comprimé, puis ouvrez le robinet de purge en bas du réservoir. Refermez-le bien quand l’eau est évacuée.

AVERTISSEMENT :

robinet de purge quand il y a une pression d’air de plus de 10 psi (0,68 bar) dans le

réservoir.

Risque de blessure corporelle. N’essayez JAMAIS d’ouvrir le

2. Assurez-vous que le commutateur du moteur du compresseur est en position d’arrêt (OFF).

3. Assurez-vous que toutes les soupapes de sécurité fonctionnent bien.

4. Vérifiez que toutes les protections et couvercles sont en place et bien fixés.

DÉMARRAGE :

1. Assurez-vous que le levier de la boîte de commutateur de pression est sur position d’arrêt (OFF).

2. Branchez la fiche secteur dans la prise secteur murale.

3. Déplacez le levier de la boîte de commutateur de pression en position AUTO.

4. OPTION démarrage/coupure (START/STOP) : Passez sur la position de marche (ON). Cela va permettre

au compresseur d’air de commencer à bâtir une pression dans le réservoir d’air et de s’arrêter quand la

pression prédéterminée correcte est atteinte. Quand la pression descend par l’utilisation de l’air

comprimé, le compresseur se met tout seul en marche pour la remonter.

5. Réglez la pression d’air de sortie en tournant le bouton du régulateur (sens du dévissage pour la

baisser, sens du vissage pour l’augmenter).

6. Si vous remarquez bruit ou vibration anormaux, arrêtez le compresseur d’air et reportez-vous à la

section Dépannage.

COUPURE :

1. Pour arrêter le compresseur d’air, déplacez le levier de la boîte de commutateur de pression en position

d’arrêt (OFF). N’arrêtez JAMAIS le compresseur d’air en débranchant sa fiche secteur. Cela peut provoquer

un risque d’électrocution.

2. Faites retomber la pression en activant un outil mu par air comprimé, ou en tirant sur l’anneau de la

soupape de sûreté.

3. Une fois que la pression dans le réservoir d’air est retombée à moins de 10 psi, ouvrez le robinet de

purge sous le réservoir pour évacuer toute l’eau résiduelle.

4. Laissez le compresseur refroidir.

5. Essuyez proprement le compresseur et entreposez-le dans un endroit sûr et hors gel.

ENTRETIEN

Lisez ce manuel d’instructions avant d’effectuer un quelconque entretien. Les procédures qui suivent

doivent être suivies au moment de l’arrêt du compresseur d’air en cas d’entretien ou de dépannage.

1. Coupez le compresseur d’air à son interrupteur.

AVERTISSEMENT : Ne présumez jamais que vous pouvez intervenir en sécurité sur le

compresseur d’air juste parce qu’il ne tourne pas. Il pourrait redémarrer inopinément

2. Débranchez le cordon secteur de la prise secteur.

3. Ouvrez toutes les vidanges.

4. Laissez refroidir le compresseur d’air avant de démarrer l’intervention.

TABLEAU D’ENTRETIEN

PROCÉDURE

Purger la condensation du réservoir d’air X

Chercher des bruits/vibrations anormaux X

Chercher des fuites d’air X

Inspecter le filtre à air

Nettoyer l’extérieur du compresseur

Vérifier la soupape de sûreté X

QUOTIDIEN

HEBDOMADAIRE

X

X

11

!

MENSUEL

Page 28

DÉPANNAGE

Symptôme 1 – Le moteur ne tourne pas ou ne redémarre pas

CAUSE PROBABLE

Le cordon secteur n’est pas branché.

Le commutateur moteur/pression est sur arrêt

(OFF).

REMÈDE

Connectez le cordon sur la prise secteur.

Passez le commutateur en position de marche

(ON).

Le rupteur thermique s’est déclenché.

Calibre de fil insuffisant ou longueur de rallonge

trop élevée.

La pression d’air du réservoir dépasse le seuil de

pression de redémarrage du moteur.

La soupape de relâchement de pression du

commutateur moteur/pression n’a pas déchargé

la pression de la tête de pompe.

Moteur, condensateur de moteur, commutateur

moteur/pression potentiellement défectueux.

Coupez le compresseur d’air, attendez que le

moteur refroidisse, puis vérifiez le rupteur du

moteur.

Vérifiez que le fusible a le bon ampérage.

Vérifiez si la tension secteur ne descend pas trop

bas.

Débranchez tous les autres appareillages de ce

circuit d’alimentation, ou aménagez un circuit

d’alimentation électrique que pour le compresseur.

Vérifiez en page 10 la bonne correspondance entre

calibre et longueur du cordon secteur.

Le moteur va démarrer automatiquement quand la

pression du réservoir sera tombée sous le seuil de

redémarrage du compresseur.

Purgez la conduite en passant le commutateur sur

l’arrêt (OFF).

Contactez le support à la clientèle de Senco.

Symptôme 2 – Sur l’option démarrage/coupure (Start/Stop) le moteur tourne sans arrêts

CAUSE PROBABLE

Le commutateur moteur/pression ne coupe pas

le moteur quand la pression d’air du réservoir

atteint le seuil haut et le soupape de sûreté doit

se déclencher.

Le compresseur d’air est sous-dimensionné.

Symptôme 3 – L’air continue de fuir à la valve de purge du commutateur moteur/pression après

l’arrêt du moteur.

CAUSE PROBABLE

Vanne de pilotage défectueuse, le clapet

anti-retour est resté bloqué en position ouverte.

REMÈDE

Passez le commutateur moteur/pression sur la

position d’arrêt (OFF). Si le moteur ne se coupait

pas, débranchez le compresseur d’air. Si les

contacts électriques se sont soudés, remplacez le

commutateur.

Limitez la pression de l’air à la capacité du

compresseur d’air. Utilisez soit un outil moins

puissant soit un compresseur d’air de plus forte

capacité.

REMÈDE

Démontez, nettoyez ou remplacez.

12

Page 29

DÉPANNAGE

Symptôme 4 – L’air continue de fuir à la valve de purge du commutateur moteur/pression quand le

moteur tourne.

CAUSE PROBABLE

Commutateur moteur/pression défectueux

Symptôme 5 – L’air fuit au niveau de la soupape de sûreté.

CAUSE PROBABLE

Commutateur moteur/pression défectueux.

Symptôme 6 – L’air fuit au niveau de raccords.

CAUSE PROBABLE

Les raccords ne sont pas assez serrés.

Symptôme 7 – L’air fuit au niveau du réservoir.

CAUSE PROBABLE

Réservoir défectueux ou percé par la rouille.

REMÈDE

Remplacement.

REMÈDE

Remplacement.

REMÈDE

Resserrez les raccords là où vous entendez l’air

s’échapper. Vérifiez l’étanchéité des raccords

avec de l’eau savonneuse.

REMÈDE

Il faut remplacer le réservoir d’air. N’essayez pas

de réparer un réservoir d’air !

Symptôme 8 – L’air fuit au niveau du filtre d’entrée.

CAUSE PROBABLE

Soupape flexible d’admission défectueuse.

Symptôme 9 – Pression d’air comprimé insuffisante au niveau de l’outil ou accessoire.

CAUSE PROBABLE

Le bouton de réglage du régulateur n’est pas

assez tourné côté pression plus élevée ou le

régulateur de pression est défectueux.

Le filtre d’admission d’air est obstrué.

Il y a des fuites d’air.

Le compresseur d’air n’est pas assez puissant

pour la demande.

REMÈDE

Contactez le service à la clientèle de Senco au

888-222-8144.

REMÈDE

Réglez le bouton du régulateur pour plus de

pression, ou changez le régulateur.

Nettoyez le filtre.

Recherchez et réparez les fuites.

Vérifiez la consommation en air comprimé de

l’accessoire. Si cette demande est supérieure à la

production (pieds cubes par minute) du

compresseur d’air, il vous faut un compresseur

plus gros.

13

Page 30

DÉPANNAGE

Symptôme 10 – Le compresseur d’air ne produit pas assez d’air comprimé.

CAUSE PROBABLE

Le filtre d’admission d’air est obstrué.

Soupape flexible d’admission défectueuse.

Symptôme 11 – Humidité dans l’air en sortie.

CAUSE PROBABLE

Condensation dans le réservoir d’air causée

par un niveau élevé d’hygrométrie

atmosphérique, ou le fait que le compresseur

d’air n’a pas tourné assez longtemps.

REMÈDE

Nettoyez le filtre.

Purgez le réservoir d’air et mesurez le temps de

fonctionnement de la pompe. Comparez-le aux

spécifications. S’il est inférieur, démontez la tête

de pompe et inspectez la plaque porte soupape,

nettoyez ou remplacez.

REMÈDE

Purgez bien le réservoir d’air après chaque

utilisation. Purgez-le plus souvent par temps

humide et utilisez un filtre sur la conduite d’air.

14

Page 31

SPÉCIFICATIONS

Référence de modèle PC0968

Moteur

Puissance 1.5 CV

Tension 115 V

Ampérage 8 A

Fréquence 60 Hz

Phase Monophasé

Vitesse de rotation 3450 tours/minute

Pompe de compresseur

Nombre de cylindres 1

Étage de compression 1

Carter Aluminium

Paliers Billes

Cylindre Aluminium/Steel Sleeve

Soupapes Flexible à ruban simple

Tête Aluminium

Filtre Insert

Réglage du commutateur moteur/pression

Seuil haut de coupure 120 psi (8,3 bar)

Seuil bas de démarrage 90 psi (6 bar)

Commandes Démarrage / coupure

Réservoir d’air

Capacité 2 gallon US (7,5 l)

Performance globale

Déplacement d’air en pieds3/min

Capacité sous 90 psi 2,2

Pression maximale 120 psi (8,3 bar)

Temps d’activation de pompe

de 0 à 120 psi 68 secondes

Temps de récupération de 90

à 120 psi 15 secondes

Poids

Net 17,25 kg (38 livres)

Dimensions

Longueur x largeur x hauteur 40,6 x 38,1 x 34,3 cm (16" x 15 "x 13.5"

4

15

Page 32

GARANTIE SENCO POUR LE COMPRESSEUR ET LES PIÈCES

Ce compresseur a été conçu et construit en utilisant les normes les plus élevées quant aux matériaux et à la main d’œuvre.

GARANTIE DU COMPRESSEUR :

La durée de cette garantie est de un an à compter de la date d’achat par le client du commerce de détail d’origine. Durant cette

période Senco Products, Inc. réparera ou remplacera à son choix toute(s) pièce(s) d’origine pour le premier acheteur. Cela sera gratuit

une fois que les pièces seront bien reconnues défectueuses pour les matériaux ou la main d’œuvre par le service de dépannage sous

garantie agréé Senco, avec les exceptions et exclusions décrites ci-dessous. Toute pièce de remplacement fournie portera une

garantie propre pour la durée de période de garantie encore applicable de la pièce qu’elle remplace. Quand la réparation ou le

remplacement de pièces ou du compresseur est nécessaire, l’acheteur d’origine doit renvoyer le compresseur complet ou la pièce,

avec les coûts de transport payés à l’avance, jusqu’au centre de réparation sous garantie agréé Senco le plus proche, accompagné de

la facture ou ticket de caisse ou autre preuve d’achat pour montrer que le compresseur ou la pièce est toujours sous garantie.

Senco garantit toutes les pièces (sauf celles listées ci-dessous) de votre compresseur d’air Senco comme étant exemptes de défauts

dus aux matériaux et à la main d’œuvre pendant les périodes suivantes

1. Pendant un an à partir de la date d’achat d’origine :

Pompe de compresseur

Ensemble de réservoir

Plomberie

Cordon secteur

2. Pendant 90 jours de date d'achat initial:

Manomètre Soupape de sûreté

Robinet de purge

Les pièces défectueuses non sujettes à usure et détérioration normale seront réparées ou remplacées, au choix de Senco, pendant

leur période de garantie. Dans tous les cas le remboursement est limité à au prix d’achat déboursé.

EXCLUSIONS :

Cette garantie ne couvre pas :

1. Les pièces endommagées par usure naturelle, application non conforme, utilisation abusive, accidents, fonctionnement à vitesse ou

tension (appareillages électriques) autres que les recommandations, mauvais stockage, ou dommages occasionnés durant le

transport.

2. Les pièces endommagées par non respect des instructions d’emploi, des spécifications, et des calendriers d’entretien.

3. Les charges de main d’œuvres, les pertes ou dommages, résultant d’un fonctionnement inadéquat, d’interventions ou de

réparations effectuées par des personnes autres que celles d’un centre de réparations sous garantie agréé Senco.

4. L’utilisation de pièces autres que des pièces Senco d’origine, qui annulerait la garantie.

:

Cette garantie est conditionnée par la bonne utilisation du compresseur par son acheteur, et ne couvre pas

(A) Conditions anormales, accident, négligence, mauvaise utilisation ou stockage incorrect de l’unité.

(B) Déviation par rapport aux instructions d’emploi et d’entretien.

(C) Modifications par des personnes non autorisées par Senco.

(D) Réparations ou maintenance (autre que la purge de routine du réservoir d’air demandée dans votre manuel d’utilisation et

d’entretien) effectués par des personnes autres que celles de Senco ou de ses agents agréés.

(E) Dommages dus au transport.

CETTE GARANTIE EST LA SEULE GARANTIE SUR CE COMPRESSEUR, ET TOUTES LES AUTRES GARANTIES, QU’ELLES

SOIENT ORALES, ÉCRITES, EXPLICITES OU IMPLICITES, INCLUANT, MAIS NON LIMITÉ À, LA GARANTIE IMPLICITE DE

VALEUR MARCHANDE OU D’ADÉQUATION À UNE FINALITÉ SPÉCIFIQUE, SONT EXCLUES. LES COMPENSATION POUR

L’ACHETEUR OU L’UTILISATEUR SONT SEULEMENT ET EXCLUSIVEMENT CELLES DÉFINIES PLUS HAUT. SENCO

PRODUCTS, INC. NE POURRA EN AUCUN CAS ÊTRE TENU POUR RESPONSABLE DE TOUS DOMMAGES ANNEXES,

CONSÉCUTIFS, INDIRECTS OU SPÉCIAUX. EN AUCUN CAS, QUE CE SOIT RÉSULTANT D’UNE RUPTURE DE CONTRAT, DE

GARANTIE, DE TORT (INCLUANT LA NÉGLIGENCE) OU AUTRE, LA RESPONSABILITÉ SE SENCO NE POURRA ÊTRE

ENGAGÉE AU-DELÀ DU PRIX DU COMPRESSEUR QUI A ÉTÉ À L’ORIGINE DE LA RÉCLAMATION OU DE LA RESPONSABILITÉ.

TOUTE RESPONSABILITÉ LIÉE À L’UTILISATION DE CE COMPRESSEUR CESSERA À L’EXPIRATION DE LA PÉRIODE DE

GARANTIE DÉFINIE PRÉCÉDEMMENT.

:

Remplacement du compresseur suite à une catastrophe naturelle

Senco remplacera également tout compresseur détruit par une catastrophe naturelle telle que inondation, tremblement de terre,

ouragan ou autre désastre majeur résultant entièrement des forces de la nature. Une déclaration dans ce cadre sera honorée à la

condition que l’acheteur d’origine concerné ait auparavant renvoyé sa carte de garantie dûment remplie, et puisse fournir la preuve de

sa possession, ainsi qu’une déclaration acceptable décrivant cette catastrophe naturelle provenant d’un expert d’assurance, de la

police, ou d’une autre source officielle. Pour obtenir des instructions sur la façon d’établir une telle demande, appelez au 1-800-543-

4596.

SENCO PRODUCTS, INC.

CINCINNATI, OHIO, 45244-1611 USA

Page 33

Consultas? Comentarios? Ilame sin cargo a la línea de asistencia de SENCO: 1-800-543-4596 ó envíe a toolprof@senco.com

Compresor de aire eléctrico PC0968

Senco Products, Inc.

8485 Broadwell Rd.

Cincinnati, OH 45244

Instruccione de Operación

© 2003 by Senco Products, Inc.

PC0968 Revised July 31, 2003

(Replaces 6/30/03)

En este manual se incluyen avisos para el uso seguro de este compresor.

Page 34

INDICE

G

INTRODUCCIÓN ............................................................................................... 3

AVISO DE SEGURIDAD..................................................................................... 3

INSPECCIÓN ....................................................................................................

ADVERTENCIAS ............................................................................................... 4

SISTEMA ELÉCTRICO....................................................................................... 4

EXPLOSIÓN O INCENDIO................................................................................

ESTALLIDO ....................................................................................................... 5

RESPIRACIÓN ..................................................................................................

QUEMADURAS .................................................................................................

OBJETOS VOLANTES....................................................................................... 6

PIEZAS MÓVILES..............................................................................................

NEGLIGENCIA .................................................................................................. 7

DAÑO AL COMPRESOR DE AIRE.................................................................... 7

CARACTERÍSTICAS DEL COMPRESOR ........................................................ 8

PREPARACIÓN................................................................................................. 10

MONTAJE INICIAL ............................................................................................ 10

EMPLAZAMIENTO............................................................................................. 10

SISTEMA ELÉCTRICO...................................................................................... 10

FUNCIONAMIENTO .......................................................................................... 11

LISTA DE COMPROBACIÓN ANTES DE LA PUESTA EN MARCHA............... 11

PUESTA EN MARCHA ...................................................................................... 11

PARADA ............................................................................................................ 11

MANTENIMIENTO............................................................................................. 11

LOCALIZACIÓN Y SOLUCIÓN DE AVERÍAS ................................................. 12-14

ESPECIFICACIONES ....................................................................................... 15

ARANTÍA .........................................................................................................16

3

5

6

6

7

2

Page 35

INTRODUCCIÓN

¡Lo felicitamos por la compra de su nuevo compresor de aire SENCO®! Puede tener la seguridad

de que su compresor de aire SENCO fue construidos con el más alto nivel de precisión y

exactitud. Cada componente fue sometido a pruebas rigurosas por los técnicos para garantizar

la calidad, duración y rendimiento de este compresor de aire.