Page 1

Metal Connectors

JoistPro250

JoistPro150

JoistPro250

JoistPro150

Senco Brands, Inc.

4270 Ivy Pointe Blvd.

Cincinnati, Ohio 45245

Questions? Comments?

e-mail: toolprof@senco.com www.senco.com

© 2011 by Senco Brands, Inc.

NFD86K7L Issued August 2, 2011

Page 2

English

Español Français

TABLE OF

CONTENTS

Tool Use 2

Maintenance 6

Troubleshooting 7

Specifications 8

Accessories 8

EMPLOYER’S

RESPONSIBILITIES

Employer must enforce

compliance with the

safety warnings and

all other instructions

which accompany this

tool as shipped from the

manufacturer.

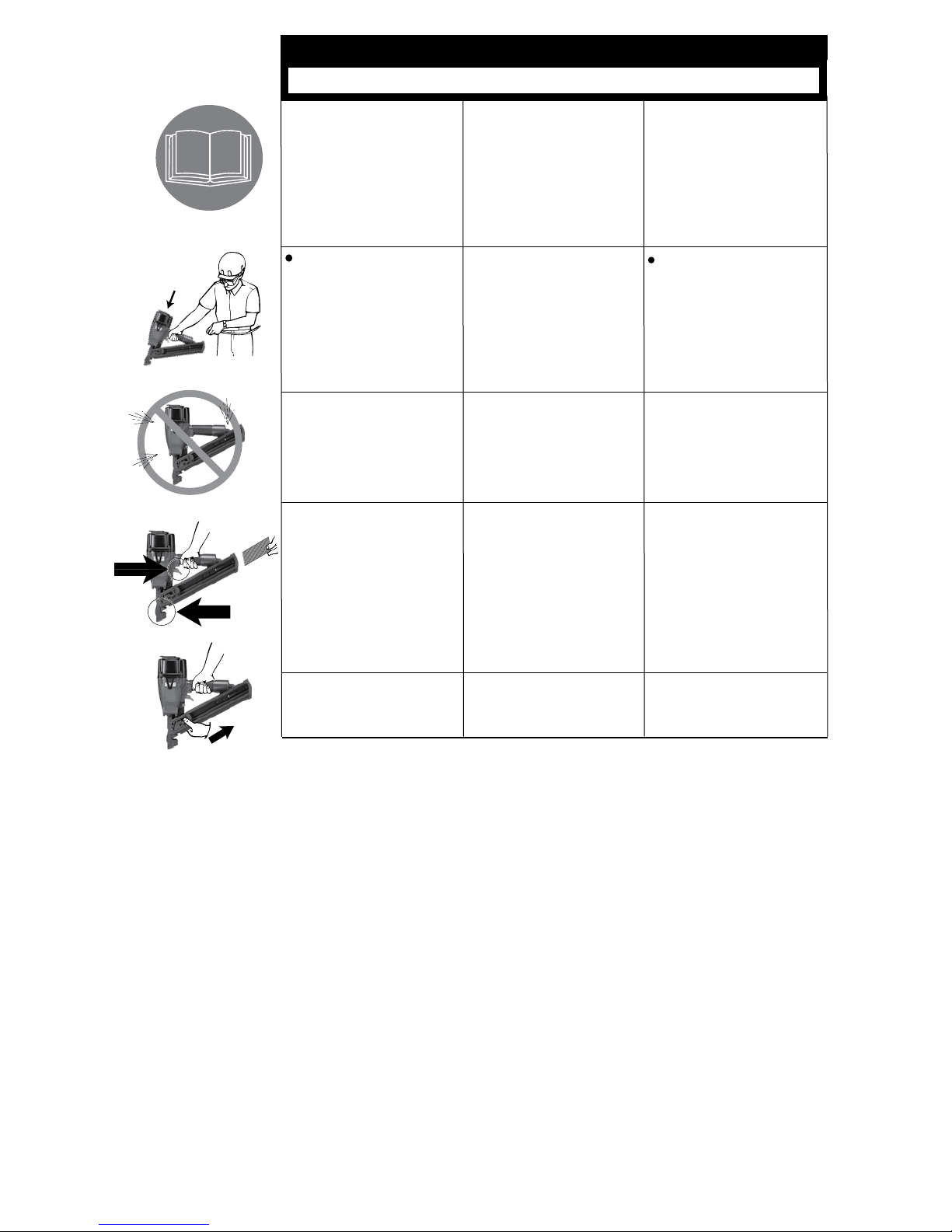

Keep this manual available for use by all people

assigned to the use of this

tool.

For personal safety and

proper operation of this

tool, read and understand

all of these instructions

carefully.

TABLA DE

MATERIAS

Uso de la

Herramienta 2

Mantenimiento 6

Identificación

de Fallas 7

Especificaciones 8

Accesorios 8

RESPONSABILIDADES DEL

EMPLEADOR

El empleador debe hacer

cumplir las advertencias de

seguridad y todas las otras

instrucciones que acompañan

a esta herramienta como se la

despacha desde el fabricante.

Mantenga este manual disponible para que lo usen todas

las personas destinadas a hacer uso de esta herramienta.

Por razones de seguridad personal y la adecuada operación

de esta herramienta, lea y

comprenda todas estas instrucciones cuidadosamente.

TABLE DES

MATIERÈS

Utilisation de l’outil 2

Entretien 6

Dépannage 7

Spécifications 8

Accessoires 8

RESPONSABILITÉS DE

L’EMPLOYEUR

L’employeur doit faire appliquer les consignes de

sécurité et toutes les autres

instructions qui accompagnent cet outil tel qu’il est

livré par son constructeur.

Ayez ce manuel à la disposition de toutes les

personnes chargées

d’utiliser cet outil.

Pour assurer la sécurité personnelle et le bon

emploi de cet outil, lisez et

assimilez soigneusement

toutes ces instructions.

2

Page 3

Tool Use

Uso de la Herramienta

Utilisation de l’Outil

English

ä=Read and understand “SAFETY

INSTRUCTIONS” manual

shipped with this tool before

using tool.

Keep tool pointed away from

yourself and others and

connect air to tool.

Tools shall be operated at the

lowest pressure needed for

the application. This will

reduce noise levels, part

wear, and energy use.

ä Never use a tool that leaks air or

needs repair.

ä=To Load:

Insert strip of nails into rear of

magazine. For optimum performance use SENCO fasteners.

Do not load with workpiece

contact (safety element) or trigger depressed.

Español

ä=Antes de usar la herramienta lea

y comprenda el manual “INSTRUCCIONES DE SEGURIDAD” despachado con ella.

ä Mantenga la herramienta

apuntandoendirecciónopuesta

de usted y de otros y conecte el

aire a la manguera.

ä=Nunca use una herramienta que

tenga escapes de aire o que

necesite ser reparada.

ä=Para cargar:

Inserte la tira de clavos en

la parte de atrás del área de

almacenamiento. Use solamente

sujetadores SENCO auténticos.

No cargue con el disparo o la

seguridad oprimidos.

Français

ä=Lisez et assimilez le manuel

“INSTRUCTIONS DE SÉCURITÉ” livré avec cet outil avant

de l’utiliser.

Maintenez l’outil pointé à

l’écart de vous-même et des

autres personnes et

raccordez l’outil à l’air

comprimé. Les outils doivent

être utilisés à la pression la

plus faible requise pour le

travail à faire. Cela réduira le

niveau de bruit, l’usure de

l’outil et la demande en

énergie.

ä N’utilisez jamais un outil qui a

des fuites d’air ou qui a besoin

d’être réparé.

ä=Pour charger :

Introduisez une bande de clous

dans la partie arrière du magasin. Utilisez uniquement les

véritables clous SENCO. Veillez

à ne pas appuyer sur le palpeur

de sécurité ou sur la détente

quand vous chargez.

ä Pull feeder shoe back.

ä Tire la zapata del alimentador.

ä Tirez le poussoir en arrière.

3

Page 4

Tool Use

1

2

Uso de la Herramienta

Utilisation de l’Outil

English

=

ä With a Single Sequential (Re-

strictive) trigger mode, nails can

only be driven one way. First depress workpiece contact (safety

element) against work surface

then pull trigger. This feature is

helpful when precise fastener

placement is required.

ä=Read the “Customer Satisfaction

=

and Safety Reminder” (CSSR)

in the tool and fastener boxes

for safety information regarding the Contact-Actuation and

Sequential trigger modes. Under

certain conditions, the Sequential trigger mode may reduce the

possibility of injury to you or to

others working with you.

Always remove finger from

trigger when not driving

fasteners. Never carry the

tool with finger on or under

trigger. Tool will eject a

fastener if the workpiece contact

is bumped.

TO AVOID SERIOUS INJURY FROM

FASTENERS AND FLYING DEBRIS WHEN INSTALLING METAL

CONNECTORS USING THE

JOISTPRO NAILER:

•UseonlygenuineSencometal

connector nails.

•Metalconnectornailsarenotdesigned to penetrate metal. When

installing metal connectors, always

place the exposed point of the

metal connector nail into the metal

connector’s pre-formed hole, and

orient so the nail is perpendicular

to the hole before attempting to

drive a fastener.

•Sencostronglyrecommendsthe

use of hardened nails in the JoistPro tools.

JoistPro150: WORK CONTACT

ELEMENT The moveable nose,

which acts as the contact trip,

is in the “depressed” position at

rest to allow visibility of the nail

points. When the tip of the nail is

placed in the pre-punched metal

connector hole and the trigger is

pulled, the moveable nose moves

out from the tool to detect the work

surface. If the moveable nose does

not detect the work surface close

to the nose of the tool, the tool will

not actuate.

Español

ä Con el modo único de acti-

vaciónSecuencial(Restrictivo),

los clavos pueden insertarse de

una sola manera. Primero oprima el contacto con la pieza de

trabajo (elemento de seguridad)

contralasuperficiedetrabajo,

y luego tire del gatillo. Esta

característica es útil cuando se

necesiteunacolocaciónprecisa

del sujetador.

Paraobtenerinformación

de seguridad referente a

losmodosdeactivaciónPor

contacto y Secuencial, lea el

‘Recordatorio de seguridad y de

satisfaccióndelcliente’(CSSR)

en las cajas de la herramienta

y de los sujetadores. Bajo

determinadas condiciones, el

mododeactivaciónSecuencial

puede reducir la probabilidad

de que usted y otras personas

que trabajen con usted sufran

lesiones.

Siempre quite el dedo del

gatillo cuando no esté

disparando clavos. Nunca

cargue la herramienta con el

dedo sobre o por debajo del

gatillo. La herramienta

disparara un clavo si se

golpea el elemento de

seguridad.

PARA EVITAR LESIONES SERIAS

POR FIJACIONES Y RESIDUOS

QUE VUELEN AL INSTALAR

CONECTORES DE METAL

USANDO CON EL ADITAMENTO CONECTOR DE METAL:

•Usesolamentelosclavosconectores de metal genuinos de Senco.

•Losclavosconectoresde

metal no están diseñados para

penetrar el metal. Al instalar

conectores de metal,siempre

ponga la punta expuesta del

clavo conector de metal en el

agujero preformado del conector

de metal, yoriente el clavo de tal

modo que quede perpendicular

al agujero antes de intentar

instalar uno.

•Sencorecomiendaclavosendurecido en las JoistPro herramientas.

JoistPro150: ELEMENTO DE

CONTACTO CON LA PIEZA

DETRABAJOLapuntamóvil,

la cual actúa comodisparo de

contacto,estáenlaposición

“oprimida” en descanso para

permitir la visibilidad de las puntas declavos. Cuando se pone

la punta del clavo en el agujero

conector demetal preperforado

y se acciona el gatillo, la punta

móvilsaledelaherramienta

paradetectarlasuperficiedetrabajo.Silapuntamóvilnodetecta

lasuperficiedetrabajocercade

la punta de la herramienta, no se

activarála herramienta.

Français

ä Avec un mode de déclenche-

ment séquentiel (restrictif), les

clous ne peuvent être plantés

que d'une seule façon. Appuyez

d'abord la surface de contact

(élément de sécurité) sur la

pièce à travailler, puis actionnez

la gâchette. Cette possibilité est

commode quand un placement

précis du clou est nécessaire.

=

Lisez le rappel sur la satisfaction

du client et la sécurité (CCSR)

sur l'outil et les boîtes de

clous, à propos des consignes

de sécurité sur les modes de

déclenchement au toucher et

séquentiel. Dans certaines conditions, le mode de déclenchement séquentiel peut diminuer

la possibilité de blessures, pour

vous ou ceux qui travaillent à

proximité.

Otez le doigt de la détente

lorsque vous n’enfoncez pas

d’agrafes. Ne transportez

jamais l’outil avec le doigt sur

la détente ; l’outil tirera une

agrafe si le palpeur de

sécurité par pression est

heurté.

POUR ÉVITER LES BLESSURES

CAUSÉES PAR DES ATTACHES

ET DES DÉBRIS PROJETÉS

AUMOMENT DE POSER DES

CONNECTEURS MÉTALLIQUES À

L’AIDE AVEC EMBOUT POUR MCNCONNECTEUR MÉTALLIQUE :

•N’utiliserquedesclouspour

connecteur métallique d’origine

Senco.

•Lesclouspourconnecteurmétallique ne sont pas conçus pour pénétrer le métal. Au moment d’installer

des connecteurs métalliques,

toujours placer la pointe visible du

clou dans le trou préformé du connecteur, et orienter l’outil de façon

que le clou soit perpendiculaire au

trou avant d’enfoncer l’attache.

•Sencorecommandefortementclous

durcis dans les JoistPro outils.

JoistPro150 : ELEMENT DE CON-

TACT AVEC PIECE Le nez de

pose mobile, quisert de déclencheur, reste en position « enfon-

cée»aureposafindegarderles

pointes de clousvisibles. Lorsque

la pointe du clou est dans le trou

pré-perfore connecteur métallique

et que la gâchette est enfoncée,

le nez sort de l’outil pour détecter

la surfacede travail. S’il ne détecte

pas la surface près du nez de

l’outil, l’outil ne s’actionnera pas.

ä=JoistPro250 To adjust the depth the

fastenerisdriven,firstdisconnect

the air supply. Using your thumb or

indexfinger,rotatewheeltoadjust

the Depth Control safety element

to achieve desired depth.

ä=JoistPro250 Para ajustar la

profundidad de sujetador, dede

primero desconectar el aire.

Usando el dedo pulgar o el

dedo indice, rote la manivela

para ajustar el seguro a la

profundidad deseada.

ä=JoistPro250 A l’aide du pouce

ou de l’index, faire tourner la

molette pour ajuster la position

du palpeur de sécurite.

4

Page 5

Tool Use

Uso de la Herramienta

Utilisation de l’Outil

English

ä Should a nail jam occur,

disconnect air supply.

ä=Release the feeder shoe

and slide it forward. Remove

fasteners from the tool.

ä=Remove the screw at the back

of the tool and remove the

magazine.

ä=Clear jammed fastener from

guide body.

Reattach the magazine and

fasten magazine mounting

screw.

Español

ä=Si se produce un altascamiento

de un clavo, desconecte el

suministro de aire.

ä=Suelte el alimentador y deslícelo

hacia adelante. Retire los

sujetadores de la herramienta.

ä=Quite el tornillo de la parte

trasera de la herramienta, y

retire el cargador.

ä=Libre el sujetador de la placa

de nariz.

t

Français

ä=Au cas ou il se produirait un

coinçage de clous, coupez

l’alimentation en air.

ä=Relâcher le poussoir et le faire

glisser vers l’avant. Enlever les

projectiles.

.

ä=Ôtez la vis à l'arrière de l'outil et

sortez son magasin.

ä=Extraire le clou coincé du front

de l’appareil.

ä=Connect air supply and replace

fasteners. Pull feeder shoe back.

ä To prevent eye injuries, always

wearOSHArequired“Z87”

safety glasses with permanently

attached rigid, hard plastic side

shields. These safety glasses

musthave“Z87”printedor

stamped on them. Be sure everyone in your work area is wearing

the same type of safety glasses.

ä Never use oxygen, carbon

dioxide or any other bottled gas

as a power source for this tool;

the tool will explode and cause

serious injury.

ä=Conecte la línea de aire y reem-

place los clavos. Tire la zapata

del alimentador.

ä

Para prevenir lesiones en los

ojos, use siempre los anteojos de

seguridad“Z87”requeridospor

OSHA con escudos lateralés rigi-

dosdeplasticóduroyadheridos

permanentemente. Estos anteojos

deseguridaddebentener“Z87”

marcado o impreso en ellos.

Asegúrese que toda persona

dentro de su area de trabajo use

el mismo tipo de anteojos.

ä Nunca use oxígeno, anhídrido

carbónicoocualquierotrogas

embotellado como fuente de

fuerza para esta herramienta;

la herramienta explotará y producirá lesiones graves.

ä Reconnectez la conduite d’air

comprimé et rechargez le magasin. Tirez le poussoir en arrière.

ä Afindeprotégervosyeuxcontre

les blessures, portez toujours

des lunettes de securité OSHA

“Z87”aveccacheslatérauxen

plastiquerigide.Lamention“Z87”

doit être imprimée ou poinçonnée

sur ces lunettes de securité. Assurez-vous que toute personne

se trouvant près du secteur de

travail porte des lunettes de

sûreté.

ä N’utilisez jamais de l’oxygène,

du gaz carbonique ou tout autre

gaz en bouteille comme source

d’énergie pour cet outil ; cela

causerait l’explosion de l’outil et

entraînerait de graves blessures.

5

Page 6

Maintenance

Mantenimiento

Entretien

English

=Disconnect the tool from the

air supply and empty

magazine. Read section

titled “Safety Warnings”

before maintaining tool.

ä All screws should be kept tight.

Loose screws result in unsafe

operation and parts breakage.

ä=With tool disconnected, make

daily inspection to assure free

movement of the workpiece contact (safety element) and trigger.

Do not use tool if safety element

or trigger sticks or binds.

Español

ä=Antes de usar la herramienta

lea y comprenda el manual

“INSTRUCCIONES DE SEGURIDAD” despachado con ella.

ä Todos los tornillos tienen que

mantenerse apretados. Los tornillos sueltos pueden producir

unaoperaciónnoseguray

quebraduras de partes.

ä Con la herramienta

desconectada, haga inspecciones diarias para asegurar el

movimiento libre del seguro y

del gatillo. No use la herramienta si el seguro o el gatillo

se atoran.

Français

ä=Lisez et assimilez le manuel

“INSTRUCTIONS DE SÉCURITÉ” livré avec cet outil avant

de l’utiliser.

ä=Toutes les vis doivent être

maintenues serrées à fond. Les

vis desserrées entraînent un

manque de sûreté du fonctionnement et la rupture de pièces.

ä=L’outil étant séparé de

l’alimentation en air, effectuez

une inspection journalière pour

assurer le libre mouvement

du palpeur de sécurité et de

la détente. N’utilisez pas l’outil

si le palpeur de sécurité ou la

détente colle ou se coince.

ä=Squirt Senco pneumatic oil (5 to

10 drops) into the air inlet twice

daily (depending on frequency

of tool use). Other oils may damage O-rings and other tool parts.

ä=Wipe tool clean daily and inspect

forwear.Usenonflammable

cleaning solutions only if necessary–DO NOT SOAK.

Caution: Such solutions may

damage O-rings and other tool

parts.

ä=Aplique aceite neumático

SENCO en la entrada de aire

dos veces al día (dependiendo

en la frecuencia de uso 5 A 10

Gotas). Otros aceites pueden

dañar los anillos en “O” y otras

piezas de la herramienta.

ä Solamente si es necesario use

soluciones para limpieza no

flamablésNOLAREMOJE.

Precaución:Talessoluciones

pueden dañar los empaques y

otras partes de la herramienta.

ä=Avec une burette, placer 5 à 10

gouttes d’huile pneumatique

dans l’arrivée d’air deux fois

par jour (dépend de l’intensité

de l’utilisation de l’appareil).

D’autres huiles pourraient endommager les joints toriques et

d’autres pièces de l’outil.

ä Nettoyez l’outil chaque jour à

l’aide d’un chiffon et inspectezle pour déceler une éventuelle

usure. Utilisez uniquement des

solvantsnoninflammablesen

cas de nécessité-NE LE FAITES

PAS TREMPER !

Attention : De tels produits

peuvent endommager les joints

et autres pièces de l’appareil.

6

Page 7

Troubleshooting

IdentificacióndeFallas

Dépannage

English

WARNING

Repairs other than those described

here should be performed only by

trained,qualifiedpersonnel.Contact

SENCO for information at

18005434596.

ä=Read section titled “Safety Warn-

ings” before maintaining tool.

SYMPTOM

Air leak near top of tool /

Sluggish operation

SOLUTION

Verify air supply / tighten screws or

install Parts Kit A.

SYMPTOM

Air leak near bottom of tool /

Poor return.

SOLUTION

Clean tool / tighten screws or install

Parts Kit B.

Español

ALERTA

Las reparaciones, fuera de aquellas

descritas aquí, deben de ser llevadas a cabo solamente por personal

entrenadoycalificado.Póngase

en contacto con SENCO para

información

18005434596.

ä=Lealaseccióntitulada“Avisosde

Seguridad” antes de darle

mantenimiento a la herramienta.

SÍNTOMA

El aire se escapa cerca de la parte

superior de la herramienta /

Operaciónlenta.

SOLUCIÓN

Aprietelostornillos/Verifiqueel

suministro de aire o instale el

Juego de Partes A (Parts Kit A).

SÍNTOMA

El aire se fuga cerca de la parte

inferior de la herramienta / Mal

retorno.

SOLUCIÓN

Apriete los tornillos / Limpié la her-

ramienta o instale el Juego de

Partes B (Parts Kit B).

Français

AVERTISSEMENT

Les réparations autres que

celles décrites ici doivent être

réalisées uniquement par du

personnelqualifiéayantreçula

formation appropriée. Pour toute information, prenez contact

avec SENCO par téléphone en

appelant Le Distributeur agréé.

ä=Lisez la section intitulée “Con-

signes

de Sécurité” avant d’effectuer

l’entretien de l’outil.

SYMPTÔME

Fuite d’air près du sommet

de l’outil / fonctionnement lent.

SOLUTION

Serrezlesvisàfond/vérifiez

l’alimentation en air ou remplacez les pièces portant la

lettre “A”.

SYMPTÔME

Fuite d’air près de la base

de l’outil / retour inadéquat.

SOLUTION

Serrez les vis à fond / nettoyez

l’outil ou remplacez les pièces

portant la lettre “B”

SYMPTOM

Other problems.

SOLUTION

Contact SENCO.

SÍNTOMA

Otros problemas.

SOLUCIÓN

PóngaseencontactoconSENCO.

SYMPTÔME

Autres problèmes.

SOLUTION

Prenez contact avec SENCO.

7

Page 8

Min. to max. operating pressure

Air Consumption (60 cycles per min)

Air Inlet

Weight

Fastener Capacity

Tool size: Height

Tool size: Length

Tool size: Width: Main Body

English

TECHNICAL SPECIFICATIONS

70–120 psi

4.1 scfm

3

/8 in. NPT

5.9 lbs.

20

14.13 in.

13.78 in.

4.33 in.

4.8–8.3 bar

117.5 liter/min.

3

/8 in. NPT

2.68 kg

20

359 mm

350 mm

110 mm

JoistPro250

Operating Temperature Range

0° to 120°F

-18° to 49°C

Pression de travail min. et max.

Consommation d’air (60 cycles par minute)

Admission d’air

Poids

Capacité de projectiles par magasin

Dimensions de l’outil: hauteur

Dimensions de l’outil: longueur

Dimensions de l’outil: largeur: corps de l’appareil

Français

SPECIFICATIONS TECHNIQUES

Presión de operación mínima y máxima

Consumo de aire (60 ciclos por minuto)

Entrada de aire

Peso

Capacidad de grapas por cargador

Tamaño de la herramienta: Altura

Tamaño de la herramienta: Longitud

Tamaño de la herramienta: Ancho (Cuerpo)

Español

ESPECIFICACIONES TECNICAS

70–120 psi

4.1 scfm

3

/8 in. NPT

5.9 lbs.

20

14.13 in.

13.78 in.

4.33 in.

4.8–8.3 bar

117.5 liter/min.

3

/8 in. NPT

2.68 kg

20

359 mm

350 mm

110 mm

JoistPro250

70–120 psi

4.1 scfm

3

/8 in. NPT

5.9 lbs.

20

14.13 in.

13.78 in.

4.33 in.

4.8–8.3 bar

117.5 liter/min.

3

/8 in. NPT

2.68 kg

20

359 mm

350 mm

110 mm

JoistPro250

Nota: Cuando usted utiliza clavos de 60 mm podría ser posible que usted necesite incrementar la presión.

Lorsque vous utilisez des clous de 60 mm, il se peut que vous deviez augmenter la pression d’air

Température de fonctionnement

0° to 120°F

-18° to 49°C

Rango de temperatura de

0° to 120°F -18° to 49°C

Note: When you use 60mm nails it could be possible that you need to increase your air pressure

70–120 psi

2.3 scfm

3

/8 in. NPT

4.6 lbs.

30

11.97 in.

10.35 in.

3.94 in.

4.8–8.3 bar

65.9 liter/min.

3

/8 in. NPT

2.08 kg

30

304 mm

263 mm

100 mm

JoistPro150

0° to 120°F

-18° to 49°C

70–120 psi

2.3 scfm

3

/8 in. NPT

4.6 lbs.

30

11.97 in.

10.35 in.

3.94 in.

4.8–8.3 bar

65.9 liter/min.

3

/8 in. NPT

2.08 kg

30

304 mm

263 mm

100 mm

JoistPro150

0° to 120°F

-18° to 49°C

70–120 psi

2.3 scfm

3

/8 in. NPT

4.6 lbs.

30

11.97 in.

10.35 in.

3.94 in.

4.8–8.3 bar

65.9 liter/min.

3

/8 in. NPT

2.08 kg

30

304 mm

263 mm

100 mm

JoistPro150

0° to 120°F

-18° to 49°C

Fastener Size

1 1/2 -2 1/2” (38-64 mm) Length

.131-.162” (3.3-4.1 mm) Diameter

1 1/2 ” (38 mm) Length

.131-.148” (3.3-3.8 mm) Diameter

Dimension d’pointe

1 1/2 -2 1/2” (38-64 mm) Longeur

.131-.162” (3.3-4.1 mm) Diametre

1 1/2 ” (38 mm) Longeur

.131-.148” (3.3-3.8 mm) Diametre

Tamano del clavo

1 1/2 -2 1/2” (38-64 mm) Larago

.131-.162” (3.3-4.1 mm) Diametro

1 1/2 ” (38 mm) Largo

.131-.148” (3.3-3.8 mm) Diametro

Limited Warranty

SENCO® Pneumatic, DuraSpin®, Cordless Tools

& Compressors

Senco Brands, Inc. (“SENCO”) designs and constructs its products using the highest standards of material and workmanship. SENCO

warrants to the original retail purchaser that the following products will be free from defects in material or workmanship for the warranty

period specified below:

SENCO® XP Series-Red Cap SENCO PRO Series SENCO Compressors

Five years One year One year

SENCO® XP Series-Black Cap SENCO DuraSpin® SENCO Cordless Hand Nailers

Two Years One year Two years One Year

SENCO FP502 SENCO Reconditioned Products Gas Cordless

Two Years One Year Two Years

During the warranty period (which begins on the purchase date), S ENCO will repair or replace, at SENCO’s option and expense, any product or part that

is defective in materials or workmanship after examination by a S ENCO Authorized Warranty Service Center, subject to the exceptions, exclusions and

limitations descri bed below. Any replacement product or part will carry a warranty for the balance of the warranty period applicable to the replaced

product or part. A DATED SALES RECEIPT OR PROOF OF PURCHASE FROM THE ORIGI NAL RETAIL PURCHASER IS REQUIRED TO MAKE A

WARRANTY CLAIM. Product registration can be accomplished through on-line Product Registration at www.senco.com or by completing and returning

the postage paid product registration form included with your Operator’s manual/p arts chart inform ation, found inside the product car ton. To make a

warranty claim, you must return the product, with proper receipt/proof of purchase and return transportation charges prepaid, t o a SENCO Authorized

Warranty Service Center. A list o f SENCO Authorized Warranty Service Centers can be fo und at www.senco.com

or by calling 1-800-543-4596 toll free.

SENCO will perform its obligations under this warranty, within a reasonable time after approval of the warranty claim.

Wheelbarrow Compressors:

1. Subject to the exceptions, exclusions and limitations described below, SENCO warrants that the compressor pump will be free from defects in

materials and workmanship for two years after the purchase date.

2. Defective parts of the compressor pump not subject to normal wear and tear will be repaired or replaced, at SENCO's option, during the two

year warranty period. If SENCO determines that repair or replacement is not feasible, SENCO will refund the purchase price less reasonable

depreciation based on actual use.

SENCO Cordless:

1. Subject to the exceptions, exclusions and limitations described below, SENCO warrants that the SENCO Cordless tool will be free from

defects in materials and workmanship for two years after the purchase date.

2. Subject to the exceptions, exclusions and limitations described below, SENCO warrants that the batteries and chargers used with SENCO

Cordless tools will be free from defects in material and workmanship for one year after the purchase date.

WARRANTY EXCLUSIONS

The following warranty exclusions apply:

1. Normal wear parts are not covered under this warranty. Normal wear parts include, for example, isolators, drive belts, air filters, rubber o-rings,

seals, driver blades, piston stops, piston/driver assembly, and fuel stems.

2. This warranty does not cover parts damaged due to normal wear, misapplication, misuse, accidents, operation at other than recommended

speeds or voltage (electric units only), improper storage, or damage resulting during shipping.

3. Products used in production/industrial applications as defined by SENCO are excluded from this warranty.

4. Labor charges or loss or damage resulting from improper operati on, maintenance or repairs are not covered by this warranty.

5. SENCO does not warrant the Wheelbarrow Compressor Engine/Motor, but the Compressor Engine/Motor may be covered under a warranty

offered by its manufacturer.

GENERAL WARRANTY CONDITIONS

This warranty will be honored, only if:

A. Clean, dry, regulated compressed air has been used, at air pressure not exceeding the maximum indicated on the tool casting;

B. No evidence o

f abuse, abnormal conditions, accident, neglect, misuse or improper modifications or storage of the product; and

C. No Deviation from operating instructions, specifications, and maintenance schedules exists (read Operator Manual for use, specifications, and

maintenance instructions).

THIS WARRANTY IS THE ONLY WARRANTY ON THE PRODUCT, AND SENCO DISCLAIMS ALL OTHER WARRANTIES. ANY IMPLIED

WARRANTIES WILL BE LIMITED IN DURATION TO THE APPLICABLE WA RRANTY PERIOD SPECIFIED ABOVE. SOME STATES DO NOT ALLOW

LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. YOUR REMEDIES ARE

SOLELY AND E XCLUSIVELY AS STATED ABOVE. SENCO SHALL IN NO EVENT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, INDI RECT,

OR SPECIAL DAMAGES. SOME STATES DO NOT ALLOW THE EXCLUSIO N OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. IN NO EVENT, WHETHER AS A RESULT OF A BREACH OF

CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL SENCO’S LIABI LITY EXCEED THE PRICE OF THE

PRODUCT WHI CH HAS GIVEN RISE TO THE CLAIM O R LIABILITY. ANY LIABILITY CONNE CTED WITH THE USE OF THIS PRO DUCT SHALL

TERMINATE UPON THE EXPIRATION OF THE WARRANTY PERIOD SPECIFIED ABOVE. NO EMPLOY

EE OR REPRESENTATIVE OF SENCO OR

ANY DISTRIBUTOR OR DEALER IS AUTHORIZED TO MAKE ANY CHANGE OR MODIFICATION TO THIS WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

REPLACEMENT OF TOOL DUE TO NATURAL DISASTER

SENCO will replace any tool destro yed by an Act of God such as flood, eart hquake, hurricane o r other disaster resulting only from the forces of nature.

Such a claim will be honored provided that such original retail purchaser had previously submitted a completed w arranty registration card for the tool,

and then submits proof of ownership and an acceptable statement describing such Act of God documented by an insurance carrier, police department,

or other official governmental source. To obtain instructions for filing a claim call 1-800-543-4596.

CUSTOMER SATISFACTION

One hundred p ercent customer satisfaction is our #1 goal. If for any reason the product does not perform to the original purcha

ser’s satisfaction, i

t can

be returned to the place of purchase within thirty days with dated sales receipt for a full refund of the purchase price.

©2006, 2009 by SENCO BRANDS, INC.

CINCINNATI, OHIO 45244-1611 USA

www.senco.com

051208

8

=

Accessories

English

SENCO offers a full line of accessories for your SENCO tools, including:

ä=Air Compressors

ä=Hose

ä=Couplers

ä=Fittings

ä=Safety Glasses

ä=Pressure Gauges

ä=Lubricants

ä=Regulators

ä=Filters

For more information or a complete

illustrated catalogue of SENCO

accessories, ask your representative

for#MK336.

SENCO ofrece una línea completa

de Accesorios para sus herramientas SENCO, incluyendo:

ä=Compresores de Aire

ä=Manguera

ä=Conectores Rapidos

ä=Conectores

ä=Anteojos De Seguridad

ä=Manometros

ä=Lubricantes

ä=Reguladores

ä=Filtros

Paramasinformacionóunpour

recevoir un catalogo completo ilustrado de los Accesorios SENCO,

pregunte a su representante pour

elnumeroMK336.

Accesorios

Español

=

=

SENCO offre une gamme étendue

d’accessoires pour vos outils

SENCO y compris :

ä=Compresseurs

ä=Tuyauterieflexible

ä=Raccords

ä=Lunettes de sécurité

ä=Manomètres

ä=Lubrifiants

ä=Régulateurs

ä=Filtres

Pour plus d’informations ou pour

recevoir un catalogue détaillé des

accessoires proposés par SENCO,

prenez contact avec votre

représentant SENCO (référence

catalogue:#MK336).

Accessoires

Français

=

Page 9

Limited Warranty

SENCO® Pneumatic, DuraSpin®, Cordless Tools

& Compressors

Senco Brands, Inc. (“SENCO”) designs and constructs its products using the highest standards of material and workmanship. SENCO

warrants to the original retail purchaser that the following products will be free from defects in material or workmanship for the warranty

period specified below:

SENCO® XP Series-Red Cap SENCO PRO Series SENCO Compressors

Five years One year One year

SENCO® XP Series-Black Cap SENCO DuraSpin® SENCO Cordless Hand Nailers

Two Years One year Two years One Year

SENCO FP502 SENCO Reconditioned Products Gas Cordless

Two Years One Year Two Years

During the warranty period (which begins on the purchase date), S ENCO will repair or replace, at SENCO’s option and expense, any product or part that

is defective in materials or workmanship after examination by a S ENCO Authorized Warranty Service Center, subject to the exceptions, exclusions and

limitations descri bed below. Any replacement product or part will carry a warranty for the balance of the warranty period applicable to the replaced

product or part. A DATED SALES RECEIPT OR PROOF OF PURCHASE FROM THE ORIGI NAL RETAIL PURCHASER IS REQUIRED TO MAKE A

WARRANTY CLAIM. Product registration can be accomplished through on-line Product Registration at www.senco.com or by completing and returning

the postage paid product registration form included with your Operator’s manual/p arts chart inform ation, found inside the product car ton. To make a

warranty claim, you must return the product, with proper receipt/proof of purchase and return transportation charges prepaid, t o a SENCO Authorized

Warranty Service Center. A list o f SENCO Authorized Warranty Service Centers can be fo und at www.senco.com

or by calling 1-800-543-4596 toll free.

SENCO will perform its obligations under this warranty, within a reasonable time after approval of the warranty claim.

Wheelbarrow Compressors:

1. Subject to the exceptions, exclusions and limitations described below, SENCO warrants that the compressor pump will be free from defects in

materials and workmanship for two years after the purchase date.

2. Defective parts of the compressor pump not subject to normal wear and tear will be repaired or replaced, at SENCO's option, during the two

year warranty period. If SENCO determines that repair or replacement is not feasible, SENCO will refund the purchase price less reasonable

depreciation based on actual use.

SENCO Cordless:

1. Subject to the exceptions, exclusions and limitations described below, SENCO warrants that the SENCO Cordless tool will be free from

defects in materials and workmanship for two years after the purchase date.

2. Subject to the exceptions, exclusions and limitations described below, SENCO warrants that the batteries and chargers used with SENCO

Cordless tools will be free from defects in material and workmanship for one year after the purchase date.

WARRANTY EXCLUSIONS

The following warranty exclusions apply:

1. Normal wear parts are not covered under this warranty. Normal wear parts include, for example, isolators, drive belts, air filters, rubber o-rings,

seals, driver blades, piston stops, piston/driver assembly, and fuel stems.

2. This warranty does not cover parts damaged due to normal wear, misapplication, misuse, accidents, operation at other than recommended

speeds or voltage (electric units only), improper storage, or damage resulting during shipping.

3. Products used in production/industrial applications as defined by SENCO are excluded from this warranty.

4. Labor charges or loss or damage resulting from improper operati on, maintenance or repairs are not covered by this warranty.

5. SENCO does not warrant the Wheelbarrow Compressor Engine/Motor, but the Compressor Engine/Motor may be covered under a warranty

offered by its manufacturer.

GENERAL WARRANTY CONDITIONS

This warranty will be honored, only if:

A. Clean, dry, regulated compressed air has been used, at air pressure not exceeding the maximum indicated on the tool casting;

B. No evidence o

f abuse, abnormal conditions, accident, neglect, misuse or improper modifications or storage of the product; and

C. No Deviation from operating instructions, specifications, and maintenance schedules exists (read Operator Manual for use, specifications, and

maintenance instructions).

THIS WARRANTY IS THE ONLY WARRANTY ON THE PRODUCT, AND SENCO DISCLAIMS ALL OTHER WARRANTIES. ANY IMPLIED

WARRANTIES WILL BE LIMITED IN DURATION TO THE APPLICABLE WA RRANTY PERIOD SPECIFIED ABOVE. SOME STATES DO NOT ALLOW

LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. YOUR REMEDIES ARE

SOLELY AND E XCLUSIVELY AS STATED ABOVE. SENCO SHALL IN NO EVENT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, INDI RECT,

OR SPECIAL DAMAGES. SOME STATES DO NOT ALLOW THE EXCLUSIO N OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. IN NO EVENT, WHETHER AS A RESULT OF A BREACH OF

CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE) OR OTHERWISE, SHALL SENCO’S LIABI LITY EXCEED THE PRICE OF THE

PRODUCT WHI CH HAS GIVEN RISE TO THE CLAIM O R LIABILITY. ANY LIABILITY CONNE CTED WITH THE USE OF THIS PRO DUCT SHALL

TERMINATE UPON THE EXPIRATION OF THE WARRANTY PERIOD SPECIFIED ABOVE. NO EMPLOY

EE OR REPRESENTATIVE OF SENCO OR

ANY DISTRIBUTOR OR DEALER IS AUTHORIZED TO MAKE ANY CHANGE OR MODIFICATION TO THIS WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

REPLACEMENT OF TOOL DUE TO NATURAL DISASTER

SENCO will replace any tool destro yed by an Act of God such as flood, eart hquake, hurricane o r other disaster resulting only from the forces of nature.

Such a claim will be honored provided that such original retail purchaser had previously submitted a completed w arranty registration card for the tool,

and then submits proof of ownership and an acceptable statement describing such Act of God documented by an insurance carrier, police department,

or other official governmental source. To obtain instructions for filing a claim call 1-800-543-4596.

CUSTOMER SATISFACTION

One hundred p ercent customer satisfaction is our #1 goal. If for any reason the product does not perform to the original purcha

ser’s satis

faction, it

can

be returned to the place of purchase within thirty days with dated sales receipt for a full refund of the purchase price.

©2006, 2009 by SENCO BRANDS, INC.

CINCINNATI, OHIO 45244-1611 USA

www.senco.com

051208

Loading...

Loading...