Page 1

PARTS LIST / TECHNICAL GUIDE

KINETIC DIRECT DRIVE Cal. 5D88A

[SPECIFICATIONS]

5D88A

Driving system Step motor 2 pieces

Additional functions

• Direct drive indicator

Power reserve indicator

Real-time power indicator

• Energy depletion forewarning function

• Overcharge prevention function

• Electronic circuit reset function

• Second hand stop function

• Date correction function

• Moon phase display func tion

Crown operation

Normal position

Free

1st click position

Day set ting ( clockwise), Date setting (counterclock wise)

2nd click position

Time setting, hand position adjustment, reset ting the circuit

Loss/gain

Monthly rate: less than 15 seconds

(worn on the wrist at temperature range between 5 to 35 ºC)

Regulation system Nil

Measuring gate by quartz tester

10-second gate

Current consumption

Movement: less than 0.65

μA

Circuit block : nil

Circuit block for calendar: less than 0.40 μA

Coil resistance

4002535 1 piece:1.90K Ω - 2.15KΩ Coil block for hour,minute, and second hand

4002540 1 piece :0.585KΩ - 0.645KΩ Generating coil block

4002529 1 piece:1.25KΩ - 1.50KΩ Power reserve coil block

Power supply

Power generator

Automatic generating system + Manual winding power generating system

Rechargeable

battery

MT920 Manganese titanium lithium rechargeable battery

Operating voltage range

1.05V - 2.50V

Maximum continuous operating time

Approximately 1 month after the watch is fully charged

Number of jewels 12 jewels

• 3 hands (Hour, Minute and Second hands) ,

24-hour hand

• Calendar (Date dial, Day dial, Moon phase)

Cal. No.

Item

Movement

• Casing diameter:

Ø 28.0 mm

• Diameter

Outside: Ø 30.0 mm

Height : 6.52 mm

Page 2

BEFORE STARTING REPAIR WORK ON CAL. 5D88A

2/51

SEIKO Kinetic Direct Drive Cal. 5D88 is an embodiment of the SEIKO’s ‘emotional technology’.

The watch features new functions but the knowledge of repairing the existing KINETIC series

will be helpful.

To repair the Cal. 5D88, therefore, you are requested to have the full knowledge of its functions

and strictly observe the repairing and checking instructions provided in this guide so that the

watch will be correctly repaired.

FEATURES

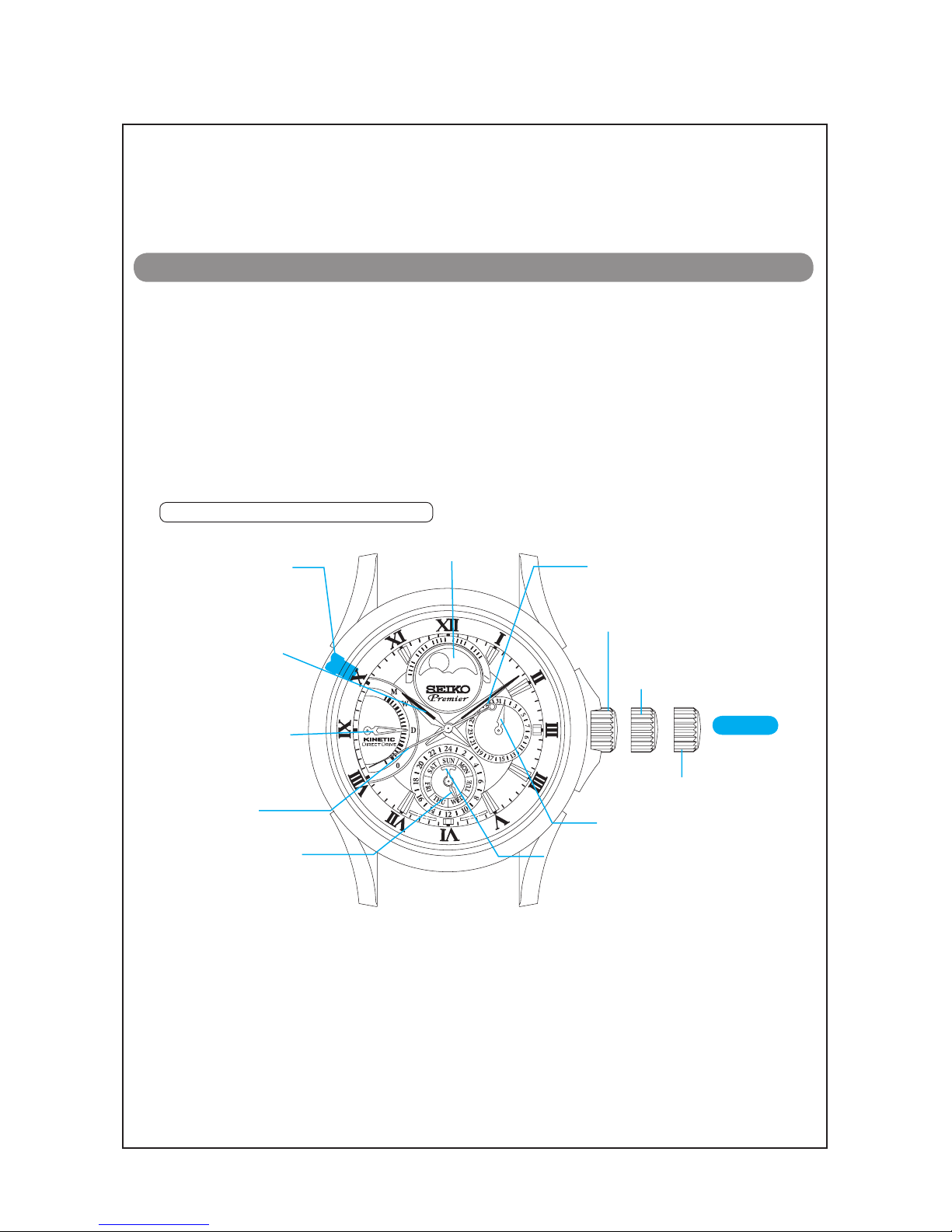

1. DISPLAY AND HOW TO USE

The Cal. 5D88 is a KINETIC watch equipped with two winding functions and two indicator

functions.

l

Two winding functions

As in all existing Kinetic calibers, the wearer automatically generates the electrical

energy by her/his wrist movement. With Kinetic Direct Drive, however, the wearer can

also generate energy by winding the crown.

l

Tw

o indicator functions

Kinetic Direct Drive shows not only the power held in reserve but also the level of power

generation when the wearer hand-winds the crown. The wearer can see and feel, in real

time, the direct transfer of power from his or her winding of the crown to the reserve.

15

10

5

0

02

15

25

29

1

2

2

First click position: Date

and day setting

Second click position:

Time setting

Hour hand

Direct drive indicator

hand (for indicating

amount of power

reserved, power

generation status and

amount of generated

power)

Date hand

Day hand

Minute hand

Normal position: Electric power

generation by manual winding

Second hand

Button (moon phase

setting / resetting the

built-in IC)

CROWN

24-hour hand

Moon phase display

Page 3

BEFORE STARTING REPAIR WORK ON CAL. 5D88A

3/ 51

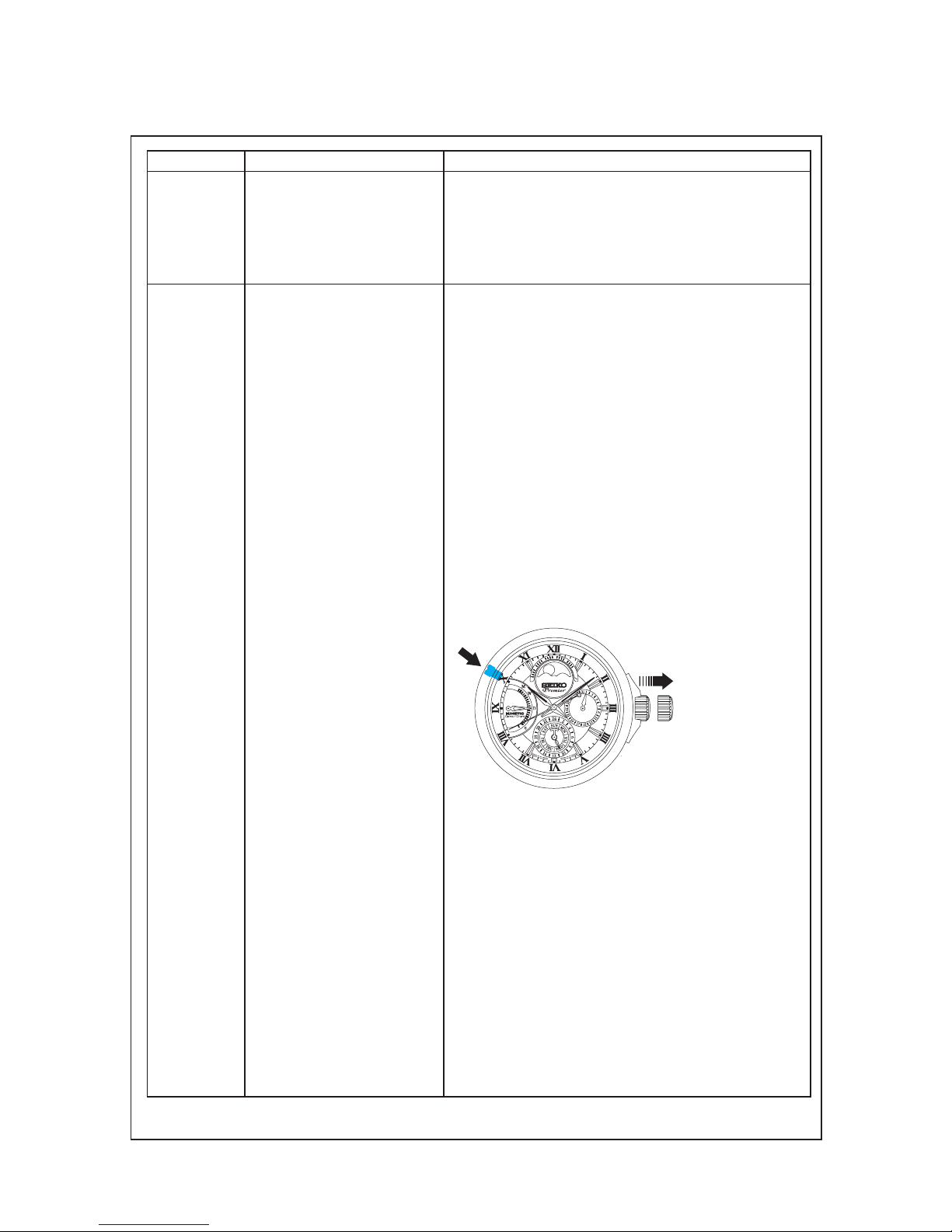

Crown position

Functions by crown operation Functions by button operation

Normal • Electric power generation

by manual winding

Clock wise turn:

charging the watch by

manual winding

Counterclockwise turn:

No function

First click • Calendar setting

Clock wise turn:

day setting

Counterclockwise turn:

date setting

Manual 0 position alignment of the direct drive

indicator hand

The watch automatically corrects the position of the

direct drive indicator hand once ever y 24 hours. While

correcting its position, the direct drive indicator hand

automatically moves, but it is not a malfunction.

How to manually correct the position of the direct

drive indicator hand

• The position of the direct drive indicator hand can be

also corrected by hand.

1. Pull out the crown to the first click.

2. Press the button located at the 10 o’clock position for

2 seconds or more.

By doing this, the direct drive indicator hand returns

to the standby position.

3. Press the button at the 10 o’clock position to set the

position of the direct drive indicator hand pointing

exactly to the 0 position.

15

10

5

0

02

15

25

2

9

1

2

2

With each pressing of the button, the direct drive indicator

hand moves up the scale by one increment. By pressing

the button, adjustment can be made upto the second

increment. At the third pressing of the button, the direct

drive indicator hand returns to the standby position. Repeat

the procedures until the direct drive indicator hand is

correctly aligned to the 0 position.

How to set the Moon Phase

• The moon phase represents the period from the time

when the last new moon occurred to noon of the

current day in day increments.

• The period between new moons is called a “synodic

month,” and its average length is approximately 29.5

days.

* Round off the number of moon phase to the nearest

whole number (Example: 7.8, 8, 24.2, 24)

* Refer to the weather report of your local newspaper

for current moon phase information.

Page 4

BEFORE STARTING REPAIR WORK ON CAL. 5D88A

4/ 51

2. CHARACTERISTICS OF MANUAL WINDING FUNCTION OF KINETIC DIRECT DRIVE

1. As for mechanical watches, the amount of power generated increases in propor tion to the

number of times the mainspring is wound. As for the KINETIC DIRECT DRIVE watches, however,

the amount of power generated by manual winding varies depending on the speed and length of

strokes in which you wind the crown.

The more efficiently the power is generated, the more the direct drive indicator hand moves.

It is even possible to reach the maximum scale value of power reserve with only one stroke.

2. The size of the crown will also affect the amount of power generated by manual winding.

Even if the crown is turned in exactly the same manner, the amount of power generated will vary

depending on the size or the shape of the crown.

Generally, the smaller the crown is, the more efficiently the watch can generate the power.

Crown position

Functions by crown operation Functions by button operation

* Do not set the moon phase between 9 pm and 1 am,

as the moon phase may not change to the correct

display on the following day.

Second click • Time setting System reset (No power is generated.)

If any improper function occurs, for example, the direct

drive indicator hand stops moving while it is pointing

anywhere other than the standby position, follow the

instruction below to reset the built-in IC.

1. Pull out the crown to the second click.

2. Press the button at the 10 o’clock position for 2

seconds or more.

3. Push the crown back into the normal position.

15

1

0

5

0

02

15

25

29

1

2

2

After pushing the crown back into the normal position,

charge the watch by manual-winding method and check

that the hands start moving. At the same time the hands

start moving, the direct drive indicator hand will return

to point at the 0 position, and the watch will resume its

normal operation.

After the built-in IC is reset, the continuous operating

time is cleared and the direct indicator hand points at the

0 position. If no power is generated subsequently, the

watch will stop operating within three minutes. In order to

avoid this, charge the watch at least until the direct drive

indicator hand points at the first indication on the dial. It is

also recommended that you correct the position of direct

drive indicator hand manually as instructed on page 3.

Page 5

BEFORE STARTING REPAIR WORK ON CAL. 5D88A

5/ 51

3. HOW THE DIRECT DRIVE INDICATOR HAND WORKS

1. Power reserve indicator function

• Except when the crown is being turned to charge the watch, the direct indicator hand functions

as a power reserve indicator which shows how long the watch will keep operating within the

range between the minimum 3 hours and the maximum 1 month.

For more details, refer to

“ How to read the power reserve indicator” below.

• If the direct drive indicator hand indicates the 0 position, the watch will stop operating within 3

hours. When the watch stops, the direct drive indicator hand moves to the standby position to

show that the watch stops operating due to a power shortage.

• T

he direct drive indicator hand constantly displays the most up-to-date amount of stored

power. If the amount of stored power is increased by the wearer’s wrist movement or by the

manual crown windings, the direct drive indicator hand displays the increased amount of power

accordingly. On the other hand, if the watch is left unworn and the stored power is decreased

as the watch consumed some power during the time it is left unworn, the direct drive indicator

hand displays the decreased amount of stored power accordingly.

•

The

maximum amount of power reserve that the watch can store is the amount of power

reserve to keep the watch operating for one month. When more power is generated after the

watch already stores this maximum amount of power, the power generated is not further

accumulated, and the direct drive indicator hand shows the power reserve of one month.

Scale marking

0 1 2 3 4 5 6 7 8 9 10

Indication on dial

0 D

Power reserve display

0 3h 6h 9h 12h 15h 18h 21h 1 day

Scale marking

11 12 13 14 15 16 17 18 19 20

Indication on dial

W

M

Power reserve amount

2 days 3 days 4 days 5 days 6 days 1W 2W 3W

30days

*note 1

How to read the power reserve indicator

*note 1 Even though the continuous operating time reaches one month, the direct drive

indicator hand remains moving to show that the power generating function is

operating.

• T

he scale marking indicates the minimum continuous operating time.

Scale marking Power reserve

3 3 hours (Not shorter than 3 hours and not longer than 6 hours)

13 4 days (Not shorter than 4 days and not longer than 5 days)

17 2 weeks (Not shorther than 2 weeks and not longer than 3 weeks)

20 *note 1

Page 6

BEFORE STARTING REPAIR WORK ON CAL. 5D88A

6/ 51

*note 1 When the watch is charged by any other method than manual winding, such as using KINETIC

ENERGY SUPPLIER, the direct drive indicator hand may move in slightly slower motion.

*n

ote 2 The direct drive indicator hand will stop at the maximum scale value pointing at the ‘M+1’ position.

If the crown is turned after the direct drive indicator hand stops at the ‘M+1’ position, the watch

continues to accumulate power reserve, but the real-time power indicator function stops. If you

want to display the a

mount of generated power

, stop turning the crown, and after the direct drive

indicator hand returns to the power reserve display, start turning the crown again.

Wh

en the electric power is generated without interruption, for example when an electric charger

is used, the direct drive indicator hand will stop and remain pointing at the ‘M+1’ position.

*n

ote 3 After the direct drive indicator hand displays the accumulated amount of generated power, it

returns to the power reserve display.

(Caution)

To

enjoy the real-time powe r indic ator functio n, power gene ration by manu al wind ing is

recommended as it enables you to check the power generating status.

2.

Real-time power indicator function

How to read the real-time power indicator

Scale marking

0 1 2 3 4 5 6 7 8 9 10

Indication on dial

0 D

Amount of generated power

h=hour(s) min=minute(s)

Standby

position

0

20 min 40 min

1h

1h

20 min1h40 min

2h

2h

20 min2h40 min

Scale marking

11 12 13 14 15 16 17 18 19 20

Indication on dial

W

M

Amount of generated power

h=hour(s) min=minute(s)

3h

3h

20 min3h40 min

4h

4h

20 min4h40 min

5h

5h

20 min5h40 min

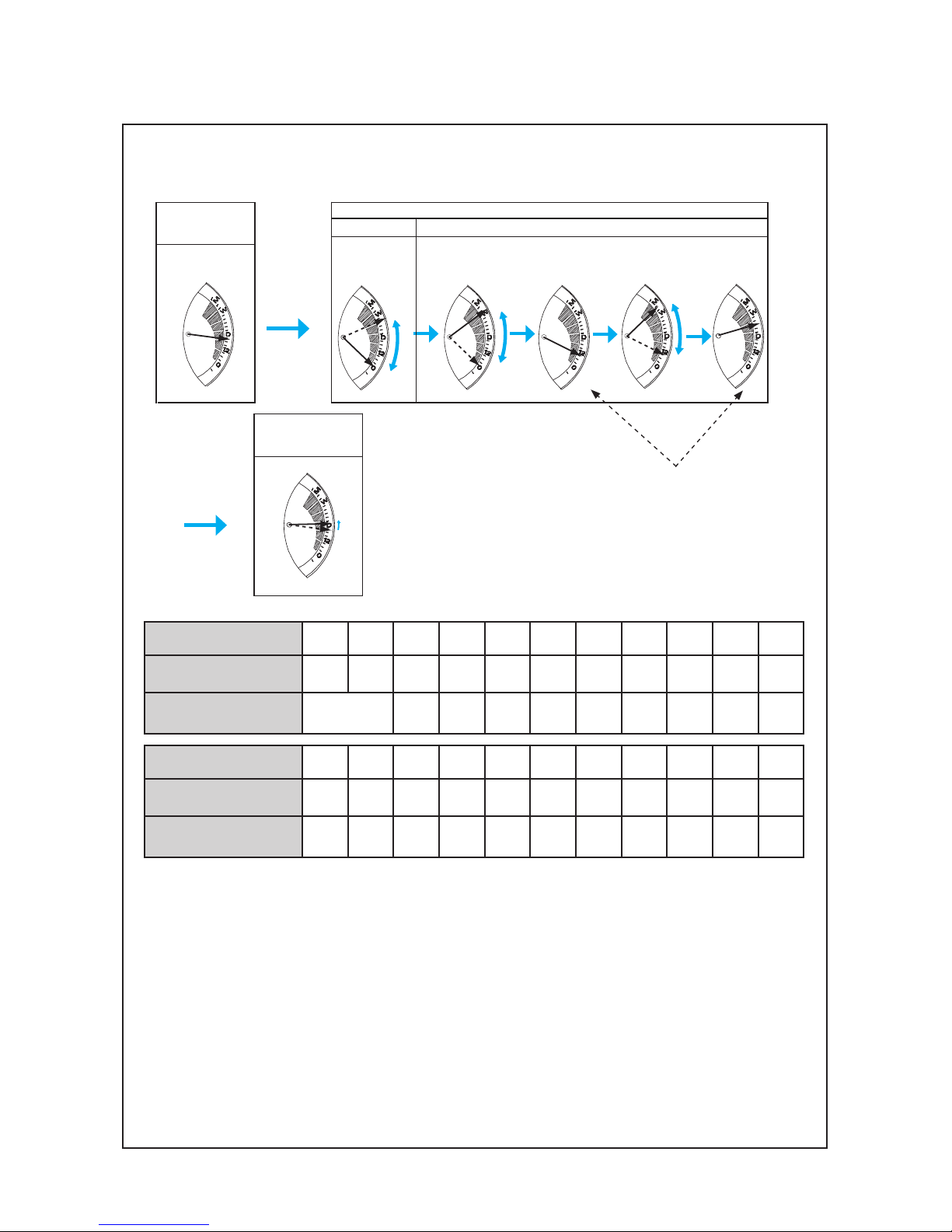

6h

<Display and movement flow of the direct drive indicator hand while charging the watch>

Power reserve

display

Power generation status and generated power display

Power reserve display

Initial status

In-progress

A. While turning the crown

B. When temporarily

stopping turning the

crown

After

approximately 4

seconds since

stopping turning

the crown

After

approximately

1 second since

starting to turn

the crown

A B

✽

The direct drive indicator hand points at

a scale marking between 0 and ”M+1”

according to power generation status.

✽

Th

e point where the indicator

hand starts moving goes up as

generated power increases.

Page 7

BEFORE STARTING REPAIR WORK ON CAL. 5D88A

7/51

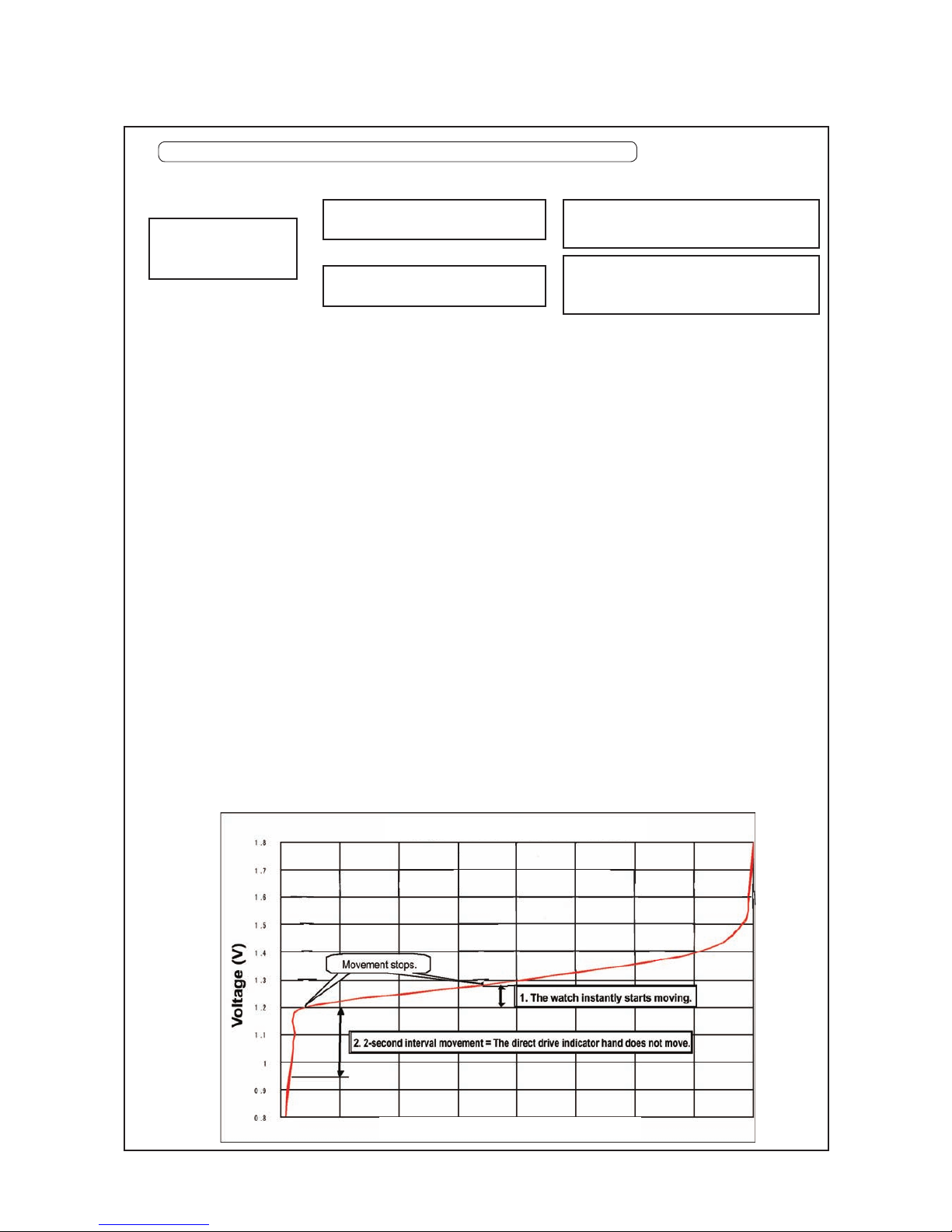

Case 1: The watch has been stopped temporarily.

The watch in this condition falls in the range shown by ‘1. The watch instantly starts moving’ in the

diagram below.

• T

he watch starts operating within a few seconds after you start turning the crown, and

automatically correct the position of the direct drive indicator hand to the 0 position (0

indication on the dial).

• After

the direct drive indicator hand returns to the 0 position, if no further power is generated

subsequently, the watch will stop operating within three minutes.

• T

o prevent the watch from stopping during the subsequent procedures such as time setting

and date setting, charge the watch at least until the direct drive indicator hand points at the first

indication on the dial (3 hours of power reserve).

Ca

se 2: The watch has been left unworn and stopped for a long time. (3 to 5 years or even more)

The watch in this condition falls in the range shown by ‘2. 2-second interval movement = The direct

drive indicator hand does not move’ in the diagram below.

Wh

en the voltage of the rechargeable battery is reduced to an extremely low level after the watch

is left unworn for a long time, the watch moves in 2-second intervals after you start turning the

crown until the voltage is increased to a reasonable level.

Ch

arge the watch by manual winding method until the direct drive indicator hand returns to the 0

position from the standby position.

•

If

power generation is stopped while the watch is moving in 2-second intervals and before the

direct drive indicator hand returns to the 0 position, the watch will stop operating within one

minute.

• E

stimated time required for manual winding to reactivate the watch in this condition:

approximately 5 to 6 minutes

4.

HOW TO REACTIVATE THE WATCH AFTER IT STOPPED

Charge the stopped

watc h manually by

turning the crown.

Th e wa t ch st ar t s ope r a ting

normally within a few seconds.

Th e

wa tch sta r t s o pera ting

in

2-second intervals.

Case 1:

The watch has been stopped temporarily.

Case 2:

Th e wat ch has bee n lef t unw orn f or a

long time.

To reactivate the stopped watch, see the condition of the watch by following the steps below.

voltage and reactivation process diagram

amount of power reserve

a

a

a

a

Page 8

BEFORE STARTING REPAIR WORK ON CAL. 5D88A

8/ 51

Set the crown to the 5D position.

• M a ke sur e th a t the wa t c h is co r r ec t ly

positioned as it may af fec t the amount of

power generated.

• T

he amount of power generated may var y

depending the models of the watch.

• I

n some cases, the dire c t dri ve indi cator

hand does not move.

• I

f the direct drive indicator indicates a fully-charged status, the KINETIC ENERGY SUPPLIER will

continue to charge the watch.

5.

HOW TO CHARGE THE WATCH WITH KINETIC ENERGY SUPPLIER YT-02A

5D

Before setting the KINETIC ENERGY SUPPLIER,

make sure that the watch is moving.

• In some cases, the KINETIC ENERGY SUPPLIER

does not start charging the watches with cal.5D

series when the watch stops.

Page 9

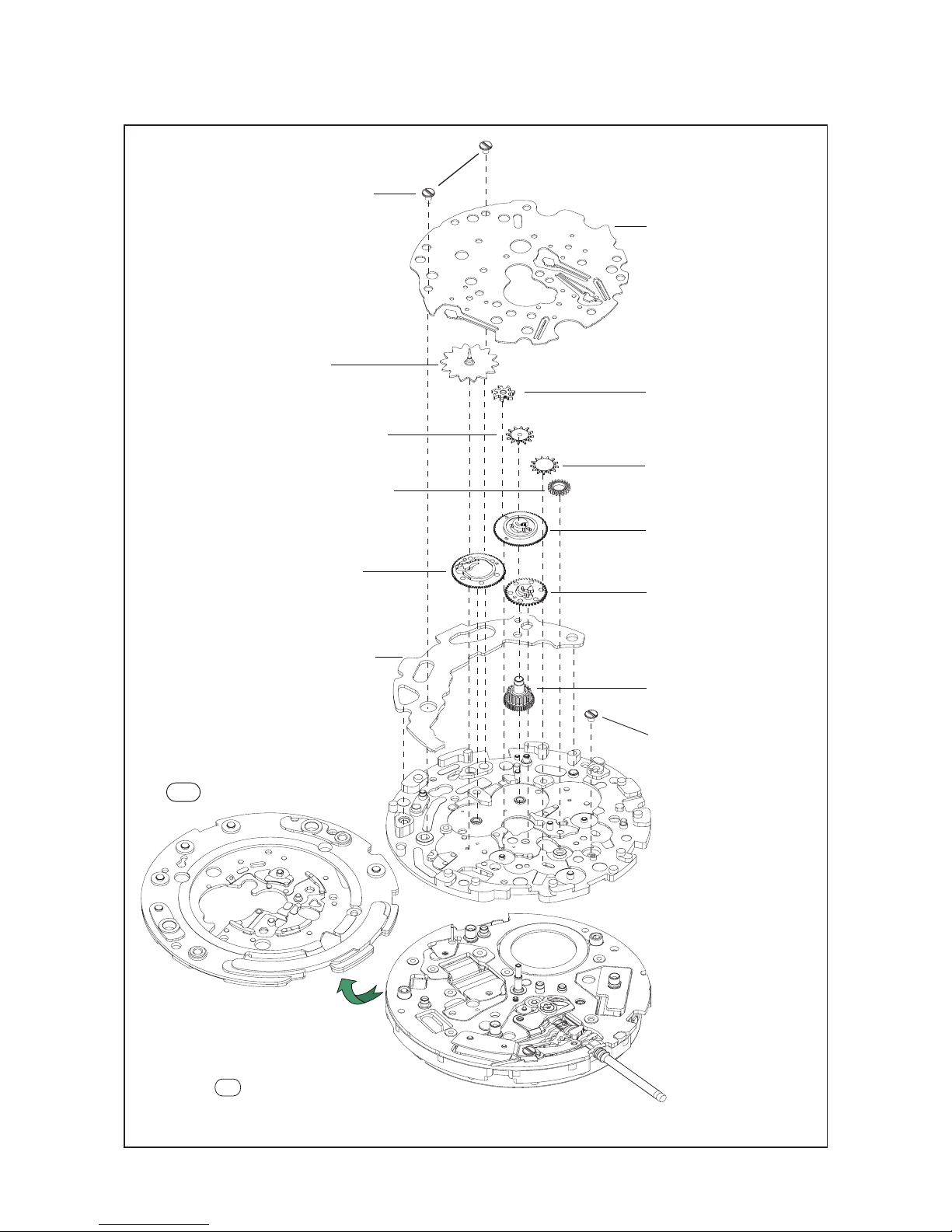

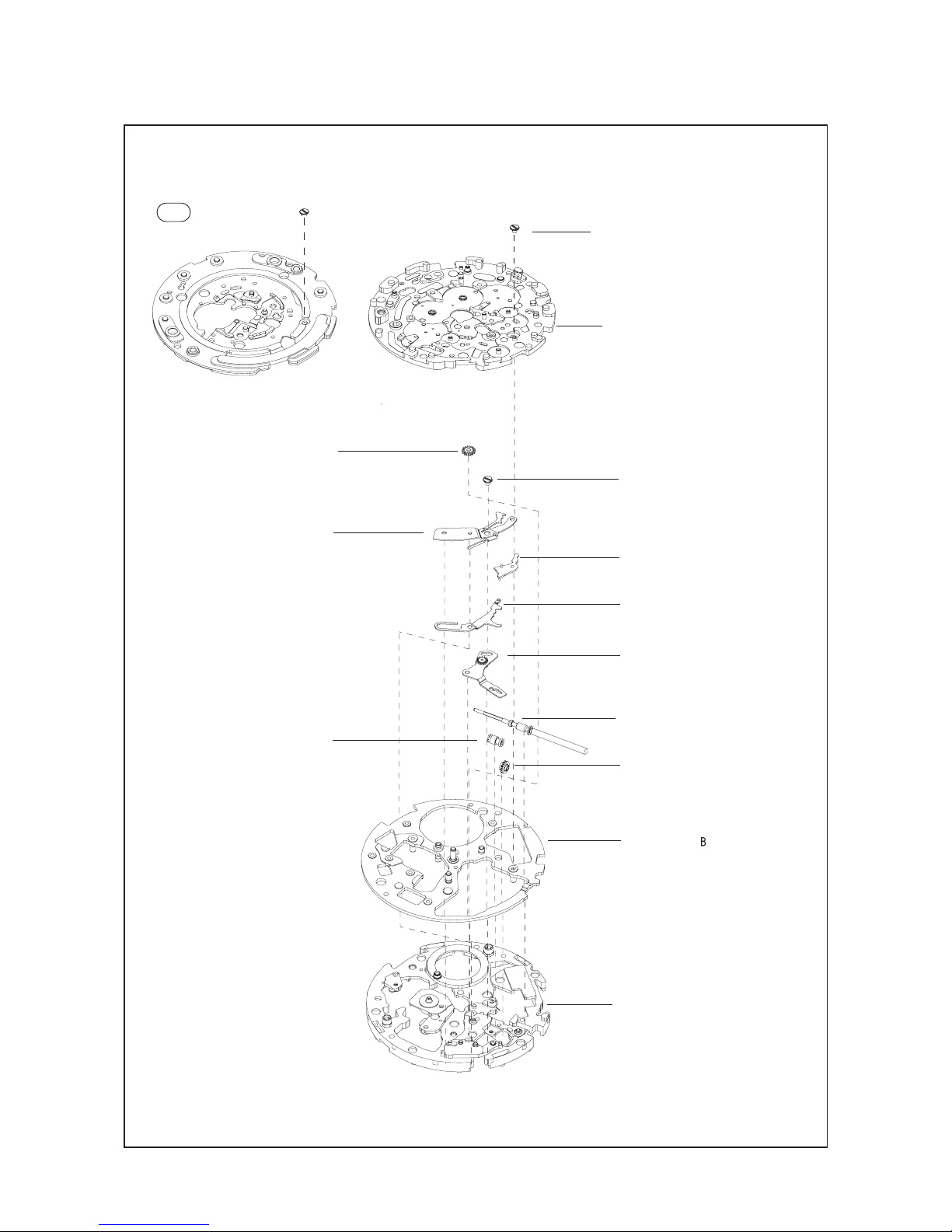

PARTS LIST

Cal. 5D88A

9/ 51

490

20

battery

Oscillating weight screw

0022

Oscillating weight

0500 509

Oscillating weight wheel

1002

Rechargeable battery guard screw

0012 354

Rechargeable battery guard

4225 563

Insulator for rechargeable

4216 546

Rechargeable battery unit

3023 24L

1

2

3

5

6

7

4

Disassembling procedures Figs.:

1

Reassembling procedures Figs. :

1

* For the t ype of oil and quantity of lubrication,

re fe r to the fo ll ow ing TEC HN ICA L GUIDE

section.

ij

ij

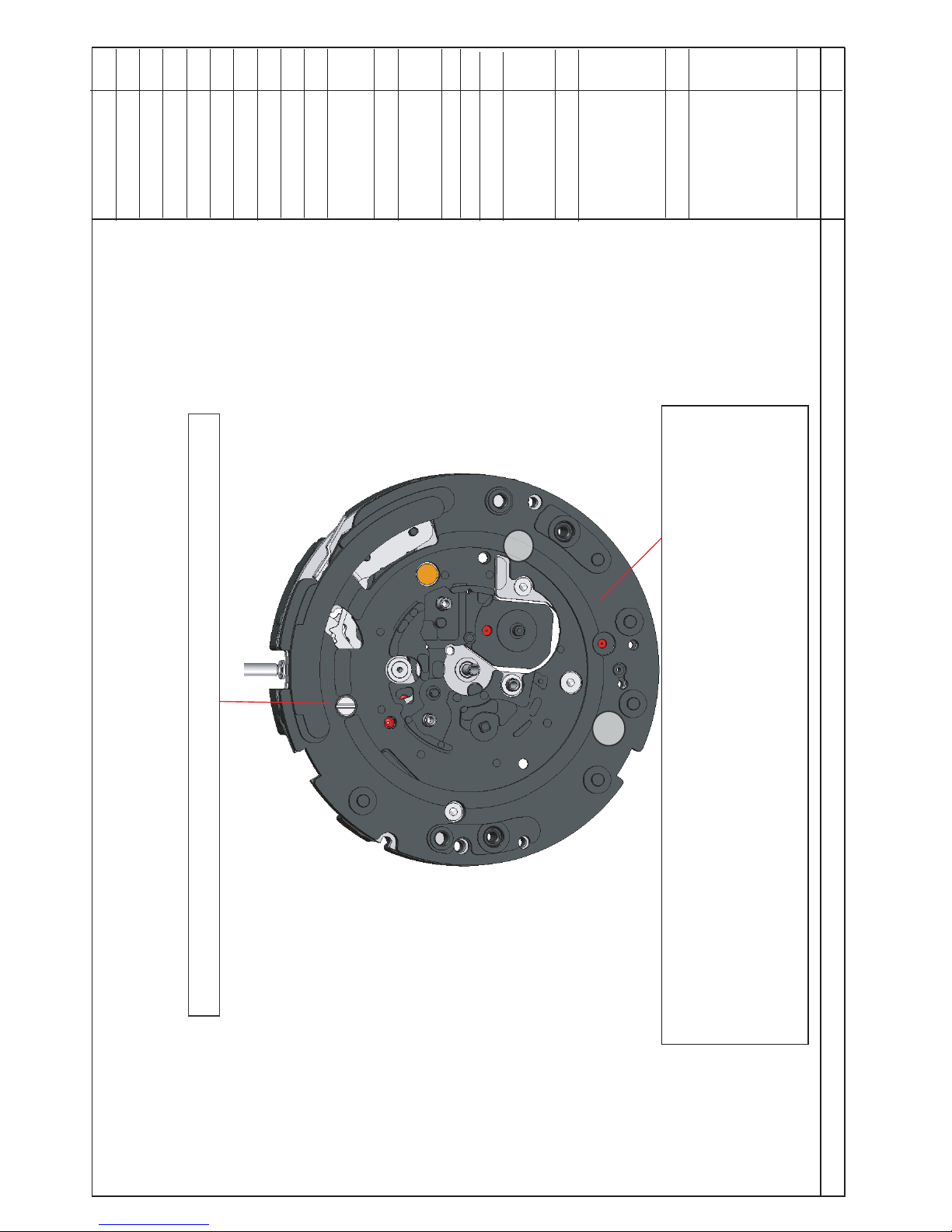

[Automatic Generating Mechanism]

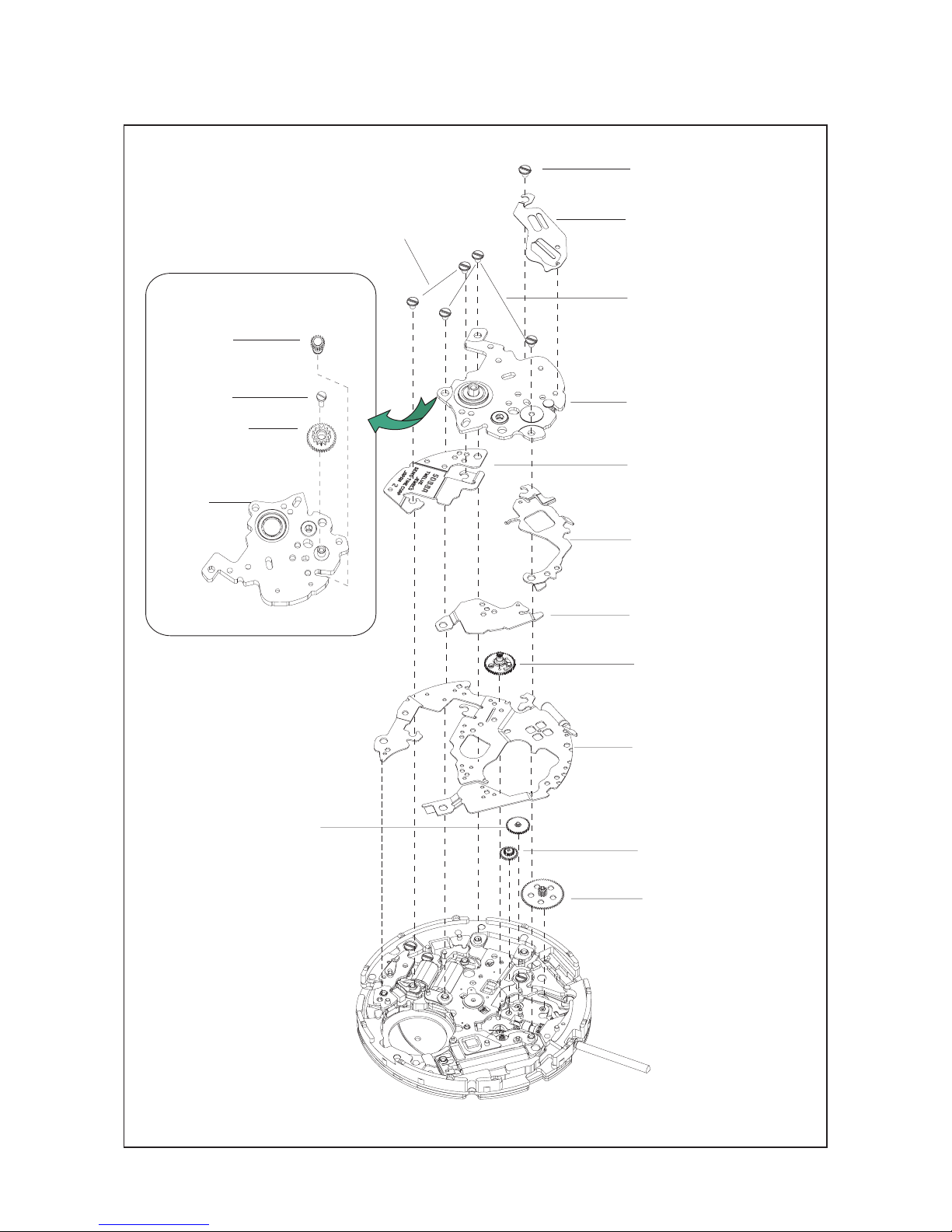

Page 10

Cal. 5D88A

PARTS LIST

10/ 51

Calendar train bridge screw

0016704

Dial Washer

Moon phase indicator wheel

0634524

Calendar train bridge

Calendar train bridge screw

0491735

0012354

0439508

Date star wheel

0970501

Date corrector wheel

0804500

Calendar train cover

4283515

24 Hour indicator wheel

1021508

Intermediate wheel for

24 Hour indicator

0817534

Moon phase corrector lever

0595500

qd

qf

qg

qh

qj

qk

8

9

q;

qa

qs

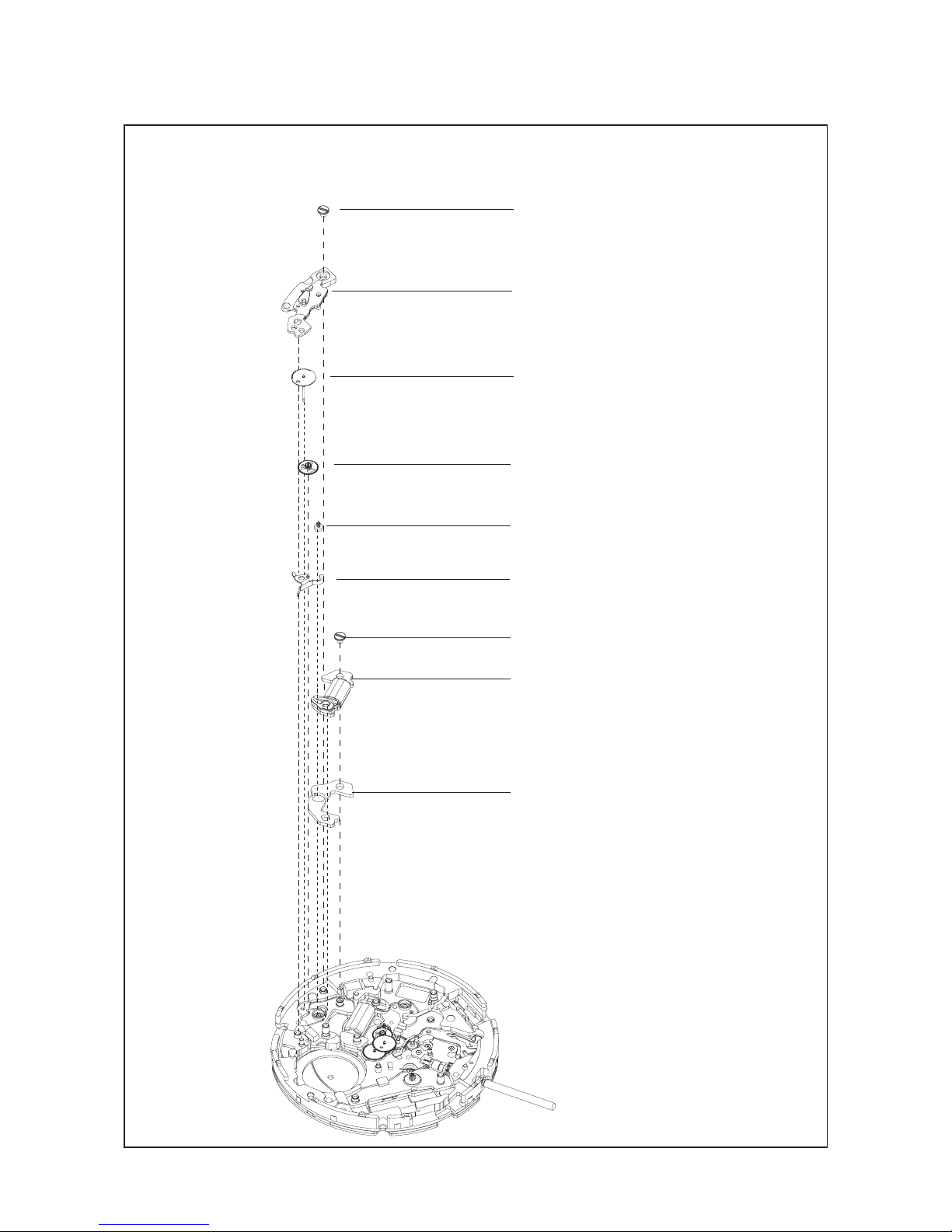

Page 11

PARTS LIST

Cal. 5D88A

11/51

Date jumper

0810503

1026506

1026504

1002531

2nd Intermediate wheel

for day corrector

3rd Intermediate wheel for

calendar corrector

Date driving wheel

Mooh phase indicator

driving wheel

0802514

0271633

Hour wheel

Calendar plate screw

0012354

0271633

Calendar plate

Dammy plate H-G001

* After assemble the oscillating weight bridge,

turn over the movement.

Release the

1026505

1026503

0898500

4259514

1st Intermediate wheel for

day corrector

2nd Intermediate wheel

for calendar corrector

Day driving wheel

Anti-magnetic shield plate

Dummy plate H-G001

32-T

Date jumper screw

0012354

1002529

Day star wheel

w;

ws

wf

wh

wk

e;

ea

es

ql

wa

wd

wg

wj

wl

Calendar plate screw and

ea

remove the

Dummy plate H-G001 and mount

32-T

the

Calendar plate.

es

[Calendar Mechanism]

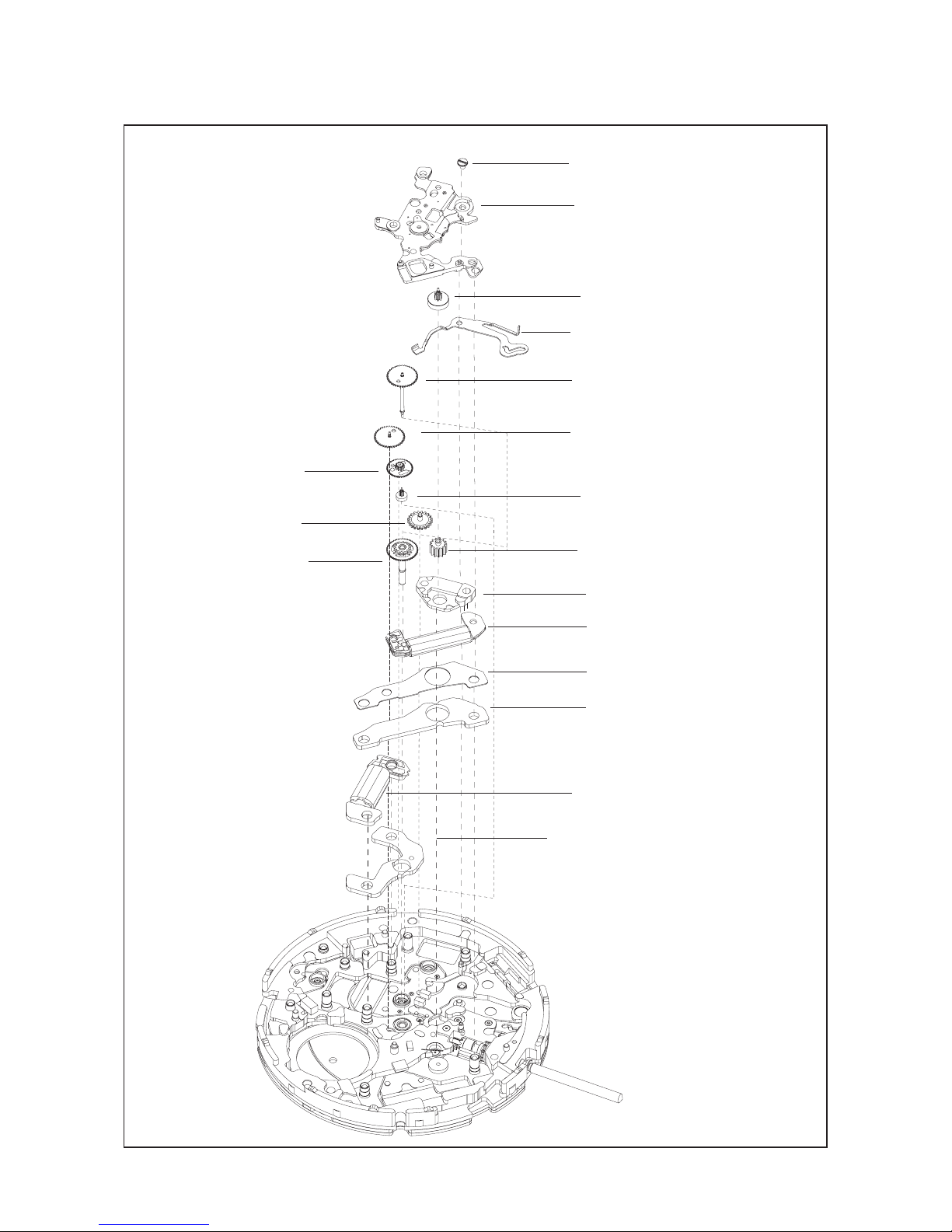

Page 12

Cal. 5D88A

PARTS LIST

12/51

Oscillating weight bridge

screw

Circuit block cover B screw

Oscillating weight bridge

0198 508

Circuit block cover B

4461511

Circuit block cover A

4457 992

2nd intermediate wheel for

manual winding

1026501

Circuit block cover C

4457 994

Switching wheel

1002 518

Circuit block

4000649

3rd intermediate wheel for

manual winding

1026502

1st intermediate wheel for

manual winding

1026500

wheel

Circuit block cover A screw

0012354

Friction spring for sliding

0353527

1002521

Crown wheel fixing

screw

0012354

Crown whee

l

0284500

Oscillating weight

bridge

0198508

Sliding crown wheel

0012354

0012354

ej

ek

r;

eh

ra

rs

rd

rf

rg

rj

rk

rh

eh

eg

ef

ed

el

[Manual Winding Mechanism and Circuit Block]

Page 13

PARTS LIST

Cal. 5D88A

13/ 51

Power reserve coil block screw

0012 354

Power reserve coil block

4002 529

Power reserve train wheel bridge screw

0012 354

Power reserve train wheel bridge

0125 512

Power reserve indicator wheel

1002 522

Intermediate wheel for power reserve

0701 504

Power reserve rotor

4146 502

Power reserve stator

4239 516

Rechargeable

battery connection (+)

4271 627

rl

t;

ta

ts

td

tf

tg

th

tj

[Power Reserve Indicator Mechanism]

Page 14

Cal. 5D88A

PARTS LIST

14/51

Generating rotor

4146 522

Generating stator

4239 542

Spacer for generating stator

4408 562

Coil block

4002 535

Train wheel setting lever

0391503

Fourth wheel

0241565

Third wheel

0231 904

Fifth wheel

0701 504

Rotor

4146886

2nd intermediate wheel

0817 520

Minute wheel

0261 505

Center wheel

0221 594

Rotor stator

4239 541

This part can be found in both silver and

gold color but they are compatible and

there is no difference in their quality and

performance. Spare parts to be supplied

are in silver color.

Train wheel bridge

0125 511

Spacer for coil block rotor

0439 506

Train wheel bridge screw

0012 354

Generating coil block

for minute wheel

tk

tl

y;

ya

ys

yd

yg

yj

yl

u;

ua

us

ud

uf

yf

yh

yk

[Gear Train Mechanism and Stepping Motor]

Page 15

PARTS LIST

Cal. 5D88A

15/51

Calendar

plate screw

0012 354

Calendar plate

4283515

1st intermediate wheel for

0817 519

Setting lever jumper screw

0012 354

Setting lever jumper

0388 500

Setting lever

0383 701

Yoke

0384 502

Switching lever with setting wheel

1017 502

Winding stem

0351 ***

Clutch wheel

0282 505

Winding pinion

0283 500

Main plate

0100 569

Main plate A

4408 571

minute wheel

and intermediate wheel for date

corrector

Mount the Dummy plate instead of

the Calenar plate when assembling

Dummy plate H-G001

32-T

and tighten it

by the Calendar plate screw

Calendar

plate screw

ea

uj

ul

ea

es

uk

i;

ia

is

id

ig

ih

ij

if

[Setting Mechanism]

Page 16

TECHNICAL GUIDE

Cal. 5D88A

16/ 51

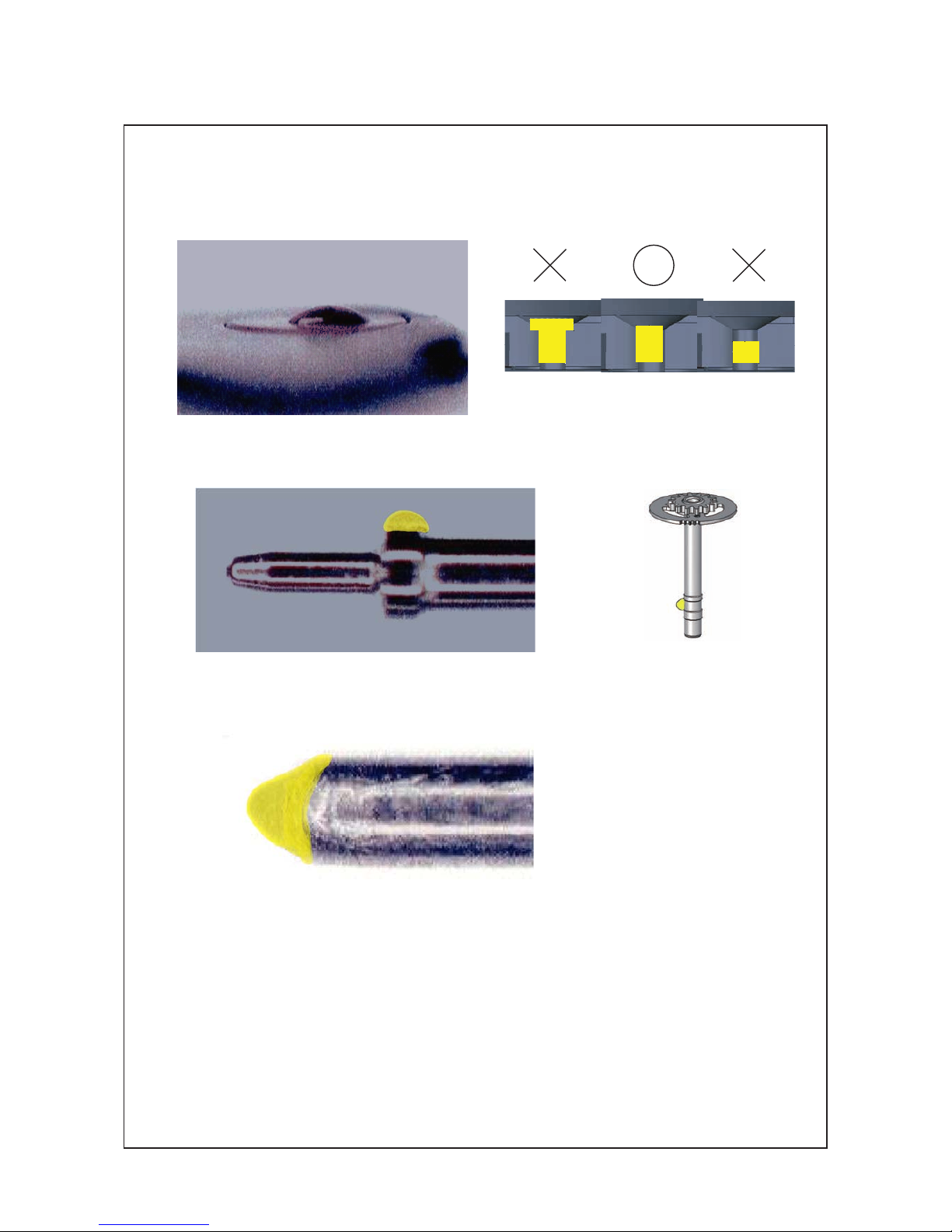

1) Pivot portions

Refer to the illustrations A and B.

1. REMARKS ON DISASSEMBLING AND REASSEMBLING

GENERAL INSTRUCTIONS FOR LUBRICATION

Illutration A

Illutration B

2) Part of axis of wheels (generally found on the center wheel and pinion and the fourth wheel.

Refer to the illustrations C and D.

3) S-6 oil on lubricating tool.

Refer to the illustrations E.

Illutration C

Illutration D

Illutration E

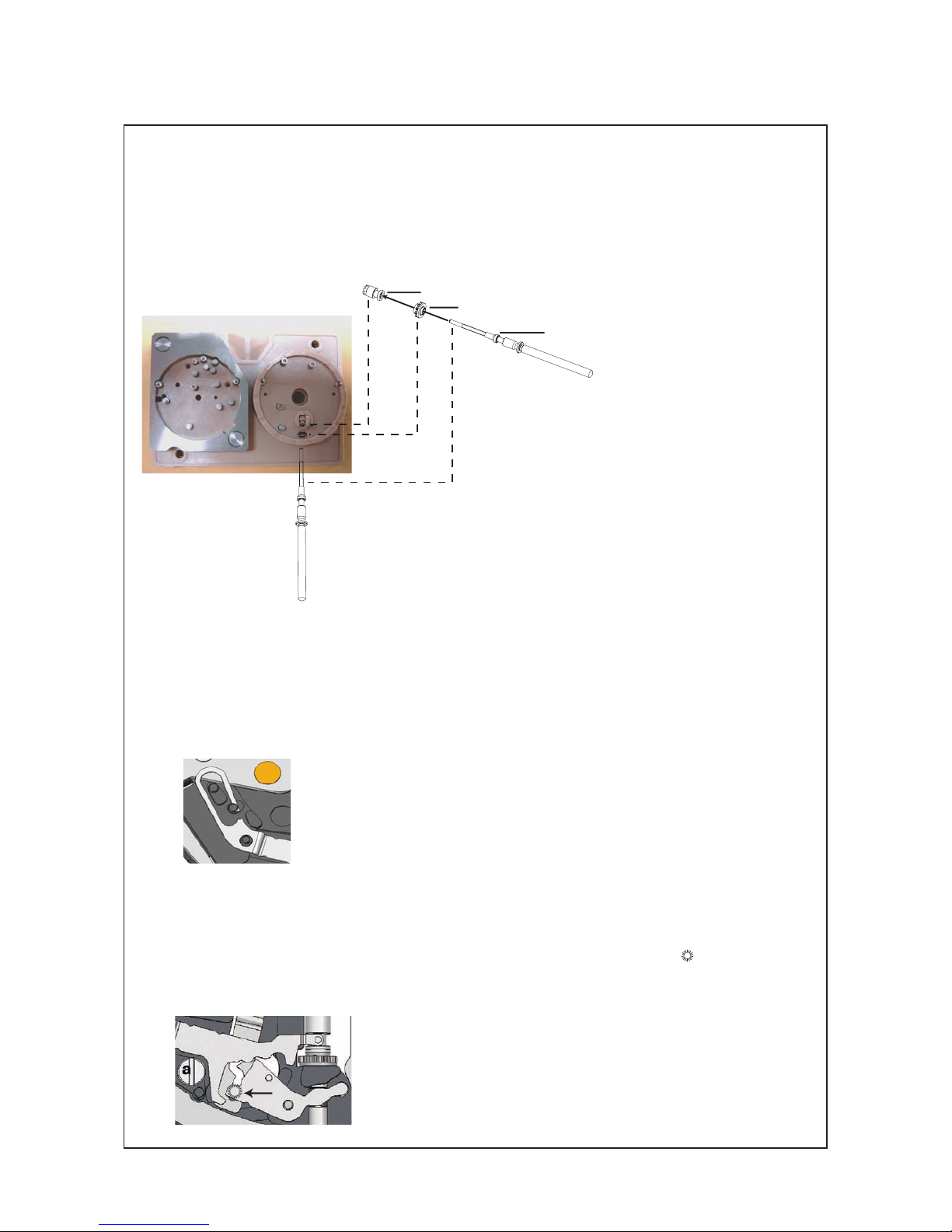

Page 17

TECHNICAL GUIDE

Cal. 5D88A

17/51

Front side

Reverse side

• Watch oils

SEIKO watch grease (S-6) and watch oils (AO-3 and AO-2)

S-6

AO-2

AO-3

l

Tools and consumables required for disassembling/reassembling

• 5D Exclusive Movement Holder

2 pins marked with red arrows should be taken out. Even after taking 2 pins out from the

movement holder, it can be used for former 5D calibers.

• UN

IVERSAL MOVEMENT HOLDER

(S-682)

•

Dammy Plate H-G001

Page 18

TECHNICAL GUIDE

Cal. 5D88A

18/ 51

id

Winding stem

iff

Clutch wheel

igg

Winding pinion

Wh

en installing the WINDING STEM, support the WI

NDING PINION and the CLUTCH WHEEL by

using the movement holder as illustrated below.

Winding stem

Winding pinion

if

ig

id

Clutch wheel

ul

Yoke

Se

curely hook the arm of the YOKE inside the pin of the main plate, taking care so as not to

deform the arm of the YOKE.

uk

Setting lever

uj

Setting lever jumper

uh

Setting lever jumper screw

Se

curely engage the pin on the backside of the SETTING LEVER (indicated by

in the illustration

below) with the guiding slit of the SW

ITCHING LEVER. Sliding the SWITCHING LEVER towards the

“a” portion in the illustration below will make this easier.

Page 19

TECHNICAL GUIDE

Cal. 5D88A

19/51

yg

Rotor

Do not mix up the ROTOR ( 65) with the POWER RESERVE ROTOR (53). To discriminate between

the two, see the illustrations below.

rotor (65) power reserve rotor (53)

yj

Second intermediate minute wheel

Do not mount the SECOND INTERMEDIATE WHEEL FOR MINUTE WHEEL (67) upside down. See

the illustrations below to make sure the correct direction.

ya

Train wheel setting lever

Insert the tail portion of the train wheel setting lever with the guiding slit at an angle into the gap

of the circuit bridge, and securely set the guiding slit to the dowel pin of the setting lever.

dowel pin of the setting lever

Hook the arm of the SETTING LEVER after fixing the SETTING LEVER JUMPER by tightening the

SETTING LEVER JUMPER SCREW, taking care so as not to deform the arm of the setting lever.

Page 20

TECHNICAL GUIDE

Cal. 5D88A

20/ 51

td

Power reserve rotor

ts

Intermediate wheel for power reserve

ta

Power reserve indicator wheel

t;

Power reserve train wheel bridge

rl

Power reserve train wheel bridge screw

Check the alignment carefully after mounting the P

O

WER RESERVE ROTOR (53), INTERMEDIATE

WHEEL FOR POWER RESERVE (52) and PO

WER RESERVE INDICATOR WHEEL (51) guided by pins

and built-in magnet on the movement holder before assembling the PO

WER RESERVE TRAIN WHEEL

BRIDGE (50) and PO

WER RESERVE TRAIN WHEEL BRIDGE SCREW (49).

[How to check the alignment]

Af ter tightening the screw, check the alignment of the INT ERMEDIATE WHEEL FOR POWER

RESERVE (52) and PO

WER RESERVE INDICATOR WHEEL (51) once again.

If it is not good, disassemble the parts from the PO

WER RESERVE

TRAIN WHEEL BRIDGE SCREW (49) to the PO

WER RESERVE ROTOR (53) and repeat the same process again. In case the alignment

of wheels and the power reserve rotor is not correct, the direct drive

indicator hand may not be able to indicate the correct value of the

power reserve.

ek

Friction spring for sliding wheel

I

n

se r t the FRICT ION SPRING FOR SLID ING W HEEL ( 3 8 ) bene ath the “ f ” por tion on the

OSCILLATING BRIDGE and securely engage with the dowel without any clearance.

Page 21

TECHNICAL GUIDE

Cal. 5D88A

21/51

2) Direct drive indicator hand

Before installing the direct drive indicator hand, force the direct drive indicator hand position

back to “ 0 ” by resetting the built-in IC (system reset).

[How to retrieve the remaining power reserve (after system reset)]

* A

fter system reset, power reserve indicator goes back to “ 0 ” but the energy is still stored in

rechargeable battery. Instead of using KINETIC energy supplier or manual charging, you can

retrieve the stored energy by following the operations below.

i)

STEP 1

1

. Pull out the crown to the second click position.

2. Hold it for two or more seconds.

3. Repeat the following action within two seconds; [push it back to the normal

position], [pull it out to the second click], [push it back to the normal positon] ,[pull

it out to the second click] and then [push it back to the normal position.]

4.

The hand goes down below "0" shaking, then goes up again toward "D" (*note).

ii) STEP 2

1

. Press the button at the 10 o'clock position.

2. Pull the crown out to the first click position then push it back to the normal

position immediately while holding down the 10 o'clock button.

3.

Af ter confirming that the hand moves up toward "M"(*note), release the 10

o'clock button. (The watch will continue working according to the duration time

indicated.)

within two second

s

*note: depending on the energy level = voltage stored

Page 22

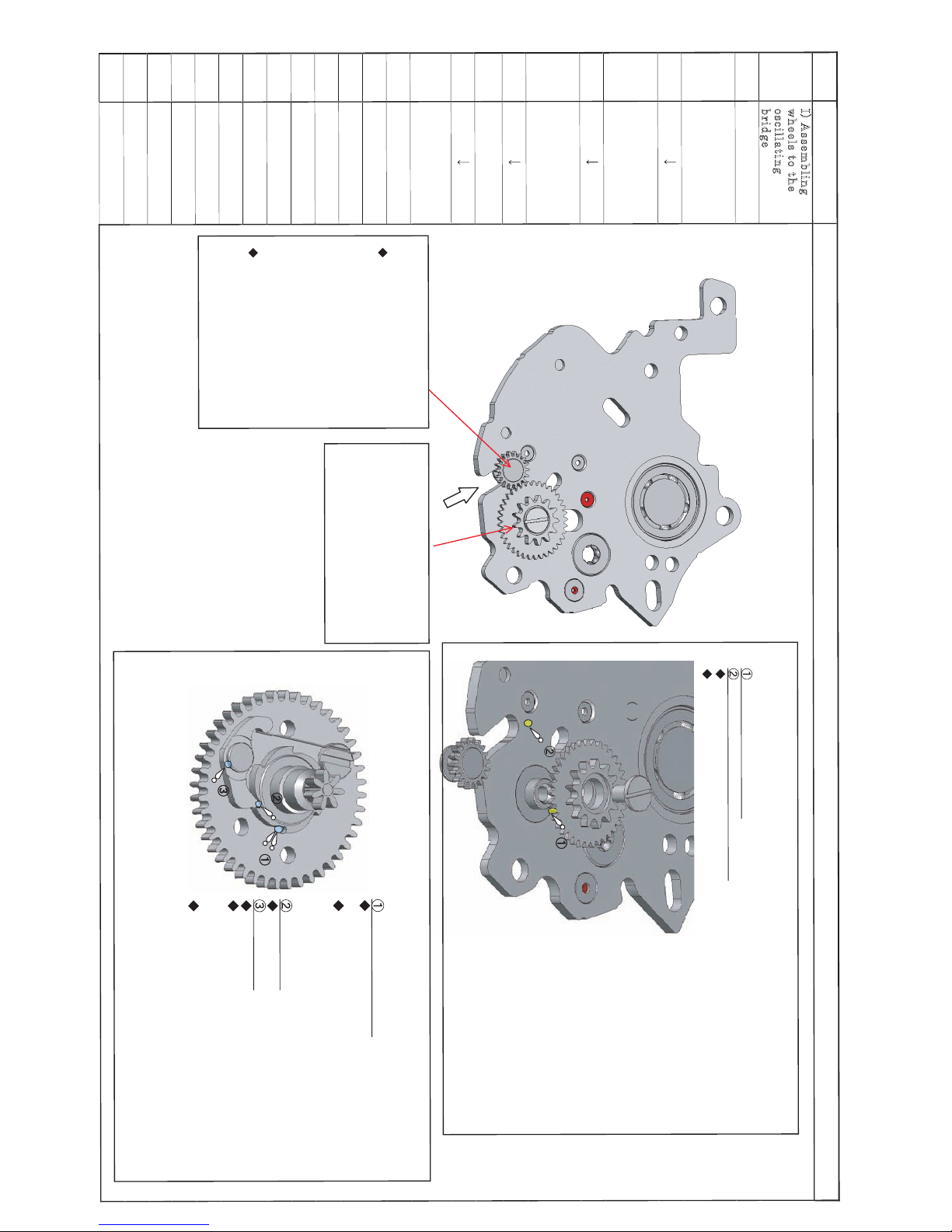

E D I U G L A C I N H C E T A 8 8 D 5 . l a C

1 .ON

l e e h w n w o r c

1.giF

33

7

0

#

s

c

r

e

w

w e r c s g n i x i f l e e h w n w o r c

3 .giF

. w o l e b 3 . g i F e h t n i d e t a c i d n i s a l e e h w g n i h c t i w s e h t e t a c i r b u L ) (

.oN

SSECORP

I

)

A

s

s

e

m

b

l

i

n

g

w

h

e

e

l

s

t

o

t

h

e

o

s

c

i

l

l

a

t

i

n

g

b

r

i

d

g

e

e h t e t a c i r b u L

t h g i e w g n i t a l l i c s o

e h t o t r e f e R . e g d i r b

. 2 . g i F

35

n w o r c e h t t n u o M

f o s i x a e h t o t l e e h w

g n i t a l l i c s o e h t

. e g d i r b t h g i e w

n w o r c e h t x i F

g n i n e t h g i t y b l e e h w

l e e h w n w o r c e h t

. w e r c s g n i x i f

) (

e h t e t a c i r b u L

. l e e h w g n i h c t i w s

. 3 . g i F e h t o t r e f e R

o t l e e h w n w o r c e h t t n u o M > 35<

t h g i e w g n i t a l l i c s o e h t f o s i x a e h t

. e g d i r b

y b l e e h w n w o r c e h t x i F > 34<

l e e h w n w o r c e h t g n i n e t h g i t

. w e r c s g n i x i f

1 .giF

2 .giF

. w o l e b 2 . g i F e h t n i d e t a c i d n i s a e g d i r b t h g i e w g n i t a l l i c s o e h t e t a c i r b u L

l e e h w n w o r c e h t r o f s i x A

n o i t r o p d e s s e c e r e p a h s - U e h t f o d n E

6 - S : l i o f o e p y T

.ylhtooms nrut leehw

d n a l e e h w n w o r c e h t t a h t e r u s e k a M

e Sliding crown h t t r e s n I > <

d e t a c i d n i n o i t c e r i d e h t m o r F

e

sliding

h t t r e s n i , w o r r a e h t y b

fo dne eht ot

n o i t r o p d e s s e c e r e p a h s - U e h t

t h g i e w g n i t a l l i c s o e h t f o

n e e b s a h 6 - S e r e h w , e g d i r b

x i f y l i r a r o p m e t d n a , d e i l p p a

. 6 - S f o y t i s u o c s i v e h t y b t i

g n i k a e r c g n i k a m t u o h t i w

. s e s i o n

s i x a e h t f o e c a f r u s e d i S

3 - O A : l i o f o e p y T

. e c i w t n o i t a c o l e m a s e h t e t a c i r b u L : e t o N

e c n a r a e l c e h t o t t n a c i r b u l e h t y l p p A

t n a c i r b u l e h t t a h t o s h t e e t e h t h t a e n r e d n u

f o e c a f r u s e d i s e h t o t d e i l p p a y l h g u o r o h t s i

. s i x a e h t

g u l e h t f o p i T

3 - O A : l i o f o e p y T

g u l e h t f o s i x A

3 - O A : l i o f o e p y T

e c n a r a e l c e h t o t t n a c i r b u l e h t y l p p A

s i t n a c i r b u l e h t t a h t o s s i x a e h t d n u o r a

. s i x a e h t f o e c a f r u s e r i t n e e h t o t d e i l p p a

l i o f o t n u o m a e t a i r p o r p p a n a t a h t e r u s n E

s a , s i x a e h t f o t r a p r e w o l e h t o t d e i l p p a s i

e s u a c y a m n o i t a c i r b u l e v i s s e c x e

. s i x a e h t f o s n o i t c n u f l a m

34

33

33

35

44

44

wheel

Make sure that the Sliding

crown wheel smoothly moves

Sliding crown wheel

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

22/51

34

Insert the sliding crown

wheel.

crown wheel

sliding crown

Page 23

E D I U G L A C I N H C E T A 8 8 D 5 . l a C

I

I

) A s s

e

m

b

l

i

n g

t

h

e

d

i a

l

s

i

d

e

o

f

t

h

e

m o v e

m

e

n t

( 1

)

& 87

86

) 85 (

e h t e t a c i r b u L

. n o i n i p g n i d n i w

& 6 . s g i F o t r e f e R

. 7

) (

e h t e t a c i r b u L

. m e t s g n i d n i w

. 8 . g i F o t r e f e R

84 , 85

83 &

g n i d n i w e h t l l a t s n I

n i a M e h t o t m e t s

h c t u l c d n a n o i n i p

. l e e h w

e h t e t a c i r b u L

. r e v e l g n i h c t i w s

9 . g i F e h t o t r e f e R

. 0 1 &

82

e h t t n u o M

. r e v e l g n i h c t i w s

e h t k c e h C (

r e f e R ) . e c n a r a e l c

. 5 . g i F e h t o t

1 8

, e k o y e h t t n u o M

k o o h y l e r u c e s d n a

. g n i r p s s t i

n o i n i p g n i d n i w e h t e t a c i r b u L ) 85 (

. w o l e b d e t a r t s u l l i s a

6 - S : l i o f o e p y T

k o o h y l e r u c e s d n a , e k o y e h t t n u o M > 81 <

. g n i r p s s t i

e d i s n i e k o y e h t f o m r a e h t t e s y l e r u c e S

e r a c g n i k a t , e t a l p n i a m e h t f o n i p e h t

e h t f o m r a e h t m r o f e d o t t o n s a o s

. e k o y

e h t n o e g d i r b t i u c r i c e h t t u P

. l a C r o f r e d l o h t n e m e v o m e h t f o t r a p A

) . w o l e b o t o h p e h t o t r e f e R ( . s e i r e s D 5

e ta l p n i a m e h t t n u o m , n e h t d n A

. e g d i r b t i u c r i c

> <

e h t o t m e t s g n i d n i w e h t l l a t s n I

n o i n i p g n i d n i w h t i w e t a l p n i a m

. l e e h w h c t u l c d n a

) 83 (

3 - O A : l i o f o e p y T

. m e t s g n i d n i w e h t f o e l i f o r p e r i t n e e h t e t a c i r b u L

S

e

t t i

n

g

w h e

e

l

t i l s g n i d i u g e h t f o s a e r a e h t e t a c i r b u L

. w o l e b d e t a r t s u l l i s a

6 - S : l i o f o e p y T

. r e v e l g n i h c t i w s e h t e t a c i r b u L

e t a i d e m r e t n i e h t r o f s i x a e h t e t a c i r b u L

. r o t c e r r o c r a d n e l a c r o f l e e h w

3 - O A : l i o f o e p y T

e c n a r a e l c e h t o t t n a c i r b u l e h t y l p p A

s i t n a c i r b u l e h t t a h t o s s i x a e h t d n u o r a

e c a f r u s e r i t n e e h t o t d e i l p p a y l h g u o r o h t

. s i x a e h t f o

t i g n i v i g , m e t s g n i d n i w e h t l l a t s n i y l e r u c e S

e h t f o e c a f t a l f e h t t a h t o s s n o i t a t o r e l t n e g

e l o h e h t h t i w d e g a g n e e b l l i w m e t s g n i d n i w

. l e e h w h c t u l c e h t f o

d e t a c i r b u l e b o t a e r A

4.giF

5.giF

iF g 7 & 6 .

8 .giF

9 .giF

01 .giF

11 .giF

Mount the switching lever with setting wheel

<82>

the intermediate wheel for calendar corrector and with the setting

Two wheels are attached to the switching lever as illustrated at

right. Check if the switching lever has appropriate clearances with

wheel so that they turn smoothly without making creaking nose.

Intermediate wheel for calendar corrector

83

Lubricate the winding stem

Lubricate the entire profile of the winding stem

Movement holder

A

B

Put the Main plate A

on the A part of the

movement holder

for Cal.5D series.

(Refer to the photo)

And then, mount

the Main plate B to

the Main plate A

plate B with winding

85, 84 & 83

B to the

<87 & 86>

2 . O N

23/51

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

PROCESS

No.

Page 24

E D I U G L A C I N H C E T A 88 D 5 . l a C

3 . O N

.oN

SSECORP

.CTE SNOITCURTSNI LAICEPS DNA SNOITARTSULLI

80

g n i t t e s e h t t n u o M

e h t o t r e f e R . r e v e l

. 3 1 . g i F

f o m r a e h t k o o H

. r e v e l g n i t t e s e h t

. 4 1 . g i F e h t o t r e f e R

, e k o y e h t e t a c i r b u L

d n a r e v e l g n i t t e s

o t r e f e R . s l e e h w

. 5 1 . g i F e h t

d n a r e v e l g n i t t e s , e k o y e h t e t a c i r b u L

. s l e e h w

e k o y e h t n e e w t e b t n e m e g a g n e f o t n i o P

g n i r p s r e v e l g n i t t e s d n a

d n a e k o y e h t n e e w t e b t c a t n o c f o t n i o P

r e v e l g n i t t e s

d n a e k o y e h t n e e w t e b t c a t n o c f o t n i o P

l e e h w h c t u l c

l e e h w h c t u l c e h t f o h t e e t e h t f o s p i T

e h t n e e w t e b t n e m e g a g n e f o t n i o p (

) l e e h w g n i t t e s d n a l e e h w h c t u l c

e t a i d e m r e t n i t s r i f e h t r o f s i x A

3 - O A : l i o f o e p y T

. r e v e l g n i t t e s e h t t n u o M > 80 <

e h t n o n i p e h t e g a g n e y l e r u c e S

r e v e l g n i t t e s e h t f o e d i s k c a b

3 1 . g i F e h t n i y b d e t a c i d n i (

e h t f o t i l s g n i d i u g e h t h t i w ) w o l e b

e h t g n i d i l S . r e v e l g n i h c t i w s

” a “ e h t s d r a w o t r e v e l g n i h c t i w s

e k a m l l i w 3 1 . g i F e h t n i n o i t r o p

. r e i s a e s i h t

a

>79<

> <

. r e v e l g n i t t e s e h t f o m r a e h t k o o H

r e v e l g n i t t e s e h t h s u p t o n o D

m r o f e d y a m o s g n i o d s a , y l e v i s s e c x e

. r e v e l g n i t t e s e h t f o m r a e h t

41 .giF

51 .giF

21 .giF

79

Place the setting lever jumper

Fix the setting lever jumper

by tightening the setting lever

jumper screw.

Fix the setting lever

jumper by tightening

the setting lever

Refer to the Fig.12

Place the setting lever

jumper

Refer to the Fig.12

78

78

jumper screw.

77

Mount the 1st

Intermediate wheel

for minute wheel

Refer to the Fig.12

<77> Mount the 1st Intermediate wheel for minute wheel

This part is reversible

Fig.13

wheel for

minute wheel of the Main plate B

24/51

✽

Page 25

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO. 4

32-T

31

Mount the

Fix the Dummy

plate by tightening

the Calendar plate

screw.

Dummy plate

25/51

Fig.16

Fix the Dummy plate to the main plate by

tightening the Calendar Plate screw.<31>

Mount the Dummy plate.

<32-T>

Firmly press down the points of engagement ( “a” and “b” portions)

so that the dummy

Before assembling the case back side of the movement, mount the Dummy plate instead of

a

b

instead of

Calendar plate.

Refer to the Fig.16

the Calendar plate.

(The Calendar plate is thicker, and if the Calendar plate is mounted,

the pins on the movement holder cannot come through the holes of the other side of the

main plate and cannot guide the alignment.)

plate is securely mounted.

PROCESS

No.

Page 26

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO.5

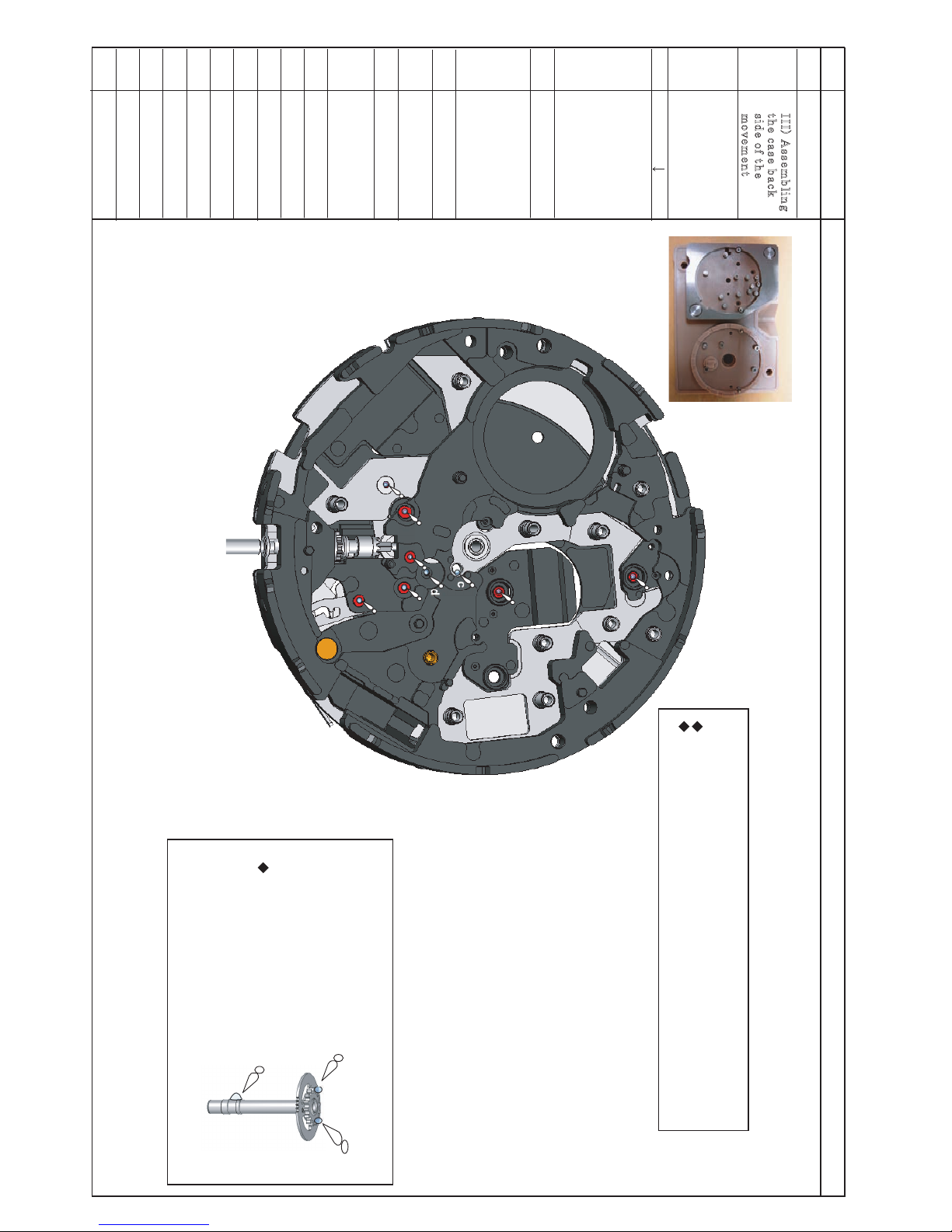

I

I

I

)

A s s

e

m

b

l

i

n g

t

h e

c

a s

e

b a c k

s i d

e

o

f

t

h e

m

o

v e m

e n t

e t a l p n i a m e h t t u P

o t n o n w o d e d i s p u

e h t f o t r a p B e h t

. r e d l o h t n e m e v o m

. o t o h p e h t o t r e f e R

r e w o l e h t e t a c i r b u L

s l e e h w e h t f o s t o v i p

” i “ o t ” a “ m o r f

n w o h s s a s n o i t r o p

. 7 1 . g i F e h t n i

e h t e t a c i r b u L

d n a l e e h w r e t n e c

e h t o t r e f e R . n o i n i p

. 8 1 . g i F

. g i F e h t n i n w o h s ” i “ o t ” a “ m o r f s l e e h w e h t f o s t o v i p r e w o l e h t e t a c i r b u L

. t f e l t a 8 1

2 - O A : ” b “ d n a ” a “ r o f l i o f o e p y T

3 - O A : ” i “ o t ” c “ m o r f l i o f o e p y T

b

a

g f

h

i

e

c

d

71 .giF

81 .giF

) 8 6 (

l e e h w r e t n e c e h t e t a c i r b u L

e h t n i n w o h s s a

. t h g i r t a 8 1 . g i F

3 - O A : l i o f o e p y T

(68)

26/51

PROCESS

No.

A

B

Movement holder

Page 27

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO.6

27/51

r o t o r e h t t n u o M

. r o t a t s

e h t t n u o M

. l e e h w e t u n i m

. r o t o r e h t t n u o M

. g i F e h t o t r e f e R

. 0 2

h t f i f e h t t n u o M

d n a l e e h w

. n o i n i p

d r i h t e h t t n u o M

d n a l e e h w

. n o i n i p

. r o t o r e h t t n u o M

r o t o r e v r e s e r r e w o p e h t t n u o m t o n o D

r o t o r e h t e t a n i m i r c s i d o T . e k a t s i m y b

e h t e e s , r o t o r e v r e s e r r e w o p e h t m o r f

r o t o r r i e h t f o s e p a h s e h t n i e c n e r e f f i d

. s e g d i r b

. l e e h w e t u n i m e t a i d e m r e t n i d n o c e s e h t t n u o M

e t a i d e m r e t n i d n o c e s e h t t n u o m o t e r u s e k a M

. n o i t c e r i d t c e r r o c e h t n i l e e h w e t u n i m

. r o t a t s r o t o r e h t t n u o M > <

, r o t a t s r o t o r e h t g n i t n u o m n e h W

r o t r o t s i d o t t o n s a o s e r a c e k a t

e s u a c y a m t i s a , t i m r o f e d

. r o t o m e h t f o n o i t a r o i r e t e d

. l ee h w r e t n e c e h t t n u o M

t n u o M e h t e t u n i m . l e e h w

> <

d n a l e e h w d r i h t e h t t n u o M

. n o i n i p

. n o i n i p d n a l e e h w h t f i f e h t t n u o M

) r o t o r e v r e s e r r e w o P (

91 .giF

12 .giF

02 .giF

e g d i r b r o t o r

) r o t o R (

74

Mount the Center

wheel.

68

Mount the Second

Intermediate wheel

for minute wheel.

Refer to Fig.21.

74

67

66

65

<68>

64

63

<65>

65

53

63

<64>

<66>

<67>

PROCESS

No.

Page 28

7 .ON

.oN

SSECORP

62

61

73

72

71

60

70

69

<73>

rotor.

72

g

e n

e

r

a t

i

n

g s t

a

t

o r

3 - O A : l i o f o e p y T

22 .giF

32 .giF

42 .giF

52 .giF

r e v e l g n i t t e s e h t f o n i p l e w o d

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

<62> Lubricate and set the fourth wheel.

Lubricate and set

the fourth wheel.

Refer to the Fig.24

Mount the train

wheel setting

lever.

Refer to the Fig.25.

Mount the coil

block.

Mount the spacer

for generating stator

Refer to the Fig.23.

<61> Mount the train wheel setting lever.

Insert the tail portion of the train wheel setting lever with

the guideing slit at an angle into the gap of the circuit bridge,

and securely set the guiding slit to the dowel pin of the setting

lever.

Mount the

generating coil

block.

Mount the

generating rotor.

Mount the

generating stator.

Refer to the Fig.23.

<69> Mount the spacer for coil block rotor.

Mount the coil block.

When mounting the coil block, take care so as not to

distort or deform the coil blocl core as it may cause

deterioration of the motor.

* Coil block resistance between 1.9KΩ and 2.15KΩ

(as reference value)

<70> Mount the generating coil block.

When mounting thegenerating coil block, take care so as not to

distort or deform the coil block core as it may cause deterioration

of the motor.

* Coil block resistance between 585Ω and 645Ω (as reference value)

<60>

Mount the

generating

rotor.

<72> Mount the spacer for generating stator.

<71> Mount the generating stator.

When mounting the spacer for generating stator and

generating

stator, take care so as not to distort or deform the

coil block

core as it may cause deterioration of the motor.

71

Mount the Spacer

for coil block rotor

28/51

Spacer for generating stator

Page 29

8 .ON

.oN

SSECORP

59

62 .giF

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

Mount the train

wheel bridge and

check the pivot hole.

<59>

Mount the train wheel bridge and check the pivot hole.

69

Fix the train wheel

bridge to the spacer

for coil block rotor

by tightening the

train wheel bridge

screw.

<69>

Fix the train wheel bridge to the spacer for coil block rotor by tightening the train wheel bridge screw.

* Do not overtighten the train wheel bridge screw as doing so may cuase sinking of the train wheel

bridge applying pressure on other parts underneath it, which may result in deterioration of the motor.

29/51

Page 30

9 . O N

.oN

SSECORP

. r o t o r e v r e s e r r e w o p e h t t n u o M > <

f o ) e v i t a g e n d n a e v i t i s o p ( s e i t i r a l o p c i t e n g a m e h t t a h t e r u s e k a M

w o l e b d e t a r t s u l l i s a d e n g i l a e r a r o t o r e v r e s e r r e w o p e h t

t c e r r o c y l l a c i t e n g a m l l i w r e d l o h t n e m e v o m e h t f o s t e n g a m n i - t l i u b e h T *

. r o t o r e v r e s e r r e w o p e h t f o t n e m n g i l a e h t

) k c e h c t n e m n g i l A ( . e v r e s e r r e w o p r o f l e e h w e t a i d e m r e t n i e h t t n u o M > <

) k c e h c t n e m n g i l A ( . l e e h w r o t a c i d n i e v r e s e r r e w o p e h t t n u o M > <

e h t n o ) w o l e b n o i t a r t s u l l i e h t n i y b d e t a c i d n i ( s e l o h g n i n g i l a e h t t e S

n o s n i p g n i n g i l a e h t o t g n i d n o p s e r r o c s n o i t i s o p e h t o t s l e e h w e h t f o e c a f r u s

) . w o l e b . g i F e h t o t r e f e R ( . r e d l o h t n e m e v o m e h t

e v r e s e r r e w o p e h t t l i t , e v r e s e r r e w o p r o f l e e h w e t a i d e m r e t n i e h t g n i t t e s r e t f A

e h t t a h t e r u s e k a M . e v r e s e r r e w o p r o f l e e h w e t a i d e m r e t n i e h t s d r a w o t r o t o r

e v r e s e r r e w o p r o f l e e h w e t a i d e m r e t n i e h t n o k r a m e h t y b d e t n i o p h t o o t r a e g

. r o t o r e v r e s e r r e w o p e h t f o n o i n i p e h t f o h t o o t r a e g a h t i w d e g a g n e y l e r u c e s s i

) . w o l e b . g i F e h t o t r e f e R (

. r o t a t s e v r e s e r r e w o p e h t t n u o M > <

30.giF

g

e a

r

t o o t

h

p

o

i

n

t e

d

b

y

t h

e m a

r k

29 .giF

(

) p

o

w

e

r

r

e

s

e

r

v

e

i

n

d

i c a

t

o

r

w

h

e

e

l

A

l

i

g

n

m e n

t

72 .giF

82 .giF

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

<54>

Mount the

rechargeable

battery

connection (+).

57

Mount the power

reserve stator.

53

Mount the power

reserve rotor.

Refer to the Fig.

28 for the align-

ment of the power

reserve rotor.

52

Mount the

Intermediate wheel

for power reserve.

Refer to the Figs.29

& 30 for the align-

ment of the inter-

mediate wheel for

Mount the power

reserve indicator

wheel. Refer to

the Figs.29 & 30 for

the alignment of the

power reserve

indicator wheel.

51

Mount the

rechargeable

battery

connection (+).

54

57

53

52

51

power reserve.

30/51

51

(52) Intermediate

wheel for power

reserv

(53) Power reserv rotor

29

30

Page 31

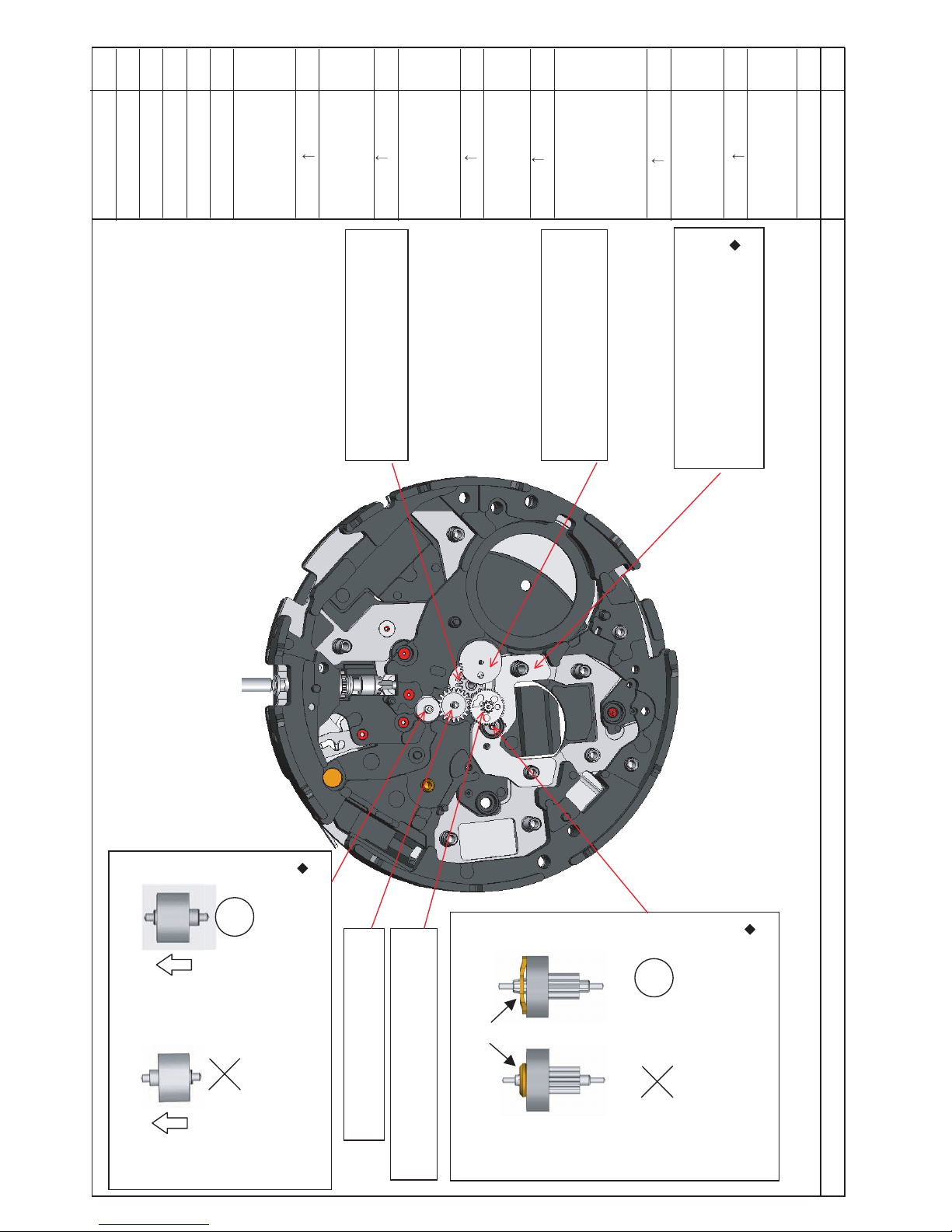

01 .ON

.oN

SSECORP

t n e m e v o m e h t e g n a h C

l a s r e v i n u n a o t r e d l o h

. ) 2 8 6 - S ( r e d l o h

e v r e s e r r e w o p e h t x i F

y b e g d i r b l e e h w n i a r t

r e w o p e h t g n i n e t h g i t

l e e h w n i a r t e v r e s e r

. w e r c s e g d i r b

r e p p u e h t e t a c i r b u L

e h t f o s t o v i p

” c “ , ” b “ , ” a “ ( . s l e e h w

r e f e R ) s n o i t r o p ” d “ d n a

. 1 3 . g i F e h t o t

g n i d i u g e h t e t a c i r b u L

lever.g n i t t e s e h t f o t i l s

.giF eht ot refeR

3.

3

r e w o p e h t t n u o M

. k c o l b l i o c e v r e s e r

e v r e s e r r e w o p e h t x i F

y b k c o l b l i o c

r e w o p e h t g n i n e t h g i t

k c o l b l i o c e v r e s e r

. w e r c s

t n e m n g i l a e h t k c e h C

e v r e s e r r e w o p e h t f o

e h t d n a ) 2 4 ( r o t a c i d n i

r o f l e e h w e t a i d e m r e t n i

) 3 4 ( e v r e s e r r e w o p

f o s e l o h e h t h g u o r h t

e g d i r b l e e h w n i a r t e h t

. ) 1 4 (

> < n i a r t e v r e s e r r e w o p e h t t n u o M

. e l o h t o v i p e h t k c e h c d n a e g d i r b l e e h w

b

c

d

a

> < e h t g n i n e t h g i t y b k c o l b l i o c e v r e s e r r e w o p e h t x i F

. w e r c s k c o l b l i o c e v r e s e r r e w o p

l i o c e v r e s e r r e w o p e h t t n u o M > <

. k c o l b

e v r e s e r r e w o p e h t g n i t n u o m n e h W

o t t o n s a o s e r a c e k a t , k c o l b l i o c

e r o c k c o l b l i o c e h t m r o f e d r o t r o t s i d

e h t f o n o i t a r o i r e t e d e s u a c y a m t i s a

. r o t o m

k 5 2 . 1 : e c n a t s i s e r k c o l b l i o C

k 5 . 1 -

) e u l a v e c n e r e f e r s a (

e v r e s e r r e w o p e h t x i F > <

y b e g d i r b l e e h w n i a r t

e v r e s e r r e w o p e h t g n i n e t h g i t

. w e r c s e g d i r b l e e h w n i a r t

e v r e s e r r e w o p e h t n o s e l o h e h t f o s n o i t i s o p e h t t a h t e r u s e k a M

) w o l e b n o i t a r t s u l l i e h t n i y b d e t a c i d n i ( e g d i r b l e e h w n i a r t

e h t n o s e l o h e h t f o s n o i t i s o p e h t o t d e d n o p s e r r o c y l t c i r t s e r a

e v r e s e r r e w o p d n a e v r e s e r r e w o p r o f l e e h w e t a i d e m r e t n i

. l e e h w r o t a c i d n i

I

n

t

e

r

m

e d

i

a

t

e

w

h e

e l

f

o

r

p

o w

e

r

r e s

e

r v e

P

o

w

e

r

r

e

s e

r v

e

i

n

d

i

c a

t

o r

P

o w e r r

e

s

e r v

e

r

o

t

o

r

: e l p m a x e d a B

r e w o p r o f l e e h w e t a i d e m r e t n i e h T

r o t o r e v r e s e r r e w o p e h t d n a e v r e s e r

. d e g a g n e y l t c e r r o c t o n e r a

23 .giF

13 .giF

. g i F e h t o t r e f e r : r e v e l g n i t t e s e h t f o t i l s g n i d i u g e h t e t a c i r b u L

. w o l e b 3 3

3 - O A : l i o f o e p y T

e h t f o t i l s g n i d i u g e h t e t a c i r b u L

r e v e l g n i t t e s

33 .giF

d n a ) 2 4 ( r o t a c i d n i e v r e s e r r e w o p e h t f o t n e m n g i l a e h t k c e h C

e h t h g u o r h t ) 3 4 ( e v r e s e r r e w o p r o f l e e h w e t a i d e m r e t n i e h t

. ) 1 4 ( e g d i r b l e e h w n i a r t e h t f o s e l o h

. s l e e h w e h t f o s t o v i p r e p p u e h t e t a c i r b u L

s n o i t r o p ” b “ d n a ” a “

2 - O A : l i o f o e p y T

s n o i t r o p ” d “ d n a ” c “

3 - O A : l i o f o e p y T

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

50

50

49

49

56

56

55

55

31/51

Mount the power

reserv train wheel

bridge and check the

pivot hole.

Page 32

1 1 . O N

.oN

SSECORP

t s r i f e h t t n u o M

e t a i d e m r e t n i

l a u n a m r o f l e e h w

. g n i d n i w

t i u c r i c e h t t n u o M

. k c o l b

e h t t n u o M

. l e e h w g n i h c t i w s

d r i h t e h t t n u o M

e t a i d e m r e t n i

l a u n a m r o f l e e h w

. g n i d n i w

d n o c e s e h t t n u o M

e t a i d e m r e t n i

l a u n a m r o f l e e h w

. g n i d n i w

. g n i d n i w l a u n a m r o f l e e h w e t a i d e m r e t n i t s r i f e h t t n u o M > <

. k c o l b t i u c r i c e h t t n u o M > <

o t ” a “ m o r f s t n i o p x i s ( s t n e m e g a g n e f o s t n i o p e h t n w o d s s e r p y l m r i F

. 4 3 . g i F e h t n i y b d e t a c i d n i ” f “

> <

. g n i d n i w l a u n a m r o f l e e h w e t a i d e m r e t n i d n o c e s e h t t n u o M

> < g n i d n i w l a u n a m r o f l e e h w e t a i d e m r e t n i d r i h t e h t t n u o M

.

a

f

d

b

c

e

43 .giF

> <

. l e e h w g n i h c t i w s e h t t n u o M

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

48

48

45

44

45

44

47

47

46

46

32/51

Page 33

21 .ON

.oN

SSECORP

t i u c r i c e h t t n u o M

. C r e v o c k c o l b

t i u c r i c e h t t n u o M

. A r e v o c k c o l b

t i u c r i c e h t t n u o M

. B r e v o c k c o l b

e h t t n u o M

g n i t a l l i c s o

n i e g d i r b t h g i e w

d n a I s s e c o r p

t o v i p e h t k c e h c

e h t o t r e f e R . e l o h

. 7 3 . g i F

e h t x i F

g n i t a l l i c s o

e g d i r b t h g i e w

k c o l b t i u c r i c d n a

y b B r e v o c

e h t g n i n e t h g i t

” a “ m o r f s w e r c s

o t r e f e R . ” e “ o t

. 6 3 . g i F e h t

s i e r e h t f i k c e h C

e t a u q e d a n a

o t e c n a r a e l c

l a c i t r e v w o l l a

e h t f o t n e m e v o m

s l e e h w

e h t h t a e n r e d n u

g n i t a l l i c s o

. e g d i r b t h g i e w

. C r e v o c k c o l b t i u c r i c e h t t n u o M > <

t o v i p e h t k c e h c d n a I s s e c o r p n i e g d i r b t h g i e w g n i t a l l i c s o e h t t n u o M > <

. e l o h

n w o r c e h t t a h t e r u s e k a m , e g d i r b t h g i e w g n i t a l l i c s o e h t g n i t t e s n e h W

s i l e e h w n w o r c e h t s a , d e g a g n e y l e r u c e s e r a n o i n i p g n i d n i w d n a l e e h w

t s u j d A . h s e m f o t u o s e o g t i n e h w n o i n i p g n i d n i w e h t e d i r r e v o o t y l e k i l

g n i d n i w e h t f i k c e h C . e s i w k c o l c m e t s g n i d n i w e h t g n i n r u t y b h s e m e h t

. y l h t o o m s s n r u t m e t s

. A r e v o c k c o l b t i u c r i c e h t t n u o M > <

> <

. B r e v o c k c o l b t i u c r i c e h t t n u o M

> <

d n a e g d i r b t h g i e w g n i t a l l i c s o e h t x i F

e h t g n i n e t h g i t y b B r e v o c k c o l b t i u c r i c

. ” e “ o t ” a “ m o r f s w e r c s

O s c i l

l

a t

i

n g

w

e

i

g

h t

b

r i

d g e

T

u

r

n

t h

e w

i

n d i

n

g

s t e

m

c

l

o

c k

w

i s e

t o s e

c u

r e

l

y

e n

g a

g

e t h

e c r

o

w

n

w h

e

e

l

a

n

d w i

n

d

i

n

g p

i n

i

o

n

.

c

e

d

b

a

C

r

o w n

w

h e

e

l

W

i

n

d i

n g

p

i

n i

o

n

53 .giF

63 .giF

73 .giF

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

43

43

42

41

36

39

42

41

39

36

&

40

&

40

33/51

88

88

Page 34

31.ON

e h t e t a c i r b u L

f o s t o v i p r e p p u

r o f s l e e h w e h t

g n i d n i w l a u n a m

e h t t a m s i n a h c e m

s n o i t r o p ” e “ o t ” a “

e h t n i n w o h s s a

. g i F

e h t e t a c i r b u L

e h t f o s g n i r a e b

n w o h s s a s l e e h w

. g i F e h t n i

e h t t r e s n I

r o f g n i r p s n o i t c i r f

l e e h w

” f “ e h t h t a e n e b

n i n w o h s n o i t r o p

. 0 4 . g i F e h t

t i u c r i c e h t x i F

) ( A r e v o c k c o l b

n o i t c i r f e h t d n a

r o f g n i r p s

y b ) (38 l e e h w

e h t g n i n e t h g i t

e h t k c e h C

t n e r r u c

n o i t p m u s n o c

e h t g n i t t e s r e t f a

t i n u y r e t t a b

. y l i r a r o p m e t

e g a p e h t o t r e f e R

. 0 3

r o f s l e e h w e h t f o s t o v i p r e p p u e h t e t a c i r b u L

” e “ o t ” a “ e h t t a ms i n a h c e m g n i d n i w l a u n a m

. 0 4 . g i F e h t n i n w o h s s a s n o i t r o p

3 - O A : l i o f o e p y T

r o f g n i r p s n o i t c i r f e h t t r e s n I > <

n o i t r o p ” f “ e h t h t a e n e b l e e h w

. w o l e b 40 . g i F e h t n i n w o h s

o t n w o d e h t s s e r p y l m r i F

l e w o d e h t h t i w t i e g a g n e y l e r u c e s

t f e l t a 8 3 . g i F e h t n i d e t a c i d n i

o s

y n a t u o h t i w d e t n u o m s i t i t a h t

g n i r p s n o i t c i r f e h t n e e w t e b e c n a r a e l c

g n i t a l l i c s o e h t d n a l e e h w r o f

. e g d i r b t h g i e w

e h t d n a ) ( A r e v o c k c o l b t i u c r i c e h t x i F > <

y b ) ( l e e h w r o f g n i r p s n o i t c i r f

g n i n e t h g i t

f

f

e

c

d

b

a

b

e

a

r

i

n

g s

s a s l e e h w e h t f o s g n i r a e b e h t e t a c i r b u L

. e v o b a .g i F eh t n i n w o h s

3 - O A : l i o f o e p y T

39 .giF

.giF

l e w o d

40 .giF

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

38

38

37

37

34/51

39

39

38

39

PROCESS

No.

sliding

sliding

rechargeable

circuit block cover

A screw.

sliding

38

circuit block cover A screw.

sliding

sliding

42

42

88

Page 35

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO. 14

32-T

31

Mount the

Calendar plate

screw.

<32> After removing the Dummy plate, mount

Firmly press down the points of engagement

(217#, 68#)

to securely set it in position.

<31> Fix the Calendar Plate by tightening

Calendar Plate screw (36#).

Target value)

lower than 350gcmTightening torque:

◆

Dummy plate.

Fig.17

Release the Calendar Plate screw.

<31>

a

b

Set the movement

upside down on

the Universal

movement holder.

Release the

Calendar plate

Remove the

32

by tightening the

Calendar plate

Remove the Dummy plate.

<32-T>

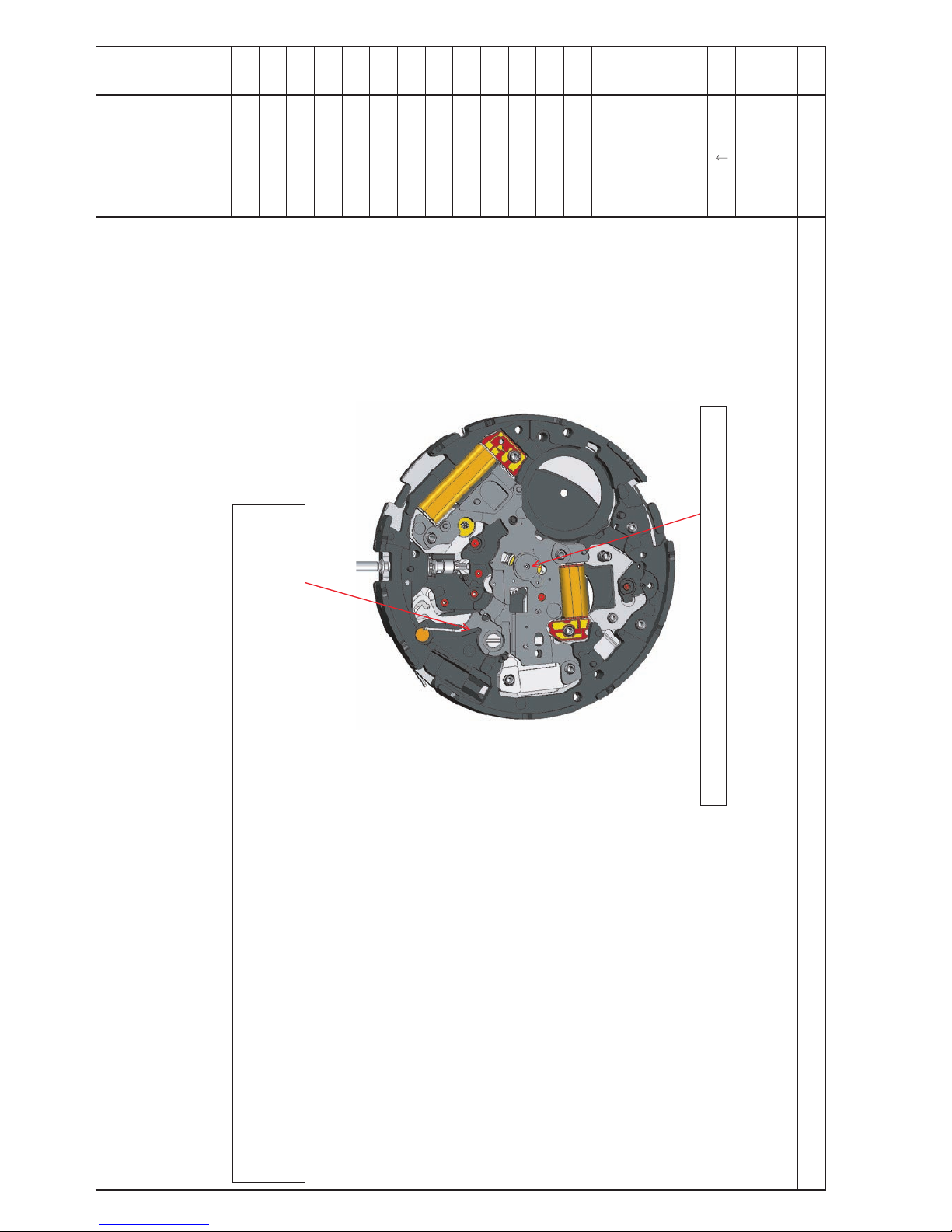

After assembling the Oscillating weight bridge, turn

plate before starting to assemble the calendar side

over the movement and disassemble the dummy

of the movement.

the Calendar Plate.

screw.

Cal.5D88A TECHNICAL GUIDE

217#

217#

68#

36#

PROCESS

No.

35/51

Page 36

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO.15

PROCESS

No.

Assembling the

Calendar

mechanism

Set the movement

upside down on

the Universal

movement holder.

Pull out the winding

click position.

Lubricating

Mount the Hour

wheel.

Mount the Anti-

magnetic shield

plate (Fig.43).

Mount the Date

driving wheel

Alignment check.

Mount the Day

driving wheel.

Alignment check

Mount the Moon

phase indicator

Alignment check

driving wheel.

30

29

28

27

26

<28>

Mount the Date driving wheel.

Alignment check

After setting the Date driving wheel,

place the hole on the marked point

on the calendar plate (indicated by

in the Fig. 45 below) by turning

the winding stem clockwise.

Lubricating

Lubricate the pipe of the

Center wheel as indicated in

Fig.44 below.

Lubricate the point of contact

the Hour wheel.

between the main plate and

◆

Type of oil: AO-3

(Reducing the resistance by

friction)

<29>

Mount the Anti-magnetic shield plate.

<30>

Mount the Hour

wheel.

<26>

Mount the Moon phase indicator

driving wheel.

Alignment check

◆

◆

<27>

Mount the Day driving wheel.

Alignment check

◆

The top of the triangle mark on

the Moon phase indicator driving

wheel should be set and aligned

within the marked area on the

stem to the 2nd

Fig.44

Fig.45

Calendar plate as indicated in

Fig.47

Fig.47

Fig.46

The peak of the mark on the Day

driving wheel should be set and

aligned within the marked area on

the Calendar plate as indicated in

Fig.46

Fig.43

2

1

1

2

36/51

Page 37

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO.16

PROCESS

No.

Mount the 2nd

25

intermediate wheel

for calendar

corrector.

24

Mount the 3rd

intermediate wheel

for calendar

corrector.

23

Mount the 1st

intermediate wheel

for day corrector.

22

Mount the 2nd

intermediate wheel

for day corrector.

21

Mount the Day

star wheel.

<21>

Mount the Day star wheel.

<22>

Mount the 2nd intermediate

wheel for day corrector.

◆

Correct dirrection is as shown

Fig.49 below.

<23>

Mount the 1st intermediate

wheel for day corrector.

<24>

Mount the 3rd intermediate wheel

for day corrector.

◆

To discriminate the 3rd Intermediate

wheel for calendar corrector from the

1st Intermediate wheel for day

corrector, see the difference in the

shapes of each wheel. Fig. 50

*3rd Intermediate

wheel for calendar

corrector

*1st Intermediate

wheel for day

corrector

<25>

Mount the 2nd Intermediate wheel for

calendar corrector.

This part is reversible.

37/51

Fig.49

Fig.49

Fig.48

✽

Page 38

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO.17

fi

★★

★

★★

★

★

★★

★

20

Mount the Date

jumper.

19

Fix the Date

jumper to the

calendar plate by

tightening the

Date jumper

screw.

Set and hook the

date jumper to the

day star wheel.

21

<20>

Mount the Date jumper.

◆

Firmly press down the points

of engagement to securely

set it in position. (455#, 456#)

<19>

Fix the Date jumper to the

calendar plate by tightening

the Date jumper screw.

Lubricate the Day

star wheel.

Lubricate the Day star wheel.

◆

◆

Apply the lubricant as shown Fig.53

below.

Type of oil: AO-3 (Reducing the

resistance by friction)

(68#, 101#)

◆

Set and hook the date jumper

to the day star wheel.

Take care so as not to deform

the date jumper.

Check the clear-

ance between the

wheels under the

Date jumper.

Check the clearance between wheels.

2nd Intermediate

wheel for calendar

corrector

3rd Intermediate

wheel for calendar

corrector

1st Intermediate

wheel for day

corrector

2nd Intermediate

wheel for day

corrector

Day driviing wheel

◆

◆

When checking, the Date jumper should be mounted without clearance (hold the point

Target value)

Tightening torque:

lower than 350gcm

38/51

Fig.53

Fig.52

Fig.51

lightly.)

The points of checking are shown in the above illustrations.

5

4

3

2

1

1

2

3

4

5

68#

455#

456#

101#

PROCESS

No.

Page 39

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO.18

Set the Moon phase corrector

18

Mount the Moon

phase corrector

lever.

Lubricant

Hook the spring

24

Lubricate the points

of engagement of

the 3rd Inter-

mediate wheel for

calendar corrector.

<18>

Lubricate the Moon phase

corrector lever.

◆

Apply the lubricant as shown

Fig. 56 below.

◆

Type of oil: S-6

Mount the Moon phase corrector

lever. Then hook the spring.

◆

<24>

3rd Intermediate wheel for

calendar corrector

Lubricate the contact point

Fig.55

Fig.56

Fig.57

Fig.54

◆

Take care so as not to deform the

spring.

of the spring.

◆

Apply the lubricant as shown Fig.55

below.

◆

Type of oil: AO-3

39/51

inside the Switch spring.

PROCESS

No.

Page 40

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO.19

◆

17

Mount the Inter-

mediate wheel for

24 Hour indicator.

16

Mount the 24 Hour

indicator wheel.

15

Mount the Date

corrector wheel.

Mount the Date

star wheel.

Set and hook the

jumper to Date

star wheel.

14

Mount the

Calendar train

bridge.

13

12

Fix the Calendar

train bridge by

tightening the

Calendar train

bridge screrw.

Check the clear-

ance between the

wheels under the

Calendar train

bridge.

<16>

Mount the 24 Hour

indicator wheel.

<17>

Mount the Intermediate wheel

for 24 Hour indicator.

<15>

Mount the Date corrector

wheel.

<13>

Mount the Calendar train bridge.

◆

Firmly press down the points of

engagement. (451#, 452#)

<12>

Fix the Calendar train bridge by

tightening the Calendar train

bridge screw. (471#)

<14>

Mount the Date star wheel.

Set and hook the jumper to Date

star wheel.

(See Fig.60.)

Take care so as not to deform the

jumper.

◆

Securely engage the Date star wheel

and the Date corrector wheel (indicated

by in the upper left diagram.)

Check the clearance between the wheels.

Date driving wheels

Moon phase

Indicator wheel

◆

Checking points are indicated in Fig.59.

40/51

Fig.58

Fig.59

Fig.60

✻

This part is reversible.

Target value)

Tightening torque:

lower than 350gcm

2

1

452#

471#

451#

1

2

PROCESS

No.

Page 41

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

NO.20

11

Mount the Moon

phase indicator

wheel.

Mount the Dial

washer.

10

9

Mount the calendar

train cover.

Set and hook the

jumper to the Moon

phase indicator

wheel.

9

Fix the calendar

8

train cover by

tightening the

calendar train

bridge screw.

<11>

Mount the Moon phase

indicator wheel.

<10>

Mount the Dial washer.

Make sure the dial washer

◆

is put in the correct direction.

(See the Fig.63 below.)

When mounting the dial

◆

washer, handle it with

care so as not to bend

or deform it.

<9>

Mount the calendar train

cover.

<How to set and hook the jumper

of the Moon phase indicator

◆

Firmly press down the point

of engagement 451# first.

Hook the jumper before

pressing down the engage-

ment 452#. Then, press down

the point of engagement 452#.

◆

Take care so as not to deform

the jumper of the Calendar

wheel>

train wheel.

<8>

Fix the Calendar train cover by

tightening the Calendar train bridge

screw (453#, 454#, 457#.)

◆

When handling the Moon

phase indicator wheel, take

care so as not to damage the

printed surface of the Moon

phase indicator.

Target value)

lower than 200gcmTightening torque:

Lubricate the

jumpers.

Lubricate the jumpers.

Lubricate the jumper of the Date driving wheel

◆

Type of oil: AO-3

Lubricate the jumper of the Day driving wheel

(See Fig.64 shown as right)

◆

Type of oil: AO-3

(See Fig.65 shown as right)

Lubricate the jumper of the Moon phase

Type of oil: S-6

(See Fig.66 shown as right)

indicator driving wheel

◆

(For preventing the abrasion of the parts)

(For preventing the abrasion of the parts)

Fig.61

Fig.62

Fig.63

41/51

Fig.63

Fig.64

Fig.65

Fig.66

3

2

1

1

2

3

452#

454#

451#

457#

453#

PROCESS

No.

Page 42

21 .ON

.oN

SSECORP

e h t t n u o M

. t i n u

e h t t n u o M

r o f r o t a l u s n i

e h t t n u o M

. d r a u g

r o t a l u s n i e h t x i F

n i t l i u b e h t t e s e R

e h t o t r e f e R . C I

. t i n u y r e t t a b y r a d n o c e s e h t t n u o M > <

y r e t t a b y r a d n o c e s e h t f o m r a e h t k o o H

e h t n i n o i t r o p ” a “ e h t o t t i n u

. w o l e b

s u n i m e h t m r o f e d o t t o n s a o s e r a c e k a T

y r a d n o c e s e h t g n i v o m e r n e h w l a n i m r e t

. t i n u y r e t t a b

a

y r a d n o c e s r o f r o t a l u s n i e h t t n u o M > <

. y r e t t a b

e h t f o e l o h e h t n w o d s s e r p y l m r i F

e h t o t y r e t t a b y r a d n o c e s r o f r o t a l u s n i

n e h t , ) ” e “ ( e t a l p n i a m e h t f o e b u t e d i u g

” d “ t n e m e g a g n e f o t n i o p e h t n w o d s s e r p

s i y r e t t a b y r a d n o c e s r o f r o t a l u s n i l i t n u

. n o i t i s o p n i t e s y l e r u c e s

. d r a u g y r e t t a b y r a d n o c e s e h t t n u o M > <

. n o i t i s o p n i t i t e s y l e r u c e s o t t n e m e g a g n e f o s t n i o p e h t n w o d s s e r p y l m r i F

” e “ : e b u t e d i u g g n i n o i t i s o P •

” d “ d n a ” c “ : t n e m e g a g n e f o s t n i o P •

y r e t t a b y r a d n o c e s d n a y r e t t a b y r a d n o c e s r o f r o t a l u s n i e h t x i F > <

. ”f “ d n a ” b “ s w e r c s d r a u g y r e t t a b y r a d n o c e s e h t g n i n e t h g i t y b d r a u g

b

f

e

c

d

. C I n i t l i u b e h t t e s e R

y b C I n i - t l i u b e h t t i u c r i c - t r o h S

e h t n o n r e t t a p t e s e r e h t g n i t c e n n o c

k c o l b t i u c r i c e h t d n a k c o l b t i u c r i c

r o f s r e z e e w t f o r i a p a g n i s u A r e v o c

. s d n o c e s 2 y l e t a m i x o r p p a

S h

o r t - c

i

r c u

i

t

R e

s e t

p

a

t

t

e

r

n

Cal.5D88A TECHNICAL GUIDE

ILLUSTRATION AND SPECIAL INSTRUCTIONS ETC.

7

7

6

6

5

5

4

4

rechargeable battery

rechargeable battery

rechargeable battery

for rechargeable

battery and

rechargeable battery

guard by tightening

the rechargeable

battery guard

screws “b” and “f ”

42/51

Fig.69

Fig.69

Fig.68

Fig.70

Fig.70.

Page 43

. O N

.oN

SSECORP

t e s d n a e t a c i r b u L

g n i t a l l i c s o e h t

. l e e h w t h g i e w

. g i F e h t o t r e f e R

e h t t n u o M

g n i t a l l i c s o

t h g i e w

g n i t a l l i c s o e h t x i F

y b t h g i e w

e h t g n i n e t h g i t

t h g i e w g n i t a l l i c s o

w e r c s

r e w o p e h t k c e h C

g n i t a r e n e g

. e c n a m r o f r e p

e h t k c e h C

e h t f o t n e m e v o m

g n i t a l l i c s o