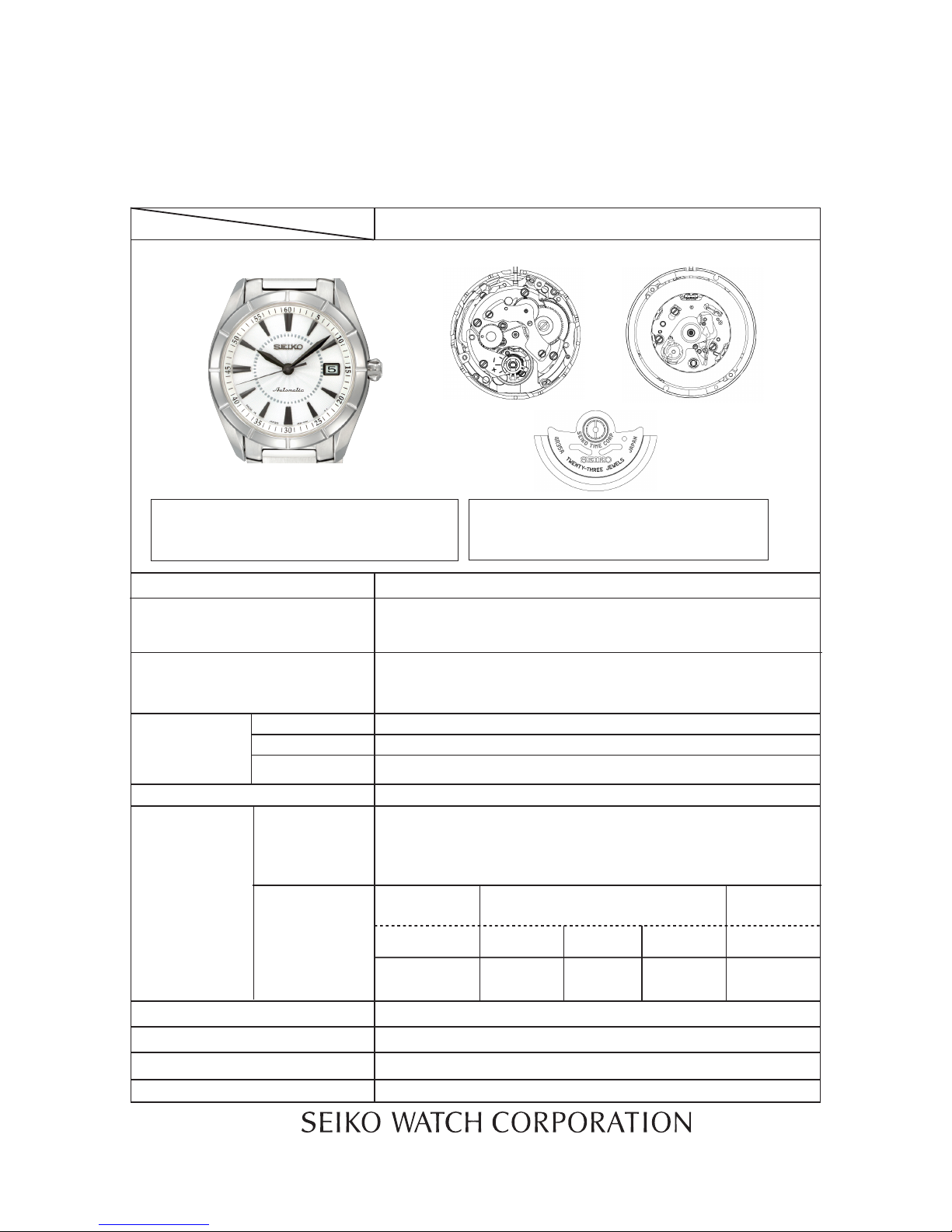

Seiko 4R35A Technical Manual

PARTS LIST / TECHNICAL GUIDE

Automatic Cal. 4

R35A

[SPECIFICATIONS]

1/18

Item

Cal. No.

4R35A

Driving system

Additional function

Crown operation

Loss/Gain

Regulation system

Number of jewels

Normal position

1st click position

2nd click position

Lift angle of the escapment

Vibration per hour

Power reserve

Time indication

•

3 hands (hour, minute and second hands)

• Date indication

• Diameter Outside: Ø 27.4 mm

Casing: Ø 27.0 mm

• Height: 5.25 mm

Movement size

Automatic winding with manual winding mechanism

• 3 hands (Hour, Minute and Small Second hands)

• Date indicator

• Date correction function

• Second hand stop function

Date setting (counterclockwise)

Time setting (Hour and minute)

Manual winding (clockwise only)

21,

600 (6 beats per second)

Between + 45 and - 35 seconds

Mainspring

wind up status

Testing positions

(Isochronism

fault: T24-T0)

± 30 s/d

Measurement

(daily rate in

seconds:s/d)

Dial upward:

T0 (CH)

Daily rate worn

on the wrist at

t e mp er a t ur e range between

5 °C and 35 °C)

St an d a r d r a te

for measurement

6 o’clock

at the top

Dial upward :

T24 (CH)

9 o’clock

at the top

A

fter 24 hours

from fully wind

up

Fully wind up

± 30 s/d

23 jewels

ETACHRON system

F

rom fully wound to stoppage: Approximately 41 hours

52 °

Second hand stop

± 20 s/d

± 30 s/d

SPECIFICATIONS

2/18

Cal. 4R35A

FEATURES

CHARACTERISTICS OF A MECHANICAL WATCH

1. This mechanical watch operates using power obtained from a mainspring.

2. While loss/gain of a quartz watch is indicated by a monthly or annual rate, accuracy of a

mechanical watch is normally indicated by a daily rate (loss/gain per day).

3. Normal usage accuracy of a mechanical watch varies according to conditions of use (time

period that the watch is worn on the wrist, temperature environment, hand movement, and

winding state of the mainspring).

4. When the watch is affected by strong magnetism, it temporarily gains or loses time. If the

watch encounters a strong magnetic field, the parts of the watch may be magnetized. In this

case, repairs such as removal of magnetism are required.

SEIKO Automatic mechanical Cal. 4R35A is developed based on Cal. 7S series and Cal. 6R series design

with two specifications as follows :

1. M

anual winding function.

2. Second hand stop function for time setting (2nd click position of the crown)

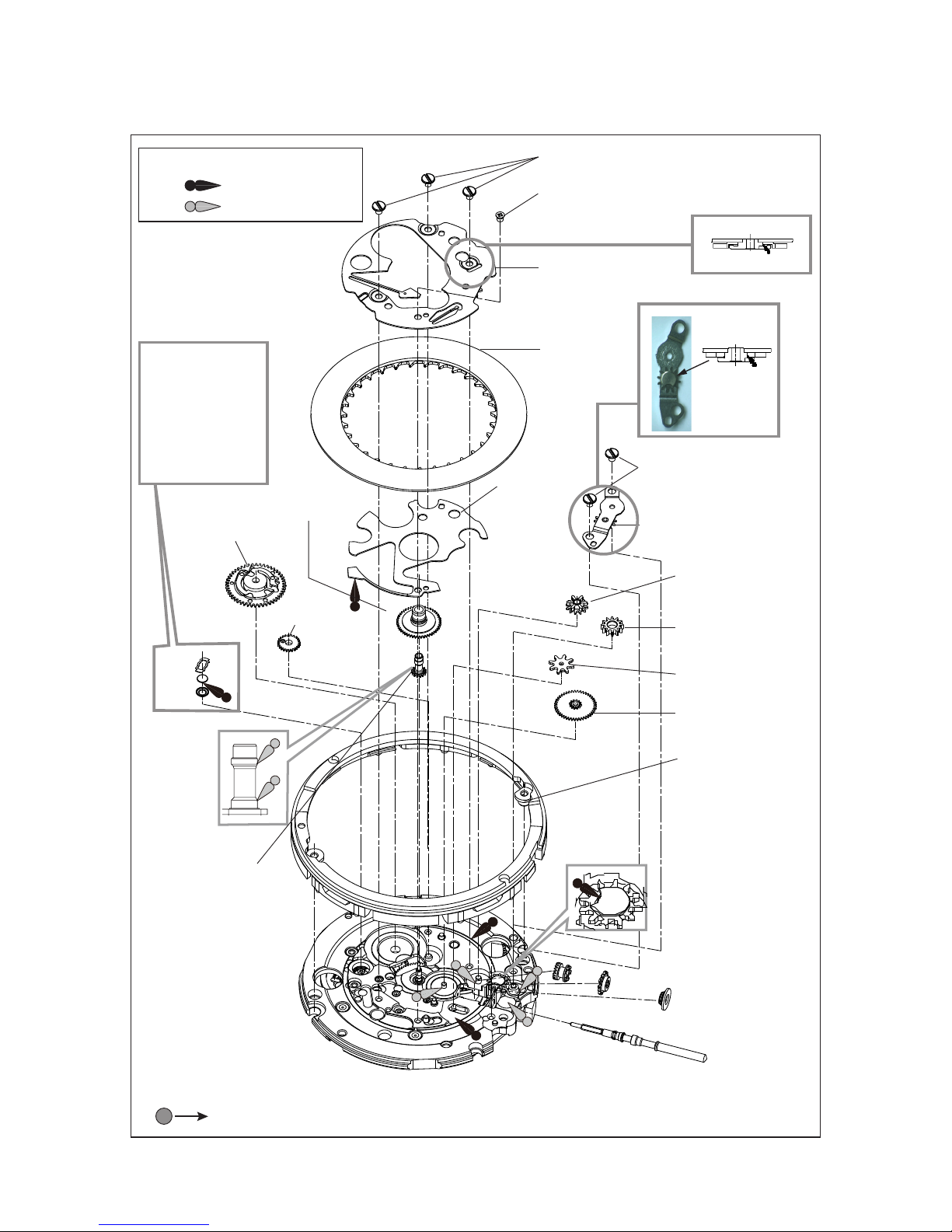

PARTS LIST

Cal. 4R35A

3/18

Please refer to the following pages.

2 DATE DISK GUARD SCREW A (3pcs.)

0012 354

4 DATE DISK GUARD

0808 060

3 DATE DISK GUARD SCREW B

0016 705

5 DATE DISK

6

DATE JUMPER

0810 030

7 GUARD SCREW OF

INTERMEDIATE WHEEL FOR

DATE SETTING

0012 354

8 GUARD OF INTERMEDIATE

WHEEL FOR DATE SETTING

0836 010

9 INTERMEDIATE WHEEL

FOR DATE SETTING E

0962 025

q; INTERMEDIATE WHEEL

FOR

DATE SETTING C

0962 024

qa DATE SETTING WHEEL

0737

300

qg MINUTE WHEEL

0261 006

qj CLUTCH WHEEL

0282 040

qk WINDING PINION

0283 020

ql CALENDAR

CORRECTOR

1ST

INTERMEDIATE

WHEEL 0962 164

qh

DIAL HOLDING SPACER

4408 ***

qsHOUR

WHEEL

0271 483

qd DA

TE DRIVING WHEEL

0802 300

qf

INTERMDIATE

WHEEL FOR

DATE DRIVING

0817 300

CANNON PINION

0225 005

(Disassemble after

CENTERWHEEL)

td

qj

qk

ql

Lubricating: Types of oil

AO-3 (Moevius A)

SEIKO Watch Oil S-6

S-6

S-6

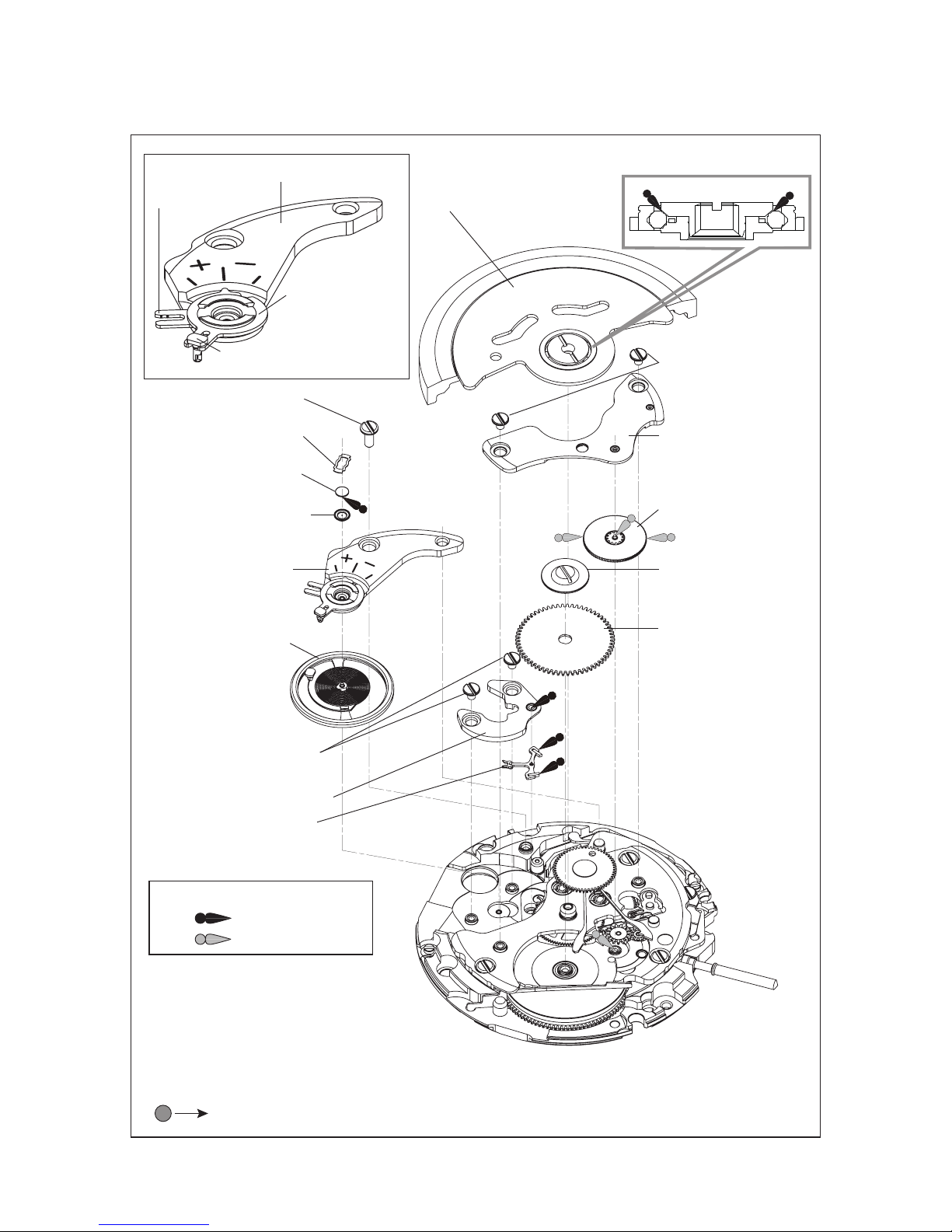

Cal. 4R35A

PARTS LIST

4/18

Please refer to the following pages.

1 OSCILLATING WEIGHT 0509***

wf-4 STUD SUPPORT

0345021

wf-1 BALANCE COCK 0171116

wf-2

REGULATOR

0341020

wf-3 REGULATOR PIN 0033364

wj PALLET BRIDGE 0161300

wk PALLET FORK 0301009

wl AUTOMATIC TRAIN

BRIDGE SCREW (2 PCS.)

0012354

e; AUTOMATIC TRAIN

BRIDGE 0191032

ea 2ND REDUCTION WHEEL

0514010

es RACHET WHEEL SCREW

0012919

ed RACHET WHEEL

0285051

wf

BALANCE COCK WITH

REGULATOR

0171353

wd BALANCE COCK SCREW

0012420

wa

SHOCK ABSORBING CAP

JEWEL

0011220

ws

HOLE JEWEL FRAME FOR

SHOCK ABSORBER 0014295

wg

BALANCE COMPLETE

0310046

wh

PALLET BRIDGE SCREW

0012354

w;

SHOCK ABSORBING SPRING

0014577

Lubricating: Types of oil

AO-3 (Moevius A)

SEIKO Watch Oil S-6

PARTS LIST

Cal. 4R35A

5/18

Please refer to the following pages.

ef BARREL AND TRAIN WHEEL BRIDGE SCREW (3PCS)

0012420

r; LOWER BRIDGE FOR CROWN

WHEEL AND REDUCTION WHEEL

0436164

ej 1ST

REDUCTION

WHEEL

0511010

eh BARREL AND TRAIN

WHEEL BRIDGE 0014348

el LOWER BRIDGE FOR CROWN WHEEL

AND REDUCTION WHEEL SCREW

0012354

eg SLIDING CROWN WHEEL SPRING 0363156

ra 1ST

REDUCTION

WHEEL HOLDER

0836020

ek PAWL LEVER

0831077

rj THIRD

WHEEL 0231070

rk CLICK

0381004

rl BARREL COMPLETE 0201267

rs HOLD

SPRING FOR ESCAPE WHEEL

0015703

rd CAP JEWEL FOR ESCAPE WHEEL

0011221

rf HOLD SPRING FOR THIRD WHEEL

0015703

rg CENTER WHEEL BRIDGE SCREW

0012354

rh CENTER

WHEEL BRIDGE

0122302

rs

rd

rf

rg

Lubricating: Types of oil

AO-3 (Moevius A)

SEIKO Watch Oil S-6

Cal. 4R35A

PARTS LIST

6/18

Please refer to the following pages.

t; CENTER WHEEL BRIDGE SCREW

0012354

tf

CENTER WHEEL

(Disassemble after CANNON PINION)

ta

CENTER WHEEL BRIDGE

0122302

ts

ESCAPE WHEEL

0251300

tg SETTING LEVER JUMPER SCREW

(2PCS.) 0012168

tj YOKE 0384061

tk SETTING LEVER 0383060

tl STOP LEVER 0601010

th SETTING LEVER JUMPER

0388177

yf MAIN PLATE 0100493

y; CLUTCH WHEEL 0282040

ya WINDING PINION 0283020

ys CALENDAR CORRECTOR 1ST

INTERMEDIATE WHEEL

0962164

yd WINDING STEM 0351***

Lubricating: Types of oil

AO-3 (Moevius A)

SEIKO Watch Oil S-6

Loading...

Loading...