1st Printing UK Version

TWIN TYPE

DEITH

025;>

LEISURE

SPARES

Before using

carefully to

After reading this manual, be sure

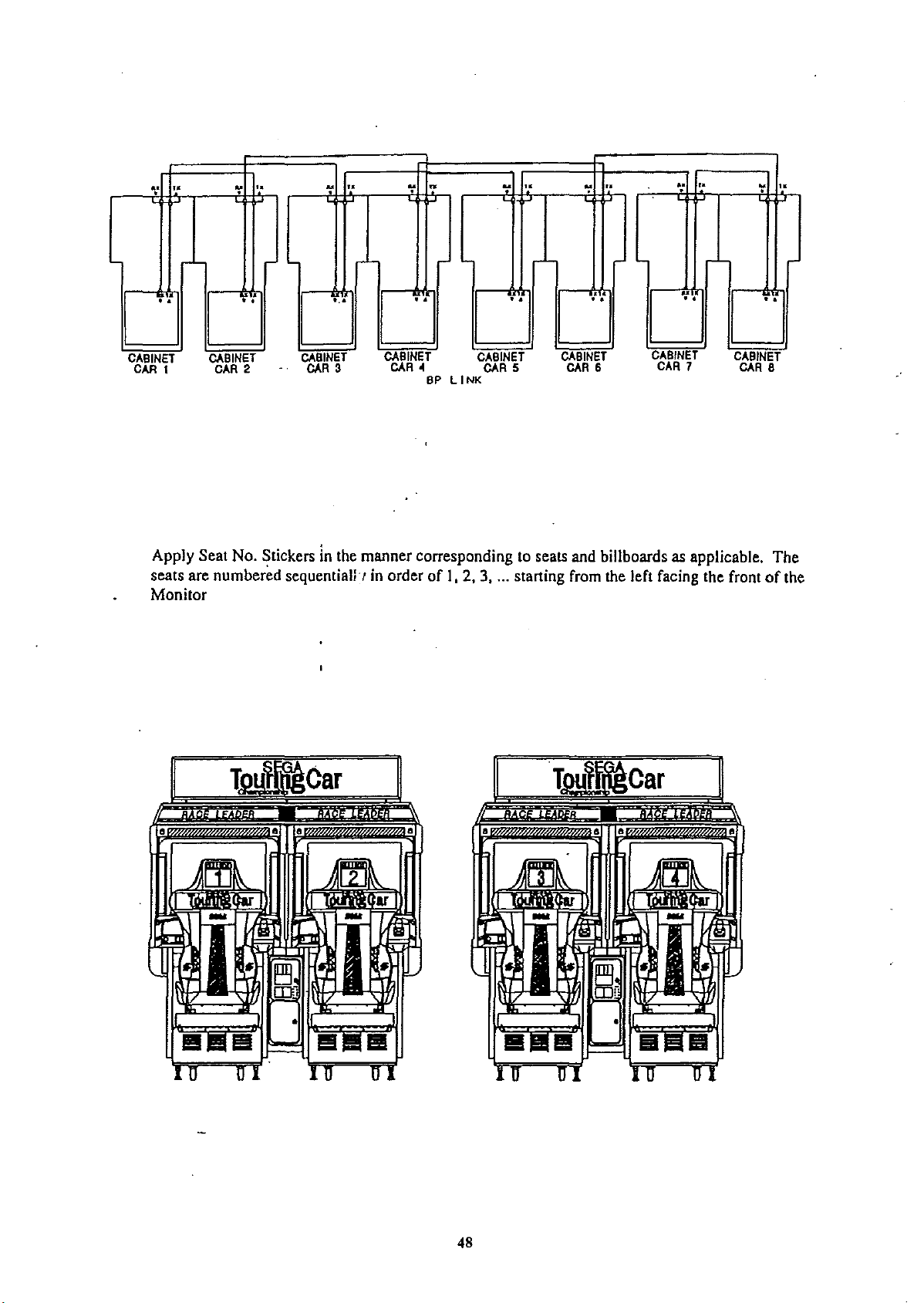

product or somewhere convenient in order to be able to refer to

Built In the UK

by

this

understand the contents stated herein.

Eo)

IMroRTANr!

product, read

it

whenever necessary.

this

to

k6GIl

"UEM8EROFmESCUGRooP

OWNERS

it available nearby the

MANUAL

420·6229-02UK

BEFORE

To ensure the safe usage of the product, be sure to read the following before using the

product. The following instructions are intended for the use of

only. After carefully reading and sufficently understanding the instructions, handle the

machine in an appropriate manner. Only qualified personnel should install or carry out

maintenance on the product.

Terms such as WARNING!, CAUTION I and IMPORTANT! are used where an explanation

is given which requires special attention, depending on the potential risk. SEGA is not

responsible, for any injury or damage caused by use in a manner contrary to the

instructions stated in this document. In order to prevent accidents, warning stickers and

printed instructions.are applied in the places where a potentially hazardous situation

relating to the product cuold arise. Be sure to comply with these warnings.

USING

THE

PRODUCT,BE

SURETOREAD

qualified

THE

FOLLOWING

service

personnel

WARNING!

Indicates that mishandling the product by

disregarding this warning will cause a

potentially hazardous situation which can

result in death or serious injury.

Indicates that mishandling the product by

disregarding this caution will cause a

potentially hazardous situation which can

result in personal injury and or material

damage.

CAUTION'

IMPORTANT!

This is cautionary information which should be complied with when handling the product.

Indicates that mishandling the product by disregarding this will cause a potentially

hazardous situation which Whilst it may not result in personal injury could damage the

equipment.

Be

suretoturn

the

machine.

Ensure

that

the

off

power

correct

and

disconnect

fuseisfitted

to the

from

the

machine.

mains

supply

before

working

on

Details of the correct fusing of the machine are enclosed in the Installation/Service Manual.

that

only

Ensure

Machine.

Specification

designated

conformity.

The parts of the product also include any Warning Labels or Safety Covers for personal

protection etc. A potential hazard will be created if the machine is operated

have been removed. Should any doors, lids or protective covers be damaged or lost, do

qualified Service Engineers

Changes (removal of

by SEGA are

not

permitted

equipment,

A

and

perform

conversion

will

invalidate

any

maintenance

and

this

addition)

products

workonthe

not

CE

While

any parts

not operate the product. SEGA is not liable in any way whatsoever for any injury and or

damage caused by Specification Changes (using other

designated by SEGA.

firms parts, or by conversion) not

Ensure

Before instailing the product, check for Electrical Specifications. SEGA products have a

nameplate on which Electrical Specifications are detailed. Ensure that the product Is

compatible with the power supply voltage and frequency requirements of the location in

which the machine is installed.

Install

allowing

To ensure maximum safety for both customers and operators, labels and printed

instructions describing potential hazardous situations are appiied to places where

accidents could occur. Ensure that where the product Is operated has sufficent lighting

allowing any warnings to be read. If any label is peeled off, replace it immediately.

When

Some of the Monitor (TV) parts are subject to high tension voltage. Even after turning off

the power some parts are still occasionally subject to high tension voltage. Monitor repair

and replacement should be performed by

In cases where commercially available monitors and printers are used only the contents

reiating to this product are stated in this manual. Some commerclaily available equipment

has functions and reactions not stated in this manual. Read this manual in conjunction with

the specific Instruction Manual of such equipment.

that

the

and

Operate the

warning

handling

productIsof

labelstobe clearly read.

the

Monitor,

appropriate

Product

in places

be very careful.

Electrical

where

(Applies

qualified

Specification.

appropriate

onlytothe

service

engineers only.

lighting

product

is available,

w/monitor).

• Descriptions herein contained may be subject to change without prior notification.

• The contents described herein are fully prepared with due care. however. should any questions

arise or errors be found. please contact SEGA.

INSPECTIONS

Normally, at the time of shipment, SEGA products are in a state allowing usage

immediately after transporting to the location. Nevertheless, an Irregular situation may

arise during transportation preventing this. Before turning on the power, check the

following points to ensure that the product has been transported safely.

• Are there any dented parts or defects (cuts, etc) on the external surfaces of the cabinet?

• Are Castors and Leg Adjusters present and undamaged.

• Do the power supply voltage and frequency requirements meet with the local supply.

• Are all wiring connectors correctly and securely connected? Unless connected in the correct

direction, connector connections can not be made successfully. Do not insert connectors

forcibly.

• Are

• Do power cords have any cuts or dents?

• Do the fuses used meet specified rating? Is the Fuse working correctly?

• Are such units as Monitors, Control equipment, IC BD, etc. firmly secured? Are all Earth

• Are all accessories available?

• Can all doors and lids be opened with the accessory Keys? Can doors and lids be closed firm?

alllC's

connected.

IMMEDIATELY

of each IC BD firmly inserted?

AFTER

TRANSPORTING

THE

PRODUCTTOTHE

LOCATION.

Wires

\

B

CONCERNING THE STICKER DISPLAY

CONCERNING WARNING

DISPLA 1 u

SEGA product has Stickers describing the product

manufacture No. (Serial No.) and Electrical

Specifications.

to contact for repair and for purchasing parts.

inquiring about or asking for repair, mention

When

the Serial No. and Name of Machine indicated on the

Sticker.

Identical machines could have different parts

depending on the date of production.

improvements and modifications might have

made after the publication of this Manual. In order to

meet the above situations, mention the Serial No.

when contacting the applicable places.

The

Also it has a Sticker describing where

Serial No. indicates the product register.

MSD,

been

SEGA

Labels

to or incorporated in the places where a potentially

hazardous situation can arise. The warning displays

are intended for accident prevention for the

customers and for avoiding hazardous situation

relating

are some portions in the Cabinet, which are subject to

high

caused only by touching. When

servicing

displays.

replacement work

performed by those technical personnel who have

knowledge of

For the

whose act runs counter to the warnings, as

effect thai he must stop the act.

product has warning displaysOnStickers,

and or printed instructions adhered / attached

to maintenance

tension voltage, etc. where accidents can be

work,

be very careful of the warning .

Especially, any complex repair and

electricity and technical expertise.

prevention of accidents, caution any customer

and

servicingwork. There

performing the

not mentioned herein, should be

to the

AWARNlNG

~

\Ii

t¥~

~"""'>Mcl-

l_erJt,...-~

""""'-

44

__

O-lISOOO2XEG

SPECIFICATION

~

ELECTRICAL

DISPLAY

~I

I¥~I>W\""",,"

~

.......

...-.

T......

e«"......~

-.

440-WSOOO2XEG

During

g.&me

play,

be sure to take

• firm gnp of 1M

St..nngWh

440-CSOO11XEG

..

1.

NlNG

°rm

c

Installation Space:

SPECIFICATIONS

I640mm (64.6in) x 1700mm

(66.9in)

Height:

Weight:

Power, Max:

1920mm (75.6in)

480 kg

Rated Voltage:

Rated Current:

Rated Power

210

-

-4.0

4.6

970W

240

V.A.C

A

NOTE: Descriptions in this manual are subject to change without prior notice.

INTRODUCTION TO THIS OWNERS MANUAL

SEGA ENTERPRISES LTD., supported by its high electronic technologyofLSI's,

microprocessors, etc. and with a wealth

supplying various innovative and popular games to the world market. This Owners Manual is

intended to provide detailed descriptions together with all the necessary information covering

the general operation

parts, etc. as regards SEGA TOURING CAR TWIN, a new SEGA product. This manual is

intended for those who have a knowledge

IC's, CRT's, microprocessors, etc. Carefully read this manual to aquire sufficient knowledge

before working on the machine. Should there be a malfunction, non-technical personnel

should under no circumstances touch the interior systems. Should such a situation

immediately contact the nearest branch listed below or our head office.

of

electronic assemblies, electromechanicals, servicing control, spare

of

experience, has for more than 30 years been

of

electricity and technical expertise especially in

arise

. I

SEGA AMUSEMENTS EUROPE LIMITED / SEGA SERVICE CENTRE

Unit 2, Industrial Estate, Leigh Close, New Malden, Surrey, KT3 3NL, England

Telephone: +44(0)

Fax: +44(0)

SEGASPAIN

C/ PLAYA DE LIENCRES, 2-EDIFICIO 3 LONDRES,

EUROPA EMPRESARIAL CTRA, NATIONAL IV KM.24, 28230 LAS ROZAS (MADRID)

Telephone: +34(1) 6315000

Fax: +34(1) 6400689

181

336 2256

1813361715

D

CONTENTS

BEFORE USING THIS PRODUCT A

STICKER DISPLAY C

INTRODUCTION TO THIS OWNERS MANUAL D

I. HANDLING AND INSTALLATION PRECAUTIONS I

2. ACCESSORIES 2

3. NAME OF PARTS 3

4. ASSEMBLING THE CABINET 4

ASSEMBLING THE COCKPIT 4

SECURING IN PLACE 6

INSTALLING THE BILLBOARD 8

INSTALLIIiO THE AC COVERS 9

POWER SUPPLY 10

TURNING ON THE POWER 10

ASSEMBLY CHECK II

5. PRECAUTIONS WHEN MOVING THE MACHINE 13

6. THE GAME 14

7. EXPLANATION OF TEST AND DATA DISPLAY 16

VTS BRACKET 17

TEST MODE 19

MEMORY TEST 19

T.G.P. TEST 19

INPUT TEST 20

OUTPUT TEST 20

SOUND TEST 2I

C.R.T. TEST 21

GAME ASSIGNMENTS 22

COIN ASSIGNMENTS 22

BOOKKEEPING 26

BACKUP DATA CLEAR 27

8. MAINTENANCE 28

HANDLE MECHA MAINTENANCE 29

ACCELERATOR

& BRAKE UNIT MAINTENANCE 32

SHIFT LEVER MAINTENANCE 34

CHANGING THE VOLTAGE ON THE TRANSFORMER 35

FUSES 36

REPLACING THE FLOURESCENT LAMP AND LAMPS 37

PERIODIC INSPECTION TABLE 38

TROUBLESHOOTING 39

GAME BOARD

& DRIVE CONTROL BOARD 41

9. COMMUNICATION PLAY 45

10. PARTS LISTS 50

TOP ASSEMBLY STC-00002/3UK 50

BILLBOARD ASSEMBLY STC-0200UK 53

BILLBOARD UPPER ASSEMBLY STC·0210UK 54

BILLBOARD LOWER ASSEMBLY STC·0220UK 55

LAMP UNIT ASSEMBLY STC-0230UK 56

FLOURESCENT ASSEMBLY STC·0240UK 57

COINCHUTE TOWER ASSEMBLY DYN·0300UK 58

VTS ASSEMBLY DYN·0350UK 59

WIRE COVER ASSEMBLY DYN·0500UK 60

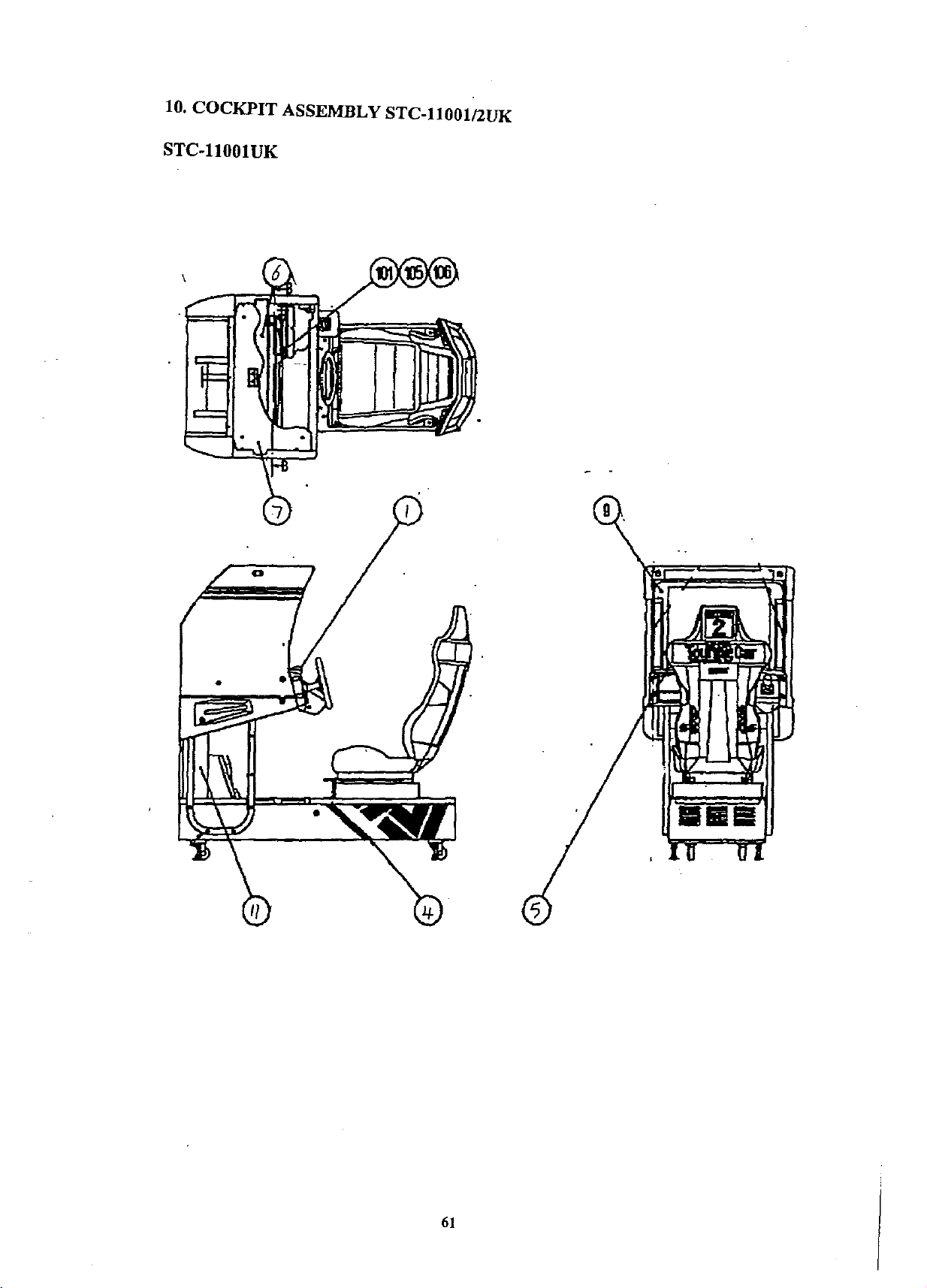

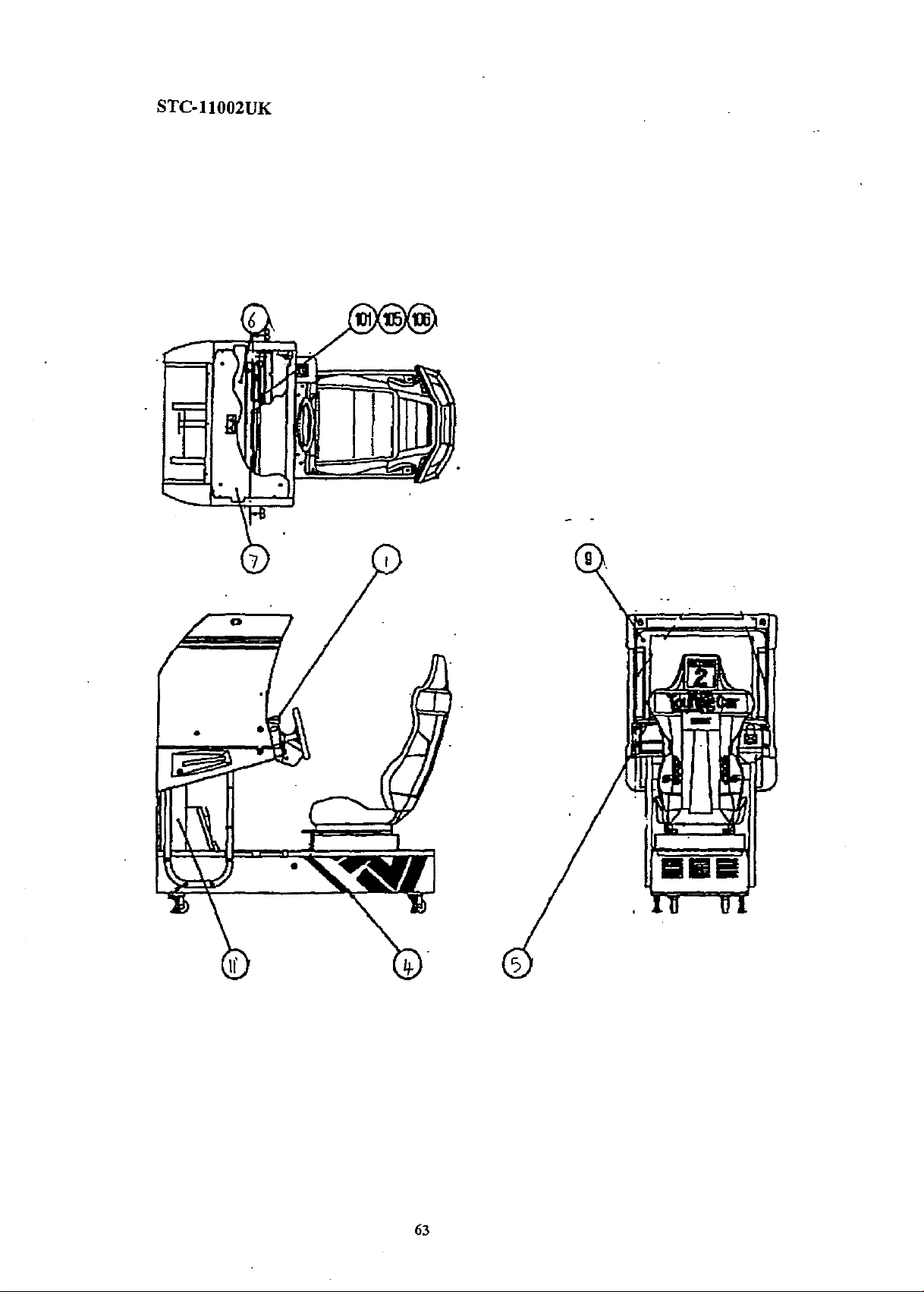

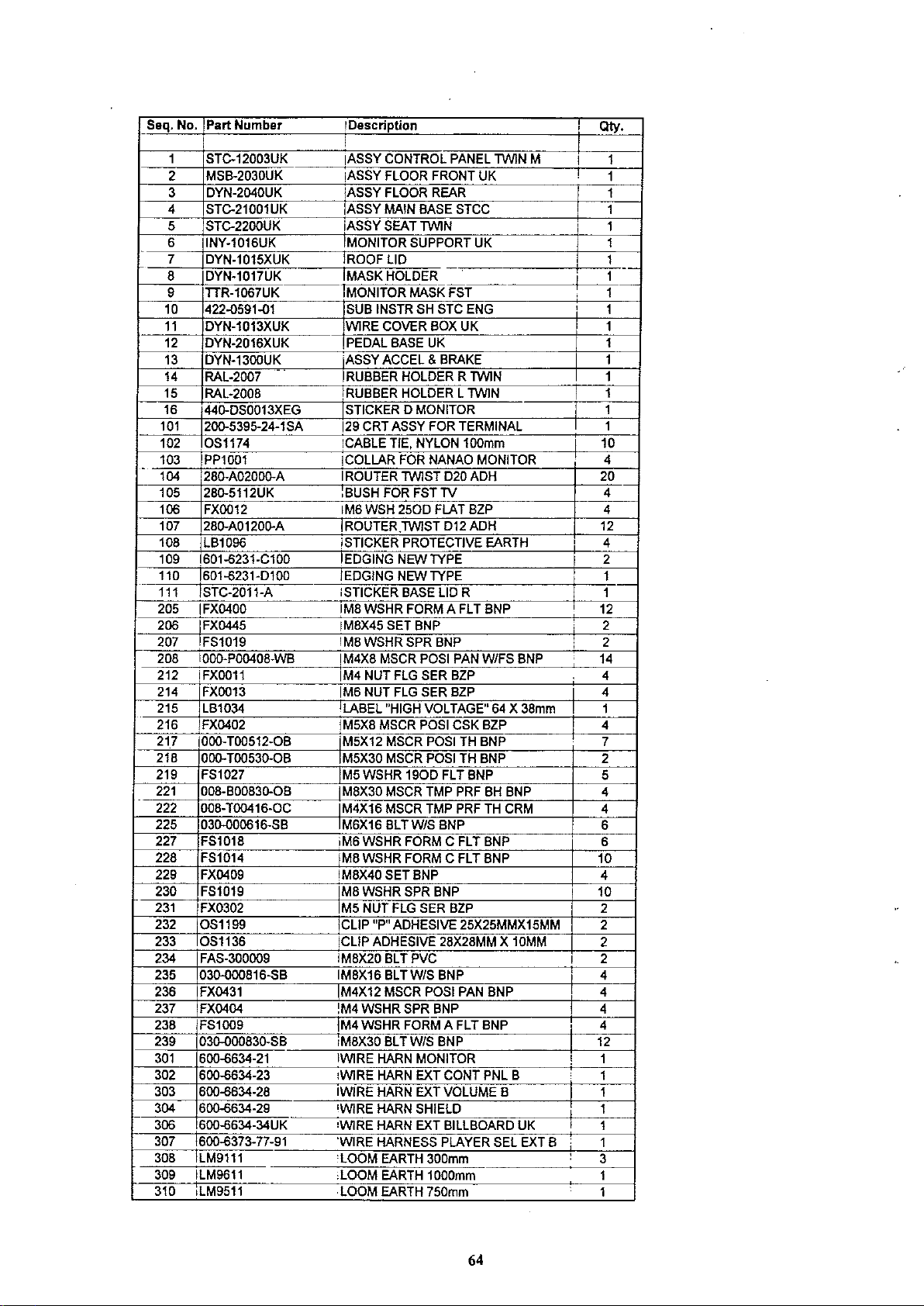

COCKPIT ASSEMBLY STC·IIOOIl2UK 61

CONTROL PANEL ASSEMBLY STC-12003UK 65

CONTROL PANEL COVER STC-1202-02 67

VIRTUAL BUTTON ASSEMBLY INY-1250 68

MONITOR HANDING KIT STC-7000UK 69

HANDING KIT STC·6000UK 70

MAIN BASE ASSEMBLY STC-2100IUK 72

BRAKE

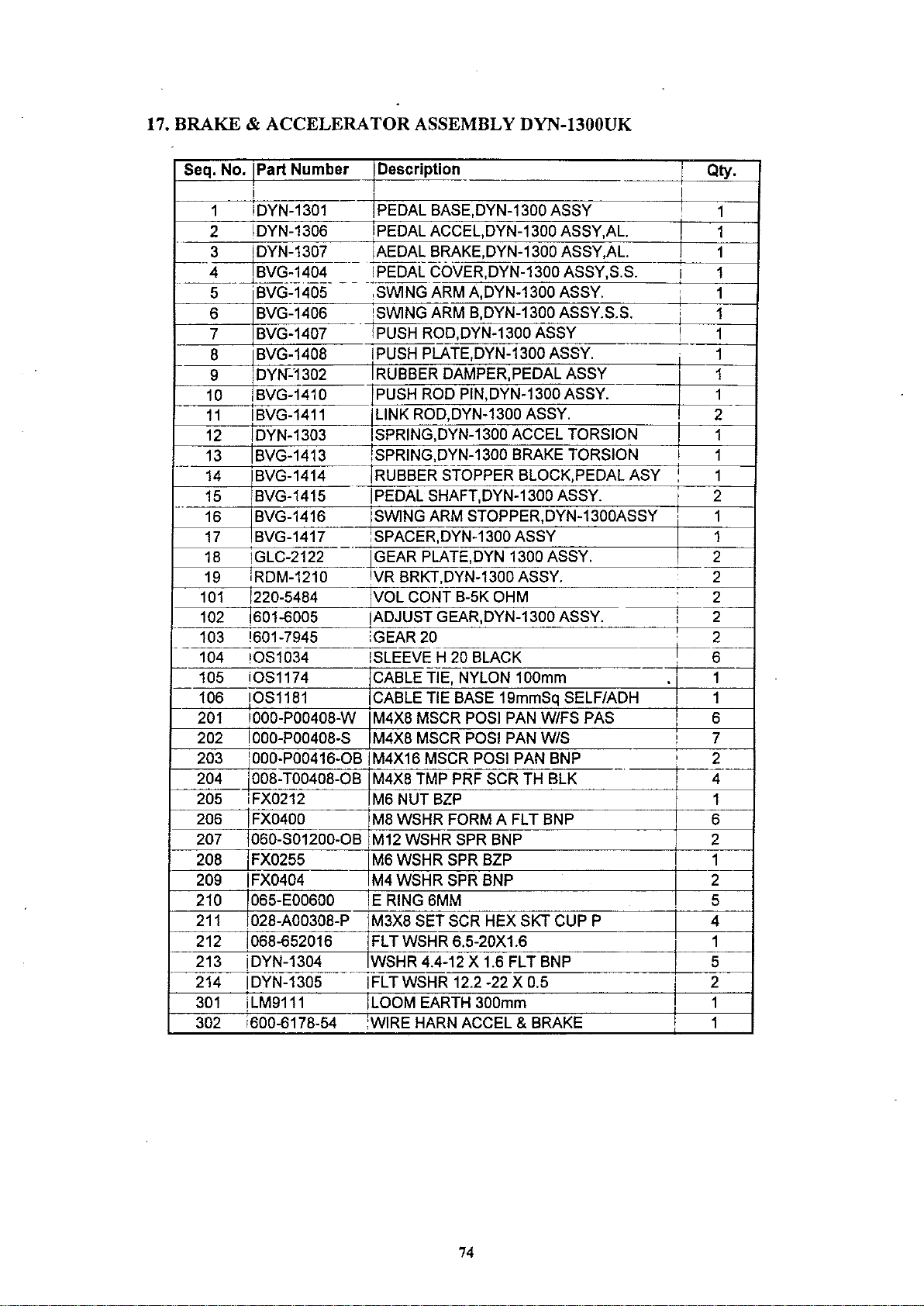

& ACCELERATOR UN[T ASSEMBLY DYN-1300UK 74

FLOOR REAR ASSEMBLY DYN·2040UK 76

FLOOR FRONT ASSEMBLY MSB-2030UK 77

SEAT ASSEMBLY STC-2200UK 78

SEAT REAR COVER IP STC-1605 80

SEAT REAR COVER 2P STC-2202 81

WOOFER ASSEMBLY STC-1650 82

MAIN BOARD ASSEMBLY STC·4400 83

ELEC ASSEMBLY STC-4500UK 85

DRIVE CONTROL BOARD INY·4600 87

INSTALLATIONKIT STC·INST-KIT 88

II.

WIRE COLOUilCODE TABLE 89

12. SCHEMATICS 91

13. COIN MECH INSTALLATION AND CREDIT BOARD SETUP 93

14. DETAILS OF SANWA MONITOR [03

15. DETAILS OF NANAO MONITOR 126

1. HANDLING AND INSTALLATION PRECAUTIONS

When installing or inspecting the machine, be very carefulofthe following points and

pay attention to ensure that the player can enjoy the game safely.

This Game is designed for indoor use only. The game must

outdoors or under the following conditions:

I. In areas directly exposed to sunlight, high humidity, dust, excessive heat or

extreme cold.

2. In locations that would present an obstacle in the case

fire equipment or emergency exits.

3. On an unstable surface or subject to vibrations.

IMPORTANT.

This machine should only be installed by Qualified Service Personnel.

Ensure that the line voltage matches that

information see the section in this manual dealing with maintenance. Please note the

voltage that the machine has been set to during manufacture. This machine has been

set to 230V.

Be sure to switch the power

before replacing any user servicable parts.

Do

NOT

attempt to repair the PCB (printed Circuit Board) yourselfas this will void

the warranty. The PCB contains static sensitive components that could be damaged.

Always return a faulty PCB to your distributor with adequate packaging and

protection.

When removing the plug from a mains outlet always grasp the plug and not the cable.

Do not use a fuse that does not meet a specified rating.

Make sure all connections are secure before restoring power.

OFF

and remove the mains plug from the wall socket

of

the transformer input tapping for more

NOT

be installed

of

an emergency i.e. near

Ensure

there

Ensure

supply

that

is a

danger

that

without

the mains lead is not exposed.Ifthe

of an electric shockora

short

mains lead becomes exposed

circuit

the power supply is fitted with circuit protection. Using

circuit protection is a fire hazard.

1

the

power

2. ACCESSORIES

When Transporting the machine ensure that the following parts are supplied;

Part

Seq.

No.

1

2

3

4

5

6

7

8

9 RAL-XXXX-14UK

10

101 600-6275-0500

201 030-o00825-SB

202 FS1031

203

204

205 FX0400 M8 WSHR FORM A FLT BNP 12

206

207

208 FX0258 M8 WSHR

209 421-9141 STICKER CAR No

210 509-5704

401 DLMEMC17 CERT OF CONFORMANCE STCC 1

402 420-6229-02UK OWNERS MANUAL STCC

403 540-0006-01 WRENCH M4 TMP PRF 1

404 540-0007-01 WRENCH M5 TMP PRF

405 540-0009-01

406

407

409

Number

STC-0200UK

DYN-0300UK

DYN-0500UK

DYN-0013UK

DYN-0014UK

DYN-0006XUK

DYN-0018UK

DYN-0019UK

PK0087

030-000820-8 M8X20 BLT W/S PAS 4

000-P00408-WB M4X8 MSCR POSI PAN W/FS BNP 15

FX0011 M4 NUT FLG SER BZP 3

FS1031 M8 WSHR

220-5484 VOL CONT B-5K OHM

390-5167 LAMP 110V

OS1019

Description

ASSY BILLBOARD STCC UK

ASSY COIN CHUTE TOWER UK

ASSY WIRE COVER UK

JOINT PIPE

BILLBOARD HOLDER DAYTONA

ACCOVER

AC COVER C

'AC

COVER D

TIE BRACKET RALLY

CARTON INST KIT STCC

CABLE FIBER OPTIC 5mm x 500cm

M8X25 BLT W/S BNP

M8 WSHR

SW

MICRO TYPE (OMRON K3L 13) 1

WRENCH M8 TMP PRF

SELF SEAL BAG

B

l'MN

250D

FLT BNP

250D

FLT BNP 4

220D

FLT BZP 4

2-8

l'MN

30W

9X12.3/4

Qty.

1

1

1

1

2

1

1

1

1

1

2

16

4

1

1

1

1

1

2

1

(TAMPERPROOF

M5

S4O-OO11.{)1

M8

S4(}.OO()9.{)l.·

WRENCH)

~

TAMPERPROOF

WRENCH

2

3. NAME OF PARTS

29

INCH

llONITOR

BILLBOARD

COIN

CHUTE

IP

TOWER

COCKPIT

OVERVIEW

COIITROL

PANEL

2P

COCKPIT

BACK

LID

A

BACK

LID

B

AC

COVER

AC

UNIT

Width Length

COCKPIT (per seat)

COIN CHUTE TOWER

820

305

BILLBOARD 1,600

When assembled

1,632

X

X

X

X

Height

1,645

330

460

1,700

3

X

X

X

X

1,520

570

405

1,920

(mm.)

Weight (kg.)

231. 0

13.5

30.0

513. 0

\

4.

ASSEMBLING

THE

FAILING TO COMPLY

WHEN

ASSEMBLING THIS AMCHINE SOME

TO

COMPLETE

THE CA13INET

ASSEMBLY OF

ASSEMBLY

IN ORDER TO AVOID PERSONAL INJURY OR PARTS DAMAGE, BE SURE

THIS

MACHINE SHOULD ONLY BE CARRIED

WORK

SHOULD BE CARRIED OUT AS PER

WITH

THESE

INSTRUCTIONS MAY CAUSE AN

MALFUNCTION IN

ASSISTANCE BEFORE ATTEMPTING THESE OPERATIONS.

PERSONNEL.

OFTHE

THE

OPERATIONS

MACHINE.

OUT

THiS

ELECTRIC

REQUffiE

BY QUALIFIEDSERVICE

MANUAL.

MORE

SHOCK

HAZARD OR A

THAN ONE PERSON

TOP

SEEK

~

CAUTIONI

When

carrying OUI the assembly work, follow the procedure in the following 7-item

sequence:

ASSEMBLING

SECURINGINPLACE

INSTALLING

INSTALLING

POWER

TURNING

ASSEMBLY

Note that the master key and the cashbox door key (see accessories) in addition to tools such as a Pozi

screwdriver, adjustable wrench and a Ratchet with a 13mm socket are required for the assembly

cabinet.

Perform

the

tighteningofhexagon

adjusting theleg

adjustments

THE

COCKPIT

THE

BILLBOARD

1"HEACCOVERS

SUPPLY,

THE

AND

POWER

CHECK

adjusters

are

made,

keep

(LEG

EARTH

ON

asper

the

ADJUSTER

(WIRING

CONNECTION

bolts

descrlbsd

ill.

Make

hexagon

bolts

ADJUSTMENT)

CONNECTION)

in m

sure

that untilthe legadjuster

above

tightened

after

temporarily.

of

this

OJ

<D

ASSEMBLING

Place the two cockpits side by side.

Position the IP cockpit which has the

THE

COCKPIT

lEe Socket at the bottom left hand side,

as viewed from the Monitor side.

Sticker

Sticker

"L"

is placed on the IP cockpit and

"R"

on the backofthe 2P cockpit.

STICKER

4

"L"

IP

COCKPIT

\1

!

1

(

® Install the coin chute tower in between

both cabinets. Open the coin chute door

and the cashbox door to secure with the 4

hexagon bolts from inside the doors. At

this time.

fastened temporarily

make sure that the bolts are

COIN

HEXAGON

M8X20

BOLT

0llJI'E

(4)

® Install the joint pipe on to the backside of

both cabinets by securing with 4 hexagon

bolts (at this time.

temporarily) 0

DOOR

FUT

COIN

lASHER

0llJI'E

TOIlER

8.5-22x 1.6 (4)

5

rn

SECURING IN PLACE (LEG ADJUSTER ADJUSTMENT)

Lt

WARNINGI

<D

® Attach the joint plate fdr the 2

ENSURE THAT ALL OF THE ADJUSTABLE

WITH

THE

FLOOR,IFTHIS IS NOT ACCOMPLISHED

MAY MOVE AND CAUSE INJURY.

BE SURE TO SEEK ASSISTANCE WHEN PERFORMING THE

OPERATIONS INVOLVED IN ASSEMBLING THIS CABINET.

This

machine

installation position is determined,

floor

directly,

approximately

Move the machine to the

installation position. When

installing the machine against or

close to a wall,

passage space to enable the

to take a ride in the machine.

internal leg adjusters shown. First,

cause the other 6 leg adjusters to

come into contact with the floor.

Make leg adjuster adjustments with

a wrench in a manner

machine's position is level

has

eight

casters

make

adjustments in a

5mm.

besure to secure a

from

the

player:

to ensure the

and

eight

cause

manner

floor and

leg adjusters (Fig. 6.2a).

the

make

FEET

leg adjusters to

so that

sure

the

casters will be raised

that the

LEGADlISTER

Attach the

joint plate

ARE IN CONTACT

THE

CABINET

come

machine

When

into

the

contact

position is level.

with the

® Aftermaking adjustments, fasten

the leg adjuster nut upward and

secure the height of the leg adjuster

(Fig.6.2b).

LEG

ADJUSTER

FASTEN

UPlARD.

CASTER

FIG.

6.

~.

BOTTOM

__

~~~l...~~2~==~Approx.

VIEW

5m

6

® Insert the notch portions

plate to the 2 leg adjuster boll

portions.

of

the joint

® Lower the leg adjuster and fasten

the nut upward. Secure the joint

plate with

of

the leg adjuster

the nuts and the bottoms

Secure the joint

by fasteninll the nuts

and the bot teas of lell

adjusters.

plate

After

securing

fastened

the

heightofthe

temporarilyasper

Jom

PLATE

adjusters,

II]

a~ve.

JOI!'ITPLATE

tighten

allofthe

•

hexagon

.

bolts

which

were

•

Refer10thisFig.

forthe

layout

installalion.

of

(Scale:I/IOO)

the

place

of

Provide

allow

liIalion

7

sufficienl

forventllatlon by

f.n.

spaceso as10

the

ven-

IT!

INSTALLING THE BILLBOARD

&

CAlmON!

ONEPERSON ALONE CANNOT PERFORM

BILLBOARD ASSEMBLY. SEEK ASSISTANCE BEFORE

TInS

When the BillboardPlate istransported it isattachedtotheBillboard case;firsttake out the Upper

Billboard Holder

Plate, ensure that the Cabinethas beensecured in placebeforehand.

I.

Take out the 3 truss head screws,openthe BillboardUpperand remove the 2 Lamp Lids.

2. Mount the Billboard

fasteningthe Bolts, beeareful ofthe lamp position.

the lamps inposition, temporarily remove the lamps,be sure to replace themonce complete.

3. Connect a total

4. Connect the earth wire to the stud on the top of the Roof Lidin the IP cockpit.

5. Fit the two BillboardHolders to the back of the Billboard case using the 4 Hexagon Bolts

supplied.

to removethe Billboard Plate from the BillboardCase. When installingthe Billboard

oW

the2 cokpits andsecure in place with the 4 HexagonBolts. When

on

connectors whichare inside the BillboardCase

OPERATION.

Ifit

THE

INSTALLATION OF THE

ATfEMPTING

difficult to carryoutthis operationwith

TRUSS

IUX8

S01Ef

UJIP

3

LID

BIl.UIOAR!l's

connector

ASSBMOUNO

8

rna

B/lJ..OOARD

~

WARNING!

The AC wire cover is used for protecting the wiring and fibre optic cables. When carrying out this

operation be very careful so as not to trap any wire between the covers. Pay attention when handling

fibre optic cables as excessive bending may cause damage.

I.

2. Make all the wiring connections between both cabinets and the coin chute tower. Insert the supplied

3.

Esure

tower.

4. Insert the Fibre Optic Cables into the Fibre Optic connectors. There are 2 connectors

ulX".

5. Secure the wiring and Fibre Optic Cables in

6. Insert AC COVER B in AC COVER A from above and secure with 2 screws, be sure

any

7. SecureAC COVER C and AC COVER D with 4 screws each.

INSTALLING THE AC COVERS (WIRING CONNECTION)

THE

ASSEMBLY OF

THE

WIRE COVER SHOULD BE CARRIED OUT BY

QUALIFIED SERVICE PERSONNEL ONLY. .

BE SURE THAT THEMACHINE IS

SUPPLY BEFORE A

Attach AC COVER A to the backofthe cabinet (see diagram below) using 5ofthe screws

provided.

wiring connectors to the cerresponding ones which are the samecolour and have the same number

of

pins,

that the correct earth connections are made between the 2 AC Brackets and the coin chute

Ensure that the

other.

"IT'

connectorofone cockpit is connected to the "RX" connectorofthe

TIEMPTING

.,' .

j,ta'i:e

wiring.

NOT

using the

CONNECTED

TO

THIS OPERATION.

..

'P'

Cliops fitted in the Wire Cover.

.'

"RX"

not

THEMAINS

and

to trap

AC

AC

AC

roYER

lXl't'EK

0lYER

A

....

=

0

8

-.0_

...

:

9

[[]

POWER

SUPPLV. AND

e.(RTH

CONNECTION

THIS

OPERATIONSHOULD BE

CARRIED our ONLY

THE

MACHINE

COMPLETELYASSEMBLED

&

WARNING!

TheACUnitIs

ofthe IP

Lead

mains

Li] TURNINGTHE

Turning the AC Units Mains SW. on willcause the machine to start the POWER ON check and

NETWORK check automatically.

With the POWER ON check, the steering wheel turns left and right, then returns to the centring

position and stops. In this check, the values

check is finished, (the steering wheel stops automatically, do not touch the steering wheel or play the

game).

If

the steering wheel is touched at this stage then the reaction during the game (reaction at the time

course-out or crashing) cannot be obtained correctly.

In the case

POWER ON check again.

During network checking,

CHECKING is finished, the DEMO mode will appear on the screen. After 10 seconds,

check is not complete, check the connections for communication.

of

an abnormal reaction during the game, tum the power

AFTER.

HAS

BEEN

Iocatcd

coctpIt

supp1lcd

socketl!t~

POWER

COlI"""1

"NETWORK

Using

...

ON

on the

the Power

this 10 the

a11.

back

POWERLEAD--"'fill

ofV.R.

CHECKING" flashes on the screen. When NETWORK

inside the control panel are corrected. Until the

off

and on again to complete the

if

the network

!lAINSI

o

ofa

o

The 'leering

wheel

tum, lerl/righliulomilicilly.

NETWORK CHECKING

THIS IS MASTER SITE.

10

i

NETWORK CHECKING

THIS IS SLAVE SITE.'

l

f

o

I

; ,/

V

I

/

[l] ASSEMBLY CHECK

In

the

TEST MODE,

satisfactory

In

the

(I)

(refertoSection

test

mode,

MEMORY

ensure

perform

TEST

that

9).

the

following

the

assembly

test:

has

been

made

correctly

and

Ie

BD. is

IC

Ie

IC

le._

le_.

IC_.

IC

IC._

••

__

••

••

PRESS

v I

START

COIN

COIN

SERVICE

TEST

GOOD

GOOD

GOOD

GOOD

GOOD

GOOD

GOOD

GOOD

TEST

INPUT

STEERING

GAS

PEDAL

BRA_K

E P E

SHifT

SHifT

V I

EWt

EW2

CHUTE

CHUTE

MEMORV

fe._

le._

I c

••

le._

le._

le*_

le._

le._

BUTTON

(2) INPUT

TE'ST

WHEEL

CAL

UP

DOWN

(ZOOM

(ZOOM

I H)

Dun

TEST

GOOD

GOOD

GOOD

GOOD

GOaD

aoOO

GOOD

GOOD

#,

#2

TO

TEST

....

....

....

OfF

OFF

OFF

OfF

OFF

OFF

OFF

OFF

OFF

H

H

H

le._

IC_.

Ie

le-.

IC

IC

EXIT

GOOD

GOOD

Selecting the

mode

menu screen

MEMORY

causes

TEST

on the test

the on-board memory

to be tested automatically. The game board is

••

GOOD

GOOD

••

GoeD

••

GOOD

satisfactory if the display beside eachIeNo.

shows

GOOD.

Selectingthe INPUT TEST on thetest mode

menu scren causes

the screen (on whicheach

switch and V.R. are tested) to be displayed.

Press each switch. For

the coinswitch test,

inserta coin in the coin inlet withthe coin

door open. Press the Credit transferbutton

and COIN CHUTE

# 1will indicateon.

Check the display ofV.R. value forthe

steering wheel and acceleratror

& brake.

PRESS

>

SELECT

AND

TEST

(3)

OUTPUT

START

V I

v I

LEA.DER

CENTERING

EXIT

EWI

EWZ

WITH

PRESS

LA""'P

(ZOOM

(ZOOM

SUTTON

OUTPUTTEST

TEST

I H)

LAMP

OUT)'

LAMP

LEVEL

SERVICE

TEST

BUTTON

TO

LAMP

BUTTON

(XIT

OFF

OFF

OFF

OFF

LEVEL-l

In

the

output test mode, carry out lamp test to

ensure

that each lamp lights up satisfactorily.

It

(4) SOUND TEST

SOUND

BG~C

SE:

>

EXIT

SoHiOh

c .

••

TEST

hOO

In the

TEST

mode, selecting SOUND TEST

causes the screen (on which sound related BD and

wiring connections are tested) to

be displayed.

Be sure to check if the sound is satisfactorily

emitted from each speaker and the sound volume is

appropriate.

SELECT

AND

PRESS

WITH

PUSH

SERViCE

TEST

BUrrON

(5) C.R.T. TEST

C. A.T. TEST

1/2

HITE

TEST

BUTTON

C. A.T. TEST

TO

2/2

BUTTON

CONTINUE

,

In the TEST mode menu; selecting C.R.T. TEST

allows the screen (on which the monitor is tested)

be displayed. Although the monitor adjustments

to

of

have been made at the time

shipmen! from the

factory. make judgment as to whether an

adjustment is needed by watching the test mode

screen. If it is necessary, adjust the monitor by

referring to Section 14. Use the

DEMAGNETIZER SW for the color deviation

caused by the monitor's magnetization

PRESS TEST

BUTTON

TO

EXIT

Perform the above inspections also at the time of monthly inspections.

12

5. PRECAUTIONS WHEN MOVING THE MACHINE

• When moving tha machine, be sure to pull out the plug from the power

it

WARNING!

supply. Moving the machine with the plug as is inserted can cause the

power cord to be damaged, resulting in a fire and or electric shock.

• When moving the machine on the floor, retract the Leg Adjusters and

ensure that Casters make contact with the floor. During transportation,

pay careful attention so that Casters do not tread power cords and

earth wires. Damaging the power cords can cause an electric shock

and or short circuit.

• When moving the machine, do not push the cabinet from the lefVright

direction. Pushing the cabinet from the letVrightdirection can cause

the cabinet to fall down, resulting in injury and or parts damage.

Do not push the

cabinet from the

left/right direction.

13

6. THE GAME

The

following

the game function any differentlyfrom the following contents, then a fault has occurred. Immediately

lookintothe cause

problemis not covered in this manual then contact the nearest agent or distributor.The Fluorescent

lamp is

displayedon thescreen and the sound is emitted from thespeakers incorporated inthe seat (Note I).

always

explanationsapply only in cases where the machine is functioning satisfactorily.Should

of

the problem and,ifexplainedin this manual, eliminatethe problem. If the

lit whenthe machine is energised. DuringADVERTISE, ADVERTISE mode is

HOWTO

PLAY

<D

Enter

the machine and be seated. The seat position is adjustable forward and backward.

Lever is located on the lower right-hand side facing the screen. Use the Lever 10adjust the seat

position.

@ Insert a coin(s). Inserting

the screen.

one

play worthofcoins allows the selection mode to be displayed on

® Choose one from among the 4 different kinds

desired

(manual) or AT (automatic). To choose MT, either step on the gas pedal while stepping on the

Brake Pedal, or press the Start button .. To choose AT, step on the Gas Pedal.

Start

Button

car

to the center of the screen. By stepping on the pedal, choose either 6-shift

of

cars.

Tum

Steering llheel

The

the Steering Wheel to bring the

MT

ShiIt Lever

View

Change

I

(Red)

2 (Blue :

@ Choosing AT or MT makes the

(§)

of

Button

:

~

IN

~

oor

screen, countdown begins. When the countdown becomes O.QUALIFY (a preliminary race)

starts automatically.

which is located in the center

automatically.

When

the type of car and transmission are determined, the QUALIFY race begins.

the

QUALIFY race determines the starting gridofthe first race.

Brake

Pedal

car

selection effective, When the select mode is shown on the

If

no action is taken until the countdown showsO.the

of

the screen will be used with

cel. Pedal

car

being selected

AT

transmission being selected

® Until several seconds after the QUALIFY race has started, other participants' entry is

acceptable.

The

first race begins after the QUALIFY race by all players has been finished.

The

results

14

(j)

The

No.ofRound

(lap frequency)

& Lap

Time is displayed on

the upper left side of

UPTIME

Lap

Frequency

Roundill

UP

TUE

r!lco'Jnx)3

1%1

(I)'

)( x

Rearview

Mirror

the screen, Time Left

in the center, the

Position

of

your

player on the upper

right-hand side, and

the Gear Position,

Tachometer

& Speed

Meter on the lower

right-hand side

respectively.

®

The

View Change button allows for a 3-step view change. Except in the case of REARVIEW

Gamemode

screen

perspective, the rearview mirror is displayed in the upper center portion.

® Simultaneously with the race.start, the remaining time (Time Left) decreases. Finishing one

Round (lap) before the Time Left becomes 0 allows the game to be continued with the

remaining time added to the next Round (lap) Time Left (Note 2). If you fail to finish the

Round within the Time Left, the game isover.

In the QUALIFY race, the gamewill not be over even after the time limit. In this case,

however, the player will

® Finishing the race's number of specified laps in each course allows you to proceed to the next

course with the present position and the remaining time being carried over. There are 3 race

courses. Play on the courses sequentially in order

@

If

you win the first position in the comprehensive results of the 3 courses, you can

course called EXTRA course. Finishing the final course with the best total time allows the

player name to be registered (Note 3).

Somesettings detailed

Note

1

No sound output during ADVERTISE can

Note 2

Note

Specified number of Round (laps) can be chosen from among I, 2 , 3 and 20 (for event). When

20 laps are selected, choose the desired course in the

Lever and make the selection effective by using the Gas Pedal or Start button, In the interactive

(communication) versus play, the course is determined by majority. In case

of

which the difficulty level is lower will be selected. As lIjecar runs more and more laps, the

tire will wear out and the grip strength will be lowered but

in to the pit.

3

The

player name registration can be set before the actual race.

above each player's car.

start the first race from the lowest position.

of

the first - second - Final (course).

above,

and

fully

detailed in Notes1;3

be

set.

below,

car

select mode by operating the Shift

can be altered (Seesection7).

of

a tie, the course

can be recovered by bringing the car

The

registered name is displayed

Course

Gear

Position

T.cOOO'lCICr

Speed

MOler

playa

bonus

Record

FEATURES

The

First

The

Second

The

Final

Course:

Course:

Course:

OF

EACH

COURSE

The road is wide and this makes it easy to drive and therefore, how to skillfully

tum the curves is important.

Inparticular, this course allows you to concentrate on

battling with the opponents.

The imageofthis course is based on the mountainous areas in Europe. The course

is rich in natural varieties and has steep as well as gentle curves.

This course is modelled after races on urban streets. Since the road is narrow, an

accurate speed control is needed.

15

7. EXPLANATION OF TEST AND DATA DISPLAY

By operationg the switches on the VTS Bracket, periodically perform the tests and data checks listed

below. When installing the machine initially Orcollecting cash, or when the machine is not

functioning correctly, perform the checks in accordance with the explanations given in this section.

The

following shows tests and modes that should be used.

ITEMS

INSTALLATION

OF

MACHINE

MEMORY

PERIODIC

SERVICING

CONTROL

SYSTEM

DESCRIPTION

When the machine is installed, perform the following:

I. Check to see that each setting is as per standard, the standard settings are

made at the time

2. In the INPUT TEST mode, check the input devices i.e, buttons, joysticks,

pedals or steering wheels.

3. In the

4. In the SELF TEST mode, check the

Choose

TEST

on the IC board are checked.

Periodically perform the following:

I. MEMORY TEST

2.

3. In the INPUT

4.

I. In the

2. Adjust or replace all switches or

3.Ifthe problem cannot be solved yet, check the

OUTPUT

lamps etc.

MEMORY

to be performed. In this test, PROGRAM

Check

each setting.

In the

OUTPUT

lamps.

INPUT

joysticks

of

shipment.

TEST mode, check the output devices i.e, monitors,

IC's

on the IC board.

TEST in the

TEST

mode, test the CONTROL device.

TEST

TEST mode, check the input devices i.e. buttons and

MENU

mode, check the output devices i.e. monitors

mode to allow the

VR's.

RAM's,

CONTROL's

ROM's

MEMORY

and

moves.

IC's

and

MONITOR

ICBOARD

DATA

CHECK

In the MONITOR (pROJECTOR)

Monitor adjustments are set correctly.

I.

MEMORY

2. In the SOUND TEST mode, check the sound related

Check such data as game play time

level etc.

TEST

ADWSTMENT

and

histogram to adjust the difficulty

mode, check to see that

16

ROM's.

1. VTS

BRACKET

WARNING!

DO NOT TOUCH PLACES OTHER THAN THOSE SPECIFIED.

TOUCHIJIIGPLACES NOT SPECIFIED COULD CAUSE AN ELECTRIC

SHOCK OR SHORT CIRCUIT.

TEST BUTTON

KLINGON BOARD

COUNTER

Openthe CoinChuteDoor,andthe VTSBracketshownabovewillappear.

TESTBUTION

0 0

0

0

0

0

0

o

o

The function of eachswitchis as

UsedduringTest

Mode.

Referto the following pages fordetails.

l---l----

o

follows;

SERVICE

DEMAG BUTTON

VOLUME CONTROL

BUTTON

SERVICE

DEMAG

SOUND VOLUME

BUTION

SWITCH

Givescredits withoutregistering on the coinmeter.Alsousedduring

TestMode. Referto the following pagesfor details.

Eliminates colourunevenness

: Adjuststhe

volume

of allspeakers on the

17

from

theMonitorscreen.

machine.

The control panel switches are also used in the test

following pageand

onward.

mode.

For each functioning, refer to the

Start Button

View

Change

(Red):ZOOU

1

2 (Blue):

Button

ZOOU

IN

OUT

CREDIT TRANSFER

Brake

Pedal

BUITON

,",.

Steering iheel

AcceI.Peda

Shi

fl

Lever

o

I

18

2. TEST MODE

The

Test

Mode

checked.

and

also coin

allows the functioning of

and

game

assignments to be performed.

each

partofthe cabinet

and

screen adjustments to be .

€3

IMPORTANT!

>

When

the Test

orderto

setting

Mode

make

by turnlnqthe

changes

TEST

MEMORY

T. G.

INPUT

OUTPUT

SOUND

C.R.T.

GAME

COiN

BOOKKEEPING

BACKUP

EXIT

Ineffective.

MENU

TEST

P.

TEST

TEST

If;ST

TEST

TEST

ASSIGNMENTS

ASSIGNMENTS

DATA

changes

after

the

the

setting

power

CLEAR

are

made

in the Test

selling changes and

changes

OFF/ON

effective.

afterchanging the setting makesthe

• Press

following

monitor.

• Press

CHANGE

is

selection.

• Bring the pointer ">" to

press

BUTTONtoenter

•

After

and

BUTTON

the

the

moved

either

the

press

Mode,

return

be sureto

to the

Returning

.

TEST

BUTTON

Test

Menu

SERVICE

BUTTON

to the desired

the

TEST

the selected item's test.

test is

complete.

the

TEST

to return to the

first

exit

normal

to the

mode

normal

mode

setting

to cause the

to be displayed on the

BUTTONorVIEW

(VR)

until the pointer ">"

item

to make a

the

desired item and

BUTTONorSTART

move

">" to "EXIT"

BUTTONorSTART

Game

Mode.

from

in

PRESS

•

TEST

MEMORY

BUTTON TO

TEST

4. T.G.P. TEST

T.G.

P.

r es r

le*_

le._

GOOD

GOOD

EXIT

The

MEMORY

on-BD

"GOOD"

displayed for abnormal ICs.

• When the test is completed, if the results are

•

• After fmishing the test, pressing the TEST

In this test, T. G. P. (screen display related

check

as

TEST

Menu

memory

shown as GOOD, it is satisfactory.

If

the TEST is not completed, theIeboard may

have malfunctioned.

BUTTON or START BUTTON to return

to MENU mode.

is automatically performed.Ifthe display is

shown

left. it is satisfactory. Press either the

buttonorSTART

mode.

TEST

is displayed for normal ICs and "BAD" is

mode

is for checking the

IC functioning.

button to return to the

Ie's)

PRESS

T.G.P.

TEST

TEST

BUTTON

TO

EXIT

19

5. INPUT TEST

INPUT

STEERING

GAS

PEDAL

BRAKE

SHIFT

SHIFT

V I

V I

START

COIN

COIN

SERVICE

TEST

PRESS

INPlIT'IEST

EW1(Z

EW2

CHUTe

CHUTe

TEST

PEDAL

UP

DOWN

OOM

(ZOOM

THE APPROPRIATE

STEERING

TEST

WHEEL

IN)

OUT)

BUTTON

_,

_2

**H

**H

Off

OFF

0 F F

Of

OFF

OFF

OFf

OfF

OFF

VALUES

WHEEL::

**H

F

TO

EXIT

OF

EACH

Under

FULL LEFT

V.A.

2DH

Selecting

shown

status

INPUT

to the left

and

game

TEST

causes

and

allows

play

relatedV.R. values 10 be

the

each

checked.

On

this screen,

each

switch& V.R.

periodically

check

the

• By pressing each switch, if the display on

of

the right hand side

the nameofeach

switch changes to ON from OFF, the SW

. and the

wirin~

co;meclions are satisfactory.

• To check CHUTE I coin switches, open

the COIN CHUTE DOOR, insert a coin in

, the door and press the credit transfer

button.

To return to tJiel\.IE"NDmode,press the

•

.

TEST Button or simultaneously press the

START Button

& VIEW CHANGE Button

I & VIEW CHANGE Button 2.

.-

7D~83H

CENTRE

-+

Over

D3H

FULL RIGHT

screen

switch

status

of

GAS

PEDAL:

BRAKE

PEDAL:

6. OUTPUT TEST

This

test

allows

Periodically

OUTPUT

>

START

V I

v I

LEADER

CENTERING

EXIT

SELECT

AND

OlTTPtrr'IEST

EWI

EW2

WITH

PRESS

LAMP

(ZOOM

(ZOOM

LAMP

the

check

TEST

I N)

OUT)

LEVEL

SERVICE

TEST

Under

Under

30H

30H

(the pedal released)

statusofeach

in this

mode.

LAMP

LAMP

BUTTON

8UTTON

lamp

OFF

OFF

OFF

OFF

LEVEL-I

Over

Over

(the pedal stepped)

and

Steering

® Bring the arrow to CENTERING J EV"E-C

Wheel's

Choose

Test

appear

<D

Press eitherofthe SERVICE or

centering

OUTPUT

0fI

the

strength

TEST10have

screen

VIEW CHANGE buttons to move

.'hr,

.•'ToWto the..

® Press

"either

If

the display on the right hand side

9.e~.i!.ed

test item.

TEST or START buttons. -

the lamp name changes to ON from OFF

and the selected lamp lights up, the lamp

anti wiring connections

are_s.a.tisf~.ctorv

and press either TESTor START. If the

display changes to LEVEL I

and the steering wheels centering

strength is gradually increased, the

centering mechanism is satisfactory.

Note that in this test mode the strength

cannot be set.

COH

COH

to be

the

- LEVEL 8

checked.

Output

of

• Choose EXIT and PRESS the TEST button

or START button to return to the TEST MENU.

20

7. SOUND TEST

BGM:

Sf:

>

EXIT

SELECT

AND

WITH

PUSH

SOUNDTEST

8. C.R.T. TEST

C. R. T. TEST

PRESS

TEST

SOUND

soHigh

CrashOD

SERViCE

TEST

BUTTON

TEST

1/2

TO

CONTINUE

BUTTON

BUTTON

Selecting SOUND

(sound effects,

TEST

allows the desired sound

BGM,

etc.) to be chesen and heard.

. In this test, sound related IC Boards and the Speakers

. incorporated into the seat are checked. Press the

; SERVICE button or

; to the desired sound test item. Pressing the

button allows the selected type

Each time the

SHIFT

TEST

button to bring the arrow

of

sound to be emilled.

button is pressed, the next sound

TEST

is emitted.

eB.G.M.

eSE

e EXIT

Background music during game.

Sound effects during game.

Causes the menu mode to return on

the screen.

Choose C.R.T.

Adjustment check screen appear. By watching the

scren, periodically check if adjustments are

required. For the Adjustment Method, refer .

to the Monitor sections. In the screen as

left, check the Monitor colour adjustments. By

watching this screen, make colour adjustments.

of

Each

white is darkest at the left

bec~mes

TEST

to have the Monitor

per·

the R (red), G (green) and B (blue) and

of

the screen and

brighter towards the right.

to

C.R.T.

C. R.T. TEST

PRESS TEST

C.R.T.

TEST

BUTTON

TEST

2/2

TO

EXIT

Press the

TEST

button to have the following

Crosshatch screen appear.

In the screen as

and position adjustments. Check size and position

adjustments by watching this screen.

Adjust the monitor to make sure that the

crosshatch lines do not appear to go beyond

the screen size and crosshatch distortion

does not occur.

per

left, check monitor size

Press the TEST button to have the menu return to

the screen.

21

9. GAME ASSIGNMENTS

>

•

ADVERTISE

SelectGAME

frequency, game

describedas

GAME

ADVERTiSE

URL

ADDRESS

COUNTRY

CABINET

LINK

DIFFICULTY

GAME

DEFAULT

NAME

EXIT

SELECT

GAME ASSIGNMENTS

TYPE

MODE

ENTRY

AND

ASSIGNMENTS

difficulty

follows:

ASSIGNMENTS

SOUND

TYPE

CAR

WITH

PUSH

TEST

SOUND

level,

xxxx>::

xxxx>::

xxxxx

xxxx>::

xxxxx

xxxxx

xxxx>::

xxxxx

xxxxx

SERVICE

BUTTON

BUTTON

Settingofsound

OFF:

No

sound

to havethe following screen

etc. to be performed. Each

ISETIING

CD

Press the SERVICE button or VIEW

CHANGE button to bring the arrow

to the desired change item.

@ Press the TEST button or the START

button to select the setting change item.

@ Move the arrow to EXIT and press the

TEST button or the START button to

return the menu mode to the screen.

to beemitted

ON:

during

Sound

Advertise

emitted.

appear.

item

CHANGE

This allows settings of lap

displays thecontents

PROCEDURE

mode.

I

(»

•

URL

ADDRESS

•

COUNTRY

•

CABINET

•

LINK

•

DIFFICULTY

•

GAME

•

DEFAULT

•

NAME

TYPE

TYPE

MODE

CAR

ENTRY

Setsthe Intemet

OFF:

Allows

Not

forlanguage setting.

Home

displayed

Pagedisplay

ON:

Displayed

during

ADVERTISE

..

Setto applicable cabinet type.

If

thisproduct is individually

(right)

toCAR2. Forcommunication

machines

thatno

toCAR I andset therest of cart to CAR2- g in themannerso

number

willbe duplicated.

Thereare4 levels, i.,e.,EASY,

difficulty

level

can bedifferentiated by

used,

set IP side(left) to CAR I and 2P side

play,

besuretoset oneofthe

NORMAL,

HARD,

varying

HARDEST.. The

the race starttimeandthe

additional timewhenpassingthecheckpoint.

Setsthespecified numberof

onelap,

Use

NORMAL

GRAND

to2 laps,

PRIXforevents.

Round

LONG

(laps)

forthe course. SHORTrefersto

to 3 lapsandGRAND

PRIX

to20 laps.

Selectthetypeofcar initially appearing in thecenter of thescreen. If set to

RANDOM,

Setswhether the nameentryisto

Incaseof

with

his

playerisentered

displayed

the

ranking

BEFORE

the

DEFAULT

AFTER

ranking

above

X, thenameof theplayer

being

displayed. Incaseof

before

game. Thenameregistered beforegameis

hiscarduringgameplayand the namewillbe displayed in

ifheaccomplishes best

shows

thenumberofcharacters thatcan be registered (3 or 7

CARwillbeunspecified.

be

performed

beforegameoraftergame.

with

best results willbe entered

BEFORE

results.

Numerals after

X, the

AFTER

name

of each

or

characters).

22

10. COIN ASSIGNMENTS

The

"COIN ASSIGNMENTS" mode permits you to set the start number of credits, as well

as the basic numbers of coins and credits. This mode expresses "how many coins corre-

spond to how many credits."

COiN

ASSIGNMENTS

>

COIH/CftEDIT

COIN

CHUTE

COIN

CHUTE

SETTING

_,

.Z

•••

•

•

COINS.

COINS.

CREDITS

CREDITS

MANUAL

EXIT

SETTING

SELECT

AND

90IN

BElTING

<D

CHANGE

PROC~DURE

Press the SERVICE button or VIEW CHANGE button to bring the arrow

desired change item.

@ Press the

®

Move

TEST

button or the START button to select the selling change item.

the arrow to EXIT and press the TEST button or the START button to return the

menu mode to the screen.

• COIN/CREDIT SETTING

WITH

'RESS

SERVICE

TEST BUTTON

BUTTON

ASSIGNMENTS

"Howmany coins correspond

credits."

to how many

(»

to the

• MANUAL SETTING

• NORMAL SETTING

Allows for finer settings.

Normal setting is 1 coin 1 credit

23

\

COIN/CREDIT

SETIING

NAMEOFSETIING

SETI1NG #1 1 COIN 1

SETI1NG #2 1 COIN

SETI1NG #3

SETI1NG #4 I COIN

SETI1NG #5 1 COIN

SETI1NG #6

SETI1NG #7 I COIN 5 CREDITS

SETI1NG #8 I COIN

SETI1NG #9 1 COIN

SETI1NG #10 1 COIN

SETI1NG #11

SETI1NG #12 2 COINS 1

SETI1NG #13 1 COIN

SETI1NG #14 1 COIN

SETI1NG #15

FUNCTIONING OF COIN CHUTE # I FUNCTIONING OF COIN CHUTE #2

CREDIT

2 CREDITS

I COIN J CREDIT

I COIN J CREDIT

1 COIN 3 CREDITS 1 COIN 1 CREDIT

4 CREDITS 1 COIN

5 CREDITS

1 COIN 2 CREDITS

I COIN 1 CREDIT

1 COIN 2 CREDITS

1 COIN 2 CREDITS

3 CREDITS 1 COIN 3 CREDITS

4 CREDITS 1 COIN

5 CREDITS 1 COIN

~

.

I COIN

6 CREDITS

I COIN

CREDIT 2 COINS

I CREDIT 2 COINS

2 CREDITS 2 COINS

1 COIN

1 CREDIT 1

2 COINS 3 CREDITS 2 COINS

SETI1NG #16 1 COIN 3 CREDITS 1 COIN

2 COINS

SETI1NG #17

SETI1NG #18

SETI1NG #19

SETI1NG #20

COINS

3

COINS

4

COIN

1

COINS

2

COINS

3

4 COINS

(WIN

1

CREDIT

1

CREDIT 4 COINS

1

3 COINS

1 CREDIT 1

2 CREDITS 2 COINS

3 CREDITS 3 COINS

5 CREDITS 4 COINS

5 CREDITS

1 COIN

2 COINS

3 COINS

4 COINS

SETI1NG #21

SETI1NG

#22·

COINS

5

1 COIN

CREDIT

1

2 CREDITS

5 COINS

3 COINS

5 COINS

SETI1NG #23

SETI1NG #24

2 COINS

4 COINS

COINS

5

1 COIN

CREDIT

I

2 CREDITS

CREDITS

3

3 CREDIT

2 COINS 1

4 COINS

5 COINS

2 COINS

4 COINS

5 COINS

SETI1NG #25

SETI1NG #26

COIN

I

2 COINS

COINS

3

COINS

4

COINS

5

COIN

I

1 CREDIT

2 CREDITS

CREDITS

3

4 CREDITS

6 CREDITS

6 CREDITS

1

COIN

2 COINS

3 COINS

4 COINS

5 COINS

I COIN

2 COINS

3 COINS

4 COINS

5 COINS

SETTING #27

FREE PLAY

COIN 1

COIN 1

5 CREDITS

2 CREDITS

2 CREDITS

3 CREDITS

1 CREDIT

2 CREDITS

3 CREDITS

1 CREDIT

2 CREDITS

3 CREDITS

4 CREDITS

6 CREDITS

I CREDIT

2 CREDITS

3 CREDITS

4 CREDITS

6 CREDITS

FREE PLAY

1 CREDIT

4 CREDITS

5 CREDITS

6 CREDITS

1

CREDIT

I CREDIT

1

CREDIT

CREDIT

3 CREDITS

1 CREDITS

3 CREDITS

1 CREDIT

I CREDIT

CREDIT

2 CREDITS

3 CREDITS

5 CREDITS

1 CREDIT

2 CREDITS

3 CREDITS

1 CREDIT

1

CREDIT

CREDIT

24

MANUAL SETTING

Selecting MANUAL

COIN

,1,1110101

I.IANUAL

COIMTOCiIIiG/l

.ONUI

ADDUI

COIN

CHUff

_,

Io&tJLTIPLIIA

COIN

CHUff

_I

WUlTI'Lllill

)oil

I'

SILlef

WITH

AND

'AI"

COIN

ASSIGNMENTS

f;) Determines Coin

... 11011$

II("

I HG

I

COINIClllOil

HG

aoltUI

I

COIN

I

COIN

1''''Vlel

Til'

ICredit

SETfING

AOOllII

------1----------

COUNT'A••

COUNT' AI •

'Ul'OM

IUTIOM

setting.

in the Coin Assignment mode displays the following screen.

------.+-----CD

COINI

---1----------------

COINI

'2'

\6J

® This sets how many coins should be inserted to obtain one Service Coin.

@ This sets how many tokens one coin represents.

®

MANUAL

COINTOCREDIT

,

BONUS

COIN

ADDER

CHlfTE

MULTIPLIER

SETIING

1

2

3

4

5

6

7

B

9

NO

2

3

4

5

6

7

B

9

1

1

1

1

1

1

1

1

1

COIN

COIN

COIN

COIN

COIN

COIN

COIN

COIN

COIN

COIN

COINS

COINS

COINS

COINS

COINS

COINS

COINS

COINS

BONUS

COINS

COINS

COINS

COINS

COINS

COINS

COINS

COINS

COUNTSAS1

COUNTSAS2

COUNTSAS3

COUNTSAS4

COUNTSAS5

COUNTSAS6

COUNTSAS7

COUNTSASB

COUNTSAS9

CREDIT

1

1

CREDIT

CREDIT

1

CREDIT

1

1

CREDIT

1

CREDIT

1

CREDIT

1

CREDIT

1

CREDIT

•

.

ADDER

GIVE1EXTRA

GIVE1EXTRA

GIVE1EXTRA

GIVE1EXTRA

GIVE1EXTRA

GIVE1EXTRA

GIVE1EXTRA

GIVE1EXTRA

COIN

COINS

COINS

COINS

COINS

COINS

COINS

COINS

COINS

COIN

COIN

COIN

COIN

COIN

COIN

COIN

COIN

25

11.

BOOKKEEPING

Selecting the BOOKKEEPING in the menu mode displays the bookkeeping data up to the

present.

Pressing the TEST button or the START button returns the test menu on the screen.

BOOKKEEPING

COIN

COIN

TOTAL

COIN

SERVICE

TOTAL

NUMBER

TOTAL

GAME

AVERAGE

LONGEST

SHORTEST

TIME

PLAY

CHUTE

CHUTE

COINS

CREDITS

CREDITS

CREDITS

OF

TIME

GAME

GAME

GAME

.1

.2

GAMES

TIME

TIME

TIME

**

••

****

****

••••

****

.*.*

••••

*O.*H.*M**S

••

H.·M.*S

*.H."'M**S

••

H**M

.*H·*M••S

...

S

OM

OS

2M OS

2M3

0 S

3M OS

3M3

0 S

4M OS

4M30

5M OS

5M3

0 S,

6M OS

OVER

BOOKKEEPING

• COIN

CHUTE#*

• TOTAL COINS

• COIN CREDITS

• SERVICE CREDITS

• TOTAL CREDITS

.TOTAL

TIME

• TIME HISTOGRAM

S

PRESS

TIME

11'.45

9 S

21'.429 S

21'.459 S

3M295

3M59S

<11'.4298

<MHS

SM2:9S

51'.4595

6M29S

6M3

OS

TesT

HISTOGRAM

BUTTON

****

•••

•••

*

****

****

•••

****

*

•••

••••

*

•••

.***

TO

*

*

EXIT

Number of coins put in each chute.

Total number

of

coins inserted in each coin chute.

Number of credits registered by inserting coins

Credits registered by the SERVICE button

Total number

of

credits (COIN CREDITS +SERVICE CREDITS)

The total energized time.

Displays the play frequency as against each play

a standard when setting Game Difficulty. etc.

time. Refer to this as

26

12. BACKUP DATA CLEAR

BACKUP

SELECT

AND

BACKUP

YES

> N 0

WITH

PRESS

DATA

DATA

(CLEAR)

(CANCEL)

SERVICE

TEST

CLEAR

CLEAR

BUTTON

BUTTON

Clears the contentsofBOOKKEEPING.

When clearing, use the SERVICE

BUTION

(CLEAR)" and press the TEST

to bring the arrow (> j.to "YES

BUTION.

When the data has been cleared,

"COMPLETED" will be displayed.

Bring the arrow to "NO (CANCEL)" and

press the TEST

BUTION

to return to the

Menu mode without clearing the data.

Also. note that the game setting contents are

not affected by BACKUP DATA CLEAR

operation.

27

8. MAINTENANCE

ALL MAINTENANCE WORK OF ANY SORT SHOULD BE CARRIED OUT

BY QUALIFIED SERVICE PERSONNEL ONLY.

BE SURE TO SWITCH OFF THE MAINS POWER AND DISCONNECT

MAINS PLUG AT

The general maintenanceofthis machine is detailed in the following section.

If

a problem should arise that is not covered in this Service Manual then contact your

nearest SEGA agent,

do not attempt to resolve the problem yourself.

The following procedures are detailed in this section.

I. HANDLE MECHA MAINTENACE .

2. ACCELERATOR

3. SHIFT LEVER MAINTENANCE

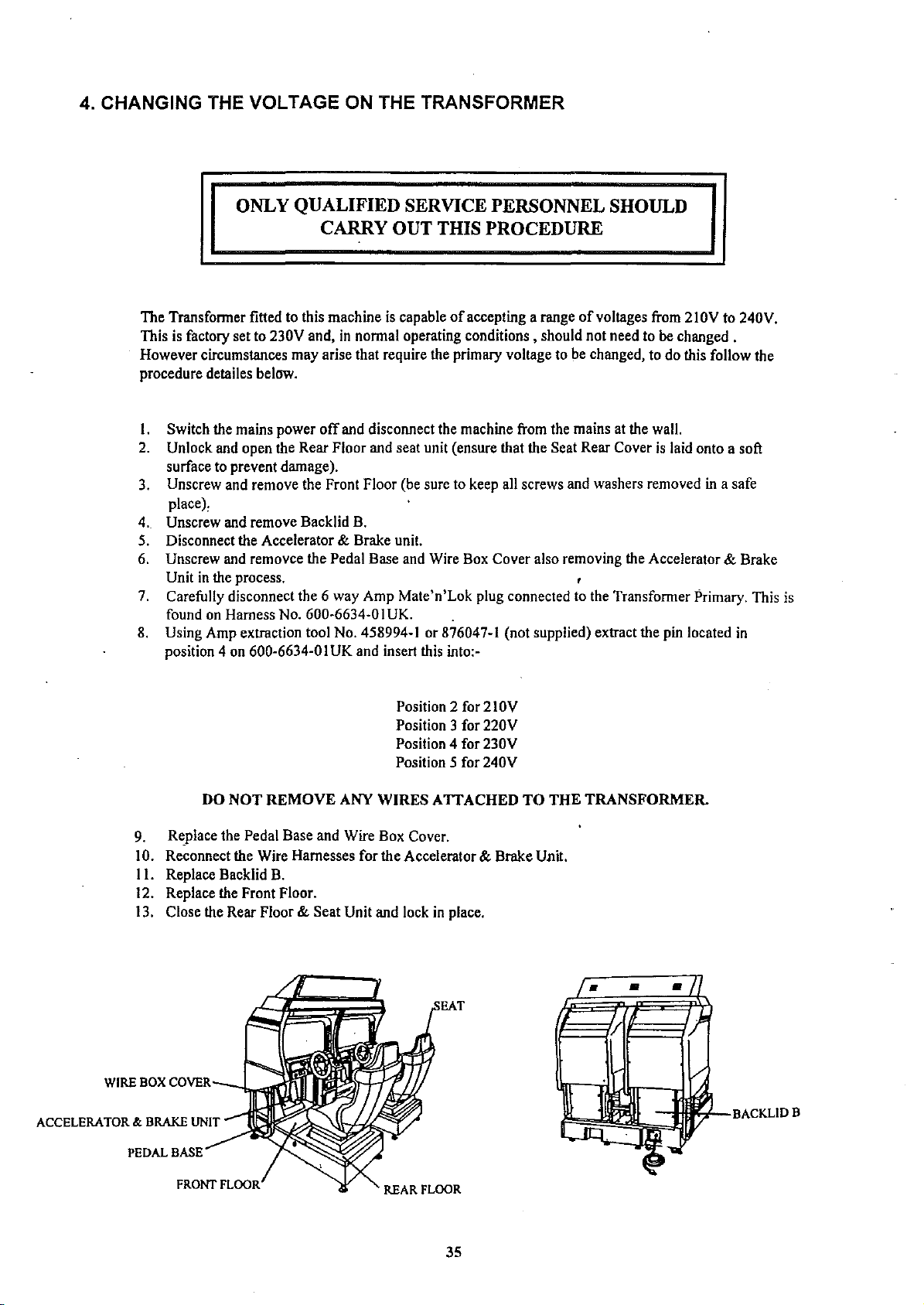

4. CHANGING THE VOLTAGE ON THE TRANSFORMER

5. FUSES

6. REPLACING THE FLOURESCENT LAMP AND LAMPS

7. PERIODIC INSPECTION

8. TROUBLESHOOTING

9. GAME BOARD

& BRAKE UNIT MAINTENANCE

& DRIVE CONTROL BOARD

THE

WALL BEFORE ATTEMPTING ANY

MAINTENANCE WORK.

THE

28

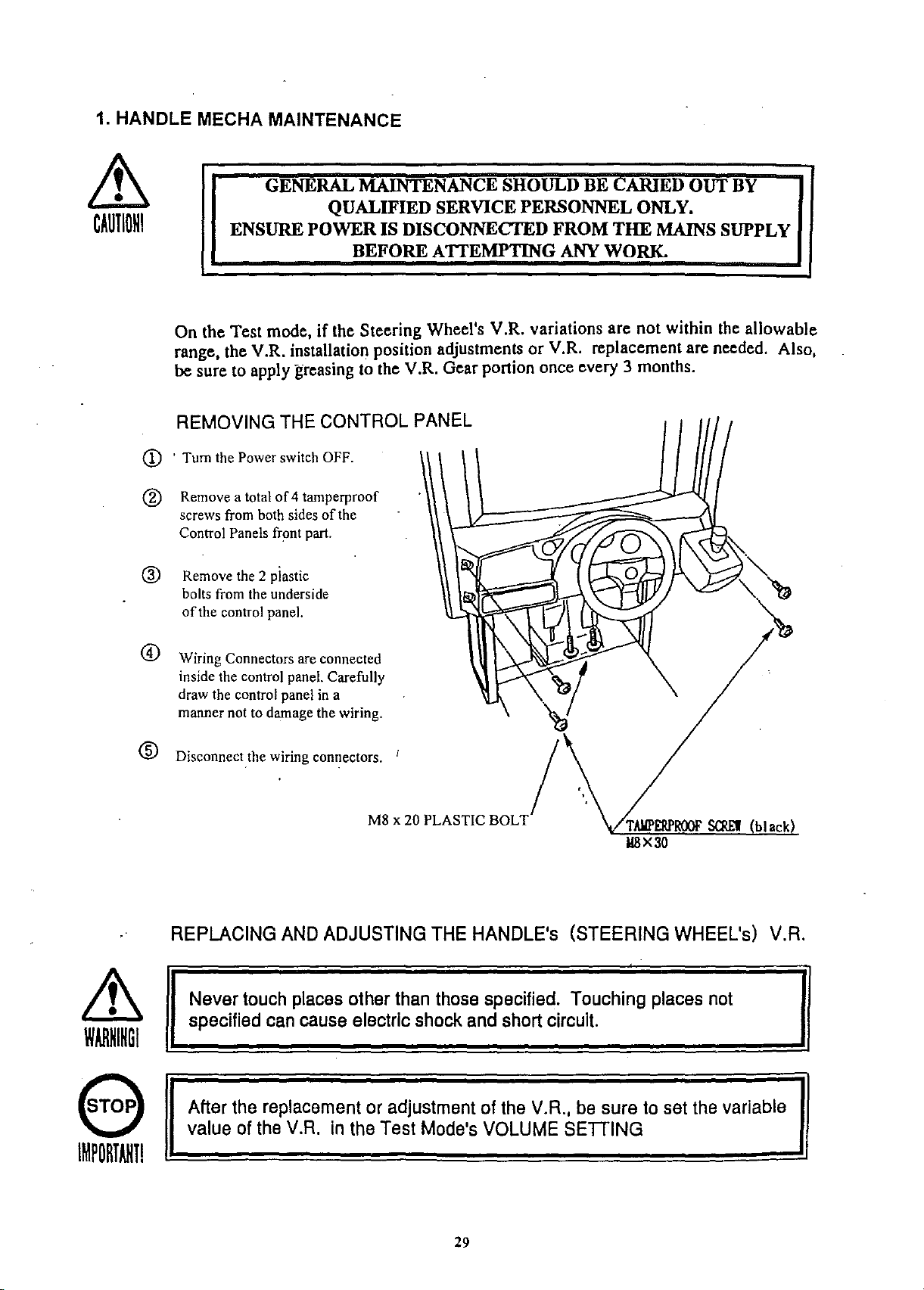

1. HANDLE MECHA MAINTENANCE

Lt

CAUliONI

CD

® Remove a total

® Remove the 2 plastic

GENERAL

ENSURE

On the Test mode, if the Steering Wheel's V.R. variations are not within the allowable

range, the V.R. installation position adjustments or V.R. replacement are needed. Also,

besure to apply greasing to the V.R. Gear portion once every 3 months.

REMOVING

.

Tum

the Power switch OFF.

screws from both sides

Control Panels front part.

bolts from the underside

ofthe

control panel.

POWERISDISCONNEcrED

THE

of

4 tamperproof

MAINTENANCE

QUALIFIED

BEFORE

CONTROL

of

the

SHOULD

SERVICE

ATTEMPTING

PANEL

BE

cARIED

PERSONNEL

FROM

ANY

THE

WORK.

ONLY.

MAINS

OUT

BY

SUPPLY

CD

®

~

WARHIHGI

Wiring Connectors are connected

inside the control panel. Carefully

draw the control panel in a

manner not to damage the wiring.

D;_"~""

REPLACING

Never

specified can

e wiring connectors. ' /

AND

ADJUSTING

touch

places

cause

other

electric

x 20 PLASTIC

M8

than

shock

THE

those

BOLT

HANDLE's

specified. Touching

andshort

(STEERING

circuit.

TAllPERPROOF

I18X30

places

SCREI

WHEEL's)

not

(black)

V.A.

€T3

Afterthe

valueof

IMPORTANTI

replacementoradjustment

the

V.A.

intheTest

Mode's

of the

VOLUME

29

V.A.,

besure to set

SETIING

the

variable

ADJUSTING THE V.R.

CD

By using the Spanner,loosen the 2 Hexagon bolts which secure the V.R. Bracket, move

the V.R. Bracket and disengage the gear mesh.

@ Ensure that the V.R. value is within the range

of

the centering position.

® Mesh the gears to secure the V.R. Bracket. At this time, ensure that an appropriate

backlash is obtained.

@ When the Steering Wheel is in the centering position, if the V.R. value is not

appropriate, make fine adjustments by loosening the 2 screws which secure the V.R.

gear, turning the gear holder and making sure that the V.R. value is appropriate.

®

Tum

the Steering Wheel to check V.R. value variations.

GREASING

Apply greasing to gear portions once every 3 months.

Use Part No. 090·0044 GREASE

NET

300g (Shell

AU~O

Grease).

Apply Grease

30

The

Steering Wheel's right-hand side V.R. is for the

the

left-hand

mode

screen.

Normally,

screen.

The

following

1

Remove

Disconnect the connectors (3P yellow, 3P red)

Connect

~3

®

®

Drive

The

the V.R.

After

and

Steering

making V.R. adjustments, connect connectors.

side

V.R. is for the Motor

the

V.R. value for the

To

check

the

the

the

value

the V.R. value for the

shows

Control Panel.

Wiring

Connector connected to the V.R. for the

Wheel

for the

each V.R. value.

Connector (3P yellow) which

value on

Motor

Game

the

INPUT

Drive BD.

Game

Drive

BD. Check the V.R. value on the

BD & Drive Control is

Motor

TEST

Drive

of

both Variable Resistors.

comes

mode

Board &

BD, follow the procedure below.

from the V.R.

Game

screen in the

shown

BD &

Drive

Drive

Test

Control, and

on the

for

the

Control.

mode

Test

Test

Motor

will be

mode

Game

For

BD&Drive

V.R.

for

Motor

Control:

Drive

REPLACING THE V.A. I

After

disconnecting the V.R. to be replaced, take

Bracket by using the Spanner, and then

replacement,

V.R.

for

Motor

DriveBO(3P

220-5373or220-5484

SCRE'II

(2)

114

X12, willat

spring washers

and

BD:

check

ellow

Left

30H or

30H or lower

V.R. value variations in the

Connector)

lower

Centering

..-

..-

remove

V.R.

220-5373or220-5484

position

7DH-83H

7DH-83H

off

the 2 screws which secure the V.R.

the V.R. with the gear as is attached. After

Test

mode.

for

Game

BD&Drive

--+

--+

Control

Right

or

(3P

higher

red

Connector)

(2)

wi!

Iat

COH

COHorhigher

SCRE'II

114x12,

spring vashers

and

VR

BRACKET

, .

VRBRACKET

31

2. ACCELERATOR & BRAKE UNIT

GENERAL MAINTEN CE SHOULD BE CARIED OUT BY

&

WARNING

I

ENSURE POWER IS DISCONNECTED FROM

QUALIFIED SERVICE PERSONNEL ONLY.

BEFORE ATTEMPTING ANY WORK.

Inthe

test

mode,ifthe

V.R.

value

isnot

an

adjustmentofV.R.

ora

replacementofV.R.isneeded.

grease

the

ACCEL-&

sliding

porions

To

perform

screws

backofthe

and

the

remove

cockpit.

ACCEL&BRAKE

within

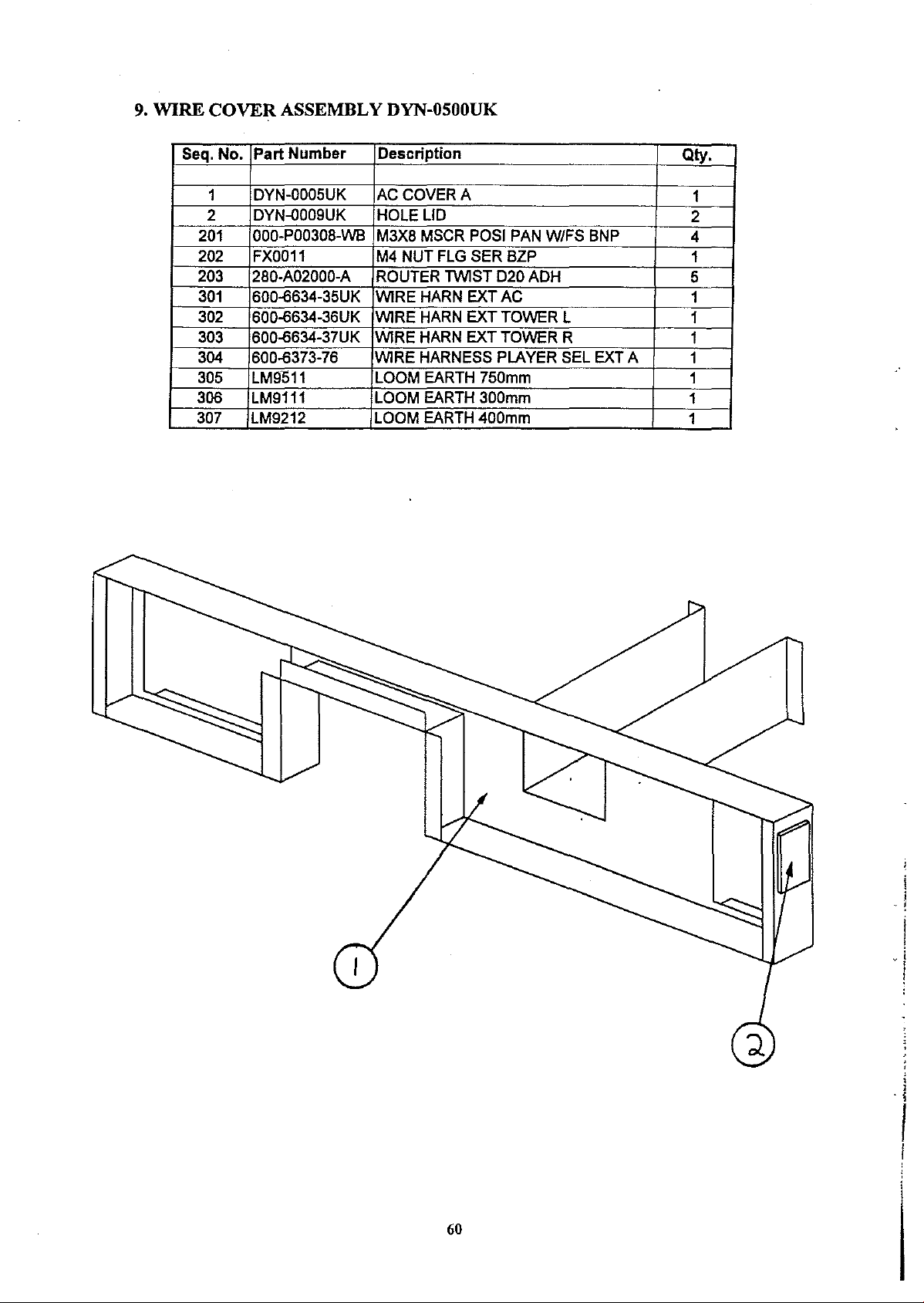

the

installation

BRAKE

once

every3months.

above

operation,

BACK

allowable

LIDBfrom

~AINTENANCE

range,

position

Also

shafts

and

take

off

the

4

the

THE

MAINS SUPPLY

ADJUSTING AND REPLACING THE V.R.

Never touch

~

specified can cause electric shock and short circuil.

WARNINGI

The ACCEL. & BRAKE

V.R. is on the left-hand side and the

Check the V.R..valueinthetest

Method of V.R. replacement

To replace the

taking

from the

replaced, take out the 2

screws which secure the

off

V.R.,

the connector

V.R.to be

V.R.Bracket, and remove

the

V.R.together with the

bracket and gear. After

the replacement, check

V.R.value variations

the

in the test mode.

places other than those specified. Touching places not

MECHA

ACCBL. :

BRAKE:

after

can beseenby removing the BACK LID B. The

BRAKE

mode.

When released:

Under 30 H

V.

R.

220-5373

V.R. is on the right-hand side of the

Theappropriatevalueof each V.R. is as

Under 30 H

,

When stepped on:

follows:

OverCOH

OverCOH

ACCEL.

MECHA.

SCREI

(2)

IU

X8.

USing

spring

washer

32

Method of V.R. adjustment I

CD

Loosen the 2 screws which secure the V.R. Bracket and move the V.R. Bracket to

disengage the gears.

@

Have

the V.R. value match with the value obtained when the pedal is released.

® Mesh the gears to secure the V.R. Bracket. At this time, be sure to obtain an

appropriate backlash.

@ Step on the pedal and check V.R. value variations. If the value is not within the above

appropriate range, loosen the 2 screws which secure the ADJUST GEAR to make an

adjustment.

GREASING

Apply greasingjothe gear and shaft portions once every 3 months.

PART

Use

Apply greasing in the following procedure:

CD

Take

(black) to pull out the unit. At this

time, be very careful so as not to'

damage the wiring.

No. 090-0044 GREASE NET 300g (SHELL AUTO).

off

the 4 Hexagon Bolts

® Disconnect the wiring connector

and move the unit,

which is 6kg." to a spacious place

in which the

performed.

work can easily be

® Remove the 4 Tamperproof

Screws (black) which secure the

Pedal Cover and remdve the Pedal

Cover

@

Remove

At this time, ensure that the ACCEL pedal and

are subjected to torsion spring force. .

by moving it forward.

the Pedal Shaft from the lower portionsofACCEL. pedal and BRAKE pedal.

® After applying.greasing to each part, assemble in the procedure opposite as when

disassembling.

th~

weight

of

AGeEL.

PEDAL

BRAKE

HEXAGON

M8x

pedal are firmly secured as they

:

16,

BOLT

'/flal l

black (4)

spring

rashers

GREASING

PEDAL

SHAFT

using

1112

spr ing washer

/

cf"/

TAMPERPROOF

(4) 1l4X8

SCREW

(black)

33 -

~

GREASING

Accel.

Gear

s.de &

part

GREASING

~p"'ed"'a'fl

Brake

"'S""ha-;f-t

-rem-oY-e-;d

side

,

-a-s

-p-e

r'"""®"ab-o~Ye:-.

3. SHIFTLEVER

MAINTENANCE

~

WARNINGI

CD

<ID

® Disconnect the Connectorto removethe Shift Lever Unit.

@)

When reinstalling, followthe procedureopposite as whenremoving. At this lime,

ensure that

In the Test mode,ifthe

SWitch.

the

When performingtheabove work, remove the Shift Lever Unit.

ENSURE POWERIS DISCONNECTED

REMOVING

Tum thePowerSW off.

Remove the4 TamperproofScrewsto lift the Shift LeverUnit.

Applygreasing.to the Mechanism'sslidingportiononce every 3 months.

GENERAL MAINTENANCE SHOULD BE

THE

"DOWN"

SHIFf

QUALIFIED SERVICE PERSONNEL ONLY.

BEFORE ATTEMPTING ANY WORK.

SHIFT

displayappearson the upper partasshown.

LEVER'sSW can notbe inputted satisfactorily,replace

CARIEDOUT

FROM

LEVER

THE

TAllPERPROOF

jp

,/

./

BY

MAINS SUPPLY

SCREI

(black) (4)

SWITCH

Method of

CD

Disconnect the wiringConnectorof

the Switch to be replaced. .

<ID

Remove the 2 TappingScrews

(M3X16)

GREASING

Apply greasingonce in 3 months 10

the specified portions.

Por spray grease,useNOK KLUBER

L 60 or Grease Mate(PartNo. 090-

0066).

REPLACEMENT

replacement