Page 1

1ST PRINTING

JAN.- 1998

TM

OWNER’S MANUAL

STD TYPE

SEGA ENTERPRISES, USA

MANUAL NO. 4200-6367

Page 2

Warranty

Your new Sega Product is covered for a period of 90 days from the date of shipment. This certifies

that the Printed Circuit Boards, Power Supplies and Monitor are to be free of defects in workmanship or materials under normal operating conditions. This also certifies that all Interactive Control

Assemblies are to be free from defects in workmanship and materials under normal operating conditions. No other product in this machine is hereby covered.

Sellers sole liability in the event a warranted part described above fails shall be, at its option, to

replace or repair the defective part during the warranty period. For Warranty claims, contact your

Sega Distributor.

Should the Seller determine, by inspection that the product was caused by Accident, Misuse, Neglect, Alteration, Improper Repair, Installation or Testing, the warranty of fered will be null and void.

Under no circumstances is the Seller responsible for any loss of profits, loss of use, or other damages.

This shall be the exclusive written Warranty of the original purchaser expressed in lieu of all other

warranties expressed or implied. Under no circumstance shall it extend beyond the period of time

listed above.

Page 3

TABLE OF CONTENTS

INTRODUCTION OF THE OWNERS MANUAL

GENERAL PRECAUTIONS

1. PRECAUTIONS TO BE HEEDED FOR OPERATION

2. NAME OF PARTS

3. ACCESSORIES

4. ASSEMBLY AND INSTALLATION

5. PRECAUTIONS TO BE HEEDED WHEN MOVING MACHINE

6. CONTENTS OF GAME

7. EXPLANATION OF TEST AND DATA DISPLAY

7-1 POWER SUPPLY UNIT AND COIN METER

7-2 TEST MODE

7-3 MEMORY TEST

7-4 VIDEO MEMORY TEST

7-5 BOUNDRY TEST

7-6 INPUT TEST

7-7 OUTPUT TEST

7-8 SOUND TEST

7-9 C.R.T. TEST

7-10 GAME ASSIGNMENTS

7-11 COIN ASSIGNMENTS

7-12 REAL TIME CLOCK TEST

7-13 VOLUME SETTING

7-14 NETWORK ASSIGNMENTS

7-15 BOOKKEEPING

7-16 BACKUP DATA CLEAR

8. HANDLEBAR

8-1 ADJUSTING/REPLACING THE FRONT BRAKE VOLUME

8-2 ADJUSTING/REPLACING THE ACCELERATOR VOLUME

8-3 ADJUSTING/REPLACING THE HANDLE BAR VOLUME

8-4 GREASING

9. FOOT BRAKE MECHA

9-1 ADJUSTING AND REPLACING THE VOLUME

9-2 GREASING

10. COIN SELECTOR

11. MONITOR

12. REPLACEMENT OF FLUORESCENT LAMP AND LAMPS

12-1 REPLACEMENT OF FLUORESCENT LAMP

12-2 REPLACEMENT OF LAMPS

13. PERIODIC INSPECTION TABLE

14. TROUBLESHOOTING

14-1 REPLACEMENT OF FUSES

15. GAME BOARD

15-1 REMOVING THE IC BOARD

15-2 COMPOSITION OF THE GAME BOARD

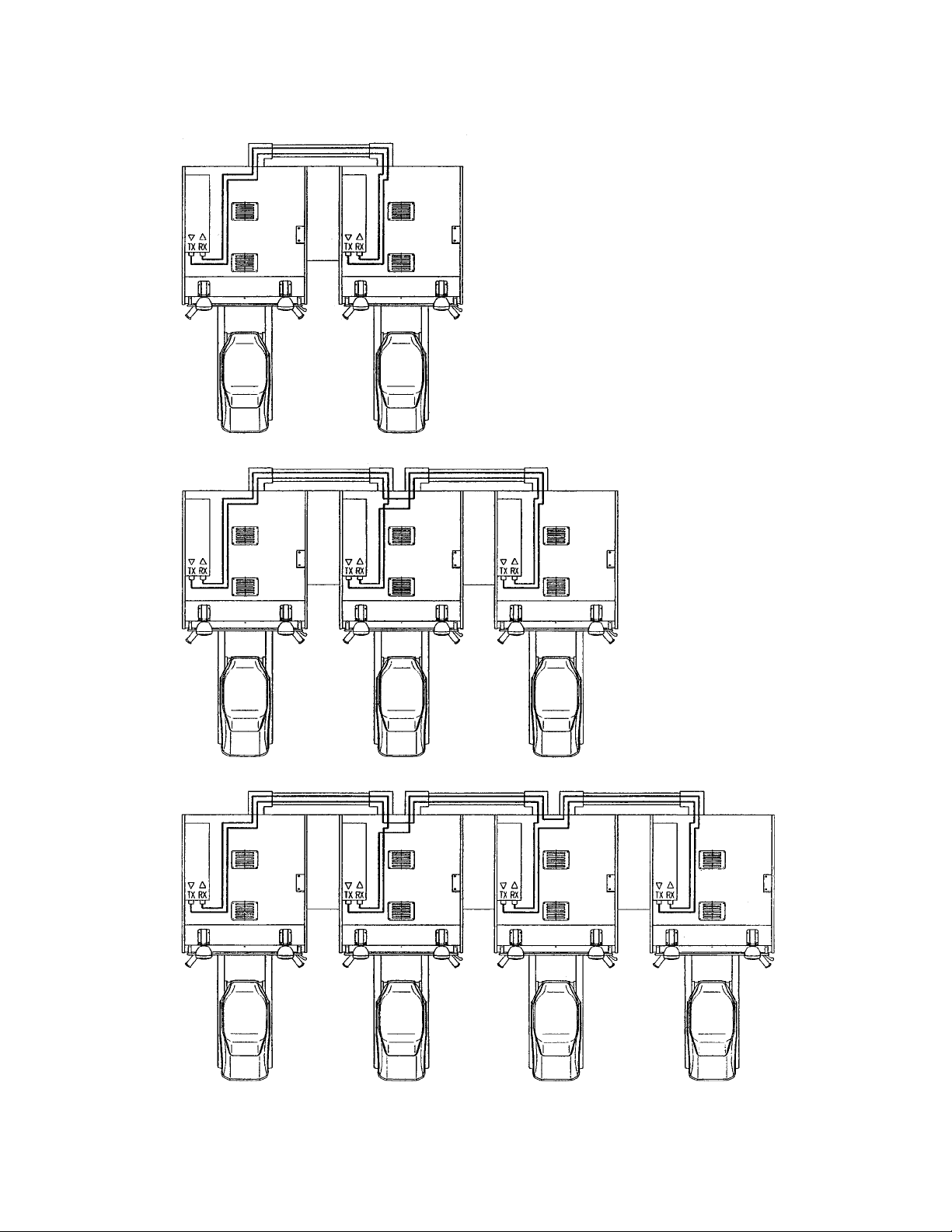

16. COMMUNICATION PLAY

16-1 INSTALLATION PRECAUTIONS

16-2 CONNECTING THE COMMUNICATION CABLES

16-3 SETTING FOR COMMUNICATION PLAY

17. DESIGN RELATED PARTS

18. PARTS LIST

19. WIRING DIAGRAMS

1

2~3

4~5

6

7~8

9~14

15

16~18

19~30

20

21

21

22

22

23

23

24

24

25

26~28

29

29

29

30

30

31

31

32

33~36

37

38

38~39

40

41~43

44~46

47~48

47

48

49

50

51

52

52~53

54

55~65

55

55~63

64~65

66

67~94

XXX

Page 4

SPECIFICATIONS

Installation space: 65 in.(L) x 31 in.(W)

Height: 78 in.

Weight: Approx. 397 lbs.

Power maximum current: 5 Amp AC 120V 60 Hz

MONITOR: 29” INCH COLR MONITOR

INTRODUCTION OF THE OWNERS MANUAL

SEGA ENTERPRISES, LTD., has for more than 30 years been supplying various innovative and

popular amusement products to the world market. This Owners Manual is intended to provide

detailed descriptions together with all the necessary installation, game settings and parts ordering

information related to the HARLEY DAVIDSON U/R, a new SEGA product.

This manual is intended for those who have knowledge of electricity and technical expertise, especially in ICs, CRTs, microprocessors, and circuit boards. Read this manual carefully to acquire

sufficient knowledge before working on the machine. Should there be a malfunction, non-technical

personnel should under no circumstances touch the interior system. Should the need arise, contact

our main office, or the closest branch office listed below.

SEGA ENTERPRISES, INC. (USA)

Customer Service

45133 Industrial Drive

Fremont, CA 94538

Phone 650-802-1750

Fax 650-802-1754

7:30 am - 4:00 pm, Pacific Standard Time

Monday thru Friday

1

Page 5

General Precautions

Follow Instructions: All operating and use instructions should be followed.

Attachments: Do not use attachments not recommended by the product manufacturer as they may cause hazards.

Accessories: Do not place this product on an unstable cart, stand, tripod, bracket, or table. The product may fall,

causing serious injury to a child or adult, and serious damage to the product. Use only with a cart, stand, tripod, bracket, or

table recommended by the manufacturer, or sold with the product. Any mounting of the product should follow the

manufacturer’s instructions, and should use only mounting accessories recommended by the manufacturer.

Moving the Product: This product should be moved with care. Quick stops, excessive force, and uneven surfaces

may cause the product to overturn.

Ventilation: Slots and openings in the cabinet are provided for ventilation, to ensure reliable operation of the product

and to protect it from overheating; these openings must not be blocked or covered. The openings should never be blocked

by placing the product in a built-in installation such as a bookcase or rack unless proper ventilation is provided or the

manufacturer’s instructions have been adhered to.

Power Sources: This product should be operated only from the type of power source indicated on the marking label.

If you are not sure of the type of power supply to your location, consult your local power company . For products intended

to operate from battery power or other sources, refer to the operating instructions.

Grounding or Polarization: This product is equipped with a three-wire grounding-type plug, a plug having a third

(grounding) pin. This plug will only fit into a grounding-type power outlet. This is a safety feature. If you are unable to

insert the plug into the outlet, contact your electrician to replace your obsolete outlet. Do not defeat the safety purpose of the

grounding-type plug.

Power Cord Protection: Power-supply cords should be routed so that they are not likely to be walked on or pinched

by items placed upon or against them, paying particular attention to cords at plugs, convenience receptacles, and the point

where they exit from the product.

Overloading: Do not overload wall outlets, extension cords, or integral convenience receptacles as this can result in

a risk of fire or electric shock.

Object and Liquid Entry: Never push objects of any kind into this product through openings as they may touch

dangerous voltage points or short-out parts that could result in a fire or electric shock. Never spill liquid of any kind on the

product.

Servicing: Do not attempt to service this product yourself as opening or removing covers may expose you to danger-

ous voltage or other hazards. Refer all servicing to qualified service personnel.

Damage Requiring Service: Unplug this product from the wall outlet and refer servicing to qualified service person-

nel under the following conditions:

a) If the power cord or plug is damaged;

b) If liquid has been spilled, or objects have fallen into the product;

c) If the product has been exposed to rain or water;

d) If the product does not operate normally when following the operating instructions. Adjust only those controls that

are explained in the operating instructions. An improper adjustment of other controls may result in damage and will

often require extensive work by a qualified technician to restore the product to its normal operation;

e) If the product has been dropped or damaged in any way;

f) When the product exhibits a distinct change in performance; this indicates a need for service.

Replacement Parts: When replacement parts are required, be sure the service technician has used replacements parts

specified by the manufacturer or that have the same characteristics as the original part. Unauthorized substitutions may

result in fire, electric shock, or other hazards.

2

Page 6

Safety Check: Upon completion of any service or repairs to this product, ask the service technician to perform safety

checks to determine that the product is in proper operating condition.

Heat: The product should be situated away from heat sources such as radiators, heat registers, stoves, or other prod-

ucts (including amplifiers) that produce heat.

Lithium Battery- Dispose of batteries only in accordance with the battery manufacturer’s recommen-

dations. Do not dispose in an open flame condition, since the battery may explode.

Cleaning: When cleaning the monitor glass, use water or glass cleaner and a soft cloth. Do not apply chemicals such

as benzine, thinner, etc.

Location: This an indoor game machine, DO NOT install it outside. To ensure proper usage, avoid installing indoors

in the places mentioned below:

• Places subject to rain/water leakage, or condensation due to humidity;

• In close proximity to a potential wet area;

• Locations receiving direct sunlight;

• Places close to heating units or hot air;

•In the vicinity of highly inflammable/volatile chemicals or hazardous matter;

• On sloped surfaces;

• In the vicinity of emergency response facilities such as fire exits and fire extinguishers;

• Places subject to any type of violent impact;

• Dusty places.

I

NSTALLATION PRECAUTIONS

• Verify the amperage of the branch circuit outlet before plugging in the power plug. Do not overload the circuit.

• Avoid using an extension cord. If one is required, use an extension cord of type SJT, 16/3 AWG

rated min. 120 VAC, 7A.

• Moving this unit requires a minimum clearance (of doors, etc.) of 32” (W) by 77” (H).

• For the operation of this machine, secure a minimum area of 32” (W) by 42”(D).

REGULATORY APPROVALS

This game has been tested and found to comply with the Federal Communications Commission Rules.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including interference

that may cause undesired operation.

This game has been tested and listed by Underwriters Laboratories, Inc., to ANSI/UL22.

LISTED

U

®

L

5K92

AMUSEMENT MACHINE

3

Page 7

1 . PRECAUTIONS TO BE HEEDED FOR OPERATION

In order to prevent accidents, be sure to comply with the following points before and during operation.

PRECAUTIONS TO BE HEEDED FOR OPERATION BEFORE STARTING THE OPERATION

In order to avoid accidents, check the following before starting the operation:

Check if all of the adjusters are in contact with the surface. If they are not,

the cabinet can move and cause an accident.

Ensure that all of the Adjusters

are in contact with the floor.

Do not climb on the product. Climbing on the product can cause falling

down accidents. To check the top portion of the product, use a step.

To avoid electric shock, check to see if door & cover parts are 508.5

To avoid electric shock, short circuit and or parts damage, do not put the

following items on or in the periphery of the product:

Flower vases, flower pots, cups, water tanks, cosmetics, and receptacles/

containers/vessels containing chemicals and water.

To avoid injury, be sure to provide sufficient space by considering the

potentially crowded situation at the installation location. Insufficient installation space can cause the player to come into contact with or hit others

and result in injury or trouble.

4

Page 8

PRECAUTIONS TO BE HEEDED DURING OPERATION

To avoid injury and accidents, those who fall under the following catagories are not

allowed to play the game:

* Intoxidated persons

* Pregnant women or those in the likelyhood od pregnancy.

* Those who need assistasnce such as the use of an apparatus when walking.

* Those who have high blood pressure or heart problems.

* Those who have experienced muscle convulsion or loss of consciousness when playing

video games, etc.

* Persons susceptible to motion sickness.

* Persons whose acts runs counter to the products warning displays.

* Instruct those who wear high-heeled shoes to refrain from

playing the game by explaining that playing the game with highheeled showes is very dangerous and likely to cause a potentially

hazardous situation.

To avoid electric shock and short circuit, do not allow customers to put hands and

fingers or extraneous matter in openings of the product or small openings in or around

doors.

To avoid falling down and injury resulting from falling down, immediatly stop the

customer’s leaning against or climbing on the product, etc.

To avoid electric shock and short circuit, do not allow the customers to unplug the

power plug without a justifiable reason.

5

Page 9

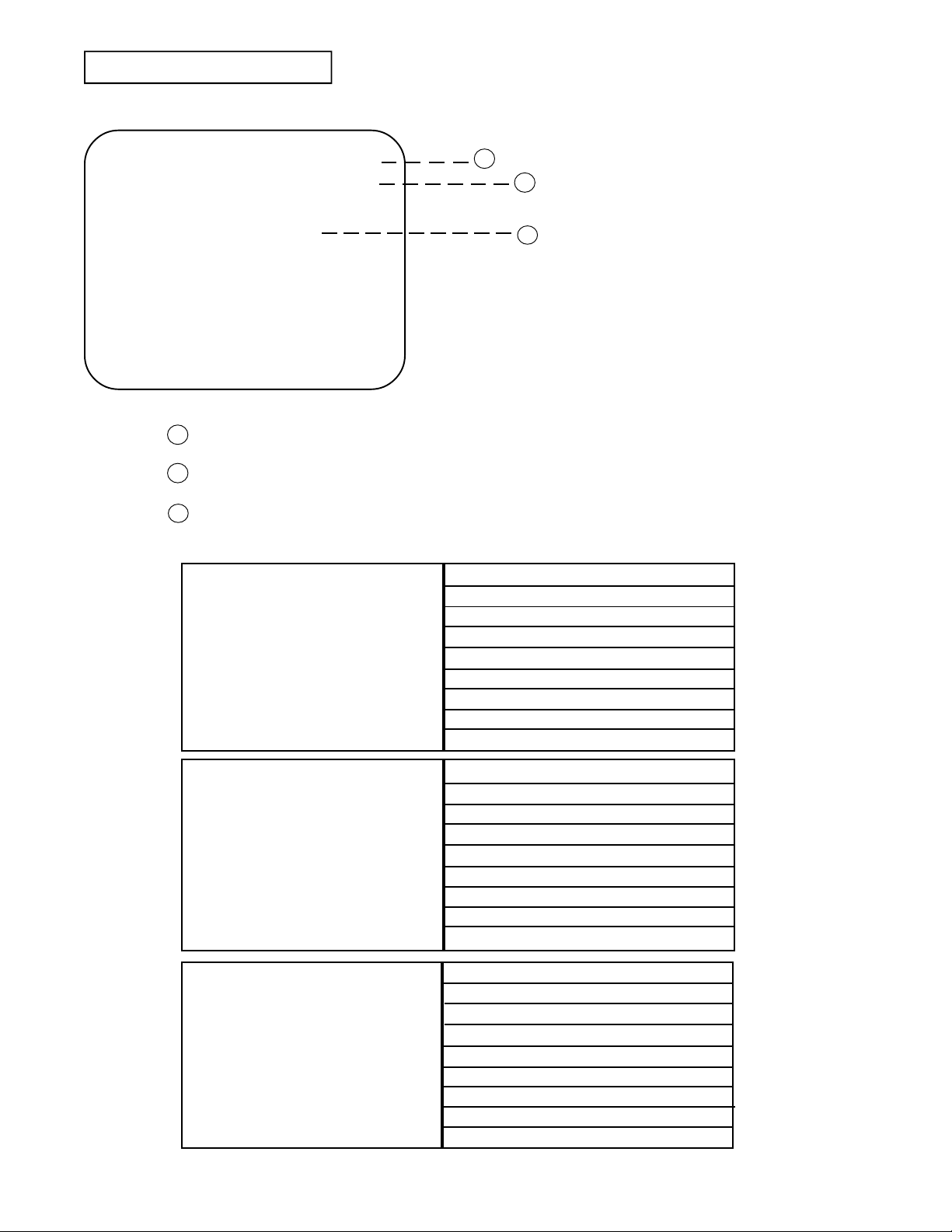

2 . NAME OF PARTS

COIN CHUTE DOOR

BILLBOARD

29 INCH MONITOR

CABINET

CASHBOX DOOR

GAME SPECIFICATIONS

DURING SHIPPING

CABINET

SEAT CABI

SEAT CABI

AC UNIT

WIDTH LENGTH HEIGHT

All measurements are in inches

31” X 38” X 78”

13.5” X 45.5” X 25”

WEIGHT

475 LBS.

350 LBS.

49 LBS.

WHEN ASSEMBLED

31” X 65” X 78”

6

400 LBS.

Page 10

3 . ACCESSORIES

7

Page 11

THE SHIPMENT METHOD DESCRIBED BELOW ONLY

APPLIES TO ‘MODEL 3’ BOARDS CONTAINED IN THE

FOLLOWING GAMES:

LOST WORLD, VIRTUA FIGHTER 3, SUPER GT, SEGA BASS FISHING, STRIKER 2

HARLEY DAVIDSON

!!NEVER SHIP MODEL 3 GAME BOARDS

!!NEVER SHIP MODEL 3 GAME BOARDS

OUTSIDE OF CAGE!!

OUTSIDE OF CAGE!!

CARTON BOX

601-8928 (1)

Used for transporting the GAME BOARD.

{SUPPLIED WITH YOUR GAME}

DO NOT SHIP GAME BOARD WITHOUT

THIS BOX AS IT MAY DAMAGE THE GAME

BOARD AND VOID YOUR W ARRANTY.

“CHECK SIDE” Display

FILTER BOARD

NO OTHER GAMES BOARDS ARE TO BE SHIPPED IN THE CAGE AS

THEY MAY BE DAMAGED BEYOND REPAIR. PLEASE SHIP THEM

WITHOUT CAGE PROPERLY PROTECTED DURING SHIPPING.

8

Page 12

4 . ASSEMBLING AND INSTALLATION

Assembling should be performed as per this manual. Since this is a

complex machine, erroneous assembling may cause damage to the

machine, or malfunctioning to occur.

When assembling, be sure to perform work by plural persons.

Depending on the assembly work, there are some cases in which

performing the work by a single person can cause personal injury or

parts damage.

When carrying out the assembly work, follow the procedure in the following 7-item sequence:

1

ASSY OFCABINET

2

SECURING IN PLACE (ADJUSTER ADJUSTMENT)

3

POWER SUPPLY

ASSEMBLING CHECK

4

Note that the tools such as a phillips screwdriver and wrench for M16 hexagon bolt w/24 mm width

across flats are required for the assembly work.

ASSY OF CABINET

1

Ensure that the connectors are accurately connected. Incomplete

connections can cause electrical shock or short circuit. Be careful

not to damage wirings. Damaged wiring can cause short circuit or

electrical shock.

To perform work safely and securely, be sure to prepare a step

which is in a secure and stable condition. Not using a step or using

an unstable step can cause a violent falling down accident.

9

Page 13

Tightly fit the seat cabi to the cabinet in a manner to insert it in.

1

2

Secure to the cabinet with 2 hexagon bolts and 2 truss screws.

3

Connect the connector. (2P white)

4

Install the joint lid.

5

Secure the Joint lid with 4 screws.

10

Page 14

2

SECURING IN PLACE (ADJUSTER ADJUSTMENT)

Be sure to have all the Adjusters make contact with the surface. Unless the Adjusters come into contact with the surface, the Cabinet

can move of itself, causing an accident.

This machine has 8 each of casters and adjusters (shown below). When the installation position is determined, cause

the adjusters to come into contact with the floor directly, make adjustments in a manner so that the casters will be

raised approximately 5mm. from the floor and make sure that the machine position is level.

CASTERS

Move the machine to the installation position.

1

Cause all of the leg adjusters to make contact

2

with the floor. By using a wrench, make

adjustments in the height of the leg adjusters to

ensure that the machine's position is level.

ADJUSTERS

After making adjustments, fasten the leg

3

adjuster nut upward and secure the height of the

leg adjuster.

Depending on the floor surface status of the installation location, the Rear Cabinet may move of itself. As

4

shown, the NON-SLIP SHEET is attached to the back side of the CAUTION MAT. Ensure that the Adjuster is

installed in the manner to match the position of NON-SLIP SHEET

After making adjustments, fasten the adjuster nut upwards and secure the height of the adjuster

5

BOTTOM VIEW

11

Page 15

3

The AC unit is mounted on the rear side of the cabinet . The AC Unit incorporates the Main SW, Earth Terminal and

Inlet. Firmly insert the Power Plug into the Socket Outlet and the other side of the plug to the Inlet. Turn the Main SW

ON to turn power ON.

1

2

POWER SUPPLY

Ensure that the power cord is not exposed on the surface (passage,

etc.). If exposed, they can be caught and are susceptible to damage.

If damaged, the cord can cause an electric shock or short circuit.

Ensure that the wiring position is not in the customer's passage way

or the wiring has protective covering.

Ensure that the Main SW is OFF.

Connect the Power cord to the Outlet

Socket. Ensure power cord is not in

customer’s passage way or wiring has

protective covering.

AC

BRACKET

FUSE

LINE STRAIN RELIEF

MAIN SW

BINDING POST NOT USED

12

Page 16

4

ASSEMBLING CHECK

The TEST MENU allows for each part of the cabinet to be checked, the Monitor to be adjusted, and the coin and

game related various functions to be performed.

CPU ROM TEST

Selecting the MEMORY TEST on the test mode menu screen

GOOD (CROM03 MASK) IC.1 *****

GOOD (CROM02 MASK) IC.2 *****

GOOD (CROM01 MASK) IC.3 *****

GOOD (CROM00 MASK) IC.4 *****

GOOD (CROM13 MASK) IC.5 *****

GOOD (CROM12 MASK) IC.6 *****

GOOD (CROM11 MASK) IC.7 *****

GOOD (CROM10 MASK) IC.8 *****

GOOD (CROM33 EPROM) IC.9 *****

GOOD (CROM32 EPROM) IC.10 *****

GOOD (CROM31 EPROM) IC.11 *****

GOOD (CROM30 EPROM) IC.12 *****

GOOD (CROM3 EPROM) IC.13 *****

GOOD (CROM2 EPROM) IC.14 *****

GOOD (CROM1 EPROM) IC.15 *****

GOOD (CROM0 EPROM) IC.16 *****

PRESS TEST BUTTON TO EXIT

INPUT TEST

causes the on-board memory to be tested automatically. The

game board is satisfactory if the display beside each IC No.

shows GOOD.

HANDLEBAR OFF

THROTTLE OFF

FRONT BRAKE OFF

REAR BRAKE OFF

VIEW CHANGE OFF

MUSIC SELECT OFF

SHIFT UP OFF

SHIFT DOWN OFF

START OFF

COIN #1 OFF

SERVICE-SW OFF

TEST-SW OFF

PRESS TEST BUTTON TO EXIT

OUTPUT TEST

START LAMP OFF

VIEW CHANGE LAMP OFF

MUSIC SELECT LAMP OFF

RACE READER LAMP OFF

Selecting the INPUT TEST on the menu screen in the test

mode to display the screen on which each SW and Volume is

tested. Press each switch. (To check the Coin SW, insert a

Coin from the inlet with the Coin Chute Door being opened.)

If the display beside each switch is ON, the switch and wiring

connection are satisfactory. Check the display of each Volume

value. The Volume could have an irregularity caused by

differences between machines and vibration during transportation. Set the Volume values by referring to Section ?

In the output test mode, carry out lamp test to ascertain that

each lamp lights up satisfactorily.

>EXIT

SELECT WITH SERVICE BUTTON

PRESS TEST BUTTON TO EXIT

13

Page 17

9

9

9

9

9

9

7

7

7

7

7

7

7

7

7

3

3

3

3

3

3

3

3

3

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

1234567890123456789012345678

SOUND TEST

NO : ( 0 )

>EXIT

SELECT WITH SERVICE BUTTON

PRESS TEST BUTTON TO EXIT

C.R.T. TEST 1/2

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456789012

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

234567890123456789012345678

234567890123456789012345678

234567890123456789012345678

234567890123456789012345678

234567890123456789012345678

234567890123456789012345678

RED

GREEN

BLUE

In the TEST mode, selecting SOUND TEST causes the

screen, on which sound related BD and wiring connections are tested, to be displayed. be sure to check if the

sound is satisfactorily emitted from each of speaker and

the sound volume is appropriate.

In the TEST mode menu, selecting C.R.T. TEST allows the

screen (on which the projector is tested) to be displayed.

Although the projector adjustments have been made at the

same time of shipment from the factory, color deviation,

etc., may occur due to the effect caused by geomagnitism,

the location building’s steel frames and other game machines in the periphery. By watching the test mode screen,

make judgement as to whether an adjustment is needed. If it

is neccessary, adjust the projector by refering to Section 9.

WHITE

PRESS TEST BUTTON TO CONTINUE

C.R.T. TEST 2/2

PRESS TEST BUTTON TO CONTINUE

Perform the above inspections also at the time of monthly inspection.

14

Page 18

5 . PRECATIONS TO BE HEEDED WHEN MOVING THE MACHINE

When moving the machine, be sure to pull out the plug from

the power supply. Moving the machine with the plug as is

inserted can damage the power cord and cause a fire or electric shock.

When moving the machine on the floor, retract the Adjusters

and ensure that Casters make contact with the floor. During

transportation, pay careful attention so that Casters do not

tread power cords. Damaging the power cords can cause an

electric shock and/or short circuit.

When lifting the cabinet, be sure to hold the catch portions or

bottom part. Lifting the cabinet by holding other portions can

damage parts and installation portions, due to the empty

weight of the cabinet, and cause personal injury.

Use care when handling glass made parts. When the glass is damaged, fragments of glass can cause injury

GRIP

Where there steps (or step-like differences

in grade), move the machine by seperating

into each unit.

CASTER

On level surfaces, move the machine by causing the

casters to make contact with the surfaces.

Pushing the glass made or plastic parts

can damage the parts and cause injury.

Also, moving machine by holding the

handlebar can damage the handle bar.

15

Page 19

6 . CONTENTS OF GAME

The following are operations and responses obtained when the machine functions satisfactorily. Any functioning

different fromt he following may have been caused by a certain fault. Immediately investigate and eliminate the cause

of the malfunctioning to ensure satisfacory operation. The explanation herein mainly refer to the case where the game

machine is used independently. In communications play, some points may differ fromthe following explanations.

When energized, the Billboard’s fluorescent lamp is always lit.

During ADVERTISE (in the status a coin(s) is not inserted), the contents of game and HOW TO PLAY, etc., are audiovisually explained.

The status of the on-tank 3 buttons will change to and from lighting up/flashing/lights out.

Although the Start button is unlit during ADVERTISE, it blinks if even one coin is inserted, and is always lit duriong

game play.

The View Change button and Music Select button are unlit during ADVERTISE and lit when the Select Mode is

displayed. During Game, the flash alternately.

The two lamps of the Billboard flash during ADVERTISE and Select Mode display, light up during game and flash for

approximately 3 seconds at the time of passing the checkpoint.

In case of communication play, the lamps light up during game, flash for approximately 3 seconds when passing the

chackpoint (in top posistion), and light out for 3 seconds when passing the checkpoint (in the second position or lower).

LAMP

BILLBOARD

SHIFT UP button

SHIFT DOWN button

START button

VIEW CHANGE button

COIN INLET

FRONT BRAKE LEVER

ACCELERATOR

MUSIC SELECT button

REAR BRAKE PEDAL

16

Page 20

1

Be seated.

Insert coin(s). When one play worth of coin(s) is inserted, the Select mode appears.

2

Select in order of BIKE and TRANSMISSION. Turn the handlebar to select and turn the ACCELORATOR GRIP

3

to decide.

When the Select Mode is displayed, countdown starts. At count 0, BIKE TRANSMISSION being selected are

automatically decided.

4

When TRANSMISSION is decided, the race starts. The checkpoint (desination) is displayed on the screen, and

Time Limit countdown starts.

At the same time the race starts, the View Change button and Music Select button alternately light up/light out.

Pressing the View Change button changes the View point in the game mode.

Pressing the Music Select button changes the BGM (background music).

The distance to the checkpoint is displayed onthe upper left section of the screen. the remaining time is indicated

5

on the upper center, score points on the upper right, navigation window(map) on the lower left, and speedometer

on the lower right.

17

Page 21

Run towards the checkpoint by judging the route from the arrow and the NAVIGATION WINDOW. Passing the

6

checkpoint within the time limit results in a Stage Clear. The time limit is extended and the next checkpoint is

displayed.

If the player fails to pass the checkpoint within the time limit, the game is over.

7

Passing all of the checkpoints results in a Game Clear. The successful player can see the ending mode.

8

9

After a Game Over, the accomplishment results are displayed on the map.

If the player scores high points, the Name Entry mode appears. Turn the Handlebar, select character, and turn the

10

Accelorator Grip to register intial, etc.

NOTE 1:

Setting change can be made to no sound output during ADVERTISE.

NOTE 2:

In the case where several machines are linked together for communication play, the bike appearing first in the Select

Mode is predetermined by the number of each cabinet set for the communication play.

NOTE 3:

The setting of the number of checkpoints required for game clear is changeable.

KNACK OF GAME PLAY

To make full use of bike characteristics;

Each of the 5 types of bike has specific characteristics. High points can be earned by fully utilizing the bike

charcteristics and selecting the type which suites best for the player.

To memorize the courses;

The player will surely acomplish a game clear by selecting the course on which he can make full use of the bike

characteristics instead of relying on the map and arrow.

18

Page 22

7 . EXPLANATION OF TEST AND DATA DISPLAY

By operating the switch unit, periodically perform the tests and data check. When installing

the machine initially or collecting cash, or when the machine does not function correctly,

perform checking in accordance with the explanations given in this section. The following

shows tests and modes that should be utilized as applicable.

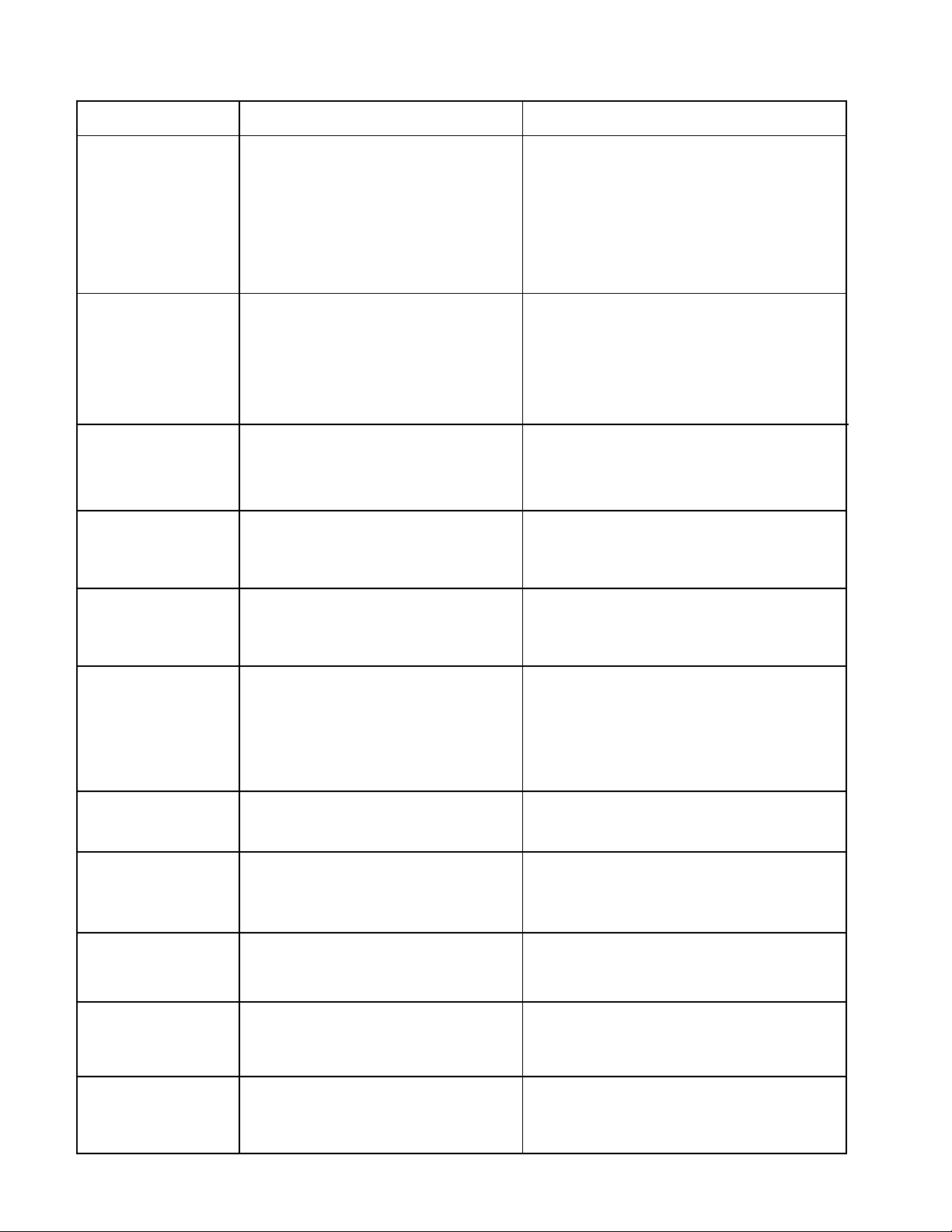

TABLE 7 EXPLANATION OF TEST MODE

ITEMS DESCRIPTION SECTIONS

When the machine is installed, perform the following:

INSTALLATION

OF MACHINE

MEMORY

PERIODIC

SERVICING

1. Check to see that each setting is as per standard setting made

at the time of shipment.

2. In the INPUT TEST mode, check each SW and VR.

3. In the OUTPUT TEST mode, check each of lamps.

4. In the MEMORY TEST mode, check ICs on the IC Board.

Choose MEMORY TEST in the MENU mode to allow the

MEMORY test to be performed. In this test, PROGRAM

RAMs, ROMs, and ICs on the IC Board are checked.

Periodically perform the following:

1. MEMORY TEST

2. Ascertain each setting.

3. In the INPUT TEST mode, test the CONTROL device

4. In the OUTPUT TEST mode, check each of lamps.

7 - 10, 7 - 11

7 - 6

7 - 7

7 - 3, 7 - 4

7 - 3, 7 - 4

7 - 10, 7 - l1

7 - 6

7 - 7

CONTROL

SYSTEM

PROJECTOR

IC BOARD

DATA CHECK

1. In the INPUT TEST mode, check each SW and VR.

2. Adjust or replace each SW and VR.

3.If the problem can not be solved yet, check the CONTROL’s moves.

In the PROJECTOR ADJUSTMENT mode, check to see if the

PROJECTOR adjustment is appropriately made.

1. MEMORY TEST

2. In the SOUND TEST mode, check the sound related ROMs.

Check such data as game play time and histogram to adjust the

difficulty level, etc

19

7 - 6

8

8

7 - 9

7 - 8

7 - 15

Page 23

7 - 1 SWITCH UNIT AND COIN METER

Never touch places other than those specified. Touching places not

specified can cause electric shock and short circuit.

Adjust to the optimum sound volume by considering the environmental

requirements of the installation location.

If the COIN METER and the game board are electrically disconnected,

game play is not possible.

Open COIN CHUTE DOOR, and the switch unit shown appears. The function of each switch is as follows:

SWITCH UNIT

1

SOUND VOLUME

Controls the speaker volume

of the right/left speakers on the

coin chute tower.

TEST BUTTON (TEST SW)

2

For the handling of the TEST BUTTON,

refer to the section on test mode.

SERVICE BUTTON (SERVICE SW)

3

Gives credits without registering on the coin

meter.

VOL. FRONT

VOL. SEAT

TEST

20

SERVICE

DEMAG. SW.

Page 24

7 - 2 TEST MODE

This mainly checks if the operation of the game BD is accurate, and allows for COIN

ASSIGNMENTS/GAME ASSIGNMENTS setting and Projector adjustments.

TEST MENU

CPU MEMORY TEST

VIDEO MEMORYTEST

BOUNDRY SCAN TEST

INPUT TEST

OUTPUT TEST

SOUND TEST

C.R.T. TEST

GAME ASSIGNMENTS

COIN ASSIGNMNETS

NETWORK ASSIGNMENTS

VOLUME ADJUSTMENTS

REAL TIME CLOCK TEST

BOOKKEEPING

BACKUP DATA CLEAR

>EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

FIG. 7.2 TEST MENU

The Following FIGURES/TABLES show the factory recommended settings.The Following FIGURES/TABLES show the factory recommended settings.

The Following FIGURES/TABLES show the factory recommended settings.

The Following FIGURES/TABLES show the factory recommended settings.The Following FIGURES/TABLES show the factory recommended settings.

7 - 3 MEMORY TEST

CPU ROM TEST

GOOD (CROM03 MASK) IC.1 *****

GOOD (CROM02 MASK) IC.2 *****

GOOD (CROM01 MASK) IC.3 *****

GOOD (CROM00 MASK) IC.4 *****

GOOD (CROM13 MASK) IC.5 *****

GOOD (CROM12 MASK) IC.6 *****

GOOD (CROM11 MASK) IC.7 *****

GOOD (CROM10 MASK) IC.8 *****

GOOD (CROM33 EPROM) IC.9 *****

GOOD (CROM32 EPROM) IC.10 *****

GOOD (CROM31 EPROM) IC.11 *****

GOOD (CROM30 EPROM) IC.12 *****

GOOD (CROM3 EPROM) IC.13 *****

GOOD (CROM2 EPROM) IC.14 *****

GOOD (CROM1 EPROM) IC.15 *****

GOOD (CROM0 EPROM) IC.16 *****

PRESS TEST BUTTON TO EXIT

Push the TEST BUTTON to cause the follow-

1

ing TEST MENU to appear:

By pushing the SERVICE BUTTON, bring the

2

“>” mark to the desired item and press the

TEST BUTTON. This will select the item’s

test.

After the test is complete, move the “>” mark

3

to “EXIT” and press the TEST BUTTON to

return to game mode.

The MEMORY TEST mode is for checking the

on-BD memeory IC functioning.

“GOOD” is displayed for normal ICs and “BAD”

is displayed for abnormal ICs

This test starts immediately after selection from

the menu in the test mode. When in execution, the

“TESTING NOW” message will be displayed at

the lower part to the screen. Press the Test Button

to proceed to CPU RAM TEST

FIG. 7.3a MEMORY TEST

CPU ROM TEST

GOOD (SDRAM) IC. 13 IC. 15

GOOD (BACK UP SRAM) IC. 21 IC. 22

GOOD (SCROLL SDRAM) IC. 94 or IC.19 IC. 20

GOOD (SCROLL SDRAM) IC. 17 IC. 18

PRESS TEST BUTTON TO EXIT

FIG. 7.3b MEMORY TEST

Test starts immediately after proceeding to this

mode from CPU ROM TEST. During execution,

the “TESTING NOW” message will be displayed

at the lower part of the screen. When an error

occurs, the ERROR message is shown. After

finising the test, press the TEST button to return

to the menu mode.

21

Page 25

7 - 4 VIDEO MEMORY TEST

VIDEO BOARD ROM TEST

GOOD (VROM01) IC.26 *****

GOOD (VROM00) IC.27 *****

GOOD (VROM03) IC.28 *****

GOOD (VROM02) IC.29 *****

GOOD (VROM05) IC.30 *****

GOOD (VROM04) IC.31 *****

GOOD (VROM07) IC.32 *****

GOOD (VROM08) IC.33 *****

GOOD (VROM11) IC.34 *****

GOOD (VROM10) IC.35 *****

GOOD (VROM13) IC.36 *****

GOOD (VROM12) IC.37 *****

GOOD (VROM15) IC.38 *****

GOOD (VROM14) IC.39 *****

GOOD (VROM17) IC.40 *****

GOOD (VROM16) IC.41 *****

PRESS TEST BUTTON TO CONTINUE

FIG. 7.4a VIDEO MEMORY TEST

VIDEO BOARD RAM TEST

This allows the functioning of the VIDEO

MEMORY IC’s on the IC board to be checked.

“GOOD” is displayed for normal IC’s and “BAD”

is displayed for abnormal IC’s if any.

Test starts immediately after proceeding to this

mode from the menu in the test mode. During

execution, the “TESTING NOW” message will be

didplayed at the lower portion of the screen. After

fininshing the test, press the TEST BUTTON to

proceed to VIDEO RAM.

Test starts immediately after proceeding to this

mode from the VIDEO BOARD ROM TEST.

During execution, the “TESTING NOW” message

will be displayed at the lower portion of the screen.

If staus is satisfactory, nothing will be displayed.

After fininshing the test, press the TEST BUTTON

to return to the menu mode.

PRESS TEST BUTTON TO CONTINUE

FIG. 7.4b VIDEO MEMORY TEST

7 - 5 BOUNDRY SCAN TEST

BOUNDRY SCAN TEST

TOTAL ERRORS 0

PRESS TEST BUTTON TO EXIT

FIG. 7.5 BOUNDRY SCAN TEST

Selecting the “BOUNDRY SCAN TEST” causes

the Game board’s testing in terms of hardware to be

performed automatically.

When the test is completed, if the results are as

shown left, it is satisfacory.

After finishing the test, press the TEST BUTTON

to have the MENU MODE return on the screen.

Next, turn power off and then turn it back on again.

To avoid malfunctioning, have the Board intialized

by turning the power off and then on.

If there is any hardware problems, an error message

is displayed. Please contact the offices herein stated

or where the product was purchased from.

22

Page 26

7 - 6 INPUT TEST

When INPUT TEST is selected, the MONITOR will show the following, allowing you to watch the status of

each switch and the value of each V.R.

INPUT TEST

HANDLEBAR OFF

THROTTLE OFF

FRONT BRAKE OFF

REAR BRAKE OFF

VIEW CHANGE OFF

MUSIC SELECT OFF

SHIFT UP OFF

SHIFT DOWN OFF

START OFF

COIN #1 OFF

SERVICE-SW OFF

TEST-SW OFF

PRESS TEST BUTTON TO EXIT

FIG. 7.6 INPUT TEST

This test mode displays the status of each switch, button, and

Volu me. When the switch/button corrsponds to the name of

the item is pressed, if OFF changes to ON, it is satisfactory.

When corresponding Volume is operated, if the Volume value

differs in a natural manner, it is satisfactory.

APPROPRIATE VALUE OF TENSION VOLUME

Tension volume values are displayed in hexadecimal numerals within the range of 00H~ffH. If the value does not satisfy

the following limitations, adjust the Volumes gear mesh so as

to meet the requiremnts.

LOWER LIMIT: Over 05H

UPPER LIMIT: Under faH

Press the test button to return to the menu mode

7 - 7 OUTPUT TEST

OUTPUT TEST

START LAMP OFF

VIEW CHANGE LAMP OFF

MUSIC SELECT LAMP OFF

RACE READER LAMP OFF

>EXIT

SELECT WITH SERVICE BUTTON

PRESS TEST BUTTON TO EXIT

FIG. 7.7 OUTPUT TEST

Choose OUTPUT TEST to cause the following lower screen

to appear. In this test, check the status of each lamp.

Pressing the TEST BUTTON causes “ON” to be

displayed and the corresponding lamp lights up.

Pressing the TEST BUTTON again cuases “OFF” to be

displayed and the lamp goes off. The Foot Controller is

locked with the Slide Lock in the ON status, and

Unlocked to become free with the Slide Lock in the

OFF status.

Press the test Button to return to the MENU MODE.

23

Page 27

8

8

8

8

8

8

7

7

7

7

7

7

7

7

7

2

2

2

2

2

2

2

2

2

7 - 8 SOUND TEST

SOUND TEST

NO : ( 0 )

>EXIT

SELECT WITH SERVICE BUTTON

PRESS TEST BUTTON TO EXIT

FIG. 7.8 SOUND TEST

7 - 9 C.R.T. TEST

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

234567890123456789012345678901212345678901

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

23456789012345678901234567

23456789012345678901234567

23456789012345678901234567

23456789012345678901234567

23456789012345678901234567

23456789012345678901234567

C.R.T. TEST 1/2

RED

GREEN

BLUE

WHITE

This enables sound used in the game to be checked.

Sound related memory and each speaker are checked.

Press the SERVICE BUTTON to increse the number by

one and the sound corresponding to the number will be

emitted. Note that No. 000 does not emit any sound.

Bring the “>” to EXIT and press the TEST BUTTON to

return to the MENU MODE.

Select C.R.T. TEST to cause the MONITOR to display the

screen shown left, allowing MONITOR adjustment status

to be checked.

Periodically check the MONITOR adjustment status on

this screen.

The screen (1/2) enables color adjustment check to be

performed. The color bar of each of the 4 colors, i.e.,red,

green, blue, and white, is the darkest at the extreme left and

becomes brighter towards the extreme right.

PRESS TEST BUTTON TO CONTINUE

C.R.T. TEST 2/2

PRESS TEST BUTTON TO EXIT

FIG. 7.9 C.R.T. TEST

Press the TEST BUTTON to shift to the next screen (2/2).

The screen (2/2) allows screen size and distortion to be

tested.

Check if the CROSSHATCH FRAME LINE goes out of

the screen and if the crosshatch lines are distorted.

Press the TEST BUTTON to return to the MENU mode.

24

Page 28

7 - 10 GAME ASSIGNMENTS

Selecting the GAME ASSIGNMENTS in the MENU mode causes the present game settings

to be displayed and also the game settings changes (game difficulty, etc.) can be made. Each

item displays the following content.

SETTING CHANGE PROCEDURE

Setting changes cannot be stored unless the TEST BUTTON is pressed

while the arrow is on EXIT.

Press the SERVICE BUTTON to move the “>” to the desired item.

1

Choose the desired setting change item by using the TEST BUTTON.

2

To return to the MENU mode, move the arrow to EXIT and press the TEST BUTTON.

3

GAME ASSIGNMENTS

ADVERTISE SOUND ON

GAME DIFFICULTY NORMAL

CABINET TYPE ST ANDARD

B.G.M. VOLUME 4

ENGINE VOLUME 8

NUMBER OF STAGES 4

TOURNAMENT MODE ON

START

MONTH DEC

DAY 25

YEAR 1998

HOUR 18

END

MONTH DEC

DAY 25

YEAR 1998

HOUR 18

DURATION DAILY

> EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTTON

ADVERTISE SOUND

Determines wether ADVERTISE SOUND is to

be emitted or not by the setting to ON when

emitting it and to OFF when not emitting it.

GAME DIFFICULTY

Sets the Game Difficulty in 5 catagories from 1 to

8. The greater the number is, the higher the

difficulty level becomes. Alternately it may

display each catagory by name;

Very Easy, Easy, Normal, Hard, Very Hard

B.G.M. VOLUME

BGM Volume Adjustment.

ENGINE VOLUME

Engine Volume adjustment

CABINET TYPE

Set to DELUXE or STANDARD as applicable. Setting to wrong type can causefailure be sure to

set correctly. (i.e. In communication Play Race Leader Lamp does not light up/flash/light out.

The Cabinet appearing in the operation explanation mode differs from the type used.)

TOURNAMENT MODE

During the period set, special bookkeeping for ranking is executed. When set to ON, as shown

above, the date of Tournament Mode Start, the end date of Tournament Mode, and itmes of

bookkeeping periods are displayed. Duration refers to the unit of bookkeeping periods. The

setting can be selected from among DAILY, WEEKLY, BI-WEEKLY, and MONTHLY.Be sure

to set the present time in the Tournament Mode.

The Following FIGURES/TABLES show the factory recommended settings.The Following FIGURES/TABLES show the factory recommended settings.

The Following FIGURES/TABLES show the factory recommended settings.

The Following FIGURES/TABLES show the factory recommended settings.The Following FIGURES/TABLES show the factory recommended settings.

25

Page 29

7 - 11 COIN ASSIGNMENTS

The “COIN ASSIGNMENTS” mode permits you to set the start number of credits, as well as the basic numbers

of coins and credits. This mode expresses “how many coins correspond to how many credits.”

SETTING CHANGE PROCEDURE

Setting changes cannot be stored unless the TEST BUTTON is pressed

while the arrow is on EXIT.

Press the SERVICE BUTTON to move the arrow to the desired item.

1

Choose the desired setting change item by using the TEST BUTTON.

2

To return to the MENU mode, move the arrow to EXIT and press the TEST BUTTON.

3

COIN ASSIGNMENTS

COIN CHUTE TYPE COMMON

CREDIT TO STAR T 2 CREDITS

CREDIT TO CONTINUE 1 CREDIT

COIN/CREDIT SETTING #1

CHUTE#1 1 COIN 1 CREDIT

COIN CHUTE TYPE

Sets the combination of the number of COIN CHUTEs and

the number of players as applicable. In the case that the

COIN CHUTE is changed, be sure the setting is made in a

manner meeting the replaced coin chute.

CHUTE#2 1 COIN 1 CREDIT

COMMON:

Coins are accepted in common for both players.

MANUAL SETTING

INDIVIDUAL:

>EXIT

Each player uses a coin chute which accepts coins independently.

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

CREDIT TO ST ART

Number of credits required for starting game (1~5 credits are selected.)

CREDIT TO CONTINUE

Number of credits required for continuing game (1~5 credits are selected.)

COIN/CREDIT SETTING

Sets the CREDITS increase increment per coin insertion. There are 27 setings from #1 to #27, expressed in

XX CREDIT as against XX COINS inserted. (TABLE 7.11a, 7.11b) #27 refers to FREE PLAY.

When the COIN CHUTE TYPE is set to INDIVIDUAL, there are some setting numbers not displayed as

indicated in TABLE 7.11b.

MANUAL SETTING

This allows credit increase setting as against coin insertion to be further set in the manner finer than COIN/

CREDIT SETTING (refer to TABLE 7.11c).

26

Page 30

TABLE 7.11a COIN/CREDIT SETTING (COIN CHUTE COMMON TYPE)

SETTING FUNCTIONING OF CHUTE#1

SETTING #1 1 COIN 1 CREDIT

SETTING #2 1 COIN 2 CREDITS

SETTING #3 1 COIN 3 CREDITS

SETTING #4 1 COIN 4 CREDITS

SETTING #5 1 COIN 5 CREDITS

SETTING #6 1 COIN 2 CREDITS

SETTING #7 1 COIN 5 CREDITS

SETTING #8 1 COIN 3 CREDITS

SETTING #9 1 COIN 4 CREDITS

SETTING #10 1 COIN 5 CREDITS

SETTING #11 1 COIN 6 CREDITS

SETTING #12 2 COINS 1 CREDIT

SETTING #13 1 COIN 1 CREDIT

SETTING #14 1 COIN 2 CREDITS

SETTING #15 1 COIN 1 CREDIT

2 COINS 3 CREDITS

SETTING #16 1 COIN 3 CREDITS

SETTING #17 3 COINS 1 CREDIT

SETTING #18 4 COINS 1 CREDIT

SETTING #19 1 COIN 1 CREDIT

2 COINS 2 CREDITS

3 COINS 3 CREDITS

4 COINS 5 CREDITS

SETTING #20 1 COIN 5 CREDITS

SETTING #21 5 COINS 1 CREDIT

SETTING #22 1 COIN 2 CREDITS

SETTING #23 2 COINS 1 CREDIT

4 COINS 2 CREDITS

5 COINS 3 CREDITS

SETTING #24 1 COIN 3 CREDITS

SETTING #25 1 COIN 1 CREDIT

2 COINS 2 CREDITS

3 COINS 3 CREDITS

4 COINS 4 CREDITS

5 COINS 6 CREDITS

SETTING #26 1 COIN 1 CREDITS

SETTING #27 FREE PLAY

27

Page 31

MANUAL SETTING

Selecting MANUAL SETTING in the COIN ASSIGNMENTS mode displays the following screen.

MANUAL SETTING

COIN TO CREDIT 1 COIN 1 CREDIT

BONUS ADDER NO BONUS ADDER

1

2

COIN CHUTE #1 MULTIPLIER

1 COIN COUNTS AS 1 COIN

COIN 1 2 3 4 5 6 7 8 9

CREDIT 1 2 3 4 5 6 7 8 9

COIN CHUTE #2 MULTIPLIER

1 COIN COUNTS AS 1 COIN

COIN 1 2 3 4 5 6 7 8 9

CREDIT 1 2 3 4 5 6 7 8 9

>EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

FIG. 7.11b MANUAL SETTING

1

Determines Coin/Credit setting.

2

This sets how many coins should be inserted to obtain one Service Coin.

This sets how many tokens one coin represents.

3

Table 7.11c MANUAL SETTING

COIN TO CREDIT 1 COIN 1 CREDIT

3

2 COINS 1 CREDIT

3 COINS 1 CREDIT

4 COINS 1 CREDIT

5 COINS 1 CREDIT

6 COINS 1 CREDIT

7 COINS 1 CREDIT

8 COINS 1 CREDIT

9 COINS 1 CREDIT

BONUS ADDER NO BONUS ADDER

2 COINS GIVE 1 EXTRA COIN

3 COINS GIVE 1 EXTRA COIN

4 COINS GIVE 1 EXTRA COIN

5 COINS GIVE 1 EXTRA COIN

6 COINS GIVE 1 EXTRA COIN

7 COINS GIVE 1 EXTRA COIN

8 COINS GIVE 1 EXTRA COIN

9 COINS GIVE 1 EXTRA COIN

COIN CHUTE MULTIPLIER 1 COIN COUNTS AS 1 COIN

1 COIN COUNTS AS 2 COINS

1 COIN COUNTS AS 3 COINS

1 COIN COUNTS AS 4 COINS

1 COIN COUNTS AS 5 COINS

1 COIN COUNTS AS 6 COINS

1 COIN COUNTS AS 7 COINS

1 COIN COUNTS AS 8 COINS

1 COIN COUNTS AS 9 COINS

28

Page 32

7 - 12 REAL TIME CLOCK TEST

REAL TIME CLOCK TEST

The system of this product has calandar functions. In the Game

Assignments, if the Tournament mode is set to ON, ensure the

present time is correct in this mode.

25 DEC 1997 THRU 18: 55’30”

BATTERY O.K.

DAY 25

MONTH DEC

YEAR 1997

HOUR 18

MINUTE 55

SECOND 30

DAY OF THE WEEK THU

SET

>EXIT

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

Fig. 7.12 REAL TIME CLOCK TEST

7 - 13 VOLUME ADJUSTMENTS

VOLUME ADJUSTMENTS

HANDLE BAR MIN (00) MAX (FF) NUETRAL (80)

THROTTLE MIN (00) MAX (FF) CHECKING (00)

FRONT BRAKE MIN (00) MAX (FF) CHECKING (00)

REAR BRAKE MIN (00) MAX (FF) CHECKING (00)

1. Press the Service button and bring arrow to the desired item to

be changed.

2. Press the test button to change year, month, day, and hour.

3. Bring the arrow to SET and press test button.

4. Move the arrow to EXIT and press the TEST button to return to

menu mode.

In the case an appropriate value is not displayed in the input

test mode, the Volume can be adjusted in this mode. Set an

appropriate Volume value by moving the HandleBar, Accelerator Grip, Front Brake, and Rear Brake fully within it’s movable

range. The numeral values are hexadecimally displayed.

HANDLE BAR: After turning the handlebar fully to the left

and right, return it to the cneter and ensure the status in

which force is not exerted.

THROTTLE: After fully moving accelerator grip, let go

your hold and return to the status in which force is not

exerted.

FRONT BRAKE: Fully grip the front brake and let go your

hold, then return to the status in which force is not exerted.

REAR BRAKE: Fully step on the rear brake pedal and then

release to return to the status of which force is not exerted.

EXIT WITH SAVE

>EXIT WITHOUT SAVE

SELECT WITH SERVICE BUTTON AND

PRESS TEST BUTTON TO EXIT

Fig. 7.13b VOLUME SETTING

7 - 14 NETWORK ASSIGNMENTS

NETWORK ASSIGNMENTS

COMMUNICATION NETWORK

PRIVILEGE MODE MASTER

CABINET ID NUMBER 1

>EXIT

SELECT WITH SERVICE BUTTON

PRESS TEST BUTTON TO EXIT

FIG. 7.14 NETWORK ASSSIGNMENTS

Bring the cursor to EXIT WITH SAVE and press the test

button to have the contents of the new input setting registered and return to the menu mode.

Bring the cursor to EXIT WITHOUT SAVE to return to the

menu mode without changing the current settings.

THIS TEST MENU ALLOWS FOR THE ADJUSTMENT

OF THE NETWORK SETUP.

COMMUNICATION: Select NETWORK or STAND

ALONE. When NETWORK is selected, the following are

displayed.

PRIVILEGED MODE: In the case plural machines are used

for interactive play, set one of them to MASTER and set the

rest of them to SLAVE. The Game Assignments set to the

MASTER cabinet will also be applied to the SLAVE

cabinets. Changing the settings by the SLAVE units is

ineffective.

CABINET ID NUMBER: In the case of plural machines are

linked for interactive play, set the CABINET ID NUMBER

in the order of 1, 2, 3, and 4 starting from the left most

cabinet as seen from the front of the cabinet. If an identical

number is set to 2 or more cabinets or if settings is made in

the wrong order, the display during the game will be

incorrect. Be careful of this point.

29

Page 33

7 - 15 BOOKKEEPING

Choosing BOOKKEEPING in the MENU mode displays the data of operating status up to the present are shown on 2

pages. Press the TEST BUTTON to proceed to PAGE 2/2.

BOOKKEEPING PAGE1/2

COIN REPORT

COIN CHUTE #1 XXXXXXXXXXX

COIN CHUTE #2 XXXXXXXXXXX

TOTAL COINS XXXXXXXXXXX

COIN CREDITS XXXXXXXXXXX

SERVICE CREDITS XXXXXXXXXXX

TOTAL CREDITS XXXXXXXXXXX

NUMBER OF GAMES

1 P GAMES XXXXXXXXXXX

2 P GAMES XXXXXXXXXXX

NUMBER OF CONTINUE

1 P GAMES XXXXXXXXXXX

2 P GAMES XXXXXXXXXXX

TOTAL TIME XDXXHXXMXXS

PLAY TIME XDXXHXXMXXS

AVERAGE PLAY TIME XXMXXS

LONGEST PLAY TIME XXMXXS

SHORTETEST PLAY TIME XXMXXS

PRESS TEST BUTTON TO CONTINUE

FIG. 7.15a BOOKKEEPING (1/2)

BOOKKEEPING PAGE 2/2

TIME HISTOGRAM

0M00S ~ 0M29S XXXXXXXX

0M30S ~ 0M39S XXXXXXXX

0M40S ~ 0M49S XXXXXXXX

0M50S ~ 0M59S XXXXXXXX

1M00S ~ 1M09S XXXXXXXX

1M10S ~ 1M19S XXXXXXXX

1M20S ~ 1M29S XXXXXXXX

1M30S ~ 1M39S XXXXXXXX

1M40S ~ 1M49S XXXXXXXX

1M50S ~ 1M59S XXXXXXXX

4M00S ~ 4M09S XXXXXXXX

4M10S ~ 4M19S XXXXXXXX

4M20S ~ 4M29S XXXXXXXX

4M30S ~ 4M39S XXXXXXXX

4M40S ~ 4M49S XXXXXXXX

4M50S ~ 4M59S XXXXXXXX

5M00S ~ XXXXXXXX

COIN CHUTE#*:

Number of coins put in each Coin Chute.

TOTAL COINS:

Total number of activations of Coin Chutes.

COIN CREDITS:

Number of credits registered by inserting coins.

SERVICE CREDITS:

Credits registered by the SERVICE BUTTON.

TOTAL CREDITS:

Total number of credits (COIN CREDITS+SERVICE

CREDITS).

TOTAL TIME:

The total energized time.

On page (2/2), each play frequency is displayed. When

setting difficulty levels, the frequency can be refered to as a

standard.

When in the PAGE 2/2 mode, press the TEST BUTTON to

return to the MENU mode.

PRESS TEST BUTTON TO EXIT

FIG. 7.15b BOOKKEEPING (2/2)

7 - 16 BACKUP DATA CLEAR

BACKUP DATA CLEAR

>NO (CANCEL)

SELECT WITH SERVICE BUTTON

PRESS TEST BUTTON TO EXIT

FIG. 7.16 BACKUP DATA CLEAR

YES (CLEAR)

Clears the contents of BOOKKEEPING and high

score player ranking entry.

When clearing, bring the arrow to “YES” and when

not clearing, to “NO”, by using the SERVICE

BUTTON, and push the TEST BUTTON.

When the data has been cleared, “COMPLETED”

will be displayed. Bring the arrow to “NO” and

press the TEST BUTTON to cause the MENU

mode to return on to the screen.

Note that the contents of the GAME SETTING,

COIN SETTING, and BOARD SETTING are not

affected by BACKUP DATA CLEAR operation

30

.

Page 34

8 . HANDLEBAR

In order to prevent an electric shock and short circuit, be sure to turn power off

before performing work by touching the interior parts of the product.

Be careful so as not to damage wirings. Damaged wiring can cause an electric shock

or short circuit accident.

8 - 1 ADJUSTING/REPLACING THE FRONT BRAKE VOLUME

In the test mode, if the Front Brake Volume’s Value movements are irregular, adjust or replace the Volume by

using the following procedure:

Take out the 4 screws and remove the VR cover.

The Front Brake Volume is inside the VR cover.

VOLUME ADJUSTMENT

Loosen the 2 screws which secure the VR bracket to move the VR Bracket.

1

Move the VR Bracket to disengage the gear mesh.

2

3

By adjusting gear mesh, fasten the 2 screws which secure VR Bracket.

4

Move the Brake Lever fully to the movable range and check if the Volume Shaft’s revolvable range is exceeded.

After adjustment, be sure to perform the Volume setting in the Test Mode.

5

SCREW (4)

M4x8

VOLUME ADJUSTMENT

Replace the Volume if it is malfunctioning.

Install the Volume in the manner so that 20+/-5

is indicated when force is not exerted.

Remove the 2 screws which secure the VR

1

Bracket.

Remove the Volume Gear from the Volume

2

Shaft and remove the Volume from the VR

Bracket to replace the volume.

After the replacement, be sure to perform the

3

Volume setting in the Test Mode.

VOLUME

220-5484

VR BRACKET

SCREW (2)

M4x8

31

Page 35

8 - 2 ADJUSTING/REPLACING THE ACCELERATOR VOLUME

In the test mode, if the Front Brake Volume’s Value movements are irregular, adjust or replace the Volume by

using the following procedure:

Take out the 4 screws and remove the VR cover.

The Front Brake Volume is inside the VR cover.

VOLUME ADJUSTMENT

Loosen the 2 screws which secure the VR

1

bracket to move the VR Bracket.

Move the VR Bracket to disengage the

2

gear mesh.

By adjusting gear mesh, fasten the 2

3

screws which secure VR Bracket.

Move the Brake Lever fully to the movable

4

range and check if the Volume Shaft’s

revolvable range is exceeded.

After adjustment, be sure to perform the

5

Volume setting in the Test Mode.

TRUSS SCREW (4)

M4x8

ACCELERATOR GRIP

VOLUME ADJUSTMENT

Replace the Volume if it is malfunctioning.

Install the Volume in the manner so that 20+/-5

is indicated when force is not exerted.

Remove the 2 screws which secure the VR

1

Bracket.

Remove the Volume Gear from the Volume

2

Shaft and remove the Volume from the VR

Bracket to replace the volume.

After the replacement, be sure to perform the

3

Volume setting in the Test Mode.

VOLUME

ACCELERATOR VR BRACKET

VR COVER

SCREW (1)

M4x8

32

Page 36

8 - 3 ADJUSTING/REPLACING THE HANDLEBAR VOLUME

In the Test Mode, if the HandleBar Volume’s value movements are irregular, adjust or replace the Volume.

Remove the 4 screws.

1

TRUSS SCREW (4)

M4x8 (black)

CONNECTORS

2

Disconnect the 3 connectors and remove

the mask cover.

When the mask cover is removed, monitor

screen adjustment knob appears.

ADJUSTMENT KNOB

33

Page 37

3

Remove the bolt w/hexagon hole and pull out the

handle from the shaft.

Bolt w/hexagon hole

M10x20,

w/flat and spring washers

4

Take out the 3 screws, disconnect the connector inside the tank, and remove the tank.

TRUSS SCREW (3)

M4x12, Flat washer

34

CONNECTOR

8P YELLOW

Page 38

SCREW (1)

M4x8,

w/ flat and spring washers

Remove the 4 hexagon nuts which secure the

5

centering mecha. By viewing the centering mecha

from above, remove the hexagon nuts from the

four corners only.

HEXAGON NUT (4)

M8

w/ flat and spring washers

6

Carefully lift the centering mecha and disconnect

the connector connected to the centering mecha.

35

Page 39

V.R. ADJUSTMENT

Do not touch places other than those specified. Touching placers not specified can

cause an electric shock and /or short circuit accident.

Loosen the 2 screws which secure the V.R.

1

Bracket to move the V.R. Bracket.

Move the V.R. Bracket to disengage ADJUST

2

GEAR mesh and move the V.R. shaft in the

manner so that the V.R. shaft cut portion faces

the oppisite side of ADJUST GEAR as shown.

Have the gears meshed and tighten the 2

3

screws.

4

Carefully turn the Handle Shaft to left/right

and check to ensure the value variation is

within the mobile range of the Volume.

After finishing adjustments, be sure to perform

5

Volume Setting in Test Mode.

SCREW (2)

M4x8

GEAR

V.R. SHAFT

ADJUST GEAR

V.R. BRACKET

V.R. REPLACEMENT

SCREW (2)

M4x8

HANDLE V.R.

Take out the 2 screws which secure the Volume

1

Bracket to remove the Volume Bracket.

2

Remove the Volume Gear fromt he V.R. to

replace the V.R.

After the replacement, perform Volume Setting

3

in the Test Mode.

36

Page 40

8 - 4 GREASING

Be sure to use the designated grease. Using undesignated grease can cause parts

damage.

Do not apply greasing to places other than those specified. Greasing to undesignated

places can cause malfunctioning and the quanlitative deterioration of parts.

Once every three months, apply greasing to the following places.

For Greasing use Grease Mate (P.No. 090-0066).

GEAR MESH PORTION

(FRONT V.R.)

GEAR MESH PORTION

(ACCELERATOR)

SLIDING FACE OF BRAKE

GEAR MESH PORTION

(FRONT V.R.)

37

Page 41

9. FOOT BRAKE MECHA

In order to prevent an electric shock and short circuit, be sure to turn power off

before performing work by touching the interior parts of the product.

Be careful so as not to damage wirings. Damaged wiring can cause an electric

shock or short circuit accident.

Do not touch places other than those specified. Touching places not specified can

cause an electric shock or short circuit accident.

9 - 1 ADJUSTING AND REPLACING THE VOLUME

In the Test Mode, if the Rear Brake’s (Foot Brake’s) volume movements are irregular, adjust or replace the Volume

by using the following procedure.

1

Remove the 6 screws.

Disconnect the connector, and remove the Foot Brake Mecha from the cabinet.

2

FOOT BRAKE MECHA

TRUSS SCREW (6)

M6x16, chrome

TRUSS SCREW (6)

M6x16, chrome

CONNECTOR

WHITE 4P

38

Page 42

V.R. ADJUSTMENT

Loosen the 2 screws which secure the V.R.

1

Plate to move the V.R. Plate.

Move the V.R. Plate to disengage ADJUST

2

GEAR mesh and move the V.R. shaft and

ensure that when force is not exerted on the

pedal, the cut face of the Volume Shaft faces in

the direction shown.

Have the gears meshed and tighten the 2

3

screws. At this time, tighten gear backlash.

4

Carefully move pedal fully within the movable

range and check if the Volume range is

exceeded.

After finishing adjustments, be sure to perform

5

Volume Setting in Test Mode.

V.R. REPLACEMENT

SCREW (2) M4x8,

w/flat and spring washers

V.R. SHAFT

V.R. PLATE

ADJUST GEAR

Take out the 2 screws which secure the Volume

1

Plate to remove the Volume Plate.

2

Remove the Volume Gear from the V.R. to

replace the V.R.

3

After the replacement, perform Volume Setting

in the Test Mode.

39

Page 43

9 - 2 GREASING

Be sure to use the designated grease. Using undesignated grease can cause parts

damage.

Do not apply greasing to places other than those specified. Greasing to undesignated

places can cause malfunctioning and the quanlitative deterioration of parts.

Once every three months, apply greasing to the following places.

For Greasing use Grease Mate (P.No. 090-0066).

GEAR MESH PORTION

SLIDING FACE OF SPRING AND SHAFT

40

Page 44

10 . COIN SELECTOR

HANDLING THE COIN JAM

If the coin is not rejected when the REJECT BUTTON is pressed, open the coin chute door

and open the selector gate. After removing the jammed coin, put a normal coin in and check

to see that the selector correctly functions.

CLEANING THE COIN SELECTOR

The coin selector should be cleaned

once every 3 months. When cleaning,

follow the procedure below:

Turn the power for the machine OFF.

1

Open the coin chute door.

Open the gate and dust off by using a

2

soft brush (made of wool, etc.).

3

Remove and cleen smears by using a

soft cloth dipped in water or diluted

chemical detergent and then squeezed

dry.

Remove the CRADLE.

4

When removing the retaining ring(Ering), be very careful so as not to bend

the shaft.

Remove stain from the shaft and pillow

5

portions by wiping off with a soft cloth,

etc.

After wiping as per #5 above, further

6

apply a dry cloth, etc. to cause the coin

selector to dry completely.

GATE

FIG. 9a

CRADLE

FIG.9b

Never apply machine oil, etc. to

the coin selector

After cleaning the Coin Selecting,

Insert a regular coin in the normal

working status and ensure that

the Selector correctly functions

COIN INSERTION TEST

Once a month, when performing the COIN SW

TEST, simultaneously check the following:

Does the Coin Meter count satisfactorily?

Does the coin drop into the Cashbox correctly?

Is the coin rejected when inserted while keeping

the REJECT BUTTON is pressed down?

.

Insert a coin

while keeping

the Reject

Button pressed

down and check

if it is

rejected.

COIN METER

FIG. 9c

41

Page 45

OPTIONAL DOLLAR BILL ACCEPTOR

THE COIN DOOR ASSEMBLY USED ON

HARLEY DAVIDSON U/R HARLEY DAVIDSON U/R

HARLEY DAVIDSON U/R

HARLEY DAVIDSON U/R HARLEY DAVIDSON U/R

COMES EQUIPPED TO ACCEPT A DOLLAR BILL ACCEPTOR. ALL

NEEDED WIRING CONNECTIONS ARE CONVIENENTLY LOCATED INSIDE

THE GAME FOR THIS APPLICATION.

THE COIN DOOR CAN ACCCOMMODATE THE FOLLOWING

VALIDATORS:

HOLE POSITION#1 Mars 2000 series

(FORWARD-MOST POSITION)

HOLE POSITION#2 Mars 2000 series

DBV45 (JCM)

HOLE POSITION #3 CURRENTLY NOT USED

HOLE POSITION #4 DSI01*

*The back flange on the chute can be removed for hold position #4.

If the flange is not removed, it may interfere with the back of the

cabinent.

The frame and cashbox enclosure on this coindoor has been modified to accomodate a Mars 2000 series

upstacker. A 2000 series stacker can be added by simply removing the top two entry door and replacing it with a one

entry door with a cut-out for a stacker. This one entry door can be ordered through Coin Controls or one of Coin Controls

autherized distributors. The part number is 91-4000-01. The Mars stacker can be obtained through an autherized Mars

distibutor.

42

Page 46

43

Page 47

11 . MONITOR

When performing such work as installing and removing the monitor, inserting and disconnecting the external connectors to and from monitor, be sure to disconnect the power connector

(plug) before starting work. Proceeding the work without following this instruction can cause

electric shock of malfunctioning.

Using the monitor by converting it without obtaining a prior permission is not allowed. SEGA

shall not be liable for any malfunctioning and accident caused by said conversion.

Primary side and secondary sidePrimary side and secondary side

Primary side and secondary side

Primary side and secondary sidePrimary side and secondary side

The monitor’s circuit which is divided into the Primary

side and secondary side, is electrically isolated. Do

not touch the primary side and the secondary side

simultaneously. Failing to observe the instruction can

cause electric shock, and this is very dangerous.

When making monitor adjustments, use a nonconductive driver and make adjustment without

touching any other part other than the Adjustment

V.R. and Knob. Also, be sure not to cause a shortcircuit to the Primary side and the Secondary side. If

short-circuited, it can cause electric shock or malfunctioning, which is very dangerous.

High tension VoltageHigh tension Voltage

High tension Voltage

High tension VoltageHigh tension Voltage

Some of the parts inside the monitor are subject to high-tension voltage in excess of 20,000

volts and very dangerous. Therefore, do not touch the monitor interior. Should soldering &

paper wastes, etc. be mixed in the monitor, turn the power off so as not to cause malfunctioning or fire hazard.

Connecting the CRT and PCBConnecting the CRT and PCB

Connecting the CRT and PCB

Connecting the CRT and PCBConnecting the CRT and PCB

For combining the CRT and PCB, use the specified part No. to maintain the status of adjustments made at the factory. The anode of the CRT itself will be accumulitavly charged as time

elapses, generating high tension voltage which is very dangerous. The monitor should be used

with the Chassis, CRT and PCB assembled. When repair, etc. is required at the time of malfunctioning, be sure to send it in an “as assembled” condition. If these are dissassembled, what’s

charged to said high tension voltage can be discharged, cuasing a very hazardous situation.

Therefore, under no circumstances should it be dissasembled.

Static ElectricityStatic Electricity

Static Electricity

Static ElectricityStatic Electricity

Touching the CRT surface sometimes cuases you to slightly feel electricity. this is because the

CRT surfaces are subject to static and will not adversly affect the human body.

Installation and removalInstallation and removal

Installation and removal

Installation and removalInstallation and removal

Ensure that the Magnetizer Coil, FBT (Fly-Back Transformer), Anode Lead and Focus Lead are

not positioned close to the sheet metal work’s sharp edges, etc. and avoid damaging the

insulated portions so as no to cause an electric shock and malfunctioning. (For the name of

parts, refer to the above figures.)

44

Page 48

For the purpose of static prevention,

special coating is applied to the CRT

face of this product. To protect the

coating, pay attention to the following

points. Damaging the coating film can

cause electric shock to the customers.

For the caution to be heeded when

clearing, refer to the Section of Periodic

inspection Table.

Do not apply or rub with a hard item (a

rod with pointed edge, pen, etc.) to or

on C.R.T. surfaces.

Avoid applying stoickers, seals, etc. on

the C.R.T. face.

Do not remove aluminum foils from the

C.R.T. corners. Removing the aluminum

foils can cause static prevention effects

to be lowered.

45

Page 49

46

Page 50

12 . REPLACEMENT OF FLUORESCENT LAMP AND LAMPS

When performing the work, be sure to turn power off. Working

with power on can cause an electric shock or short circuit accident.

The Flourescent Lamp, when it gets hot, can cause burns. Be

very careful when replacing the Fluorescent Lamp.

To perform work safely and securely, be sure to prepare a step which is in a

secure and stable condition. Not using a step or using an unstable step can

cause a violent falling down accidents.

12 -1 REPLACEMENT OF FLUORESCENT LAMP

Take off the 3 screws which secure the Holder on the upper part of Billboard.

1

2

Take out the billboard from the cabinet and replace the fluorescent lamp (20W)

47

Page 51

12 - 2 REPLACING THE LAMP

1

Take out the screw to remove the lamp from the lamp body.

By using a flat blade screwdriver, remove the 3 inside fasteners.

2

As shown left, dissassmble the lamp parts and replace the lamp.

3

48

Page 52

13 . PERIODIC INSPECTION TABLE

The items listed below require periodic check and maintenance to retain the performance of

this machine and ensure safe operation.

Be sure to check once a year to see if Power Cords are damaged,

the plug is securley inserted, dust is accumulated between the

Socket Outlet and the Power Plug, etc. Using the product with

dust as is accumulated can cause a fire or electrical shock.

Periodically once a year, request the place of contact herin stated

or the Distributer, etc. where the product was purchased from, as

regards the interior cleaning. Using the product with dust as is

accumulated in the interior without cleaning can cause a fire or

accident. Note that cleaning the interior parts can be performed

on a pay-basis.

ITEMS DESCRIPTION PERIOD REFERENCE

BIKE MECHA Volume V.R. inspection Monthly 7, 8

Greasing to gears and springs Monthly 8

Memory T est Monthly 7

Setting Check Monthly 7

BRAKE MECHA SW Volume inspection Monthly 7, 8

Greasing to gears and springs Tri-monthly 8

Check Volume V alue. Monthly 7

COIN SELECTOR Check COIN SW Monthly 7

COIN SELECTOR cleaning Trimonthly 10

PROJECTOR Screen cleaning Weekly 11

Check adjustments Monthly 4, 7, 11

GAME BD Setting check Monthly 7

INTERIOR Cleaning Annually see above.

POWER PLUG Inspection and cleaning

CABINET SURFACES Cleaning As necessary see below

CLEANING CABINET SURFACES

If the cabinet is badly stained, use a cloth which is dipped in the chemical detergent liquid diluted with water and then

suezzed dry. Do not use thinner, benzine, alcohol or chemical dustcloth as these can damage Cabinet surfaces.

49

Page 53

14 . TROUBLESHOOTING

Should trouble occur, first check connector connections.

PROBLEMS CAUSE COUNTERMEASURES

With Main SW Power is not supplied. Plug in correctly

ON, no activation

Power supply/voltage is not correct. Make sure that power supply/voltage is

correct.

AC main fuse causes the Check fuse. Remove the cause of

power to be cut off due to momentary overload and replace fuse

overload.

Operation is Volume Setting Failure Perform Volume setting

unsatisfactory Adjust or replace V.R.

Poor mesh of V.R. gear.

Adjust Gear mesh..

Spring failure due to secular change

of Accelerator and brake mecha. Replace the Spring.

Irregular sound Greasing to gear mesh portion is not Apply greasing or eliminate extraneous

emitted from satisfactory, or extraneous matter matter.

inside Rear Cabinet mixed in.

The color of the Connector connections are defective. Check the connection for the RGB and

image on PROJ. SYNC connectors of the PROJ. TERM.

screen is incorrect. BD and VPM BUFFER BD.

The image on PROJ. Affected by the magnetic field of Make CONVERGENCE adjustment.

screen has color installation location. (Refer to Section 9.)

deviation.