Page 1

A

www.securitron.com | techsupport@securitron.com

© 2015, Hanchett Entry Systems, Inc., an ASSA ABLOY Group company.

C

B

C

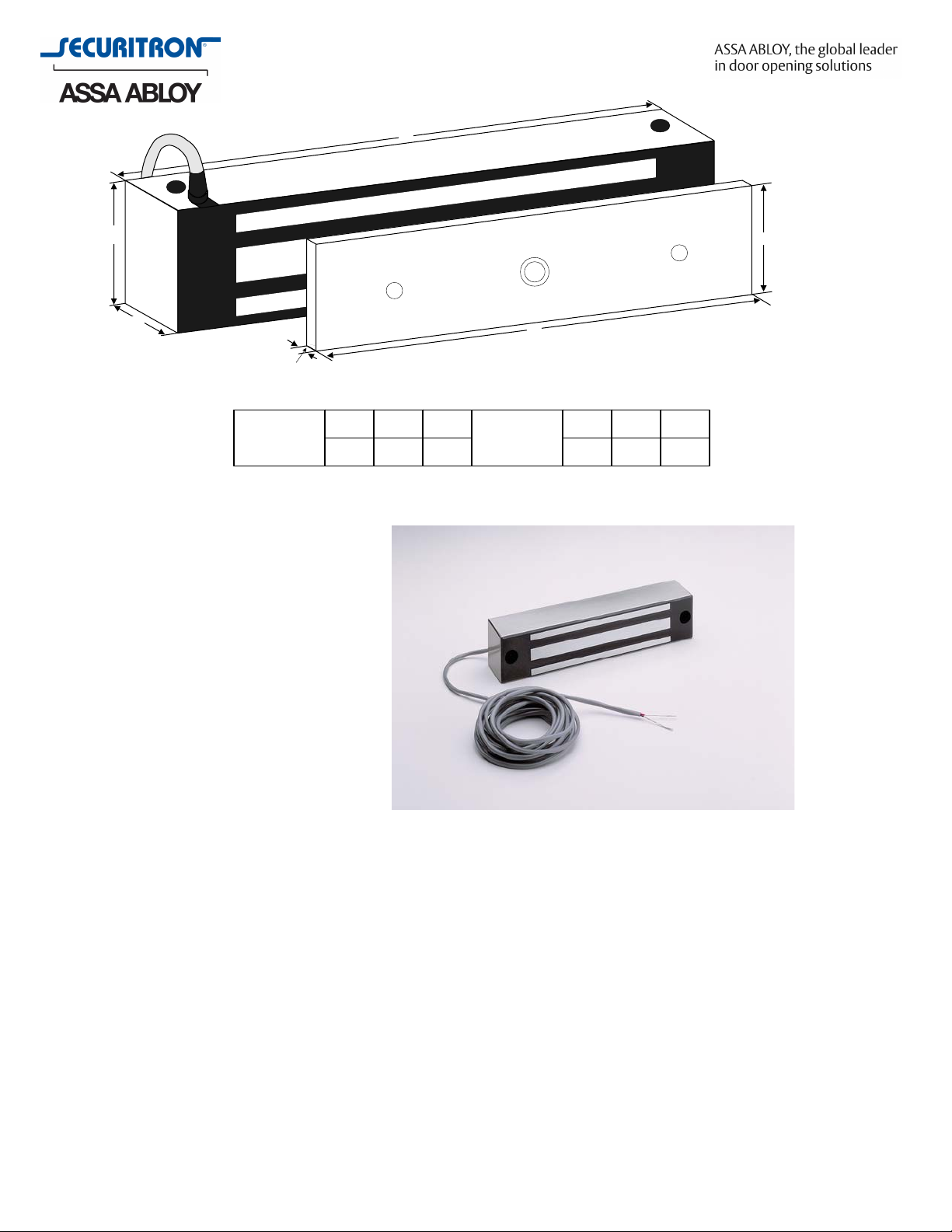

MODEL 32

MAGNET

A

8B1.5C1.88

MODEL 32

A

STRIKE

A

6.25B1.63C.5

B

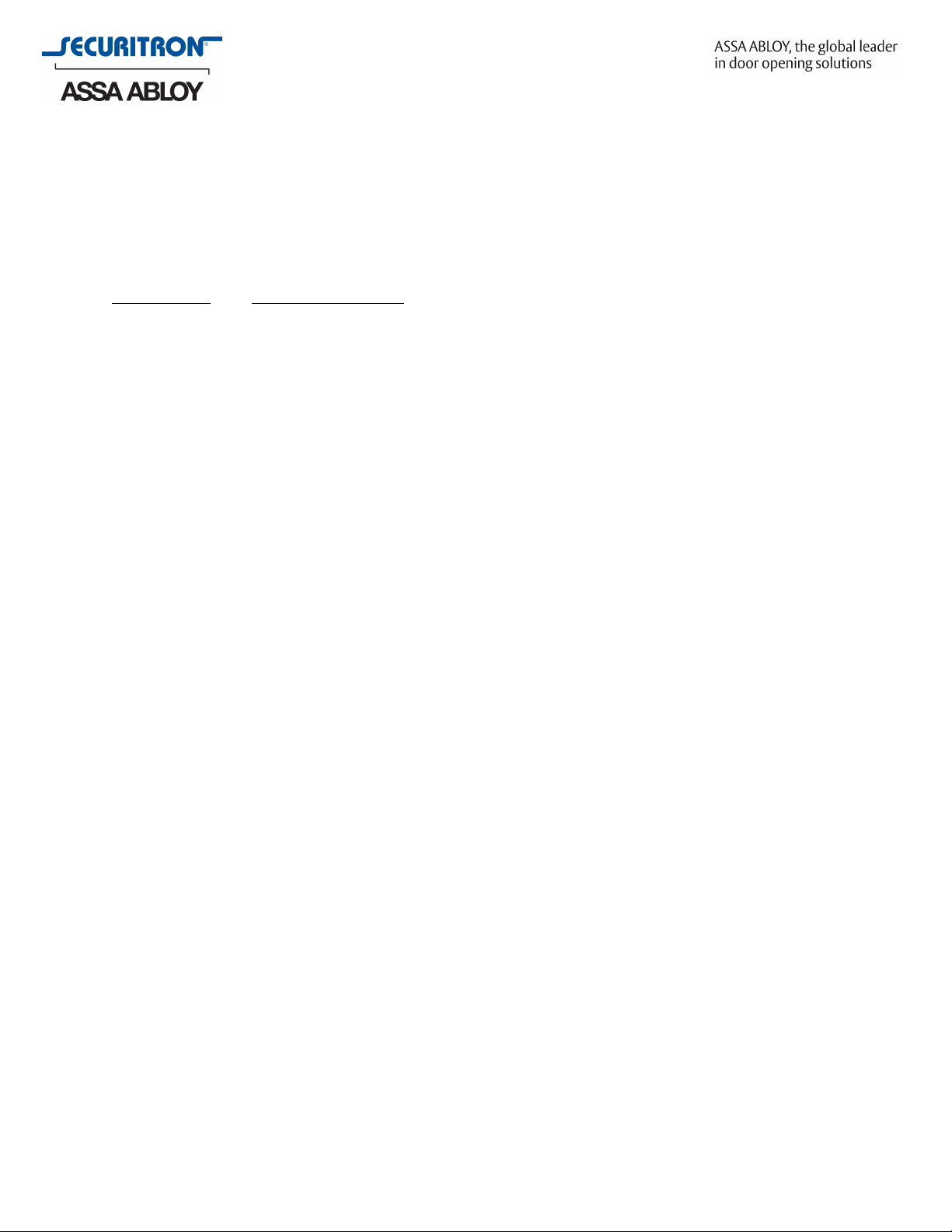

ELECTROMAGNETIC LOCK – Model 32

Features

• 600 pounds of pull-apart holding

force

• Lifetime replacement warranty

• Power consumption of 300mA @

12VDC & 150mA @ 24VDC

• Availabl

• Instant release circuit, no

residual magnetism

• Surface mounts using only a drill

and allen wrench

• Fully sealed electronics, tamper

proof & weather proof

• Mounted using steel machine

screws into blind finishing nuts

• Architectural brushed stainless

steel finish

• Polished brass, clear anodized, & polished stainless finish dress covers available

• Hardware accessories include brackets, housings, and dress covers as needed for every

opening type

• Ten feet of jacketed stranded conductor

• Lock and strikes plated to provide corrosion resistance

• Fail Safe

• UL listed

e in 12 VDC or 24 VDC

Options

• Bondstat Form ‘C’ – Instantaneous lock status sensing without the use of auxiliary

switches or reed relays

• DPS Door Status – Integrated door reed switch w/ built in resettable polyswitch

• Face Mount – Mounting holes on the face of the lock for mounting on inswing doors and

gates

Page 2

ELECTROMAGNETIC LOCK – Model 32 (cont’d)

www.securitron.com | techsupport@securitron.com

Operating Temperature

-40 to 60C [-40 to 140F]

How to Order

Part Numbe

M32 Maglock Model 32, 12VDC, 24VDC

M32F Maglock Model 32, 12VDC, 24VDC, Face Mount

M32B Maglock Model 32, 12VDC, 24VDC, Bondstat

M32D Maglock Model 32, 12VDC, 24VDC, Door Position

M32FD Maglock Model 32, 12VDC, 24VDC, Face Mount, Door Position

M32FB Maglock Model 32, 12VDC, 24VDC, Bondstat, Face Mount

M32BD Maglock Model 32, 12VDC, 24VDC, Bondstat, Door Position

M32FBD Maglock Model 32, 12VDC, 24VDC, Face Mount, Bondstat Door Position

ARCHITECTURAL SPECIFICATION – Electrom

Product Description

r

agnetic Lock

Model 32

2.x MAGNETIC LOCKS

A. All electromagnetic locks shall be manufactured by Securitron Magnalock Corp.,

Sparks, NV, an ISO 900

B. Locks shall be capable of providing a pull-apart or tensile holding force of at least

600 pounds. A laboratory test certifying the minimum holding force shall be

submitted by the manufacturer upon request.

C. Electromagnetic locks shall have a lifetime replacement warranty.

D. Locks shall not consume more than three and one-half (3.5W) watts of power

(300mA @ 12VDC) and (150mA @ 24VDC).

E. Locks shall not exceed 21 cubic inches (8 inches x 1.75 inches x 1.5 inches) in size.

F. Locks shall be fully sealed in resin to provide tamper and weather proofing.

G. Mount locks using two .25 inch x 2.25 inch machine screws into blind finishing nuts

with steel threads that extend through the entire body of the lock.

H. Mount strike plates to provide a "floating" movement to assure automatic self-

alignment with the lock.

I. Finish is architectural brushed stainless steel, other finishes available by selecting

optional dress covers.

J. Hardware accessories shall include brackets, housings, and dress covers.

K. Ten feet of jacketed stranded conductor shall be provided for electrical connection.

L. Anti-tamper caps shall be provided for any exposed holes.

M. The locks and strikes shall be plated to provide corrosion resistance.

1 certified manufacturer.

Loading...

Loading...