Page 1

500-10420, Rev G

10027 S. 51st St. Ste 102

Phoenix, AZ 85044

Tel: 1-800-624-5625

Mon-Fri: 6:00am - 4:00pm PDT

securitron.com

techsupport@securitron.com

Magnalock®

Models M32, M62, and M82B

Installation and Operating Instructions

1

Page 2

500-10420, Rev G

TABLE OF CONTENTS

INTRODUCTION ............................................................................................. 3

SPECIFICATIONS ........................................................................................... 3

GENERAL ........................................................................................................ 4

Perform a Product Inventory ........................................................................ 4

Have the Recommended Tools ................................................................... 4

Perform a Pre-Installation Survey ................................................................ 4

INSTALLING A MAGNALOCK ......................................................................... 6

Attach the Template and Mark the Drill Holes ............................................. 6

Drill the Holes for the Lock Body and Strike Plate ....................................... 7

Install the Blind Nuts .................................................................................... 8

Install the Strike Plate .................................................................................. 9

Install the Magnalock ................................................................................. 12

Wire Double Door Status ........................................................................... 15

Wire Double Door Status—DPS ................................................................ 15

Wire for Emergency Release ..................................................................... 16

MAINTAINING A MAGNALOCK .................................................................... 16

Perform an Inspection ................................................................................ 16

Clean the Magnalock ................................................................................. 16

TROUBLESHOOTING A MAGNALOCK ........................................................ 17

DETERMINING WIRE GAUGE ...................................................................... 18

WARRANTY .................................................................................................. 20

2

Page 3

500-10420, Rev G

[

g]

[

g]

[

g]

INTRODUCTION

The Securitron Magnalock® family is state of the art in electromagnetic locking,

and includes operational electrical characteristics and mounting configuration

options addressed in this document.

The BondSTAT “B” Magnalock Series, Bond Sensor, monitors the magnetic field.

An internal sensor activates a single pull double throw (SPDT) dry-contact relay

connection designed for interface to access control and/or alarm systems, which

reports the status of the Magnalock.

The DPS “D” Magnalock Series, Door Position Sensor, is activated by a special

magnetic strike armature assembly. This isolated SPDT reed switch, with an

internal resettable protection device, is designed for interface to access control

and/or alarm system for door status.

SPECIFICATIONS

MODEL M32 M62 M82B

Holding Force:

Dimensions:

Length: 8" [203 mm] 8" [203 mm] 12" [305 mm]

Height:

1.88" [48 mm] 3" [76 mm] 3" [76 mm]

Depth:

1.6" [41 mm] 1.75" [44 mm] 1.75" [44 mm]

Current @ 12 VDC: 300 mA 250 mA 350 mA

600 Pounds (lbs)

272 k

1200 lbs

544 k

1800 lbs

816 k

Current @ 24 VDC: 150 mA 150 mA 200 mA

Capacitance @ 12 VDC: 6.8 mF 44 mF 44 mF

Capacitance @ 24 VDC: 6.8 mF 11 mF 11 mF

Dual Voltage: 12/24 Volts DC

BondSTAT Rating: Voltage: 30 VDC (Maximum) ~ Current: 1 Amp (Maximum)

DPS Rating: Voltage: 30 VDC (Maximum) ~ Current: 125 mA (Maximum)

3

Page 4

500-10420, Rev G

GENERAL

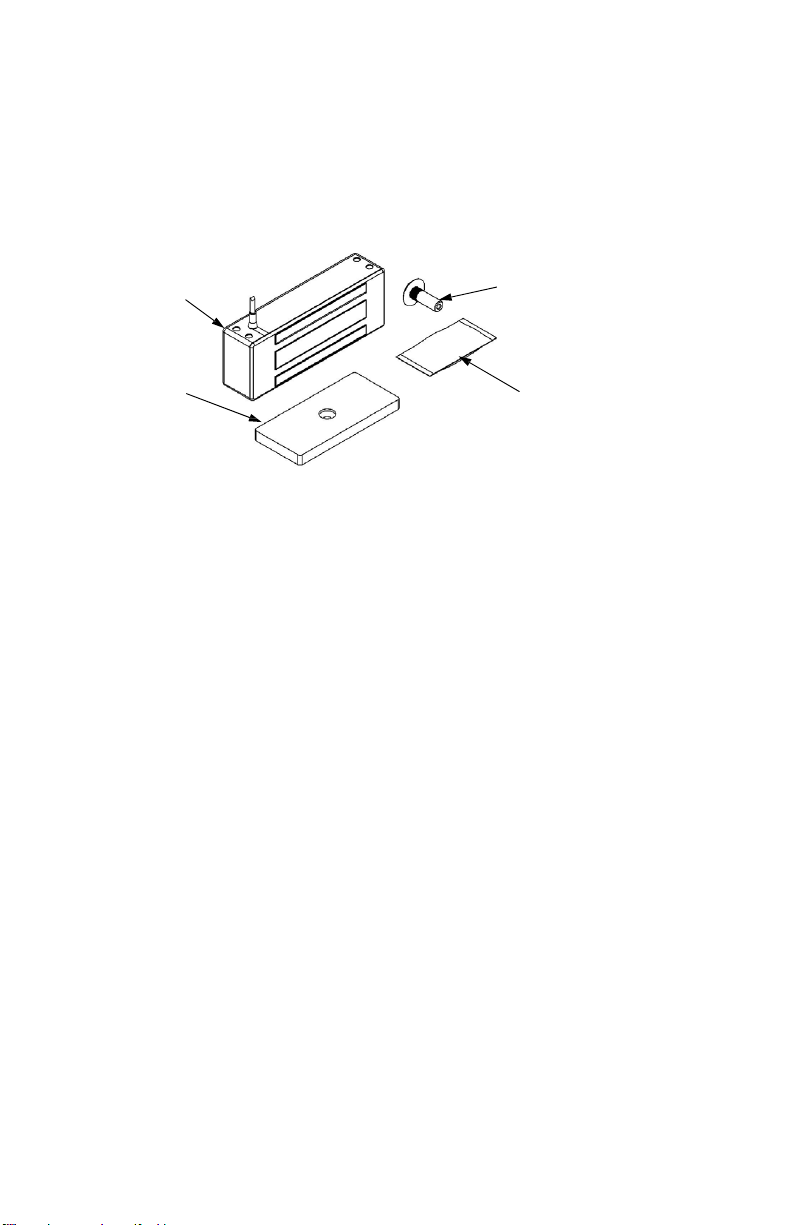

Perform a Product Inventory

1. Upon unpacking this product, PERFORM an inventory to ensure that all of

the required components and hardware have been included; this should

include the items detailed in Figure 1, “Magnalock Inventory.”

Magnalock

Strike Plate

Sex Bolt

Hardware

Figure 1. Magnalock Inventory

Have the Recommended Tools

1. ENSURE the following recommended tools are available for installation of

the applicable Magnalock:

Power Drill Hammer Wire Strippers/Cutter

1/8”, 3/8”, 1/2” Drill Bits Center Punch Crimp Wire Connectors

Masking Tape Crimp Tool 3/16” Hex Key (Allen Wrench)

Fish Tape or Lead Wire Multimeter 1/2” Open end or Crescent Wrench

Perform a Pre-Installation Survey

NOTE 1: Additional brackets may be needed for proper installation.

Specialized brackets are available through Securitron and its many

product distributors.

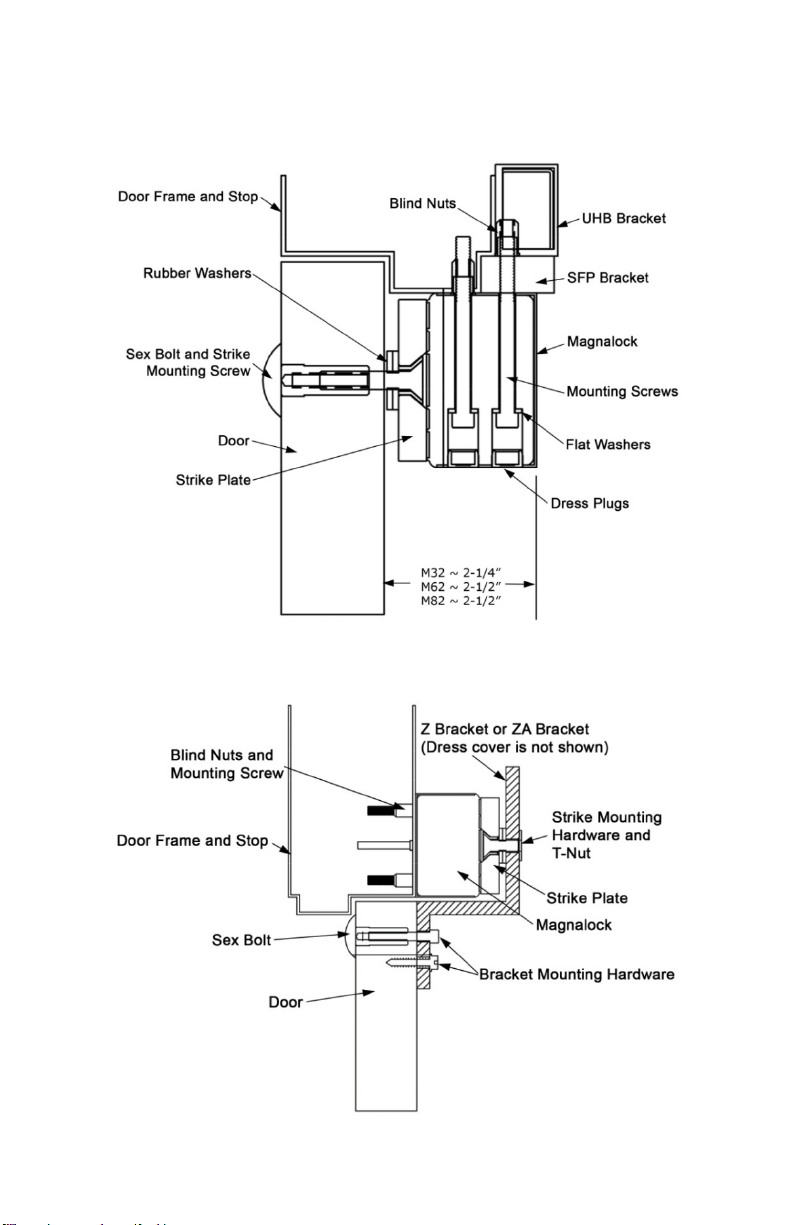

NOTE 2: Figure 2, Magnalock Installation on an Out-Swinging Door,” and

Figure 3, “Magnalock Installation on an In-Swinging Door,” illustrate

the typical mounting methods.

1. PERFORM an initial onsite survey to determine a method of mounting and to

review the installation plan, taking the following into consideration:

• Physical strength of mounting areas should be strong enough to meet or

exceed the holding force of the required Magnalock.

• Placement of the Magnalock wiring and protection from potential

damage due to intruders or vandal’s external attack.

4

Page 5

500-10420, Rev G

• Accessibility for prevention of potential safety hazards.

Figure 2. Magnalock Installation on an Out-Swinging Door

5

Page 6

500-10420, Rev G

Figure 3. Magnalock Installation on an In-Swinging Door

INSTALLING A MAGNALOCK

Attach the Template and Mark the Drill Holes

1. SELECT a mounting location for the Magnalock and strike assembly.

NOTE: The edge of the template should be about 1” (25.4 mm) from the latch

side of the door to allow proper access at the mounting locations for

drilling and tool access.

2. ATTACH the template to the

door and frame as shown in

Figure 4, “Attaching the

Template.”

a. IF Installing a strike

plate horizontally,

THEN ENSURE the top

edge of the strike will be

approximately

1/8" [3.2 mm] below the

door frame stop.

Figure 4. Attaching the Template

b. IF the strike and magnet are to be mounted vertically,

THEN INCREASE the clearance between the strike and frame to

3/16" [4.8 mm].

3. WHEN the template is

attached,

THEN MARK the location of

all holes to be drilled using a

center punch (see Figure 5,

“Marking Drill Hole

Locations”).

Figure 5. Marking Drill Hole Locations

6

Page 7

500-10420, Rev G

Drill the Holes for the Lock Body and Strike Plate

NOTE 1: Figure 6, “Installation

Drill Holes,” provides

illustration for the

following steps.

NOTE 2: Holes #1 and #3 are

1/2” diameter and

1”deep into door.

Hole #2 is 1/2”

diameter and all of the

way through the door.

1. DRILL the three holes for the

installation of the strike plate.

Figure 6. Installation Drill Holes

NOTE 1: Figure 7, “Lock Body

Drill Holes,” provides

illustration for the

following steps.

NOTE 2: Holes A–C are 3/8”

diameter.

NOTE 3: It is recommended to

start drilling with a

smaller bit and then

use a 3/8” bit to not

over size the holes.

2. DRILL the three holes for the

installation of the lock body.

Figure 7. Lock Body Drill Holes

7

Page 8

500-10420, Rev G

Install the Blind Nuts

NOTE: Figure 8, “Blind Nut Components,” Figure 9, “Installing the Blind

Nuts,” and Figure 10, “Blind Nut Before and After Collapse,” provide

illustration for the steps in this section.

Figure 8. Blind Nut Components

Figure 9. Installing the Blind Nuts

Figure 10. Blind Nut Before and After Collapse

8

Page 9

500-10420, Rev G

1. INSTALL the blind nuts using the provided collapsing tool.

a. INSERT the assembled blind nut and installation tool into a mounting

hole to install a blind nut into the 3/8” [9.5 mm] hole (see Figure 8).

b. HOLD the install nut using a 1/2” [13 mm] box-end wrench and, at the

same time, COLLAPSE the blind nut using a 3/16” [5.0 mm] hex wrench

to turn the socket cap screw (see Figure 9).

NOTE: The collapsing tool is reusable for several blind nut installations.

c. REMOVE the collapsing tool when finished.

NOTE: Once installed, the blind nuts leave a threaded insert that will accept

the case-hardened machine screws provided in the hardware pack.

d. VERIFY that the blind nut is properly collapsed (see Figure 10).

Install the Strike Plate

1. ENSURE the following

parts are available for

strike plate installation

(see Figure 11, “Strike

Plate Components”):

• 5/16-18 screw

• Funnel Bushing

• Roll Pins (2X)

• Roll Pin Bushings

(2X)

• Rubber Washers

• Sex Bolt

2. Using a hammer, TAP the

roll pins into the strike

plate until seated (see

Figure 12, “Seating the

Roll Pins”).

9

Figure 11. Strike Plate Components

Figure 12. Seating the Roll Pins

Page 10

500-10420, Rev G

3. INSTALL the roll pin

bushings into the door

(see Figure 13, “Installing

the Roll Pin Bushings”).

NOTE: Figure 14, “Strike

Plate Assembly,”

provides illustration

for the Steps 4–6.

4. INSERT the 5/16-18 bolt

through the funnel bushing

and strike plate

NOTE: It may be necessary

to use either 2 or 3

rubber washers

depending on final

adjustments.

5. INSTALL 2 rubber

washers on the 5/16-18

bolt.

6. APPLY thread lock to the

5/16-18 bolt threads.

Figure 13. Installing the Roll Pin Bushings

Figure 14. Strike Plate Assembly

10

Page 11

500-10420, Rev G

NOTE: The strike plate is

secured to the door

via the supplied sex

bolt.

7. From the outside of the

door, gently TAP the sex

bolt into place (see Figure

15, “Installing the Sex

Bolt”).

NOTE: The center screw

should not be over

tightened; strike

should float.

8. INSTALL the strike by

aligning it with the sex bolt

and roll pin bushing and

then tightening the center

screw (see Figure 16,

“Installing the Strike

Plate”).

Figure 15. Installing the Sex Bolt

Figure 16. Installing the Strike Plate

11

Page 12

500-10420, Rev G

Install the Magnalock

1. PULL the lock wire into

frame and to desired

location.

2. APPLY thread lock to

mounting screws.

3. MOUNT lock body to

frame using supplied

hardware (see Figure 17,

“Installing the

Magnalock”).

4. INSERT the tamper finish

caps into the mounting

screw holes (see Figure

18, “Installing the Tamper

Finishing Caps”).

Figure 17. Installing the Magnalock

Figure 18. Installing the Tamper Finishing Caps

CAUTION: The Magnalock and strike plate must be in proper alignment or

the BondSTAT and DPS functions will not operate correctly.

NOTE 1: When installing the Magnalock and strike plate, each should be in

proper alignment to the other (see Figure 19, “Magnalock and Strike

Plate Alignment”). This is considered critical for the operation of both

the BondSTAT and DPS. However, there are alignment tolerances for

each model of Magnalock, but these should be viewed as the extreme—

the installation desire is always total alignment.

NOTE 2: The following are the alignment tolerances for the M32, M62, and M82:

Model X-Coordinate

Alignment (+/–)

M32 B/D 9/32” 1/8”

M62 B/D 5/16” 1/8’

M82 B/D 9/16” 1/8”

12

Y-Coordinate

Alignment (+/–)

Page 13

500-10420, Rev G

r

f

Figure 19. Magnalock and Strike Plate Alignment

5. ENSURE the Magnalock and strike plate are in proper alignment.

WARNING: A shock hazard may occur if the Magnalock is operated from a

DC power supply that is connected to earth ground or not

isolated.

CAUTION: The Magnalock must be operated from DC powe

appropriate capacity and voltage. The DC output of the

power supply must not be

connected to earth ground but

must be isolated, or possible damage to the

result.

NOTE: In order to confirm that the DC outputs of a power supply ar e

isola t e d , it c a n b e checked with an ohmmeter between earth

ground

and +V, and then between earth and 0V (negative). There

should not be continuity.

supply o

product could

6. CONNECT the wiring per Figure 20, “Typical Magnalock Wiring,” Figure 21,

“Connections for BondSTAT ‘B’ Version,” Figure 22, “Connections for DPS

‘D’ Version,” and Figure 23, “Connections for ‘BD’ Version.”

Figure 20. Typical Magnalock Wiring

13

Page 14

500-10420, Rev G

NOTE 1: In Figure 21, the green and white wires supply electrical connection

when the lock is ON

NOTE 2: In Figure 21, the orange and white wires supply electrical

connection when the lock OFF

Figure 21. Connections for BondSTAT “B” Version

NOTE 1: In Figure 22, the blue and yellow wires supply electrical connection

when the door condition is closed

NOTE 2: In Figure 22, the brown and yellow wires supply electrical

connection when the door condition is open

and secure.

or unsecure.

.

.

Figure 22. Connections for DPS “D” Version

14

Page 15

500-10420, Rev G

Figure 23. Connections for “BD” Version

Wire Double Door Status

NOTE: When two Magnalocks are used for double door installation, the

BondSTAT contacts should be wired in series for proper reporting.

CONNECT the green wire of one lock to the white wire of the other as

1.

shown in Figure 24, “Double Door Status Wiring.”

Figure 24. Double Door Status Wiring

Wire Double Door Status—DPS

NOTE: When two Magnalocks are used for double door installation, the

DPS contacts should be wired in series for proper reporting.

1.

CONNECT the blue wire of one lock to the yellow wire of the other as shown

in Figure 25, “Double Door Status Wiring—DPS.”

Figure 25. Double Door Status Wiring—DPS

15

Page 16

500-10420, Rev G

Wire for Emergency Release

NOTE 1: Magnalocks are often wired into a system for quick release in case

of emergency.

NOTE 2

: Manual switching or automatic triggering from a fire alarm system is

practical.

NOTE 3:

It is the user's responsibility to correctly hookup the Magnalock

according to the instructions.

NOTE 4: Securitron power supplies have terminals for connecting

emergency release switches.

1. USE a switch or relay to perform break of power.

MAINTAINING A MAGNALOCK

Perform an Inspection

1. CHECK the rubber washers for elasticity and proper pivoting; TIGHTEN as

required.

2. CHECK for the build-up of debris on the Magnalock and strike armature;

CLEAN as required.

3. CHECK for rust on the Magnalock and strike plate armature; CLEAN as

required.

Clean the Magnalock

1. CLEAN the Magnalock at the following intervals:

• Once a year for normal maintenance

• Every 6 months when minor rusting occurs

• Every 3 months if rust conditions are severe

2. APPLY rubbing alcohol onto a clean cloth and thoroughly WIPE DOWN the

Magnalock and strike plate armature (indoor applications).

NOTE: An example of a silicon-based cleaner/lubricant is the following:

Super Lube® Aerosol with SYNCOLON® (PTFE)

Part Number: 31040 ~ 6oz. / 31110 ~ 11 oz. / 32015 ~ 14 oz.

Phone: (631) 567-5300 / Website: www.super-lube.com

3. APPLY a silicone-based cleaner/lubricant onto a clean cloth and thoroughly

WIPE DOWN the Magnalock and strike plate armature (outdoor

applications).

4. USE a plastic dishwashing scrub pad to aid in the removal of rust.

16

Page 17

500-10420, Rev G

TROUBLESHOOTING A MAGNALOCK

CHALLENGE SOLUTION

Lock does not generate a

magnetic field

Reduced holding force

BondSTAT does not report

secure

DPS does not report door

status

CHECK for specified voltage at Magnalock.

CHECK for specified current draw at Magnalock.

CHECK DC power source is Full-Wave Rectified

(Half-wave Rectifier or AC Power unacceptable).

CHECK for specified voltage at Magnalock.

CHECK for specified current draw at Magnalock.

CHECK strike mounting for proper installation.

CHECK the Magnalock and strike for obstructions

and that contact surfaces are properly cleaned.

CHECK for specified voltage at Magnalock.

Check for specified current draw at Magnalock.

CHECK strike mounting for proper alignment and

pivoting for proper closure to Magnalock.

CHECK the Magnalock and strike for obstructions

and that contact surfaces are properly cleaned.

CHECK strike mounting for proper alignment.

CHECK for proper door closure.

CHECK for proper voltage/current on switch.

CHECK resettable protection device.

ENSURE no voltage is present at Magnalock.

ENSURE the Magnalock is not drawing current.

Magnalock does not release

Magnalock is dirty or rusty ENSURE the Magnalock is properly cleaned.

17

CHECK if the strike is sticky and hard to release.

CHECK the Magnalock and strike for obstructions

and that contact surfaces are properly cleaned.

Page 18

500-10420, Rev G

CHALLENGE SOLUTION

Electronic noise interference

with Access Control System

CHECK for voltage from Magnalock to door

frame; there should be no voltage present.

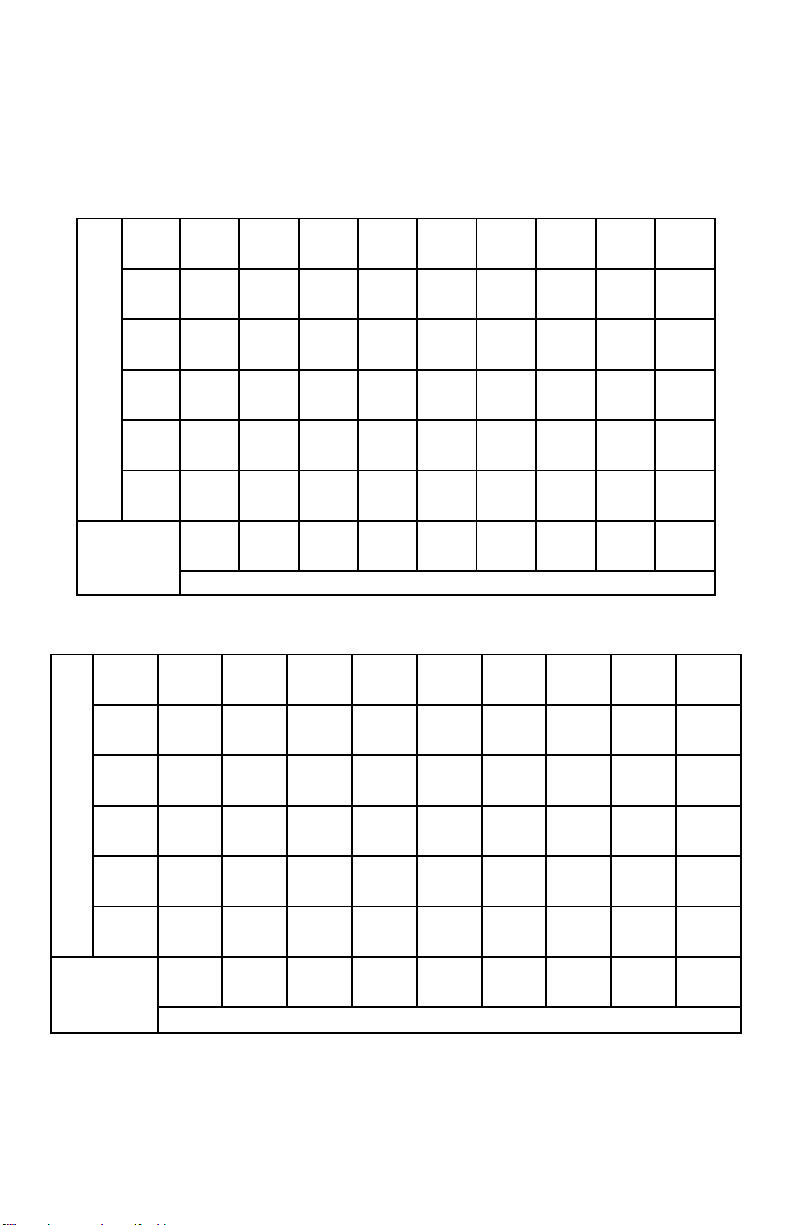

DETERMINING WIRE GAUGE

The Magnalock requires adequate voltage and current for proper operation.

Resistance is created by the length and gauge (size) of the wire being used. An

accurate estimated distance from the power supply to the opening is crucial. For

superior operation the correct size gauge wire must be used—the devices used

operate optimally with the least amount of resistance on the source. Using the

correct gauge wires protects against large voltage and current (load) losses. The

gauge is determined by the wire distance, voltage and current of all devices.

1. CALCULATE total current for either a 12 VDC system (see Table 1, “12 VDC

System”) or a 24 VDC system (see Table 2, “24 VDC System), as required.

Table 1..12 VDC System Current Used

Devices Used Amps (12 VDC)

M62 Magnalock 0.250 0.250

DK-26 Access 0.160 0.410

XMS Motion 0.050 0.460

EEB2 Timer 0.025 0.485

Total Current (Rounded Up) 0.600A

Table 2. 24 VDC System

Progressive

Totals

Devices Used Amps (24 VDC)

M82 Magnalock 0.200 0.200

TSB Touch Bar 0.025 0.225

DK-11 Access 0.070 0.295

XDT-24 Delay 0.050 0.345

MK Bypass/Reset 0.020 0.365

Total Current (Rounded Up)

Progressive

Totals

0.400A

18

Page 19

500-10420, Rev G

2. Using the value obtained in Step 1, DETERMINE the proper wire gauge and

length using Table 3, “ 12 VDC Wire Gauge and Length,” for a 12 VDC

system, or Table 4, “24 VDC Wire Gauge and Length,” for a 24 VDC system.

Table 3. 12 VDC Wire Gauge and Length

1.0A

C

U

R

R

E

N

T

12 VDC

Table 4. 24 VDC Wire Gauge and Length

1.0A

.80A

C

U

R

.60A

R

R

E

.40A

N

T

.30A

.20A

24 VDC

.80A

.60A

.40A

.30A

.20A

20

Gauge

22

Gauge

22

Gauge

22

Gauge

24

Gauge

24

Gauge

50’

[15m]

22

Gauge

22

Gauge

24

Gauge

24

Gauge

24

Gauge

24

Gauge

50’

[15m]

18

Gauge

18

Gauge

20

Gauge

22

Gauge

22

Gauge

22

Gauge

100’

[30m]

20

Gauge

22

Gauge

22

Gauge

22

Gauge

24

Gauge

24

Gauge

100’

[30m]

16

Gauge

18

Gauge

18

Gauge

20

Gauge

22

Gauge

22

Gauge

150’

[46m]

20

Gauge

20

Gauge

22

Gauge

22

Gauge

22

Gauge

24

Gauge

150’

[46m]

14

Gauge

16

Gauge

18

Gauge

18

Gauge

20

Gauge

22

Gauge

200’

[61m]

18

Gauge

18

Gauge

20

Gauge

22

Gauge

22

Gauge

22

Gauge

200’

[61m]

14

Gauge

14

Gauge

16

Gauge

18

Gauge

18

Gauge

20

Gauge

300’

[91m]

WIRE DISTANCE

16

Gauge

18

Gauge

18

Gauge

20

Gauge

22

Gauge

22

Gauge

300’

[91m]

WIRE DISTANCE

12

Gauge

12

Gauge

14

Gauge

16

Gauge

18

Gauge

18

Gauge

400’

[122m]

14

Gauge

16

Gauge

18

Gauge

18

Gauge

20

Gauge

22

Gauge

400’

[122m]

10

Gauge

10

Gauge

14

Gauge

14

Gauge

16

Gauge

18

Gauge

500’

[152m]

14

Gauge

14

Gauge

16

Gauge

18

Gauge

20

Gauge

20

Gauge

500’

[152m]

10

Gauge8 Gauge

10

Gauge8 Gauge

12

14

14

16

12

Gauge

14

Gauge

14

Gauge

16

Gauge

18

Gauge

20

Gauge

750’

[229m]

10

Gauge

12

Gauge

14

Gauge

14

Gauge

1000’

[305m]

Gauge

Gauge

Gauge

Gauge

Gauge

Gauge

1000’

[305m]

Gauge

Gauge

Gauge

Gauge

750’

[229m]

10

12

14

14

16

18

19

Page 20

500-10420, Rev G

WARRANTY

Magnalock M32, M62, and M82 are covered by the MagnaCare® lifetime

replacement no fault warranty. No registration is required. Product will be

replaced forever, for any reason, including but not limited to installation error,

vandalism, or acts of God. Replacement product is shipped at Securitron’s

expense next day air if needed.

For more information, visit www.securitron.com

20

© 2015, Hanchett Entry Systems, Inc., an ASSA ABLOY Group Company.

Loading...

Loading...