Page 1

Securitron Magnalock Corp. Tel 775.355.5625

550 Vista Boulevard Fax 775.355.5633

ASSA ABLOY, the global leader

in door opening solutions

Sparks, NV 89434 info@securitron.com

www.securitron.com

MAGNALOCK MODELS M32, M62 AND M82B

INSTALLATION INSTRUCTIONS

1. INTRODUCTION

The Securitron Magnalock family represents the state of the art in electromagnetic locking.

There are three (3) models with operational electrical characteristics including mounting

configuration options addressed in this manual.

The BondSTAT “B” Magnalock Series, Bond Sensor, monitors the magnetic field. An internal

sensor activates a SPDT dry contact relay connection designed for interface to access control

and/or alarm systems for reporting the status of the Magnalock. (Section 5.2.4)

The DPS “D” Magnalock Series, Door Position Sensor, is activated by a special magnetic strike

armature assembly. The isolated SPDT reed switch, with an internal resettable protection device,

is designed for interface to access control and/or alarm system for door status. (Section 5.2.4)

2. SPECIFICATIONS

MODEL M32 M62 M82B

Holding Force 600 Lbs [272 kg] 1200 Lbs [544 kg] 1800 Lbs [816 kg]

Dimensions: Length 8" [203mm] 8" [203mm] 12" [305mm]

Height 1.88" [48mm] 3" [76mm] 3" [76mm]

Depth 1.6" [41mm] 1.75" [44mm] 1.75" [44mm]

Dual Voltage 12/24 Volts DC

Current: @ 12 VDC 300mA 250mA 350mA

@ 24 VDC 150mA 150mA 200mA

Capacitance: @ 12 VDC 6.8 mF 44 mF 44 mF

@ 24 VDC 6.8 mF 11 mF 11 mF

BondSTAT Rating Voltage: 30 VDC (Maximum) ~ Current: 1 Amp (Maximum)

DPS Rating Voltage: 30 VDC (Maximum) ~ Current: 125 mA (Maximum)

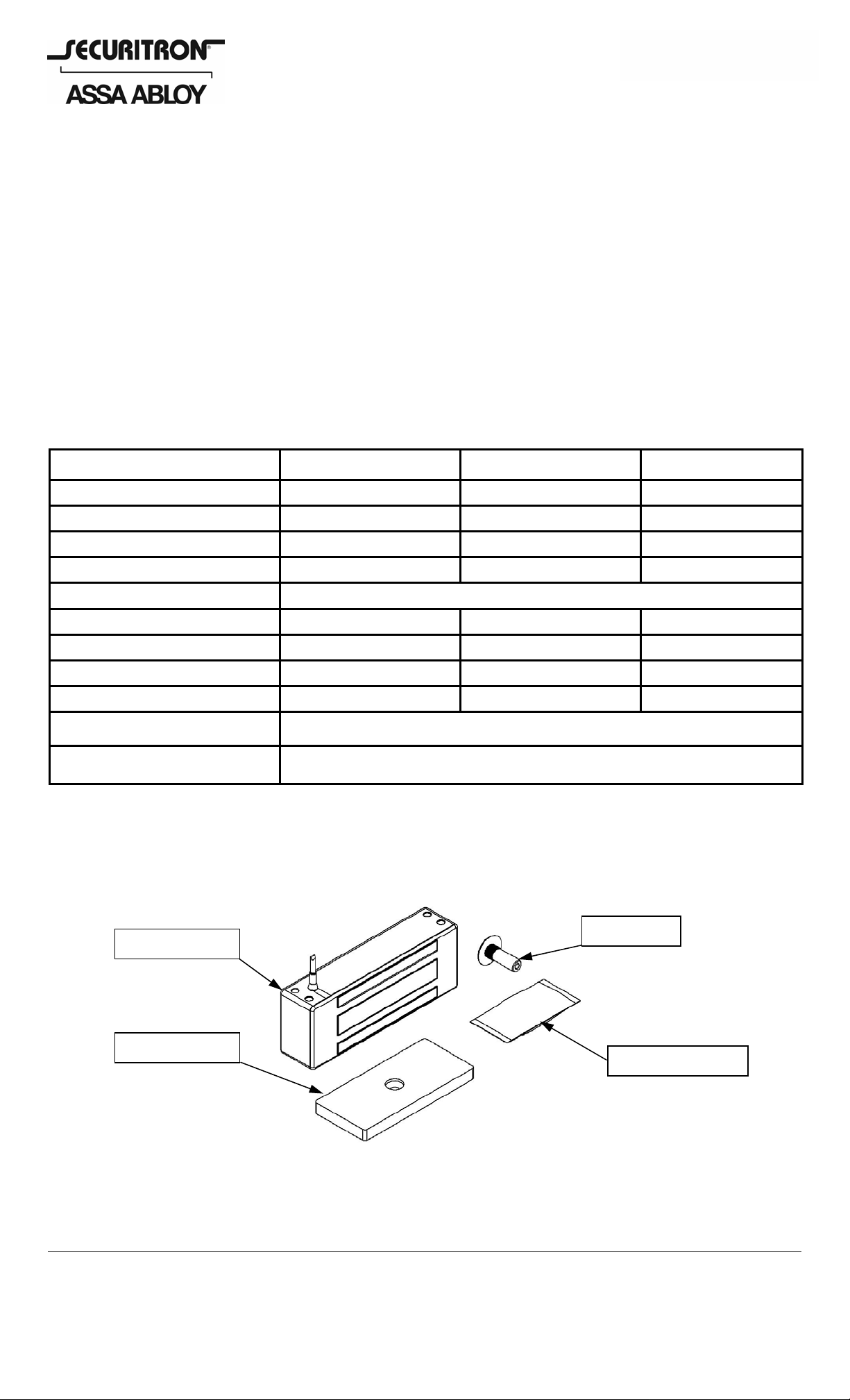

3. PRODUCT OVERVIEW

Upon unpacking this product, an inventory should be made to ensure that all the required

components and hardware have been included. Along with these instructions and the

installation template, the lock assembly should include the following items:

Magnalock

Sex Bolt

Strike Plate

Hardware Pack

Figure 1

© Copyright, 2008, all rights reserved PN# 500-10420

Page 1 Rev. E, 05/08

Page 2

4. RECOMMENDED TOOLS

Power Drill Hammer Wire Strippers/Cutter

1/8”, 3/8”, 1/2” Drill Bits Center Punch Crimp Wire Connectors

1/2” Open end or Crescent Wrench Masking Tape Crimp Tool

3/16” Hex Key (Allen Wrench) Fish Tape or Lead Wire Multimeter

5. INSTALLATION INSTRUCTIONS

5.1 Pre-Installation Survey

It is recommended that an initial on sight survey be performed. A method of mounting should

be determined and an installation plan should be reviewed as follows:

• Physical strength of mounting areas should be strong enough to meet or exceed the

holding force of the required Magnalock.

• Placement of the Magnalock wiring and protection from potential damage due to intruders

or vandals external attack should be considered during the survey.

• Accessibility should be considered for prevention of any potential safety hazard.

Additional brackets may be needed for proper installation. Specialized brackets are available

through Securitron and their many product distributors. (Section 6)

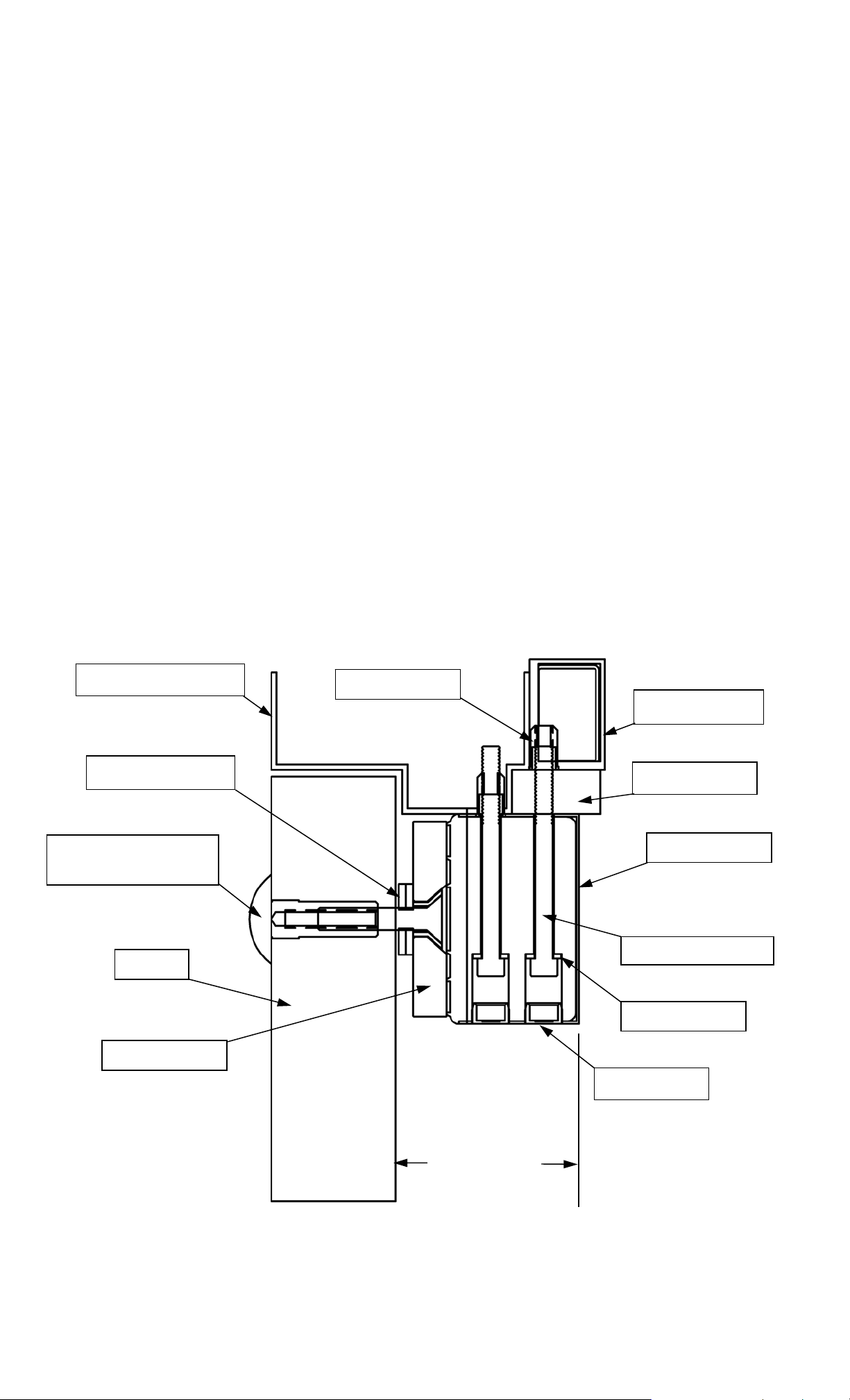

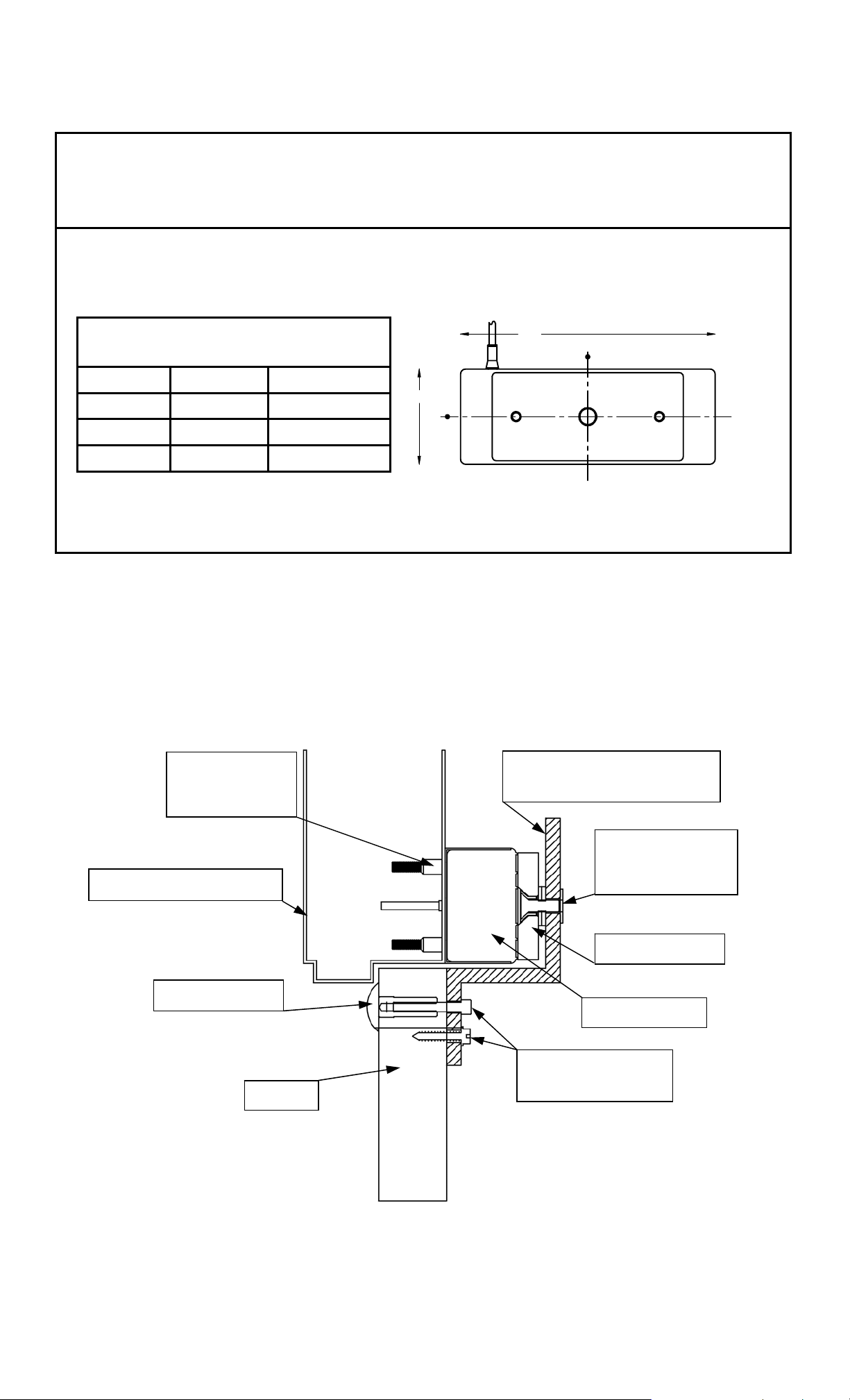

5.2 Out-Swinging Door

The installation shown below in Figure 2 illustrates the door swinging away from the Magnalock.

This is a common configuration on the secure side of exit doors. The Magnalock mounts to the

door frame header near the corner opposite the hinge side. The Magnalock may be mounted

horizontally or vertically depending on the installation required. The brackets shown in Figure 2

are to assist installation to door frames that may need modifications to complete the installation.

Door Frame & Stop

Blind Nuts

UHB Bracket

Rubber Washers

Sex Bolt & Strike

SFP Bracket

Magnalock

Mounting Screw

Mounting Screws

Door

Flat Washers

Strike Plate

Dress Plugs

M32 ~ 2-1/4”

M62 ~ 2-1/2”

M82 ~ 2-1/2”

Figure 2

PN# 500-10420

Page 2 Rev. E, 05/08

Page 3

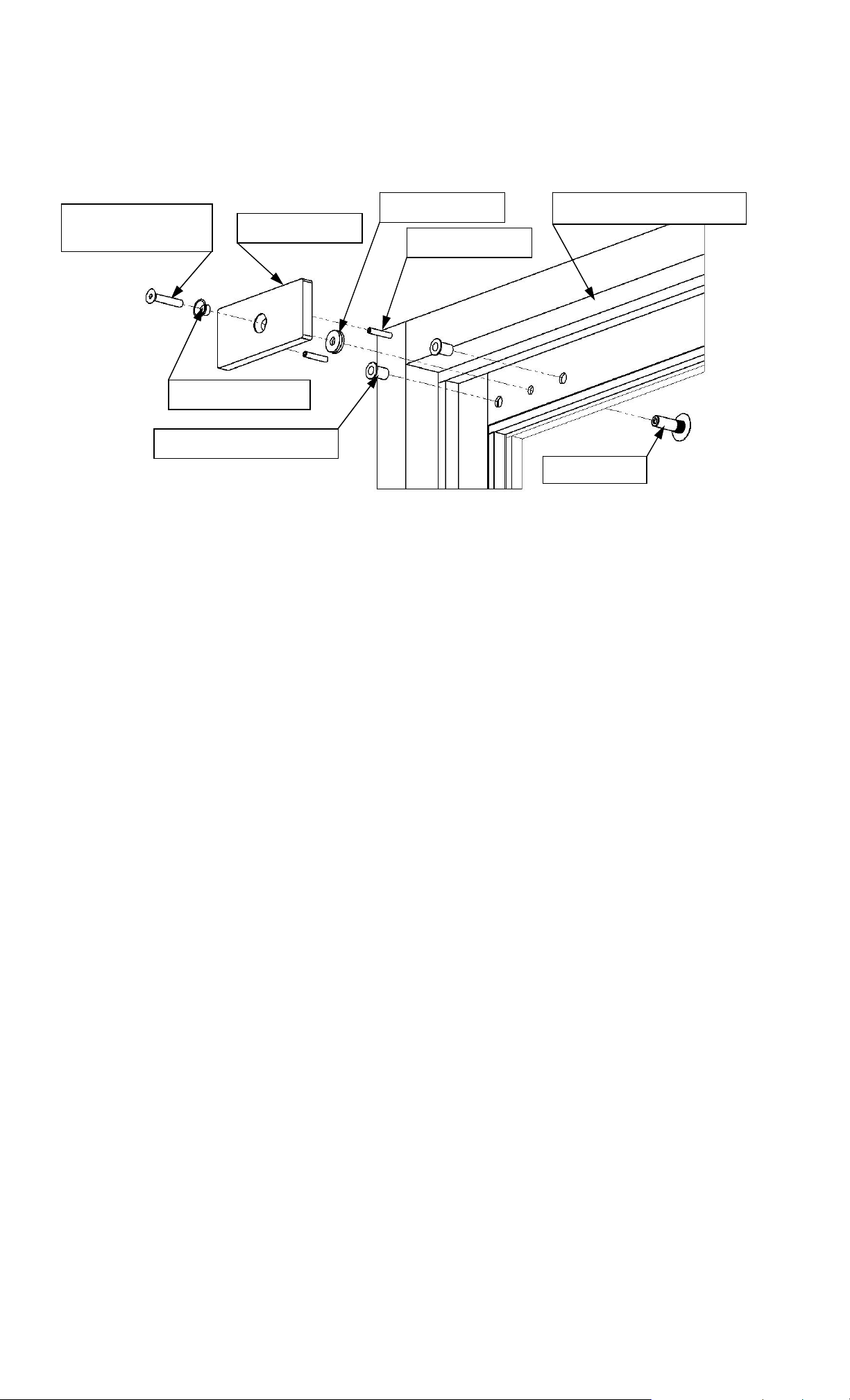

5.2.1 Mounting the Strike Plate

The strike plate should be mounted prior to the magnet in out-swinging door applications.

Figure 3 below illustrates a typical strike mounting configuration.

Strike Mounting

Screw

2-3 Washers

Strike Plate

2X Roll Pins

Door Frame & Stop

Strike Bushing

2X Roll Pin Bushings

Sex Bolt

Figure 3

Select a mounting location for the Magnalock and st rike assembly as mentioned in Section 5.1.

The following general guideline should be used for consideration during the installation review:

• Read and follow the template instructions which include drilling and mounting instructions.

• Installing a strike plate horizontally, the top edge of the strike will be approximately 1/8"

[3.2mm] below the door frame stop. If the strike and magnet are to be mounted

vertically, increase this clearance between the strike and frame to 3/16" [4.8mm].

• An approximated 1” [25.4mm] clearance should be considered between the Magnalock

and the edge corner of the door frame. This will allow proper access for the mounting

locations for drilling and tool access.

• Use the template provided for positioning and marking the mounting locations of the

Magnalock and strike. Check the external and internal areas of the marked door and

frame for any obstacles such as wire chases or internal structural features. Make

necessary adjustments to avoid these obstacles.

• Offset strikes are available for lowering a strike alignment 1/4” [6.0mm] allowing

clearance when door construction contains obstructions in the mounting locations.

5.2.2 Mounting the Magnet

Installations with blade stops require an Aluminum Spacer Bracket (ASB) for clea rance without

having to cut the stop as shown in Figure 4. Information on mounting brackets is located in

Section 6 of this manual.

To properly install the Magnalock, the following condition s sho uld be verified:

• The entire Magnalock mounting area for the magnet must be a flat surface.

• The frame area selected must be structurally strong enough for support.

• The magnet face must be mounted parallel to the door face when closed.

• The installed strike must still allow the door to close properly by clearance and alignment.

• The Magnalock face and strike plate must be aligned so that they are centered.

ALIGNMENT IS IMPORTANT FOR “B” & “D” MAGNALOCKS (Se c ti o n 5.2.4)

ALIGNMENT IS CRITICAL FOR THE MAGNALOCK HOLDING FORCE (Section 2)

• Mark and drill all holes for the mounting screws as instructed on the template.

• Make wire connections, apply power and test for proper operation.

• Mount the Magnalock using the hardware and thread locking compound provided.

• Tighten the screws until secure.

DO NOT OVER-TIGHTEN SCREWS

NEVER DRILL MAGNALOCK MOUNTING HOLES

– DAMAGE MAY OCCUR –

PN# 500-10420

Page 3 Rev. E, 05/08

Page 4

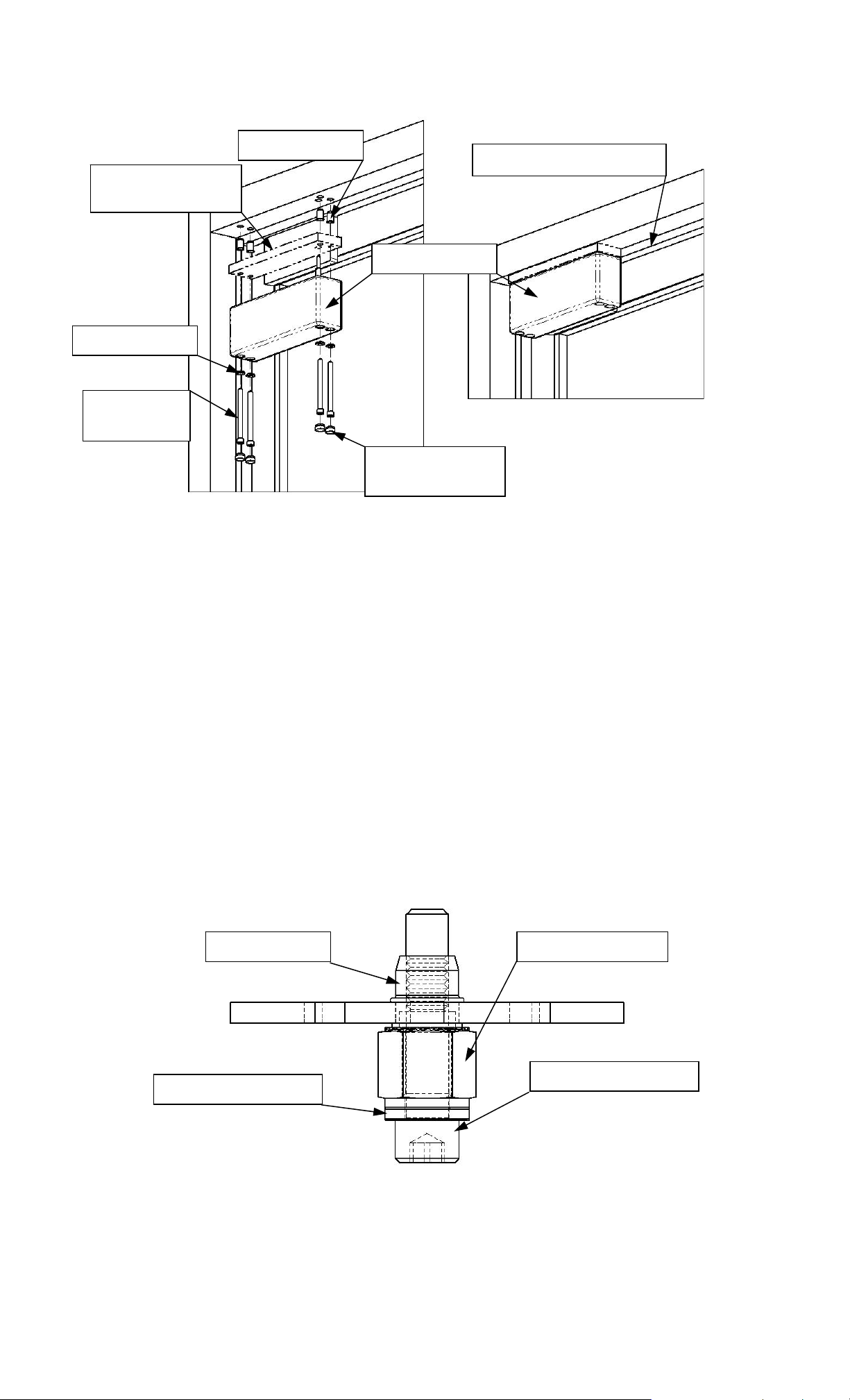

Figure 4 below illustrates a typical Magnalock out-swinging door installation.

(

ASB Bracket

Not Included)

Flat Washers

Mounting

Screws

Blind Nuts

Magnalock

Mounting Hole

Dress Plugs

Figure 4

Door Frame & Stop

Blind nuts MUST be used for mounting Magnalocks to aluminum and/or hollow metal frames.

These items are included with the Magnalock hardware pack.

NEVER USE SHEET METAL SCREWS TO MOUNT MAGNALOCKS

5.2.3 Blind Nut Installation

Install a blind nut into each of the 3/8” [9.5mm] hole using the blind nut collapsing tool

provided. Use the following instructions and Figure 5 for the installation of the blind nuts:

• Drill 3/8” [9.5mm] diameter mounting holes into the marked locations of the frame.

• Insert the assembled Blind Nut and Installation Tool into a mounting hole.

• Use 1/2” [13mm] box-end wrench for holding the Install Nut.

• Use a 3/16” [5.0mm] Hex Wrench with the Socket Cap Screw to collapse the Blind Nut.

• Remove the collapsing tool when finished.

• Check that the blind nut is collapsed properly.

• The collapsing tool is reusable for several blind nut installations.

Blind Nut

Install Nut

2X Flat Washers

Socket Cap Screw

Figure 5

PN# 500-10420

Page 4 Rev. E, 05/08

Page 5

5.2.4 Lock/Strike Installation for “B” and “D” Magnalocks

IMPORTANT!

PLEASE READ AND APPLY THIS INFORMATION WHEN ALIGNING/INSTALLING THE

LOCK AND STRIKE. THE ALIGNMENT TOLERANCES INDICATED FOR EACH LOCK

MODEL ARE CONSIDERED CRITICAL FOR THE PROPER OPERATION OF BOTH THE

MAGNETIC BOND SENSING AND DOOR POSITION SENSING SYSTEMS!

SENSOR RANGES (PHYSICAL POSITIONING):

The BondSTAT “B” and DPS “D” Magnalock “Secure Zone” sensing ranges for each lock

model is listed in Table A.

Secure Sensor Indication Range

(Dimensions from Center)

X

(-)

0

(+)

Model "X" (+/-) "Y" (+/-)

M32B/D 9/32" 1/8"

M62B/D 5/16" 1/8"

(+)

0

(-)

(+)

(-)

Y

M82B/D 9/16" 1/8"

(-)

Table A

(+)

Figure 6

(The Figure 6 illustration is a visual reference to the sensing ranges outlined in Table A).

5.2.5 In-swinging Door Installation

Figure 7 below illustrates a typical in-swinging door mounting configuration. This installation

requires the use of a face mount style Ma gnalock ( i.e. M32F, M62F, or M8 2FB) and a “Z” bra cket

(Z-32, Z-62, or Z-82) or an adjustable “ZA” bracket (ZA-32/62 or ZA-82) for offsetting the

mounting of the strike must be used. Follow the installation instructions provided with the “Z” or

“ZA” bracket product to correctly install the Magnalock in this arrangement.

THE M62F AND M82FB INCLUDE FIVE (5) MOUNTING HOLES FOR FLEXIBILITY

Blind Nuts

and Mounting

Screws

Door Frame and Stop

Sex Bolt

Z-Bracket or “ZA Bracket

(Dress cover not shown)

Strike Mounting

Hardware and

T-Nut

Strike Plate

Magnalock

Bracket Mounting

Hardware

Door

Figure 7

PN# 500-10420

Page 5 Rev. E, 05/08

Page 6

5.2.5 Single Lock - Double Door Magnalock Mounting

A single Magnalock can be used to secure double doors using a split strike plate. The part

numbers reduction of holding force for each model is listed below in Table B. Use the template

and instructions provided with the split strike package for proper installation. (See Section 7)

Model

M32 N/A ASS-32 230 lbs. [104 kg]

Offset Strike

Part Number

Split Strike

Part Number

Holding Force

(per leaf)

M62 AOS-62 ASS-62 550 lbs. [250 kg]

M82 AOS-82 ASS-82 850 lbs. [385 kg]

Table B

5.2.6 DM62 Double 62 Magnalock

The DM62 consists of two (2) Model 62 Magnalocks arranged in one (1) stainless steel housing

as shown in Figure 8. This product individually secures out-swinging double door applications.

Figure 8

Use the template diagram installation instructions included with the DM62 Magnalock assembly.

The features to consideration during the installation procedure:

• Position the Magnalock centered between the doors.

• The mounting diagram measurement and marking placement are critical.

• The mounting diagram is NOT a scaled template.

• Refer to the Magnalock out-swinging door mounting procedures in Section: 5.2.

• Refer to the strike mounting procedures in Section: 5.2.1.

• Refer to the blind nut instructions in Section: 5.2.3.

5.2.7 Mounting Magnalocks for Gates

The “G” Series Magnalock is suitable for use on outdoor gates. Figure 9 illustrates a variety of

typical gate operations for application types and installation techniques. Special mounting

brackets are available. See Section 6.2 for gate bracket information.

IMPORTANT

THE STRIKE PLATE SHOULD NOT BE WELDED DIRECTLY TO THE GATE

THE STRIKE MUST BE MOUNTED USING THE HARDWARE PROVIDED

HOLDING FORCE AND ALIGNMENT WILL OTHERWISE BE AFFECTED

PN# 500-10420

Page 6 Rev. E, 05/08

Page 7

GATE STYLE OPERATIONS AND INSTALLATION TECHNIQUES

Figure 9

5.3 ELECTRICAL INSTALLATION

5.3.1 General Characteristics

The Magnalock is a low current load device using specialized internal circuitry. The normal

characteristic of an inductive load, such as inductive kick-back, is not present. See Section 2 for

more information.

5.3.2 Electrical Standards

DC voltage, full-wave rectified, must be provided for proper operation of the Magnalocks. The

red wire receives +12VDC or +24VDC, and the black wire, 0 Volts (negative). If the lock is

connected with reverse polarity, it will not operate. The M32, M62 and M82B Magnalocks are

auto sensing dual voltage locks. The Magnalock circuit design will au tomat ically select the p roper

operational conditions for the applied voltage. See Section 2 for more information.

5.3.3 Poor Release Characteristics

The Magnalock is designed with quick release circuitry. Wiring errors may cause a Magnalocks to

release slowly. Figure 10 illustrates a parallel installation of a resistive load (correct). Figure

11 illustrates a parallel reverse diode (incorrect).

Figure 10 Figure 11

5.3.4 Sensor Ranges (ELECTRICAL)

The “B” version monitoring system is also voltage sensitive. The specified voltage ranges must

be properly applied. Refer to Section 2 for the recommended operating voltage ranges.

PN# 500-10420

Page 7 Rev. E, 05/08

Page 8

5.3.5 Electrical Wiring

The following diagrams, Figures 12, 13, 14 and 15 represent the proper electrical wiring

connections required for Magnalock Standard, BondSTAT “B”, DPS “D” and “BD” versions.

Figure 12

Figure 13

Figure 14

Figure 15

PN# 500-10420

Page 8 Rev. E, 05/08

Page 9

5.3.6 BondSTAT Sensor status wiring description

• The green and white wires supply electrical connection when the lock is ON and secure.

• The orange and white wires supply electrical connection when the lock OFF or unsecure.

5.3.7 DPS – Door Position Sensor status wiring description

• The blue and yellow wires supply electrical connection when the door condition is closed.

• The brown and yellow wires supply electrical connection when the door condition is open.

5.3.8 Double Door Status Wiring – BondSTAT

When two Magnalocks are used for double door installation the BondSTAT contacts should be

wired in series for proper reporting. Connect the green wire of one lock to the white wire of the

other as shown below in Figure 16.

Figure 16

5.3.9 Double Door Status Wiring – DPS

When two Magnalocks are used for double door installation the DPS contacts should be wired in

series for proper reporting. Connect the blue wire of on e lock to the yellow wire of the other as

shown below in Figure 17.

Figure 17

5.3.10 Emergency Release

Magnalocks are often wired into a system for quick release in case of emergency. Manual

switching or automatic triggering from a fire alarm system is practical. It is the user's

responsibility to correctly hookup the Magnalock according to the instructions. It is

recommended to use a switch or relay to perform break of power. Securitron power supplies

have terminals for the interconnection of such emergency release switches.

THE END USER & INSTALLER ARE LIABLE FOR FIRE & BUILDING CODES COMPLIANCE

6. SPECIALIZED MOUNTING BRACKETS

• ASB – Aluminum Shim Bracket – The ASB bracket is designed for 1/2” [12.7mm]

blade stop and/or weather trim clearance mounting of Magnalocks on aluminum frame

glass doors.

• CWB – Concrete/Wood Header Bracket – The CWB bracket is designed for mounting

Magnalocks on concrete filled and/or wood headers.

• FMK-SL & FMK-SW – FLEX-MOUNT Kit – The FMK (FLEX-MOUNT) bracket kits are

designed to install on most gate applications. Adapts to round or square posts from 1”

[25.4mm] to 3” [76.2mm]. The FMK-SL is designed for slide gate type applications. The

FMK-SW is designed for swing gate type applications.

• GDB – Glass Door Bracket – The GDB bracket is designed for mounting a Model 32 or

Model 62 strike to solid-type framed and unframed glass doors. An AKG ad hesive kit used

for bonding.

• HEB Bracket – The HEB is a 90 degree bracket designed to extend the door stop and

create a flat surface for mounting the Magnalock.

• HEB-3G Bracket – The HEB-3G bracket is a 90 degree bracket designed for mounting to

solid-type framed and unframed glass headers. An AKG adhesive kit used for bonding.

PN# 500-10420

Page 9 Rev. E, 05/08

Page 10

• SFP – Stop Filler Plate – The SFP bracket is designed for extending the door frame

mounting surface 1-1/4” [31.8mm]. Thicknesses available in 1/4” [6.4mm], 3/8”

[9.5mm], 1/2” [12.7mm] and 5/8” [15.9mm]. Lengths available in 8” [20 3mm] for M32

or M62 and 12” [305mm] for M82B Magnalocks.

• UHB – Universal Header Bracket – The UHB bracket is designed to extend the frame

width 1” [25.4mm] to 1-1/2” [38.1mm] deeper on steel and aluminum headers not wide

enough to mount the Magnalock. Lengths available in 8” [203mm] for M32 or M62 and

12” [305mm] for M82B Magnalocks.

• Z-Bracket – The “Z” bracket is designed for use with installations of “F” Series

Magnalocks for in-swinging doors and gates.

• ZA-Bracket – The “ZA” bracket is designed to allo w a full range of adjustability for use

with installations of “F” Series Magnalocks for in-swinging doors and gates.

7. SPECIALIZED STRIKES

• The AOS – Armature Offset strike is designed for offset drilling doors with mechanical

interference hardware present in the door structure. It is also accommodates errors that

may have occurred in the field from incorrect mounting placement. (See Section 5.2.5)

• The ASS – Armature Split strike is designed for single lock/double door in stallation. There

is a reduced holding force when using the split strike. (See Section 5.2.5)

8. SPECIALIZED ACCESSORIES

8.1 Dress Covers

• Single Magnalock Dress Covers – The covers are designed to meet architectural

finishes for matching specified installations. Available in four (4) architectural finishes.

• Double Dress Covers – The covers are designed to fit over a double door/dual lock

installation. Available in two (2) architectural finishes.

8.2 Installation Tool Kit – Securitron offers an installation tool kit which includes special drill

bits, a heavy duty drill guide, a blind nut collapsing tool, e xtra fasteners and hardware.

Metric is also available.

8.3 Tamper Proofing – Special tamper proof screws are available for Magnalock and strike

armature mounting. The screws are pinned-socket hex head. A special hex wrench is

required and is available when purchasing the screws.

9. MAGNALOCK MAINTENANCE

9.1 Visual Inspection

• Check the rubber washers for elasticity and proper pivoting. Tighten as required.

• Check for build-up of debris on the Magnalock and strike armature. Clean as required.

• Check for rust on the Magnalock and strike plate armature. Clean as required.

9.2 Cleaning Methods

• Cleaning once a year is recommended.

• Clean every six months where minor rusting occurs.

• Clean every three months if rust conditions are severe.

• Use a plastic dishwashing scrub pad to aid in the removal of rust.

DO NOT USE PETROLEUM BASED PRODUCTS FOR CLEANING

DO NOT USE STEEL WOOL BASED SCRUB PAD OR SANDPAPER

9.2.1 Indoor Applications

• Apply rubbing alcohol onto a clean cloth and thoroughly wipe down the Magnalock and

strike plate armature.

9.2.2 Outdoor Applications

• Apply a silicone based cleaner/lubricant onto a clean cloth and thoroughly wipe down

Magnalock and strike plate armature.

Example: Super Lube® Aerosol with SYNCOLON® (PTFE)

Part No.: 31040 ~ 6oz. / 31110 ~ 11 oz. / 32015 ~ 14 oz.

Phone: (631) 567-5300 / Website: www.super-lube.com

PN# 500-10420

Page 10 Rev. E, 05/08

Page 11

APPENDIX A

Troubleshooting

Problem Lock Does Not Generate a Magnetic Field Points of Reference

Check for specified voltage at Magnalock

Section 2

Solution

Check for specified current draw at Magnalock Section 2

Problem Reduced Holding Force Points of Reference

Check DC power source is Full-Wave Rectified

(Half-wave Rectifier or AC Power unacceptable)

Check for specified voltage at Magnalock

Section 2

Section 5.3.2

Solution

Check for specified current draw at Magnalock Section 2

Check strike mounting for proper installation Section 5.2.1 and 5.2.5

Check the Magnalock and strike for obstructions

and that contact surfaces are properly cleaned

Section 8

Problem BondSTAT Does Not Report Secure Points of Reference

Check for specified voltage at Magnalock

Section 2

Check for specified current draw at Magnalock Section 2

Solution

Check strike mounting for proper alignment and

pivoting for proper closure to Magnalock

Check the Magnalock and strike for obstructions

and that contact surfaces are properly cleaned

Table A / Section 5.2.4

Section 8

Problem DPS Does Not Report Door Status Points of Reference

Check strike mounting for proper alignment Table A / Section 5.2.4

Solution

Check for proper door closure

Check for proper voltage/current on switch

Check resettable protection device

Section 8.1

Section 2

Section 1

Problem The Magnalock Does Not Release Points of Reference

Make sure no voltage is present at Magnalock Section 2

Solution

Make sure the Magnalock is not drawing current Section 2

Check if the strike is sticky and hard to release Section 8

Check the Magnalock and strike for obstructions

and that contact surfaces are properly cleaned

Section 8

Problem The Magnalock is Dirty or Rusty Points of Reference

Solution

Problem

Improper cleaning – Maintenance Equipment Section 8

Electronic Noise Interference with

Access Control System

Points of Reference

Solution

Check for voltage from Magnalock to door frame.

There should be no voltage present.

Section 2

IF PROBLEMS PERSIST CALL SECURITRON TOLL FREE

(800) MAG-LOCK

(800) 624-5625

PN# 500-10420

Page 11 Rev. E, 05/08

Page 12

Appendix B

Wire Gauge Factoring

1.1 Remote Power Supply

• The Magnalock requires adequate voltage and current for proper operation.

• Resistance is created by the length and gauge (size) of the wire being used.

• An accurate estimated distance from the power supply to the opening is crucial.

• For superior operation the correct size gauge wire must be used.

• The devices used operate the best with the least amount of resistance on the source.

• Using the correct gauge wires protects against large voltage and current (load) losses.

• The gauge is determined by the wire distance, voltage and current of all devices.

1.2 Determining Wire Gauge

• Follow Example A (12VDC system) and Example B (24VDC system) below.

• Use Tables 1 and Table 2 to choose the corr ect wire gauge for the application.

1.2.1 Example A: (12VDC system)

Devices Used Amps (12VDC) Progressive Totals

M62 Magnalock 0.250 0.250

DK-26 Access 0.160 0.410

XMS Motion 0.050 0.460

EEB2 Timer 0.025 0.485

Total Current Rounded Up (Table 1)

Using Table 1 (12VDC) Find: - Current Draw .600 Amps

Solution: 18 Gauge is indicated for proper installation

1.2.2 Example B: (24VDC system)

Devices Used 24VDC Amps Progressive Totals

M82 Magnalock 0.200 0.200

TSB Touch Bar 0.025 0.225

DK-11 Access 0.070 0.295

XDT-24 Delay 0.050 0.345

MK Bypass/Reset 0.020 0.365

Total Current Rounded Up (Table 2)

Using Table 2 (24VDC) Find: - Current Draw .400 Amps

Solution: 14 Gauge is indicated for proper installation

0.600A

- Wire Distance 200 Feet (One-Way)

0.400A

- Wire Distance 1000 Feet (One-Way)

PN# 500-10420

Page 12 Rev. E, 05/08

Page 13

TO SOLVE: INTERSECT ROW (Current) and INTERSECTING COLUMN (Wire Distance)

1.00A

.800A

C

U

.600A

R

R

E

.400A

N

T

.300A

.200A

12VDC

20

Gauge

22

Gauge

22

Gauge

22

Gauge

24

Gauge

24

Gauge

50’

[15m]

18

Gauge

18

Gauge

20

Gauge

22

Gauge

22

Gauge

22

Gauge

100’

[30m]

16

Gauge

18

Gauge

18

Gauge

20

Gauge

22

Gauge

22

Gauge

150’

[46m]

14

Gauge

16

Gauge

18

Gauge

18

Gauge

20

Gauge

22

Gauge

200’

[61m]

Table 1

14

Gauge

14

Gauge

16

Gauge

18

Gauge

18

Gauge

20

Gauge

300’

[91m]

12

Gauge

12

Gauge

14

Gauge

16

Gauge

18

Gauge

18

Gauge

400’

[122m]

WIRE DISTANCE

10

Gauge

10

Gauge

14

Gauge

14

Gauge

16

Gauge

18

Gauge

500’

[152m]

10

Gauge 8 Gauge

10

Gauge 8 Gauge

12

Gauge

14

Gauge

14

Gauge

16

Gauge

750’

[229m]

10

Gauge

12

Gauge

14

Gauge

14

Gauge

1000’

[305m]

1.0A

.800A

22

Gauge

22

Gauge

20

Gauge

22

Gauge

20

Gauge

20

Gauge

18

Gauge

18

Gauge

16

Gauge

18

Gauge

14

Gauge

16

Gauge

14

Gauge

14

Gauge

12

Gauge

14

Gauge

10

Gauge

12

Gauge

C

U

R

.600A

24

Gauge

22

Gauge

22

Gauge

20

Gauge

18

Gauge

18

Gauge

16

Gauge

14

Gauge

14

Gauge

R

E

N

.400A

24

Gauge

22

Gauge

22

Gauge

22

Gauge

20

Gauge

18

Gauge

18

Gauge

16

Gauge

14

Gauge

T

.300A

.200A

24VDC

24

Gauge

24

Gauge

50’

[15m]

24

Gauge

24

Gauge

100’

[30m]

22

Gauge

24

Gauge

150’

[46m]

22

Gauge

22

Gauge

200’

[61m]

22

Gauge

22

Gauge

300’

[91m]

20

Gauge

22

Gauge

400’

[122m]

20

Gauge

20

Gauge

500’

[152m]

18

Gauge

20

Gauge

750’

[229m]

16

Gauge

18

Gauge

1000’

[305m]

WIRE DISTANCE

Table 2

• The Wire Distance indicated on the table above represents a 2-wire “One-Way”

length from the power supply source to entryway installation area.

• The Gauge values specified on the table above represent a 2-wire “Round Trip”

length from the power supply source to entryway installation and retur ning back

to the power supply source.

IMPORTANT

THE 200’ [61m] WIRE RUN IN EACH TABLE FACTORS A 400’ [122m] ROUND TRIP

PN# 500-10420

Page 13 Rev. E, 05/08

Page 14

®

MAGNACARE

LIMITED LIFETIME WARRANTY

SECURITRON MAGNALOCK CORPORATION warrants that it will replace at customer’s request,

at any time for any reason, products manufactured and branded by SECURITRON.

SECURITRON will use its best efforts to ship a replacement product by next day air freight at

no cost to the customer within 24 hours of SECURITRON’s receipt of the product from

customer. If the customer has an account with SECURITRON or a valid credit card, the

customer may order an advance replacement product, whereby SECURITRON will charge the

customer’s account for the price of the product plus next day air freight, and will credit back

to the customer the full amount of the charge, including outbound freight, upon

SECURITRON’s receipt of the original product from the customer.

SECURITRON’s sole and exclusive liability, and customer’s sole remedy, is limited to the

replacement of the SECURITRON product when delivered to SECURITRON’s facility (freight

and insurance charges prepaid by customer). The replacement, at SECURITRON’s sole

option, may be the identical item or a newer unit which serves as a functional replacement.

In the event that the product type has become obsolete in SE CURITRON’s product line, this

MAGNACARE warranty will not apply. This MAGNACARE warranty also does not apply to

custom, built to order, or non-catalog items, items made by others (such as batteries),

returns for payment, distributor stock reductions, returns seeking replacement with anything

other than the identical product, or products installed outside of the United States or Canada.

This MAGNACARE warranty also does not apply to removal or installation costs.

SECURITRON will not be liable to the purchaser, the customer or anyon e else for incidental

or consequential damages arising from any defect in, or malfunction of, its products.

SECURITRON does not assume any responsibility for damage or injury to perso n or property

due to improper care, storage, handling, abuse, misuse, or an act of God.

EXCEPT AS STATED ABOVE, SECURITRON MAKES NO WARRANTIES, EITHER EXPRESS OR

IMPLIED, AS TO ANY MATTER WHATSOEVER, INCLUDING WITHOUT LIMITATION THE

CONDITION OF ITS PRODUCTS, THEIR MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

PATENTS

The Securitron Magnalock is listed under U.S. patent #4,516,114 and 4,682,801.

Additional patents pending.

PN# 500-10420

Page 14 Rev. E, 05/08

Page 15

PN# 500-10420

Page 15 Rev. E, 05/08

Page 16

Why choose a genuine Magnalock ?

The Securitron Advantages...

Electrical Advantages

• Low Current Consumption (125mA-350mA)

Less Heat for Longer Product Life

Smaller Gauge Wire

Longer Wire Runs

Smaller Power Source

Job Cost Savings

Double/Triple the Battery Back-up Time for a Secure Facility

• Patented “State of the Art” Electronic Circuitry

Instant Release Circuit “50 Milliseconds”

No Inductive Kickback

No Welded Switch Contacts

Built-in Noise Suppression

No Interference with Sensitive Electronics

• Smart Auto Switching Dual Voltage

No Jumpers, No Switches, No Errors

Sealed and Weatherproof

• Securitron Magnetic Locks are 100% Plated & Sealed

(excludes M38 & M68 series)

Outdoor Installation; Gates, Pool Areas, and Marina

Stainless Steel lock casing will not rust

Operating Temperature: -40F to +140F [-40C to +60C]

• Optional Universal Conduit Fitting (M62 & M82)

Secures and Conceals Magnetic Lock cable

Increases the Integrity of the Lock

Mounting Hardware, Brackets and Tools

• Aerospace Collapsing Blind Nuts

1000 lbs tensile strength per blind nut

• Grade One Machine Screws 1/4-20

Allows use of “Thread Locker” adhesive

• Complete Line of Mounting Hardware for Doors & Frames

Herculite, glass, aluminum, metal clad, and wood

• Optional Installation Kit

A real “Tools of the Trade” kit that reduces installation error and speeds

installation time - increasing profits

• M38 & M68

Integrated mounting bracket and built-in wire access chamber

Fast, easy and fool-proof installation

You don’t become the best selling or best warrantied products in the industry without a few

firsts.

ST

1

“E” profile electromagnetic lock

ST

1

sealed & weatherproof electromagnetic lock

1ST electromagnetic lock that suppresses inductive kickback and electronic noise and provides

instant release

1ST electric lock to mount in a standard door strike opening without cutting the frame (UnLatch)

1ST manufacturer in the security industry to offer a “no strings attached” lifetime replacement

warranty (MagnaCare)

ST

1

electromagnetic lock manufacturer to achieve ISO 9001 certification

PN# 500-10420

Page 16 Rev. E, 05/08

Loading...

Loading...