Page 1

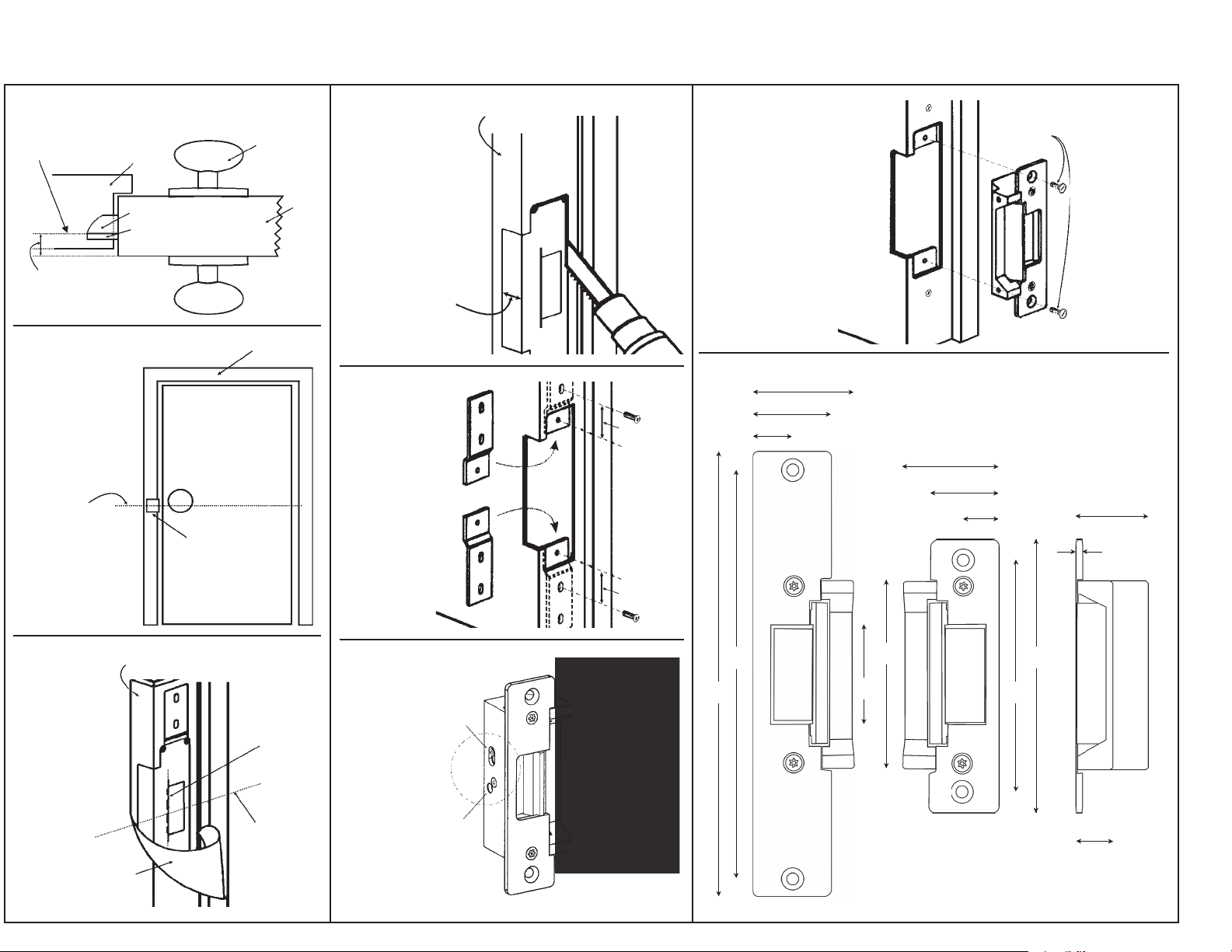

FIX THE MOUNTING TABS - METAL DOORS

Using the two small (M4x12) screws and two of the black clips provided, fix the mounting tabs to the inside of the jamb (see fig. 5).

PROGRAM FAIL-SECURE OR FAIL-SAFE

The unit can be programmed for fail-secure operation (when power is lost or cut, the door is locked) or fail-safe operation (when

power is lost or cut, the door is unlocked). Default is fail-secure. To program for fail-safe, remove the flat screw in the failsecure hole, push the round screw to the right until you see a hole appear in the fail-safe hole, and screw the flat screw into the

fail-safe hole (see fig. 6).

CONNECT WIRES AND INSULATE

Connect the two wires to the access control or egress device, such as a digital keypad, push-button switch, push bar, or other

device. Polarity is not important. Insulate the wire connections carefully

MOUNTING

Push all the wires into the door frame. If needed, cut away the dust catcher inside the frame, or carefully chip away part of the

drywall, being careful to not hurt the wall. Use the two large (M5x12) screws to mount the unit to the mounting tabs. Adjust as

needed to ensure the door closes smoothly every time someone passes through the protected opening. See fig. 7.

TROUBLE SHOOTING

1. If the door does not release when the electric strike is activated — Open the door, and leave it open. Activate the electric

strike to ensure if it is operating properly:

a. If the strike operates properly with the door open, the problem is probably a poor door latch, or the position of the

electric strike needs to be adjusted by moving it or adding washers or shims. Test again.

b. If the strike does not operate properly with the door open, dismount the strike and check that the two wires are

connected properly. Also ensure the wires are connected to the correct power supply (12VDC for SD-995C or

SK-994C, 24VDC for SD-995C24 or SD-994C24). Test again.

c. Use a multimeter to test that the strike is receiving the proper voltage and amperage. If not, it may be necessary to

use heavier gauge wires, or increase the output of the power supply.

d. If all the above tests do not locate the problem, then make sure the activation device (keypad, push-button switch,

or whatever) is activating properly.

2. If the door does not lock properly when closed — This is probably a problem with the installation or with a bad door latch.

In this case, it may be necessary to adjust the position of the strike, or possibly replace the latch.

3. For any other problems, replace the unit, and test again. The problem unit can also be substituted for a working unit in

another door frame to see if it works there.

WARRANTY:

workmanship while used in normal service for a period of one (1) year from the date of sale to the

original customer. Our obligation is limited to the repair or replacement of any defective part if the unit

is returned, transportation pre-paid, to SECO-LARM.

SECO-LARM Electric Door Strikes are warranted against defects in material and

NOTICE

The information and specifications printed in this manual are current at the time of publication.

However, the SECO-LARM policy is one of continual development and improvement. For this reason,

SECO-LARM reserves the right to change specifications without notice. SECO-LARM is also not

responsible for misprints or typographical errors.

Copyright © 2003 SECO-LARM U.S.A., Inc. All rights reserved. This material may not be reproduced

or copied, in whole or in part, without the written permission of SECO-LARM.

S A

SECO-LARM

S ASECO-LARM

16842 Millikan Avenue, Irvine, CA 92606

Tel: 800-662-0800 / 949-261-2999 Fax: 949-261-7326

U.S.A., Inc.

I.,

., IU.S.A., Inc.

Website: www.seco-larm.com

E-mail: sales@seco-larm.com

SD995C24ElectricDoorStrike MU.pmd

P TGW1

Installation Manual

SECO-LARM

SD-995C

Electric Door Strike for Metal Doors, 12VDC

SD-994C

Electric Door Strike for Wood Doors, 12VDC

Field programmable for Fail-Safe or Fail-Secure

SD-995C24 - 24VDC version of SD-995C

SD-994C24 - 24VDC version of SD-994C

• Converts cylindrical lock sets into an electronic accesscontrolled locking system.

• Field-programmable in just seconds for fail-secure or

fail-safe applications.

• Can be used with virtually any cylindrical door locking

system.

• Use with an optional digital keypad.

• Suitable for office-type applications.

• Metal door, ANSI-sized:

7

4

/8" x 11/4" x 11/4" (124 x 32 x 32 mm)

• Wood door: 7

15

/16" x 17/16” x 11/4” (202 x 36 x 32mm)

• Symmetrical-sized, reversible for right-hand or

left-hand doors.

• Shallow design for use with most metal doors.

• Powered by a solenoid, not a buzzer coil.

• Jaw strength — 2,000 pounds.

• Stainless steel lip (keeper) for strength and long life.

• 250mA@12VDC current draw;

150mA@24VDC current draw.

• Non-polarized connection. Wires can be reversed.

• Tested to 1 million cycles.

• Optional lip-extension bracket available.

MEASURE

Note: The door strike is not weatherproof. The unit must be installed indoors.

SD-995C and SD-994C are mounted the same way.

1. Latch line (see figure 1):

a. Measure the distance between the face of the door jamb and the face of the door latch. If the door latch has a deadlatch pin,

ignore the deadlatch pin when measuring. This is the vertical latch distance.

b. Measure the vertical latch distance on the door jamb from the face of the door jamb. At that point, draw a vertical line. This is the

latch line.

2. Center line (see fig. 2):

a. Measure the distance from the floor to the center of the door latch. Ignore the location of the deadlatch pin when measuring.

b. Measure that distance from the floor along the inside of the door jamb. At that point, draw a horizontal line. This is the center line.

MOUNT THE TEMPLATE

Align and tape the template on the door jamb to the latch line and the center line, and tape it (see fig. 3).

CUT

Cut into the door jamb as shown on the template (see fig. 4). Cut into the door jamb to a depth of 17mm. Toss or recycle the

metal which was cut out.

Note: If wood door, use a chisel to knock out a 3mm. (1/8 inch) deep space as shown on the template. (see fig. 4)

DOUBLE-CHECK THE CUT

Place the unit in the hole, and make sure it fits properly. Make any adjustments.

SD-995C

SD-994C

Page 2

INSTALLATION INSTRUCTIONS

Fig. 1 - Measuring

the latch line.

Latch line

Vertical latch

distance

Door jamb

Door latch

Deadlatch pin

Fig. 2 Measuring

the center

line.

Center line

Fig. 3 -

Door jamb

Aligning

the

template.

Door jamb

Door latch

Doorknob

Latch line

Center line

Door

Fig. 4 -

Door jamb

Cutting the

hole using

the template.

Note:If wood door,

use a chisel to

knock out a 3mm.

(1/8 inch) deep

space as shown on

the template.

17mm

Fig. 5 Fixing the

metal tabs

(metal door).

Fig. 6 - Programming

for fail-secure or

fail-safe.

Round

screw

Flat

screw

M4x12

screw

15mm

15mm

M4x12

screw

Fig. 7 - Mounting.

Connect the wires

and insulate

before installing

the strike.

1.77”

45mm

1.42”

36mm

0.71”

- - - - - - - - - - - -

7.95”

202mm

7.32”

186mm

18mm

- - - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - -

M5x12

screws

Dimensions

1.69”

43mm

1.25”

31.75mm

0.625”

15.9mm

- - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - -

45mm

- - - - - - - - -

1.77”

3.37”

85.6mm

- - - - - - - - - - - - - - - - - - - - -

- - - - - - -

- - - - - - - - - - - - - - -

- - - - - - - - -

- - - - - - - - - - -

105mm

- - - - - - - - - - -

- - - - - - -

4.13”

4.88”

123.85mm

33mm

- - - - - -

0.12”

3mm

- - - - - - - - -

0.67”

17mm

1.3”

- - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - -

Template

Fail-Secure

Fail-Safe

- - - - - - - - - - - -

- - - - - - - - - -

Loading...

Loading...