Page 1

Installation Manual

SECO-LARM

SD-993B-SS

Electric Shear Lock

• Concealed security for remote access and

exit control of aluminum and steel doors

or gates.

• Smaller size for use with most metal

door jambs.

• Zinc-plated magnet and armature,

aluminum anodized housing.

• Works with sliding, single-action, and

double-action (swing-through) doors

and gates.

• Use with an optional digital keypad for

keyless high security.

• Spring-loaded locking bolts and magnetic

bond holds doors securely in place with

approximately 1,500 pounds (680kg) of

shear holding force.

• Fail-safe operation (unlocks if power

is lost).

Bracket kits for SD-993B-SS

Contact your SECO-LARM sales

rep for infomation about

optional bracket kits.

• SD-993S-SB

Surfacemounting kit.

• SD-993S-UB

U-bracket kit

for glass.

See the last page of the

manual for a copy of the

bracket installation manual.

—

—

• Armature plate adjusts to compensate for

gaps between door and frame.

Specifications:

Holding force 1,500 lbs. (680 kg.)

1

Magnet housing dimensions (faceplate) 7

Armature assembly dimensions (faceplate)

Power 420mA @ 12VDC, 210mA @ 24VDC.

Door gap Max. 1/16” (2mm).

IMPORTANT — IT IS THE RESPONSIBILITY OF THE END USER AND THE

DEALER/INSTALLER TO ENSURE THIS UNIT IS MOUNTED IN ACCORDANCE

WITH ALL LOCAL FIRE AND OTHER SAFETY REGULATIONS. THIS UNIT IS

NOT FIRE-RATED.

IMPORTANT — SOME METHOD, SUCH AS A RELAY, MUST BE USED TO

ENSURE DOORS PROTECTED BY THIS UNIT CAN BE OPENED IN CASE OF

AN EMERGENCY.

/8” x 13/16” x 11/16” (180 x 30 x 27 mm).

71/8” x 13/16” x 15/8” (180 x 30 x 42 mm).

Page 2

ELECTRIC SHEAR LOCK Installation Manual

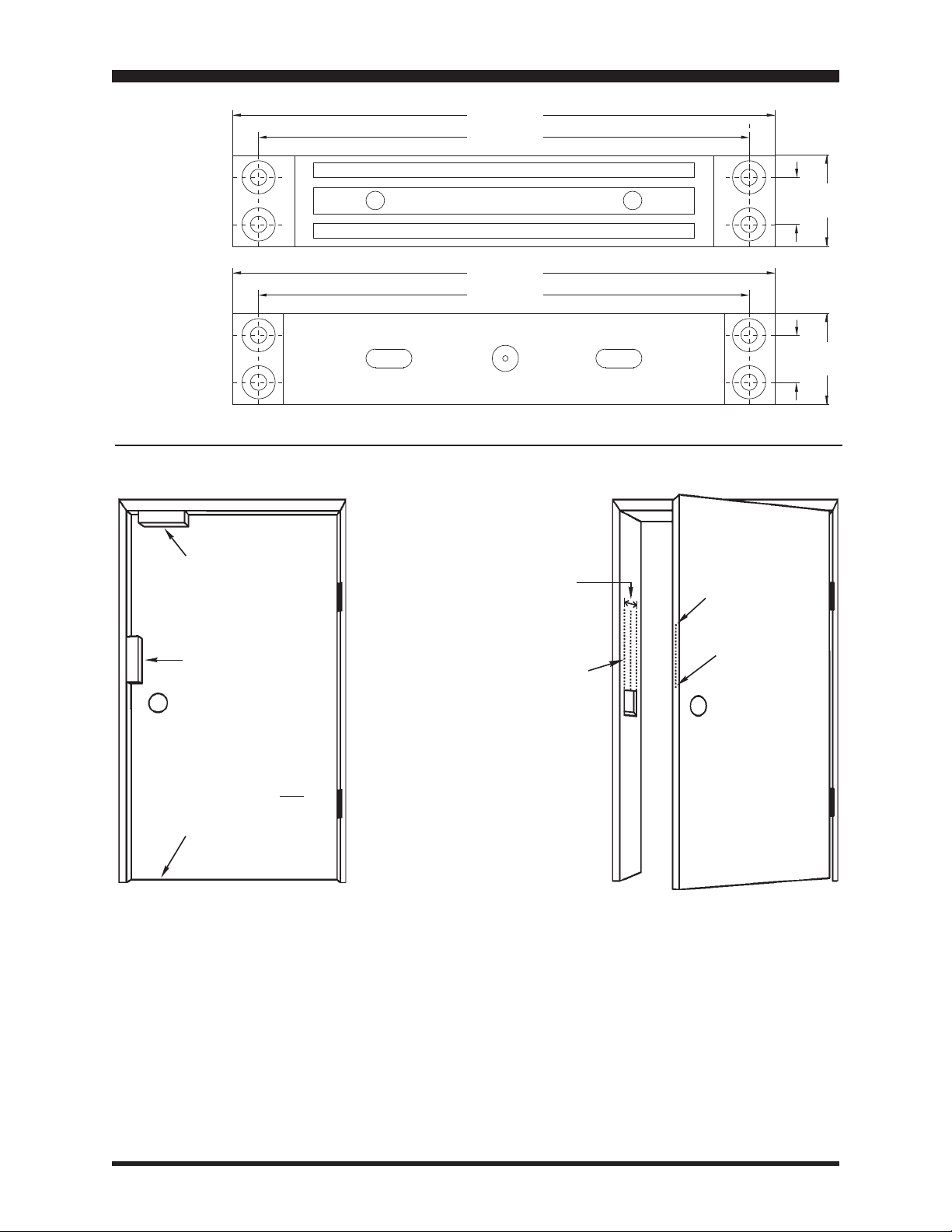

MOUNTING LOCATION (see Fig. 1)

1. Top of door — Mount here for best results, as this allows flexibility against direct

attacks against the door. Mount close to the corner opposite the hinges.

2. Middle of door, opposite the hinges — This works well in most situations. If

mounting is required here, mount halfway up the door for greatest strength. Add

extra springs to the armature assembly (see Fig. 4).

3. Bottom of door — Not recommended, as dirt buildup could affect operation.

INSTALLATION NOTE

Install the magnet assembly into the door frame before installing the armature assembly

into the door. The magnet assembly requires space to run wires, as well as space for the

recessed portion of the unit. However, make sure that the position selected for the

magnet assembly leaves enough room in the door to install the armature assembly.

INSTALLATION — CUT THE DOOR FRAME (see Fig. 2)

1. Find the center line:

a. Close the door and let it rest naturally.

b. Use a pencil to trace the position of the outside face of the door on the door

frame. If mounting on the top of the door, this line should be near the top corner

away from the door hinges. Leave enough room to mount the magnet assembly

in the door. If mounting on the side of the door, this line should be drawn near

the center of the door, but not near any physical locking mechanisms.

c. Measure the width of the door, then draw a line on the door frame parallel to

the first line at that distance. These two lines will show where the door rests

relative to the door frame when it is closed.

d. Measure and trace a line between these two lines. This is the door frame center

line.

e.

IMPORTANT — Make sure the place you choose to mount the magnet assembly is

clear of obstructions and door adjustment bolts before making any cuts. Allow

enough room inside the door frame at both ends of the magnet assembly to

install the mounting tabs.

2. Tape the door frame template to the door frame, lining the template’s door frame

center line with the door center line you just drew.

3. (For hollow metal door frames)

a. Cut out the rectangular piece of metal as shown on the door frame template.

b. Drill the four holes (two on each end) as shown on the door frame template.

c. Using the included metal screws, mount the mounting tabs.

d. Run the wires.

4. (For wood door frames)

a. Rout or cut a 1

of the magnet assembly as shown in the door frame template.

b. Rout a

c. Run the wires.

3

/16” (5mm) deep, 5/8” x 13/16” (17 x 30 mm) hole at each end of the cavity.

1

/16”(27mm) deep, 513/16” x 13/16” (147 x 30 mm) hole for the cavity

SECO-LARM U.S.A., Inc.Page 2

Page 3

Magnet

ELECTRIC SHEAR LOCK Installation Manual

7-1/8” (180mm)

6-7/16” (164mm)

Assembly

Armature

Assembly

Fig. 1 -Preferred mounting locations

Top of door - BEST

Middle of door GOOD

Note: Add extra

springs for vertical

mount (see Fig. 4)

7-1/8” (180mm)

6-7/16” (164mm)

Fig. 2 -Preparing the mounting positions

Width

of door

Door

center

line

Outside of

door when

closed

5/8”

5/8”

(16mm)

(16mm)

1-3/16”

(30mm)

1-3/16”

(30mm)

Bottom mounting not

suggested

Parts List:

1 x Magnet assembly

1 x Armature assembly

4 x Spacers

2 x Springs (for use

when the SD-993B-SS

is mounted vertically)

16 x Metal screws

1 x Hex wrench

Page 3

Page 4

ELECTRIC SHEAR LOCK Installation Manual

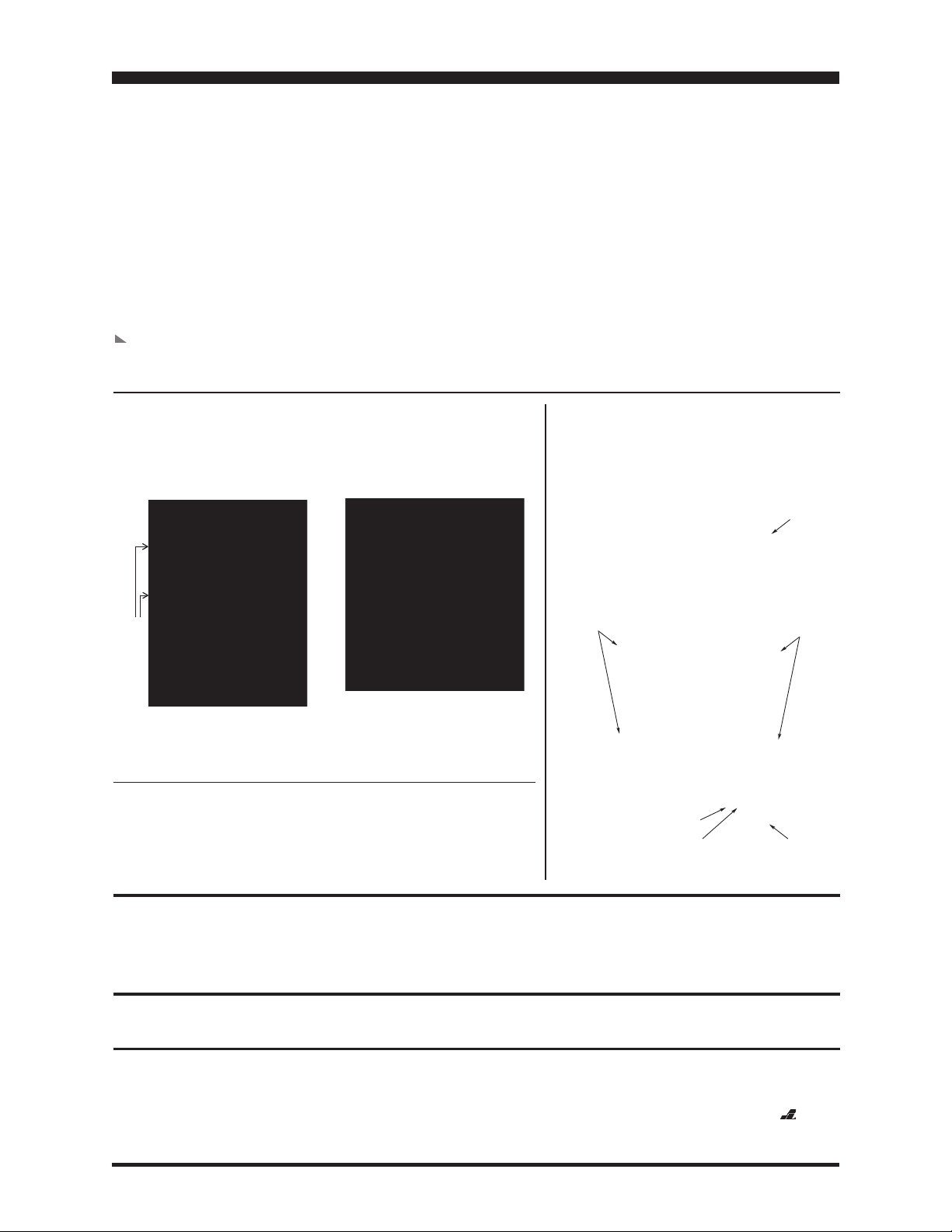

WIRING (see Fig. 3)

Fig. 3 - Power supply settings and connections

1. Set for power supply type

(12VDC or 24VDC) —

Use the jumpers to set voltage setting.

2. Connect to power —

Power nput

Power

Supply

One terminal positive, one to negative

(non-polarized)

INSTALLATION —

12VDC

24VDC

}

}

Control Device

N.C. contact or relay or keypad

Voltage setting jumpers -- must be

set properly before connecting

power. Incorrect settings can

damage the SD-993B-SS.

CUT THE DOOR

NOTE: When mounting vertically near the center of the door, disassemble the armature

assembly and add the two included springs. This improves the unit’s push-off.

(See fig. 4.)

1. Determine where to mount the armature assembly in the door. It should line up with

the magnet assembly (see Fig. 4).

2. Draw a line between the front and back door faces. This is the door center line

(see Fig. 2).

3. Tape the door template to the door, lining the door template’s door center line with

the door center line you just drew.

4. (For hollow metal doors)

a. Cut out the rectangular piece of metal as shown on the door template.

b. Drill the four holes (two on each end) as shown on the door template.

c. Using the included metal screws, mount the mounting tabs.

5. (For wood doors)

a. Rout or cut a 1

5

/8” (42mm) deep, 513/16” x 13/16” (147 x 30 mm) hole for the cavity

of the armature assembly as shown in the door template.

3

b. Rout a

/16” (5mm) deep, 5/8” x 13/16” (17 x 30 mm) hole at each end of the cavity.

Fig. 4 Lining up magnet assembly and armature assembly

Adjust armature

screws to

compensate for

the gap between

door and frame.

Max. 2mm

gap

Armature

adjustment

screw

7 1/8” (180mm)

5 13/16” (147mm)

MAGNET ASSEMBLY

Locking bolts

Push-off

button

ARMATURE ASSEMBLY

Armature

adjustment

screw

1-1/16”

(27mm)

1-1/16”

(27mm)

1-5/8”

(42mm)

Note — When

mounting vertically,

disassemble the

armature assembly

and add extra

springs for better

push-off.

SECO-LARM U.S.A., Inc.Page 4

Page 5

ELECTRIC SHEAR LOCK Installation Manual

INSTALLATION — MOUNT THE MAGNET ASSEMBLY AND

ARMATURE ASSEMBLY (see Fig. 5)

1. Double-check your work — Make sure the

magnet assembly and armature assembly

line up properly. Make any adjustments.

2. Using the screws provided, mount the magnet

assembly onto the door frame, and the

armature assembly onto the door.

3. Use washers or flat pieces of metal to act as

shims as necessary to mount the magnet

assembly and armature assembly flush with

the surface.

4. Close the door, and note the gap between the

armature assembly and the magnet assembly.

Using the included hex wrench, adjust the

nickelto make the gap as small as possible without

interfering with the opening and closing of

the door.

5. Apply power and test the operation.

plated portion of the armature assembly

Fig. 5 Mounting the magnet assembly and

armature assembly

Use tapping screws

for wood doors

(not included)

Leading edge of door

Fig. 6 Adjustment of SD-993B-SS Electric Shear Lock

Magnet

Min.

2mm

gap

Armature

Use hex wrench (included) to adjust

armature plate to approx. 2mm gap.

Page 5

Page 6

ELECTRIC SHEAR LOCK Installation Manual

TROUBLE SHOOTING

1. If the shear lock does not activate when the door is closed, it may be because the

magnet assembly is too far away from the armature assembly. You can either:

a. Adjust the distance between the magnet and armature assembly by adding more

shims under the back portion of the armature assembly.

b. Re-adjust the position of the armature assembly or the magnet assembly.

2. Poor attraction between the magnet assembly and the armature assembly — Check

the power supply, and make sure it is according to specifications. If the power

supply is adequate, replace the unit.

3. If the magnet assembly pulls the armature assembly, but the door can still be

opened, check to make sure the locking bolts are in the armature assembly’s keeper

hole when the unit is activated.

4. If the door can be kicked in or pushed in with your shoulder, check to make sure the

magnet assembly and armature assembly surfaces are clean and free from dirt. Even

a little dirt could reduce the attraction between the two surfaces.

5. For any other problems, replace the unit, and test again. The problem unit can also

be substituted for a working unit in another door frame to see if it works there.

REGULAR MAINTENANCE

• Clean the contact surfaces of the electromagnet or armature plate with a soft cloth and non-

abrasive, non-corrosive cleaner.

• Apply a light coat of a silicon lubricant to prevent rust. Wipe away the excess.

• Check that the armature plate is securely attached to the door, yet can pivot slightly around the

armature screw.

• Check that the electromagnet is securely attached to the door frame.

WARRANTY:

for a period of one (1) year from the date of sale to the original consumer customer. SECO-LARM’s obligation is limited to the repair or

replacement of any defective part if the unit is returned, transportation prepaid, to SECO-LARM.

This Warranty is void if damage is caused by or attributed to acts of God, physical or electrical misuse or abuse, neglect, repair, or alteration,

improper or abnormal usage, or faulty installation, or if for any other reason SECO-LARM determines that such equipment is not operating

properly as a result of causes other than defects in material and workmanship.

The sole obligation of SECO-LARM, and the purchaser’s exclusive remedy, shall be limited to replacement or repair only, at SECO-LARM’s option.

In no event shall SECO-LARM be liable for any special, collateral, incidental, or consequential personal or property damages of any kind to the

purchaser or anyone else.

This SECO-LARM product is warranted against defects in material and workmanship while used in normal service

NOTICE: The information and specifications printed in this manual are current at the time of publication. However, the SECO-LARM

policy is one of continual development and improvement. For this reason, SECO-LARM reserves the right to change specifications without notice.

SECO-LARM is also not responsible for misprints or typographical errors.

Copyright © 2011 SECO-LARM U.S.A., Inc. All rights reserved. This material may not be reproduced or copied, in whole or in part, without the

written permission of SECO-LARM.

SECO-LARM U.S.A., Inc.Page 6

Page 7

ELECTRIC SHEAR LOCK Installation Manual

Installation Notes:

Date: _____________________________________ Name: ______________________________________

Phone #___________________________________ Company: ___________________________________

Voltage Used:

12VDC 24VDC

Special Circumstances: ___________________________________________________________________

Additional Notes:________________________________________________________________________

Please sketch connection diagram below:

Page 7

Page 8

ELECTRIC SHEAR LOCK Installation Manual

For optional surface-mount bracket and U-bracket kits:

SD-993S-SB

Surface-mount bracket kit

SD-993S-SB

SD-993S-UB

U-bracket (glass door) kit

Bracket kits for SD 993B SS Electric Shear Lock

SD-993S-UB

FOR SURFACE MOUNTING (SD-993S-SB)

Surface-mount

(magnet and armature).

Use 2 x surface-mount brackets

Flush mount (magnet).

Surface mount (door).

Use 1 x surface mount bracket

Header

M6 x 45 screw

Magnet

Assembly

Armature

Assembly

Surface

mount

bracket

The magnet assembly is in

the bracket above the door,

and the armature assembly

is in the bracket on the door.

SD 993S SB includes:

2 x Surface mount brackets

4 x Aluminum trim plates

3 x Blind nuts

3 x Hex screws

1 x Blind nut assembly

Blind Nut

M6 x 45 screw

Blind Nut

Metal

Door

2mm

The magnet assembly is flush to

the door frame or header, and

the armature assembly is in the

bracket on the door.

SD 993S UB includes:

2 x U brackets

8 x Aluminum spacers

4 x Hex screws

1 x Hex wrench

Surface

mount

bracket

Magnet

Assembly

Armature

Assembly

Header

M6 x 45 screw

Blind Nut

Metal

Door

FOR GLASS DOOR MOUNTING (SD-993S-UB)

May require 1 or more SD 993S SB

and SD 993S UB bracket kits,

depending on the glass door

configuration.

Glass

frame

2 x Surface

mount

brackets

Min. gap:

2mm

U bracket

Spacer

NOTES: One glass door with a glass frame illustrated above.

2 x U brackets

Glass

door

Min.

Clearance:

7mm

WARRANTY:

original consumer customer. SECO LARM’s obligation is limited to the repair or replacement of any defective part if the unit is returned, transportation prepaid, to SECO LARM.

This Warranty is void if damage is caused by or attributed to acts of God, physical or electrical misuse or abuse, neglect, repair, or alteration, improper or abnormal usage, or faulty installation, or

if for any other reason SECO LARM determines that such equipment is not operating properly as a result of causes other than defects in material and workmanship.

The sole obligation of SECO LARM, and the purchaser ’s exclusive remedy, shall be limited to replacement or repair only, at SECO LARM’s option. In no event shall SECO LARM be liable for any

special, collateral, incidental, or consequential personal or property damages of any kind to the purchaser or anyone else.

NOTICE

improvement. For this reason, SECO LARM reserves the right to change specifications without notice. SECO LARM is also not responsible for misprints or typographical errors.

Copyright © 2006 SECO LARM U.S.A., Inc. All rights reserved. This material may not be reproduced or copied, in whole or in part, without the written permission of SECO LARM.

EC . ., .S

SECO-LARM U.S.A., Inc.

16842 Millikan Avenue, Irvine, CA 92606

Tel: 800-662-0800 / 949-261-2999 Fax: 949-261-7326

This SECO LARM product is warranted against defects in material and workmanship while used in normal service for a period of one (1) year from the date of sale to the

The information and specifications printed in this manual are current at the time of publication. However, the SECO LARM policy is one of continual development and

:

MiSD-993B-SScEmailb.pmd

Website: www.seco-larm.com

@

E-mail: sales

seco-larm.com

PITGW1

SECO-LARM U.S.A., Inc.Page 8

Loading...

Loading...