Page 1

WT-Series

INLINE TURBINE METER

INSTRUCTIONS

WTP

PVC Body

WT-SERIES INLINE TURBINE METER INSTRUCTIONS

WTC

Carbon Steel

ISO

WTS

Stainless Steel

9001:2008

CERTIFIED COMPANY

Page 2

GENERAL INFORMATION and SPECIFICATIONS

GENERAL INFORMATION

This unique system of 2" to 8" turbine meters uses just

one moving part, a precision helical rotor. Rotation of

the rotor is electronically detected and processed. The

high-quality jewel bearings and shafts minimize friction

while providing long wear life in non-lubricating fluids.

The entire rotor assembly can be easily removed for

field service without removing the meter from the pipe.

WTP bodies are fabricated from Schedule 80 PVC ttings,

WTC bodies from carbon steel tubing, and WTS bodies from

stainless steel tubing. The turbine insert on WTC and WTS

meters is machined from a stainless steel casting. The WTP

turbine insert is machined from a solid piece of PVC. Turbine

rotors on all models are Kynar (PVDF).

WT meters can be ordered with various output options.

The basic model (100) comes with pulse output only. An

electronic display (Seametrics FT420) is mounted on the

101 model to display flow rate and total (resettable or

non-resettable), and provide a programmable pulse or

4-20 mA output. Other electronics options include a blind

4-20 mA transmitter (AO55) on the 102 model and a

battery-powered (FT415) rate/totalizer plus pulse output

for applications that lack power (104 model). All of these

controls/displays can be mounted on the meter or remotely

mounted on a wall or panel up to 2,000 feet away. WTSeries meters are compatible for use with most other

remote-mount Seametrics displays and controls as well.

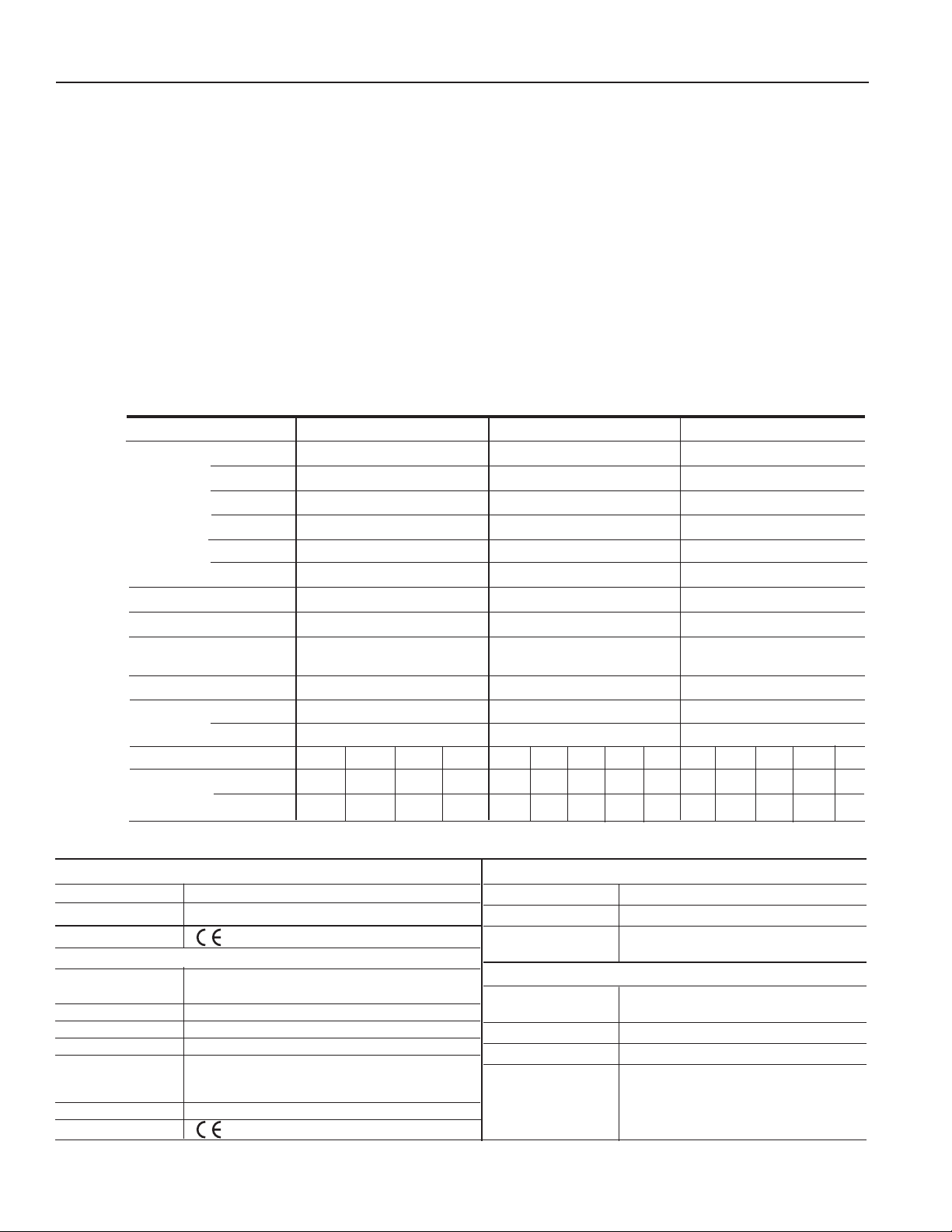

SPECIFICATIONS*

Pipe Sizes

Materials Meter Body

Turbine Insert

Rotor

Shaft

Shaft

Bearings

Cable

Flanges

Maximum Pressure

Maximum Temperature

Accuracy 3”-8”

2”

Flow Range (GPM)

Minimum

Maximum

Electronic Options Specications*

WTP WTC WTS

2”, 3”, 4”, 6”

PVC Schedule 80 ttings

PVC

Kynar (PVDF)

Zirconia ceramic 3”-6”

Tungsten Carbide 2”

Sapphire journal, ruby endstone

#22 AWG, 2000’ max

Optional (See Dimensions)

150 psi @ 75˚ F

(10 bar @ 24˚ C) (see chart)

120˚ F (50˚ C) (see chart)

+/- 1% of full scale

+/- 2.5% of full scale

2” 3” 4” 6”

2 3 6 12

150 400 600 1200

2”, 3”, 4”, 6”, 8”

Painted carbon steel

CF8M cast stainless

Kynar (PVDF)

Zirconia ceramic 3”-8”

Tungsten Carbide 2”

Sapphire journal, ruby endstone

#22 AWG, 2000’ max

150 lb. drilling (3-8” only)

200 psi (14 bar)

200˚ F (93˚ C)

+/- 1% of full scale

+/- 2.5% of full scale

2” 3” 4” 6” 8”

2 3 6 12 30

150 400 600 1200 3000

2”, 3”, 4”, 6”, 8”

304 Stainless steel (316 SS optional)

CF8M cast stainless

Kynar (PVDF)

Zirconia ceramic 3”-8”

Tungsten Carbide 2”

Sapphire journal, ruby endstone

#22 AWG, 2000’ max

150 lb. drilling (3-8” only)

200 psi (14 bar)

200˚ F (93˚ C)

+/- 1% of full scale

+/- 2.5% of full scale

2” 3” 4” 6” 8”

2 3 6 12 30

150 400 600 1200 3000

WT100 (Pulse Output Only)

Power 6-24 Vdc

Pulse Output 0-160 pulse/second current sinking

Regulatory

Mark

WT101 (Powered Rate/Totalizer) (e.g. FT420)

Power 12-32 Vdc (for 4 mA DC min);

24-32 Vdc (for accuracy of 4-20 mA loop)

Rate 6-digit autorange

Total 8-digit

Memory Non-volatile (no battery needed)

Pulse Output 0.1 second open collector (scaled);

0-75 pulse/second passthrough

(unscaled); High alarm or low alarm

Analog Output 4-20 mA loop (24-32 Vdc required)

Regulatory

*Specications subject to change • Please consult our website for current data (www.seametrics.com).

Mark

WT102 (Blind 4-20 Transmitter) (e.g. AO55)

Power 24 - 36 Vdc (isolated)

Analog Output 4-20 mA loop

Response Time 2-60 seconds, 90% of full scale

(depends on input averaging)

WT104 (Battery-powered Rate/Totalizer) (e.g. FT415)

Power 3.6 Vdc Lithium battery

replaceable, 3-5 year life

Rate 6-digit auto range

Total 8-digit

Pulse Output 0.1 second open collector (scaled);

0-75 pulse/second passthrough

(unscaled); High alarm or low alarm

Page 2

Page 3

INSTALLATION, CONNECTIONS, MAINTENANCE and REPAIR

10X Dia. 5X Dia.

Straight coupling can

be part of length

FLOW

WTP

A

A

INSTALLATION

CAUTION: These water meters are not

recommended for installation downstream

of the boiler feedwater pump where installation fault may expose the meter to boiler

pressure and temperature. Maximum recom-

mended temperature is 120˚ (PVC) or 200˚ (Metal).

Piping Conditions. Installing the meter with 10 diameters of

straight pipe upstream and 5 downstream is recommended.

Flanges. For 3-8” WTC and WTS meters, standard anges

are 150 lb. ANSI drilling. 2” WTC or WTS meters and all PVC

meters can be installed with optional anges according to pipe

manufacturer’s recommendations. For PVC a bolt torque of

10-20 ft-lbs. for 2” anges, 20-30 ft-lbs. for 3” and 4” anges,

and 35-50 ft-lbs. for 6” anges is recommended.

Either partial or full-face gaskets can be used. Tighten the

bolts evenly. Use care to prevent a misaligned gasket from

entering the ow stream.

Position. The WT-Series are all-position meters, operable in

a vertical or horizontal position, with the meter insert in any

radial position. A horizontal position is preferred if there is a

risk of air becoming trapped due to constant low ows. Operating the meter in partially-lled pipe will result in inaccuracies.

CONNECTIONS

Loop Power Supply

24-36 Vdc (dep on device)

Black

4-20 mA

4-20 mA Device

Red

Black

Red

White

Black

Power

Sensor

Output

Sensor

Pulse

Output

For operating instructions for the various electronic modules,

consult the manual for the specic module, included with the meter

at purchase.

To Other

Control

WTC and WTS Meters

2"

2” FEMALE NPT

(150 lb. Flange opt.)

3"- 8"

Size Dim A

2" * 8"/‡10"

3" 12"

4" 14"

6" 18"

8" 20"

*Without ange

‡With ange

WTP Meter

Optional

Flanges

B

A

MAINTENANCE and REPAIR

Recalibration. If it is necessary to recalibrate the meter for any

reason, this can be done by any Seametrics-authorized facility.

Call your supplier for information.

Turbine Insert Removal and Installation. CAUTION: First

remove all pressure from the line. Then remove the screws or

bolts that hold the insert in place (or the U-clip in the 2” meters)

and tug gently until the insert comes free. A twisting motion

can help to loosen the O-ring seal. Reverse the procedure to

reinstall, after coating the O-ring with lubricant (plastic compatible in the WTP). Do not overtighten.

Rotor and Shaft Replacement. Examine the rotor to determine

if bearings or shaft are damaged or excessively worn. The rotor

should spin smoothly and freely, with no visible wobble. Back

and forth play should be very minor, less than 1/64”. If it is

necessary to replace the rotor or shafts, rst back out both

shafts with a small blade screwdriver. The rotor will come free

as soon as the shaft ends come free of the rotor bearings. Reverse the procedure to reinstall. Note: Do not overtighten the

shaft screws. Check to be sure that a small amount of free play

between the shaft ends and the bearings remains.

Sensor Replacement. This is rarely necessary. However, certain electrical conditions can damage the sensor. To replace

it, rst remove the electronics module. Disconnect the sensor

leads from the electronics module terminals and remove the

threaded plug over the sensor. Finally, remove the sensor by

pulling on the sensor leads. A gentle tug should be sufcient.

Reverse the process to replace the sensor.

Size A B

2” 10" 7.5"

3" 12" 6.5"

4" 14" 7.0"

6" 18" 8.5"

Page 3

Page 4

REPLACEMENT PARTS

2” METERS

1-6

Housing see 3 - 8”

7 Strain relief 101850

8 Square housing adapter

9 Pickup retaining screw 100298

Pickup, Micropower (for WT104) 100508

10

Pickup, Standard (for WT101) 100419

11 O-ring, EPDM 100264

12 Insert

13/14 Rotor Repair Kit, Polypro/Tungsten Carbide 101912

14 Rotor Assembly, Polypro/Tungsten Carbide 101862

15 U-clip, stainless 100154

Not Available

Contact Factory

After

1-1-2011

After

1-1-2011

Electronics Module Repair.

4

1

2

3

8

65

None of the electronics modules have replaceable components. Printed circuit boards

7

must be replaced as complete

units. In order to replace

an entire electronics module, loosen the four retaining

9

10

11

12

13

14

15

screws and the unit will lift

free from the insert housing.

3” - 8” METERS WTC WTP WTS

1 Upper blind housing assembly 100662 100662 100662

1 Powered rate/totalizer 100495 100495 100495

1 Blind 4-20 mA transmitter 100471 100471 100471

1 Battery-powered rate/totalizer 100469 100469 100469

2 Lower housing gasket 100411 100411 100411

3 Lower housing 100502 100502 100502

4

Upper housing screw assembly (4 req)

100414 100414 100414

5 Plug, steel 100360 100360 100360

6 Water seal assembly 100364 100364 100364

7 Strain relief 101850 100850 100850

8 Square housing adapter

Part Not Replaceable

9 Pickup retaining screw 100298 100298 100298

Pickup, Micropower (for WT104) 100508 100508 100508

10

Pickup, Standard (for WT101) 100419 100419 100419

11a Insert, 3”-8” WTC and WTS 100440 100440 100440

11b Insert, 3” PVC N/A 100438 N/A

11c Insert, 4”-6” PVC N/A 100439 N/A

12

Shaft assembly, ceramic (2 req) 100227 100227 100227

13 Rotor (PVDF) /bearing assembly 100152 100333 100152

14 O-ring, EPDM 100270 100214 100270

15 Insert screw (4 req’d) N/A 100023 N/A

4

1

2

3

8

9

10

11a

12

13

14

WTC/WTS

WTC/WTS

WTP

65

7

WTP

11b

11c

12

13

14

15

FLOW

WTP

Page 4

Seametrics Incorporated • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com

LT-65200056-043015

4/30/2015

Loading...

Loading...