Page 1

WMX-SERIES

9 001:2008

CERTIFIED COMPANY

ISO

MUNICIPAL/INDUSTRIAL MAGMETER

INSTRUCTIONS

WMX-SERIES MUNICIPAL/INDUSTRIAL MAGMETER INSTRUCTIONS

WMX104

WMX101-168

WMX104-300

Page 2

TABLE OF CONTENTS

General Information

General Information, Features ................................................................................................... Page 1

Specications

Specications, Flow Range ............................................................................................................ Page 3

Installation and Grounding

Positioning the Meter,

Straight Pipe Recommendations, Full Pipe Recommendations, Fittings,

Calibration, Chemical Injection, Installing Gaskets............................................................ Page 4

Tightening Flange Bolts, Metal Pipe Installations, Plastic Pipe Installations....................... Page 5

Straight Pipe Recommendations ................................................................................................ Page 6

Full Pipe Recommendations ...................................................................................................... Page 7

Inputs/Outputs and Operation

Power, Pulse Output, High Frequency, K-Factor, Display Reading ................................................... Page 8

Connections Diagrams

AO55/WMX101, FT420/WMX101, DL75 or DL76/WMX101 ........................................................... Page 9

Troubleshooting

Problem, Probable Cause, Things to Try .................................................................................... Back

TABLES, DIAGRAMS & CHARTS

Features ...................................................................................................................................Page 1

Specifications .......................................................................................................................... Page 3

Flow Range ............................................................................................................................. Page 3

Metal Pipe Installation, Plastic Pipe Installation ..................................................................... Page 5

Straight Pipe Recommendations ............................................................................................. Page 6

Full Pipe Recommendations .................................................................................................... Page 7

High Frequency Output ............................................................................................................. Page 8

Display Readings ..................................................................................................................... Page 9

Connections Diagrams ................................................................................................................................ Page 10

Troubleshooting ......................................................................................................................... Back

Page 3

GENERAL INFORMATION

The WMX-Series are anged electromagnetic owmeters

for use in 3” to 12” pipe in municipal or industrial water and

wastewater applications where propeller meters have typically

been used in the past. Because the WMX has no moving

parts and has electrodes designed to discourage fouling, this

magmeter performs well and requires much less frequent

maintenance in applications where debris would impede

propeller meters. There is no rotor to stop turning or bearings

to wear out. Minimal straight pipe requirements allow WMXSeries meters to be used in piping congurations where there

is little space between the meter and an elbow.

In chemical injection applications, the chemical injection

point must be placed downstream of the magmeter OR far

enough upstream for complete mixing to occur before the

uid reaches the meter.

The submersible units, -168 option, are rated IP68 (NEMA 6P)

for applications where the meter may be under water up to a

depth of 3 meters for prolonged periods of time.

Rate and total indication are standard on both models. Units

are customer-selected and factory-set. No set-up is required.

The WMX101 is externally powered with 8-32 Vdc at 30

mA max (see NOTE in Specications). Two Lithium 3.6V

“AA” batteries provide auxiliary power during power failures,

allowing the meter to continue recording ow rate and total

without interruption for the duration of the outage. Where

external power loss is infrequent, battery life exceeds 10 years.

The 20-foot power cable also provides pulse output for use

with a variety of Seametrics and other displays and controls for

remote reading, data logging, pulse-to-analog conversion, and

telemetry applications. High frequency pulse rate (required

for use with 4-20 mA converters) is standard; additional pulse

rates are optional.

The WMX104 is a battery-operated unit for use when pulse

output is not required. Two Lithium 3.6V “D” batteries provide

power and are replaceable with an approximate 1-year life

under continuous use. An optional input/output cable can be

installed post-factory if needed for changing applications.

*Extended battery life is standard on all IP68 meters.

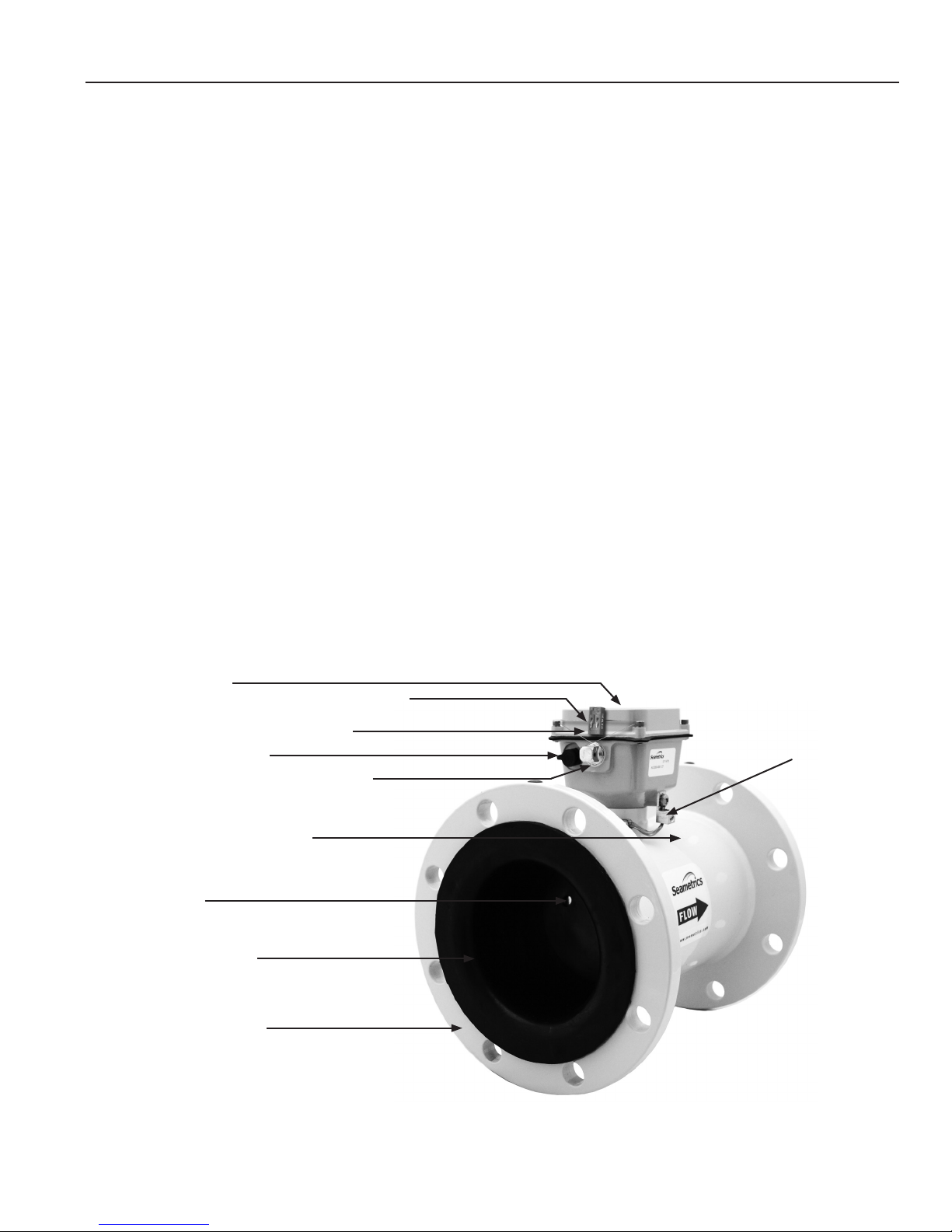

FEATURES

Rate and total indicator

Powder-coated diecast-aluminum electronics housing

Tamper-evident security seal &

cross-drilled screws (2) for tamper-evidence

Internal Data Logger (Optional)

Power/Output cable port access, tamper-sealed

(NOTE: WMX101 comes with standard 20’ cable installed)

Welded steel epoxy-coated ow tube

316SS electrodes

Dual durometer rubber liner

Flanges, ANSI 150 lb. drilling

Equalization lug

WMX104

Page 1

Page 4

GENERAL INFORMATION

FEATURES Continued

Rate and total indicator

Tamper-evident security seal &

cross-drilled screws (2) for tamper-evidence

Internal Data Logger (Optional)

Power/Output cable port access, tamper-sealed

(NOTE: WMX101 comes with standard 20’ cable installed)

Powder-coated ductile cast iron body & electronics housing

Glass lled molded plastic liner

316SS electrodes

Flanges, ANSI 150 lb. drilling

Rate and total indicator

Tamper-evident security seal &

cross-drilled screws (2) for tamper-evidence

Power/Output cable port access, tamper-sealed

(NOTE: WMX101 comes with standard 20’ cable installed)

Internal Data Logger (Optional)

Powder-coated ductile cast iron electronics housing

Equalization lug

WMX104-300

(IP68 housing standard for 3” models)

Equalization lug

Page 2

IP68 Housing Option

(For 4”-10” meter;

standard for 3” models)

Page 5

SPECIFICATIONS

SPECIFICATIONS*

Pipe Sizes

Fittings

Pressure

Temperature Operating

Accuracy

Materials Body (3” Only)

Body (4”-12”)

Liner (3” Only)

Liner (4”-12”)

Electronics Housing

Electrodes

O-ring (3” Only)

Display

Power

Non-Operating

Digits

Units

3”,4”, 6”, 8”, 10”, 12”

ANSI 150 lb. drilling

150 psi (10.3 bar) working pressure

10˚ to 130˚ F (-12˚ to 54˚ C)

-40˚ to 158˚ F (-40˚ to 70˚ C)

+/- 1% of reading for ow between 10% to 100% of max ow

+/- 2% of reading for ow from cutoff to 10% of max ow

Ductile cast iron, powder coated

Welded steel, epoxy-coated

Noryl®

Santoprene/Polypropylene

Diecast aluminum, powder-coated (non-IP68) Ductile Cast Iron (IP68)

316 stainless steel

EPDM

Rate Total

5 8

Gallon/Minute, Liter/Minute, Liter/Second, Gallon, Gallon x 1000, Liter, Liter x 1000, Mega Liter,

Cubic Feet/Minute, Cubic Meter/Hour, Cubic Meters, Cubic Meter x 1000, Cubic Feet,

Million Gallon/Day, Mega Liter/Day Cubic Feet x 1000

WMX101: 8-32 Vdc at 30 mA max, with auxiliary battery for continuous operation during power failures

NOTE: Using an unregulated power supply >18 Vdc may damage the meter due to AC line input voltage uctuation

WMX104: 2 Lithium 3.6V “D” batteries, replaceable, 1 year life under continuous use.

Pulse Output Signal

Pulse Rates

High Frequency

(pulse/gal)

Conductivity

Empty Pipe Detection

Environmental

Regulatory

*Specications subject to change. Please consult our website for the most current data (www.seametrics.com).

WMX101: Current sinking pulse, opto-isolated, 30 Vdc at 10 mA max

WMX104: Pulse output available only with addition of post-factory output cable

High Frequency; 10 units/pulse; 100 units/pulse; 1000 units/pulse

3” 4” 6” 8” 10” 12”

25.228

>20 microSiemens/cm

Hardware/software, conductivity-based

NEMA 4X Standard (IP68 Option)

NSF-61 (3” ONLY)

16.362 6.307 3.344 2.150

FLOW RANGE (3” - 12”)

Meter

Size

Minimum

Maximum

3” 4” 6” 8” 10” 12”

Gal/Min Liter/Sec Gal/Min Liter/Sec Gal/Min Liter/Sec Gal/Min Liter/Sec Gal/Min Liter/Sec Gal/Min Liter/Sec

7.5 .47 12 .75 32 2 60 3.8 95 6 130 8.2

700 44.2 1,000 63 2,400 151.4 4,400 27 7. 6 7,000 441.6 10,000 630.9

1.530

Page 3

Page 6

INSTALLATION and GROUNDING

INSTALLATION

Caution: These ow sensors are not recommended

where installation fault may expose the ow sensor to

boiler pressure and temperature. Maximum

recommended temperature is 130˚ F.

Positioning the Meter. These meters can be installed

horizontally, vertically, and in any radial position. Using a

check valve on the upstream side of the meter, and/or an air

vent (vacuum relief valve) in the same, unobstructed run of

pipe as the meter, is required in any installation where the

meter may be exposed to suction when the system is not in

normal operation. Suction can cause damage to the liner.

Liner damage caused by suction, without the use of a check

valve and/or air vent, may void the warranty.

Straight Pipe Recommendations. As with most flow

meters, the WMX requires some straight pipe before and

after the meter for best accuracy. However, the ability of

electromagnetic meters to average the ow across the entire

pipe allows for shorter straight pipe recommendations than

most mechanical meters (see page 4).

Full Pipe Recommendations. All magmeters require a

method for determining that the pipe is empty, to prevent false

reading. This meter is designed to go to zero reading if one

or more electrodes is exposed. For highest accuracy, install

the meter so that the pipe will be full when there is ow. If air

bubbles may be present in the pipe or sludge accumulation

is an issue, rotate the meter by one ange hole to position

the control housing at a 45˚ angle (see diagrams on page 5).

Fittings. The WMX anges have standard ANSI 150 lb. drilling

and mate with any other ANSI 150 lb. ange.

Installing Gaskets

GASKETS

Gaskets are required at all junctions.

(Not applicable to 3” model.)

1. Select a suitable full-face gasket.

• Only use at compressible gaskets (either pliable

or hard ber will work).

• Use a material compatible with the uid you will be

using.

• Thickness should be 1/8” - 1/4” (3 - 6 mm),

depending on the atness of the pipe ange

surface.

• Inner diameter must be larger than opening in ow

meter.

2. Be sure all mating surfaces are smooth and free of

debris.

3. Install gaskets on each end of meter as shown in

diagrams below. If using grounding rings, install one

gasket on each side of the grounding ring.

Gaskets

Installation without gaskets

Calibration. The WMX is factory-calibrated and will not require

any form of eld calibration.

Chemical Injection. When any magmeter, by any manufacturer, is used in a chemical injection application, the chemical

injection point must be placed downstream of the magmeter OR far enough upstream for complete mixing to occur

before the uid reaches the meter. When unmixed chemical

alternates with water passing through the meter, the rapid

changes in conductivity may cause sudden spikes and drops

in the meter’s reading, resulting in inaccurate measurement.

The magmeter will restabilize, however, with a steady ow of

uid of uniform conductivity.

Caution: In chemical injection applications, install

chemical injection point downstream of magmeter,

or far enough upstream to allow complete mixing of

uids before the meter.

Page 4

Grounding

Rings

Gaskets

Installation with gaskets

Page 7

INSTALLATION and GROUNDING

Tightening Flange Bolts

NOTE: Mating pipe anges must be ANSI 150# full face (FF)

and/or raised face (RF).

1. Tighten ange bolts in an alternating pattern.

• Tighten left ange bolt-1 to 20% recommended

torque.

• Tighten right ange bolt-1 to 20% of

recommended torque.

• Repeat steps a and b for each bolt in an

alternating order, such as shown at right,

tightening to 40%, then 60%, then 80%, and then

100%.

2. Test for leaks.

3. If needed, tighten further in 10% increments until

leaking stops. DO NOT over-tighten. Over-tightening

can cause serious damage to the ow meter.

4. Recheck after 24 hours, adjusting if needed.

1

5

8

Equalization and Grounding

WARNING: ELECTRICAL SHOCK HAZARD

When the is installed in a plastic piping

system, or when externally powered, the

piping system must be grounded to meet

national and local electrical safety codes.

Failure to do so can result in electrocution.

Metal Pipe Installations. To equalize the electrical potential

of the uid, the meter, and the surrounding pipe, secure the

ange plates (factory-installed on the equalization wire) to

both pipe anges at one of the bolt holes, as shown below.

Be sure the lock washer ts between the pipe ange and the

ange plate. For the best electrical bonding, remove rust

and paint to expose clean, bare metal where the equalization

ange plate lock washer contacts the pipe ange. Connection

must be inspected periodically for corrosion to maintain the

necessary low resistance connection.

Meter Flange

Gasket

Pipe Flange

Lockwasher

Flange Plate

Equalization Lug

3

7

4

6

2

Suggested Tightening Sequence

Caution: Improper tightening sequence

can cause serious damage to the ow

meter.

• Do not tighten one side at a time.

• Do not tighten each bolt completely at

one time.

SUGGESTED FLANGE BOLT TORQUE

Santoprene Liner

Pipe Size ft-lb Nm

3” 25 34

4” 20 27

6” 42 57

8” 65 88

10” 73 99

12” 97 132

Meter

Flange

Gaskets

Pipe

Flange

Metal PipeMetal Pipe

Plastic Pipe Installations. When the meter is installed in a

plastic piping system, grounding rings are recommended

(except 3” pipe size), especially in the presence of electrical

interference sources such as VFD pump drives. As shown in

the diagram below, the equalization wires should then be

connected to the grounding ring tabs instead of the ange

bolts as in metal piping installations. Where lightning is a

threat, or in severe electrical environments, an optional

connection to a nearby equipment ground or ground rod may

be advisable.

Equalization Lug

Grounding Ring

Gaskets

Plastic

Pipe

#6, #8, or #12 AWG Stranded

Copper Ground Wire < 5’

Grounding Ring Part Numbers:

4” = 100876 10” = 100879

6” = 100877 12” = 103288

8” = 100878

Grounding Ring

Gaskets

Plastic

Pipe

Ground Clamp

(Exothermically weld when

corrosion is a concern)

Earth

8’ Ground Rod

Page 5

Page 8

STRAIGHT PIPE RECOMMENDATIONS

(X = diameter)

Reduced Pipe

Two Elbows In Plane

Two Elbows, Out Of Plane

1X

2X

WMX

1X

2X

WMX

1X

2X

Expanded Pipe

Swirling Flow

Propeller Meter

5X

5X

WMX

WMX

5X

1X

1X

WMX

1X

Swirling Flow

Partially Open

Buttery Valve

Page 6

WMX

Page 9

FULL PIPE RECOMMENDATIONS

Recommended:

Keep pipe full at meter for accuracy

WMX

WMX

Not Ideal:

Allows air pockets to form at meter

WMX

Recommended:

Keeps pipe full at meter for accuracy

WMX

Recommended:

Allows air to bleed off

Intermittent air

Electrode

moved from

top by rotating

meter

WMX

miss electrode

Electrodes free

from sediment

bubbles

build-up

WMX

Not Ideal:

Post-valve cavitation can create air pocket

WMX

Not Ideal:

Air can be trapped

Intermittent air

bubbles

pass over

electrode

Possible

sediment

build-up

WMX

Recommended:

Improved accuracy results from

unimpeded electrodes

Not Ideal:

Air bubbles and sediment on the

electrodes can affect accuracy

Page 7

Page 10

INPUTS/OUTPUTS and OPERATION

WMX101

External Power (WMX101). The WMX101 operates on 8 to

32 Vdc at 30 mA max external power (see WARNING in wiring

diagrams). The display reads “P” when external power is in

use (see illustration below).

The Lithium battery pack installed in the WMX101 serves as

backup in the event of a power failure, when it will keep the

meter operating without interruption for the duration of the

outage. When battery power in is use, the WMX101 display

continues to read out the rate and total, but the “P” indicating

external power is extinguished. When power resumes, the

WMX101 will seamlessly return to normal power mode, and

the “P” will again display.

When used for occasional emergency backup, battery life is

approximately ten years.

Pulse Output (WMX101). The WMX101 cable also provides

pulse output that can be used for remote reading, 4-20 mA

signal conversion, datalogging, and telemetry applications.

See page 7 for connection diagrams to Seametrics controls

and displays.

Pulse Output (WMX104). Pulse output capabilities are built

in to the WMX104, but cannot be utilized without the addition

of an optional output cable. A WMX104 can be retrotted with

this cable in the eld. IMPORTANT: When eld installing the

input/output cable, be sure to snugly tighten the cable strain

relief to prevent water ingress.

OPERATION

Caution: There are no user-adjustable

connections or settings inside the display

housing. Use caution when opening the

housing for a battery change, to avoid

damage to internal components.

Display Reading. The WMX display has two lines, the bottom

line for ow rate and the top line for accumulated total.

Measurement units are pre-ordered and factory-set and can

be changed in the eld only by an authorized individual.

Refer to the diagrams below to read your display.

Note: For data logger setup and operation, refer to Flow

Inspector Manual

Pulse rates are selected by the customer at time of order,

factory-set, and can only be changed in the field by an

authorized Seametrics dealer. Three pulse rates are possible:

One pulse per ten gallons (or liters), one pulse per thousand

gallons (or liters), or High Frequency (required for use with

4-20 mA converters; see below):

High Frequency Output/K-Factor

Meter Size Pulses per Gallon Pulses per Liter

3” 25.228 6.665

4” 16.362 4.323

6” 6.307 1.666

8” 3.344 0.883

10” 2.150 0.568

12” 1.530 0.405

WMX104

Battery Power (WMX104)*. The WMX104 is powered by a

non-rechargeable battery pack with an approximate 1-year life

under continuous use. Actual lifespan will vary from application

to application, depending on the duty cycle.

External Power Indicator

(WMX101 Only)

Battery Power

(WMX104 Standard Operation)

(WMX101 Backup Operation)

No Power

Empty Pipe

“Low Batt” will display when there are approximately

three days of use left in the batteries (see illustration).

Replacement instructions come with the custom

battery pack available from your dealer or Seametrics.

Page 8

Low

Batt

Low Battery Indicator

(3 days remaining)

Meter Installed Backwards

Page 11

CONNECTIONS DIAGRAMS (WMX101)

The WMX101 requires a power source of 8 to 32 Vdc at 30

mA max (see WARNING). The WMX101 power cable also

serves as a pulse output if needed for remote reading, data

logging, signal conversion, or telemetry.

AO55/WMX101

Blue

Do

Not

{

Orange

Use

4-20 mA

Power

5

6

4

3

2

1

0

S

Sensor

Not

Used

Frequency

5

6

4

7

8

9

7

3

8

2

9

1

0

5

5

6

6

4

4

7

7

3

3

2

8

8

2

9

9

1

1

0

0

Power Supply

at 30 mA max

(see WARNING)

White (-)

Green (+)

Black

Red

(-) (+)

8-32 Vdc

AO55W Pulse-to-Analog Converter

FT420/WMX101

External Power Input Required - 12-32 Vdc

WMX101 Cable Color Codes

Orange and Blue: Serial Output (Do Not Use)

Green (+) and White (-): Pulse Output, 30 Vdc max, 10 mA max

Red (+) and Black (-): External Power, 8-32 Vdc at 30 mA max

Drain: Connect to earth ground (see WARNING)

WMX101 Cable

Shielded

Drain Wire

Direct Burial Cable

22 AWG Stranded

WARNING: Using an unregulated power

supply >18 Vdc may damage the meter

due to AC line input voltage uctuation.

WMX101

PASSTHRU

PULSE

SCALED

PULSE

Power

4-20 mA

Input

Sensor

Not

Used

FT420W Remote Rate/Total Display

DL75 or DL76/WMX101

Battery

-

S

+

Not

Used

Blue

Do

Not

{

Orange

Use

White (-)

Green (+)

Black

Red

(-) (+)

Power Supply

8-32 Vdc

at 30 mA max

(see WARNING)

Blue

Do

Not

{

Orange

Use

White (-)

Green (+)

Black

Red

Drain Wire

WMX101 Cable

Shielded

Direct Burial Cable

22 AWG Stranded

WARNING: Using an unregulated power

supply >18 Vdc may damage the meter

due to AC line input voltage uctuation.

WMX101 Cable

Shielded

Direct Burial Cable

22 AWG Stranded

WMX101

WMX101

DL75W or DL76W Data Logger

(-) (+)

Power Supply

8-32 Vdc

at 30 mA max

(see WARNING)

Drain Wire

WARNING: Using an unregulated power

supply >18 Vdc may damage the meter

due to AC line input voltage uctuation.

Page 9

Page 12

TROUBLESHOOTING

Problem

Blank Display

Flow rate steadily reads

zero when there is ow

Flow rate intermittently

drops when there is ow

Probable Cause Try...

Dead battery (WMX104)

No power plus dead battery (WMX101)

Replace battery pack

Replace battery pack, check power

connections

Flow is below cutoff (very low)

Pipe is not full

Meter is installed backwards

Reading will resume when ow increases

Reposition meter for full pipe (see page 4)

Note ow direction arrow, reverse meter

(display reads [ - ] )

Power connections reversed (WMX101)

Fluid conductivity <20microSiemens/cm

Pipe is not full

Change power connections

Select another ow meter

Reposition meter for full pipe (see page 4)

Jumpy reading

Meter reads, but no

pulse output (WMX101)

Output pulses missing

Missing or incorrect ground wire

Pulsing ow

Rapidly changing conductivity

(in chemical injection applications)

External device needs pull-up resistor

Reversed leads (polarity sensitive)

Meter not reading

Check for proper ground

Use external power source

(allows more ow averaging)

Install chemical injection line downstream

of meter (or far enough upstream to allow

complete mixing of uids before meter)

Add pull-up resistor

(For details, refer to ‘Connecting to PLCs’

Technical Bulletin at www.seametrics.com)

Change output connections

Check display

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com

LT-65200289r1.2 20161020

10/20/16

Loading...

Loading...