Page 1

d

C

WMP-Series

Plastic-Bodied Magmeter

Instructions

3 inch

2 inch 1 inch

o

m

e

i

p

f

PROUDLY

MADE

IN THE

USA

i

t

r

e

C

ISO

9001:2008

a

n

y

Page 2

GENERAL INFORMATION

General Information

General Information ...................................................................................................................................................Page 2

Features ...........................................................................................................................................................................Page 3

Specications ................................................................................................................................................................Page 3

Dimensions ....................................................................................................................................................................Page 4

Flow Range .....................................................................................................................................................................Page 4

Installation

Piping Conditions ........................................................................................................................................................Page 5

End Connections ..........................................................................................................................................................Page 5

Positioning......................................................................................................................................................................Page 5

Straight Pipe Recommendations ...........................................................................................................................Page 6

Full Pipe Recommendations ....................................................................................................................................Page 6

Connections and Operation

Electrical Connections ................................................................................................................................................Page 7

Cable Connections ......................................................................................................................................................Page 7

Grounding ......................................................................................................................................................................Page 7

Operation ........................................................................................................................................................................Page 7

Maintenance and Troubleshooting

Maintenance ..................................................................................................................................................................Back

Troubleshooting ...........................................................................................................................................................Back

WMP-SERIES INSTRUCTIONS

The WMP-Series meters are full-bore, plastic-bodied

electromagnetic ow meters designed for ow and usage

monitoring applications in 1, 2, and 3 inch pipe. The

polypropylene ow tube offers corrosion resistance to

a wide range of chemicals. It’s light weight and easy to

install or remove from the pipe for inspection.

With no moving parts, the magmeter permits unobstructed

ow, minimizing ow disturbances and hence, straight

pipe requirements. The WMP-Series can be used in piping

congurations where there is little space between the

meter and an elbow or valve. The WMP-Series meters are

resistant to wear from sand and debris found in ground

or surface water. Since there are no bearings or propeller

to wear out, downtime, maintenance, and repair costs are

kept to a minimum. Because there are no mechanical parts

in the ow stream, the meter tolerates high ows without

damage.

The hinged, opaque polyethylene cover protects from dust

and UV rays, while permitting easy access to the LCD ow

rate and total display. The electronics housing is made of

rugged powder-coated diecast aluminum. It can be tted

with cross-drilled screws and seal wire for tamper-evidence.

Flow rate and total can be displayed in a variety of units,

customer-selected and factory-set.

The WMP101 is externally powered via a 5-pin connector

and the power cable also provides pulse output for use with

a variety of Seametrics and other displays and controls for

remote reading, data logging, pulse-to-analog conversion,

and telemetry applications.

The WMP104 is a battery-operated unit for use when pulse

output is not required. The standard batteries are user

replaceable with an approximate 1–2 year life depending on

usage. An extended battery life option offers an estimated

2–4 year life depending on usage.

In the event of DC power loss, or when changing the

battery, the WMP is designed to retain the internal settings

and ow total.

Seametrics • 253.872.0284 Page 2 seametrics.com

Page 3

GENERAL INFORMATION

WMP-SERIES INSTRUCTIONS

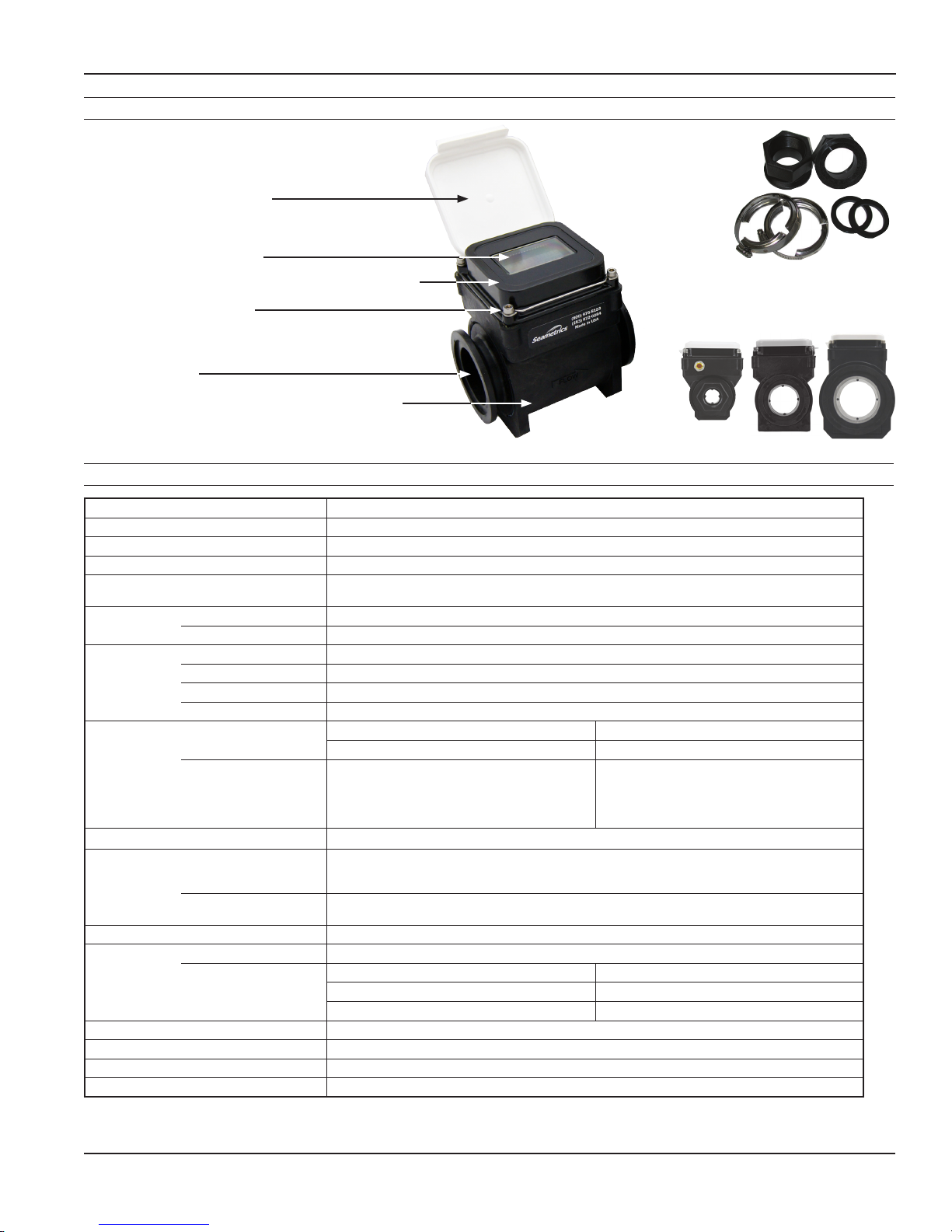

Features

Polyethylene protective cover

LCD rate and total indicator

Powder-coated diecast aluminum electronics housing

Seametrics Fitting Kit

Cross-drilled screws (2) for

tamper-evidence

316SS electrodes

Corrosion-resistant glass-lled polypropylene body

Lightweight for easy handling

Unobstructed Flow

Specications*

Pipe Size 1, 2, or 3 inch full port

Fittings 1 inch NPTF, 2 or 3 inch ange clamps with 2 or 3 inch NPTF tting kit

Pressure 150 psi or 10.3 bar working pressure @ 70˚ F

Operating Temperature Range Operating: 10˚ to 130˚ F (-12˚ to 54˚ C), Non-operating: -40˚ to 176˚ F (-40˚ to 80˚ C)

Accuracy ±1% of reading (between 10% and 100% of maximum ow)

Flow Range Minimum 1”: 2.3 gpm (0.145 l/s) 2”: 6 gpm (0.38 l/s) 3”: 14 gpm (0.88 l/s)

Maximum 1”: 110 gpm (6.94 l/s) 2”: 300 gpm (18.9 l/s) 3”: 670 gpm (42.3 l/s)

Materials Body Glass-lled polypropylene

Electrodes 316 stainless steel

Electronics Housing Power-coated diecast aluminum

Display Cover Polyethylene

Display Rate Total

Digits 6 8

Units Gallons/Minute, Million Gallons/Day,

Security Cross-drilled screws and tamper-evident seal (optional)

Power WMP101 10–30 Vdc @ 60 mA maximum (15 mA average)

WMP104 6 - AA alkaline cells, replaceable. Estimated life is 1 year depending on usage (standard)

Pulse Output Signal (WMP101 only) Current sinking pulse, opto-isolated, 32 Vdc maximum @ 10mA maximum

Pulse Rate Low Frequency (-PxU) 1 unit/pulse out, pulse width of 10 ms, depending on unit selection

(WMP101 only)

Empty Pipe Detection Hardware/software, conductivity based

Conductivity >20 microSiemens/cm

Environmental NEMA 4X standard

Electrical Connection (WMP101 only) 5-pin male circular connector, mates to industry standard cable

*Specications subject to change • Please consult our website for current data (seametrics.com).

High Frequency (-HF) 1” 2” 3” Pulse width 1.1 ms, min–max frequency, 3–150 Hz

Pulse/Gal 80 30 13

Pulse/Liter 21.14 7.93 3.44

±3% of reading (between cutoff and 10% of maximum ow)

Cubic Feet/Second,

Cubic Feet/Minute, Liters/Second, Liters/Minute,

Million Liters/Day, Cubic Meters/Minute,

Cubic Meters/Hour

Note: Using an unregulated power supply >18 Vdc may damage the meter due to AC line input voltage

uctuation.

2 - C lithium batteries, replaceable. Estimated life is 2–4 years depending on usage (extended battery life opt)

Acre-Feet, Acre-Inch, Gallons, Gallons x 1000,

Cubic Feet, Liters, Megaliters, Cubic Meters,

Cubic Meters x 1000

for 2 & 3 inch model

Seametrics • 253.872.0284 Page 3 seametrics.com

Page 4

4.625”

10.75”

4.40”

3.00”

7.30”

7.30”

2.625”

GENERAL INFORMATION

Dimensions

Dimensions shown without the Seametrics WMP Fitting Kit.

WMP-SERIES INSTRUCTIONS

4.3”

1.00”

5.50”

4.55”

8.8”

5.38”

4.625”

3.25”

2.00”

5.50”

2 Inch1 Inch

9.50”

3 Inch

6.03”

1.63”

2.03”

Flow Range

1” 2” 3”

Gal/Min Liter/Sec Gal/Min Liter/Sec Gal/Min Liter/Sec

Minimum 2.3 0.145 6 0.38 14 0.88

Maximum 110 6.94 300 18.9 670 42.3

Seametrics • 253.872.0284 Page 4 seametrics.com

Page 5

INSTALLATION

WMP-SERIES INSTRUCTIONS

Piping Conditions

It is highly recommended that the meter be installed with

a length of straight pipe at least two times the diameter

upstream and one diameters downstream. Some piping

conditions require more than this. See next page for

recommendations.

Step 1

Position gasket

at either end

Step 2

Place adapter

against gasket,

open screw clamps

to clear anges

End Connections

The meter comes with Banjo™ union-type ange

connections for ease in servicing the meter. To connect

these to piping ends, a variety of kits are available from any

Banjo dealer or from Seametrics.

Follow the diagrams below to make the connections.

Step 3

Place screw-clamps

over both adapter

and meter anges

and tighten screws

NOTE: Above installation instructions are for WMP101/104-200 (2”) and WMP101/104-300 (3”) only.

The WMP101/104-100 (1”) is provided with integrated NPT female threaded ends.

Positioning

This is an all position meter which can be installed either vertically or horizontally, register up, down, or angled. However,

entrained air or solids may make some positions preferable to others.

WMP

Intermittent air

bubbles pass over

electrode

Possible

sediment

build-up

Not ideal:

Air bubbles and sediment on the

electrodes can affect accuracy

Recommended:

May prevent sediment

or bubble problems

WMP

Electrode moved

from top by

rotating meter

Intermittent air

bubbles

miss electrode

Electrodes free

from sediment

build-up

Seametrics • 253.872.0284 Page 5 seametrics.com

Page 6

INSTALLATION

Straight Pipe Recommendations (X = pipe diameter)

WMP-SERIES INSTRUCTIONS

Reduced Pipe

2X

Elbows

2X

Full Pipe Recommendations

Possible Problem

1X

1X

Expanded Pipe

Swirling Flow: Partially Open

Buttery Valve

Better Installation

5X

5X

1X

1X

Allows air pockets to form at sensor

Possible Problem

Better Installation

Post-valve cavitation can create air pocket

Possible Problem Better Installation

Air can be trapped

Ensures full pipe

Keeps pipe full at sensor

Allows air to bleed off

Seametrics • 253.872.0284 Page 6 seametrics.com

Page 7

CONNECTIONS and OPERATION

Electrical Connections

WMP-SERIES INSTRUCTIONS

WMP104. The WMP104 is battery-powered, totally self-

contained, and does not require any electrical connections

(there is no output on the WMP104 model).

Cable Connections

Gray: Pin 5 = Ground

Black: Pin 4 = (–) Power

Blue: Pin 3 = (+) Pulse

White: Pin 2 = (–) Pulse

Brown: Pin 1 = (+) Power

Shield Drain Wire

WMP101. A connector is provided on the outside of the

WMP101. To connect to the meter, plug the cable in and

hand tighten the retaining threads. Follow the diagram

to make connections. If you are using the pulse output,

connect power rst and determine that the meter is

working properly by observing the display. Then connect

the pulse output.

Grounding

Grounding (WMP101). For best performance, especially

in chemically noisy environments, the gray ground wire

and the bare drain wire should be connected together and

to a good earth ground as close to the meter as possible.

Metal pipe and ttings in contact with the uid should

also be bonded to the same earth ground with corrosion-

resistant connections.

Seametrics • 253.872.0284 Page 7 seametrics.com

Operation

Display. The display reads ow rate and accumulated total,

in the units for which it was ordered. The top line is the

total, the bottom line is the rate, and indicators give the

units (ac-ft, GPM for instance.) Empty or partially full pipe

is automatically detected and is indicated by a reading of

“ – EP – “.

Battery. The standard batteries are user replaceable

with an approximate 1–2 year life depending on usage.

An extended battery life option offers an estimated 2–4

year life depending on usage. On the battery-powered

WMP104 there is a low-battery indicator (“low bat”) when

the battery voltage drops below a certain point. Batteries

should be changed within four weeks of the appearance of

this indicator.

Page 8

MAINTENANCE and TROUBLESHOOTING

Maintenance

WMP-SERIES INSTRUCTIONS

There are no user-serviceable parts in the WMP-Series

meters except the batteries in the WMP104.

Battery Replacement. When the “low bat” indicator

appears, the batteries should be changed. Either six AA

alkaline cells are required, or two C lithium cells with

integrated wiring harness, depending on power option

ordered with meter.

To change the batteries, rst remove the four screws which

hold the top cover in place. Be careful not to lose the

washers. Move the top cover to one side and remove the

foam retainer which covers the battery tray or pack.

Warning!

Use Extreme Caution not to pinch wiring

or other assembly parts under the

housing seal—this may cause an ingress

of water, voiding the product warranty.

• For units with AA alkaline batteries, remove the old

bat teries from the battery tray and replace them

with fresh ones, taking care to fol low the polarity

indicators in the battery tray.

• For units with the optional C lithium batteries,

carefully unplug each of the two battery wiring

harness connectors. Slip the batteries out from

under the elastic retainer, and replace them with

the new batteries. Reconnect each of the two wiring

harness connectors. The connectors are indexed for

correct installation.

Replace the foam retainer, and then put the top cover

back in place. Replace the four screws and washers, and

then tighten them securely using cross-pattern to evenly

compress the gasket.

Environmental and Safety Note

Take care to dispose of all batteries in

accordance with Federal, State, and Local

regulations.

Troubleshooting

Problem Probable Causes Things to try…

Blank Display (WMP101) No power to unit Check power supply; check wiring

Blank Display (WMP104) Batteries dead or misinstalled Check polarity; replace batteries

Reading “-EP-” Empty or partly lled pipe or

Rearrange piping to ensure full pipe

excessive air pockets or foaming

Flow but no ow rate reading Heavily coated electrodes Remove meter and wipe electrodes

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • seametrics.com

LT-65650290r1.2 20161006

10/6/16

Loading...

Loading...