Page 1

WJ-Series

TURBINE METER

INSTRUCTIONS

WJ-SERIES TURBINE METER INSTRUCTIONS

ISO

6” Meter

3” Meter

9001:2008

CERTIFIED COMPANY

Page 2

GENERAL INFORMATION and SPECIFICATIONS

GENERAL INFORMATION

WJ-Series turbine meters are dry-register mechanical totalizers

that offer accurate, economical reading of high ows with low

pressure loss. The horizontal-axis turbine drives a vertical

shaft, which is magnetically coupled to the sealed register.

In addition to mechanical totalizing, registers can be equipped

with magnetic pulse reed sensors well suited for remote totalizing, pacing of electronic metering pumps, and water treat-

ment applications.

FEATURES

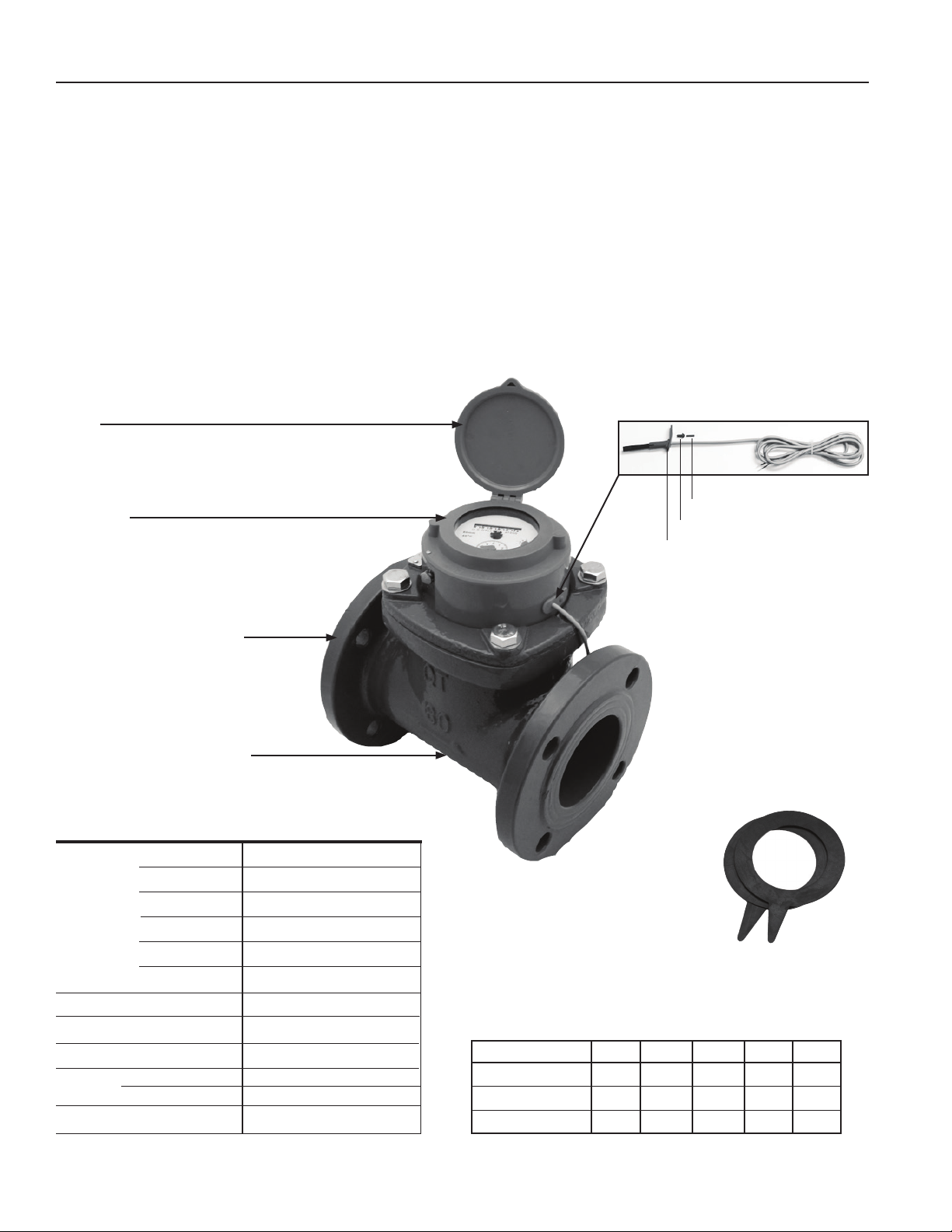

Lid

Display

Bodies are manufactured of tough cast iron and epoxy-coated

for protection. Tungsten steel shafts and jewel bearings further

enhance the durability of these meters. Simple removal of the

top ange brings out all parts for inspection, repair, or replacement. The meter has a tamper-evident seal to call attention to

unauthorized access.

Compatible Seametrics controls include the PT35 pulse timer,

the PD10 pulse divider, and the PS40 pulse splitter for running

multiple pulse-responsive devices (e.g. pumps, counter timers

and remote totalizers) with a single WJ meter.

Rivet Pin #103107

Rivet, plastic #103106

Reed Switch Assembly #103109

150 lb. ANSI drilling ange

Epoxy-coated cast iron body

SPECIFICATIONS

Materials Meter Body

Register Plate

Drive Magnet

Turbine

Turbine Shafts

Bearings

Flanges

Maximum Pressure

Maximum Temperature

Accuracy* Above Transition

Below Transition

Reed Switch

*Specications subject to change

Please consult our website for current data (www.seametrics.com).

Cast iron, epoxy coating

ABS plastic

Alnico

Plastic

Tungsten steel

Jewel

150 lb. ANSI drilling

150 psi (10 bar)

105˚ F (40˚ C)

+/-2% of reading

+/-5% of reading

100 mA @ 24 Vac/dc

3” Meter

Gaskets

included

FLOW RANGE (GPM)

2" 3" 4" 6” 8”

2 5.3 8 20 33

Minimum

Max. Continuous

132 352 528 1320 2200

13 35 53 132 220

Transition*

*The ow rate at which accuracy changes from +/-2% of reading

(above Transition) to +/-5% of reading (below Transition).

Page 2

Page 3

INSTALLATION

The following installation recommendations are adapted from

the American Water Works Manual M6, and will result in the

best meter life and accuracy.

Piping Conditions. It is recommended that the meter be in-

stalled with at least ten diameters of straight pipe upstream

and ve diameters downstream from elbows, tees, crosses,

valves, and other ttings. If less straight pipe is available, or if

debris are likely to go through the meter, installation of a standard plate-type strainer directly upstream is recommended.

If a basket-type strainer is used, it should be located at least

ve diameters upstream. Avoid conditions of trapped air or

partially-lled pipe. This can occur when there is low ow and

open discharge near to the meter.

10X Dia. 5X Dia.

Flanges. The WJ meter is compatible with any standard 150

lb. ANSI drilling, at or raised face. Take care that gaskets

(included) do not protrude into the meter due to misalignment.

Adhering the gasket to the meter ange with gasket adhesive

is a good practice that will aid installation.

Position. WJ-Series are all-position meters, and can be installed horizontally or vertically. Horizontal with register facing

up is recommended when possible.

Flow

Flow Arrow

DIMENSIONS

H H1 H2

L

2” 3” 4”

7.87” (19.99 cm) 8.86” (22.5 cm) 9.84” (24.99 cm)

L

10.08” (25.60 cm) 10.87” (27.61 cm) 11.26” (28.60 cm)

H

12.91” (32.79 cm) 13.70” (83.29 cm) 14.09” (35.79 cm)

H1

15.79” (32.79 cm) 15.75” (40 cm) 15.75” (40 cm)

H2

26.5 lbs (12.02 kg) 35.3 lbs (16.01 kg) 39.7 lbs (18.01 kg)

Wt.

H1 = Lid clearance for reading display

H2 = Head clearance for replacing turbine insert

2", 3", 4"

H H1 H2

L

6” 8”

11.81” (30.00 cm) 13.78” (35.00 cm)

L

13.60” (34.54 cm) 14.67” (37.26 cm)

H

16.44” (41.76 cm) 17.50” (44.45 cm)

H1

1969” (50.01 cm) 19.69” (50.01 cm)

H2

92.6 lbs (42.00 kg) 141 lbs (63.96 kg)

Wt.

H1 = Lid clearance for reading display

H2 = Head clearance for replacing turbine insert

6", 8"

Page 3

Page 4

MAINTENANCE AND REPAIR

CAUTION: Before breaking the tamper-

evident seal on your meter, be sure that

you are in compliance with any regulatory

requirements (if applicable).

Adding Reed Switch. For the contacting head option, WJ

meters use a meter-mounted reed switch to provide a twowire dry contact. To add a reed switch in the eld, remove

one of the black rubber plugs from the side of the register

housing and slide the reed switch assembly into the housing in the direction of the dial with the desired pulse rate.

Lock in place with the rivet and pin (see page 2).

Note: If changing the pulse rate, you need to rst remove

the reed switch from the position it is in. In doing so, the

small plastic rivet & pin will be damaged and should not

be reused. Have a replacement plastic pin & rivet before

beginning. If you do not have a spare, contact factory for

a replacement (see page 2 for part reference).

Changing the Pulse Rate. When changing the pulse rate, you

must rst remove the existing reed switch (see note above).

Recalibration. For meters used for revenue-billing purposes,

some states require periodic calibration checking. This type

of turbine meter is most commonly checked every four years.

Testing may be done by a local mobile meter service or in a

private or municipal meter shop. Changes in calibration should

be made at an authorized meter shop.

The Register (2”, 3” & 4” version shown)

Cover Hinge

Retaining ring

0 0 0 0 0 0

U.S. GALLONS X1000

80mm

40°C

0

1

9

8

1

2

2

3

7

46

5

3

5

4

0

9

1

2

8

3

7

46

5

X 100

X 10

8

7

6

Totalizer

2”, 3” & 4” = X1000

6” & 8” = X10000

Pulse rate dial #1

2”, 3” & 4” = X100

6” & 8” = X1000

Pulse rate dial #2

2”, 3” & 4” = X10

6” & 8” = X100

1. Choose desired pulse rate and switch position.

Setting Your Pulse Rate

Size Size Pulse Reed Switch

(inches) (mm) Rate Position

2” 50

3” 80

4” 100

6” 150

8” 200

100 x10

1,000 x100

100 x10

1,000 x100

100 x10

1,000 x100

1,000 x100

10,000 x1,000

1,000 x100

10,000 x1,000

2. Remove the black rubber plug from the other hole

and move it to the position the reed switch was

removed from.

3. Insert the reed switch assembly into the side of the

register housing in the direction of the dial with desired

pulse rate.

4. Lock in place with rivet and pin.

Register Removal. Clip and remove the copper security wire

from the security pin. Remove the security pin that holds

the lid in place, twist the lid and lift it off. Lift the register

free from the meter, noting orientation.

Turbine Insert Replacement. The entire turbine insert comes

out as a unit without removing the meter from the pipe. Carefully

noting position and retaining parts for reassembly.

1. Remove the lid and register as described.

2. After relieving pressure inside the meter, remove

the four ange hex-screws and washers.

3. Lift the ange and insert out in one piece, rocking

gently to break the seal.

4. Remove the four retaining ring screws, and lift

the retaining ring and ange off the turbine insert.

5. Remove and replace the large O-ring around the

top opening of the meter body.

6. Reassemble the retaining ring and ange on top of

the new insert. Be sure the alignment notch in the

retaining ring is directly above the screw in the

insert’s top plate.

7. Replace the entire mechanism in the meter body

with the drilled screw head in the same corner as

the security pin.

8. Replace the lid with a twist of the wrist, insert

the security pin in the tiny hole in the retaining ring,

and thread the security wire through the screw

head and the security pin. Afx lead seal and crimp.

Page 4

Seametrics Incorporated • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com

LT-65200309-081314

8/13/2014

Loading...

Loading...