TX800-Series

ISO

FLOW SENSOR

INSTRUCTIONS

•TX81x

•TX82x

TX800SERIES FLOW SENSOR INSTRUCTIONS

9 001:2008

CERTIFIED COMPANY

TABLE OF CONTENTS

TX800 SERIES INSTRUCTIONS

General Information

Generial Information, Features .................................................................................................................................Page 3

Specications ..............................................................................................................................................................Page 4

Installation

Fitting Installation, Distorted Flows, Meter Installation, Orienting the Meter .......................................................Page 5

Straight Pipe Recommendations ..............................................................................................................................

Full Pipe Recommendations ......................................................................................................................................Page 7

Connections

FT430, FT440 ............................................................................................................................................................. Page 8

FT450, Connecting to PLC's ......................................................................................................................................Page 9

Operation and Maintenance

Modularity, Output, Fittings, Minimum Flow, Flow Rate Tables, Calibration (“K-Factor”) ..................................Page 10

Rotor Replacement, Signal Troubleshooting, Sensor Replacement ....................................................................Page 11

Parts List ...................................................................................................................................................................Page 12

Troubleshooting

Problem, Probable Cause, Things to Try .................................................................................................................Page 13

Page 6

TABLES AND DIAGRAMS

Features ......................................................................................................................................................................Page 3

Specications ..............................................................................................................................................................Page 4

Distorted Flows, Orienting the Meter ........................................................................................................................ Page 5

Straight Pipe Recommendations ..............................................................................................................................

Full Pipe Recommendations ......................................................................................................................................Page 7

Connection Diagrams ..............................................................................................................................................Page 8-9

Flow Rate Table .........................................................................................................................................................Page 10

Rotor Replacement ...................................................................................................................................................Page 11

Parts Explosion, Parts List .......................................................................................................................................Page 12

Troubleshooting ........................................................................................................................................................Page 13

Page 6

Page 2

Seametrics • 253.872.0284 • www.seametrics.com

GENERAL INFORMATION

TX800 SERIES INSTRUCTIONS

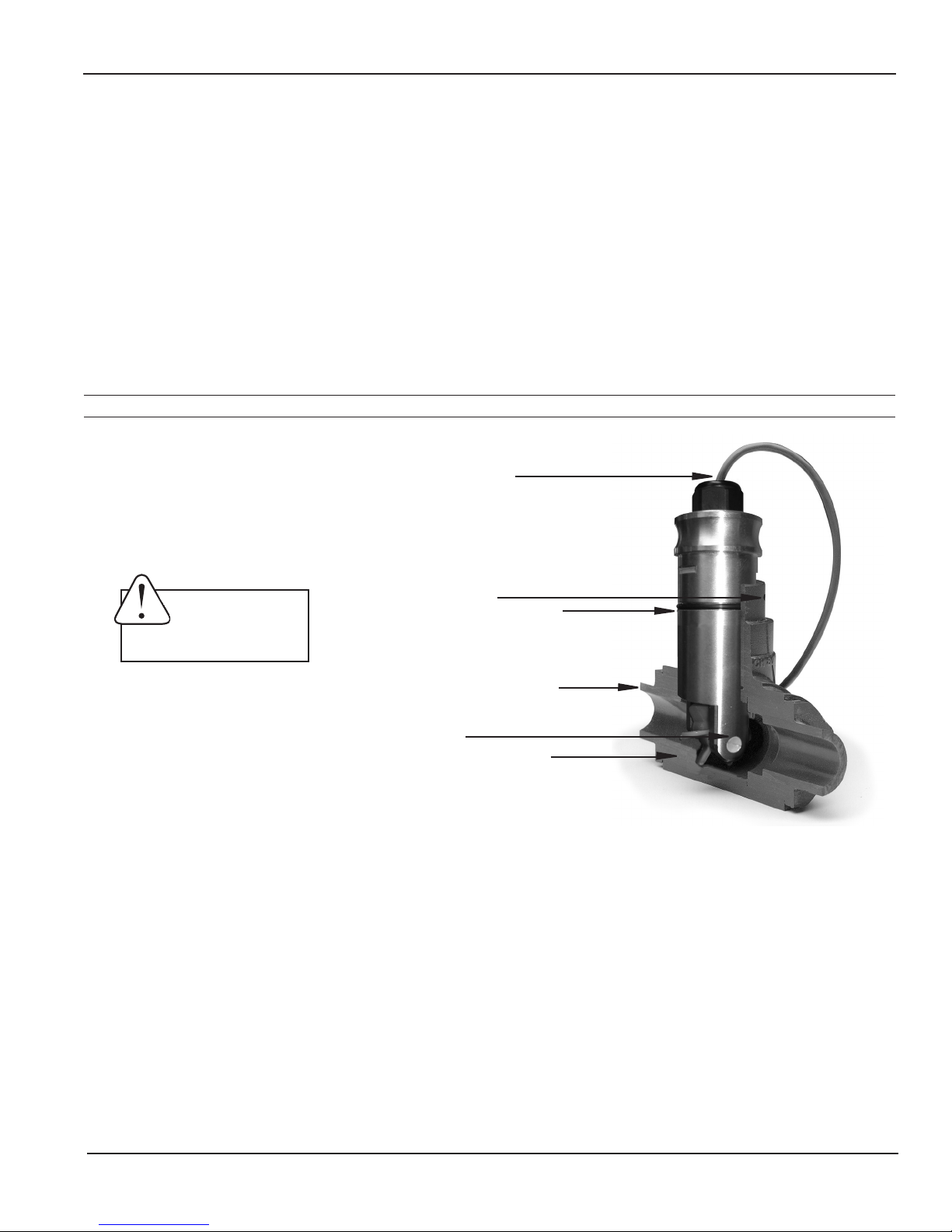

The TX800-Series are insertion turbine meters designed for use

in 1-1/2" to 8" pipe. High-quality jewel bearings and precision

shafts ensure long life and low friction. Available in 316

stainless steel, brass and PVC, sensor bodies are machined

from solid rod for maximum low-ow performance. The TX800Series use special ttings that ensure ease of installation and

correct depth setting in the pipe.

The rotation of the turbine is detected by a non-drag Hall-effect

sensor. Output is a pulse-type square wave, which can be sent

long distances (up to 2,000 feet) without a transmitter. This

Features

Cable-Seal Strain Relief

signal can be connected directly to Seametrics controls and

displays, as well as PLC's, counters, and computer cards.

Seametrics TX800 meters are ideal for chemical proportioning

applications. If no display is required, a simple divider such as

the PD10 provides adjustable pump pacing. For rate and total

display, as well as pump pacing, the FT420 ow indicator can

be mounted directly on the TX800-Series, or remotely on a wall

or panel. The FT415 offers a battery-operated rate/totalizer

where power is not available.

Caution: U-clip

must be installed

before use.

U-Clip Insertion Point

O-Ring

Fitting

Bearing Housing

Rotor

Seametrics • 253.872.0284 • www.seametrics.com

Page 3

GENERAL INFORMATION

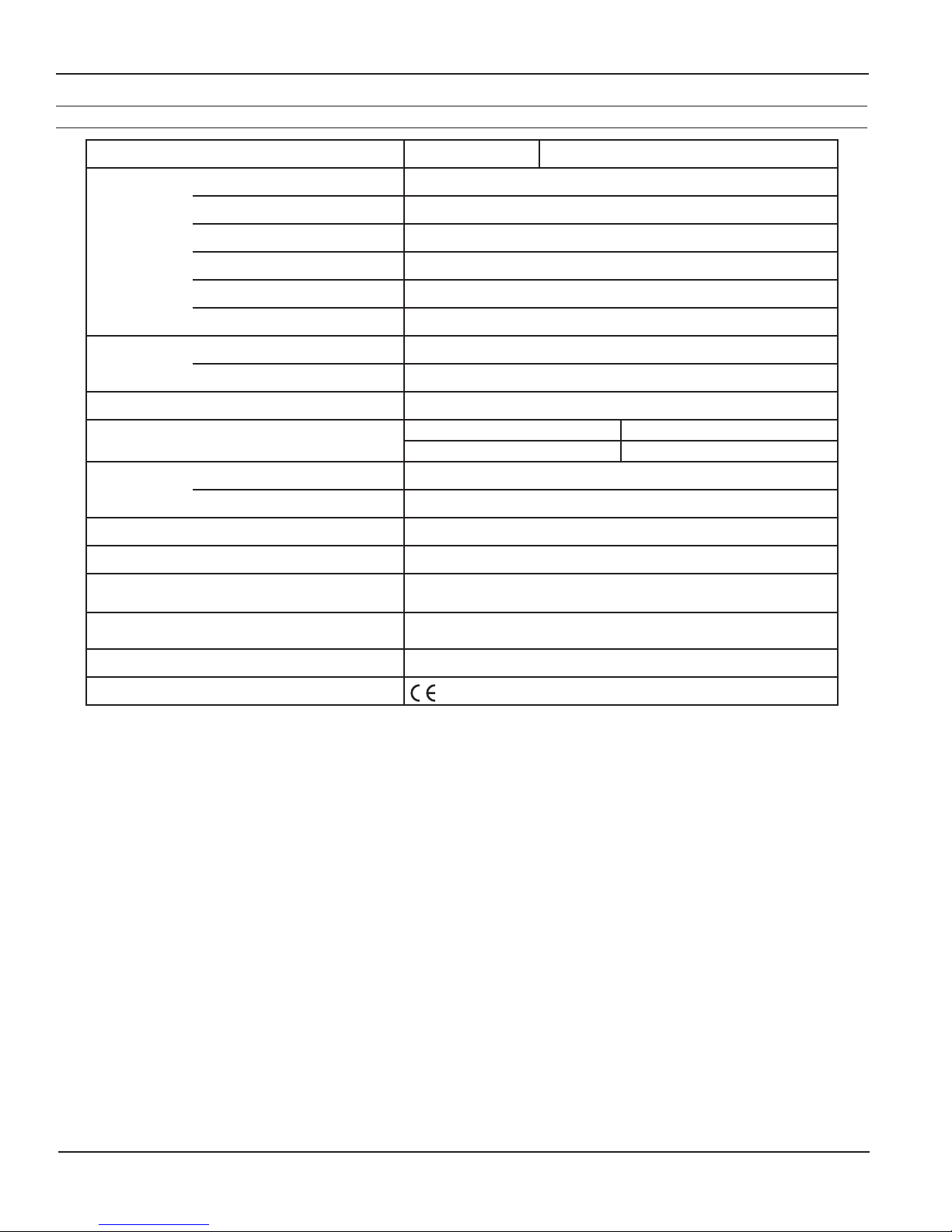

Specications*

Pipe Sizes EX11x/15x: 3” to 10” EX21x/25x: 10” to 48” (up to 72” optional)

Materials Shaft/Fitting 316 SS or Brass

Electrodes Hastelloy

Electrode Cap PVDF

Housing Cast powder-coated aluminum

Valve Assembly (15x/25x only) Bronze (stainless optional) with bronze ball valve

O-Ring (15x/25x only) EPDM

Power Full Power 12-25 Vdc, 250 mA

Low Power 12-25 Vdc, 40 mA average with 250 mA peaks

Flow Range 0.28 to 20 ft/sec (0.08 - 6.09 m/sec)

Fitting Size Required

Temperature Ambient 0˚ to 160˚F (-17˚ to 72˚C)

Fluid 32˚ to 200˚F (0˚ to 93˚C)

EX11x/21x EX15x/25x

1-1/2” FNPT 2” FNPT

TX800 SERIES INSTRUCTIONS

Pressure 200 psi (14 bar)

Minimum Conductivity 20 microSiemens/cm

Calibration Accuracy +/- 1% of full scale

Output

Empty Pipe Detection Software, defaults to zero ow

Regulatory

Square wave pulse, opto isolated, 550 Hz@20ft/sec 6mA max, 30 Vdc forward

ow standard; reverse ow optional

*Specications subject to change. Please consult our website for the most current data (www.seametrics.com).

Page 4

Seametrics • 253.872.0284 • www.seametrics.com

INSTALLATION

TX800 SERIES INSTRUCTIONS

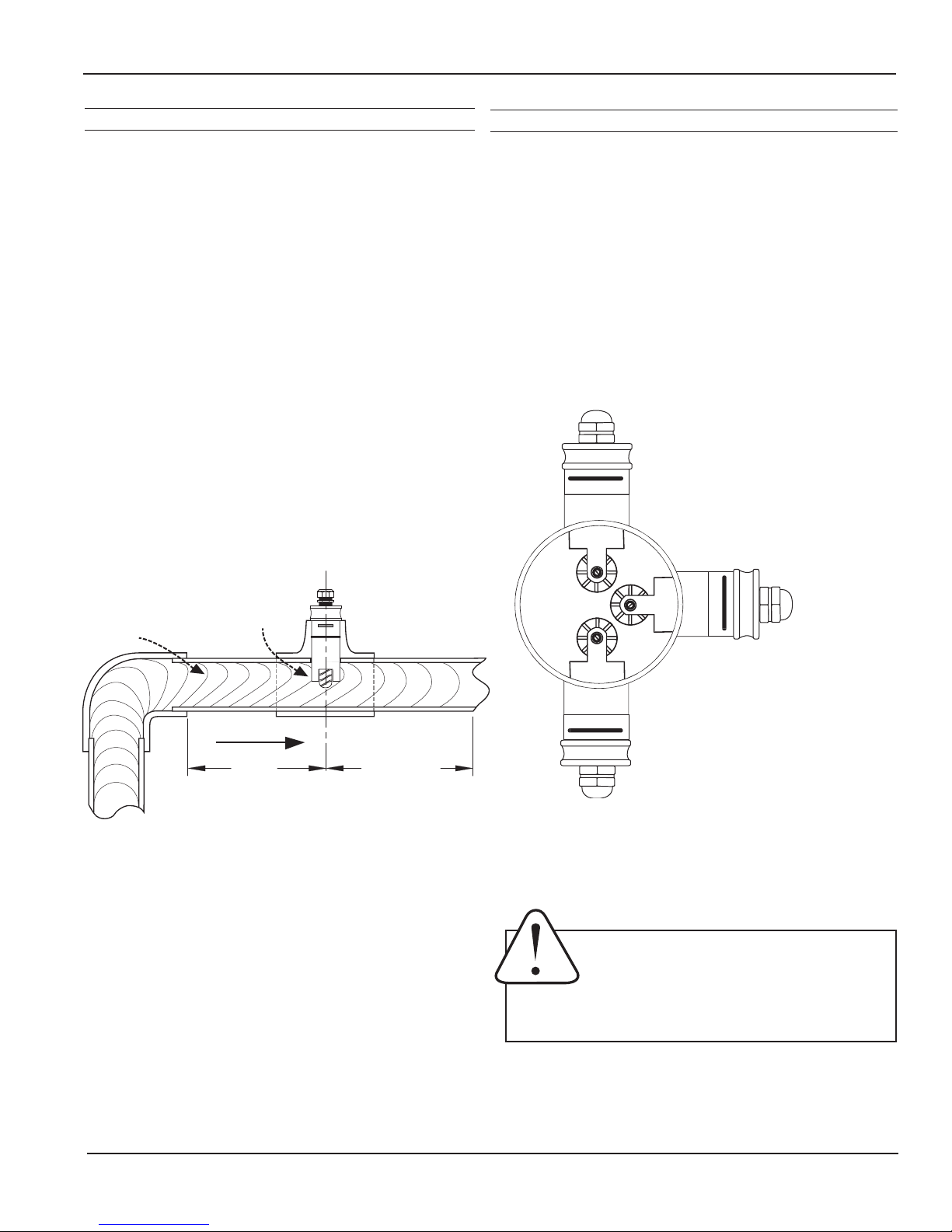

Fitting Installation

TX800-Series meters require special ttings. The meter tting

must rst be installed in the pipeline. Straight pipe of at

least ten times the diameter upstream of the meter and ve

diameters downstream is strongly recommended in order to

achieve proper accuracy. These are minimum values. As the

diagrams on the the next page will show, you may need more

straight run under specic adverse circumstances.

If you can’t provide enough run to smooth out the turbulence

caused by valves, ttings, and changes in direction, some

decrease in accuracy may result. This does not mean that

the ow meter’s reading is meaningless, however. In some

applications (for instance, where the ow meter is part of

a control system, operating a valve or controlling chemical

addition), a repeatable reading may be more important than

a highly accurate one.

TX800-Series PVC meter tees are supplied with some

upstream straight pipe. The length provided may be less

than ten diameters upstream and ve downstream. It is not

advisable to connect directly to the end of these ttings with

a ow-disturbing device such as a valve or elbow. If possible,

straight pipe should be added to the upstream end of these

ttings.

Meter Installation

After the meter tting is installed in the pipeline, the meter

can be installed in the tting. After noting the direction of the

ow arrow, press the meter into the tting as far as it will go.

Retain the meter in place by inserting the U-clip. The pin can

be installed from either side. It may be necessary to rotate the

probe back and forth slightly to start the pin into the slots on the

probe. Slide the pin in as far as it will go.

Horizontal (3 o’clock or 9 o’clock position) is the preferred

installation orientation, since it improves low-ow performance

and avoids problems with trapped air and sediment. (See

Orienting the Meter diagram below.) Bottom (6 o’clock), top

(12 o’clock), and vertical pipe installations are all acceptable if

required by the piping layout.

Fair

Unacceptable if pipe

contains air

Faster flow causes

Distorted flow

profile

meter to read high

FLOW

10X

Diameter Minimum

Distorted Flows

Diameter Minimum

A PVC tting is usually installed by solvent welding. The

stainless steel and brass meter ttings have female pipe

threads, requiring the appropriate male threaded ttings.

Saddle ttings (size 3” and above) require a hole to be cut in

the pipe. The recommended hole size is 1-3/4”.

5X

Best

Position

Fair

Unacceptable if pipe

contains sediment

Orienting the Meter

Caution: Never remove the u-clip retainer when

the pipe is under pressure. Always remove

pressure from the pipe before you attempt to

remove the meter. Removal under pressure

may result in damage or serious injury.

Seametrics • 253.872.0284 • www.seametrics.com

Page 5

Loading...

Loading...