Page 1

Precision Environmental Sensors

d

C

An ON

I

CON Brand

PT2X

Pressure/Temperature Smart Sensor

and Data Logger Instructions

For PSIG

sensors, refer

to page 23

regarding

desiccant

use!

o

m

e

i

p

f

PROUDLY

MADE

IN THE

USA

i

t

r

e

C

ISO

9001:2008

a

n

y

Page 2

TABLE OF CONTENTS

General Information

General Information ........................................................................................................................................................................Page 3

Dimensions .........................................................................................................................................................................................Page 3

Specications .....................................................................................................................................................................................Page 4

How Pressure Sensors Work ........................................................................................................................................................Page 5

Initial Inspection and Handling ...................................................................................................................................................Page 6

Do’s and Don’ts .................................................................................................................................................................................Page 6

Installation

Connecting External Power ...........................................................................................................................................................Page 7

Connecting a PT2X to a Computer ............................................................................................................................................Page 7

Connecting to Sensors ...................................................................................................................................................................Page 8

Cable Wiring ......................................................................................................................................................................................Page 9

Installing Aqua4Plus2.0 ..................................................................................................................................................................Page 9

Using the PT2X without Aqua4Plus 2.0 ...................................................................................................................................Page 9

Installing the Sensor ........................................................................................................................................................................Page 10

Desiccant Use .....................................................................................................................................................................................Page 10

Grounding Issues ..............................................................................................................................................................................Page 10

Settings and Calibration

Sensor Settings ..................................................................................................................................................................................Page 11

Program Settings ..............................................................................................................................................................................Page 11

Pressure Calibration.........................................................................................................................................................................Page 12

Depth to water ..................................................................................................................................................................................Page 13

Ground Elevation ..............................................................................................................................................................................Page 14

Sta Gauge .........................................................................................................................................................................................Page 14

Removing calibration setup values ............................................................................................................................................Page 14

Operation

Real-time Data ...................................................................................................................................................................................Page 15

Data Logging......................................................................................................................................................................................Page 16

Reports .................................................................................................................................................................................................Page 18

A Word About Units ........................................................................................................................................................................Page 18

Barometric Compensation ............................................................................................................................................................Page 19

Direct Read Modbus/SDI-12

Setting Units for Direct Read .......................................................................................................................................................Page 20

Power Consideration .......................................................................................................................................................................Page 20

Reading via Modbus RTU ..............................................................................................................................................................Page 20

Reading via SDI-12...........................................................................................................................................................................Page 21

Maintenance

Removing Debris from End Cone ...............................................................................................................................................Page 23

Desiccant Tubes ................................................................................................................................................................................Page 23

Sensor/Cable/End Connections ..................................................................................................................................................Page 24

Changing Batteries ...........................................................................................................................................................................Page 24

Troubleshooting

Problems/Probable Causes/Things to Try ...............................................................................................................................Page 27

Warranty

Seametrics Limited Warranty .......................................................................................................................................................Page 28

PT2X INSTRUCTIONS

IF USING ALKALINE BATTERIES—PREVENT BATTERY LEAKAGE!

PT2X sensors are typically shipped with lithium batteries. If, however, you are

using alkaline batteries, be aware that under some circumstances alkaline

batteries can leak, causing damage to the sensor. To prevent leakage, the

following is recommended. (Does not apply to lithium batteries.)

• Change the batteries at least every 18 months.

• If the sensor will not be deployed for 3 months or more, remove the

batteries.

Seametrics • 253.872.0284 Page 2 seametrics.com

Page 3

GENERAL INFORMATION

PT2X INSTRUCTIONS

The Seametrics PT2X Smart Sensor is an integrated data

logger and pressure/temperature sensor and is ideal for

monitoring groundwater, well, tank, and tidal levels, as well

as for pump and slug testing. This sensor networks with

all of the Seametrics Smart Sensor family. IThe PT2X is a

microprocessor based digital intelligent sensor designed

to measure and record pressure, temperature, and time,

using low power, battery operated circuitry.

Pressure is measured with an extremely rugged and stable

piezo-electric media-isolated pressure element combined

with a 16-bit analog-to-digital converter. This provides

extremely accurate and stable pressure input into the

microprocessor on the circuit board.

This industry standard digital RS485 interface device records

up to 520,000 records of pressure/level, temperature, and

time data, operates with low power, and features easy-touse software with powerful features. Constructed with 316

stainless steel or titanium, PTFE, and uoropolymer, this

sensor provides high-accuracy readings in rugged and

corrosive eld conditions.

Two internal 1.5V AA batteries power the PT2X. (Auxiliary

power supplies are available for data intensive applications.)

The unit is programmed using Seametrics’ easy-to-use

Aqua4plus 2.0 control software. Once programmed the

unit will measure and collect data on a variety of time

intervals.

Several PT2Xs, or a combination of PT2Xs and other

Seametrics Smart Sensors, can be networked together and

controlled directly from a single computer.

While most will use the PT2X with our free, easy-to-use

Aqua4Plus 2.0 software, it is by no means limited to that

software. You can use your own Modbus® RTU or SDI-12

software or logging equipment to read measurements,

thus tying into your existing systems and databases.

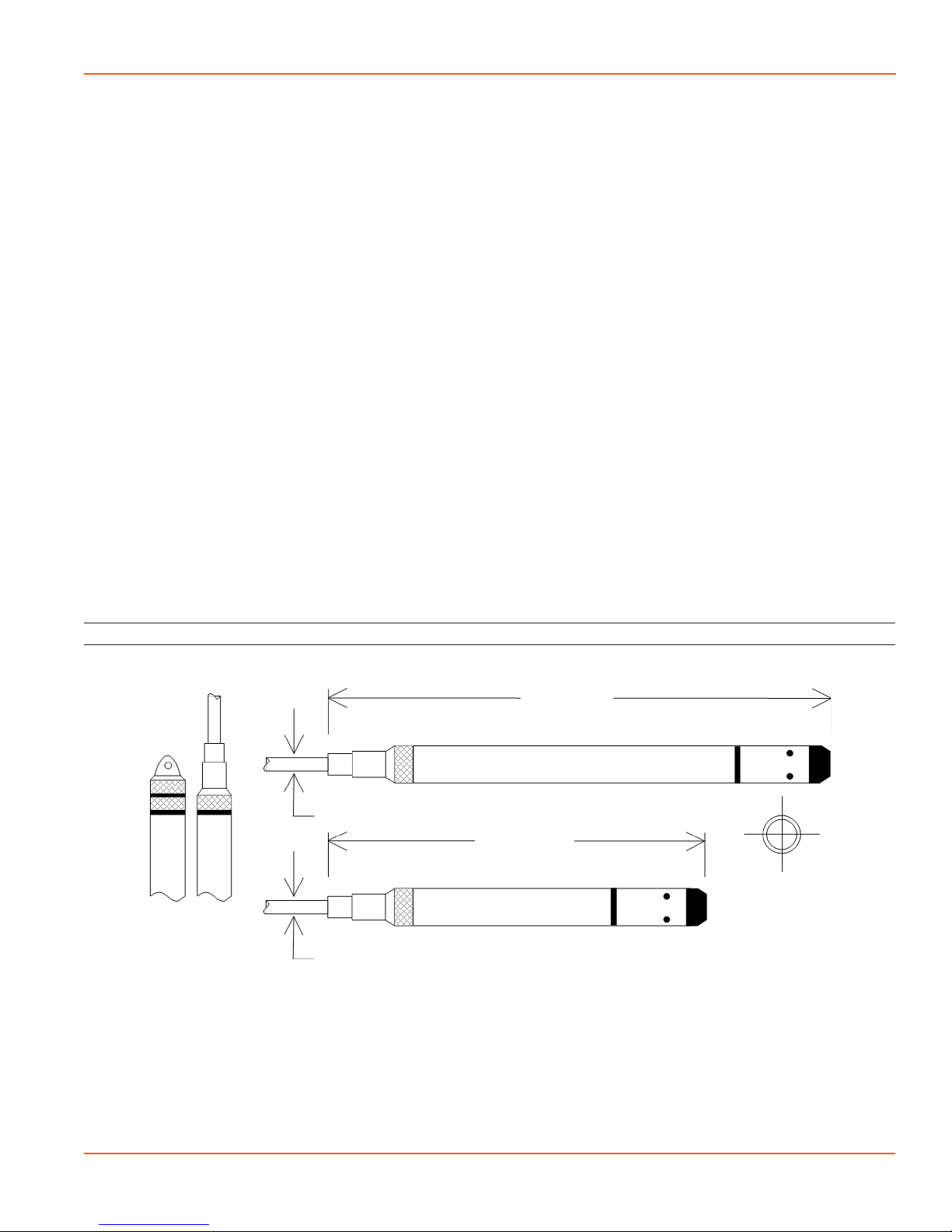

Dimensions

Cableless

0.25” (0.6

cm) Shorter

0.28” (0.7 cm)

0.28” (0.7 cm)

12.18” (30.9 cm)

Battery Version

8.37” (21.3 cm)

Non-Battery Version

Diameter

0.75” (1.9 cm)

Seametrics • 253.872.0284 Page 3 seametrics.com

Page 4

GENERAL INFORMATION

PT2X INSTRUCTIONS

Specications*

Housing & Cable Weight 0.8 lb. (0.4 kg)

Body Material Acetal & 316 stainless or titanium

Wire Seal

Material

Cable Submersible: polyurethane, polyethylene, or ETFE (4 lb./100 ft., 1.8 kg/30 m)

Desiccant 1-3 mm indicating silica gel

Field Connector Standard

Temperature Operating Range Recommended: -15˚ to 55˚C (5˚ to 131˚F) Requires freeze protection kit if using pressure option in water

Storage Range Without batteries: -40˚ to 80˚C (-40˚ to 176˚F)

Power Internal Battery Two lithium ‘AA’ batteries - Expected battery life: 18 months at 15 min. polling interval (may vary do to

Auxiliary 12 Vdc - Nominal, 6-16 Vdc - range

Communication Modbus® RS485 Modbus® RTU, output=32bit IEEE oating point

SDI-12 SDI-12 (ver. 1.3) - ASCII

Logging Memory 4MB - 520,000 records

Logging Types Variable, user-dened, proled

Logging Rates 8x/sec maximum, no minimum

Baud Rates 9600, 19200, 38400

Software Complimentary Aqua4Plus 2.0

Networking 32 available addresses per junction (Address range: 1 to 255)

File Formats .a4d and .csv

Output Channels Temperature Depth/Level¹

Element Digital IC on board Silicon strain gauge transducer, 316 stainless or Hastelloy

Accuracy ±0.5°C — 0° to 55°C (32˚ to 131˚F)

Resolution 0.1˚C 0.0034% FS (typical)

Units Celsius, Fahrenheit, Kelvin PSI, FtH₂O, inH₂O, mmH₂O, mH₂O, inH₂O, cmHg, mmHg, Bars, Bars,

Range -15˚ to 55˚C (5˚ to 131˚F) Gauge

Compensated --- 0˚ to 40˚C (32˚ to 104˚F)

Max operating pressure 1.1 x full scale

Over pressure protection 3x full scale up to 300psi - for > 300psi (650 ft or 200 m) contact factory

Burst pressure 1000 psi (approx. 2000 ft or 600 m)

Environmental IP68, NEMA 6P

Fluoropolymer and PTFE

below freezing.

environmental factors)

±2.0°C — below 0°C (32˚F)

±0.05% FSO (typical, static)

±0.1% FSO (maximum, static)

(B.F.S.L. 20˚C)

kPa

PSI: 12, 5, 7, 15, 30, 50, 100, 300

FtH₂O: 2.32, 12, 35, 69, 115, 231, 692

Absolute³

mH₂O: 0.72, 3.5, 5, 10.5, 21, 35, 70, 210

PSI: 30, 50, 100, 300

FtH₂O: 35, 81, 196, 658

mH₂O: 10, 24, 59, 200

*Specications subject to change. Please consult out web site for the most current data (seametrics.com).

Modbus is a registered trademark of Schneider Electric.

1 Higher pressure ranges available upon request

2 ±0.25% accuracy FSO (max) at this range

3 Depth range for absolute sensors has 14.7 PSI subtracted to give actual depth allowed.

Seametrics • 253.872.0284 Page 4 seametrics.com

Page 5

GENERAL INFORMATION

PT2X INSTRUCTIONS

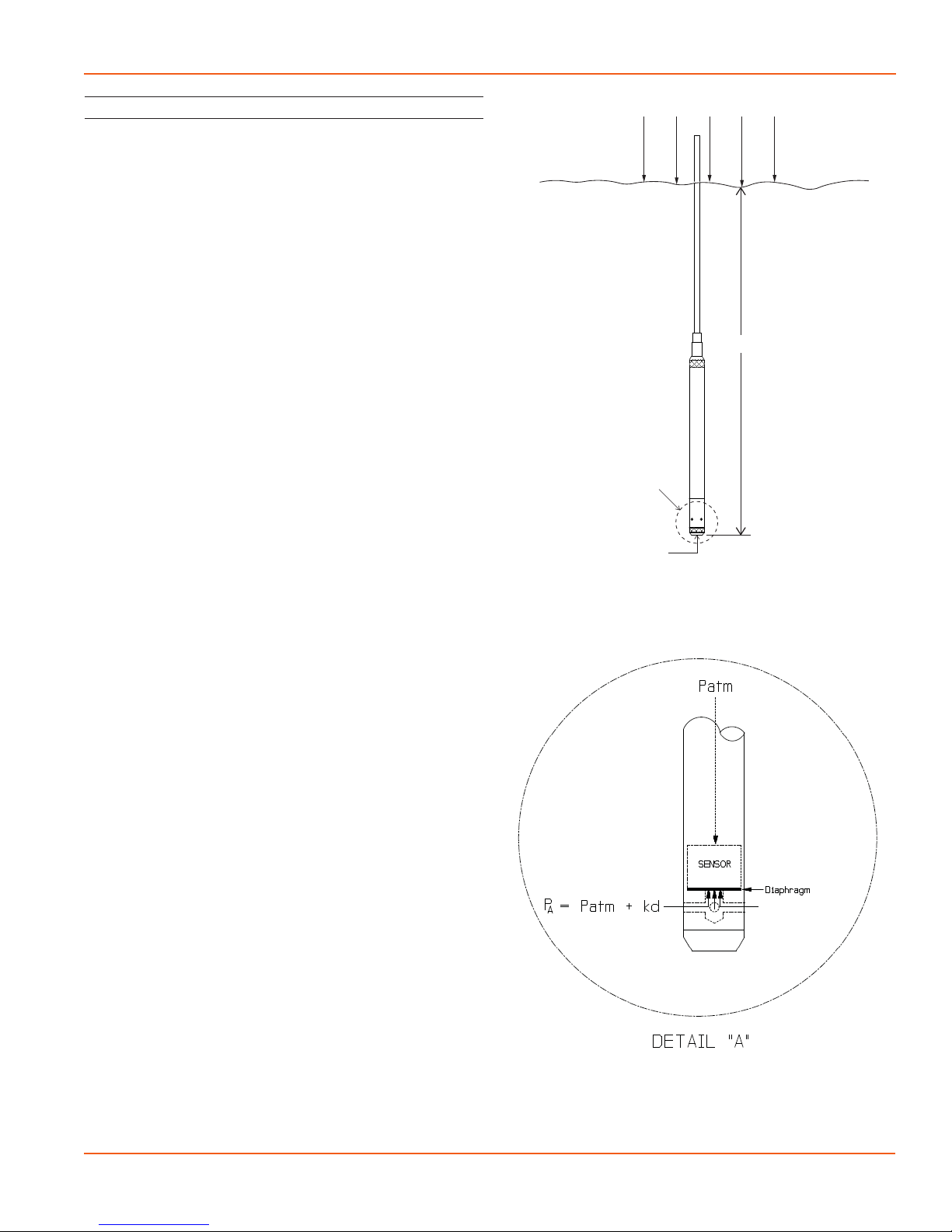

How Pressure Sensors Work

Liquids and gasses do not retain a xed shape. Both

have the ability to ow and are often referred to as

uids. One fundamental law for a uid is that the uid

exerts an equal pressure in all directions at a given level.

Further, this pressure increases with an increasing depth of

“submergence”. If the density of a uid remains constant

(noncompressible...a generally good assumption for water

at “normal” pressures and temperatures), this pressure

increases linearly with the depth of “submergence”.

We are all “submerged” in the atmosphere. As we increase

our elevation, the pressure exerted on our bodies decreases

as there is less of this uid above us. It should be noted

that atmospheric pressure at a given level does vary

with changes in the weather. One standard atmosphere

(pressure at sea level at 20º C) is dened to be 14.7 PSI

(pounds per square inch).

There are several methods to reference a pressure

measurement. Absolute pressure is measured with respect

to an ideal vacuum (no pressure). Gauge pressure is the

most common way we express pressure in every day life

and is the pressure exerted over and above atmospheric

pressure. With this in mind, gauge pressure (Pg) can be

expressed as the dierence between the absolute pressure

(Pa) and atmospheric pressure (Patm):

Water Line

P = Patm + kd

A

Patm

d

“A”

Pressure Diagram: See Detail A.

Pg = Pa - Patm.

To measure gauge pressure, atmospheric pressure is

subjected to one side of the system and the pressure to be

measured is subjected to the other. The result is that the

dierential (gauge pressure) is measured. A tire pressure

gauge is a common example of this type of device.

Recall that as the level of submergence increases (in a

noncompressible uid), the pressure increases linearly.

Also, recall that changes in weather cause the absolute

atmospheric pressure to change. In water, the absolute

pressure (Pa) at some level of depth (d) is given as follows:

Pa = Patm + kd

where k is simply a constant

(i.e.: 2.307 feet of water = 1 PSI)

Seametrics’ standard gauge submersible pressure

devices utilize a vent tube in the cable to allow the

device to reference atmospheric pressure. The resulting

gauge pressure measurement reects only the depth of

submergence. That is, the net pressure on the diaphragm

is due entirely to the depth of submergence.

Seametrics • 253.872.0284 Page 5 seametrics.com

Absolute pressure is given as Pa = Patm + kd

(where k is 2.307 feet of water)

Page 6

GENERAL INFORMATION

PT2X INSTRUCTIONS

Initial Inspection and Handling

Upon receipt of your smart sensor, inspect the shipping package for damage. If any damage is apparent, note the signs

of damage on the appropriate shipping form. After opening the carton, look for concealed damage, such as a cut cable.

If concealed damage is found, immediately le a claim with the carrier.

Check the etched label on the sensor to be sure that the proper range and type were provided. Also check the label

attached to the cable at the connector end for the proper cable length.

Do’s and Don’ts

Do handle sensor with

care

Do store sensor in a

dry, inside area when

not in use

Do install a desiccant

tube if using a gauge

sensor

Do install sensor so the

connector end is kept

dry

Don’t drop into well

Lower gently to prevent

damage

Seametrics • 253.872.0284 Page 6 seametrics.com

Don’t scrape cable

over edge of well

May nick or fray the

cable

Don’t bend cable sharply

May close o vent tube

and/or weaken internal

wires

Don’t support sensor

with the connector

Use a strain relief device

Page 7

INSTALLATION

PT2X INSTRUCTIONS

Connecting External Power

The PT2X comes with two 1.5V AA internal batteries.

If auxiliary power is desired, you can use a 6–16 VDC supply

that can provide 15 mA. Connect to Vaux++ (pin 1 - white)

and Ground (pin 5 - blue) or contact Seametrics for auxiliary

power supplies.

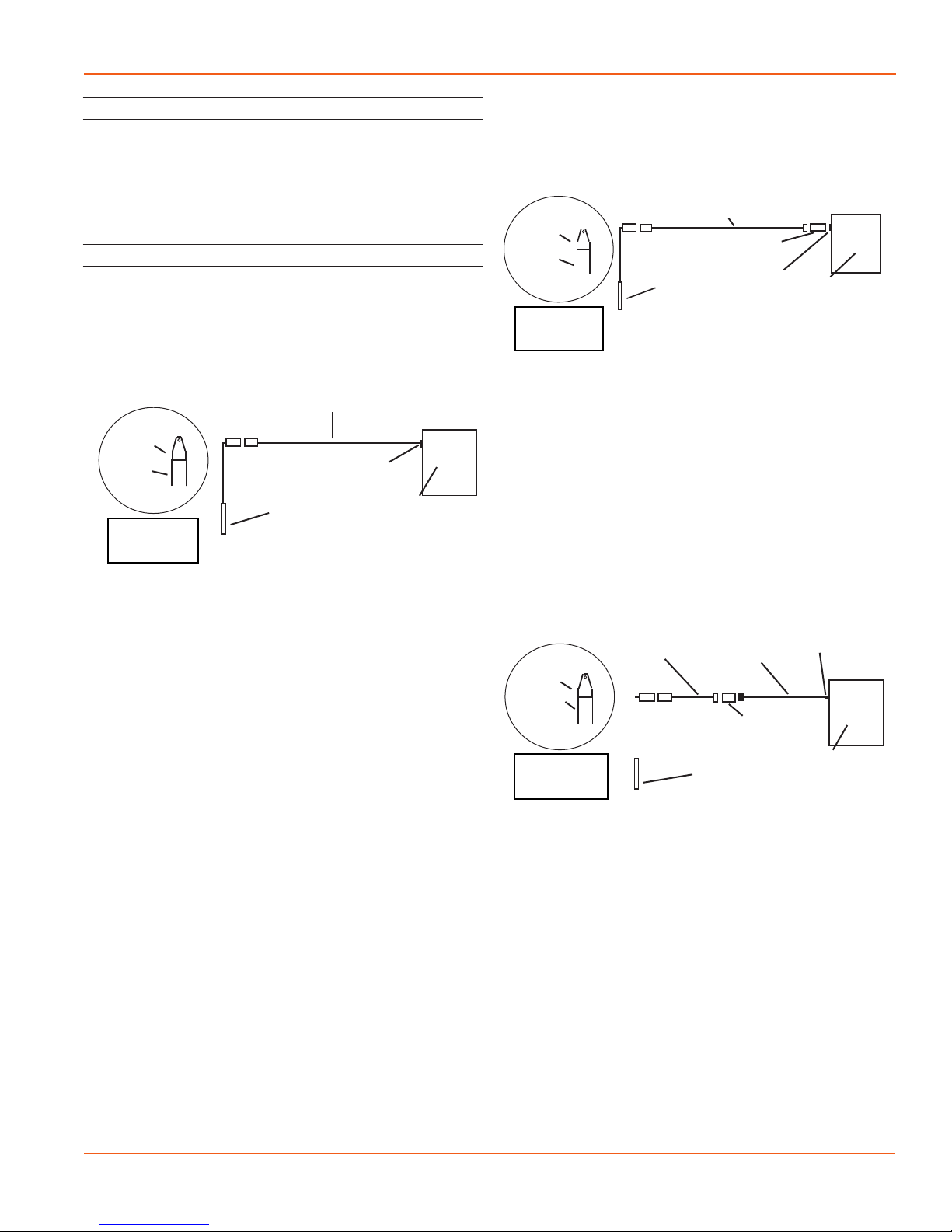

Connecting the PT2X to a Computer

Cabled sensors are terminated with a weather-resistant

connector. Cableless sensors are terminated with a weatherresistant connector that is inside a screw-cap. Connect the

weather-resistant connector to your computer’s USB port

as shown below.

USB to RS485

Adapter

Screwcap

Sensor

Sensor

Cableless

Conguration

USB Port

PC or Laptop

Computer

Connecting sensor to your computer using

Seametrics’ USB to RS485 adapter.

Connecting via RS232 Serial Port

Connect the weather-resistant connector to your

computer’s serial port as shown below.

Interface Cable

Screwcap

Sensor

Cableless

Conguration

Sensor

RS485/RS232

Adapter

Serial Port

PC or Laptop

Computer

Connecting sensor to your computer using

an RS485/RS232 adapter and an interface cable.

Connecting with a USB/Serial Adapter

USB-to-Serial cables are readily available from many

electronics and computer stores, as well as numerous sites

on the Internet. Seametrics has tested and recommends

the Keyspan USA-19HS. Install as follows:

• Plug into USB port.

• Install the drivers provided with the particular unit.

• Once drivers are installed connect to sensor

Aqua4Plus 2.0 communicates with the sensor using the

USB to RS485 adapter cable. This cable requires drivers to

be installed on your computer. If you are connected to the

Internet when you rst plug in the cable, it will normally

obtain and install the correct drivers automatically.

Alternate Connection Options

Seametrics recommends connecting the sensor to your

computer using the Seametrics USB cable. However, when

using Aqua4Plus 2.0, the sensor can also be connected

using an RS232 serial port or a USB-to-Serial cable, as

described below.

Interface

Screwcap

Sensor

Cableless

Conguration

Cable

Adapter

RS232/RS485

Adapter

Sensor

Connecting sensor to your computer using

a USB to Serial adapter and an interface cable.

USB PortUSB-to-Serial

PC or Laptop

Computer

Seametrics • 253.872.0284 Page 7 seametrics.com

Page 8

INSTALLATION

PT2X INSTRUCTIONS

Connecting to Sensors

Aqua4Plus 2.0 is designed to automatically detect your communication cable and scan for sensors. It is recommended

you connect your USB/RS485 cable to your PC and have the sensor connected before opening Aqua4Plus 2.0.

If your cable and sensor were not connected before opening Aqua4Plus 2.0 simply connect and click Rescan. While

scanning is active you’ll see a green dot ash in the upper right corner of the program. Scanning is complete when this

dot stops ashing.

If your sensor still won’t connect you can expand the Modbus address range under program settings here:

Simply drag the Address Range slider higher up to increase the maximum Modbus address scanned. If you’ve scanned

all the way up through address 255 and still have no connection click Troubleshooting for further troubleshooting or

contact Seametrics Tech Support for assistance.

Click at any time to refresh sensor information.

Seametrics • 253.872.0284 Page 8 seametrics.com

Page 9

INSTALLATION

PT2X INSTRUCTIONS

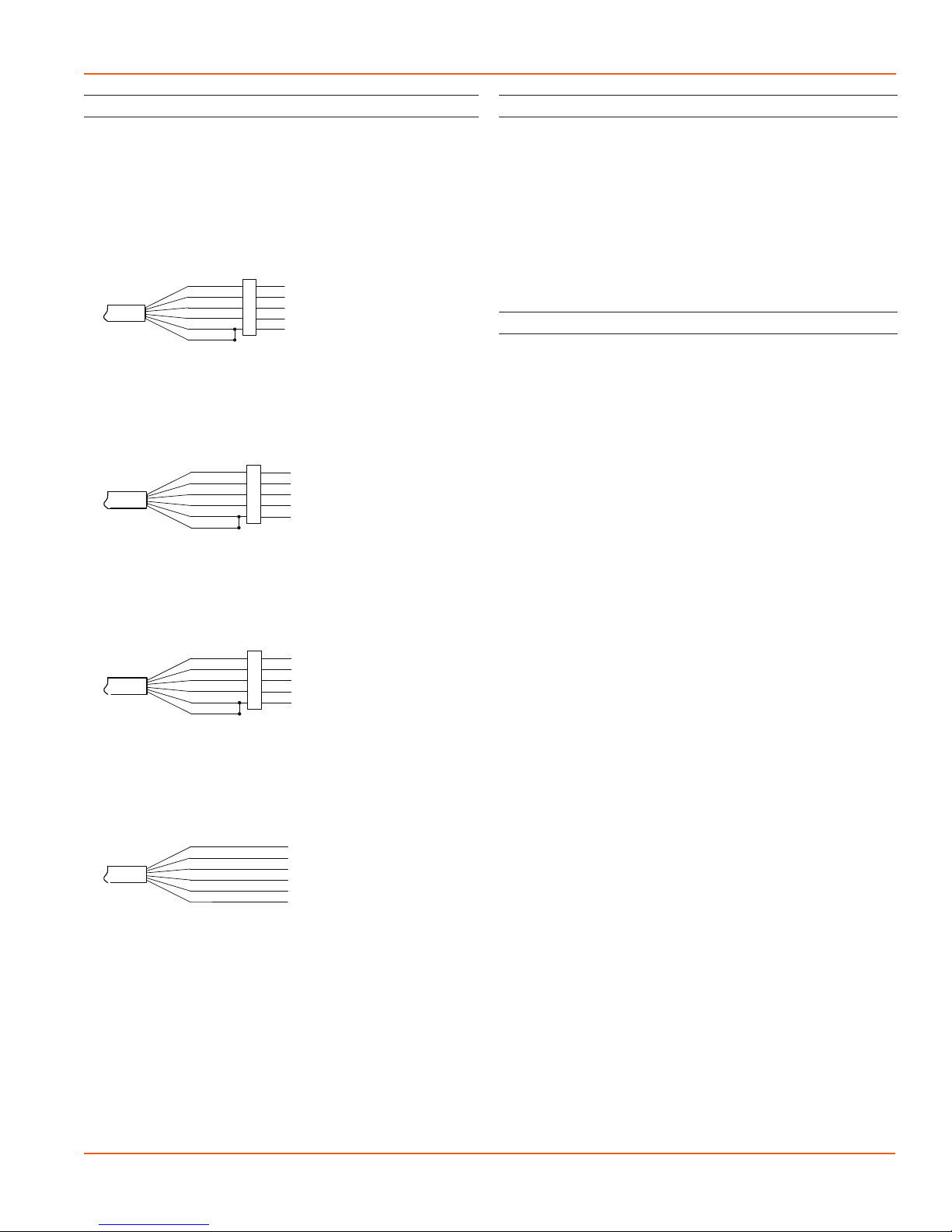

Cable Wiring

If you buy your cabled sensor with a connector installed

(the normal conguration), no further wiring is needed.

For reference purposes, the rst three diagrams below

show the pinout from the connector for various scenarios.

The nal diagram shows the pinout if you bought your

sensor without a connector for use with SDI-12.

White

Purple

Yellow

Brown

Blue

Shield

1

2

3

4

5

5-Pin

Connector

12 VDC+ (Vaux)

Modbus DModbus D+

Digital I/O (Not used)

12 VDC- (GND)

For Modbus® with rmware lower than 2.0

— with 5-pin connector

White

Purple

Yellow

Brown

Blue

Shield

1

2

3

4

5

5-Pin

Connector

12 VDC+ (Vaux)

Modbus DModbus D+

SDI-12 (Not used)

12 VDC- (GND)

For Modbus® with rmware 2.0 or higher

— with 5-pin connector

Installing Aqua4Plus 2.0

The PT2X comes with the Aqua4Plus 2.0 host software

that is installed on your PC or laptop. Use this software to

program the datalogger, to retrieve data from the logger,

to view collected data, and to export data to external les

for use with spreadsheets or databases.

Refer to the software manuals for details on installing and

using Aqua4Plus 2.0.

Using the PT2X Without Aqua4Plus 2.0

Most users will use the PT2X with Seametrics’ Aqua4Plus

2.0 software. However, the PT2X is quite versatile,

communicating via either Modbus® or SDI-12 interfaces,

allowing you to do the following:

®

• Read a PT2X via Modbus

using your own software.

• Read a PT2X via SDI-12 protocol.

• Display readings from a PT2X on a panel meter.

If you want to use one of these methods, see page 20.

White

Purple

Yellow

Brown

Blue

Shield

1

2

3

4

5

5-Pin

Connector

12 VDC+ (Vaux)

Modbus D- (Not used)

Modbus D+ (Not used)

SDI-12 Signal

12 VDC- (GND)

For SDI-12 with rmware 2.0 or higher

— with 5-pin connector

White

Purple

Yellow

Brown

Blue

Shield

12 VDC+ (Vaux)

Modbus D- (Not used)

Modbus D+ (Not used)

SDI-12 Signal

12 VDC- (GND)

Earth ground

For SDI-12 with rmware 2.0 or higher

— without connector

Seametrics • 253.872.0284 Page 9 seametrics.com

Page 10

INSTALLATION

PT2X INSTRUCTIONS

Installing the Sensor

The PT2X measures pressure. The most common application

is measuring liquid levels in wells and tanks. In order to do

this, the sensor must be installed below the water level at a

xed depth. The installation depth depends on the range

of the sensor. One (1) PSI is equal to approximately 2.31

feet of water. If you have a 5 PSI sensor, the range is 11.55

feet of water and the sensor should not be installed at a

depth below 11.55 feet. If the sensor is installed below its

maximum range, damage may result to the sensor and the

output reading will not be correct.

Note: If you are using an absolute sensor and

you want to enter a depth-to-water reference

after data is collected, then see page 19 before

proceeding.

• Lower the sensor to the desired depth.

• Fasten the cable to the well head using a weather

proof strain-relief system. When securing a vented

cable, make sure not to pinch the cable too tightly

or the vent tube inside the cable jacket may be

sealed o.

• Take a measurement to insure the sensor is not

installed below its maximum range.

Be sure the supplied cap is securely placed on the weatherresistant connector at the top of the cable. Do not install

such that the connector might become submerged with

changing weather conditions. The connector can withstand

incidental splashing but is not designed to be submerged.

For vented sensors, install the sensor so that the desiccant

tube will not ood or lie in water.

The sensor can be installed in any position; however, when

it leaves the factory it is tested in the vertical position.

Strapping the sensor body with tie wraps or tape will not

hurt it. Seametrics can provide an optional 1/4” NPT input

adapter which is interchangeable with the standard end

cone for those applications where it is necessary to directly

attach the sensor to a pipe, tank, or other pipe port. If the

sensor is being installed in a uid environment other than

water, be sure to check the compatibility of the uid with

the wetted parts of the sensor.

Desiccant Use

On vented sensors a desiccant tube prevents moisture in

the air from being sucked into the vent tube, which can

cause erratic readings and sensor damage.

The desiccant tube is lled with blue silica gel beads. A

locking barb and a hydrophobic water lter are attached to

the end of the desiccant tube. This lter prolongs the life of

the desiccant as much as three times over a desiccant tube

without the lter.

Install the sensor so that the desiccant tube and cable

connector will not ood or lie in water.

The desiccant is a bright blue color when active and dry. See

Maintenance section for care and changing of desiccant.

Grounding Issues

It is commonly known that when using electronic

equipment, both personnel and equipment need to be

protected from high power spikes that may be caused by

lightning, power line surges, or faulty equipment. Without

a proper grounding system, a power spike will nd the path

of least resistance to earth ground—whether that path is

through sensitive electronic equipment or the person

operating the equipment. In order to ensure safety and

prevent equipment damage, a grounding system must be

used to provide a low resistance path to ground.

When using several pieces of interconnected equipment,

each of which may have its own ground, problems with

noise, signal interference, and erroneous readings may be

noted. This is caused by a condition known as a Ground

Loop. Because of natural resistance in the earth between

the grounding points, current can ow between the points,

creating an unexpected voltage dierence and resulting

erroneous readings.

The single most important step in minimizing a ground loop

is to tie all equipment (sensors, dataloggers, external power

sources, and any other associated equipment) to a single

common grounding point. Seametrics recommends

connecting the shield to ground at the connector end.

Seametrics • 253.872.0284 Page 10 seametrics.com

Page 11

SETTINGS AND CALIBRATION

PT2X INSTRUCTIONS

Sensor Settings

Once connected you’ll see the Sensor screen appear and

display the connected sensor(s) details. Mousing over---

icons will provide tool-tips, mouse over to view sensor

rmware and serial number details.

To change general sensor settings click in the sensor

screen. This allows you to change the following:

Program Settings

To view/change Aqua4Plus 2.0 settings click in the blue

side-bar menu

Under the General Settings tab you can change the default

data folder location. This is where your Reports are saved

to on your PC.

The Zoom Factor slider can be used to adjust the font size

within Aqua4plus 2.0.

Uncheck the Allow app to collect anonymous usage

statistics box if you would like to opt out. This information

is used to track Aqua4plus 2.0 reliability across dierent

system congurations.

Click to rename the sensor

To change Modbus address and/or Baud Rate simply select

the desired address and/or Baud Rate from the drop down

menus. Sensor will automatically reconnect at new address

and/or Baud Rate

To change the Direct Read output units (for direct Modbus

or SDI12 integration) simply select the desired output

units from the drop down menus. To change Aqua4plus

2.0 display units scaling see Program Settings.

Sensor Clock can be synced with your PC time or set

manually if desired. To set manually enter your desired

date/time and click Set Time.

When batteries are changed out make sure to reset the

battery information here, simply check the I have just put

in new batteries box and select the battery type that was

installed from the drop down menu.

Under the Display Units tab you can select your desired

display units for the supported channels. These may be

changed at any time and associated Real-Time readings and

Reports will rescale to the currently selected display unit. To

change Direct Read units scaling see Sensor Settings.

Seametrics • 253.872.0284 Page 11 seametrics.com

Page 12

SETTINGS AND CALIBRATION

PT2X INSTRUCTIONS

Pressure Calibration

To perform a calibration setup on the pressure channel

rst connect to the sensor and ensure all data has been

uploaded and erased from the sensor. Next select the

calibration button (example images can be found under

conductivity calibration page 12).

Next select the calibration setup you’d like to perform:

Comrm desired measurement units and click Continue.

Submergence:

Under the Communications tab you can change your

Modbus communication settings. Typically you will only

need to change the address range to connect to sensors

outside of Modbus address 1-10. In certain cases we

may need to change the Retry and Timeout settings to

overcome communication issues on very long, or corroded

cabling. See Troubleshooting section or contact Seametrics

Tech Support for details.

To restore factory default settings click

One Point/Zero Point Calibration:

To zero pressure output to atmospheric pressure position

the sensor in air in its desired installation position (typically

vertical, if sensor will be installed horizontally position as

such during 0 point calibration). Select 1 point Calibration

under Calibration Type.

For PSIG sensors use 0 as the reference value and click

Measure.

For PSIA sensors enter current barometric pressure from

a known accurate barometer set to matching units. Enter

your reference value in the Ref. Point box and click Measure.

Seametrics • 253.872.0284 Page 12 seametrics.com

Page 13

SETTINGS AND CALIBRATION

PT2X INSTRUCTIONS

Aqua4Plus 2.0 will take 10 readings and display the average.

Watch for stability while Aqua4Plus 2.0 is measuring to

ensure an accurate calibration.

Click Ok to accept the reading and Aqua4Plus 2.0 will

calculate a new pressure oset. Click Apply to conrm the

new oset value and Aqua4Plus 2.0 will provide a real time

reading to verify calibration was successful:

Select 2 point Calibration under Calibration Type

Perform rst point calibration as listed above and click Next

Enter known pressure value in matching units in the Ref.

Point box for second point measurement

2 Point submergence calibration ONLY RECOMMENDED

IF YOU HAVE AN ACCURATE PRESSURE REFERENCE.

Our Smart Sensors rarely change slope during normal

use, however if you have an accurate pressure source it is

possible to perform a 2 point calibration on the pressure

channel.

Aqua4Plus 2.0 will take 10 measurements and display

the average. Watch for stability while Aqua4Plus 2.0 is

measuring to ensure an accurate calibration.

Click Ok and Aqua4Plus 2.0 will calculate the new slope

and oset values. Click Apply to conrm the new slope and

oset values and Aqua4Plus 2.0 will provide a real time

reading to verify calibration was successful.

Depth to water (for PSIG sensors only, see Barometric

Compensation Utility for PSIA sensors)

Position the sensor in its desired location and ensure all

data has been uploaded and erased from the sensor before

proceeding with calibration.

Once positioned connect to sensor and select the

calibration button, followed by selecting the Depth to

Water option. Double check measurement units selection

before proceeding.

Enter your current depth to water (Typically obtained from

a water level indicator) value in the Ref. Point box, making

sure to match measurement units.

Seametrics • 253.872.0284 Page 13 seametrics.com

Page 14

SETTINGS AND CALIBRATION

PT2X INSTRUCTIONS

Click Measure and Aqua4Plus 2.0 will take 10 readings and

display the average. Watch for stability while Aqua4Plus 2.0

is measuring to ensure an accurate calibration.

Click Accept and Aqua4Plus 2.0 will calculate a new slope

and oset, click Apply to accept the new slope and oset

and Aqua4Plus 2.0 will provide a real time reading to verify

calibration was successful.

Groundwater Elevation

Position the sensor in its desired location and ensure all

data has been uploaded and erased from the sensor before

proceeding with calibration.

Once positioned connect to sensor and select the calibration

button, followed by selecting the Groundwater Elevation

option. Double check measurement units selection before

proceeding.

Enter your current Groundwater Elevation reading in the

Ref. Point box, making sure to match measurement units.

Click Measure and Aqua4Plus 2.0 will take 10 readings and

display the average. Watch for stability while Aqua4Plus 2.0

is measuring to ensure an accurate calibration.

Click Accept and Aqua4Plus 2.0 will calculate a new oset,

click Apply to accept the new oset and Aqua4Plus 2.0

will provide a real time reading to verify calibration was

successful.

Removing calibration setup values

To return to factory default simply enter an oset of 0 and

slope of 1 in the Oset and Slope boxes:

Click Accept and Aqua4Plus 2.0 will calculate a new oset,

click Apply to accept the new oset and Aqua4Plus 2.0

will provide a real time reading to verify calibration was

successful.

Sta Gauge

Position the sensor in its desired location and ensure all

data has been uploaded and erased from the sensor before

proceeding with calibration.

Once positioned connect to sensor and select the

calibration button, followed by selecting the Sta Gauge

option. Double check measurement units selection before

proceeding.

Enter your current Sta Gauge reading in the Ref. Point

box, making sure to match measurement units.

Click Measure and Aqua4Plus 2.0 will take 10 readings and

display the average. Watch for stability while Aqua4Plus 2.0

is measuring to ensure an accurate calibration.

Click Apply to conrm settings and Aqua4Plus 2.0 will

provide a real time reading to conrm.

Adjusting for specic gravity

You man enter the specic gravity of your uid in the Slope

eld to adjust for specic gravity when needed. Click Apply

to conrm settings and Aqua4Plus 2.0 will provide a real

time reading to conrm.

Seametrics • 253.872.0284 Page 14 seametrics.com

Page 15

OPERATION

Real-time Data

Connect to sensor and select the Real-time data tab

To start real-time readings click Start, readings default to

table view

PT2X INSTRUCTIONS

Real-time readings default to a 1 second interval for 1

minute, to adjust enter your desired settings here:

Note: Currently this data is not saved and is for viewing

current conditions only. To save the data to sensor memory

see Data Logging section. You can run Real-time Data

while logging is active.

To switch to Real-time graphing view click the graph

icon

Seametrics • 253.872.0284 Page 15 seametrics.com

Page 16

OPERATION

Data Logging

Select Set Up Logging from the sensor screen

PT2X INSTRUCTIONS

If there are no les currently on the sensor you’ll see the

Set Up Logging button active under the Data Files tab as

well as in the upper menu. Once les have been started/

logged on the sensor they will be displayed under the Data

Files tab.

Setting Up Logging Window

Here you will name your data le and set up the recording

interval and duration of each logging phase. Select your

desired recording interval and duration for each phase,

Aqua4Plus will display the available memory at the bottom

of the window.

Click to switch between interval and continuous

data recording (PT2X & CT2X only) Select your continuous

rate from the drop down box here.

Duration can be set by either number of records

Or by setting a duration time

When set by number of records the time of the recording

phase will be displayed detailing how long that phase will

run. When set by time, the total number of records for that

phase will be displayed.

If you need to check settings or perform a calibration click

before proceeding with logging setup to switch to the

Settings and Calibration screen.

You may sync the sensor clock with the PC clock when

starting logging by clicking the slider here.

Check the Delayed Start box and enter the desired date/

time you would like logging to start. This is useful for

syncing data when setting up multiple sensors on a site.

Data will start logging at the set date/time rather than

immediately when Start is pressed.

Seametrics • 253.872.0284 Page 16 seametrics.com

Page 17

OPERATION

PT2X INSTRUCTIONS

Data le name defaults to Test File # and may be re-named

here.

The 3 previous Logging Schedules that were programmed

to a sensor will be listed under the Select Template drop

down menu. There you will also nd pre-programmed

logging schedules such as 24 hour pump test, along with

any custom logging schedules saved by the user.

To save a logging schedule as a template enter desired

settings and click This will add your custom schedule

to the Select Template menu.

Once all the desired settings are made simply click Start to

begin logging.

Data les already downloaded will show in the Reports

column, clicking here will bring you to the reports screen to

view the data. See Reports section for details.

You may only have 1 active data le recording on each

sensor, however you can store multiple les in memory if

desired.

Starting a new le will automatically terminate the active

logging and begin the new logging schedule. Real-time

data is available during active logging.

This will return you to the Sensor screen and your status

will change to Active with the data le displayed under the

Data Files tab. Mouse over an active le to pause, terminate,

download, or view logging setup details.

Seametrics • 253.872.0284 Page 17 seametrics.com

To delete les from memory make sure they have all been

downloaded to Reports. Files are removed from memory

all at once rather than individually.

Once conrmed les are permanently deleted from the

sensor memory.

Page 18

OPERATION

Reports

Data downloaded from your sensor is stored in the Reports

section of Aqua4Plus 2.0 for viewing and editing. The les

will be saved to default data folder on your PC as well. See

Program Settings for default data folder location.

In the main view you’ll see a list of reports sorted by date,

size, or le name as selected here

PT2X INSTRUCTIONS

Click to view data as a table

Click to view data statistics

The Information tab is a new feature allowing users to add

metadata to their reports such as site location, eld notes,

or comments.

You can also search reports by keyword using the search

box

Click on a report to bring up the report details

Reports are displayed in graphing view by default. You can

zoom to specic sections by selecting a section with you

mouse or by adjusting the slider below the graph, shown

below.

Click to switch to full screen graphing view

Graph saving and export options are available here

The Schedule tab will display the logging setup details for

the report

Click Export to export the report as a .csv le or .a4d le for

distribution or use in 3rd party software.

Click Delete to delete the report from Aqua4Plus 2.0

You can also import .a4d les from compatible sensors into

Aqua4Plus 2.0 by clicking at the top of the Reports

screen.

A Word About Units

Readings from the PT2X Smart Sensor can be displayed in

various units, such as PSI, Ft. H2O, or mm H2O for pressure,

or degrees Celsius or degrees Fahrenheit for temperature.

Select the units you want from the Options | Display Units

menu or from the Congure Menu | Program Conguration

| Set Computer Display Units.

Seametrics • 253.872.0284 Page 18 seametrics.com

Page 19

OPERATION

Barometric Compensation

PT2X INSTRUCTIONS

For PSIA sensors we’ve built a new barometric compensation

utility into the Reports section. Click on a report to

compensate the data for barometric pressure.

Corresponding barometric les are ltered by date/time

and displayed to the left. Select the barometric le you

would like to use to compensate the report, select either the

Submergence or Depth To Water tab, then click Continue.

Aqua4Plus 2.0 will perform the barometric compensation

and create a new compensated report. Original reports are

retained as uploaded.

Compensated report can then be viewed and exported as

needed.

If compensating for Depth to Water enter your depth

to water reference measurement and the date/time the

measurement was taken (typically taken with a water level

indicator before data is uploaded from the sensor) before

clicking Continue.

Seametrics • 253.872.0284 Page 19 seametrics.com

Page 20

DIRECT READ MODBUS/SDI-12

Direct Read (Modbus® or SDI-12)

PT2X INSTRUCTIONS

While the PT2X comes with Seametrics’ easy to use

Aqua4Plus 2.0, you can also use standard Modbus® RTU

or SDI-12 equipment to easily take readings, so as to tie

into your existing equipment or networks.

You may need to use Aqua4Plus 2.0 to make a few settings

prior to directly reading the PT2X with your equipment.

These might include the units for the returned values

and/or the Modbus baud rate. These are described in the

following sections.

For Modbus direct read, you must have PT2X rmware 1.5

or higher. For SDI-12, you must have rmware 2.0 or higher.

Setting Units for Direct Read

By default, the PT2X uses the following units:

Temperature Degrees Celsius

Pressure PSI

If you want to change to dierent units, for example,

degrees Fahrenheit for temperature or feet of water for

pressure, set these units using Aqua4Plus 2.0. See sensor

settings.

Power Consideration

change the baud rate for Aqua4Plus 2.0, as follows:

• Click the Options menu, and then select Baud Rate.

• On the popup box, click the down-arrow, select the

baud rate you need, and then click OK.

The current Aqua4plus 2.0 baud rate is displayed in the

lower right corner of the main Aqua4plus 2.0 window.

Taking Measurements

Reading Registers

Read measurements using Modbus function 03 – Read

Holding Registers. Readings are located in two registers

each, starting at address 62592. (PT2X register addressing

is zero based, i.e., starts at zero. If your equipment uses one

based addressing, you will need to add one to the register

addresses.)

Addresses for PT2Xs with rmware lower than 2.0

Zero based One based

Pressure 62592 62593

Temperature 62594 62595

Addresses for PT2Xs with rmware 2.0 or higher

Zero based One based

Temperature 62592 62593

Pressure 62594 62595

If your sensor does not have internal batteries and is not

powered continuously by an auxiliary power supply, then

you must turn power on to the sensor at least two seconds

before a reading is to be taken to allow the sensor to warm

up.

Reading Via Modbus® RTU

Setting Baud Rate

Your PT2X comes congured to communicate at 38,400

baud, with 8 data bits, one stop bit, and no parity. The

sensor can also be set to 19,200 or 9600 baud, if needed

for your application. You must use Aqua4Plus 2.0

If needed, set your PT2X to the desired baud rate as follows:

• Click on the Congure menu, and then select

Advanced.

• From the yout menu, select Sensor Baud Rate. (You

may be asked for a password. Enter admin.)

• On the popup box, click the down-arrow, select the

baud rate you need, and then click OK.

Once you have changed the baud rate on the PT2X, you

will not be able to talk to it with Aqua4plus 2.0 until you

Measurement Timing

When you request a reading via Modbus, the sensor wakes

up, returns the current values in the registers, and then

starts taking new readings and updating the registers.

After approximately 10 seconds, if no more readings have

been requested, the sensor goes back to sleep.

Because of this, the rst reading you get will be old. If you

are taking readings at intervals of less than 10 seconds,

simply ignore the rst reading — all remaining readings will

be current. On the other hand, if you are taking readings

at intervals of greater than 10 seconds, take a reading,

ignore it, wait one second, take another reading. Record

this second reading.

Data Format

The data is returned as 32-bit IEEE oating-point values,

highword rst, also referred to as big-endian or oat

inverse.

For further information and detailed Modbus examples,

see Seametrics’ Technical Bulletin, available on www.

seametrics.com.

Seametrics • 253.872.0284 Page 20 seametrics.com

Page 21

DIRECT READ MODBUS/SDI-12

PT2X INSTRUCTIONS

Reading Via SDI-12

Note: The default units setting for pressure is PSI. The default units setting for temperature is Celsius.

To change these, use the Direct Read Units in the Aqua4Plus 2.0 Control Software.

Addressing

Default SDI-12 Address: 0

SDI-12 Command Nomenclature

<a> = Sensor address

{crc} = SDI-12 compatible 3-character CRC

<cr> = ASCII carriage return character

<lf> = ASCII line feed character

highlighted values indicate variable data

All SDI-12 requests consist

of a command followed by

a request for values. Some

software or equipment may

combine these, making the

second one unnecessary. Refer

to your software or equipment

documentation for details.

Request Response

<a>M1! <a>0021<cr><lf>

Address

Command

Request Response

Address

Time until

(in seconds)

response

<a>D0! <a>+7.15863<cr><lf>

Address

Request for

values read

Address

Returned

value(s)

SDI-12 Commands

Sensor Identication

<a>I! <a>13 INWUSA PT2X 213ssssssssss<cr><lf> Note: 213 will change to reect current rmware version.

Acknowledge Active, Address Query

<a>! <a><cr><lf>

?! <a><cr><lf>

ssssssssss = device serial number

Carriage Return

Linefeed

# of values to

be returned

Carriage Return

Linefeed

Change Address

<a>A<b>! <b><cr><lf> Change address to <b>

Request Measurement

<a>M! <a>0022<cr><lf> Request all measurements

<a>D0! <a>+22.0512+12.0512<cr><lf> Read temperature and pressure

<a>M1! <a>0021<cr><lf> Request temperature measurement only

<a>D0! <a>+22.0512<cr><lf> Read temperature

<a>M2! <a>0021<cr><lf> Request pressure measurement only

<a>D0! <a>12.0512<cr><lf> Read pressure

Seametrics • 253.872.0284 Page 21 seametrics.com

Page 22

DIRECT READ MODBUS/SDI-12

Request Measurement with CRC

<a>MC! <a>0022<cr><lf> Request all measurements with CRC

<a>D0! <a>+22.0512+12.0512{crc}<cr><lf> Read temperature and pressure

<a>MC1! <a>0021<cr><lf> Request temperature measurement only with CRC

<a>D0! <a>+22.0512{crc} <cr><lf> Read temperature

<a>MC2! <a>0021<cr><lf> Request pressure measurement only with CRC

<a>D0! <a>12.0512{crc} <cr><lf> Read pressure

Concurrent Measurement

<a>C! <a>0022<cr><lf> Request all measurements

<a>D0! <a>+22.0512+12.0512<cr><lf> Read temperature and pressure

<a>C1! <a>0021<cr><lf> Request temperature measurement only

<a>D0! <a>+22.0512<cr><lf> Read temperature

PT2X INSTRUCTIONS

<a>C2! <a>0021<cr><lf> Request pressure measurement only

<a>D0! <a>12.0512<cr><lf> Read pressure

Concurrent Measurement with CRC

<a>CC! <a>0022<cr><lf> Request all measurements with CRC

<a>D0! <a>+22.0512+12.0512{crc}<cr><lf> Read temperature and pressure

<a>CC1! <a>0021<cr><lf> Request temperature measurement only with CRC

<a>D0! <a>+22.0512{crc} <cr><lf> Read temperature

<a>CC2! <a>0021<cr><lf> Request pressure measurement only with CRC

<a>D0! <a>12.0512{crc} <cr><lf> Read pressure

For further information and SDI-12 examples, see Seametrics application note, “PT2X SDI-12 Interface Specication”

available from our web site at www.seametrics.com.

Seametrics • 253.872.0284 Page 22 seametrics.com

Page 23

MAINTENANCE

PT2X INSTRUCTIONS

Removing Debris from End Cone

At times mud, silt, or other debris may foul the water inlets

to the pressure element. The end cone can be removed to

clean out the debris.

Twist Open Housing

1. Gently twist o end cone portion only - do not twist

o pressure element!

2. Remove debris. Do not poke anything into the

sensor. This can damage the sensor element and

void the warranty.

3. Replace and retighten the end cone.

Pressure element

Water inlet

End cone

Gently twist o the end cone and carefully remove debris

Set Screw Housing

1. Remove the two set screws at the bottom of the

housing tube, using a 1/16” allen wrench.

2. Gently remove the end cone.

3. Remove debris. Do not poke anything into the

sensor. This can damage the sensor element and

void the warranty.

4. Replace the end cone and secure with set screws.

Desiccant Tubes

On vented sensors, inspect the desiccant tube at least once

every two months. The desiccant tube prevents moisture

in the air from being sucked into the vent tube, which can

cause erratic readings and sensor damage.

The desiccant tube is lled with blue silica gel beads. A

locking barb and a hydrophobic water lter are attached to

the end of the desiccant tube. This lter prolongs the life of

the desiccant as much as three times over a desiccant tube

without the lter.

Install the sensor so that the desiccant tube and cable

connector will not ood or lie in water.

The desiccant is a bright blue color when active and dry.

As moisture is absorbed the color will begin to fade,

becoming a light pink, which indicates full saturation and

time to replace. Replacement desiccant and hydrophobic

lters can be purchased from Seametrics.

To Change the Desiccant:

• Pulling gently remove the black tube tting from

the clear desiccant tube.

• Using needle-nose pliers, remove the dark gray

foam plug. Do not discard the plug.

• Dump out the old desiccant beads and rell with

new desiccant beads – tapping desiccant tube

frequently during relling to ensure that the beads

are fully seated in tube.

• Push the foam plug back into the tube.

• Reinsert the black tting.

Pressure element

Water inlet

Set screw

End cone

Remove end cone by removing set screws.

Gently clean out debris.

Seametrics • 253.872.0284 Page 23 seametrics.com

Page 24

MAINTENANCE

PT2X INSTRUCTIONS

Sensor

There are no user-serviceable parts, other than the

batteries. If problems develop with sensor stability or

accuracy, contact Seametrics. If the transducers have

been exposed to hazardous materials, do not return them

without notication and authorization.

Cable

Cable can be damaged by abrasion, sharp objects, twisting,

crimping, crushing, or pulling. Take care during installation

and use to avoid cable damage. If a section of cable is

damaged, it is recommended that you send your sensor

back to replace the cable harness assembly.

End Connections

The contact areas (pins & sockets) of the connectors will

wear out with extensive use. If your application requires

repeated connections other types of connectors can be

provided. The connectors used by Seametrics are not

submersible, but are designed to be splash-resistant.

Changing Batteries

Battery Type: Two 1.5V AA batteries—Lithium or Alkaline

(lithium recommended)

IMPORTANT!

Because changing the batteries involves

opening the water-tight seal, this must be

done in a clean, dry environment to avoid

contamination or moisture damage to the

circuitry.

IF USING ALKALINE BATTERIES

—

PREVENT BATTERY LEAKAGE!

PT2X sensors are typically shipped with

lithium batteries. If, however, you are using

alkaline batteries, be aware that under some

circumstances alkaline batteries can leak,

causing damage to the sensor. To prevent

leakage, the following is recommended. (Does

not apply to lithium batteries.)

• Change the batteries at least every 18

months.

• If the sensor will not be deployed for 3

months or more, remove the batteries.

Battery Life Calculator (Firmware 2.13 or higher)

When changing batteries, it is important to reset the

Battery Life Calculator. If the battery life calculator is not

reset, the remaining life information will be incorrect.

Access the Battery Life Calculator from the Congure

Menu - Battery Information and Reset. If you have put in

new batteries, checkmark the box “I have just put in fresh

batteries.” Click Save and Close. See sensor settings.

Tips

• Never place a tool on the sensor body, it is very

thin and will deform causing leaks at o-ring seals

and potentially crushing the circuit board!

• Always twist the sensor body o the top cap

assembly rather than twisting the top cap assembly

o of the sensor body.

• For cabled sensors, always clamp the sensor on the

swaged area when applicable, the shoulder above

it will allow you to press down without the worry of

the sensor slipping out of the clamping device.

• If the sensor body is slippery or you are unable to

grip it hard enough to twist, try a piece of rubber

cabinet liner for additional friction.

There is a black, compressible square ring near the top of

the sensor. This ring acts as a spring to lock the cable in.

This needs to be compressed in order to allow removal

of the top cap. Once this ring is compressed, a gentle

counterclockwise twist is all that is needed to remove the

cable from the sensor body. Compressing the black square

ring does take force, twisting does not.

HousingTop cap

Swage Knurling Black square ring

Cabled Sensor

Top cap

Housing

Seametrics • 253.872.0284 Page 24 seametrics.com

Knurling Black square ring

Cableless Sensor

Page 25

MAINTENANCE

PT2X INSTRUCTIONS

Care must be taken to compress the black square ring

before attempting to twist the housing. Forceful twisting

of the housing can permanently damage the sensor.

Securing the Sensor

In order to compress the black square ring, the sensor

must be secured so that you can apply downward pressure

to compress the ring. This can be done by holding in your

hand, using a vise, or using pliers, as follows.

By Hand—cabled version only

1. Tightly grasp the top cap in one hand.

2. Brace your hand against something such as a

table or the ground. (Do not allow the cable to be

pinched against the brace.)

Continue to Removing the Housing on the next page.

With Vise—recommended method

Cabled Sensor

1. If possible, use a set of soft jaws as shown to

prevent marring the surfaces of the top cap

assembly.

2. Place the sensor in a vise clamping gently on the

swaged area. You do not need to clamp the vise

very hard.

Continue to Removing the Housing on the next page.

Continue to Removing the Housing on the next page.

Cableless Sensor—gripping on knurled area

With Pliers or Vise Grips—good for eld use

Cabled Sensor

1. Grasp the pliers on the swaged area (do not grab

the knurled diameter).

2. Find a hard edge and place the tips or side of the

jaws of the pliers onto this edge as shown. This

will allow you to press down with your weight to

compress the square ring.

Continue to Removing the Housing in on the next page.

Cabled Sensor—gripping on swage

Cableless Sensor

1. If possible, use a set of soft jaws as shown to

prevent marring the surfaces of the top cap

assembly.

2. Remove the cableless top cap.

3. Place the sensor in a vise clamping gently on the

knurled area. You do not need to clamp the vise

very hard.

Seametrics • 253.872.0284 Page 25 seametrics.com

Cabled Sensor

Cableless Sensor

1. Leave the cableless cap on in order to protect the

pins inside.

2. Grasp the pliers on the knurled area tightly being

careful to avoid grabbing the knurled cap.

3. Find a hard surface and place the cableless cap

down onto it. This will allow you to press down with

your weight to compress the square ring.

Page 26

MAINTENANCE

PT2X INSTRUCTIONS

Continue to Removing the Housing below.

Cableless Sensor

Removing the Housing

1. With your free hand, grasp the sensor body. Press

down to compress the square ring. Twist gently.

Once the body begins to twist, you can stop the

compression action.

2. Finish gently twisting until the sensor body is

removed.

3. Carefully disconnect the wiring connector inside

from the circuit board in the top cap.

Replacing Batteries and Resealing Sensor

4. Hold the top cap assembly at 90° to the housing

opening as shown. Depress the spring with your

ngertip and tuck the wiring into the cutaway on

the circuit board with your thumb to protect it while

being installed back into the housing.

Wires tucked into slot and spring tucked into housing

5. Rotate the top cap assembly into the opening in the

housing being very careful not to nick or pinch any

wires.

Push top cap in before twisting and locking

1. Gently pull wiring to one side in order to allow

batteries to fall out. Shake gently if needed.

2. Replace batteries with button (+) facing open end.

3. Reinstall wiring connector — it only goes in one

way, so make sure not to force it.

Pull wires gently to the side to allow battery removal

6. Gently press down until the assembly stops

and then twist it into place. It will click in and

decompress the gasket when it is fully engaged.

Properly completed—black ring uncompressed

Connector connected properly

Seametrics • 253.872.0284 Page 26 seametrics.com

Page 27

TROUBLESHOOTING

Problem Probable Causes Things to try…

PT2X INSTRUCTIONS

Software will not

Loose cable Make sure all cable connections are secure

communicate with

sensor

Contacts in connector loose Be sure all wires are securely fastened inside the

USB driver not installed See Connecting the PT2X to a Computer in

Incorrect USB or COM port selected If using Aqua4Plus, be sure USB is selected in

SEE ALSO ERRATIC READINGS BELOW

Erratic readings Poor connection due to moisture between

contacts in connector

Loose or broken wires in connector Repair or return for evaluation and repair

Damaged cable, cracked or fraying Replace cable

round connector

the Installation section or see the USB/RS485

Adapter Installation application note on our

web site.

the dropdown box on the tool bar or the correct

COM port if using an alternate connection

method. (Aqua4Plus Lite automatically uses only

the USB connection.)

Dry thoroughly. Be sure desiccant is fresh (see

Maintenance section).

Oscillating readings

over time (usually

0.5 to 1.5 feet of

water)

Zero readings when

pressurized

Moisture in the unit Return for evaluation and repair

Damaged transmitter Return for evaluation and repair

Plugged vent tube (if using a vented unit) Be sure desiccant tube is installed. Test by

gently applying a small amount of pressure

to the end of the desiccant tube and seeing

if this aect the transmitter reading. If it does

not, then the vent tube is plugged. Return for

evaluation and repair.

Actual water level changes in the aquifer

itself in response to barometric pressure

changes. This eect can occur in tight

You will need to record barometric pressure as

well as the water level pressure and compensate

the data

formations where the transmitter will

immediately pick up barometric changes

but the the aquifer will not.

Poor connection due to moisture between

contacts in connector

Dry thoroughly. Be sure desiccant is fresh (see

Maintenance section).

Loose or broken wires in connector Repair or return for evaluation and repair

Damaged cable, broken, cracked, or fraying Replace cable

No apparent damage upon visual inspection Return for evaluation and repair

Seametrics • 253.872.0284 Page 27 seametrics.com

Page 28

SEAMETRICS LIMITED WARRANTY

The limited warranty set forth below is given by Seametrics, with respect to Seametrics branded purchases in the United States of America.

Seametrics warrants that products manufactured by Seametrics, when delivered to you in new condition in their original containers and

properly installed, shall be free from defects in material and workmanship. Seametrics products are warranted against defects for a

period of two (2) years from date of installation, with proof of install date. If no proof of install date can be provided, warranty

period will be two (2) years from date of shipment from Seametrics, as dened on Seametrics’ invoice. Seametrics’ obligation under

this warranty shall be limited to replacing or repairing the part or parts, or, at Seametrics’ option, the products, which prove defective in

material or workmanship. The following are the terms of Seametrics’ limited warranty:

a. Buyer must give Seametrics prompt notice of any defect or failure and satisfactory proof thereof.

b. Any defective part or parts must be returned to Seametrics’ factory or to an authorized service center for inspection.

c. Buyer will prepay all freight charges to return any products to Seametrics’ factory, or another repair facility. as designated by

Seametrics.

d. Defective products, or parts thereof, which are returned to Seametrics and proved to be defective upon inspection, will be repaired

to factory specications.

e. Seametrics will deliver repaired products or replacements for defective products to the buyer (ground freight prepaid) to the

destination provided in the original order.

f. Products returned to Seametrics for which Seametrics provides replacement under this warranty shall become the property of

Seametrics.

g. This limited warranty covers all defects encountered in normal use of Seametrics products, and does not apply to the following

cases:

i. Loss of or damage to Seametrics product due to abuse, mishandling, or improper packaging by buyer

ii. Failure to follow operating, maintenance, or environmental instructions prescribed in Seametrics’ instruction manual

iii. Products not used for their intended purpose

iv. Alterations to the product, purposeful or accidental

v. Electrical current uctuations

vi. Corrosion due to aggressive materials not approved for your specic product

vii. Mishandling, or misapplication of Seametrics products

viii. Products or parts that are typically consumed during normal operation

ix. Use of parts or supplies (other than those sold by Seametrics) which cause damage to the products, or cause abnormally

frequent service calls or service problems

h. A new warranty period shall not be established for repaired or replaced material, products, or supplied. Such items shall remain

under warranty only for the remainder of the warranty period on the original materials, products, or supplies.

i. In the event that equipment is altered or repaired by the buyer without prior written approval by Seametrics, all warranties are void.

Damage caused by equipment or accessories not manufactured by Seametrics may void the product’s warranty.

j. SOFTWARE: The Seller grants the user a non-exclusive license to use Seametrics’ software, according to the following limitations

and conditions:

i. The user may install the software on one or more desktop or laptop computers.

ii. All title and intellectual rights to the software are owned by Seametrics.

iii. No copies may be made or distributed except as described above.

iv. The user may not modify or reverse-engineer the software.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, WHETHER ORAL, WRITTEN, EXPRESSED, IMPLIED OR STATUTORY.

NO IMPLIED WARRANTY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

APPLIED TO THE PRODUCTS AFTER THE APPLICABLE PERIOD OF THE EXPRESS LIMITED WARRANTY STATED ABOVE, AND NO OTHER

EXPRESS WARRANTY OR GUARANTY, EXCEPT AS MENTIONED ABOVE, GIVEN BY ANY PERSON OR ENTITY WITH RESPECT TO THE

PRODUCTS, SHALL BIND SEAMETRICS. SEAMETRICS SHALL NOT BE LIABLE FOR LOSS OF REVENUES, OR PROFITS, OR INCONVENIENCES,

EXPENSE FOR SUBSTITUTE EQUIPMENT OR SERVICE, STORAGE CHARGES, LOSS OF DATA, OR ANY OTHER SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGE CAUSED BY THE USE OR MISUSE OF, OR INABILITY TO USE THE PRODUCTS, REGARDLESS OF THE LEGAL

THEORY ON WHICH THE CLAIM IS BASED, AND EVEN IF SEAMETRICS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN NO

EVENT SHALL RECOVERY OF ANY KIND AGAINST SEAMETRICS BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE PRODUCT

SOLD BY SEAMETRICS AND CAUSING THE ALLEGED DAMAGE. WITHOUT LIMITING THE FOREGOING, YOU ASSUME ALL RISK OF LIABILITY

FOR LOSS, DAMAGE, OR INJURY TO YOU AND YOUR PROPERTY AND TO OTHERS AND THEIR PROPERTY ARISING OUT OF USE OR MISUSE

OF, OR INABILITY TO USE THE PRODUCTS NOT CAUSED DIRECTLY BY THE NEGLIGENCE OF SEAMETRICS.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE DURATION OF AN IMPLIED WARRANTY, SO THE ABOVE LIMITATIONS MAY NOT

APPLY TO YOU. SIMILARLY, SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATIONS OF CONSEQUENTIAL DAMAGE, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS; HOWEVER,

YOU MAY ALSO HAVE OTHER RIGHTS WHICH MAY VARY FROM STATE TO STATE.

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • seametrics.com

LT-14310r23 20180226

2/26/18

Loading...

Loading...