Page 1

Precision Environmental Sensors

d

C

For Sales & Service Contact

2650 E. 40th Ave. • Denver, CO 80205

Phone 303-320-4764 • Fax 303-322-7242

1-800-833-7958

www.geotechenv.com

An ON

I

CON Brand

PT12

Pressure/Temperature Sensor

Instructions

For PSIG

sensors, refer

to page 16

regarding

desiccant

o

m

e

i

p

f

PROUDLY

MADE

IN THE

USA

i

t

r

e

C

ISO

9001:2008

a

n

y

use!

Page 2

TABLE OF CONTENTS

General Information

General Information ...................................................................................................................................................Page 3

Dimensions ....................................................................................................................................................................Page 3

Specications ................................................................................................................................................................Page 4

How Pressure Sensors Work....................................................................................................................................Page 5

Initial Inspection and Handling ..............................................................................................................................Page 6

Do’s and Don’ts ............................................................................................................................................................Page 6

Installation

Cable Wiring ..................................................................................................................................................................Page 7

Installing the Sensor ...................................................................................................................................................Page 7

Desiccant Use ................................................................................................................................................................Page 7

Grounding Issues .........................................................................................................................................................Page 8

Sensor/Data Logger Conguration ......................................................................................................................Page 8

Operation/Modbus RTU

Power Consideration ..................................................................................................................................................Page 9

Communication Settings ..........................................................................................................................................Page 9

Modbus Functions.......................................................................................................................................................Page 9

Register Denitions .....................................................................................................................................................Page 9

Sensor Conguration/Control ................................................................................................................................Page 10

Readings and the Auto-Enable Setting ...............................................................................................................Page 10

Calibration and Conversion Constants ................................................................................................................Page 10

PT12 INSTRUCTIONS

Operation/SDI-12

Reading via SDI-12 ......................................................................................................................................................Page 11

Calibration Register Denitions .............................................................................................................................Page 15

Maintenance

Removing Debris from End Cone ..........................................................................................................................Page 16

Desiccant Tubes ...........................................................................................................................................................Page 16

Sensor/Cable/End Connections .............................................................................................................................Page 17

Troubleshooting

Problems/Probable Causes/Things to Try ..........................................................................................................Page 18

Seametrics • 253.872.0284 Page 2 seametrics.com

Page 3

GENERAL INFORMATION

PT12 INSTRUCTIONS

The Seametrics PT12 Pressure/Temperature Sensor

has been designed to provide trouble-free submersible

operation in liquid environments. This sensor communicates

via SDI-12 (v1.3) or Modbus® RTU (RS485)protocol.

Pressure/level is measured with an extremely rugged and

stable piezo-electric, media isolated pressure element

and compensated for temperature using Seametrics’

proprietary calibration methodology. Temperature is

measured using an on-board digital chip.

Dimensions

8.44” (21.4 cm)

Seametrics also carries a special version of the PT12

designed to measure barometric pressure in reference

to absolute pressure. If you are using an absolute PT12,

contact your representative for details on how our PT12-BV

can facilitate obtaining barometrically compensated

pressure/level.

0.28” (0.7 cm)

Water inlets

Diameter

0.75” (1.9cm)

Seametrics • 253.872.0284 Page 3 inwusa.com

Page 4

GENERAL INFORMATION

PT12 INSTRUCTIONS

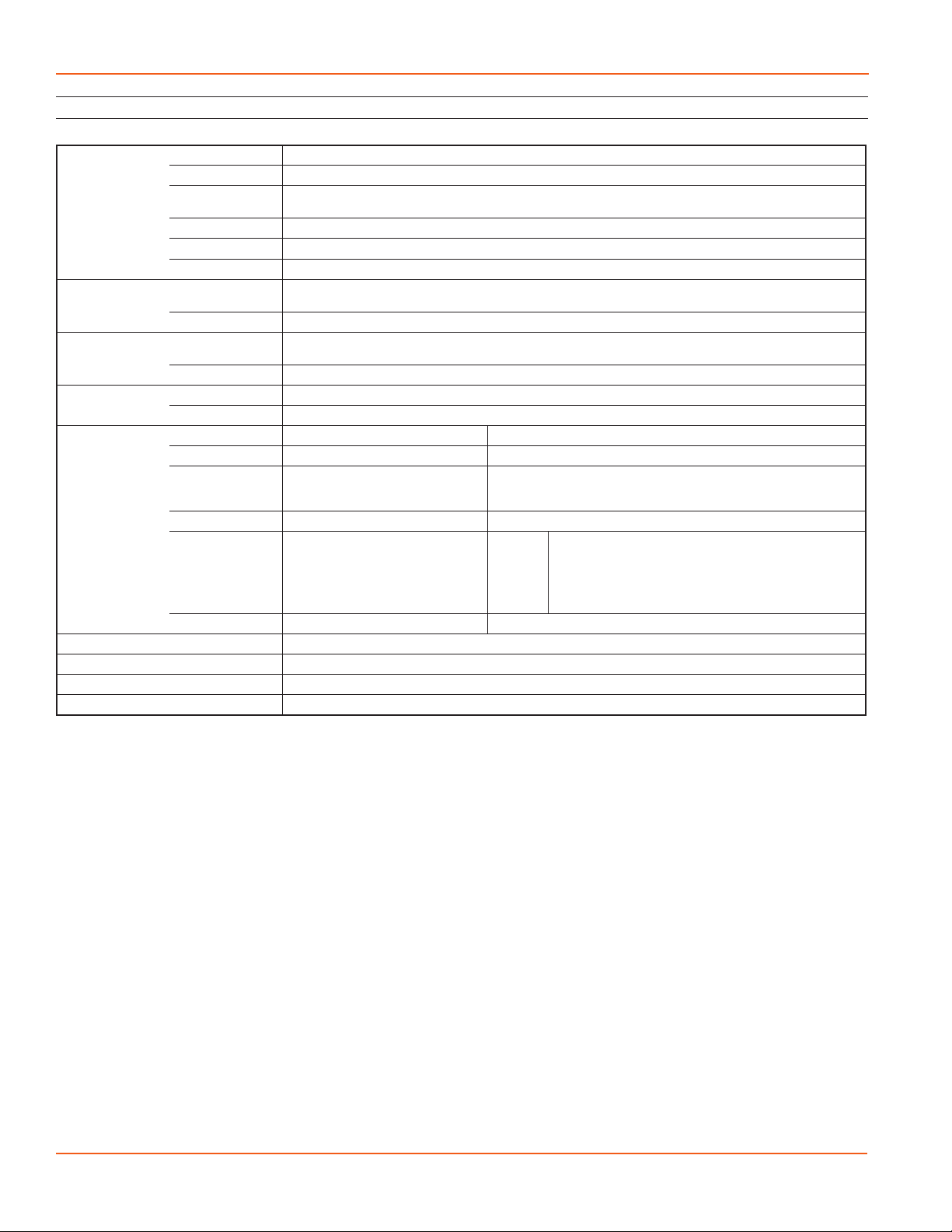

Specications*

Housing & Cable Weight 0.8 lb. (0.4 kg)

Body Material 316 stainless or titanium

Wire Seal

Material

Cable Submersible: polyurethane, polyethylene, or ETFE; 4 lb./100 ft., 1.8 kg/30 m; 2000 ft max for Modbus®

Desiccant 1-3 mm indicating silica gel

Field Connector Available as an option

Temperature Operating Range Recommended: -15˚ to 55˚C (5˚ to 131˚F) Requires freeze protection kit if using pressure option in water

Storage Range -40˚ to 80˚C (-40˚ to 176˚F)

Power Voltage 9-16Vdc, 24Vdc over voltage protection, electromagnetic & transient protection IEC-61000 - 4-3, 4-4,

Supply Current Active 3mA average/ 10mA peak; sleep 150 µA

Communication Modbus® RS485 Modbus® RTU, output=32bit IEEE oating point

SDI-12 SDI-12 (ver. 1.3) - ASCII

Output Channels Temperature Depth/Level¹

Element Digital IC on board Silicon strain gauge transducer, 316 stainless or Hastelloy

Accuracy ±0.5°C — 0° to 55°C (32˚ to 131˚F)

Resolution 0.06˚C 0.0034% FS (typical)

Range -15˚ to 55˚C (5˚ to 131˚F) Gauge

Compensated --- 0˚ to 40˚C (32˚ to 104˚F)

Max operating pressure 1.1 x full scale

Over pressure protection 3x full scale up to 300psi - for > 300psi (650 ft or 200 m) contact factory

Burst pressure 1000 psi (approx. 2000 ft or 600 m)

Environmental IP68, NEMA 6P

*Specications subject to change. Please consult out web site for the most current data (seametrics.com). Modbus is a registered trademark of Schneider Electric.

1 Higher pressure ranges available upon request

2 ±0.25% accuracy FSO (max) at this range

3 Depth range for absolute sensors has 14.7 PSI subtracted to give actual depth allowed.

Fluoropolymer and PTFE

below freezing.

4-5, 4-6

±2.0°C — below 0°C (32˚F)

±0.05% FSO (typical, static)

±0.1% FSO (maximum, static)

(B.F.S.L. 20˚C)

PSI: 12, 5, 7, 15, 30, 50, 100, 300

FtH₂O: 2.32, 12, 35, 69, 115, 231, 692

mH₂O: 0.72, 3.5, 5, 10.5, 21, 35, 70, 210

Absolute

3

PSI: 30, 50, 100, 300

FtH₂O: 35, 81, 196, 658

mH₂O: 10, 24, 59, 200

Seametrics • 253.872.0284 Page 4 seametrics.com

Page 5

GENERAL INFORMATION

PT12 INSTRUCTIONS

How Pressure Sensors Work

Liquids and gasses do not retain a xed shape. Both

have the ability to ow and are often referred to as

uids. One fundamental law for a uid is that the uid

exerts an equal pressure in all directions at a given level.

Further, this pressure increases with an increasing depth of

“submergence”. If the density of a uid remains constant

(noncompressible...a generally good assumption for water

at “normal” pressures and temperatures), this pressure

increases linearly with the depth of “submergence”.

We are all “submerged” in the atmosphere. As we increase

our elevation, the pressure exerted on our bodies decreases

as there is less of this uid above us. It should be noted

that atmospheric pressure at a given level does vary

with changes in the weather. One standard atmosphere

(pressure at sea level at 20º C) is dened to be 14.7 PSI

(pounds per square inch).

There are several methods to reference a pressure

measurement. Absolute pressure is measured with respect

to an ideal vacuum (no pressure). Gauge pressure is the

most common way we express pressure in every day life

and is the pressure exerted over and above atmospheric

pressure. With this in mind, gauge pressure (Pg) can be

expressed as the dierence between the absolute pressure

(Pa) and atmospheric pressure (Patm):

Water Line

P = Patm + kd

A

Patm

d

“A”

Pressure Diagram: See Detail A.

Pg = Pa - Patm.

To measure gauge pressure, atmospheric pressure is

subjected to one side of the system and the pressure to be

measured is subjected to the other. The result is that the

dierential (gauge pressure) is measured. A tire pressure

gauge is a common example of this type of device.

Recall that as the level of submergence increases (in a

noncompressible uid), the pressure increases linearly.

Also, recall that changes in weather cause the absolute

atmospheric pressure to change. In water, the absolute

pressure (Pa) at some level of depth (d) is given as follows:

Pa = Patm + kd

where k is simply a constant

(i.e.: 2.307 feet of water = 1 PSI)

Seametrics’ standard gauge submersible pressure

devices utilize a vent tube in the cable to allow the

device to reference atmospheric pressure. The resulting

gauge pressure measurement reects only the depth of

submergence. That is, the net pressure on the diaphragm

is due entirely to the depth of submergence.

Absolute pressure is given as Pa = Patm + kd

(where k is 2.307 feet of water)

Seametrics • 253.872.0284 Page 5 inwusa.com

Page 6

GENERAL INFORMATION

PT12 INSTRUCTIONS

Initial Inspection and Handling

Upon receipt of your sensor, inspect the shipping package for damage. If any damage is apparent, note the signs of

damage on the appropriate shipping form. After opening the carton, look for concealed damage, such as a cut cable. If

concealed damage is found, immediately le a claim with the carrier.

Check the etched label on the sensor to be sure that the proper range and type were provided. Also check the label

attached to the cable at the connector end for the proper cable length.

Do’s and Don’ts

Do handle sensor with

care

Do store sensor in a

dry, inside area when

not in use

Do install a desiccant

tube if using a gauge

sensor

Do not disassemble—

will void warranty!

Don’t drop into well

Lower gently to prevent

damage

Seametrics • 253.872.0284 Page 6 seametrics.com

Don’t scrape cable

over edge of well

May nick or fray the

cable

Don’t bend cable sharply

May close o vent tube

and/or weaken internal

wires

Don’t support sensor

with the connector

Use a strain relief device

Page 7

INSTALLATION

5-Pin

PT12 INSTRUCTIONS

Cable Wiring

White

Purple

Yellow

Brown

Blue

Shield

12 VDC+ (Vaux)

Modbus D- (Not used)

Modbus D+ (Not used)

SDI-12 Signal

12 VDC- (GND)

Earth ground

For SDI-12

White

Purple

Yellow

Brown

Blue

Shield

5-Pin

Connector

1

2

3

4

5

12 VDC+ (Vaux)

Modbus D- (Not used)

Modbus D+ (Not used)

SDI-12 Signal

12 VDC- (GND)

For SDI-12

— with optional 5-pin connector

White

Purple

Yellow

Brown

Blue

Shield

For Modbus

White

Purple

Yellow

Brown

Blue

Shield

1

2

3

4

5

12 VDC+ (Vaux)

Modbus DModbus D+

SDI-12 Signal (Not used)

12 VDC- (Gnd)

Earth ground

®

12 VDC+ (Vaux)

Modbus DModbus D+

SDI-12 (Not used)

12 VDC- (GND)

For Modbus®

— with optional 5-pin connector

Installing the Sensor

The PT12 measures pressure. The most common application

is measuring liquid levels in wells and tanks. In order to do

this, the sensor must be installed below the water level at a

xed depth. The installation depth depends on the range

of the sensor. One (1) PSI is equal to approximately 2.31

feet of water. If you have a 5 PSI sensor, the range is 11.55

feet of water and the sensor should not be installed at a

depth below 11.55 feet. If the sensor is installed below its

maximum range, damage may result to the sensor and the

output reading will not be correct.

• Lower the sensor to the desired depth.

• Fasten the cable to the well head using a weather

proof strain-relief system. When securing a vented

cable, make sure not to pinch the cable too tightly

or the vent tube inside the cable jacket may be

sealed o.

• Take a measurement to insure the sensor is not

installed below its maximum range.

For vented sensors, install the sensor so that the desiccant

tube will not ood or lie in water.

The sensor can be installed in any position; however, when

it leaves the factory it is tested in the vertical position.

Strapping the sensor body with tie wraps or tape will not

hurt it. Seametrics can provide an optional 1/4” NPT input

adapter which is interchangeable with the standard end

cone for those applications where it is necessary to directly

attach the sensor to a pipe, tank, or other pipe port. If the

sensor is being installed in a uid environment other than

water, be sure to check the compatibility of the uid with

the wetted parts of the sensor.

Desiccant Use

On vented sensors a desiccant tube prevents moisture in

the air from being sucked into the vent tube, which can

cause erratic readings and sensor damage.

The desiccant tube is lled with blue silica gel beads. A

locking barb and a hydrophobic water lter are attached to

the end of the desiccant tube. This lter prolongs the life of

the desiccant as much as three times over a desiccant tube

without the lter.

Install the sensor so that the desiccant tube and cable

connector will not ood or lie in water.

The desiccant is a bright blue color when active and dry. See

Maintenance section for care and changing of desiccant.

Seametrics • 253.872.0284 Page 7 inwusa.com

Page 8

INSTALLATION

PT12 INSTRUCTIONS

Grounding Issues

It is commonly known that when using electronic

equipment, both personnel and equipment need to be

protected from high power spikes that may be caused by

lightning, power line surges, or faulty equipment. Without

a proper grounding system, a power spike will nd the path

of least resistance to earth ground—whether that path

is through sensitive electronic equipment or the person

operating the equipment. In order to ensure safety and

prevent equipment damage, a grounding system must be

used to provide a low resistance path to ground.

When using several pieces of interconnected equipment,

each of which may have its own ground, problems with

noise, signal interference, and erroneous readings may be

noted. This is caused by a condition known as a Ground

Loop. Because of natural resistance in the earth between

the grounding points, current can ow between the points,

creating an unexpected voltage dierence and resulting

erroneous readings.

The single most important step in minimizing a ground

loop is to tie all equipment (sensors, data loggers,

external power sources, and any other associated

equipment) to a single common grounding point.

Seametrics recommends the following:

Sensor/Data Logger Conguration

The PT12 submersible pressure/temperature transducer is

designed for use with SDI-12 or Modbus® data loggers.

Every sensor is individually calibrated at the factory, using

an environmental test chamber and dead-weight tester.

Sensor specic calibration values are stored in the sensor.

When taking measurements, the internal microprocessor

uses these calibration values to thermally compensate the

pressure readings.

In addition to the factory set calibration values, the user can

enter a eld calibration slope and oset for the pressure

and temperature channels. Pressure readings default to

psi and temperature readings to degrees Celsius. The user

can enter a units conversion slope and oset to change

units, if desired. See the operation sections for details on

changing these values. The power supply voltage channel

always returns values in volts.

• The sensor cable shield (the wrapped shield inside

the cable) be attached to the power ground on the

data logger

• The grounding lug be connected via a 12 AWG

or larger wire, to a grounding rod driven into the

earth.

• If you are using an external power supply to power

the data logger that it be tied to the same earth

ground.

Seametrics • 253.872.0284 Page 8 seametrics.com

Page 9

OPERATION/MODBUS RTU

PT12 INSTRUCTIONS

This section explains how to read your PT12 via Modbus®

RTU. (If you want to read via SDI-12, see the next section

beginning on page 11.)

Power Consideration

If your sensor is not powered continuously by an auxiliary

power supply, then you must turn power on to the sensor

at least two seconds before a reading is to be taken to

allow the sensor to warm up.

Communication Settings

The PT12 is congured to communicate with 8 data bits,

one stop bit, and no parity. Default baud rate is 19200.

Modbus® Functions

All readings are obtained using Modbus® function 03-Read

Holding Registers. Readings are located in two registers

each. The data is returned as a 32-bit IEEE oating-point

value, high word rst, also referred to as big-endian, oat

inverse, or Float AB CD.

Register Denitions

The physical register addresses on the PT12 start numbering

from zero – the rst address is 0, the second is 1, etc. On the

other hand, Modbus® protocol considers the rst logical

address to be 1, the second logical address to be 2, etc. For

example, to take a pressure reading you have to read the

physical address 0.

Some programs and equipment when asked to read

address 0 will read that physical address. Others however

will read that logical address, which is actually the physical

address -1 (which does not exist). With these programs and

equipment you must add a one to the address – thus in this

example you would request a read at address 1.

Still other programs and equipment require the addition

of 40,000 or 400,000 to the address to indicate reading

holding registers. These usually also require the addition of

one to the physical address. Check with your program and/

or equipment documentation to determine what style of

register addressing is required.

Like many common Modbus® devices the PT12 returns

readings starting at register address 0 (or 1 if using onebased addressing). In addition, for compatibility with other

Seametrics Smart Sensor equipment, the PT12 also returns

these same readings starting at a register address 62592 (or

62593 if using one-based addressing).

Channel Registers Using Standard Addressing

Zero-Based One-Based +40,001 +400,001

Pressure 0 1 40001 400001

Temperature 2 3 40003 400003

Power Supply Voltage 4 5 40005 400005

Averaged Pressure 6 7 40007 400007

Maximum Pressure 8 9 40009 400009

Minimum Pressure 10 11 40011 400011

Averaged Temperature 12 13 40013 400013

Channel Registers Using High Addressing—to match Seametrics Smart Sensors

Available with rmware 0.13 and higher)

(

Zero-Based One-Based +40,001

Pressure 62592 62593 462593

Temperature 62594 62595 462595

Power Supply Voltage 62596 62597 462597

Averaged Pressure 62598 62599 462599

Maximum Pressure 62600 62601 462601

Minimum Pressure 62602 62603 462603

Averaged Temperature 62604 62605 462605

Seametrics • 253.872.0284 Page 9 inwusa.com

Page 10

OPERATION/MODBUS RTU

PT12 INSTRUCTIONS

Sensor Conguration/Control

ZeroBased

300=n 301=n 40301=n Set averaging: This enables sensor for n

400=a 401=a 40401=a Set sensor address = a (Write Only)

500=b 501=b 40501=b Set baud rate = b (Write only)

600=w 601=w 40601=w Set auto-enable. Causes sensor to be enabled

700=L 701=L 40701=L Set serial number. L= unsigned longword value

800 801 40801 Read sensor rmware revision. Word MSB =

OneBased

+40,001 Description

seconds. Each second, the statistical data

registers will be updated to contain new

averages, max and min. At the completion of n

seconds, the nal statistical values will be left in

the registers, and the sensor will be put to sleep.

n = 0..10,800. If n = 0, the sensor is put to sleep,

and the statistical data values are not updated.

0=38400, 1=19200 (default), 2=9600, 3=4800,

4=2400, 5=1200

automatically for w seconds after a read of any

parameter data register. W=0 disables autoenable. (This is normally set to 10 seconds at the

factory.) For lowest power usage, set this to zero.

For fastest readings while still retaining as much

power savings as possible, set slightly longer

than your read frequency. See section below

for information on how this setting aects your

readings.

0x0000000 .. 0xFFFFFFF (0 .. 4,294,967,295)

Major revision, LSB = minor revision.

E.g., 0013 = revision 0.13

Readings and the Auto-Enable Setting

When a reading is requested, four things happen:

• The sensor wakes up.

• The current value in the register is returned.

• The sensor turns on the analog portion, begins

sampling, and begins putting the new values in the

registers.

• If auto-enable is set to a positive value w, the sensor

stays awake for w seconds, sampling and moving

values into the registers all the while, and then goes

to sleep.

• If auto-enable is set to zero, the sensor immediately

goes to sleep after putting the reading in the

register.

If your read frequency is less than the auto-enable value,

the sensor will stay on continuously, and your readings will

always be fresh, with the exception of the very rst reading.

Calibration and Conversion Constants

The data is returned as a 32-bit IEEE oating-point value,

high word rst, also referred to as big-endian, oat inverse,

or Float AB CD.

Field calibration values and units conversion values can be

set by the user. If set, these values will be applied to the

readings before values are returned.

ZeroBased

200-01 201-02 40201-02 Factory Calibration* - Pressure Scale

202-03 203-04 40203-04 Factory Calibration* - Pressure Linearization 1

204-05 205-06 40205-06 Factory Calibration* - Pressure Linearization 2

206-07 207-08 40207-08 Factory Calibration* - Pressure Slope 0

208-09 209-10 40209-10 Factory Calibration* - Pressure Slope 1

210-11 211-12 40211-12 Factory Calibration* - Pressure Slope 2

212-13 213-14 40213-14 Factory Calibration* - Pressure Oset 0

214-15 215-16 40215-16 Factory Calibration* - Pressure Oset 1

216-17 217-18 40217-18 Factory Calibration* - Pressure Oset 2

218-19 219-20 40219-20 Field Calibration - Pressure Slope

220-21 221-22 40221-22 Field Calibration - Pressure Oset

222-23 223-24 40223-24 Field Calibration - Temperature Slope

224-25 225-26 40225-26 Field Calibration - Temperature Oset

226-27 227-28 40227-28 Factory Calibration* - Temperature Alpha

228-29 229-30 40229-30 Factory Calibration* - Temperature Oset

230-31 231-32 40231-32 Factory Calibration* - Tempearture Slope

232-33 233-34 40233-34 Pressure Units - Conversion Slope

234-35 235-36 40235-36 Pressure Units - Conversion Oset

236-37 237-38 40237-38 Temperature Units - Conversion Slope

238-39 239-40 40239-40 Temperature Units - Conversion Oset

One-

Based

+40,001 Description

* Factory calibration values are set at the factory.

Writing to Factory Calibration

registers will void calibration!

If your read frequency is greater than the auto-enable

value, the following reading sequence is recommended:

1. Request a reading. This begins the wakeup process

on the sensor and returns the value currently in the

register, which will be old data. Throw this value

away.

2. Wait one second, then take another reading. This

reading will have fresh data. Record this reading.

Seametrics • 253.872.0284 Page 10 seametrics.com

Page 11

OPERATION/SDI-12

Reading via SDI-12

PT12 INSTRUCTIONS

Addressing

Request Response

Carriage Return

Default SDI-12 Address: 0

SDI-12 Command Nomenclature

<a> = Sensor address

{crc} = SDI-12 compatible 3-character CRC

<cr> = ASCII carriage return character

<lf> = ASCII line feed character

highlighted values indicate variable data

All SDI-12 requests consist

of a command followed by

a request for values. Some

software or equipment may

combine these, making the

second one unnecessary. Refer

to your software or equipment

documentation for details.

<a>M1! <a>0021<cr><lf>

Address

Command

Request Response

Address

Time until

(in seconds)

response

# of values to

<a>D0! <a>+7.15863<cr><lf>

Address

Request for

values read

Address

Returned

value(s)

SDI-12 Commands

Sensor Identication

<a>I! <a>13 INWUSA PT12 0.13ssssssssss<cr><lf> Note: 0.13 will change to reect current

Acknowledge Active, Address Query

<a>! <a><cr><lf>

?! <a><cr><lf>

rmware version.

ssssssssss = device serial number

Linefeed

be returned

Carriage Return

Linefeed

Change Address

<a>A<b>! <b><cr><lf> Change address to <b>

Request Measurement

<a>M! <a>0023<cr><lf> Request all basic measurements

<a>D0! <a>+7.15863+25.0000+12.0512<cr><lf> Read: pressure, temperature, voltage

<a>M1! <a>0021<cr><lf> Request pressure measurement only

<a>D0! <a>+7.15863<cr><lf> Read pressure

<a>M2! <a>0021<cr><lf> Request temperature measurement only

<a>D0! <a>+25.0000<cr><lf> Read temperature

<a>M3! <a>0021<cr><lf> Request power supply voltage

<a>D0! <a>+12.0512<cr><lf> Read power supply voltage

<a>M4! <a>0ttt4<cr><lf> Request averaged data. ttt depends on

programmed average duration.

<a>D0! <a>+7.15863+7.23215+7.051283+25.0000

<cr><lf> Read average pressure, max. pressure, min.

pressure, average temperature

Seametrics • 253.872.0284 Page 11 inwusa.com

Page 12

OPERATION/SDI-12

M5!, M6!, and M7! only available on PT12-BV/PT12 combination units!

<a>M5! <a>0023<cr><lf> Request barometrically compensated down-

hole pressure, down-hole temperature, surface

temperature

<a>D0! <a>+2.58613+19.2100+21.05122<cr><lf> Read: barometrically compensated down-hole

pressure, down-hole temperature, surface

temperature

PT12 INSTRUCTIONS

<a>M6! <a>0024<cr><lf> Request non-barometrically compensated

<a>D0! <a>+17.31813+19.2100+14.732+21.0512<cr><lf> Read non-barometrically compensated down-

<a>M7! <a>ttt1<cr><lf> Request averaged barometrically compensated

<a>D0! <a>+7.12050<cr><lf> Read temperature averaged barometrically

Request Measurement with CRC

<a>MC! <a>0023<cr><lf> Request all basic measurements

<a>D0! <a>+7.15863+25.0000+12.0512{crc}<cr><lf> Read: pressure, temperature, voltage

<a>MC1! <a>0021<cr><lf> Request pressure measurement only

<a>D0! <a>+7.15863{crc}<cr><lf> Read pressure

<a>MC2! <a>0021<cr><lf> Request temperature measurement only

<a>D0! <a>+25.0000{crc}<cr><lf> Read temperature

down-hole pressure, down-hole temperature,

surface pressure, surface temperature

hole pressure, down-hole temperature, surface

pressure, surface temperature

pressure. ttt depends on programmed

average.

compensated pressure

<a>MC3! <a>0021<cr><lf> Request power supply voltage

<a>D0! <a>+12.0512{crc}<cr><lf> Read power supply voltage

<a>MC4! <a>0ttt4<cr><lf> Request averaged data. ttt depends on

<a>D0! <a>+7.15863+7.23215+7.051283+25.0000{crc

MC5!, MC6!, and MC7! only available on PT12-BV/PT12 combination units!

<a>MC5! <a>0023<cr><lf> Request barometrically compensated down-

<a>D0! <a>+2.58613+19.2100+21.05122{crc}<cr><lf> Read: barometrically compensated down-hole

<a>MC6! <a>0024<cr><lf> Request non-barometrically compensated

<a>D0! <a>+17.31813+19.2100+14.732+21.0512{crc}<cr><lf> Read non-barometrically compensated down-

Seametrics • 253.872.0284 Page 12 seametrics.com

}<cr><lf> Read average pressure, max. pressure, min.

programmed average duration.

pressure, average temperature

hole pressure, down-hole temperature, surface

temperature

pressure, down-hole temperature, surface

temperature

down-hole pressure, down-hole temperature,

surface pressure, surface temperature

hole pressure, down-hole temperature, surface

pressure, surface temperature

Page 13

OPERATION/SDI-12

PT12 INSTRUCTIONS

<a>MC7! <a>ttt1<cr><lf> Request averaged barometrically compensated

<a>D0! <a>+7.12050{crc}<cr><lf> Read temperature averaged barometrically

Concurrent Measurement

<a>C! <a>0023<cr><lf> Request all basic measurements

<a>D0! <a>+7.15863+25.0000+12.0512<cr><lf> Read: pressure, temperature, voltage

<a>C1! <a>0021<cr><lf> Request pressure measurement only

<a>D0! <a>+7.15863<cr><lf> Read pressure

<a>C2! <a>0021<cr><lf> Request temperature measurement only

<a>D0! <a>+25.0000<cr><lf> Read temperature

<a>C3! <a>0021<cr><lf> Request power supply voltage

<a>D0! <a>+12.0512<cr><lf> Read power supply voltage

<a>C4! <a>0ttt4<cr><lf> Request averaged data. ttt depends on

<a>D0! <a>+7.15863+7.23215+7.051283+25.0000

<cr><lf> Read average pressure, max. pressure, min.

pressure. ttt depends on programmed

average.

compensated pressure

programmed average duration.

pressure, average temperature

C5!, C6!, and C7! only available on PT12-BV/PT12 combination units!

<a>C5! <a>0023<cr><lf> Request barometrically compensated down-

<a>D0! <a>+2.58613+19.2100+21.05122<cr><lf> Read: barometrically compensated down-hole

<a>C6! <a>0024<cr><lf> Request non-barometrically compensated

<a>D0! <a>+17.31813+19.2100+14.732+21.0512<cr><lf> Read non-barometrically compensated down-

<a>C7! <a>ttt1<cr><lf> Request averaged barometrically compensated

<a>D0! <a>+7.12050<cr><lf> Read temperature averaged barometrically

hole pressure, down-hole temperature, surface

temperature

pressure, down-hole temperature, surface

temperature

down-hole pressure, down-hole temperature,

surface pressure, surface temperature

hole pressure, down-hole temperature, surface

pressure, surface temperature

pressure. ttt depends on programmed

average.

compensated pressure

Seametrics • 253.872.0284 Page 13 inwusa.com

Page 14

OPERATION/SDI-12

Concurrent Measurement with CRC

<a>CC! <a>0023<cr><lf> Request all basic measurements

<a>D0! <a>+7.15863+25.0000+12.0512{crc}<cr><lf> Read: pressure, temperature, voltage

<a>CC1! <a>0021<cr><lf> Request pressure measurement only

<a>D0! <a>+7.15863{crc}<cr><lf> Read pressure

<a>CC2! <a>0021<cr><lf> Request temperature measurement only

<a>D0! <a>+25.0000{crc}<cr><lf> Read temperature

<a>CC3! <a>0021<cr><lf> Request power supply voltage

<a>D0! <a>+12.0512{crc}<cr><lf> Read power supply voltage

PT12 INSTRUCTIONS

<a>CC4! <a>0ttt4<cr><lf> Request averaged data. ttt depends on

<a>D0! <a>+7.15863+7.23215+7.051283+25.0000{crc

CC5!, CC6!, and CC7! only available on PT12-BV/PT12 combination units!

<a>CC5! <a>0023<cr><lf> Request barometrically compensated down-

<a>D0! <a>+2.58613+19.2100+21.05122{crc}<cr><lf> Read: barometrically compensated down-hole

<a>CC6! <a>0024<cr><lf> Request non-barometrically compensated

<a>D0! <a>+17.31813+19.2100+14.732+21.0512{crc}<cr><lf> Read non-barometrically compensated down-

<a>CC7! <a>ttt1<cr><lf> Request averaged barometrically compensated

<a>D0! <a>+7.12050{crc}<cr><lf> Read temperature averaged barometrically

Extended Commands

Set duration for averaging reading

<a>XAttt! <a>ttt<cr><lf> Set duration of averaged data for M4, MC4, C4,

}<cr><lf> Read average pressure, max. pressure, min.

programmed average duration.

pressure, average temperature

hole pressure, down-hole temperature, surface

temperature

pressure, down-hole temperature, surface

temperature

down-hole pressure, down-hole temperature,

surface pressure, surface temperature

hole pressure, down-hole temperature, surface

pressure, surface temperature

pressure. ttt depends on programmed

average.

compensated pressure

and CC4 commands. ttt = 1–997 seconds

Read/Modify Calibration Values

<a>XCnn{=<value>}! <a><value><cr><lf> Read {modify} calibration value nn

Examples:

<a>XC00! <a>+1.591600e-5<cr><lf> Read the value from calibration register 00

<a>XC00=1.704e-4! <a>+1.704000e-4<cr><lf> Set the value of calibration register 00

Set number of signicant digits

<a>XSt! <a>t<cr><lf> Set number of signicant digits for SDI-12

Seametrics • 253.872.0284 Page 14 seametrics.com

report data. t = 1–7

Page 15

OPERATION/SDI-12

PT12 INSTRUCTIONS

Calibration Register Denitions

Field calibration values can be set by user. If set, these values will be applied to readings before values are returned. All

calibration registers contain oating point values.

SDI-12 Reg. ID Mnemonic Description Default value

00 Scale Units scale (counts * Scale = base units, default psi) 1.591600e-5

01 a Factory calibration linearized correction factor 1* 0.000000e+00

02 b Factory calibration linearized correction factor 2* 1.000000e+00

03 m0 Factory calibration slope coeent 0* 1.000000e+00

04 m1 Factory calibration slope coeent 1* 0.000000e+00

05 m2 Factory calibration slope coeent 2* 0.000000e+00

06 b0 Factory calibration oset coeent 0* 0.000000e+00

07 b1 Factory calibration oset coeent 1* 0.000000e+00

08 b2 Factory calibration oset coeent 2* 0.000000e+00

09 mField Field pressure calibration slope 1.000000e+00

10 bField Field pressure calibration oset 0.000000e+00

11 mT Field temperature calibration slope 1.000000e+00

12 bT Field temperature calibration oset 0.000000e+00

13 T_Alpha Factory temperature calibration–Alpha* 0.000000e+00

14 T_Oset Factory temperature calibration–Oset* 0.000000e+00

15 T-ZeroSlope Factory temperature calibration–ZeroSlope* 0.000000e+00

16 P_mUnits Pressure units conversion slope 1.000000e+00

17 P_bUnits Pressure units conversion oset 0.000000e+00

18 T_mUnits Temperature units conversion slope 1.000000e+00

19 T_bUnits Temperature units conversion oset 0.000000e+00

* Factory calibration values are set at the factory.

Writing to Factory Calibration

registers will void calibration!

Seametrics • 253.872.0284 Page 15 inwusa.com

Page 16

MAINTENANCE

PT12 INSTRUCTIONS

Removing Debris from End Cone

At times mud, silt, or other debris may foul the water inlets

to the pressure element. The end cone can be removed to

clean out the debris.

Twist Open Housing

1. Gently twist o end cone portion only - do not twist

o pressure element!

2. Remove debris. Do not poke anything into the

sensor. This can damage the sensor element and

void the warranty.

3. Replace and retighten the end cone.

Pressure element

Water inlet

End cone

Gently twist o the end cone and carefully remove debris

Set Screw Housing

1. Remove the two set screws at the bottom of the

housing tube, using a 1/16” allen wrench.

2. Gently remove the end cone.

3. Remove debris. Do not poke anything into the

sensor. This can damage the sensor element and

void the warranty.

4. Replace the end cone and secure with set screws.

Desiccant Tubes

On vented sensors, inspect the desiccant tube at least once

every two months. The desiccant tube prevents moisture

in the air from being sucked into the vent tube, which can

cause erratic readings and sensor damage.

The desiccant tube is lled with blue silica gel beads. A

locking barb and a hydrophobic water lter are attached to

the end of the desiccant tube. This lter prolongs the life of

the desiccant as much as three times over a desiccant tube

without the lter.

Install the sensor so that the desiccant tube and cable

connector will not ood or lie in water.

The desiccant is a bright blue color when active and dry.

As moisture is absorbed the color will begin to fade,

becoming a light pink, which indicates full saturation and

time to replace. Replacement desiccant and hydrophobic

lters can be purchased from Seametrics.

To Change the Desiccant:

• Pulling gently remove the black tube tting from

the clear desiccant tube.

• Using needle-nose pliers, remove the dark gray

foam plug. Do not discard the plug.

• Dump out the old desiccant beads and rell with

new desiccant beads – tapping desiccant tube

frequently during relling to ensure that the beads

are fully seated in tube.

• Push the foam plug back into the tube.

• Reinsert the black tting.

Pressure element

Water inlet

Set screw

End cone

Remove end cone by removing set screws.

Gently clean out debris.

Seametrics • 253.872.0284 Page 16 seametrics.com

Page 17

MAINTENANCE

Sensor

There are no user-serviceable parts. If problems develop

with sensor stability or accuracy, contact Seametrics. If the

transducers have been exposed to hazardous materials, do

not return them without notication and authorization.

Cable

Cable can be damaged by abrasion, sharp objects, twisting,

crimping, crushing, or pulling. Take care during installation

and use to avoid cable damage. If a section of cable is

damaged, it is recommended that you send your sensor

back to replace the cable harness assembly.

End Connections–if using optional eld connector

The contact areas (pins & sockets) of the connectors will

wear out with extensive use. If your application requires

repeated connections other types of connectors can be

provided. The connectors used by Seametrics are not

submersible, but are designed to be splash-resistant.

PT12 INSTRUCTIONS

Seametrics • 253.872.0284 Page 17 inwusa.com

Page 18

TROUBLESHOOTING

Problem Probable Causes Things to try…

PT12 INSTRUCTIONS

Erratic readings Poor connection due to moisture between

contacts in connector

Loose or broken wires in connector Repair or return for evaluation and repair

Damaged cable, cracked or fraying Replace cable

Moisture in the unit Return for evaluation and repair

Damaged transmitter Return for evaluation and repair

Oscillating readings

Plugged vent tube (if using a vented unit) Be sure desiccant tube is installed. Test by

over time (usually

0.5 to 1.5 feet of

water)

Actual water level changes in the aquifer

itself in response to barometric pressure

changes. This eect can occur in tight

formations where the transmitter will

immediately pick up barometric changes

but the the aquifer will not.

Zero readings when

pressurized

Poor connection due to moisture between

contacts in connector

Dry thoroughly. Be sure desiccant is fresh (see

Maintenance section).

gently applying a small amount of pressure

to the end of the desiccant tube and seeing

if this aect the transmitter reading. If it does

not, then the vent tube is plugged. Return for

evaluation and repair.

You will need to record barometric pressure as

well as the water level pressure and compensate

the data

Dry thoroughly. Be sure desiccant is fresh (see

Maintenance section).

Loose or broken wires in connector Repair or return for evaluation and repair

Damaged cable, broken, cracked, or fraying Replace cable

No apparent damage upon visual inspection Return for evaluation and repair

Seametrics • 253.872.0284 Page 18 seametrics.com

Page 19

WARRANTY/DISCLAIMER

PT12 INSTRUCTIONS

LIMITED WARRANTY/DISCLAIMER - PT12

SUBMERSIBLE PRESSURE TRANSDUCER

A. Seller warrants that products manufactured by Seller when properly installed, used and maintained with a properly

installed desiccant tube, shall be free from defects in material and workmanship. Seller’s obligation under this warranty

shall be limited to replacing or repairing the part or parts or, at Seller’s option, the products which prove defective in

material or workmanship within TWO (2) year from the date of delivery, provided that Buyer gives Seller prompt notice

of any defect or failure and satisfactory proof thereof. Any defective part or parts must be returned to Seller’s factory

or to an authorized service center for inspection. Buyer will prepay all freight charges to return any products to Seller’s

factory, or any other repair facility designated by Seller. Seller will deliver replacements for defective products to Buyer

(ground freight prepaid) to the destination provided in the original order. Products returned to Seller for which Seller

provides replacement under this warranty shall become the property of Seller.

This limited warranty does not apply to lack of performance caused by abrasive materials, corrosion due to aggressive

uids, mishandling or misapplication. Seller’s obligations under this warranty shall not apply to any product which (a)

is normally consumed in operation, or (b) has a normal life inherently shorter than the warranty period stated herein.

In the event that equipment is altered or repaired by the Buyer without prior written approval by the Seller, all warranties

are void. Equipment and accessories not manufactured by the Seller are warranted only to the extent of and by the

original manufacturer’s warranty.

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, WHETHER ORAL, WRITTEN, EXPRESSED,

IMPLIED OR STATUTORY. IMPLIED WARRANTIES OF FITNESS AND MERCHANTABILITY SHALL NOT APPLY. SELLER’S

WARRANTY OBLIGATIONS AND BUYER’S REMEDIES THEREUNDER (EXCEPT AS TO TITLE) ARE SOLELY AND EXCLUSIVELY

AS STATED HEREIN. IN NO CASE WILL SELLER BE LIABLE FOR CONSEQUENTIAL DAMAGES, LABOR PERFORMED IN

CONNECTION WITH REMOVAL AND REPLACEMENT OF THE SENSOR SYSTEM, LOSS OF PRODUCTION OR ANY OTHER

LOSS INCURRED BECAUSE OF INTERRUPTION OF SERVICE. A NEW WARRANTY PERIOD SHALL NOT BE ESTABLISHED

FOR REPAIRED OR REPLACED MATERIAL, PRODUCTS OR SUPPLIES. SUCH ITEMS SHALL REMAIN UNDER WARRANTY

ONLY FOR THE REMAINDER OF THE WARRANTY PERIOD ON THE ORIGINAL MATERIALS, PRODUCTS OR SUPPLIES.

B. With respect to products purchased by consumers in the United States for personal use, the implied warranties

including but not limited to the warranties of merchantability and tness for a particular purpose, are limited to twenty

four (24) months from the date of delivery.

Some states do not allow limitations on the duration of an implied warranty, so the above limitation may not apply to

you. Similarly, some states do not allow the exclusion or limitation of consequential damages, so the above limitation or

exclusion may not apply to you. This limited warranty gives you specic legal rights; however, you may also have other

rights which may vary from state to state.

Seametrics • 253.872.0284 Page 19 inwusa.com

Page 20

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • seametrics.com

LT-14372r18 20180306 3/6/2018

Loading...

Loading...