Page 1

d

C

PE202

Low Flow Magmeter

Instructions

o

m

e

i

p

f

PROUDLY

MADE

IN THE

USA

i

t

r

e

C

ISO

9001:2008

a

n

y

Page 2

TABLE OF CONTENTS

General Information

General Information ...................................................................................................................................................Page 3

Features ..........................................................................................................................................................................Page 3

Specications ................................................................................................................................................................Page 4

Dimensions ....................................................................................................................................................................Page 5

Pressure Drop Curve ...................................................................................................................................................Page 5

Installation

Positioning......................................................................................................................................................................Page 6

Mounting ........................................................................................................................................................................Page 6

Piping ...............................................................................................................................................................................Page 6

Power Supply .................................................................................................................................................................Page 6

Grounding ......................................................................................................................................................................Page 6

Connections

General Connection Information ...........................................................................................................................Page 7

Pulse Output Only with FT520 ................................................................................................................................Page 7

4-20 mA Device and FT430/440 with Single Power Supply ........................................................................Page 7

Dual Power Supply with Loop Isolation ..............................................................................................................Page 7

Operation

General Operation Information..............................................................................................................................Back

PE202 INSTRUCTIONS

Troubleshooting

Problem ...........................................................................................................................................................................Back

Probably Causes ...........................................................................................................................................................Back

Things to Try ..................................................................................................................................................................Back

Seametrics • 253.872.0284 Page 2 seametrics.com

Page 3

GENERAL INFORMATION

PE202 INSTRUCTIONS

The PE202 magmeter is designed for low-ow chemical

injection or difcult-to-meter applications with pulsating

metering pumps in 3/4” to 1/4” pipe/tube. The housing is

made of sturdy splashproof HDPE plastic.

With no moving parts, the PE202 can handle uids

containing particulate matter without clogging or jamming,

keeping maintenance at a minimum. With no metallic parts

(100% PVDF body and PVDF carbon ber-lled electrodes),

the meter is corrosion-resistant and compatible with a

wide range of chemicals (consult factory for chemicals and

concentrations). Accuracy is maintained with conductive

uids (>20 microSiemens) of varying viscosities and

densities.

FEATURES

8-pin circular bulkhead connector, 20 foot (6 meter) cable provided

The PE meter is compact enough to t most pump/injection

systems. With zero straight pipe required after an elbow,

it can be easily mounted in tight spaces. The mounting

bracket adds stability.

The PE meter has an optoisolated current sinking pulse

output that can be connected to the Seametrics FT430/440

rate/total display or FT520 batch processor, as well as an

optoisolated 4-20 mA current loop for analog devices.

Outputs and power are provided through a cable with

8-pin female circular connector.

Mounting bracket

Internals made of chemical and corrosion-resistant PVDF

Sturdy HDPE housing

½” male NPT

ttings standard

Threaded male or female NPT adapters

can be purchased separately

(available in PVDF and PP)

(Female NPT available in 1/2” only)

Seametrics • 253.872.0284 Page 3 seametrics.com

Page 4

GENERAL INFORMATION

PE202 INSTRUCTIONS

Specications*

Pipe Size 3/4”, 1/2”, 3/8”, 1/4” **

Fittings 1/2” NPT ttings standard in 3/4” or 3/8” owbody. NPT threaded adapters available for above

Materials Body PVDF

Electrodes PVDF carbon ber lled

Ground PVDF carbon ber lled

Housing HDPE with 25% glass

Adapters (NPT) Polypropylene or PVDF

Temperature Ambient 0˚ to 130˚ F (-18˚ to 54˚ C)

Fluid 32˚ to 200˚ F (0˚ to 93˚ C)

Pressure 150 psi

Flow Range -075 20 GPM max. (0.2 GPM cutoff)

-038 3 GPM max. (0.03 GPM cutoff)

Accuracy -075 ±1% plus ±0.005 GPM of reading across rated range

-038 ±1% plus ±0.002 GPM of reading across rated range

Output Signal Optoisolated current sinking or current sourcing pulse output: 30 Vdc, 5 mA max

-075 500 pulses/liter (1892 pulses/gallon)

-038 1000 pulses/liter (3785 pulses/gallon)

Power 10–15 Vdc, 150 mA (linear power supply recommended)

Conductivity >20 microSiemens

Empty Pipe Detection Hardware/software, conductivity-based

Environmental

* Specications subject to change • Please consult our website for current data (seametrics.com).

** Requires adaptors

NOTE: Consult factory for applications owing sodium hypochlorite, sodium chlorite, sodium chlorate.

For applications with the listed chemicals, the following conditions apply:

• Max concentration 15% / Max temperature 100˚ F

• Flow is greater than 20% of max for accurate reading

pipe sizes.

Optoisolated 4-20 mA current loop: 7 Vdc plus load voltage drop min; 50 Vdc max

NEMA 4X standard; IP66 splashproof standard

Seametrics • 253.872.0284 Page 4 seametrics.com

Page 5

GENERAL INFORMATION

D

C

B

8

7

6

5

4

3

2

1

4.2"

2.1"

METER ID

-038

.19

-075

.50

D

C

8

7

6

5

4

3

2

1

Dimensions

PE202 INSTRUCTIONS

Mounting

Bracket

7.2” (18.3 cm) (with adapters as shown)

7.2" (WITH ADAPTERS AS SHOWN)

4.2” (10.7 cm) (meter without adapters)

4.2" (METER WITHOUT ADAPTERS)

3.5”

3.5"

(8.9 cm)

2.0”

2.0"

(5.0 cm)

7.2” (18.3 cm) (with adapters as shown)

7.2" (WITH ADAPTERS AS SHOWN)

4.2" (METER WITHOUT ADAPTERS)

4.2” (10.7 cm) (meter without adapters)

4.2” (10.7 cm)

4.2"

2.1"

2.1” (5.3 cm)

Meter ID

-038 0.19”

-038

.19

-075

.50

-075 0.50”

3.5”

3.5"

(8.9 cm)

2.0"

2.0”

(5.0 cm)

Pressure Drop Curve

-038

3

PE202-075 with 3/4” adapters.

PE202-038 with 3/8” adapters.

Actual curve dependant on pipe size/ttings

-075

Seametrics • 253.872.0284 Page 5 seametrics.com

Page 6

INSTALLATION

PE202 INSTRUCTIONS

Positioning

The PE202 can be mounted vertically or horizontally. It is

important to choose a position that will ensure full pipe.

(Under certain conditions of empty or partially-full pipe

the meter may give a pulse out when there is no ow.)

With a zero straight pipe requirement after an elbow, the

PE meter can be installed in tight spaces.

FLOW

FLOW

FLOW

Mounting

It is highly recommended to use the mounting bracket

provided. The mounting bracket uses two #8 screws on a

1.5” center.

Piping

Metal pipe, metal tube, or plastic tubing can be used with

the meter. The standard NPT ttings can be used with or

without NPT adapters on 3/4” or 3/8” pipe. If used, apply

Teon tape onto the NPT ttings. NPT adapters should be

hand tightened onto the ttings. Thoroughly clean the

pipe threads and nose and apply Teon tape to adapter

threads. Hold adapters with a wrench while tightening the

pipe to prevent damage to the meter.

Power Supply

A 12 Vdc linear, regulated power supply with an output

current of at least 0.25A is recommended. If a switching

power supply must be used, consult Seametrics for

approved manufacturer’s model numbers.

Grounding

In addition, it is necessary for proper operation to ground

the unit to a good quality earth ground. Assure negative

power supply is grounded to earth and to the entire

electrical/mechanical system. If metal piping is used,

jumper inlet and outlet pipes together and connect to

ground for best results in metering accuracy. The cable

shield drain wire should be left unconnected.

The PE202 may be supported by its piping connections IF

the piping is rigid. The meter and pipe must be perfectly

aligned with no exion at the ttings to prevent leakage or

damage to the meter.

Seametrics • 253.872.0284 Page 6 seametrics.com

Page 7

CONNECTIONS

Green

Green

PE202 INSTRUCTIONS

Power and signal connections are provided through the

8-pin male bulkhead connector on the meter housing

(20 ft (6 m) cable provided). See the Pin Assignment and

Connections diagrams.

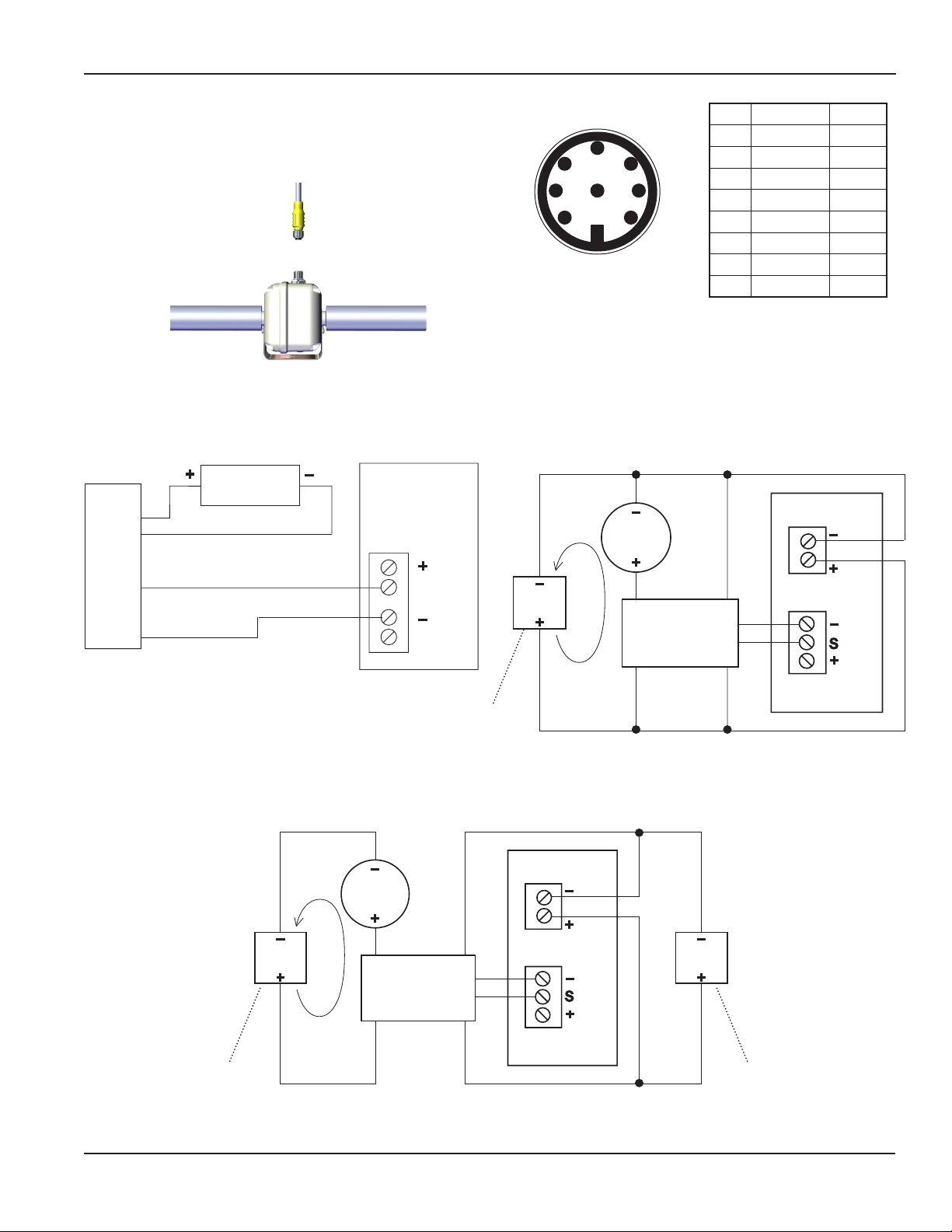

Pulse Output Only with FT520

_

FT520

12

+

SEN 1

_

G

SEN 2

Pin 8

Pin 2

PE202

Pin 3

Pin 1

Red

+

White

12 Vdc

power

Brown

Green

5

4

6

3 7

8

2

Cable Plug Contact

Arrangement

1

Pin # Function Color

1 Pulse (-) White

2 Ground Brown

3 Pulse (+) Green

4 4-20 (+) Yellow

5 Not used Grey

6 Not used Pink

7 4-20 (-) Blue

8 Power (+) Red

4-20 mA Device and FT430/440 with Single Power Supply

Important: 4-20mA device input resistance must not exceed 250 Ω

4-20 mA

_

12–15

Vdc

+

loop

_

4-20 mA

device

+

7

4

Blue

PE202

2

8

1

3

Brown

White

Power

FT430/440

_

S

+

_

+

May be external

or internal to the

FT430/440

4-20 mA

_

24

Vdc

+

loop

May be external

or internal to the

FT430/440

Dual Power Supply with Loop Isolation

_

4-20 mA

device

+

7

4

Yellow

Blue

PE202

2

8

1

3

Brown

White

Red

Power

_

+

FT430/440

_

S

+

Sensor Input

Yellow

_

12–15

Vdc

+

May be external

or internal to the

FT430/440

Sensor Input

Red

Seametrics • 253.872.0284 Page 7 seametrics.com

Page 8

OPERATION

PE202 INSTRUCTIONSOPERATION AND TROUBLESHOOTING

The meter will output one pulse when powered up. The

newly-installed meter takes from a few seconds to a minute

for the signal to stabilize at startup, especially if it has been

dry. In normal operation, keep the meter lled with uid

and powered on to prevent this delay. When the meter

is mounted properly, an empty pipe detection feature will

normally detect absence of liquid in the pipe and register

The 4-20 mA signal outputs 4 mA at zero ow and 20 mA at

20 gallons/minute ow or 3 gallons per minute, depending

on model.

The pulse signal is a 50% duty cycle pulse set at:

PE202-075: 500 pulses/liter (1892 pulses/gallon)

PE202-038: 1,000 pulses/liter (3785 pulses/gallon)

zero ow.

TROUBLESHOOTING

Problem Probable Causes Things to try…

No output Reversed ow direction Reverse ow connections

Empty pipe Check piping conditions

Flow rate below minimum Select a different ow meter

Loose or incorrect wiring Check electrical connections

Fluid conductivity too low Select a different ow meter

Electrical noise Relocate meter or reduce noise

Flow rate incorrect Fluid conductivity too low Select a different ow meter

Empty pipe Check piping conditions

Electrical noise Relocate meter or reduce noise

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • seametrics.com

LT-14229r2.0 20160912

9/12/16

Loading...

Loading...