MD-Series Pulse Meter

DISCONTINUED

Instructions

General Information

MD-Series meters use the multi-jet principle, which has

been an internationally-accepted standard for many

years. This type of meter is known for its wide range,

simplicity, and accuracy in low-quality water. The

impeller is centered in a ring of jets, with inlet jets on

one level and outlet jets on another. A gear train drives

the register totalizer dials. For pulse output, one of the

dials is replaced by a gear, which turns a magnet that

is detected by an encapsulated sensor threaded into

the outside of the lens. Pulse rate is determined by the

gear and the dial on which the gear is placed.

Mechanically , all MD-Series meters are the same. The

difference between MDE and MDR meters is in the sensor. MDE meters use a solid-state, long-lasting Halleffect sensor, which requires power. They are suited

for use with SeaMetrics controls and metering pumps

(LMI for instance) which have sensor power. MDR

meters use a two-wire reed switch. They provide a dry

contact closure and do not require power. MDT meters

do not have a sensor, totalize only.

Specifications

Materials

Case Cast bronze

Internals Engineered thermoplastic

Magnet Ceramic permanent

Temperature 105° F, 40° C

Max. Pressure 150 PSI operating

Accuracy 1-1/2% of reading

Sensor

MDE Solid state

MDR Reed switch

Max. Current

MDE 20 mA

MDR 50 mA

Max. Voltage

MDE 24 VDC

MDR 24 VDC or 24 VAC

Sensor Power (MDE) Minimum 6 mA at 12 VDC

Cable Length 18 ft. standard, 2,000 ft. max.

Flow Rates (GPM):

3/4" 1" 1-1/2" 2"

Minimum 0.22 0.44 0.88 1.98

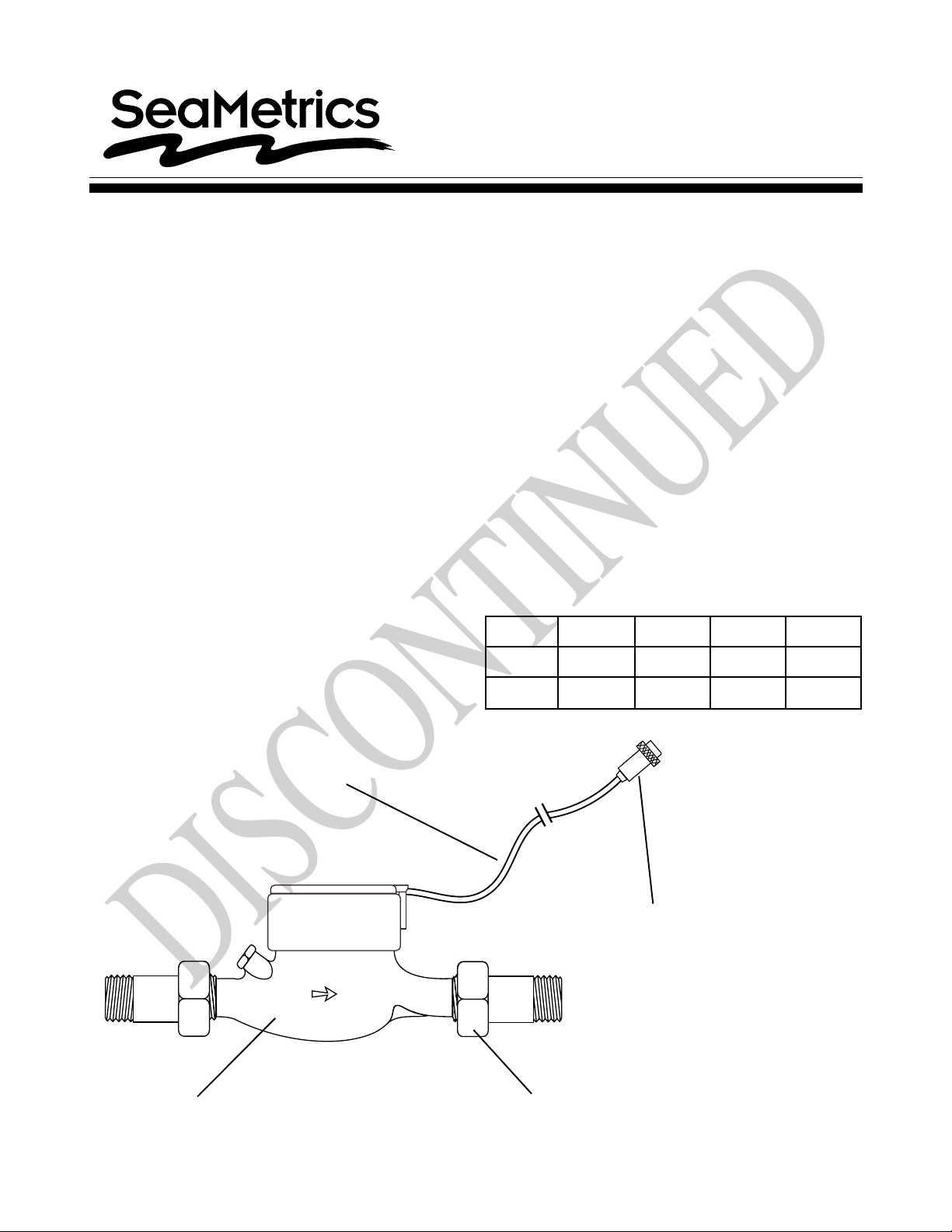

Features

Cast bronze body-

Either MDE or MDR sensor

threads into lens without

removing top

meets AWW A

specifications

Maximum 22 52 88 132

Connector for metering pump or

SeaMetrics control - optional

Union end couplings

for easy service

Page 1 of 4

Installation

DISCONTINUED

WARNING

DO NOT INSTALL

meter in overhead

Indoor piping or where

leakage

may cause damage

Position. MD-Series meters should be installed horizontally with the register up. Vertical mounting will result

in some degree of under-measurement and shortened

life of the bearings.

Couplings. Couplings are included with each meter.

These provide male NPT threads the same nominal size

as the meter. The threads on the end of the meter are

IPS straight threads one size bigger than the meter size.

It is possible to thread a standard pipe coupling directly

onto the meter for close coupling, but the meter couplings are much preferable because they provide a union

connection for meter service. Be sure to use the included

gasket between the end of the meter and the coupling.

Inlet Conditions. No upstream straight pipe is required.

A strainer is built in to protect from solids, and should be

periodically cleaned.

Air Bleed. When the meter is first installed, trapped air

should be removed. To do this, loosen the meter couplings slightly and rotate the meter to an inverted

position. Allow water to flow, then rotate the meter

back to an upright position and tighten.

Connections. MDE and MDR sensors are supplied with

a color coded output cable. See the diagram for color

codes and polarity . Optional connectors can be ordered

to plug directly into a SeaMetrics control or a specific

brand of metering pump.

sensor connection

MDE

MDRsensor connection

These water meters are not

recommended for installation

indoors or anywhere leakage

may cause damage.

(BLACK) Power (-)

(WHITE) Signal

(RED) Power (+) 6-24 VDC

(BROWN) Common

(WHITE) N.O.

Pulse Output. Both MDE and MDR sensors respond to

a magnet which rotates on the face of the meter under

the lens. The sensor turns on and off once each time

the magnet passes under it. Sensors are designed for

electronic control loads, and should not be used to switch

power loads or line voltages. See maximum current and

voltage ratings, under Specifications.

Maintenance

SeaMetrics recommends all service to be performed by

authorized distributor or factory to maintain the integrity

of the protective tamper-proof wire-and-seal.

Inlet Strainer. Clean the strainer yearly, or as required,

depending on water condition. Pull out the strainer or

backflush the meter to loosen trapped particulates.

Calibration. Meters used for billing or billing exemption

may be regulated by state or local authorities. New

meters are factory-tested to meet the A WWA C-708 MultiJet Meter accuracy specification. Some states

require retesting at various intervals, typically eight years

for 3/4" meters, six for 1", and four for 1-1/2" and 2".

Meters used for control should be tested every 5-10

years. Testing can be done by local meter shops authorized for this purpose, or can be done by the factory.

Please contact SeaMetrics before sending meter in for

calibration or servicing.

Internal Parts Replacement. All of the internal parts of

an MD-Series meter lift out as a unit, after the top has

been unscrewed. The lens can then be removed and the

internal assembly lifted out. The three pieces of the

assembly can be separated by hand.

Excessive flow can cause breakage. Compare maximum

flow with the flow rating table.

Changing Pulse Rates. After removing the meter top,

lift off the center magnet to expose the gears. If the only

change required is moving the drive gear (for example

from one gallon/pulse to ten gallons/pulse), gently pull

the drive gear off its shaft. Remove the pointer on the

target shaft and push the drive gear onto the target shaft

as far as it will go. Put the pointer on the vacant shaft

and push on.

If a different gear set is required, follow the same procedure, replacing rather than moving the drive gear. To

install a drive gear on another shaft, remove the pointer

and then press the gear down until it bottoms. Use the

pulse rate chart to determine the position.

2 of 4

3/4" - 10 gallons/pulse

DISCONTINUED

Standard

(X1) gearset

3/4"

1"

1-1/2"

2"

Pulse

Rate

20 P/G

10 P/G 1

2 P/G X0.1 2

1 P/G X0.1 1

5 G/P X1 2

10 G/P X1 1

50 G/P X10 2

100 G/P X10 1

20 P/G

10 P/G

2 P/G X0.1 2

1 P/G X0.1 1

5 G/P X1 2

10 G/P X1 1

50 G/P X10 2

100 G/P X10 1

2 P/G 2

1 P/G 1

5 G/P X1 2

10 G/P X1 1

50 G/P X10 2

100 G/P X10 1

500 G/P X100 2

1000 G/P X100 1

2 P/G 2

1 P/G 1

5 G/P X1 2

10 G/P X1 1

50 G/P X10 2

100 G/P X10 1

500 G/P X100 2

1000 G/P X100 1

* Unlabeled position

Drive Gear

Position

*

*

*

*

*

*

*

*

Gear Set

(X...)

2

move

gear to

match

2

1

X1 Drive gear

on position

3/4" - 50 gallons/pulse

X2

gearset

X10

Drive

gear on

position

3/4" - 1 gallon/pulse

X2 gearset

*Unlabelled position

X0.1 Drive

gear on

position

3 of 4

MD-Series Parts

DISCONTINUED

reed switch

w/cable

cap screw

(over)

calibration plug

(under)

strainer

slip ring

pair

lens

register

assembly

O-ring

multi-jet

assembly

Part # FOR ALL SIZES

30387 Gear Assembly , x1

30342 Gear Assembly , x2

30290 Hinge Pin

30293 Lens, Glass

30289 Lid

30296 O-ring

30300 Pickup, Reed Switch, 12' Cable

30346 Pickup, Solid State, 12' cable, MDE

30292 Slip Ring (pair)

Part # FOR 3/4" MD METERS

16125 Calibration Plug

16105 Calibration Plug Cap Screw

30381 Coupling Assembly (2 required)

30416 Coupling Gasket (2 required)

30311 Multi-jet Assembly

30308 Register Assembly

30479 Strainer

Part # FOR 1" MD METERS

16125 Calibration Plug

16105 Calibration Plug Cap Screw

30382 Coupling Assembly (2 required)

30417 Coupling Gasket (2 required)

30297 Drive Magnet

30323 Multi-jet Assembly

30321 Register Assembly

30480 Strainer

Part # FOR 1-1/2" MD METERS

30303 Calibration Plug

30305 Calibration Plug Cap Screw

30383 Coupling Assembly (2 required)

30418 Coupling Gasket (2 required)

30297 Drive Magnet

30304 Gasket

30332 Multi-jet Assembly

30330 Register Assembly

30481 Strainer

Part # FOR 2" MD METERS

30303 Calibration Plug

30305 Calibration Plug Cap Screw

30384 Coupling Assembly (2 required)

30419 Coupling Gasket (2 required)

30297 Drive Magnet

30304 Gasket

30326 Multi-jet Assembly

30328 Register Assembly

16240 Strainer

19026 72nd Ave. S., Kent, WA 98032 USA

Phone: 253-872-0284 Fax: 253-872-0285

4 of 4

www.seametrics.com 1-800-975-8153

LT-11857-B

Rev. 8-04

Loading...

Loading...