Page 1

IP800-SERIES

INSERTION PADDLEWHEEL

FLOW SENSOR

253.872.0284 seametrics.com

PROUDLY

MADE

IN THE

USA

C

e

r

t

i

f

i

e

d

C

o

m

p

a

n

y

ISO

9001:2008

APPLICATIONS

Industrial water/wastewater

treatment

Cooling water monitoring

Industrial uid control

Chemical proportioning

Features

• Low-friction, long-life jewel

bearings

• One moving part

• Fully eld-repairable

• Choice of materials for

compatibility with a variety of

chemicals

• Fits 1/2” to 8” pipe

• Fixed depth in tting ensures

proper placement in pipe

Contact Your Supplier

The IP800-Series are impeller (or “paddlewheel”) insertion meters

designed for use with a wide variety of liquids in pipe sizes 1/2” to 8”.

Sensors are available in brass, 316 stainless steel, PVC, and polypropylene.

Bodies are machined from a solid rod for maximum precision. Highquality jewel bearings and nickel-bound tungsten carbide shafts are

used for extreme low friction and long life. Low-ow performance is

good, although other Seametrics ow meters are recommended where

extremely low ows are being measured.

The rotation of the rotor is detected by a non-drag Hall-eect sensor.

Output is a current-sinking pulse, which can be sent long distances (up

to 2,000 feet) without a transmitter. This signal can be connected directly

to PLC’s, counters, and computer cards, as well as a variety of Seametrics

controls and displays.

Seametrics IP meters are ideal for chemical proportioning applications.

If no display is required, a simple divider such as the PD10 provides

adjustable pump pacing. For rate and total display, a modular system

of electronics can be installed directly on the ow sensor or mounted

remotely. The FT430 (externally powered with pulse), FT440 (loop

powered), and FT450 (battery powered) all provide digital rate and total

displays, as well as a programmable pulse; the FT440 also provides a 4-20

mA analog output. The AO55 blind analog transmitter can be used to

convert to a 4-20 mA output. Electronic modules can be wall- or metermounted. (Note: PD10 available only as wall mounted unit.) IP meters are

also compatible with the DL76 data logger and FT520 batch processor.

The IP800-Series require special ttings that ensure correct depth

placement in the pipe. Fittings come in a variety of materials for

compatibility with specic applications. Tee ttings are individually wet-

calibrated at the factory and marked with the K-factor (pulses per gallon).

Saddle ttings must be eld-installed on the pipe and do not come wet-

calibrated. K-factors for saddles are based on factory-testing.

Page 2

IP800-SERIES

INSERTION PADDLEWHEEL

FLOW SENSOR

Features

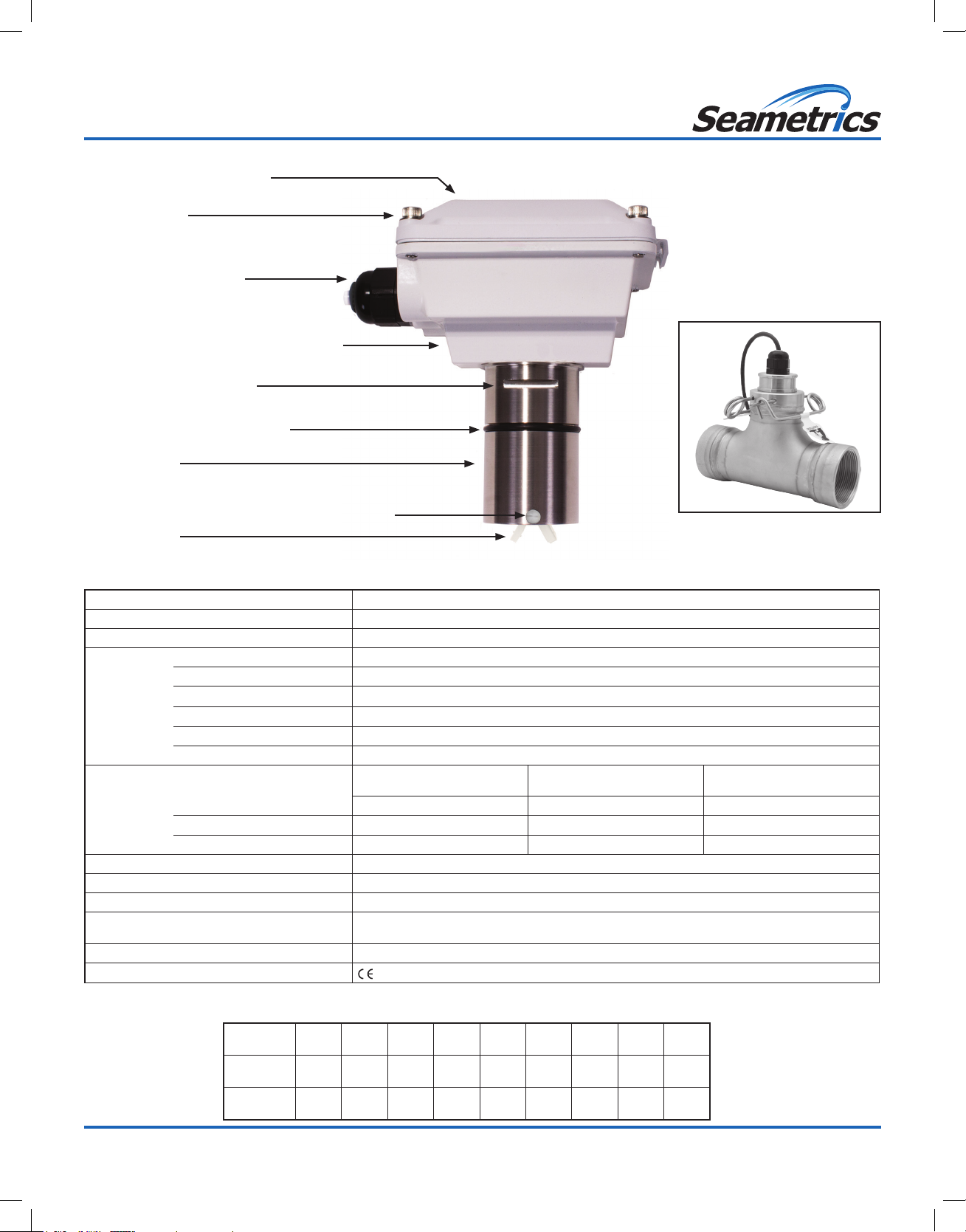

Electronics Module or Cover

Housing Screw

(connect ground wire to one)

Cable Gland Strain Relief

Powder-Coated Cast Aluminum Housing

Included when meter mounted electronics are ordered

Retaining Slot (for U-Clip)

(for easy installation at correct depth setting)

O-Ring (EPDM, Viton® optional)

Sensor Body

Jewel Bearings for superior low-ow performance

Rotor (PVDF)

High Pressure

Specications*

Pipe Size 1/2” to 8”

Power Low Power: 6-36 Vdc/< 2 mA Micropowered (-04 Option): 3.1-16 Vdc/60 μA @ 3.6 Vdc

Sensor Low Power: Digital Magnetoresistive Micropowered (-04 Option): Giant Magnetoresistance (GMR)

Materials Optional Housing Powder-coated cast aluminum

Sensor Body Brass, 316 Stainless Steel, PVC, or Polypropylene

O-ring EPDM (Viton® optional)

Rotor PVDF (Kynar®)

Shaft Kynar® /Tungsten Carbide (Kynar® /Ceramic or Kynar®/Silicon Carbide optional)

Bearings Ruby jewel

Maximum Brass 316 Stainless Steel PVC or Polypropylene

Pressure 200 psi (14 bar) 200 psi (14 bar) 175 psi (12 bar) @ 75˚ F (24˚ C)

High Pressure Not available 400 psi (28 bar) Not available

Temperature 200˚ F (93˚ C) 200˚ F (93˚ C) 130˚ F (55˚ C)

Flow Velocity 0.3 to 30 ft/sec (0.9 to 9.14 m/sec)

Accuracy ± 1.5% of full scale

Output Transistor Maximum Current Sinking 150mA (low power version only)

Cable #22 AWG 3-con, 18’ (6m); 2,000’ (610m) maximum cable run Note: 50’ (15m) maximum for battery powered or

Environmental See meter mounted electronics specication for rating

Regulatory

*Specications subject to change • Please consult our website for current data (www.seametrics.com).

Kynar is a registered trademark of Arkema, Inc., Viton is a registered trademark of DuPont Corporation.

micropowered versions.

Mark

(See Pressure vs. Temp. Chart)

Flow Range

Nominal

Pipe Size

Min GPM

Min LPM

Max GPM

Max LPM281065018980302

½” ¾” 1” 1½” 2” 3” 4” 6” 8”

0.28

1.06

0.5

1.89

0.8

3.03

1.9

7.2

190

719

3.1

11.7

314

1188

6.9

26.11245

691

2615

1190

4504

27

102

2700

10221

46.8

177

4680

17716

253.872.0284 Page 2 seametrics.com

Page 3

IP800-SERIES

INSERTION PADDLEWHEEL

FLOW SENSOR

50

100

150

200

60˚ 70˚ 80˚ 90˚ 100˚ 110˚ 120˚ 130˚ 140˚

P.S.I.

(10.4 cm)

4.33 in

F

C

D

Dimensions

0.75 in

(1.9 cm)

TOP OF TEE

IP815 = 6.5 in (16.5 cm)

IP825 = 7.5 in (19.1 cm)

NOTE:

Housing Optional

(11.0 cm)

4.09 in

Available Fittings

Tee Saddle Weld Braze Sweat

Bronze 1/2”- 4” 3”- 4” x 3”- 8” 1/2”- 4”

PVC 1/2”- 2” 3”- 8” x x x

Stainless Steel 1/2”- 2”

304SS

Carbon Steel 1/2”- 2” x 3”- 8” x x

Ductile Iron x 3”- 8” x x x

x 3”- 8”

316SS

x x

Tee

PVC Block Tee Fitting (Figure 1)

B

A

PVC Tee Fittings (Figure 2)

Pressure vs. Temperature (PVC/Polypro)

E

Ø

Figure Pipe Size A B C D E F Ø

1 1/2” 1.50” (3.81 cm) 3.80” (9.65 cm) 6.00” (15.24 cm) 2.00” (5.08 cm) 3.15” (8.00 cm) 2.00” (5.08 cm) 0.83” (2.11 cm)

1 3/4” 1.90” (4.83 cm) 4.00” (10.16 cm) 6.00” (15.24 cm) 2.00” (5.08 cm) 3.05” (7.75 cm) 2.00” (5.08 cm) 1.06” (2.69 cm)

1 1” 1.88” (4.77 cm) 4.00” (10.16 cm) 6.00” (15.24 cm) 2.00” (5.08 cm) 3.06” (7.77 cm) 2.00” (5.08 cm) 1.325” (3.36 cm)

2 1 1/2” — 4.50” (11.43 cm) 19.4” (49.28 cm)

2 2” — 4.90” (12.45 cm) 19.9” (50.55 cm)

253.872.0284 Page 3 seametrics.com

C

B

(nominal)

(nominal)

E

— 3.35” (8.51 cm) — —

— 3.45” (8.76 cm) — —

Page 4

LT-65650023r4.5 20180115

1/15/18

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • seametrics.com

IP800-SERIES

INSERTION PADDLEWHEEL

FLOW SENSOR

How to Order

Description Size Sensor Material Options

Sensor Only. ½” - 3” = IP810

Sensor Only

Description Size Sensor Material Options

Blind 4-20 mA analog

transmitter (AO55)

AO55

FT430

mounted on the sensor.

Mounted

on Sensor

Description Size Sensor Material Options

Rate & total indicator

with pulse, externally

powered (FT430)

mounted on the sensor.

Mounted

on Sensor

4” - 8” = IP820

½” - 3” = IP812

4” - 8” = IP822

½” - 3” = IP813

4” - 8” = IP823

Brass = B

316 Stainless Steel = S

PVC = P

Polypro = Y

Brass = B

316 Stainless Steel = S

PVC = P

Polypro = Y

Brass = B

316 Stainless Steel = S

PVC = P

Polypro = Y

Rotor with Ceramic Shaft, PVDF, Kynar® = -01

Micropower Pickup = -04

Standard Power, LMI 4-pin Connector = -06

Standard Power, Seametrics Control Connector = -07

*Immersible = -40

Viton® O-Ring = -60

Rotor with Kynar®/Silicon Carbide Shaft = -68

Roytronic® Series A Pump 5-pin Connector = -106

**High Pressure (Stainless Only) = -HP

Rotor with Ceramic Shaft, PVDF, Kynar® = -01

Standard Power, LMI 4-pin Connector = -06

Viton® O-Ring = -60

Rotor with Kynar®/Silicon Carbide Shaft = -68

Roytronic® Series A Pump 5-pin Connector = -106

**High Pressure (Stainless Only) = -HP

Rotor with Ceramic Shaft, PVDF, Kynar® = -01

Tamper Evident Kit = -32

Viton® O-Ring = -60

Non-resettable Total = -64

Rotor with Kynar®/Silicon Carbide Shaft = -68

Hinged Display Cover = -126

**High Pressure (Stainless Only) = -HP

Description Size Sensor Material Options

DL76

Mounted

Data logger (DL76)

mounted on the sensor.

on Sensor

½” - 3” = IP816

4” - 8” = IP826

Brass = B

316 Stainless Steel = S

PVC = P

Polypro = Y

Rotor with Ceramic Shaft, PVDF, Kynar® = -01

Micropower Pickup = -04

Tamper Evident Kit = -32

Viton® O-Ring = -60

Rotor with Kynar®/Silicon Carbide Shaft = -68

**High Pressure (Stainless Only) = -HP

Description Size Sensor Material Options

FT450

Mounted

Rate & total indicator

with pulse, battery

powered (FT450)

mounted on the sensor.

on Sensor

½” - 3” = IP817

4” - 8” = IP827

Brass = B

316 Stainless Steel = S

PVC = P

Polypro = Y

Rotor with Ceramic Shaft, PVDF, Kynar® = -01

Tamper Evident Kit = -32

Viton® O-Ring = -60

Non-resettable Total = -64

Rotor with Kynar®/Silicon Carbide Shaft = -68

Hinged Display Cover = -126

**High Pressure (Stainless Only) = -HP

Description Size Sensor Material Options

Rate & total indicator

with pulse & 4-20 mA

output, loop powered

FT440

* Immersible to maximum of 3 ft (1m), up to 2 weeks

**Requires appropriate tting.

Kynar is a registered trademark of Arkema, Inc. Roytronic is a registered trademark of Milton Roy Company. Viton is a registered trademark of DuPont Corporation.

(FT440) mounted on the

sensor.

Mounted

on Sensor

½” - 3” = IP819

4” - 8” = IP829

Brass = B

316 Stainless Steel = S

PVC = P

Polypro = Y

Rotor with Ceramic Shaft, PVDF, Kynar® = -01

Tamper Evident Kit = -32

Viton® O-Ring = -60

Non-resettable Total = -64

Rotor with Kynar®/Silicon Carbide Shaft = -68

Hinged Display Cover = -126

**High Pressure (Stainless Only) = -HP

Loading...

Loading...