Page 1

d

C

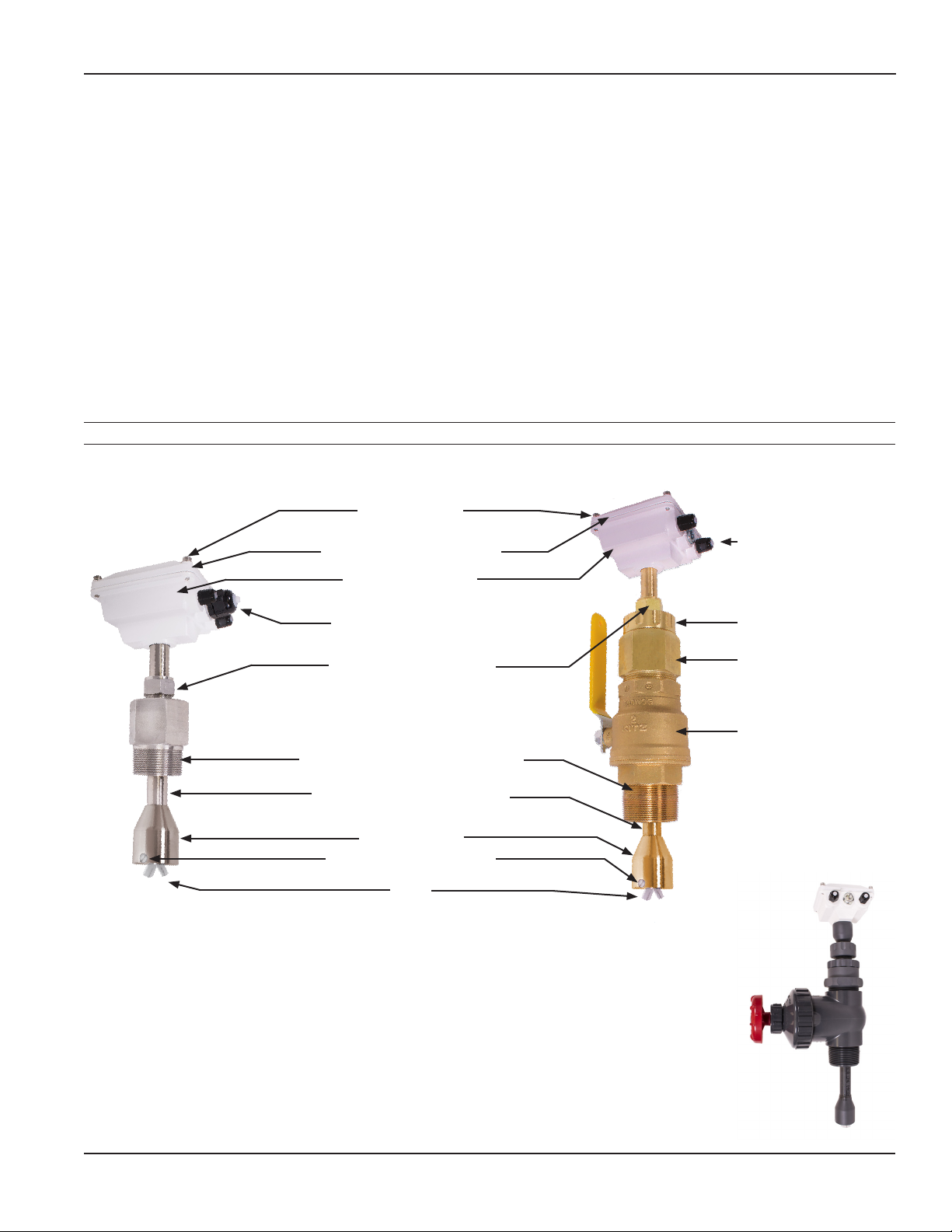

IP100/200 Series

Adjustable Depth Insertion

Paddlewheel Instructions

IP11x/21x

(Shown with externally

powered electronics)

IP15x/25x

(Shown with battery

powered electronics)

o

m

e

i

p

f

PROUDLY

MADE

IN THE

USA

i

t

r

e

C

ISO

9001:2008

a

n

y

Page 2

TABLE OF CONTENTS

General Information

General Information ...................................................................................................................................................Page 3

Features ...........................................................................................................................................................................Page 3

Specications ................................................................................................................................................................Page 5

Installation

Positioning the Meter ................................................................................................................................................Page 5

Immersion .......................................................................................................................................................................Page 5

IP11x/21x Installation .................................................................................................................................................Page 6

IP15x/25x Installation .................................................................................................................................................Page 6

Depth Setting ................................................................................................................................................................Page 7

Pipe Wall Thickness .....................................................................................................................................................Page 8

Flow Range .....................................................................................................................................................................Page 8

Straight Pipe Recommendations ...........................................................................................................................Page 9

Full Pipe Recommendations ....................................................................................................................................Page 10

Connections

Overview .........................................................................................................................................................................Page 11

FT430 ................................................................................................................................................................................Page 11

FT440 ................................................................................................................................................................................Page 12

FT450 ................................................................................................................................................................................Page 12

Operation and Maintenance

Operation Theory ........................................................................................................................................................Page 13

Flow Rate ........................................................................................................................................................................Page 13

Calibration (K-Factor) .................................................................................................................................................Page 13

Rotor Replacement .....................................................................................................................................................Page 13

Checking Signal ............................................................................................................................................................Page 13

Parts Explosion .............................................................................................................................................................Page 14

Parts List ..........................................................................................................................................................................Page 14

IP100/200 SERIES INSTRUCTIONS

Troubleshooting

Problem ...........................................................................................................................................................................Page 15

Probable Cause .............................................................................................................................................................Page 15

Things To Try..................................................................................................................................................................Page 15

Warranty

Seametrics Limited Warranty ..................................................................................................................................Back

Seametrics • 253.872.0284 Page 2 seametrics.com

Page 3

GENERAL INFORMATION

IP100/200 SERIES INSTRUCTIONS

The IP100/200-Series are adjustable depth insertion

paddlewheels that come in brass, PVC, or 316 stainless

models to t 3” to 40” pipe. Adapters mate with standard

1-1/2” (11x/21x) or 2” (15x/25x), or PVC (11x/21x) NPT

threaded ttings such as saddles and weldolets which may

be purchased either locally or from Seametrics.

Ruby bearings and a non-drag Hall-effect sensor give these

meters the widest ow range of any of the paddlewheel

types. A sensor detects the passage of miniature magnets

in the six rotor blades. The resulting square-wave signal

can be sent for hundreds of feet over unshielded cable

without a transmitter and connected directly to many PLC’s

and other controls without any additional electronics.

Features

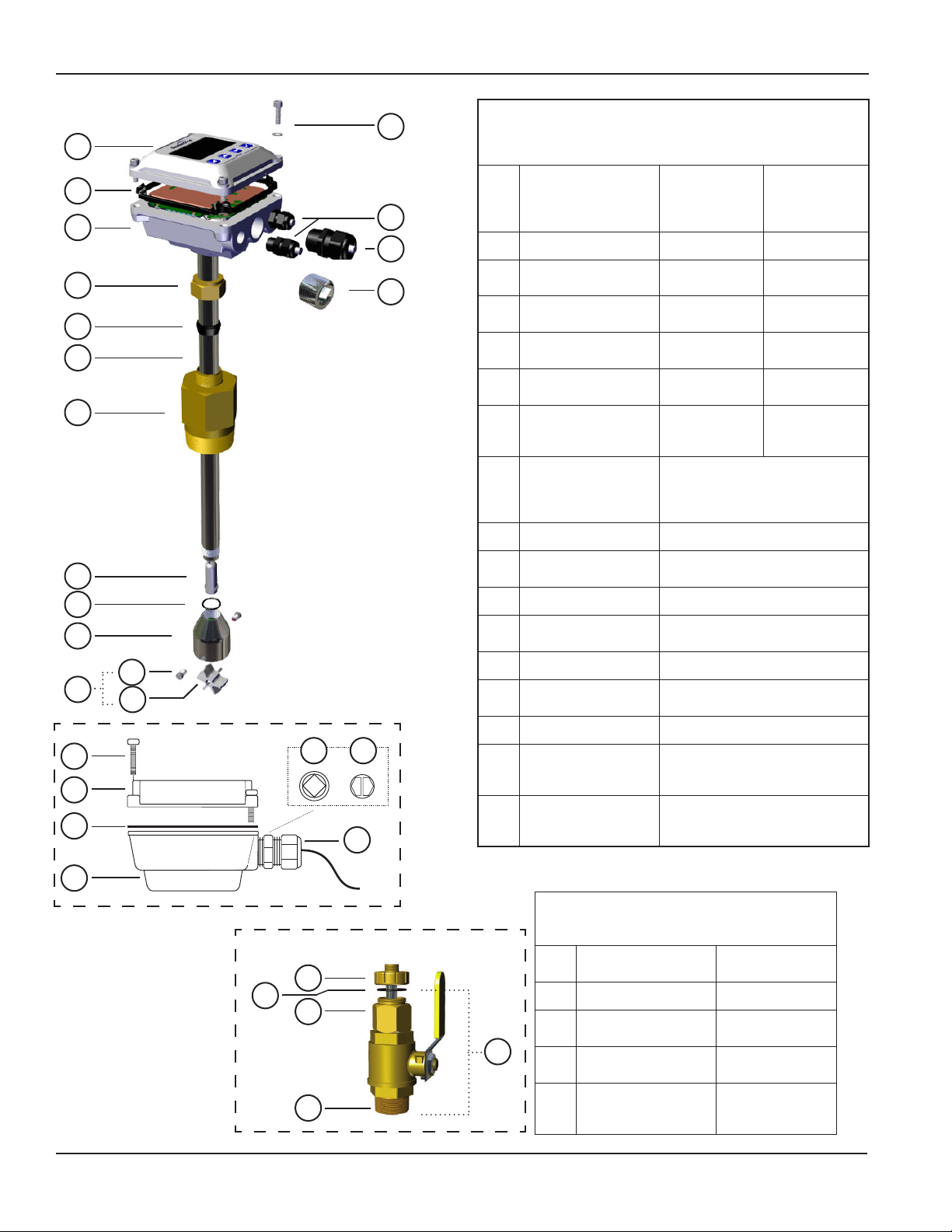

Housing Screw

(connect one to ground)

Optional Electronics Module

A modular system of electronics can be installed directly

on the ow sensor or mounted remotely. The FT430

(externally powered with pulse), FT440 (loop powered),

and FT450 (battery powered) all provide digital rate and

total displays, as well as a programmable pulse; the FT440

also provides a 4-20 mA analog output. The AO55 is a

blind analog (4-20 mA) transmitter. Programmable pulse

for pump pacing is available with the PD10 (available as

wall mounted unit only).

The “hot-tap” models (IP15x/25x) can be installed or

serviced without shutting down the line by means of a

2” full-port isolation valve that comes with a nipple for

installation on the pipe tting. In most circumstances, no

special tool is required.

Cable Gland Strain Relief

IP11x/21x

(Shown with optional externally

powered electronics)

Powder-Coated Cast

Aluminum Housing

Cable Gland Strain Relief

Compression Nut for easy

adjustment, secure locking

Adapter mates with threaded tting

FNPT 1 1/2” FNPT 2”

3/4” tubing, low insertion force

(Typically no tool required)

Rotor Housing

Removable Jewel Bearings

Rotor

Locking Collar

2” Adapter (removes to

mount hot-tap machine)

Valve Assembly for hot-

tap installation

IP15x/25x

(Shown with optional

battery powered

electronics)

Hot-tap valve on

PVC version

Seametrics • 253.872.0284 Page 3 seametrics.com

Page 4

GENERAL INFORMATION

IP100/200 SERIES INSTRUCTIONS

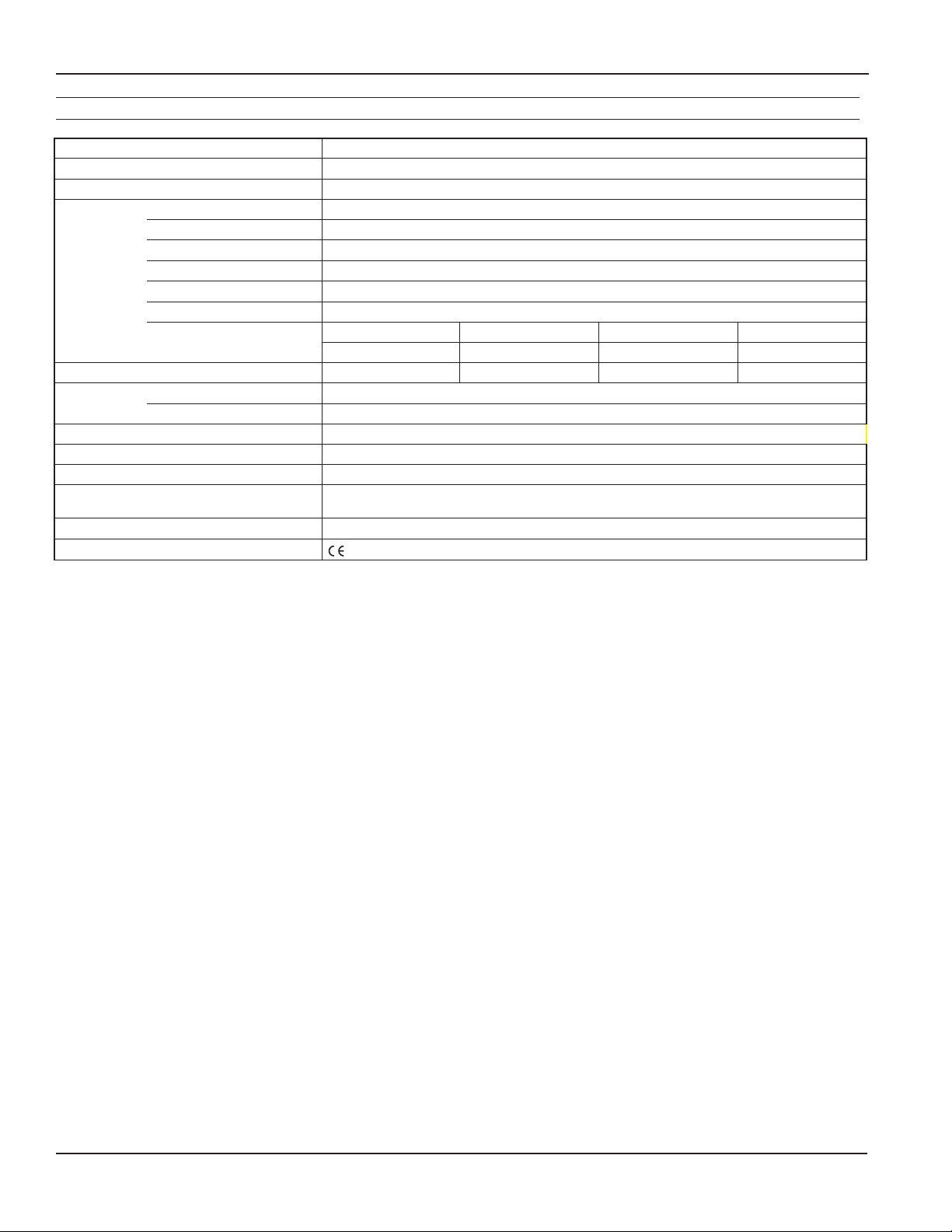

Specications*

Pipe Size 3” to 40”

Power Low Power: 6-36 Vdc/< 2 mA Micropowered (-04 Option): 3.1-16 Vdc/60 μA @ 3.6 Vdc

Sensor Low Power: Digital Magnetoresistive Micropowered (-04 Option): Giant Magnetoresistance (GMR)

Materials Housing Powder-coated cast aluminum

Tubing/Fitting/Sensor Housing Brass, PVC, or 316 Stainless Steel

Rotor PVDF (Kynar®)

Shaft Kynar® /Tungsten Carbide (Kynar® /Ceramic or Kynar®/Silicon Carbide optional)

Bearings Ruby jewel

O-Ring (15x/25x only) EDPM

Valve Assembly for: IP11x/21x (Brass/SS) IP11x/21x (PVC) IP15x/25x (Brass/SS) IP15x/25x (PVC)

None None Bronze (316SS optional) Uses gate valve

Fitting Size Required 1.5” FNPT 2” FNPT 2” FNPT 2” FNPT

Maximum Pressure Brass/SS: 200 psi (14 bar) PVC: 150 psi (10 bar)

Temperature Brass/SS: 200˚ F (93˚ C) PVC: 130˚ F (55˚ C)

Flow Velocity 0.3 to 30 ft/sec (0.9 to 9.14 m/sec)

Accuracy ± 1.5% of full scale

Output Transistor Maximum Current Sinking 150mA (low power version only)

Cable #22 AWG 3-con, 18’ (6m); 2,000’ (610m) maximum cable run Note: 50’ (15m) maximum for battery powered

Environmental

Regulatory

*Specications subject to change. Please consult our website for the most current data (www.seametrics.com).

Kynar is a registered trademark of Arkema, Inc.

or micropowered versions.

See meter mounted electronic specication for rating.

Mark

Seametrics • 253.872.0284 Page 4 seametrics.com

Page 5

INSTALLATION

IP100/200 SERIES INSTRUCTIONS

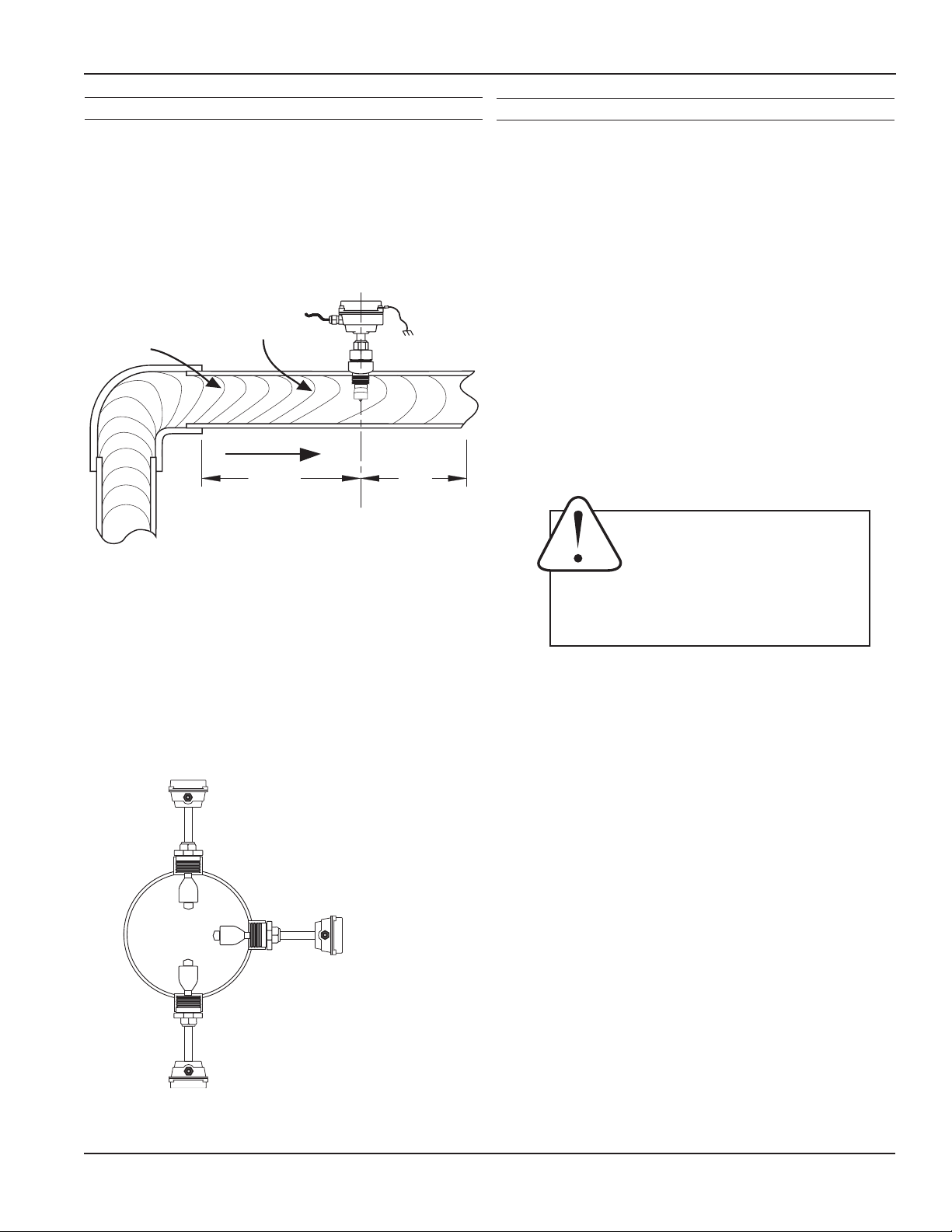

Positioning the Meter

For best results, the IP sensor should be installed with

at least ten diameters of straight pipe upstream and

ve downstream. Certain extreme situations such as

partially-opened valves are particularly difcult and may

require fteen diameters upstream. (See Straight Pipe

Recommendations.)

Faster Flow

Causes Meter

Distorted

Flow Prole

To Read High

FLOW

10X

5X

Distorted Flows

Horizontal (3 o’clock or 9 o’clock position) is the preferred

installation orientation, since it improves low-ow

performance and avoids problems with trapped air and

sediment. (See Orienting the Meter diagram below.)

Bottom (6 o’clock), top (12 o’clock), and vertical pipe

installations are all acceptable if required by the piping

layout.

Immersion

The IP100/200 Series standard sensors are not designed

for continuous underwater operation. If this is a possibility,

as in a ooded vault, a unit modied for immersion should

be specied (Option -40).

Caution: These ow sensors are

not recommended for installation

downstream of a boiler feedwater

pump where installation fault may

expose the ow sensor to boiler pressure

and temperature. Maximum recommended

temperature is 200°F.

Fair

Unacceptable if pipe

contains air

Best

Position

Fair

Unacceptable if pipe

contains sediment

Orienting the Meter

Seametrics • 253.872.0284 Page 5 seametrics.com

Page 6

INSTALLATION

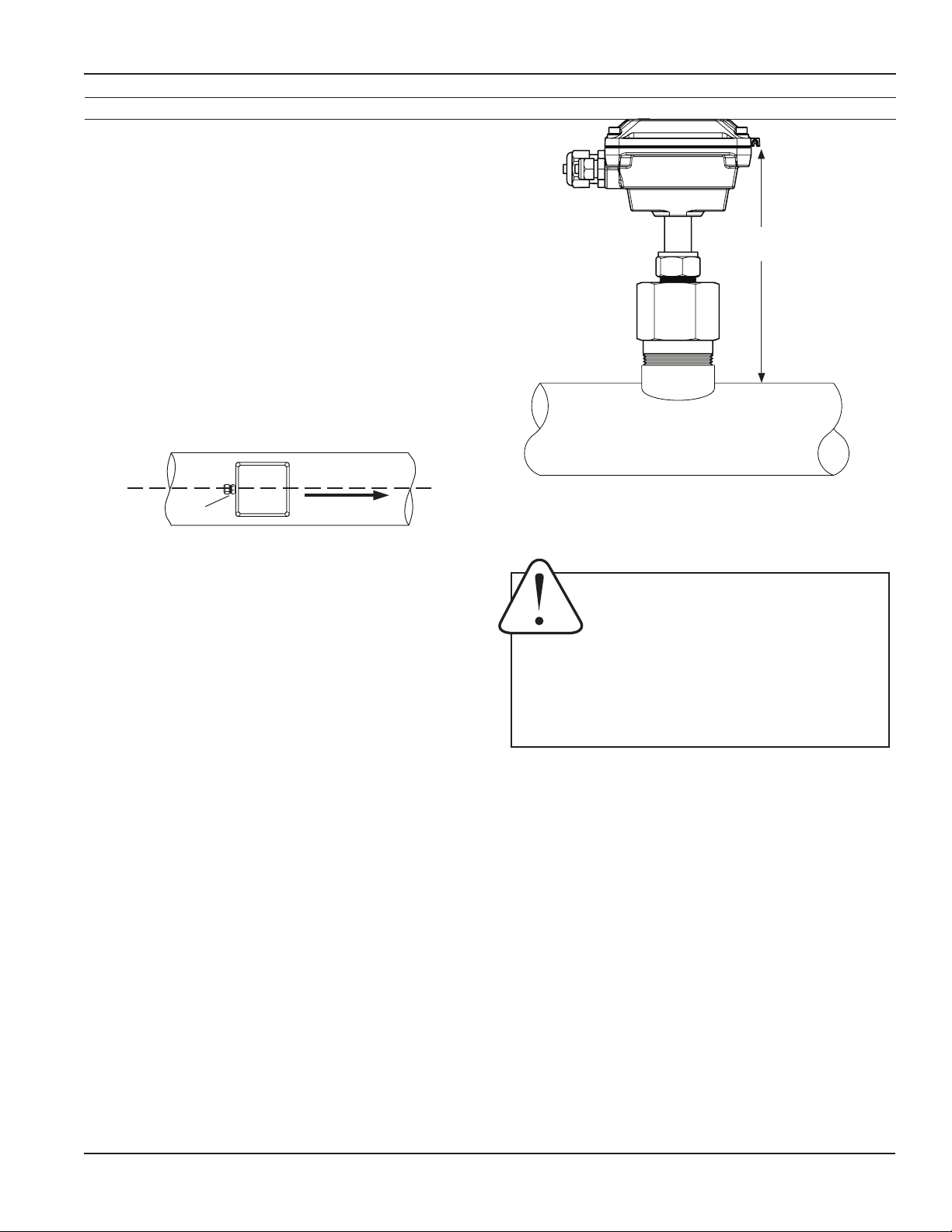

IP11x/21x Installation

Fitting Installation. IP11x/21x brass/SS adapters mate with a

1-1/2” female NPT pipe thread adapter tting (2" for PVC). Any

tting that provides the matching NPT female thread may be used.

Installation procedure compensates for tting height differences.

Cut a minimum 1-3/4” hole in the pipe. If possible, measure the wall

thickness and write it down for use in depth setting. Then install the

threaded tting (saddle, weldolet, etc.) on the pipe.

Meter Installation. Loosen the compression nut so that the adapter

slides freely. Pull the meter fully upward and nger-tighten the

compression nut. Using a thread sealant, install the adapter in the

pipe tting. Do not overtighten. Now loosen the compression

nut, lower the meter to the appropriate depth setting (see diagram

and instructions that follow). Caution: Do not allow the meter to

fall into the pipe uncontrolled, as this may damage the meter.

Be sure ow is in the direction of the arrow on the housing. Fully

tighten compression nut.

IP15x/25x Installation

IP100/200 SERIES INSTRUCTIONS

Compression nut

Adapter mates with

FNPT threads

Hot tap’ IP meters are designed to be installed and serviced without

depressurizing the pipe.

Fitting Installation. The IP15x and 25x adapters mate with a 2”

FNPT threaded tting for compatibility with the 2” isolation valve.

Any tting that provides matching NPT female thread may be used.

The installation procedure compensates for differences in tting

height.

If initial installation is performed on an unpressurized pipe, cut a

minimum 1-3/4” hole in the pipe. If possible, measure the wall

thickness and write it down for use in depth setting. Then install the

threaded tting (saddle, weldolet, etc.) on the pipe.

If it is necessary to do the initial installation under pressure, any

standard hot tap drilling machine with 2” NPT adapter, such as a

Transmate or a Mueller, can be used. Ordinarily, it is not necessary

to use an installation tool, since the small-diameter tube can be

controlled by hand at all but the highest pressures.

Meter Installation. Remove the sensor unit from the valve assembly.

Using a thread sealant, install the valve assembly on the pipe tting.

If the initial installation is a pressure (“hot”) tap, remove the 1-1/2”

x 2” adapter bushing at the back of the valve. Thread the tapping

machine on, open the valve, and tap using a minimum of 1-3/4” or

maximum 1-7/8” cutter. After retracting the machine and closing

the valve, reinstall the ow sensor. When the sensor is secure, open

the valve and adjust depth setting (see diagram and instructions that

follow). Be sure ow is in the direction of the arrow on the housing.

Tighten locking collar and compression nut fully.

Compression nut

Locking collar

2” adapter removes

to mount hot-tap

machine

Full-port 2” ball

valve allows sensor

removal

Mates with 2”

FNPT threads

IP15x/25x Sensor

Removal

Seametrics • 253.872.0284 Page 6 seametrics.com

Page 7

INSTALLATION

Depth Setting

It is important for accuracy that the sensor be inserted to

the correct depth into the pipe.

IP100/200 SERIES INSTRUCTIONS

1. Go to www.seametrics.com and select the K-factor

Calculator located at the bottom of the home page

to nd dimension D (insertion depth setting)*.

2. Measuring from the outside of the pipe to the joint

in the housing, as shown in the diagram, adjust

the sensor to Dimension D and hand-tighten

compression nut.

3. Align the conduit housing with the centerline of the

pipe, as shown. Be sure the arrow on the housing

points in the direction of ow.

strain

relief

FLOW

4. Check Dimension D one more time.

5. Fully tighten the compression nut.

Record your settings. Once you have the meter set up and

operational, it is important to record you meter settings

and save them future reference.

“D”

Proper Depth Setting

Caution! Never attempt to remove a

ow sensor when there is pressure in the

pipe unless it is specically designed for

hot tap installation and removal. Loosen

the compression nut slowly to release any trapped

pressure. If uid sprays out when removing the

sensor, stop turning and depressurize the pipe. Failure

to do so could result in the sensor being thrown from

the pipe, resulting in damage or serious injury.

K-Factor ______________________________________

Insertion Depth (Dim. D) _____________________

* For pipe sizes larger than 50”, please consult factory.

Seametrics • 253.872.0284 Page 7 seametrics.com

Page 8

INSTALLATION

IP100/200 SERIES INSTRUCTIONS

Table 1: Pipe Wall Thickness (inches)

Nominal Pipe Size*

3" 4" 6" 8" 10" 12" 14" 16" 18" 20" 24" 30" 36"

Schedule 40 0.216 0.237 0.280 0.322 0.365 0.406 0.438 0.500 0.562 0.593 0.687 -- --

Schedule 80 0.300 0.337 0.432 0.500 0.593 0.687 0.750 0.843 0.937 1.031 1.218 -- --

Stainless Steel

(10S)

Stainless Steel

(40S)

Copper Tubing

(Type L)

Copper Tubing

(Type K)

Brass Pipe 0.219 0.250 0.250 0.312 0.365 0.375 -- -- -- -- -- -- --

Duct. Iron

(Class 52)

0.120 0.120 0.134 0.148 0.165 0.180 0.188 0.188 0.188 0.218 0.250 0.312 0.312

0.216 0.237 0.280 0.322 0.365 0.375 0.375 0.375 0.375 0.375 0.375 0.375 0.375

0.090 0.100 0.140 0.200 0.250 0.280 -- -- -- -- -- -- --

0.109 0.134 0.192 0.271 0.338 0.405 -- -- -- -- -- -- --

0.280 0.290 0.310 0.330 0.350 0.370 0.390 0.400 0.410 0.420 0.440 0.470 0.530

* Call factory for larger pipe sizes.

Table 2: Flow Range in Sched. 40 pipe (in GPM)

Nominal Pipe Size*

Velocity

(ft/sec)

0.3 6.9 11.9 18.7 27 46.8 73.7 105 165 376 874 1060 1690

0.5 11.5 19.8 31.2 45 78 123 174 275 627 1460 1770 2820

1.0 23 39.7 62.4 90 156 246 349 551 1250 2910 3530 5640

2.0 46.1 79.4 125 180 312 492 698 1100 2510 5830 7070 11280

5.0 115 198 312 450 780 1230 1740 2750 6270 14570 17670 28200

10.0 230 397 624 900 1560 2460 3490 5510 12530 29140 35350 56400

20.0 461 794 1250 1800 3120 4920 6980 11020 25060 58270 70700 112800

30.0 691 1190 1870 2700 4680 7370 10470 16520 37600 87410 106050 170000

3" 4" 5" 6" 8" 10" 12" 16" 24" 36" 38" 48"

* Call factory for larger pipe sizes.

Seametrics • 253.872.0284 Page 8 seametrics.com

Page 9

INSTALLATION

Straight Pipe Recommendations (X = diameter)

Reduced Pipe

IP100/200 SERIES INSTRUCTIONS

5X10X

Two Elbows In Plane

Two Elbows, Out Of Plane

Expanded Pipe

20X

20X

5X10X

5X

5X

30X

Spiral Flow

Propeller Meter

20X

Swirling Flow

Partially Open

Buttery Valve

Seametrics • 253.872.0284 Page 9 seametrics.com

Page 10

INSTALLATION

Full Pipe Recommendations

Allows air pockets to form at sensor Ensures full pipe

IP100/200 SERIES INSTRUCTIONS

Better InstallationPossible Problem

Better InstallationPossible Problem

Post-valve cavitation can create air pocket Keeps pipe full at sensor

Better InstallationPossible Problem

Air can be trapped Allows air to bleed off

Caution: These ow sensors are not recommended for installation downstream of

a boiler feedwater pump where installation fault may expose the ow sensor to

boiler pressure and temperature. Maximum recommended temperature is 200°F.

Seametrics • 253.872.0284 Page 10 seametrics.com

Page 11

CONNECTIONS

RED (+) 6-24 Vdc

WHITE (signal)

BLACK (-) Power

18' cable standard

IP100/200 SERIES INSTRUCTIONS

Sensors are supplied with 18 ft. (6m) of cable. For sensors with no additional electronics, see diagram for color coding

of connections. For sensors with on-board electronics, see the manual accompanying the electronic module.

RED (+)

Low Power: 6-36 Vdc

Micropowered: 3.1 - 16 Vdc

WHITE

Signal

BLACK (-)

Power

FT430

_

7-45Vdc

Supply

+

BLACK

WHITE

RED

POWER

SENSOR

S

_

+

ENGD

_

+

FT430

Pulse

Pass-thru

_

+

_

S

+

_

PULSE

OUT 2

_

+

+

_

PULSE

OUT 1

_

+

+

Pulse Responsive

Metering Pump

Flow

Sensor

Seametrics • 253.872.0284 Page 11 seametrics.com

Page 12

CONNECTIONS

FT440

_

4-20mA

Device

9-30 Vdc

_

Loop Power

Supply

IP100/200 SERIES INSTRUCTIONS

FT440

+

POWER

_

SENSOR

S

_

+

ENGD

_

+

+

_

S

+

_

PULSE

OUT 2

_

+

+

_

PULSE

OUT 1

_

+

+

Electronic

Metering Pumps

+

BLACK

WHITE

RED

FT450

Flow

Sensor

BLACK

WHITE

RED

POWER

SENSOR

S

_

+

ENGD

_

+

FT450

Pulse

Pass-thru

Lithium C,

3Vdc

Replaceable

_

S

+

Battery

_

PULSE

OUT 2

_

+

+

_

PULSE

OUT 1

_

+

+

Pulse Responsive

Metering Pump

Micropower

Flow Sensor

Current Sinking

Polarity-Sensitive

Seametrics • 253.872.0284 Page 12 seametrics.com

Page 13

OPERATION AND MAINTANENCE

IP100/200 SERIES INSTRUCTIONS

Operation Theory

In principle, an insertion ow sensor measures the velocity

of ow at one point in the pipe, and ow rate and total

can be inferred from this one point. Accuracy is decreased

by any factor which makes the ow at the measured point

unrepresentative of the entire ow stream. This includes

distorted ow patterns caused by upstream ttings too

close to the sensor. The worst offenders are ttings that

increase the ow on one side of the pipe, such as partiallyopened gate or buttery valves. Fluid moving in a pipe

does not all ow at the same velocity. Toward the center

of the pipe, uid moves faster than at the wall, and the

relationship between the two changes as overall ow rate

increases. This change in the “velocity prole” can result

in non-linearity, which means that the K-factor that is

correct for one ow rate may be incorrect for another. The

recommended depth settings have been carefully chosen

to minimize this source of error, and should be followed

carefully, especially in the smaller pipe sizes.

Flow Rate

These sensors are designed to operate at ow velocities

of 0.3 to 30 feet per second. (See chart for conversion to

gallons per minute.) If erratic readings are encountered at

low ows, check the chart to see if ow is below minimum

for the pipe size. The standard shaft and bearings should

have a long life at continuous high ow.

All Seametrics ow sensors are repairable, and can be

returned to the factory or distributor for repair after a

Return Material Authorization (RMA) number has been

issued.

Rotor Replacement

Rotors are easily eld-replaced. Shaft and rotor are a single

unit, and are not replaced separately. If replacement is due

only to normal shaft wear, bearing replacement is probably

not necessary. If the rotor has been damaged by impact,

the bearings should also be replaced. Rotor and bearings

can be ordered as a kit, Part No. 25902. Follow these steps:

1. Unscrew the threaded bearing housings to expose

the shaft ends. If bearings are being replaced, back

them completely out.

2. Remove the rotor. Put the new rotor in its place.

3. Thread in one bearing housing part way, then the

other. Take care to start the end of the shaft into

the bearing hole before tightening further.

4. Screw in bearing housings until they bottom.

Note: Do not use excessive force.

5. Check for free spin. Blowing lightly on the rotor

should result in it spinning rapidly and coasting to a

smooth stop.

Calibration (“K-Factor”)

In order to properly process pulses from the ow sensor,

a number must be entered into the control to which the

sensor is connected. This number, called the K-factor, is

the number of pulses the sensor puts out per unit of

uid passing through the pipe. It is normally provided

for Seametrics sensors in pulses per gallon, and is given

on the chart “K-factors for Various Pipe Sizes.” These

numbers are based on extensive testing, which has shown

close agreement between different IP sensors in the same

installation. Typically, most K-factor error can be attributed

to installation variables, such as depth setting and tting

conguration.

It is occasionally possible to eld calibrate a sensor by

catching the uid in a measured container and comparing

with the number of pulses recorded. (To record individual

pulses, set the K-factor on the control to 1.00.) This is

especially desirable if the installation has less than the

recommended length of straight pipe upstream of the

sensor.

Checking Signal

The ow sensor has only one moving part, the rotor. If

this is turning properly and there is no signal, the Halleffect sensor is not operating properly. To check the signal,

apply 12 Vdc regulated* power to the red (+) and black

(-) leads. Set a multimeter to voltage reading. Put the

positive multimeter lead on the red wire and the negative

lead on the white wire. Slowly turn the rotor. Voltage

reading should swing between +12 Volts and 0 Volts as

the rotor turns. If it does not, the Hall effect sensor is not

working properly. Checking for continuity is not a useful

test of these sensors.

*NOTE: An unregulated power supply can exceed max

voltage of micro-powered sensor pickup (gray cable) and

damage sensor.

Seametrics • 253.872.0284 Page 13 seametrics.com

Page 14

OPERATION AND MAINTANENCE

IP100/200 SERIES INSTRUCTIONS

1a

2a

3a

10

11

12

13

14

17

4b

1b

2b

4a

1 Upper housing/

electronics

6a

7a

2 Housing gasket/seal 102025 100411

3 Lower housing Not eld

5a

4 Housing screw/washer

kit (4 each)

5 Plug, steel (battery

9

units)

6 Strain relief kit, small

(includes 2)

7 Strain relief kit, large

(includes 1) (externally

powered units)

8 Sensor pickup 100508 (Micropower, gray cable,

9 Tube Not eld replaceable

10 Compression nut 100064 (brass)

8

11 Compression ferrule 100358

12 Adapter 100845 (brass)

15

16

Blue Housing

5b

6b

13 Rotor housing o-ring 100218 (EPDM)

14 Rotor housing 100068 (brass)

15 Bearings (includes 2) 103315

16 Rotor with shaft 100035 (Kynar®/tungsten carbide)

17 Rotor repair kit (#15 &

#16 above)

7b

White Housing

1a thru 7a

Contact service

representative

for your specic

model

replaceable

100414 100414

100360 100360

100364 100364

101850 101850

FT450)

100419 (Standard, blue cable,

FT430/440)

100084 (ss)

100846 (ss)

100118 (ss)

100036 (Kynar®/ceramic)

100435 (Kynar®/silicone carbide)

100317 (Kynar®/tungsten carbide)

100043 (Kynar®/ceramic)

100556 (Kynar®/silicone carbide)

Blue Housing

1b thru 7b

Contact service

representative

for your specic

model

Not eld

replaceable

IP 11x/21x Parts

3b

IP 15x/25x Parts (Hot Tap)

All parts are the same except those below, which

Hot Tap

A

B

C

E

D

Seametrics • 253.872.0284 Page 14 seametrics.com

replace #12

A Locking collar 100061 (brass)

B Adapter tting O-ring 100345 (EPDM)

C Adapter, hot tap 100384 (brass)

D Nipple, 2 inch 100066 (brass)

E Valve assembly

(includes valve plus B,

C, & D above)

100116 (ss)

100385 (ss)

100103 (ss)

100069 (brass)

100119 (ss)

Page 15

TROUBLESHOOTING

IP100/200 SERIES INSTRUCTIONS

Problem Probable Cause Things to Try...

No pulse output Below minimum ow cutoff Check velocity vs. pipe size (see page 8)

Empty pipe Check plumbing

No power Check connections

Output pulses incorrect Incorrect depth setting Check depth setting (see page 7)

Pipe not full Refer to installation recommendations

(see pages 5 and 10)

Not enough straight pipe Refer to installation recommendations

(see pages 5 and 9)

Jumpy reading Fluctuating ow rate Refer to installation recommendations

(see pages 5 - 10)

Fluctuating around low ow cutoff Check velocity vs. pipe size (see page 8)

Not enought straight pipe Refer to installation recommendations

(see pages 5 and 9)

Seametrics • 253.872.0284 Page 15 seametrics.com

Page 16

SEAMETRICS LIMITED WARRANTY

IP100/200 SERIES INSTRUCTIONS

The limited warranty set forth below is given by Seametrics, with respect to Seametrics and INW brand products purchased in the

United States of America.

Seametrics warrants that products manufactured by Seametrics, when delivered to you in new condition in their original containers

and properly installed, shall be free from defects in material and workmanship. Seametrics products are warranted against

defects for a period of two (2) years from date of installation, with proof of install date. If no proof of install date can be

provided, warranty period will be two (2) years from date of shipment from Seametrics, as dened on Seametrics’ invoice.

Seametrics’ obligation under this warranty shall be limited to replacing or repairing the part or parts, or, at Seametrics’ option, the

products, which prove defective in material or workmanship. The following are the terms of Seametrics’ limited warranty:

a. Buyer must give Seametrics prompt notice of any defect or failure and satisfactory proof thereof.

b. Any defective part or parts must be returned to Seametrics’ factory or to an authorized service center for inspection.

c. Buyer will prepay all freight charges to return any products to Seametrics’ factory, or another repair facility. as designated by

Seametrics.

d. Defective products, or parts thereof, which are returned to Seametrics and proved to be defective upon inspection, will be

repaired to factory specications.

e. Seametrics will deliver repaired products or replacements for defective products to the buyer (ground freight prepaid) to the

destination provided in the original order.

f. Products returned to Seametrics for which Seametrics provides replacement under this warranty shall become the property

of Seametrics.

g. This limited warranty covers all defects encountered in normal use of Seametrics products, and does not apply to the

following cases:

i. Loss of or damage to Seametrics product due to abuse, mishandling, or improper packaging by buyer

ii. Failure to follow operating, maintenance, or environmental instructions prescribed in Seametrics’ instruction manual

iii. Products not used for their intended purpose

iv. Alterations to the product, purposeful or accidental

v. Electrical current uctuations

vi. Corrosion due to aggressive materials not approved for your specic product

vii. Mishandling, or misapplication of Seametrics products

viii. Products or parts that are typically consumed during normal operation

ix. Use of parts or supplies (other than those sold by Seametrics) which cause damage to the products, or cause

abnormally frequent service calls or service problems

h. A new warranty period shall not be established for repaired or replaced material, products, or supplied. Such items shall

remain under warranty only for the remainder of the warranty period on the original materials, products, or supplies.

i. In the event that equipment is altered or repaired by the buyer without prior written approval by Seametrics, all warranties

are void. Damage caused by equipment or accessories not manufactured by Seametrics may void the product’s warranty.

j. SOFTWARE: The Seller grants the user a non-exclusive license to use Seametrics’ software, according to the following

limitations and conditions:

i. The user may install the software on one or more desktop or laptop computers.

ii. All title and intellectual rights to the software are owned by Seametrics.

iii. No copies may be made or distributed except as described above.

iv. The user may not modify or reverse-engineer the software.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, WHETHER ORAL, WRITTEN, EXPRESSED, IMPLIED OR STATUTORY. NO

IMPLIED WARRANTY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, APPLIED TO

THE PRODUCTS AFTER THE APPLICABLE PERIOD OF THE EXPRESS LIMITED WARRANTY STATED ABOVE, AND NO OTHER EXPRESS WARRANTY

OR GUARANTY, EXCEPT AS MENTIONED ABOVE, GIVEN BY ANY PERSON OR ENTITY WITH RESPECT TO THE PRODUCTS, SHALL BIND

SEAMETRICS. SEAMETRICS SHALL NOT BE LIABLE FOR LOSS OF REVENUES, OR PROFITS, OR INCONVENIENCES, EXPENSE FOR SUBSTITUTE

EQUIPMENT OR SERVICE, STORAGE CHARGES, LOSS OF DATA, OR ANY OTHER SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGE CAUSED

BY THE USE OR MISUSE OF, OR INABILITY TO USE THE PRODUCTS, REGARDLESS OF THE LEGAL THEORY ON WHICH THE CLAIM IS BASED,

AND EVEN IF SEAMETRICS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN NO EVENT SHALL RECOVERY OF ANY KIND

AGAINST SEAMETRICS BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE PRODUCT SOLD BY SEAMETRICS AND CAUSING THE

ALLEGED DAMAGE. WITHOUT LIMITING THE FOREGOING, YOU ASSUME ALL RISK OF LIABILITY FOR LOSS, DAMAGE, OR INJURY TO YOU AND

YOUR PROPERTY AND TO OTHERS AND THEIR PROPERTY ARISING OUT OF USE OR MISUSE OF, OR INABILITY TO USE THE PRODUCTS NOT

CAUSED DIRECTLY BY THE NEGLIGENCE OF SEAMETRICS.

SOME STATES DO NOT ALLOW LIMITATIONS ON THE DURATION OF AN IMPLIED WARRANTY, SO THE ABOVE LIMITATIONS MAY NOT

APPLY TO YOU. SIMILARLY, SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATIONS OF CONSEQUENTIAL DAMAGE, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS; HOWEVER, YOU MAY

ALSO HAVE OTHER RIGHTS WHICH MAY VARY FROM STATE TO STATE.

Seametrics • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • seametrics.com

LT-65200042r2.4 20170503

5/3/2017

Loading...

Loading...