9 001:2008

CERTIFIED COMPANY

ISO

ISO

Flow Meters & Controls

Municipal/Industrial Magmeter Instructions

9001:2008

CERTIFIED COMPANY

iMAG

PROUDLY

MADE

IN THE

USA

TABLE OF CONTENTS

General Information

General Information, Features ............................................................................................................. Page 1

Specications

Specifications, Dimensions, Flow Range ................................................................................................. Page 3

Installation and Grounding

Positioning the Meter,

Straight Pipe Recommendations, Full Pipe Recommendations, Fittings,

Calibration, Chemical Injection, Installing Gaskets............................................................................... Page 6

Tightening Flange Bolts

, Metal Pipe Installations, Plastic Pipe Installations ........................................ Page 7

Straight Pipe Recommendations ..................................................................................................... Page 8

Full Pipe Recommendations ............................................................................................................. Page 9

Inputs/Outputs and Operation

Remote Sensor Cable Installation ....................................................................................................... Page 10

External Power and Wiring .................................................................................................................. Page 11

Battery Power, Pulse Output, Analog Output, Hart Communication .................................................... Page 12

Digital Output, Serial Communication, Cable Control Wiring, K-Factors for High Speed Digital ......... Page 13

Output Applications .............................................................................................................................. Page 14

Changing Flow Meter Settings ............................................................................................................ Page 15

Troubleshooting

Problem, Probable Cause, Things to Try ............................................................................................. Page 15

TABLES, DIAGRAMS & CHARTS

Features ..................................................................................................................................................Page 1-2

Specications ..........................................................................................................................................Page 3

Flow Range, Accuracy, Dimensions .........................................................................................................Page 4-5

Metal Pipe Installation, Plastic Pipe Installation ......................................................................................Page 7

Straight Pipe Recommendations ............................................................................................................. Page 8

Full Pipe Recommendations ....................................................................................................................Page 9

Control Cable Wiring ................................................................................................................................Page 13

K-factors for High Speed Digital Output (High Frequency).......................................................................Page 13

Display Operation .................................................................................................................................... Page 15

Troubleshooting .......................................................................................................................................Page 16

GENERAL INFORMATION

The iMAG-Series is the most economical anged electromagnetic

owmeter on the market. It is used in 3” to 12” pipe in municipal

or industrial water, waste and reclaimed water, pump stations

and packaged plant applications. The iMAG has no moving

parts and electrodes are designed to discourage fouling. This

magmeter requires no maintenance in applications where

debris would impede mechanical meters. There are no parts to

wear out. Minimal straight pipe requirements allow iMAG-Series

meters to be used in piping congurations where there is little

space between the meter and an elbow.

iMAG-Series meters are rated IP68 for applications where the

meter may be under water up to a depth of 10 feet (3 meters)

for prolonged periods of time.

Rate and total indication are standard. Rate and total units and

pulse output are settable via the front panel touch key pad by

FEATURES

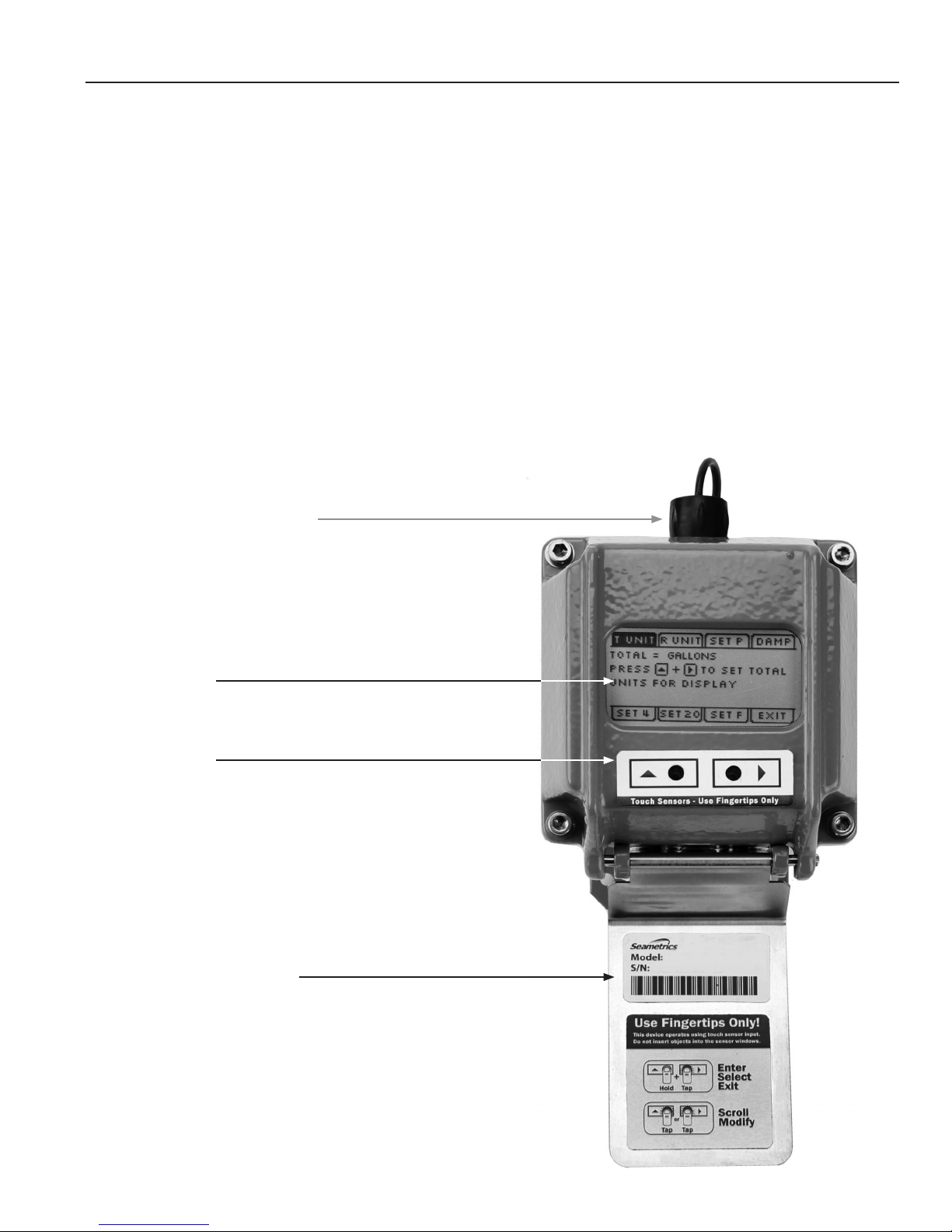

Conguration Port (For Factory Use Only)

the user. Bi-directional ow is standard. Forward, reverse and

net ow can be read from the display. If forward and reverse

ow data needs to be sent to another device, Modbus output

is required.

The iMAG 3600 and 4600 can be externally powered with 9-36

Vdc at 30 mA average. The 4600 is also available in a battery

powered version.

The standard 20-foot (6 meter) cable also provides outputs for

use with a variety of Seametrics and other displays and controls

for remote reading, data logging and telemetry applications.

4-20mA passive current loop and high frequency outputs

are optional on the externally powered models. Pulse output

is standard on the battery powered model. The iMAG 3600

remote display meter can be supplied with an optional internal

AC power supply.

Multifunction Display

Light Sensor Keypad

Protective Cover with Magnetic Seal

Page 1

GENERAL INFORMATION

FEATURES Continued

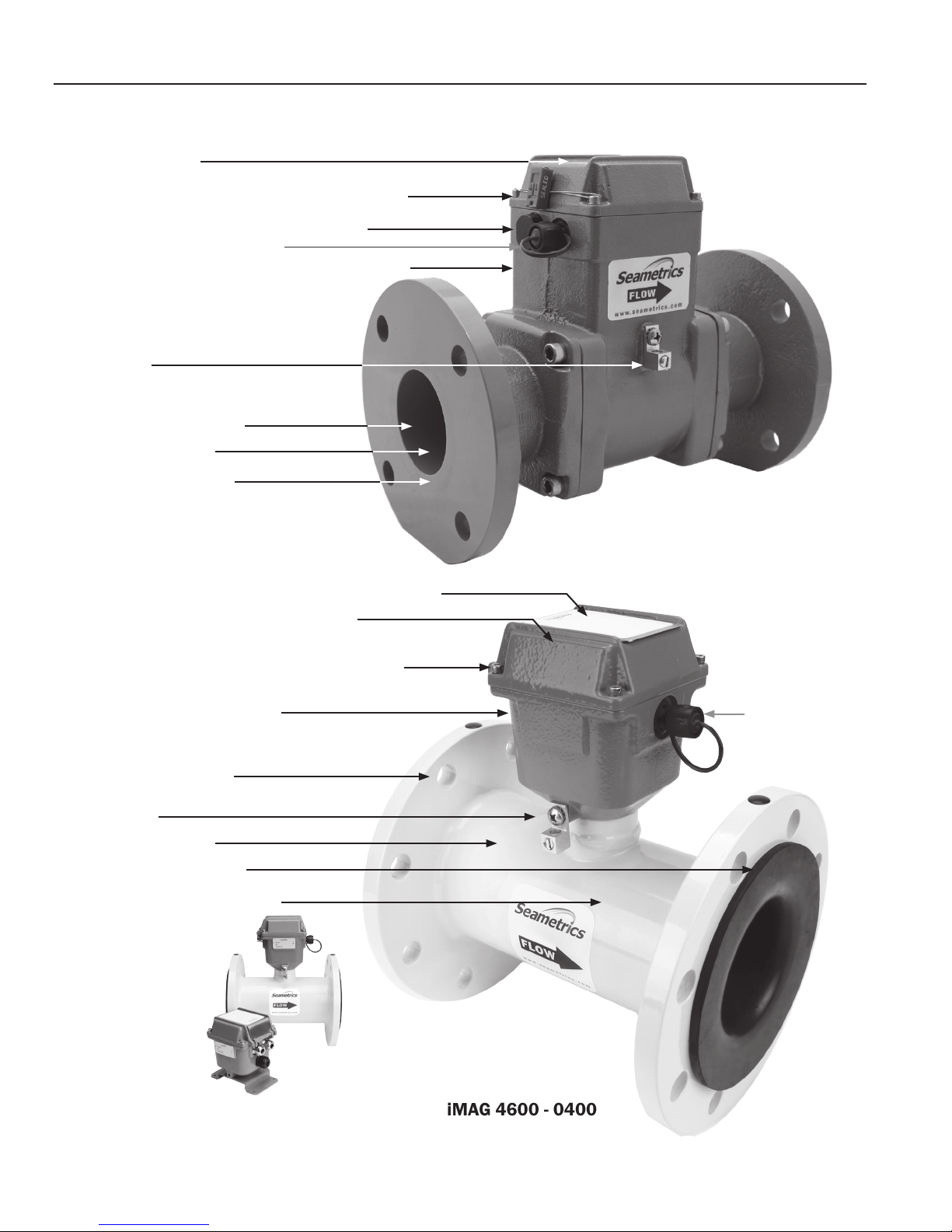

Rate and total indicator

Security seal & cross-drilled screws (2) for tamper-evidence

Power and Output cable port access, tamper-sealed

Conguration Port (For Factory Use Only)

Powder-coated ductile cast iron body & electronics housing

Equalization lug

Glass lled molded plastic liner

316SS electrodes (Inside)

Flanges, 150 lb. ANSI pattern

Rate and total indicator with protective cover and keypad sensors

Powder-coated ductile cast iron electronics housing

Security seal & cross-drilled screws (2) for tamper-evidence

Power and Output cable port access

Flanges, 150 lb. ANSI pattern

Equalization lug

316SS electrodes (Inside)

Santoprene/Polypropylene Liner

Welded steel epoxy-coated ow tube

iMAG 4600 - 300

Conguration Port

(For Factory Use Only)

iMAG 3600-0400

(Remote indicator)

Page 2

iMAG 4600 - 0400

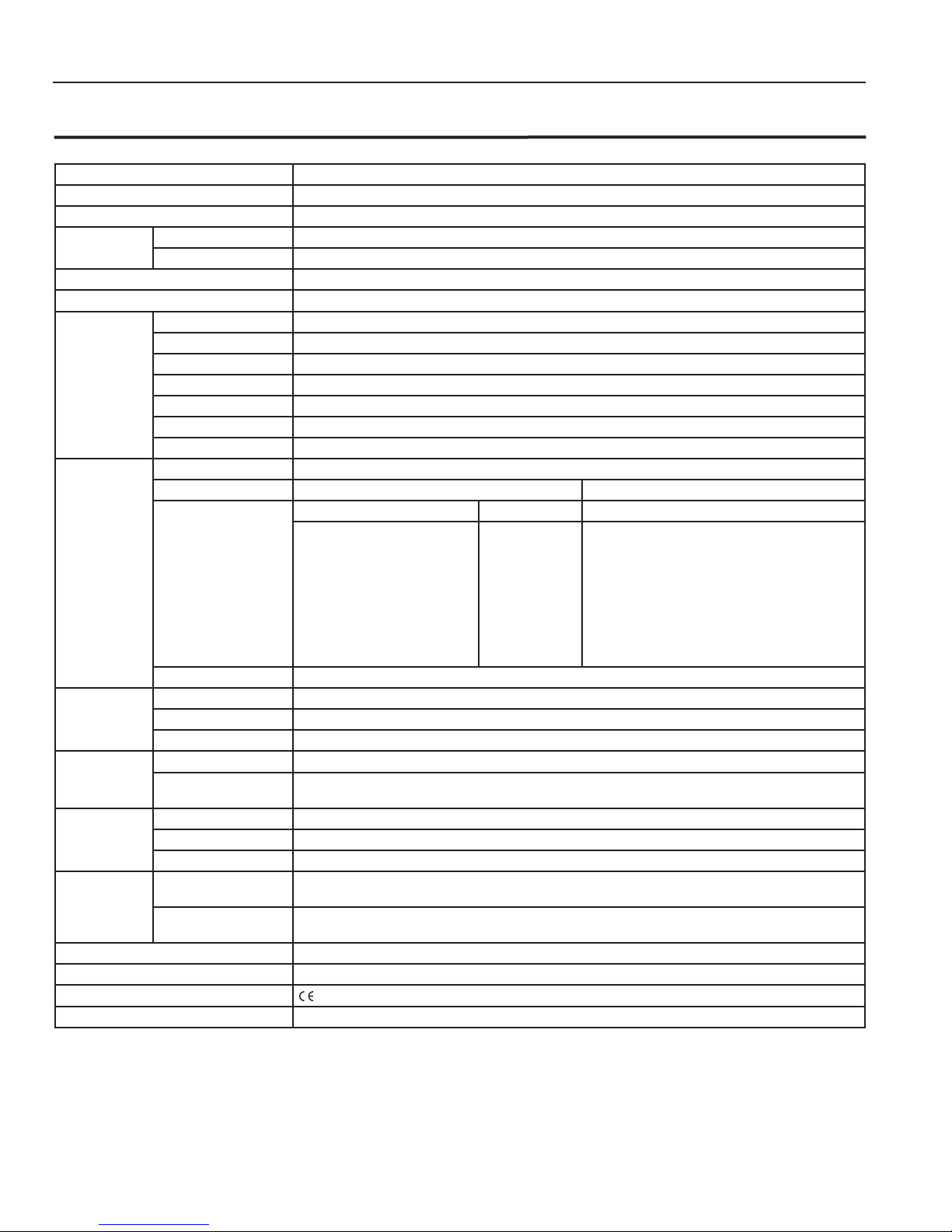

SPECIFICATIONS

SPECIFICATIONS*

Pipe Sizes 3”,4”, 6”, 8”, 10”, 12”

Flanges 150 lb. ANSI pattern

Pressure 150 psi (10.3 bar) working pressure

Temperature Operating 10˚ to 130˚ F (-12˚ to 54˚ C)

Storage -40˚ to 158˚ F (-40˚ to 70˚ C)

Accuracy +/- 1% of reading +/- 0.025% of full-scale ow from low ow cutoff to maximum ow rate of 10 m/sec

Low Flow Cutoff 0.5% of maximum ow rate

Materials Body (3” Only) Ductile cast iron, powder-coated

Body (4”-12”) Welded steel, epoxy-coated

Liner (3” Only) Noryl®

Liner (4”-12”) Santoprene/Polypropylene

Electronics Housing Ductile cast iron, powder-coated

Electrodes 316 stainless steel

O-ring (3” Only)

Display Type 128x64 dot-matrix LCD

Digits 5 Digit Rate 8 Digit Total

Units

Please Note:

All iMAG meters are factory set

for gallons per minute (GPM)

rate and gallons total. If other

units are required, they can be

programmed in the eld.

Bi-directional

1

Power DC Power 9-36 Vdc @ 250 mA max, 30 mA average

2

3

Pulse Frequency

Output

AC Power

Battery

Signal Current sinking pulse, isolated, 36 Vdc at 10 mA max

Pulse Rates User-scalable from 0.1 to 99,999.9 volume units/pulse. Pulse width is one-half of pulse period with

Options 4-20mA Current Loop Isolated, passive, 24Vdc, error less than +/- 0.1% of pulse/frequency output

Digital Output Isolated, open collector, 24 Vdc, 650 Ω maximum loop resistance

Serial Communications Isolated, asynchronous serial RS485 (Recongurable for RS232 or 3.3V CMOS), Modbus RTU protocol

Cable Control Cable Six-conductor water-blocked cable, polyurethane jacket, 20ft (6m) standard length for power, pulse

Remote Display Cable

(iMAG 3600)

Conductivity >20 microSiemens/cm

Empty Pipe Detection Hardware/software, conductivity-based

Regulatory

Environmental IP68 to 10ft (3m) depth

EPDM

Rate Volume Units Rate Time Units Total Volume Units

Gallons

Liters

Barrels (42 gallon)

Cubic Feet

Cubic Meters

Million Gallons

Mega Liters

Imperial Gallons

Million Imperial Gallons

Second

Minute

Hour

Day

Gallons

Gallons x 1000

Million Gallons

Liters

Kilo Liters

Mega Liters

Barrels (42 gallon)

Cubic Meters

Cubic Meters x 1000

Cubic Feet

Cubic Feet x 1000

Million Cubic Feet

Imperial Gallons

Imperial Gallons x 1000

Million Imperial Gallons

Forward Total, Reverse Total, Net Total

85-264Vac, 50/60Hz, 0.12A

Two lithium 3.6V ‘D’ batteries, replaceable. See chart on page 11 for battery life expectancy.

minimum pulse width of 2.5 ms, 200 pulses/sec max, 10 pulses/sec max battery option

frequency or optional outputs (optional lengths up to 100’ available)

33ft (10m) standard length (optional lengths up to 100’ available)

(EN 61326) pending, NSF-61 on 3” ONLY

*Specications subject to change. Please consult our website for the most current data (www.seametrics.com).

1

If forward and reverse ow data needs to be sent to another device, either the -ADDX, -DDDX or Modbus output is required.

2

iMAG3600 only, iMAG4600 requires external AC power supply

3

iMAG4600 only

Page 3

SPECIFICATIONS

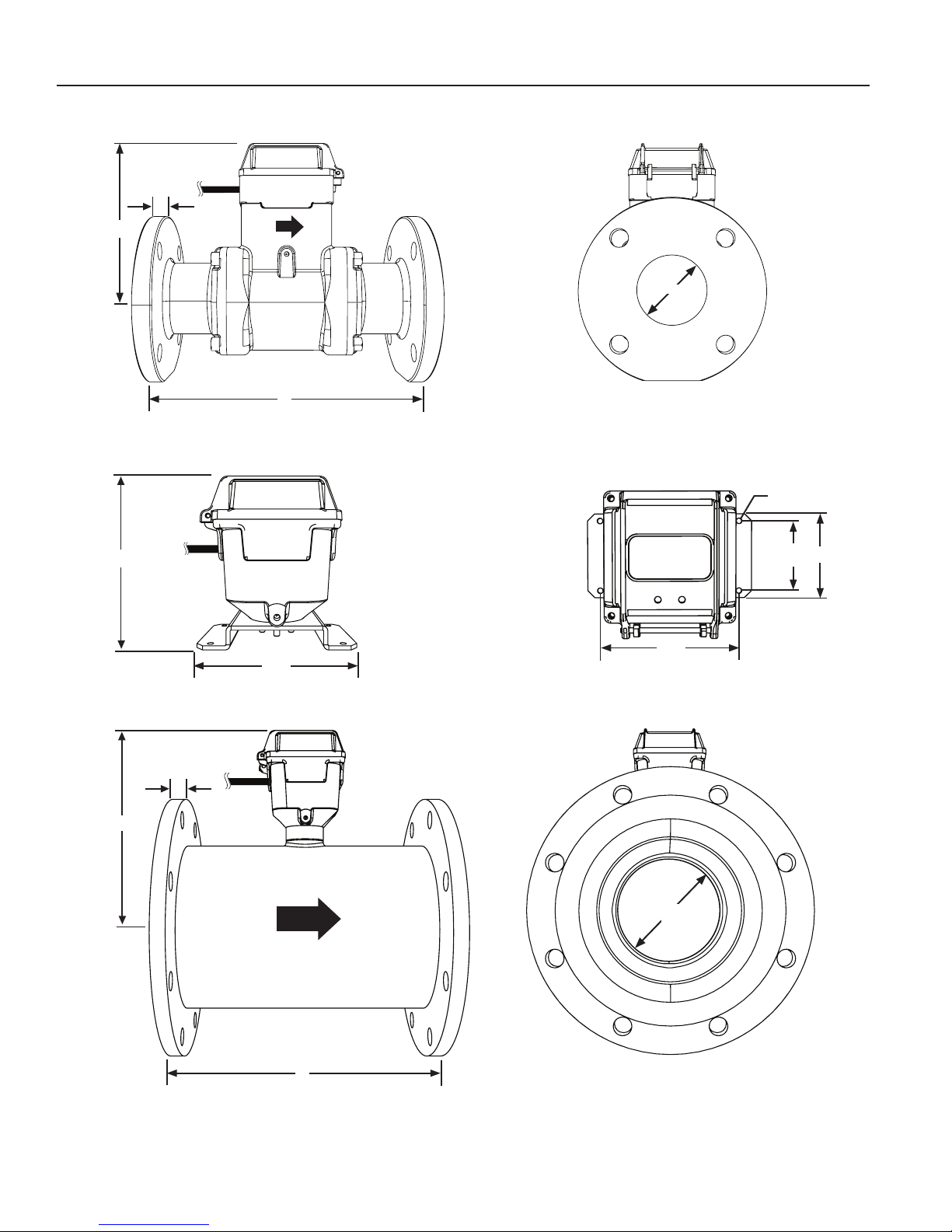

DIMENSIONS

H

Cable Exit

T

(Metal Flange)

L

(Including Rubber Gaskets)

iMAG4600 - 0300 Shown

ID

iMAG3600 Remote Shown

.20” Dia.

5.62”

H

Cable Exit

T

(Metal

Flange)

Cable Exit

5.27”

iMAG4600 - 0400 to 1200

Shown

4.38”

ID

2.5”

3”

L

(Including Rubber Gaskets)

Page 4

Loading...

Loading...