Page 1

9 001:2008

CERTIFIED COMPANY

ISO

ISO

Flow Meters & Controls

Municipal/Industrial Magmeter Instructions

9001:2008

CERTIFIED COMPANY

iMAG

PROUDLY

MADE

IN THE

USA

Page 2

TABLE OF CONTENTS

General Information

General Information, Features ............................................................................................................. Page 1

Specications

Specifications, Dimensions, Flow Range ................................................................................................. Page 3

Installation and Grounding

Positioning the Meter,

Straight Pipe Recommendations, Full Pipe Recommendations, Fittings,

Calibration, Chemical Injection, Installing Gaskets............................................................................... Page 6

Tightening Flange Bolts

, Metal Pipe Installations, Plastic Pipe Installations ........................................ Page 7

Straight Pipe Recommendations ..................................................................................................... Page 8

Full Pipe Recommendations ............................................................................................................. Page 9

Inputs/Outputs and Operation

Remote Sensor Cable Installation ....................................................................................................... Page 10

External Power and Wiring .................................................................................................................. Page 11

Battery Power, Pulse Output, Analog Output, Hart Communication .................................................... Page 12

Digital Output, Serial Communication, Cable Control Wiring, K-Factors for High Speed Digital ......... Page 13

Output Applications .............................................................................................................................. Page 14

Changing Flow Meter Settings ............................................................................................................ Page 15

Troubleshooting

Problem, Probable Cause, Things to Try ............................................................................................. Page 15

TABLES, DIAGRAMS & CHARTS

Features ..................................................................................................................................................Page 1-2

Specications ..........................................................................................................................................Page 3

Flow Range, Accuracy, Dimensions .........................................................................................................Page 4-5

Metal Pipe Installation, Plastic Pipe Installation ......................................................................................Page 7

Straight Pipe Recommendations ............................................................................................................. Page 8

Full Pipe Recommendations ....................................................................................................................Page 9

Control Cable Wiring ................................................................................................................................Page 13

K-factors for High Speed Digital Output (High Frequency).......................................................................Page 13

Display Operation .................................................................................................................................... Page 15

Troubleshooting .......................................................................................................................................Page 16

Page 3

GENERAL INFORMATION

The iMAG-Series is the most economical anged electromagnetic

owmeter on the market. It is used in 3” to 12” pipe in municipal

or industrial water, waste and reclaimed water, pump stations

and packaged plant applications. The iMAG has no moving

parts and electrodes are designed to discourage fouling. This

magmeter requires no maintenance in applications where

debris would impede mechanical meters. There are no parts to

wear out. Minimal straight pipe requirements allow iMAG-Series

meters to be used in piping congurations where there is little

space between the meter and an elbow.

iMAG-Series meters are rated IP68 for applications where the

meter may be under water up to a depth of 10 feet (3 meters)

for prolonged periods of time.

Rate and total indication are standard. Rate and total units and

pulse output are settable via the front panel touch key pad by

FEATURES

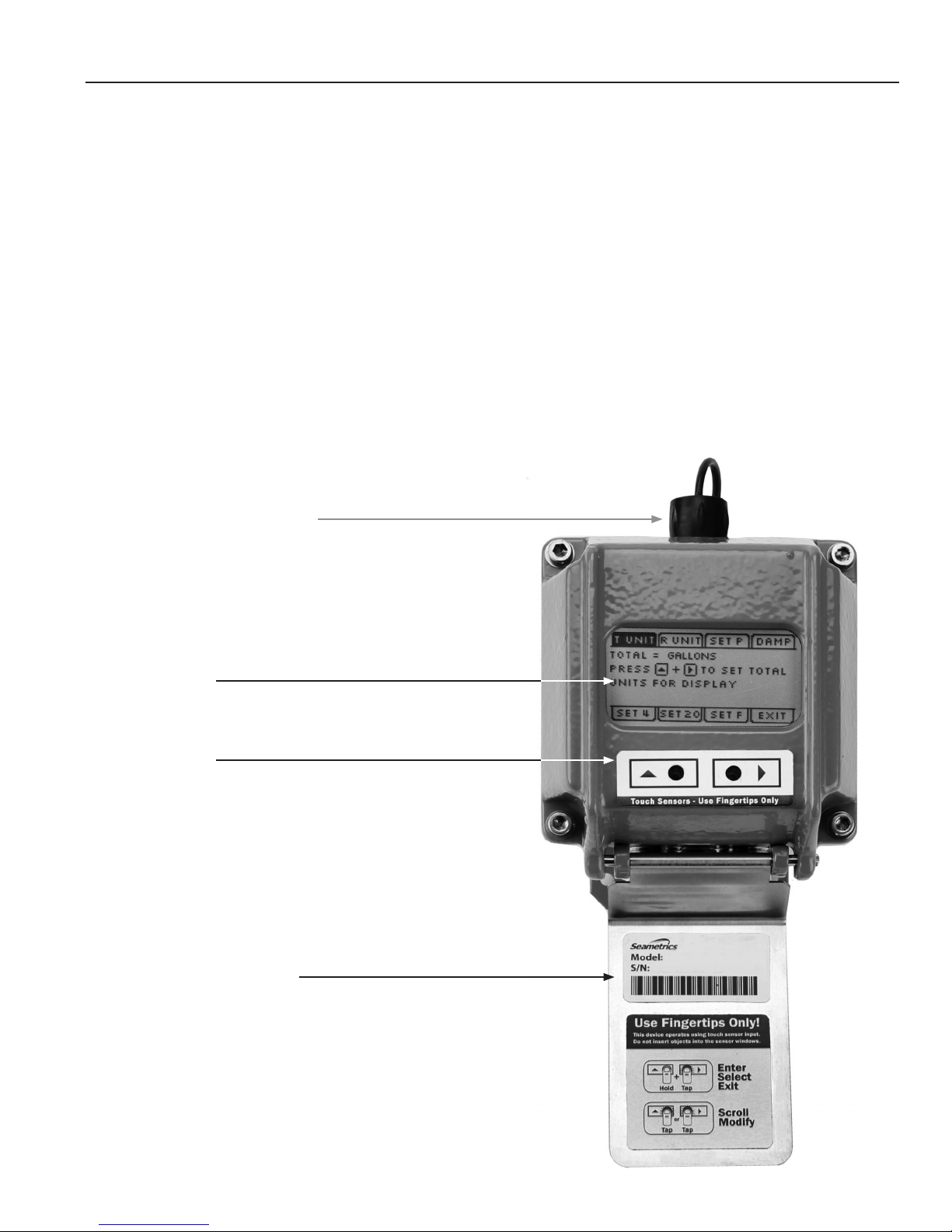

Conguration Port (For Factory Use Only)

the user. Bi-directional ow is standard. Forward, reverse and

net ow can be read from the display. If forward and reverse

ow data needs to be sent to another device, Modbus output

is required.

The iMAG 3600 and 4600 can be externally powered with 9-36

Vdc at 30 mA average. The 4600 is also available in a battery

powered version.

The standard 20-foot (6 meter) cable also provides outputs for

use with a variety of Seametrics and other displays and controls

for remote reading, data logging and telemetry applications.

4-20mA passive current loop and high frequency outputs

are optional on the externally powered models. Pulse output

is standard on the battery powered model. The iMAG 3600

remote display meter can be supplied with an optional internal

AC power supply.

Multifunction Display

Light Sensor Keypad

Protective Cover with Magnetic Seal

Page 1

Page 4

GENERAL INFORMATION

FEATURES Continued

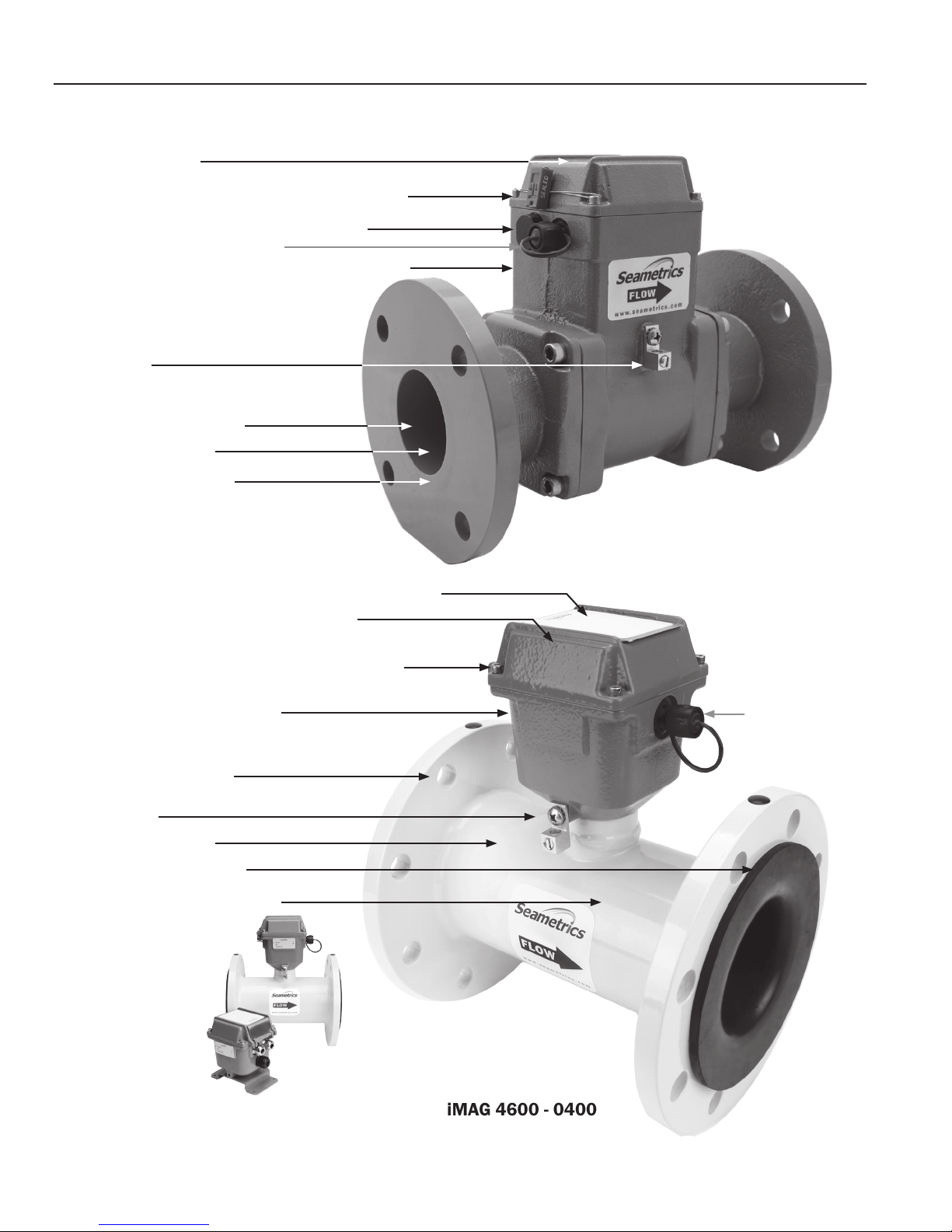

Rate and total indicator

Security seal & cross-drilled screws (2) for tamper-evidence

Power and Output cable port access, tamper-sealed

Conguration Port (For Factory Use Only)

Powder-coated ductile cast iron body & electronics housing

Equalization lug

Glass lled molded plastic liner

316SS electrodes (Inside)

Flanges, 150 lb. ANSI pattern

Rate and total indicator with protective cover and keypad sensors

Powder-coated ductile cast iron electronics housing

Security seal & cross-drilled screws (2) for tamper-evidence

Power and Output cable port access

Flanges, 150 lb. ANSI pattern

Equalization lug

316SS electrodes (Inside)

Santoprene/Polypropylene Liner

Welded steel epoxy-coated ow tube

iMAG 4600 - 300

Conguration Port

(For Factory Use Only)

iMAG 3600-0400

(Remote indicator)

Page 2

iMAG 4600 - 0400

Page 5

SPECIFICATIONS

SPECIFICATIONS*

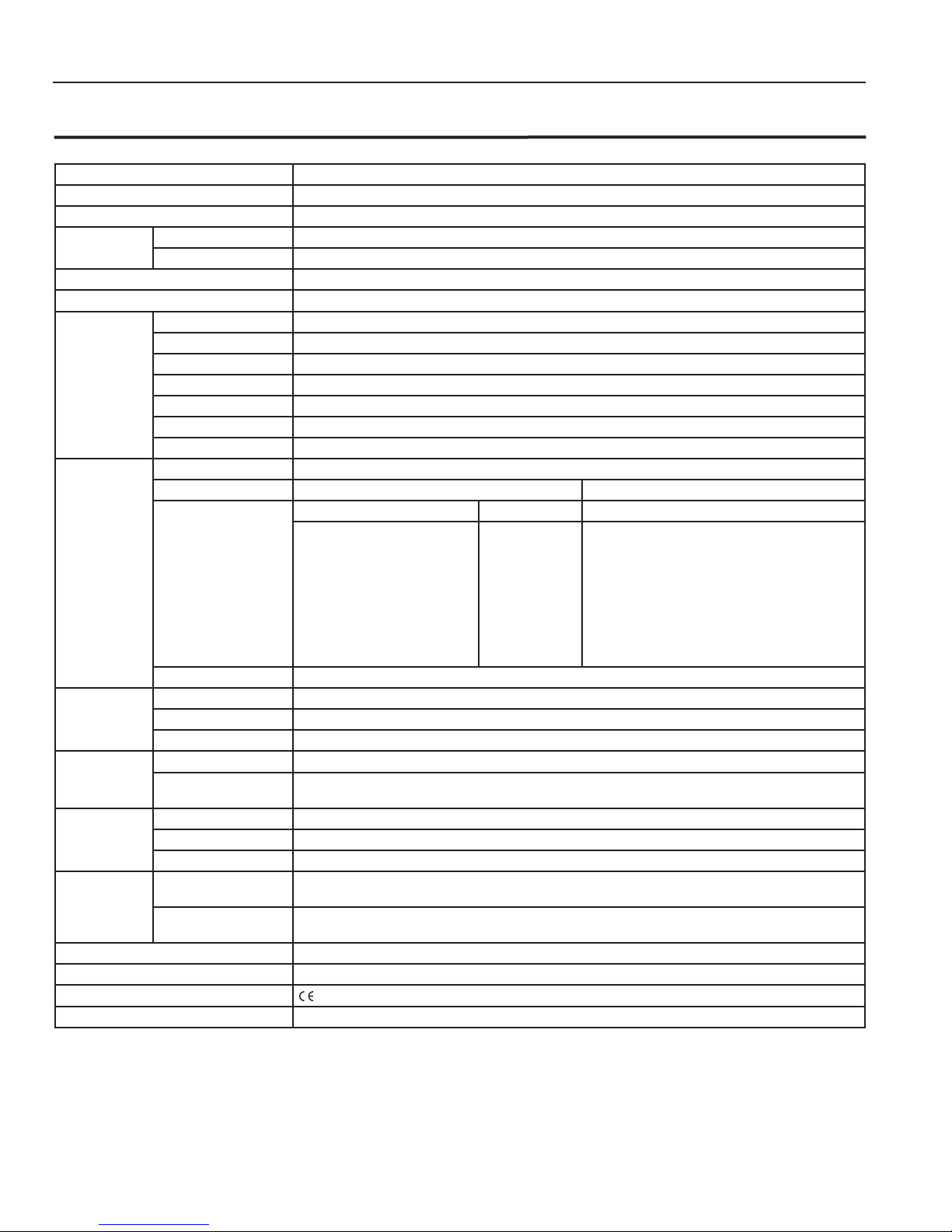

Pipe Sizes 3”,4”, 6”, 8”, 10”, 12”

Flanges 150 lb. ANSI pattern

Pressure 150 psi (10.3 bar) working pressure

Temperature Operating 10˚ to 130˚ F (-12˚ to 54˚ C)

Storage -40˚ to 158˚ F (-40˚ to 70˚ C)

Accuracy +/- 1% of reading +/- 0.025% of full-scale ow from low ow cutoff to maximum ow rate of 10 m/sec

Low Flow Cutoff 0.5% of maximum ow rate

Materials Body (3” Only) Ductile cast iron, powder-coated

Body (4”-12”) Welded steel, epoxy-coated

Liner (3” Only) Noryl®

Liner (4”-12”) Santoprene/Polypropylene

Electronics Housing Ductile cast iron, powder-coated

Electrodes 316 stainless steel

O-ring (3” Only)

Display Type 128x64 dot-matrix LCD

Digits 5 Digit Rate 8 Digit Total

Units

Please Note:

All iMAG meters are factory set

for gallons per minute (GPM)

rate and gallons total. If other

units are required, they can be

programmed in the eld.

Bi-directional

1

Power DC Power 9-36 Vdc @ 250 mA max, 30 mA average

2

3

Pulse Frequency

Output

AC Power

Battery

Signal Current sinking pulse, isolated, 36 Vdc at 10 mA max

Pulse Rates User-scalable from 0.1 to 99,999.9 volume units/pulse. Pulse width is one-half of pulse period with

Options 4-20mA Current Loop Isolated, passive, 24Vdc, error less than +/- 0.1% of pulse/frequency output

Digital Output Isolated, open collector, 24 Vdc, 650 Ω maximum loop resistance

Serial Communications Isolated, asynchronous serial RS485 (Recongurable for RS232 or 3.3V CMOS), Modbus RTU protocol

Cable Control Cable Six-conductor water-blocked cable, polyurethane jacket, 20ft (6m) standard length for power, pulse

Remote Display Cable

(iMAG 3600)

Conductivity >20 microSiemens/cm

Empty Pipe Detection Hardware/software, conductivity-based

Regulatory

Environmental IP68 to 10ft (3m) depth

EPDM

Rate Volume Units Rate Time Units Total Volume Units

Gallons

Liters

Barrels (42 gallon)

Cubic Feet

Cubic Meters

Million Gallons

Mega Liters

Imperial Gallons

Million Imperial Gallons

Second

Minute

Hour

Day

Gallons

Gallons x 1000

Million Gallons

Liters

Kilo Liters

Mega Liters

Barrels (42 gallon)

Cubic Meters

Cubic Meters x 1000

Cubic Feet

Cubic Feet x 1000

Million Cubic Feet

Imperial Gallons

Imperial Gallons x 1000

Million Imperial Gallons

Forward Total, Reverse Total, Net Total

85-264Vac, 50/60Hz, 0.12A

Two lithium 3.6V ‘D’ batteries, replaceable. See chart on page 11 for battery life expectancy.

minimum pulse width of 2.5 ms, 200 pulses/sec max, 10 pulses/sec max battery option

frequency or optional outputs (optional lengths up to 100’ available)

33ft (10m) standard length (optional lengths up to 100’ available)

(EN 61326) pending, NSF-61 on 3” ONLY

*Specications subject to change. Please consult our website for the most current data (www.seametrics.com).

1

If forward and reverse ow data needs to be sent to another device, either the -ADDX, -DDDX or Modbus output is required.

2

iMAG3600 only, iMAG4600 requires external AC power supply

3

iMAG4600 only

Page 3

Page 6

SPECIFICATIONS

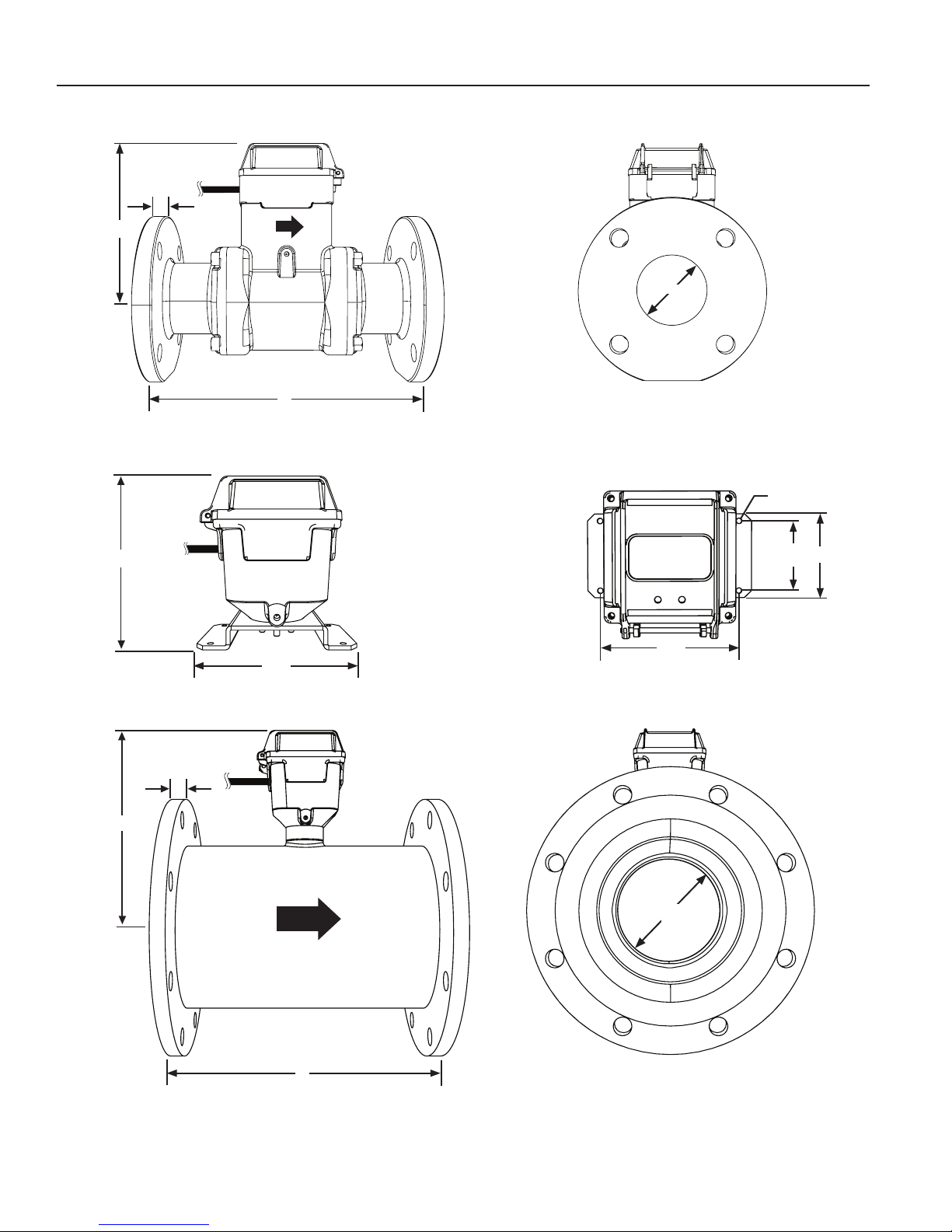

DIMENSIONS

H

Cable Exit

T

(Metal Flange)

L

(Including Rubber Gaskets)

iMAG4600 - 0300 Shown

ID

iMAG3600 Remote Shown

.20” Dia.

5.62”

H

Cable Exit

T

(Metal

Flange)

Cable Exit

5.27”

iMAG4600 - 0400 to 1200

Shown

4.38”

ID

2.5”

3”

L

(Including Rubber Gaskets)

Page 4

Page 7

SPECIFICATIONS

0

1

2

3

4

5

33 0 5 10 15 20 25 30

iMAG Dimensions

Shipping

Weight

iMAG

Meter Size

L H T ID

inch mm inch mm inch mm inch mm pounds

3” 12.0 305 6.80 173 .68 17.3 2.60 66.04 41 19

4” 10.24 260 8.12 206 .62 20.9 3.12 79.25 35 16

6” 12.27 312 9.22 234 .69 23.3 5.05 128.27 50 23

8” 14.24 362 10.22 260 .69 23.3 6.44 163.58 72 33

10” 18.18 462 11.22 285 .69 23.3 8.61 218.69 128 58

12” 19.68 500 12.28 312 .81 20.6 10.55 267.97 170 78

Flanges Standard ANSI 150 lb. drilling

Cable 1 lb.

iMAG Accuracy

5

4

3

Kg

Accuracy (%)

2

1

33

(m/s)

(ft/s)

0

0

5

10 15

420 6 8 10

20

25 30

Flow Velocity

FLOW RANGE (3” - 12”)

Pipe Size

(Inches in diameter)

Max Flow Rate

(Gallons/Minute)

Cut-off (min) Flow Rate

(Gallons/Minute)

Max Flow Rate

(Liters/Second)

Cut-off (min) Flow Rate

(Liters/Second)

Max Flow Velocity

(Meters/Second)

3” 4” 6” 8” 10” 12”

723 1285 2891 5140 8031 11565

3.62 6.43 14.46 25.70 40.15 57.82

46 81 182 324 507 730

0.23 0.41 0.91 1.62 2.54 3.65

10 10 10 10 10 10

Page 5

Page 8

INSTALLATION and GROUNDING

INSTALLATION

Caution: These ow sensors are not recommended

where installation may expose the ow sensor to boiler

pressure and temperature. Maximum

recommended operating temperature is 130˚ F.

Positioning the Meter. These meters can be installed

horizontally, vertically, and in any radial position. Using a

check valve on the upstream side of the meter, and/or an air

vent (vacuum relief valve) in the same, unobstructed run of

pipe as the meter, is required in any installation where the

meter may be exposed to suction when the system is not in

normal operation. Suction can cause damage to the liner.

Liner damage caused by suction, without the use of a check

valve and/or air vent, may void the warranty.

Straight Pipe Recommendations. As with most ow meters,

the iMAG requires straight pipe before and after the meter for

best accuracy. However, the ability of electromagnetic meters

to average the ow across the entire pipe allows for shorter

straight pipe recommendations than most mechanical meters

(see page 7).

Installing Gaskets

GASKETS

Gaskets are required at all junctions.

(Not applicable to 3” model.)

1. Select a suitable full-face gasket.

• Only use at compressible gaskets (either pliable

or hard ber will work).

• Use a material compatible with the uid you will be

using.

• Thickness should be 1/8” - 1/4” (3 - 6 mm),

depending on the atness of the pipe ange

surface.

• Inner diameter must be larger than opening in ow

meter.

2. Be sure all mating surfaces are smooth and free of

debris.

3. Install gaskets on each end of meter as shown in

diagrams below. If using grounding rings, install one

gasket on each side of the grounding ring.

Full Pipe Recommendations. All magmeters require a

method for determining that the pipe is empty, to prevent false

reading. This meter is designed to indicate ‘EMPTY PIPE’ if one

or more electrodes is exposed. For highest accuracy, install

the meter so that the pipe will be full when there is ow. If air

bubbles may be present in the pipe or sludge accumulation

is an issue, rotate the meter by one ange hole to position

the control housing at a 45˚ angle (see diagrams on page 8).

Fittings. The iMAG anges have standard ANSI 150 lb. drilling

pattern and mate with any other ANSI 150 lb. ange. See table

on next page for ange bolt tightening torque specications.

Calibration. The iMAG is factory-calibrated and will not require

any form of eld calibration.

Chemical Injection. When any magmeter, by any manufacturer, is used in a chemical injection application, the chemical

injection point must be placed downstream of the magmeter OR far enough upstream for complete mixing to occur

before the uid reaches the meter. When unmixed chemical

alternates with water passing through the meter, the rapid

changes in conductivity may cause sudden spikes and drops

in the meter’s reading, resulting in inaccurate measurement.

The magmeter will restabilize, however, with a steady ow of

uid of uniform conductivity.

Gaskets

Installation without gaskets

Grounding

Rings

Gaskets

Installation with gaskets

Caution: In chemical injection applications, install

chemical injection point downstream of magmeter, or

far enough upstream to allow complete mixing of uids.

Page 6

Page 9

INSTALLATION and GROUNDING

Tightening Flange Bolts

NOTE: Mating pipe anges must be ANSI 150# full face (FF)

and/or raised face (RF).

1. Tighten ange bolts in an alternating pattern.

• Tighten left ange bolt-1 to 20% recommended

torque.

• Tighten right ange bolt-1 to 20% of

recommended torque.

• Repeat steps a and b for each bolt in an

alternating order, such as shown at right,

tightening to 40%, then 60%, then 80%, and then

100%.

2. Test for leaks.

3. If needed, tighten further in 10% increments until

leaking stops. DO NOT over-tighten. Over-tightening

can cause serious damage to the ow meter.

4. Recheck after 24 hours, adjusting if needed.

1

5

8

Equalization and Grounding

WARNING: ELECTRICAL SHOCK HAZARD

When the iMAG is installed in a plastic

piping system, or when externally powered,

the piping system must be grounded to meet

national and local electrical safety codes.

Failure to do so can result in electrocution.

Metal Pipe Installations. To equalize the electrical potential

of the uid, the iMAG meter, and the surrounding pipe, secure

the ange plates (factory-installed on the equalization wire)

to both pipe anges at one of the bolt holes, as shown below.

Be sure the lock washer ts between the pipe ange and the

ange plate. For the best electrical bonding, remove rust

and paint to expose clean, bare metal where the equalization

ange plate lock washer contacts the pipe ange. Connection

must be inspected periodically for corrosion to maintain the

necessary low resistance connection.

Meter Flange

Gasket

Pipe Flange

Lockwasher

Flange Plate

Equalization Lug

3

7

4

6

2

Suggested Tightening Sequence

Caution: Improper tightening sequence

can cause serious damage to the ow

meter.

• Do not tighten one side at a time.

• Do not tighten each bolt completely at

one time.

SUGGESTED FLANGE BOLT TORQUE

Santoprene Liner

Pipe Size ft-lb Nm

3” 25 34

4” 20 27

6” 42 57

8” 65 88

10” 73 99

12” 97 132

Meter

Flange

Gaskets

Pipe

Flange

Metal PipeMetal Pipe

Plastic Pipe Installations. When the iMAG is installed in a

plastic piping system, grounding rings are recommended

(except 3” pipe size), especially in the presence of electrical

interference sources such as VFD pump drives. As shown in

the diagram below, the equalization wires should then be

connected to the grounding ring tabs instead of the ange

bolts as in metal piping installations. Where lightning is a

threat, or in severe electrical environments, an optional

connection to a nearby equipment ground or ground rod may

be advisable.

Equalization Lug

Grounding Ring

Gaskets

Plastic

Pipe

#6, #8, or #12 AWG Stranded

Copper Ground Wire < 5’

Grounding Ring Part Numbers:

4” = 100876 10” = 100879

6” = 100877 12” = 103288

8” = 100878

Grounding Ring

Gaskets

Plastic

Pipe

Ground Clamp

(Exothermically weld when

corrosion is a concern)

Earth

8’ Ground Rod

Page 7

Page 10

STRAIGHT PIPE RECOMMENDATIONS

(X = diameter)

Reduced Pipe

Two Elbows In Plane

Two Elbows, Out Of Plane

1X

2X

iMAG

1X

2X

iMAG

1X

2X

Expanded Pipe

Swirling Flow

Propeller Meter

5X

5X

iMAG

iMAG

5X

1X

1X

iMAG

1X

Swirling Flow

Partially Open

Buttery Valve

Page 8

iMAG

Page 11

FULL PIPE RECOMMENDATIONS

Recommended:

Keep pipe full at meter for accuracy

iMAG

iMAG

Not Ideal:

Allows air pockets to form at meter

iMAG

Recommended:

Keeps pipe full at meter for accuracy

iMAG

Recommended:

Allows air to bleed off

Intermittent air

Electrode

moved from

top by rotating

meter

iMAG

miss electrode

Electrodes free

from sediment

bubbles

build-up

iMAG

Not Ideal:

Post-valve cavitation can create air pocket

iMAG

Not Ideal:

Air can be trapped

Intermittent air

bubbles

pass over

electrode

Possible

sediment

build-up

iMAG

Recommended:

Improved accuracy results from

unimpeded electrodes

Not Ideal:

Air bubbles and sediment on the

electrodes can affect accuracy

Page 9

Page 12

INPUTS/OUTPUTS and OPERATION

g

.20” (15mm) Splice4” (102mm) Wire Length

AC

Sealing Nut

REMOTE SENSOR CABLE INSTALLATION (iMAG3600 ONLY)

and tighten securely. A loose nut could cause moisture ingress

and compromise the meter head’s IP68 rating, voiding the

The standard 33 foot (10m) cable connecting the iMAG3600

sensor body to the remote display head is shipped with the

cable disconnected at the display end. To connect during

installation:

1. Remove the four cap screws securing the top housing

to the lower housing and swing the top open to expose the

internal wiring (see photo.)

2. Remove the sensor cable hole plug and discard.

3. After removing the cable gland bulkhead nut, insert the

5-postion plug and cable gland threaded bushing into the

open hole. (see drawing.) Do not loosen the cable jacket

sealing nut.

Control Cable

Power Cable

Sensor Cable

Bulkhead Nut

warranty.

6. Slide the cable outward through the loosened cable gland

until the jacket just protrudes past the cable gland bulkhead

threads.

7. Retighten the gland sealing nut until cable cannot be

pushed in by hand and then tighten an additional full turn.

Pull on cable to assure sufcient tightness.

8. Insert the ve-position plug into the mating receptacle on

the small circuit board attached to the larger main display

circuit board.

9. Close the top cover and replace the four cap screws,

securing tightly to reseal the housing against moisture ingress.

Lower Housing Bulkhead

5-Position Plu

Cable from

Sensor

Position 1 - Drain

Position 2 - Brown

Position 3 - Yellow

Position 4 - Orange

Position 5 - Black

1

2

3

4

5

4. Install the bulkhead nut back onto the cable gland threads

inside the housing and tighten securely. A loose nut could

cause moisture ingress and compromise the meter head’s

Top Housing

IP68 rating, voiding the warranty.

5. Insert the ve-position plug into the mating receptacle on

the small circuit board attached to the larger main display

5-Position Plug

1

2

3

4

5

Mating Receptacle

circuit board.

6. Close the top cover and replace the four cap screws, securing

tightly to reseal the housing against moisture ingress.

7. Do not remove gel packs.

Lengthening the Sensor Cable. Replacing the entire cable

Shortening the Sensor Cable. The sensor cable may be

shortened by cutting the cable at the display head end. Under

no circumstances should the cable gland at the sensor body

end be removed as this will compromise the IP68 moisture

ingress protection causing meter failure and voiding the

warranty. To shorten the cable follow the steps below:

1. Before cutting, loosen the cable gland sealing nut and slide

the gland back past where the cable will be cut.

2. After cutting, remove the jacket and outer braid shield

and cut and strip conductors to the dimensions shown in the

drawing (right). Tinning the bare wire ends is recommended

when possible for easier reinsertion into the 5-position plug.

3. Insert a small jeweler’s screwdriver or pick into the slot

next to the black wire on the 5-position plug and pull the wire

out. Then insert the black wire from the shortened cable into

the same position as the wire just removed. Repeat this step,

one wire at a time, for all ve positions.

4. Remove the sensor cable hole plug and discard.

5. After removing the cable gland bulkhead nut, insert the

plug and cable gland bushing through the open hole. Install

the nut back onto the cable gland threads inside the housing

with a longer cable is not recommended. To extend the

distance from the sensor body to the remote display head:

1. Install a junction box with two holes for 5/8” connector

bushings at the cable splicing location.

2. Install the sensor cable gland threaded bushing into one

junction box hole and secure with the bulkhead nut.

3. Obtain the required additional length of 2-pair Seametrics

sensor cable and two additional cable glands, installing the

additional cable and glands from the junction box to the display

head. Secure all cable gland sealing and bulkhead nuts to

tightness required to prevent moisture ingress as described

in previous instructions. Use pull test to assure sufcient

tightness.

4. Splice wires in junction box using moisture-sealed wire

connectors or pot to seal against moisture ingress. Replace

junction box sealing cover.

5. Connect 5-position plug to the small circuit board receptacle

in the display head as described in previous instructions.

6. Warning! Extending the length of the sensor cable

beyond 100 feet (30 meters) may cause the meter to

malfunction.

Page 10

Page 13

INPUTS/OUTPUTS and OPERATION

Sealing Nut

Contr

AC

Sealing Nut

Control Cable

AC

2” (50mm)

(10mm)

(Nor

GROUND

NEUTRAL

th America)

LINE

WIRING TO POWER SOURCES AND EXTERNAL MONITORING

AND CONTROL EQUIPMENT

The six-conductor Control Cable exiting the display head

provides user connections for DC power as well as for external

monitoring and control equipment needed for pump control,

SCADA equiment, Programmable Logic Controllers, remote

displays and other monitoring equipment. A four-character

Option Identier (OID) code found in the “Control Cable Wiring”

table on page 11 shows available combinations of external

wiring connections. In addition, it gives the corresponding

electrical function for each of the wires in the cable. The OID

code is also included in the model number on the meter as well

as on the label attached to the control cable as shipped from

the factory. The rst character in the OID code identies the

power source as either external DC (D) or internal AC (A). The

next two characters identify the functions of the other wiring

options such as Pulse Output (P), Analog Output (L), Digital

Output (D) or Serial Output (SS.) (The fourth character (X) is

reserved for future applications.) Application, wiring and other

electrical interface guidelines for each of these is outlined in

the following paragraphs.

2. Loosen the cable gland sealing nut, remove the plug

and insert the unconnected cable end through the open

hole.

ol Cable

Power Cable

Sensor Cable

Bulkhead Nut

3. Strip cable jacket and conductors (see below) and install

3-conductor power cable and wire to Line (L), Neutral (N)

and Ground (G) positions on power supply terminal block

as shown below

Green

th America)

Green-Yellow

(International)

White

(North America)

Blue

(International)

Black

(Nor

Brown

(International)

Sensor Cable

Power Cable

Bulkhead Nut

DC Power Connection. When the rst OID code character is

a “D”, connect the RED and BLACK wires to the positive and

negative terminals respectively of a clean (low-noise) source

of dc power in the range of 9-32Vdc and able to supply at least

250mA. AC line-operated power supplies with outputs greater

than 18Vdc must be regulated. Where possible, connections

from either power supply terminal to the cable shield or any

other ground should be avoided.

AC Power Connection. When the rst OID code character

is “A”, the RED and BLACK wires are not used. Instead, 85264Vac power is supplied to the ow meter via a separate

meter housing cable-entry gland and user-supplied threeconductor power cord having local regulatory agency approval.

If installed outdoors or less than 33 ft. (10m) from a utility

power service entrance, ac power should be supplied via a

properly-grounded surge suppression device. See diagrams

below for wiring instructions.

WARNING

!

HIGH VOLTAGE

DISCONNECT AC

POWER SOURCE

BEFORE SERVICING.

3/8”

4. Tighten terminal block screws securely using 1/8”

(3mm) screwdriver. Tighten the cable gland sealing nut

securely. A loose nut could cause moisture ingress and

compromise the meter head’s IP68 rating, voiding the warranty.

1. Using a 5/32” hex driver, remove the four cap screws

securing the top housing to the lower housing and swing the

top open to expose the internal wiring and components.

5. Close the top cover and replace the four cap screws,

securing tightly to reseal the housing against moisture

ingress.

Page 11

Page 14

INPUTS/OUTPUTS and OPERATION

Tap

Tap

Battery Power. The iMAG 4600 meter can come congured

with two replaceable 3.6V lithium ‘D’ batteries. In this

conguration, the only option/output is the scaled pulse

output which comes standard. The scaled output for the

battery powered option has a maximum frequency of 10Hz,

with a xed pulse width of 10ms. Be sure to set your P value

such that the meter will function properly over the ow range

in your application. See the tech bulletin on this topic for

more details. The sample rate of the meter is user selectable

through the SAMP tab in the meter’s sub-menu. Sample

periods of 0.2, 0.33, 1, 3, 5, 15, 30, and 60 seconds can

be selected. Larger sample periods will yield longer battery

life but slower response time. Care must be taken to select

a sample period that us suitable for your application. See

the table on the next page for the expected battery life as a

function of sample period.

Battery Life/Sample Period

Sensor sample period(s)

Expected battery life*

(Seconds)

1/5 (0.2) 1 year

1/3 (0.33) 1.5 years

1 2.5 years

3 4 years

5 5 years

15 5.5 years

30 6 years

60 6.5 years

*Based on 75% battery capacity at room temperature with no option cards

installed. NOTE: If a large percentage of the meter’s life will be spent below

0.5 meters/second and above cutoff, battery life will be reduced.

Pulse Output Connection. When the second OID code

character is “P”, refer to the “Digital Output Application”

diagrams on page 12 for recommended pulse output

connections to external equipment. Since this is an isolated

output, the external equipment must include a dc power

source to regenerate the pulse from the open-collector

output (transistor equivalent of a contact closure). A pull-up

or pull-down resistor may be needed if not included in the

user equipment as shown in the diagrams. Both the power

source and resistor may be supplied internally in some

types of control and monitoring devices. If not, as for most

PLC discrete input modules, they must be added externally

at the module input terminals. Pulse output rate in volume

units/pulse is user-settable via the SET P tab on the meter’s

setup menus.

Analog Output (4-20mA) Connection. When the second or

third OID code character is “L” or “H”, refer to the “Analog

Output Application” diagram on page 12 for 4-20mA current

loop output connections to external analog input devices.

Since the meter’s analog output is isolated and passive, loop

power must be supplied externally as shown. (In addition, an

external resistor RL will be needed to convert the loop current

to voltage for voltage-only input devices.) The meter’s loop

transmitter minimum voltage drop is 6Vdc (8Vdc with HART)

which, with wiring resistance and loop power supply voltage,

will determine the maximum resistance for RL. The ow rates

corresponding to 4 and 20mA are user-settable via the SET

4 and SET20 tabs on the meter’s setup menus.

(Optional) Setup and Connection to a HART Network. The

HART protocol, rev.7.5, allows for a Polling address of 0-63.

The default value in the iMAG is 0. To change the Polling

address, use iMAG menu HPOLL to set the Polling address.

To get to this menu, move to the EXIT tab and tap the

4 times. This will bring up another menu page

containing the tab HPOLL. Use the

to select the

Polling address.

A minimum of 250 ohms of loop resisitance must be present

in order for the HART modem to correctly and reliably

demodulate FSK voltage. With this in mind, the maximum loop

resistance* for the iMAG HART interface cannot be exceeded

in order to assure correct operation.

Use of HART Communicator. The iMAG HART interface is

HART compatible. All the commands have been implemented

in accordance with the HART Protocol Specication published

by HART Foundation. A HART Communicator can be used with

the iMAG, even in the absence of DD les, by taking advantage

of the Generic Online Menu capability of a Communicator.

This means that a generic menu is automatically available

when DD les are not present.

The following information from the iMAG HART can be

displayed on the Communicator using the generic menu:

PV Flowrate in units selected for iMAG

PV Loop Current Loop current in mA

PV LRV

PV URV

Lower range value of PV in units

selected for iMAG

Upper range of PV in units selected for

iMAG

*4-20 mA loop has maximum loop resistance of 650ohms

and requires a 24Vdc power supply.

Page 12

Page 15

INPUTS/OUTPUTS and OPERATION

Digital Output Connection. When the second or third OID code

character is “D”, refer to “Digital Output Application” diagrams on

page 12 for recommended connections to external equipment.

These outputs are electrically similiar to the Pulse Output described

above except they are capable of output frequencies up to 10kHz.

Frequency output scaling is user-settable via the FOUT tab on the

meter’s setup menus. Selections are: 500Hz and 1, 2, 5 and 10

KHz at maximum ow rate.

Serial Communication Connection. When the second and third

OID code characters are “SS”, refer to “Control Cable Wiring” table

below for recommended connections to external equipment. These

Control Cable Wiring

Power

Source

AC

DC

DC

DC

DC

DC

DC

AC

AC

AC

AC

AC

Battery

4-20mA Output 1 Digital Output DDLX DC PWR + DC PWR - Out 1 + Out 1 - 4-20mA Out + 4-20mA Out -

4-20mA Output 1 Digital Output ADLX Do Not Connect Do Not Connect Out 1 + Out 1 - 4-20mA Out + 4-20mA Out -

Options

Installed

One Pulse, HART APHX Do Not Connect Do Not Connect Pulse + Pulse - 4-20mA Out + 4-20mA Out -

One Pulse, HART DPHX DC PWR + DC PWR - Pulse + Pulse - 4-20mA Out + 4-20mA Out -

One Pulse, 4-20mA Output DPLX DC PWR + DC PWR - Pulse + Pulse - 4-20mA Out + 4-20mA Out -

Two Digital Outputs DDDX DC PWR + DC PWR - Out 1 + Out 1 - Out 2 + Out 2 -

RS-485 Serial Comm DSSX DC PWR + DC PWR - RTS Signal Ground B A

One Pulse Output DPXX DC PWR + DC PWR - Pulse + Pulse - Do Not Connect Do Not Connect

One Pulse, 4-20mA Output APLX Do Not Connect Do Not Connect Pulse + Pulse - 4-20mA Out + 4-20mA Out -

Two Digital Outputs ADDX Do Not Connect Do Not Connect Out 1 + Out 1 - Out 2 + Out 2 -

RS-485 Serial Comm ASSX Do Not Connect Do Not Connect RTS Signal Ground B A

One Pulse Output APXX Do Not Connect Do Not Connect Pulse + Pulse - Do Not Connect Do Not Connect

One Pulse Output BPXX Do Not Connect Do Not Connect Pulse + Pulse - Do Not Connect Do Not Connect

OID

Codes

Red Black Green White Orange Blue

connections provide a half-duplex, isolated, RS485 serial

communications port using the Modbus messaging protocol.

The port is recongurable by internal jumper settings to

full-duplex RS232 or 3.3V CMOS. The TXD connection

is the transmitted data output from the meter and RXD

is the received data input to the meter. See Seametric’s

Modbus Interface Description, LT-103393 (available at www.

seametrics.com) for supported Modbus message protocol

and electrical interface specications.

Cable Shield. In general, the cable shield and its bare drain

wire should be left unconnected at the user equipment end

of the cable to minimize “ground loop” problems.

Cable Conductor Usage

K-factors for High Speed Digital Output (High Frequency)

Size 500 1K 2K 5K 10K

3” 41.55125 83.10249 166.205 415.5125 831.0249

4” 23.3463 46.69261 93.38521 233.463 466.9261

6” 10.37703 20.75406 41.50813 103.7703 207.5406

8” 5.836576 11.67315 23.3463 58.36576 116.7315

10” 3.735525 7.47105 14.9421 37.35525 74.7105

12” 2.594034 5.188067 10.37613 25.94034 51.88067

FOUT (Hz)

Page 13

Page 16

Current Sourcing Pulse

INPUTS/OUTPUTS and OPERATION

Pulse or Digital Output Application - Sourcing Mode (Recommended for Rin < 30kΩ)

Open

Collector

Transistor

+

_

Green*

White*

+

_

Power

+

Source

V

s=3-36Vdc

47k Ω

Pull-down

Resistor

_

і

out

Vs

+

V Out

V Out

_

Rin

0

Meter Cable User Equipment

Pulse or Digital Output Application - Sinking Mode (Recommended for Rin > 30kΩ)

Waveform

Power

_

Source

+

V

s=3-36Vdc

Open

Collector

Transistor

+

_

Green*

White*

+

_

Pull-up

Resistor**

Meter Cable User Equipment

Analog (4-20mA Current Loop) Output Application

Power

Source

+

s=6-36Vdc

V

_

Analog

Output

+

_

Orange*

*

Blue

+

_

Meter Cable User Equipment

і

out

RL***

і

Loop

+

V Out

_

_

+

Current Sinking Pulse

Vs

V Out

Rin

0

4-20mA

Current Output***

Waveform

* Wire colors shown are typical but because there are exceptions, always refer to the color codes shown on the cable label or “Control Cable Wiring” table on page 11.

** Minimum resistor value is (100 x Vs) ohms. Higher resistances maybe used depending on frequency and cable length. Longer cables and high frequencies require

lower resistance.

*** Resistor RL converts 4-20mA current to voltage for voltage input only devices.

Page 14

Page 17

Tap

Tap

Hold Tap

INPUTS/OUTPUTS and OPERATION

1.2345678

1.2345678

100

TOTAL

CU FT

X1000

RATE

GPM

T UNIT R UNIT S ET PDAMP

SET 4SET 20 S ET F EXIT

TOTAL = GALLONS

PRESS + TO SET TOTAL

UNITS FOR DISPLAY

FWD TOTAL

Hold Tap

Tap

Hold Tap

Tap

Tap

Tap

Tap

Hold Tap

Tap

Hold Tap

1.2345678

100

TOTAL

CU FT

X1000

RATE

GPM

FWD TOTAL

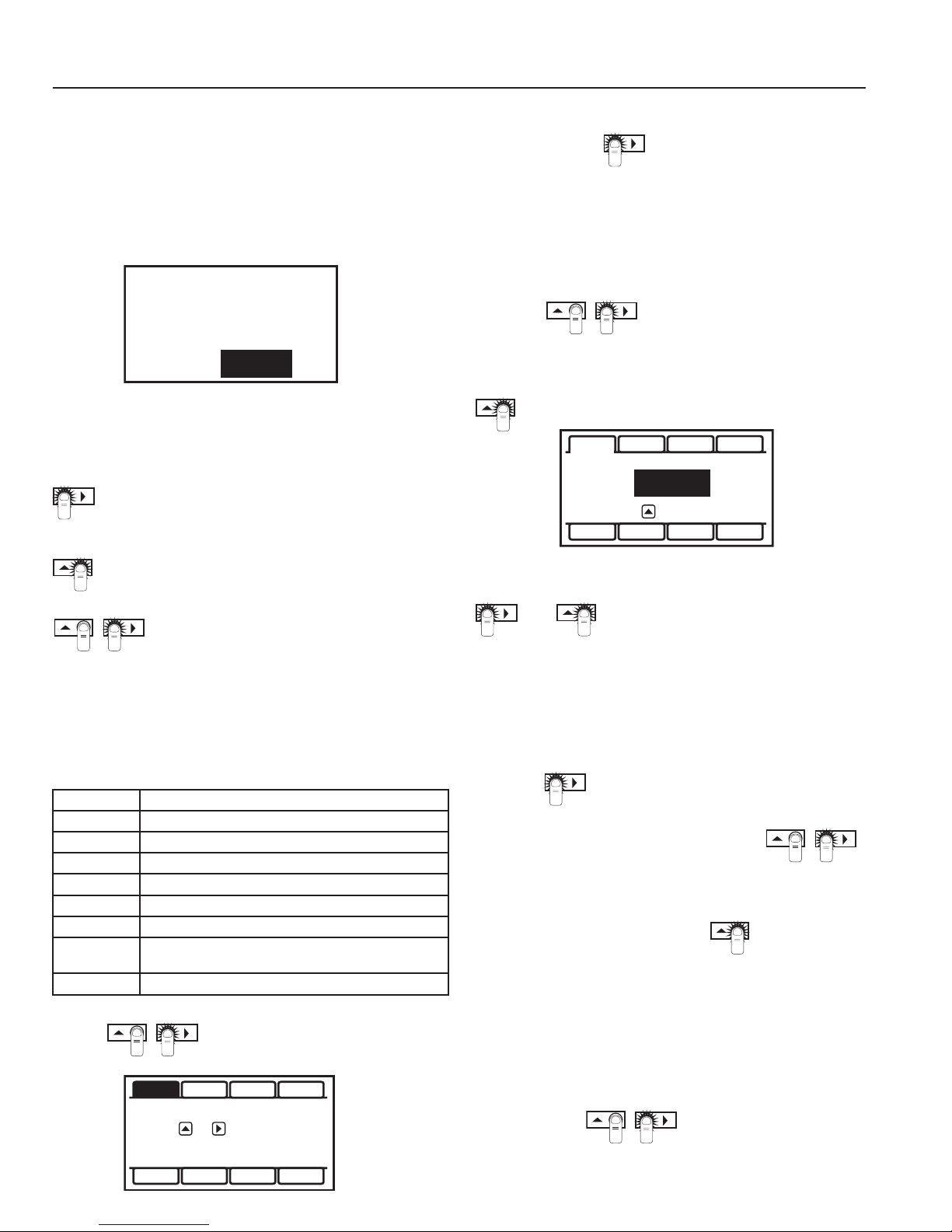

CHANGING FLOWMETER SETTINGS

The HOME Screen. The HOME Screen shown below is the normal

screen which displays TOTAL FORWARD ow volume, direction of

the ow total and ow RATE along with status conditions such as

Empty Pipe. Two buttons below the LCD display are used to access

menu screens for viewing and changing meter setup parameters.

TOTAL

CU FT

X1000

RATE

100

FWD TOTAL

GPM

Button Sensors. The two buttons are light sensors which can

detect when a nger is covering them. Only three button touch

actions are needed to control navigation through the menus,

settings changes and back to the home screen. They are:

HORIZONTAL SCROLLING: Tap right-hand button

to scroll horizontally through menu tabs or move

horizontally within a tab dialog when applicable.

SELECT: Tap left-hand button to change a highlighted

item within a tab dialog.

ENTER/EXIT: Hold left button while tapping

+

right button once to enter or exit a tab dialog

or to navigate between the HOME and other

menu screens.

Main Menu. All menu screens consist of two rows of tabs

surrounding a dialog box that lets you view and change setup

parameters. For the MAIN MENU, the tabs have the following

functions:

TAB FUNCTION

T UNIT View or change TOTAL volume units

R UNIT View or change ow RATE units

SET P View or change pulse output scaling

DAMP View or change lter settings

SET 4 View or change ow rate corresponding to 4mA

SET 20 View or change ow rate corresponding to 20mA

SET F View or change high frequency output scaling

EXIT Return to HOME SCREEN or Enter SUBMENU

To enter the MAIN MENU perform the hold and tap sequence:

(See chart on page 12)

+

T UNIT R UNIT SET PDAMP

TOTAL = GALLONS

PRESS + TO SET TOTAL

UNITS FOR DISPLAY

SET 4SET 20 S ET F EXIT

Once in the main menu you can move from tab to tab by

tapping the button:

In the dialog box for the currently highlighted tab you will

see that tab parameter’s current value. In the previous

screen illustration, the rst line indicates that the current unit for the TOTAL is GALLONS. The next two lines in

the dialog box tell you what to do next. If you would like

to change the TOTAL units, just perform the hold and tap

sequence to bring up a dialog box that will

tell you how to change the setting.

+

You select the new setting by scrolling through a list of

selections as in the screen illustration below by tapping

to nd a different TOTAL unit.

T UNIT R UNIT S ET PDAMP

TOTAL:

PRESS TO CHANGE

SET 4SET 20 S ET F EXIT

GALLONS

Similiarly, for the SET tabs, the dialog box instructions will

tell you how to change a numerical value using both the

and buttons.

To accept any changes you’ve made just hold and tap

again, and the changes will be saved and you will be

returned to the MAIN MENU screen where you can move to

another tab.

When you are nished making changes, move to the EXIT

tab using:

To return to the HOME screen, hold and tap:

+

Submenu. The EXIT tab in the MAIN MENU has a second

function. If, instead of using the hold and tap sequence to

return to the HOME screen, you tap four times.

You will be redirected to a SUBMENU screen which provides access to more information about the meter, such as

serial numbers, rmware revisions, Modbus, HART, battery

options and the bi-directional ow options display which

toggles between FWD, REV and NET TOTAL. Navigation in

this SUBMENU is the same as for the MAIN MENU. Whenever you wish, go to the EXIT tab in the SUBMENU and use

the hold and tap sequence to return to the

MAIN MENU.

Please Note:

All iMAG meters are factory set for gallons per minute (GPM) rate and gallons total. If other

units are required, they can be programmed in the eld.

+

Page 15

Page 18

TROUBLESHOOTING

PROBLEM PROBABLE CAUSES Tr y…

Blank Display Faulty wiring from power source to

meter or faulty AC power supply

Check for miswiring. Measure voltage with DMM

where red and black wires connect to terminal

block TB2 inside meter display head. Verify correct polarity and conrm that voltage is steady and

between 9Vdc and 32Vdc

Flow rate reads zero continuously

Flow is below cutoff Increase ow above cutoff

regardless of ow

Flow rate shows [-] negative ow

Meter is installed backwards Reinstall correctly

and FWD total remains at [0] zero,

when ow is greater than cutoff

Flow rate reading uctuates excessively when ow is unchanging

Excessively turbulent or unsteady

ow due to partially closed valves

or other ow obstructions

Eliminate or minimize causes of ow disturbances

or increase meter damping

Flow Rate appears correct but

pulse/ frequency output is low,

erratic or absent

Flow Rate appears correct but

pulse/frequency output is erratic

and/or too high

Pipe not full.

Pulsing ow due to combining mul-

tiple upstream ow sources

Insufcient mixing of upstream

chemicals

Low uid conductivity < 20 µS/cm

Noisy electrical environment

Defective or noisy ac switching

power supply

Wiring incorrect

External device input impedance

too low

Cable too long

Electrical noise sources interfering

with pulse frequency signal

Wrong type of cable

Provide back pressure or other means to ensure

pipe is lled

Move connection point further upstream

Move chemical injection downstream from meter

Replace with different type of meter

Improve grounding at meter and nearby potential

ly noisy electrical equipment. Increase distance

between meter and electrical noise sources.

Replace power supply

Compare wiring with appropriate wiring recommendations

Use sourcing rather than sinking interface connec-

tion

Reduce interface pull-up resistance

Isolate, remove or reduce noise sources. Move

meter control cable away from noise sources.

Use only twisted pair cable and ensure both signal

wires are on same twisted pair

Grounding problem

Flow rate reads “COMM FAIL”

instead of rate

Cable between ow sensor body

and display head is disconnected,

miswired or damaged

Page 16

Improve or try different grounding method.

Inspect cable for damage. Check cable connection

inside display head for correct wiring to ve-position connector, ensure that connector is properly

inserted, inspect for broken connections.

Page 19

NOTES

Page 17

Page 20

Seametrics Incorporated • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com

LT-103199r1.5 20161101

11/1/16

Loading...

Loading...