Sealer Sales SS-48ST-110V User Manual

SERVICE MANUAL

Model SS-48ST

____________________________________________________________

_

INSTRUCTIONS FOR OPERATION AND REPAIR OF THE

MODEL SS-48ST “ALL-IN-ONE” MACHINE

Sealer Sales, Inc. Page 2

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

IMPORTANT - PLEASE READ THIS CAREFULLY

The development of a good safety program, that is rigidly

enforced, is absolutely imperative when involved in the operation of

industrial equipment. Our machinery is well designed and includes

extremely important safety features. The part you the user play

through proper installation and maintenance procedures is of far

greater significance than our designs. Only properly trained

individuals following rigidly enforced safety rules, as recommended

by A.N.S.I. and O.S.H.A., should be allowed to operate these

machines.

Sealer Sales, Inc. Page 3

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

SAFETY PRECAUTIONS

1. To avoid damage to the machine and injury to the

operator, DO NOT use liquids of any kind: flammable

materials, explosive materials, materials under extreme

pressure, pressurized gases, volatile powders, or bulk

materials that could fall through holes in grate, or any

materials and/or products not listed but which could

cause harm to operator.

2. Do not touch the band ribbon soon after sealing due to

residual heat that may burn.

3. Do not touch the heater cover plate while machine is

on.

4. Do not touch the fan while in operation or use machine

without grate in place.

Sealer Sales, Inc. Page 4

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

TABLE OF CONTENTS

___________________________________________________________

Preface

Unpacking 6-9

Warranty Notice 10

Warranty 11-12

Warranty Exceptions 13

Warnings 14-16

SS-48ST Instructions

Description and Specifications 17

Installation and Basic Set-Up 18-19

Installation of Film Rack 20

Installation of Plexiglass Hood 21-22

Mounting Film 23

Pin Perforator 24

Product Tray 25

Film Threading Diagram 26

Front Panel 27-29

Sequence of Operation 30-35

Adjusting product grate 35-36

Troubleshooting 37-50

No Heat to Band Ribbon 37-42

Weak Seals/Poor Cut Off 43-44

Magnet Won’t Hold on Chamber 45-46

No Air Flow 47-48

Maintenance 49

Band ribbon replacement 50-52

Tape replacement 53

Silicone seal pad replacement 54

Adjust height of hooded chamber 55

Pulse switch adjustment 56

Magnets adjustment 57

Replace transite bars 58

Sealer Sales, Inc. Page 5

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

Electrical Panel Diagram

Electrical Schematic –

SS-48ST Parts Nomenclature

Replacement Parts List

59

60

61

62-71

Spare Parts List 72

Sealer Sales, Inc. Page 6

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

UNPACKING

THOROUGHLY INSPECT EQUIPMENT UPON ARRIVAL.

If goods are received short or in a damaged condition, it

is important that you notify the carrier’s driver before he leaves

your company and insist on a notation of the loss or damage

across the face of the freight bill. Unless this is done, no claim can

be enforced against the transportation company.

If concealed loss or damage is discovered, notify the

carrier at once and insist on an inspection. This is absolutely

necessary! A concealed damage report must be made no later than

five (5) days from the date the shipment was delivered. Unless you

do this, the carrier will not consider any claim for loss or damage.

The carrier’s agent will then make an inspection and grant a

concealed damage notation. If you give the transportation company

a clear receipt for the goods that have been damaged or lost in

transit, you do so at your own risk and expense.

All claims must be filed within 5 days of delivery date or

carrier will not accept them.

Sealer Sales is willing to assist in every possible manner

to collect claims for loss or damage; however, this does not hold

Sealer Sales responsible for collection on claims or replacement of

material.

UNPACKING

Sealer Sales, Inc. Page 7

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

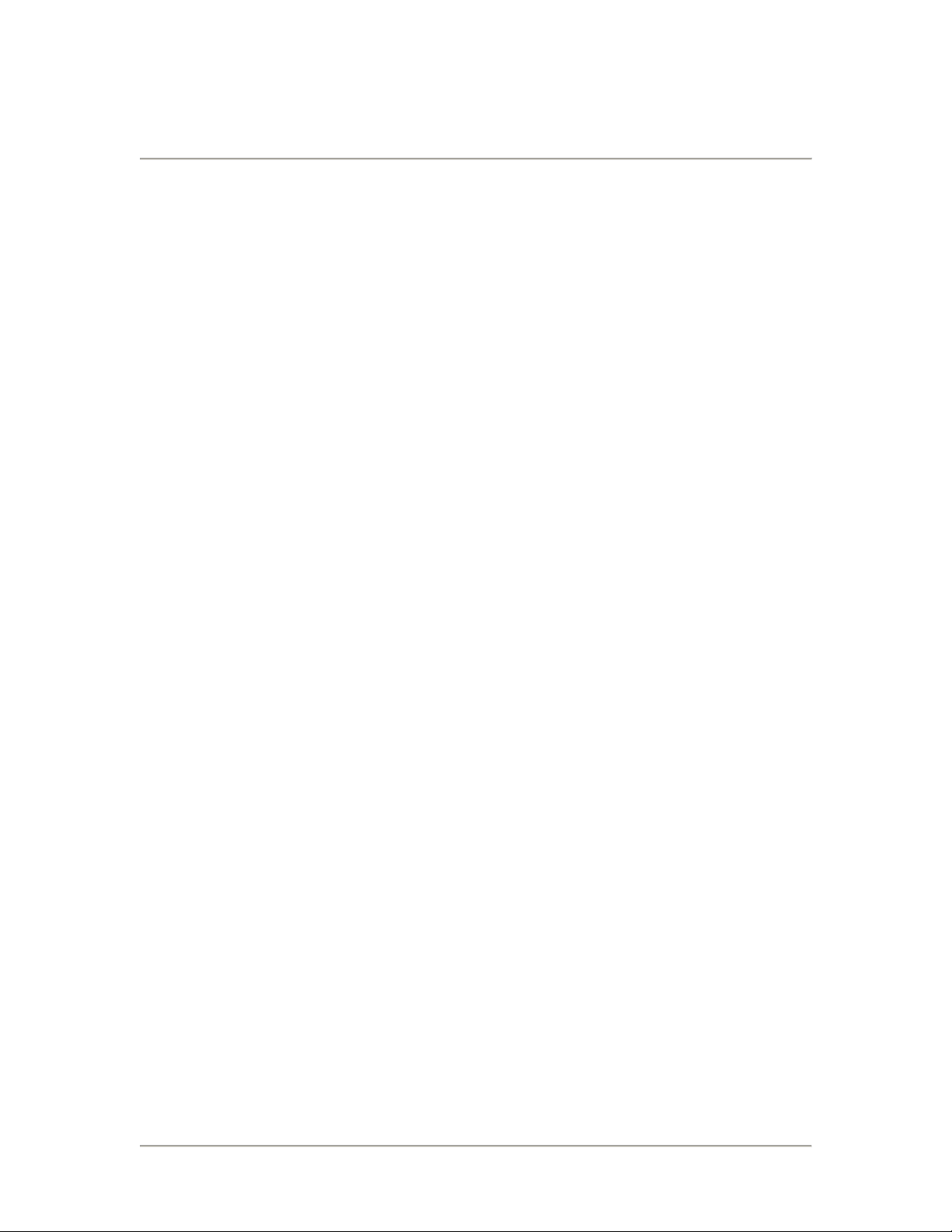

Your new Model SS-48ST comes bolted to a pallet and has a

tri-walled corrugated box strapped to the pallet to protect it. Cut

steel straps and remove corrugated box.

1. If your machine does not arrive in this condition, write on

shipping paperwork that outside of box is damaged. (Concealed

damage may have occurred. Before you sign off on delivery

paperwork, open box and inspect for damage.)

2. Remove protective plastic covering from machine.

UNPACKING

Sealer Sales, Inc. Page 8

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

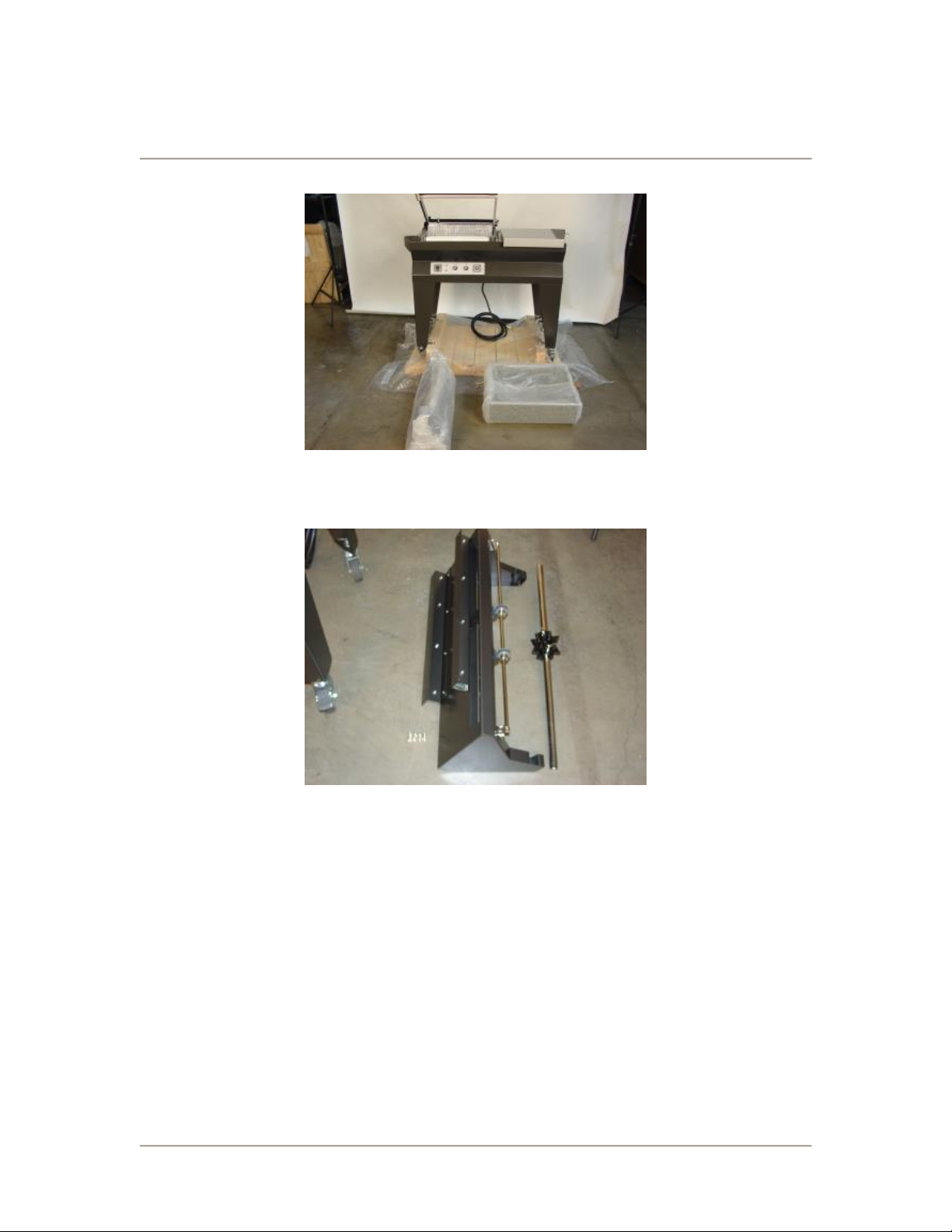

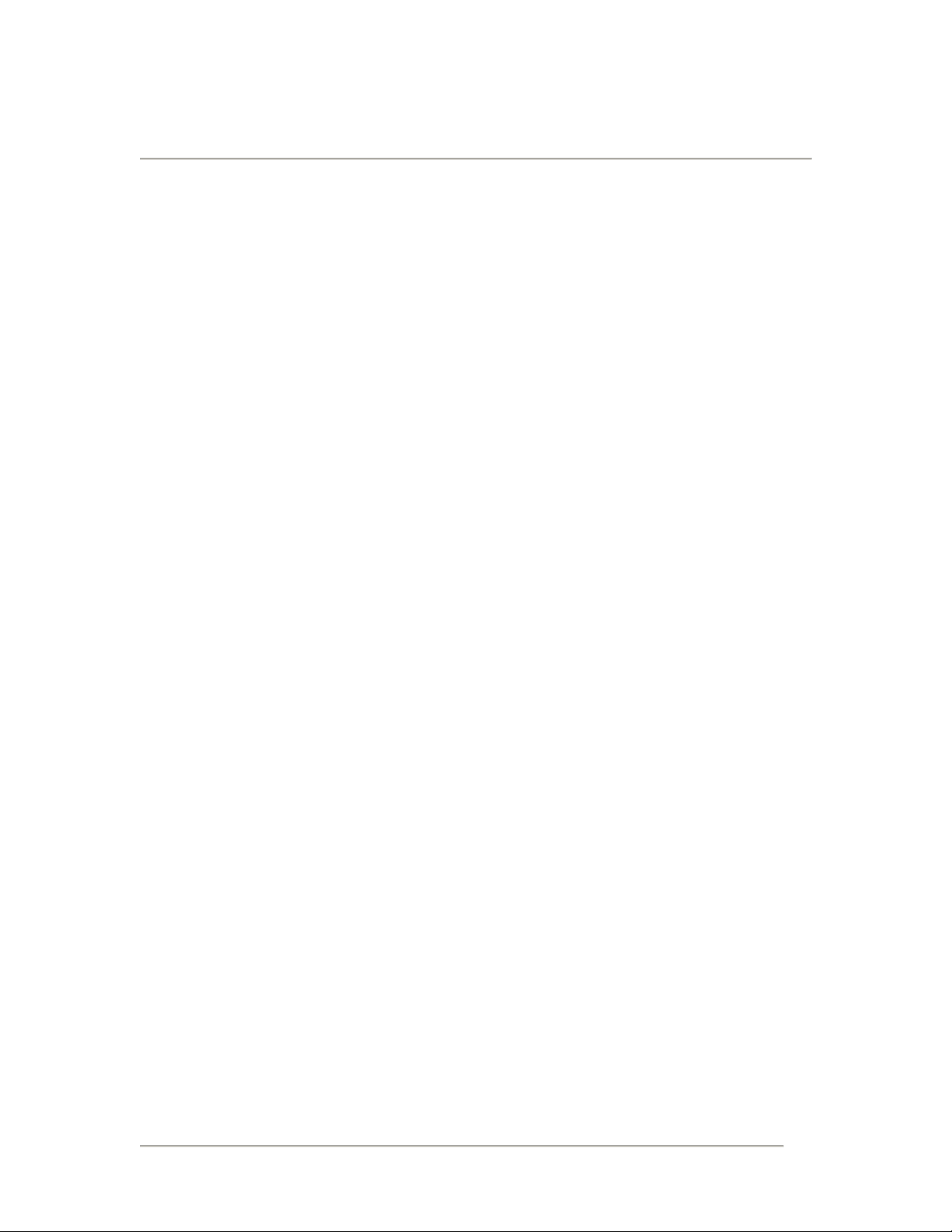

3. Check contents. You should have

(a) (1) Film Rack

(b) (1) Film Shaft

(c) (2) Film Roll Core Chucks

(d) Plexiglass chamber hood

Remove plastic covering film rack and hood.

4. Remove bolts holding machine to pallet using 10mm wrench.

UNPACKING

Sealer Sales, Inc. Page 9

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

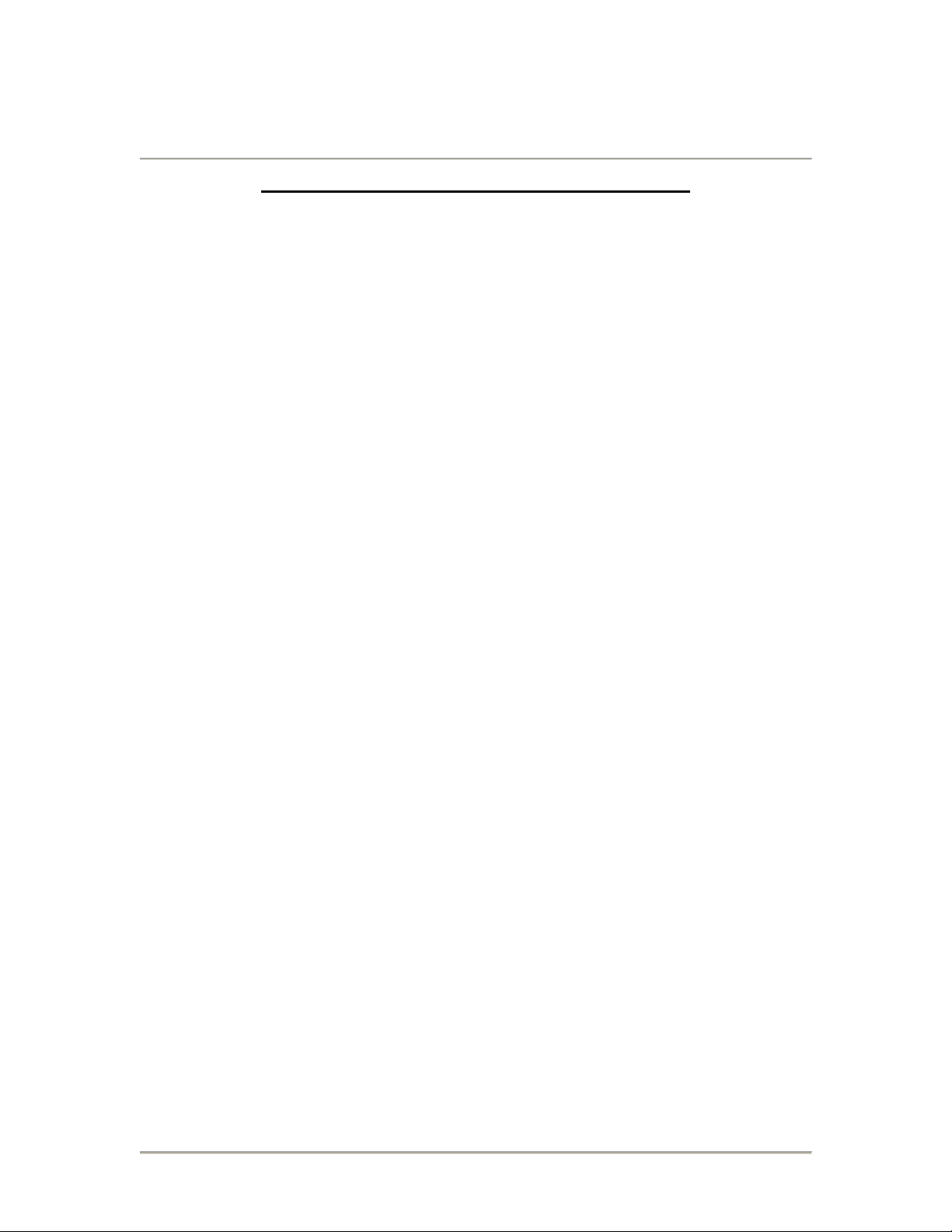

Unwrap plexiglass hood and film rack from the protective bubble

wrap.

Film rack includes rack, roll shaft, 8 mounting screws.

Sealer Sales, Inc. Page 10

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

IMPORTANT WARRANTY NOTICES

OPERATING AND MAINTENANCE MANUAL

The operating and maintenance manual has been

carefully prepared to provide the user with all the information needed

to properly install, operate, and maintain your Preferred Packaging

equipment.

Please read this manual carefully and refer to it for

information on the care and use of your Preferred Packaging

equipment. It is recommended that additional copies be ordered for

use by production, maintenance, and supervisory personnel.

Although the design of this equipment incorporates safeguards to

protect personnel, care should be used in operating, adjusting, and

servicing.

Attention is directed to the warranty which accompanies

all your Preferred Packaging equipment. The terms and conditions of

this warranty apply only to unmodified units. Any unauthorized

modifications to the equipment automatically voids this

warranty.

Sealer Sales provides a one year warranty on

parts, excluding shipping or freight costs for replacement

parts. All warranty parts are shipped F.O.B.

Rancho Cucamonga, California.

Sealer Sales, Inc. Page 11

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

Sealer Sales

WARRANTY

Sealer Sales Inc. warrants each new product

manufactured to be free from defects in material and

workmanship for a period of (2) year from date of shipment by

Sealer Sales

This warranty is not transferable with any subsequent resale.

Defective parts under warranty must be returned to

Sealer Sales freight prepaid. EXCEL PACKAGING’s sole obligation

and purchaser’s sole remedy in the event of a warranty dispute

shall be, at EXCEL PACKAGING’s option, to repair or replace

the part in question. Labor incurred in removing or installing the

defective part is not covered by this warranty. Prior to returning

any parts for any reason, contact Sealer Sales for a Return

Authorization Number. This number must accompany all returns.

This warranty shall not apply if equipment has been

tampered with, misused, improperly installed, altered, or has

received damage due to abuse, carelessness, accident or

failure to follow recommended regular maintenance procedures

or has been serviced by someone other than a duly authorized

factory representative without the express written consent of Sealer

Sales , Inc.

This warranty is in lieu of all other warranties, expressed or

implied, including but not limited to warranties of merchantability

and

WARRANTY

Sealer Sales, Inc. Page 12

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

fitness for a particular purpose, non-infringement or any other

matter.

Sealer Sales shall have no liability to any person for direct,

indirect, incidental or consequential damages or delay

resulting from any defect negligence, or tort and customer

hereby waives for itself any and all claims for punitive damages

and all claims of negligence of strict liability or both. In no event

shall our liability exceed the purchase price of the product that

was actually paid.

Sealer Sales reserves the right to make changes,

additions, or improvements to our products with no obligation

to make such changes in any previously shipped product covered by

this warranty.

Sealer Sales shall not be held liable for any damages arising

out of or in connection with the operation of the equipment should

customer or its agent fail to maintain equipment in safe

operating condition. This warranty shall become unenforceable if and

to the extent the customer or its agents remove, disconnect,

or otherwise render useless any safety device and/or parts designed

or affixed by us or fails to maintain and service equipment in a

manner as advised.

Sealer Sales provides a one-year warranty on parts,

excluding shipping or freight costs for replacement parts. All

warranty parts are shipped F.O.B. Rancho Cucamonga,

California. Service Labor to install part is not covered under

warranty!

WARRANTY

Sealer Sales, Inc. Page 13

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

WARRANTY EXCEPTIONS

The following sealer parts are considered to be consumable and

not under warranty:

1. Silicone Sponge

2. Band Ribbon

3. Teflon Tapes

4. Transite Channels/Band Holder

WARRANTY EXCEPTIONS

Sealer Sales, Inc. Page 14

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

WARNINGS

Every effort has been taken to ensure your safety while

operating this machine; however, there still remain certain risks. Do

not allow this machine to be operated before informing all personnel

of the following warnings.

WARNING........

Do not tamper with the electrical wiring. Only use a

licensed electrician for maintenance. Always disconnect the electrical

power before attempting any maintenance to all electrical and/or

moving parts.

WARNING........

In order to prevent injury to personnel and/or machinery

DO NOT INCREASE SETTINGS OR RATINGS ON EITHER ELECTRICAL

OR MECHANICAL OVERLOAD SAFETY DEVICES.

WARNING........

KEEP HANDS AWAY FROM MOVING CONVEYORS AND

ASSEMBLIES. Conveyor belts that have become worn or frayed are

capable of being hazardous. They should be replaced promptly.

WARNING........

NEVER OPERATE THIS OR ANY MOVING EQUIPMENT

WITHOUT ALL COVERS AND GUARDS IN PLACE. The internal

mechanism of most packaging machinery contains numerous shear,

pinch, and inrunning nip points, many of which are capable of

causing severe injury and/or permanent disfigurement.

WARNINGS

Sealer Sales, Inc. Page 15

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

WARNING........

To minimize the potential for personnel injury, always be

sure that machine operators and others working on the machinery

are properly trained in the correct usage of the equipment and

properly instructed regarding the safety procedures for operation.

WARNING........

Heat sealing arms and jaws on packaging machinery can

become very warm after a period of use. KEEP HANDS AWAY WHILE

IN OPERATION AND USE CAUTION IF THE MACHINE HAS BEEN

RUNNING RECENPPY.

WARNING........

ANY MODIFICATIONS TO EITHER THE ELECTRICAL

CIRCUITRY OR THE MECHANICAL ASSEMBLIES OF THE MACHINERY

WILL VOID ANY WARRANTIES ASSOCIATED WITH THIS

EQUIPMENT. Such modifications may introduce hazards that

would not otherwise be associated with this machinery. Sealer Sales

will not be responsible for any consequences resulting from

such unauthorized modifications.

WARNING........

The use of certain types of plastic films in sealing

and/or shrinking equipment may result in the release of

HAZARDOUS FUMES due to the degradation of the film at high

temperatures. Before using any plastic film in this equipment,

the manufacturer or supplier of the film should be contacted for

specific information concerning the potential release of

hazardous fumes. ADEQUATE VENTILATION MUST BE

PROVIDED AT ALL TIMES.

WARNINGS

Sealer Sales, Inc. Page 16

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

WARNING........

It is important that the machine operator unplug the

machine when he/she has finished operating the unit.

WARNINGS

Sealer Sales, Inc. Page 17

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

DESCRIPTION AND SPECIFICATIONS

OF

MODEL SS-48ST

DESCRIPTION

This compact “all-in-one” unit allows the operator to seal and

shrink all in one step. The operator simply places the product in the

sealing area and lowers the hood to apply the seal pressure

necessary to cut the film. Once the seal cycle is complete, the

operator releases the handle and the shrink chamber is automatically

held shut by the magnet. Once the shrink time is complete, the

chamber opens and the operator removes the finished product.

The purpose of a SS-48ST is for low to medium

volume packaging requiring excellent seals and minimal

maintenance. It features an impulse mode for sealing of films

using “Band Seal Technology.”

SPECIFICATIONS

Model:

Seal Area:

Width:

Machine Size:

Width:

Height:

Volts:

Phase:

Amperage:

Net Weight:

Shipping weight:

SS-48ST

Length: 18.5”

12”

50” L x 26” W x 45” H

26”

45”

110

1

20

215

275

DESCRIPTION AND SPECIFICATIONS

Sealer Sales, Inc. Page 18

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

INSTALLATION AND BASIC SET-UP

OF MACHINE

IMPORTANT

Read this manual carefully, and make it available to

everyone connected with the supervision, maintenance, or production

of this machine. Additional copies are available at your request.

(Contact your distributor for this information.) Be very careful when

operating, adjusting, or servicing this equipment. If in doubt, stop

and obtain qualified help before proceeding.

INSTALLATION OF SS-48ST

Place the SS-48ST in the desired location with

the required electrical power source available. (See

power requirements.) Make certain that proper electrical wiring is

provided to guard against low voltage. If the voltage is too

low, the equipment will not function properly.

Finding the proper location is a most important function

of the initial set-up. One must take several factors into

consideration:

1. Adequate power source.

2. Relationship to source of product.

3. Relationship to machine.

4. Relationship to any conveyors necessary to remove

finished product.

5. Convenience of operator.

The SS-48ST machine comes complete with power

cord and 110 volt plug. Simply plug machine into 110 volt outlet.

Make sure you have no other machine connected to this

power source. If there is any doubt, get qualified assistance to do

the initial installation. Do not take any chances

INSTALLATION AND SET UP

Sealer Sales, Inc. Page 19

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

Do not attempt to install, adjust, or operate this machine

without first reading the contents of this manual. Although the

design of the equipment incorporates safeguards to protect operating

and maintenance personnel, care should be used in operating,

adjusting, and servicing.

INSTALLATION AND SET UP

Sealer Sales, Inc. Page 20

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

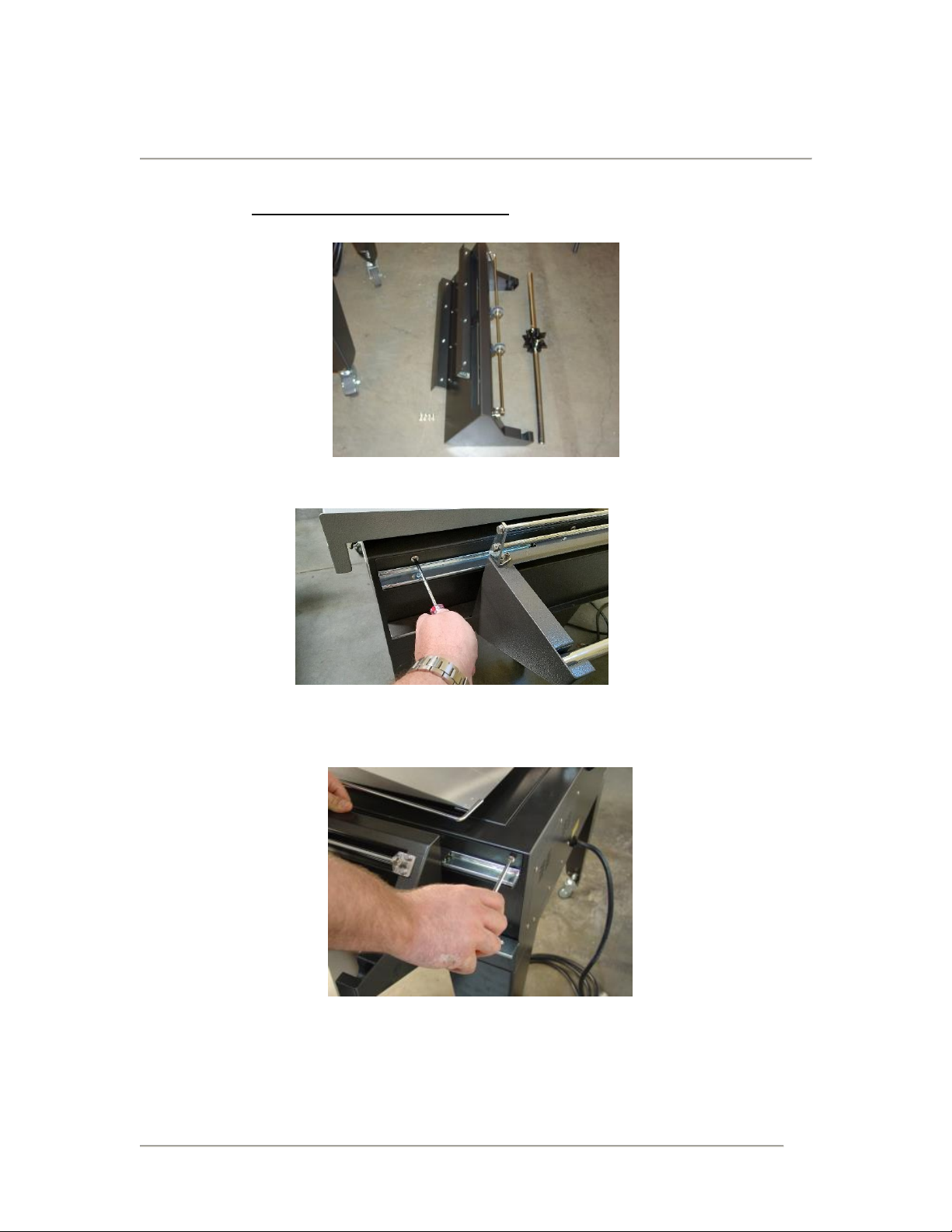

Installation of film rack

1.

Remove bubble wrap on film rack as shown.

2.

Hold film rack and slide bearing to the far right side

exposing mounting hole for screw. Tighten firmly.

Slide film rack to the far left side to expose mounting holes on right

side. Tighten firmly.

INSTALLATION OF FILM RACK

Sealer Sales, Inc. Page 21

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

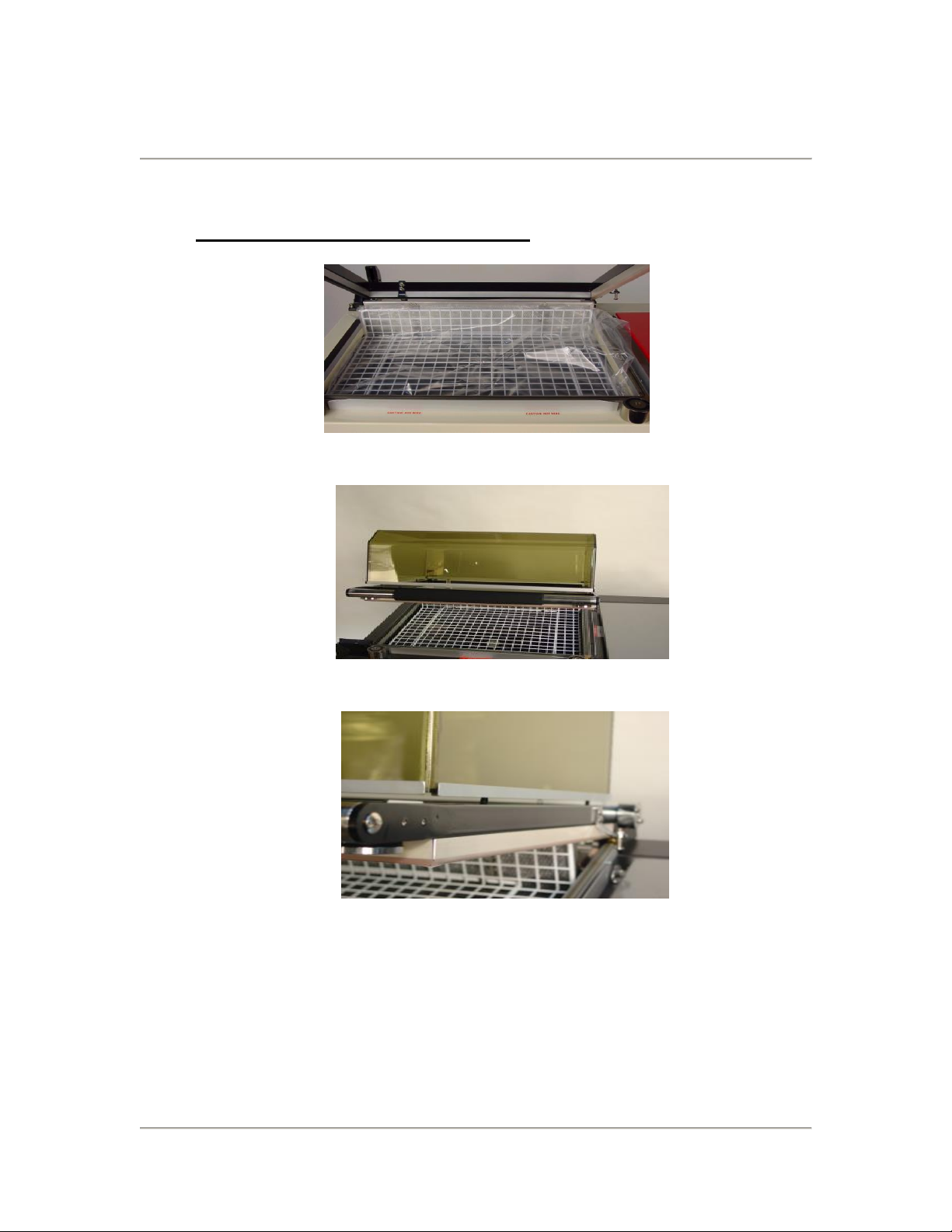

Installation of Plexiglass Hood

4. Remove plastic bag covering grate and throw away.

Place plexiglass hood over metal frame and line up metal

locking clips over holes in frame.

Locking clips hold hood in place.

INSTALLATION OF PLEXIGLASS HOOD

Sealer Sales, Inc. Page 22

SS-48ST “ALL-IN-ONE” HOOD MACHINE SERVICE MANUAL

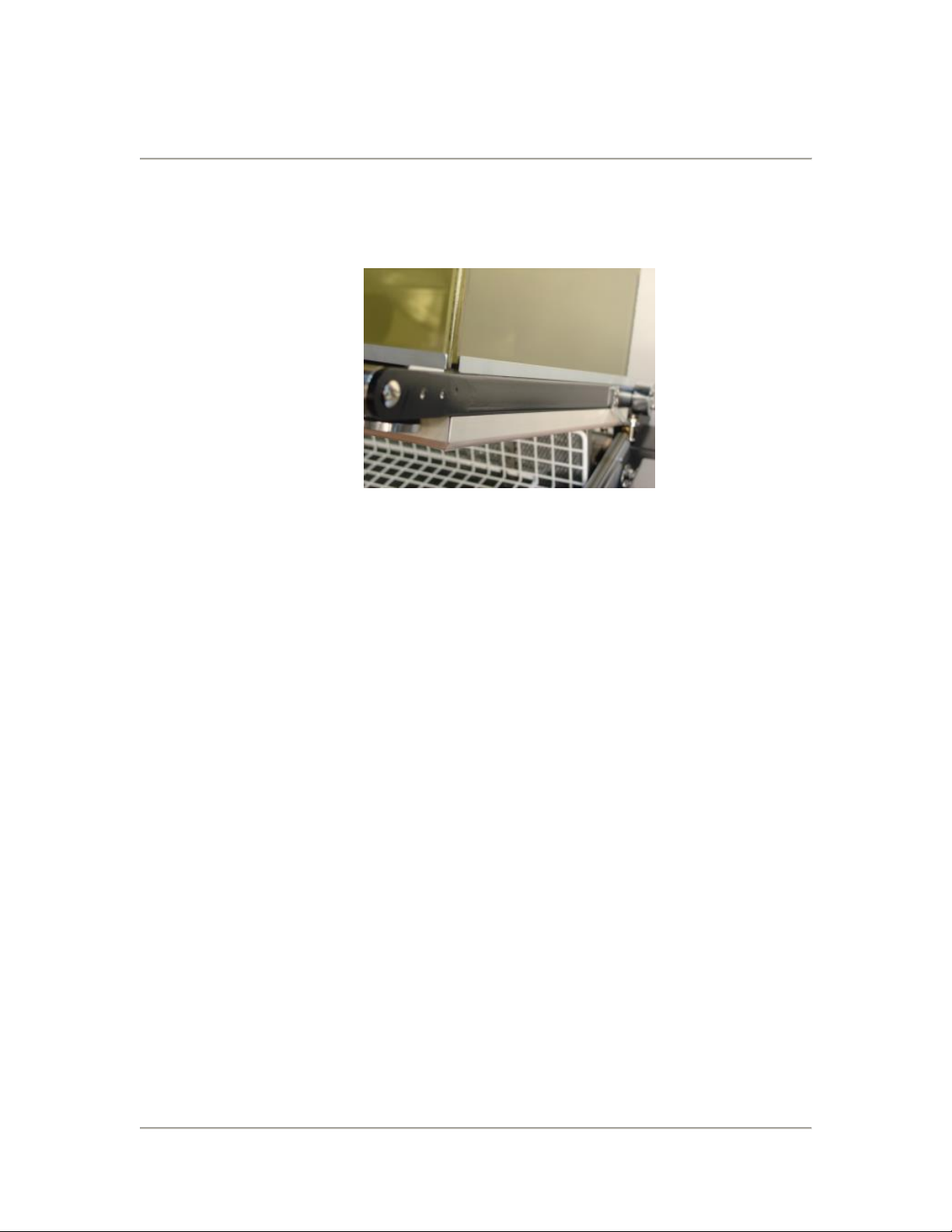

Push down firmly and evenly by hand to secure metal

clips snap into holes.

INSTALLATION OF PLEXIGLASS HOOD

Loading...

Loading...