Page 1

SealerSales KF-210HC

8" Hand Impulse Sealer w/ Sliding

Cutter (10mm Seal Width)

Instruction Manual

Page 2

IMPULSE

SEALER

100H,

(

\

200HC. 300HC, 400HC,

200H, 300H,

INSTRUCTION

Thanks

sealers.

products.

instruction

your

for

To

obtain

Please

before

purchase

the

benefit

read

the following

operation.

400H,

520H

500HC

MANUAL

of

our impuse

from

our

)

'

Page 3

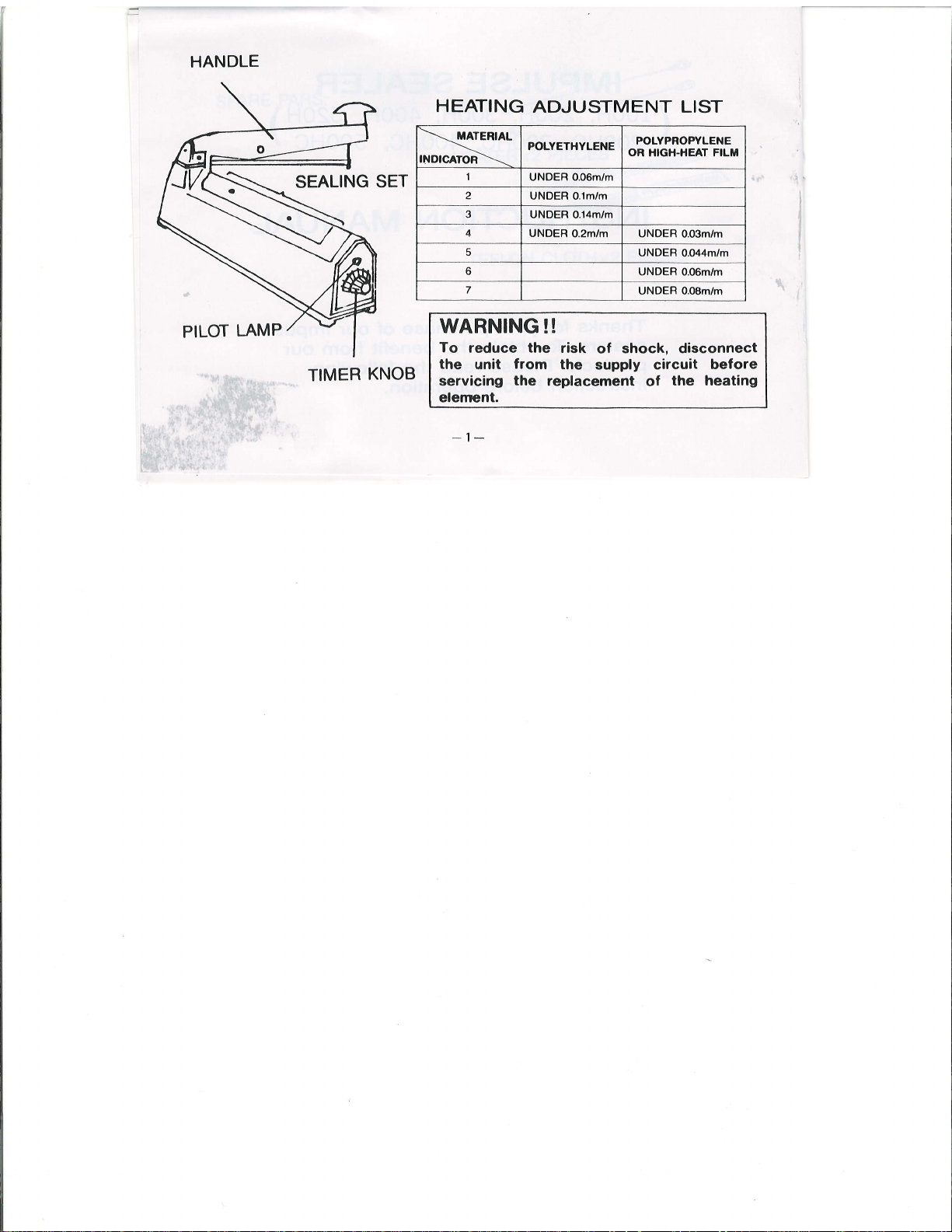

HANDLE

TIMER

KNOB

HEATING

{enrlt-

trOlClfOR---'-

2

3

4

q

6

7

WARNING !!

To

reduce the

the

unit

servicing

element.

-1-

ADJUSTMENT

POLYETHYLENE

UNDER 006m/m

UNDER 0.1m/m

UNDER 0.14m/m

UNDER 0.2mlm UNDER

risk

from

the

the

replacement

POLYPROPYLENE

OR HIGH-HEAT FILiI

UNDER

UNDER

UNDER

of shock,

supply circuit

of

LIST

0.03m/m

0.044m/m

0.06m/m

OOBm/m

disconnect

before

heating

the

\

Page 4

I

II

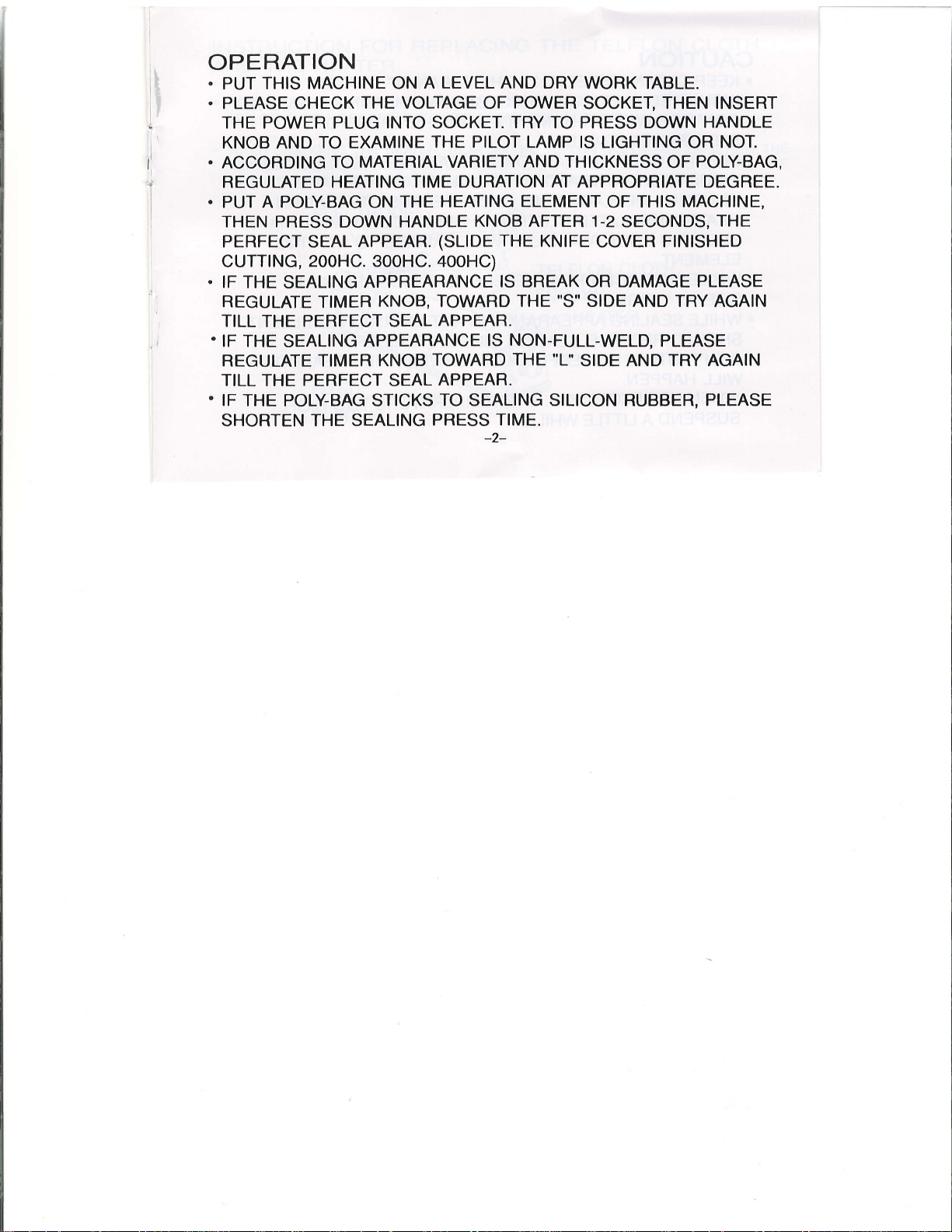

OPERATION

.

.

.

THIS MACHINE

PUT

PLEASE CHECK

THE

POWER

KNOB AND

ACCORDING

PLUG INTO SOCKET. TRY TO PRESS DOWN

TO EXAMINE

TO

THE VOLTAGE

MATERIAL VARIETY

REGULATED HEATING TIME

.

PUT A POLY-BAG ON

THEN PRESS DOWN HANDLE

PERFECT

cuTTlNG,

.

IF

THE

SEALING

REGULATE

SEAL

200HC. 300HC.

APPEAR.

APPREARANCE

TIMER

TILL THE PERFECT SEAL

.IF

THE

SEALING

APPEARANCE

REGULATE TIMER

TILL THE PERFECT SEAL

.

IF

THE POLY-BAG STICKS

SHORTEN

SEALING

THE

A LEVEL AND DRY

ON

THE PILOT LAMP IS LIGHTING

THE HEATING

(SLIDE THE

400HC)

KNOB,

TOWARD

APPEAR.

KNOB

TOWARD

APPEAR.

TO SEALING SILICON

PRESS

WORK TABLE.

POWER

OF

AND

DURATION AT

ELEMENT

KNOB AFTER

IS BREAK OR DAMAGE PLEASE

THE

NON-FULL.WELD,

IS

THE

SOCKET, THEN INSERT

THICKNESS

OF

APPROPRIATE DEGREE.

MACHINE,

THIS

OF

1.2 SECONDS,

KNIFE

COVER FINISHED

'S"

SIDE AND TRY AGAIN

PLEASE

"L'

SIDE AND TRY AGAIN

RUBBER.

TIME.

-2-

HANDLE

NOT.

OR

POLY-BAG,

THE

PLEASE

Page 5

CAUTION

O

KEEP CLEAN,

.

INSULATED

.

DON'T BE WET OR HUMIDITY

ELECTRIC

.

BEFORE

INSULATED

UNUSUAL,

HEATER

ELECTRIC

ELEMENT,

.

WHILE

SIZE

.

WHILE

SHOULD

.

DON'T STRIKE POWERFULLY

WILL

.

WHEN USE

SUSPEND

INSULATED

REPLACED

AS

ORIGINAL.

SEALING

HAPPEN.

ESPECIALLY

CLOTH, UPPER CLOTH AND

OBSTACLE.

OPERATION OR

CLOTH

REPLACE IT AT

SHORTWAY

REPLACE

EXCESSIVE.

A LITTLE

AND

CLOTH

HEATING ELEMENT

APPEARANCE

SEALING SILICON

WHILE,

THE

CLEAN

FOR

ON

OPERATION,

UPPER

ALSO WILL DAMAGE

THE

CLOTH. IF

ONCE,

AND

UPPER

NOT ENOUGH

IS

OTHERWISE

TEMPERATURE

-3-

OF HEATER

HEATING

THE

CAUSE

CHECK

THEY ARE

BECAUSE

CLOTH

MUST BE

RUBBER.

THE

ELEMENT.

OF

HEATER

THE WORN

WILL MAKE

TO HEATING

SAME

EXCELLENT

BREAKDOWN

TOO

HIGH,

Page 6

INSTRUCTION

FOR REPLACING THE

AND THE HEATER.

TELFLON

CLOTH

REMOVE THE TEFLON

TEFLON

WHEN

HEATER.

OTHER END

CLOTH,

CHANGING

PLACE ONE END OF THE HEATER

SECURE

THE HEATER,

WITH SCBEWS. THEN

ELECTRODE

FIXED

PLATE

CLOTH FROM THE FIXED PLATE.

THE FIXED

PLATE WITH

REMOVE

SCREW ON THE TEFLON CLOTH.

THE

SCREWS.

TEFLON CLOTH AND

ON THE ELECTRODE AND

TELFLON

SCREW

HEATER

SCREW

REPLACE WITH A NEW

UNSCREW

SECURE

CLOTH

THE

THE

Page 7

MALFUCTIONS

MALFUCTIONS

POWER

OF

WIRE AND

POWER

BUT

LAMP

PILOT

ON

CLOTH

HEATING

BROKEN

TO

FAILURE

THE HEATING

FAILURE

PILOT

THE

STILL

IS

LAMP STILL

THE TEFLON

AND

OVERHEATS

WIRE

SUDDENLY

CONTINUED

BE

PILOT

ON

REASONS

.

DISCONNE

.

SHORT

.

AC

.

HEATER BROKEN

.

DISCONNECTED

SPRING

.

TTMER

O

PROLONGED HEATING

O

TOO

NEED

COOLING

.

FRACTURED

OF

CIRCUIT

MALFUNCTION

FREQUENT

APPROPRIATE

PLUG

TED

AC CORD

DISCONNE

ELECTRODE

OPERATION

PERIOD.

GI-ASS

-5-

TIME

TAPE

TED

SUGGESTIONS

.

CHANGE

.

BEPAIR

.

REPAIR

.

REPLACE

.

REPLACE

OR CHECK

WIRE

.

CONTACT

.

DECREASE

.

KEEP AT

AFTER

PUSH

THEN

OPERATION

DAILY

NOT EXCEED

O

REPALCE THE GLASS

PLUG

THE

REPLACE

OR

AC

CIRCUIT

THE HEATING

ELECTRODE

THE

SUPPLIER

YOUR

HEATING

THE

LEAST

THE

I SECOND

LED

THE

1,OOO

WIRE

VOLTAGE

TIME

LAMP OFF,

HANDLE.

SHOULD

TIMES

TAPE

Page 8

IMPERFECT

l,'

I

CONNECTION

il

FRACTURED

l.

DIAGRAM

TEFLON

CLOTH

REpLnCe

l.

.

KEEP

COOLING

THE TEFLON

AT

LEAST 1

TIME.

CLOTH

SECOND

MICRO

SWITCH

AC

SOURCE

HEATING

TRANSFORMER

-6-

ELEMENT

TIMER

SET

Page 9

F

1ooH,-2OoH,

PARTS

DIAGRAM

3OOH'

4OoH'

52ofl

-7-

'

Page 10

ITEM

I

2

3

4

6

I

I

10

l1

12

PARTS

HANDLE

KNOB

ARM

HINGE

COIL

BRACKET

SPRING

MICROSWITCH

SEALING

SEALING

UPPER

FIXED

TIMER

WIRE

PLATED

SILICON

CLOTH

II\(]

tsLhMENT

PLATE

SET

CONNECTOR

,100H,

NAME

'I'

BRACKET

RUBBER

200H,300H,

400H,

ITEM

13

HEATER

't4

MICHOSWITCH

15

POWER

16

HEAIING

'17

MIUHO

18

TRANSFORMER

19

I

HANSFORMER

INSULATED

CORD

ELEMENT

SWITCH

20

21

TRANSFORMER

---

22

RUBBER

FOOT

23

-8-

520H

PARTS

NAME

CLOTH

BRACKET

PIN

(OUT.PI

SUPPORTOR

SPRTNG

JN TFFII\i|INA

Page 11

2o0HC.

sooHc'

400HC

PARTS

DIAGRAM

Page 12

ITEM

BODY

1

2

TIMER

\'

SCREW

4

BOW

SPBING

5

TRASFORMER

6

TMNSFORMER

7

SCBM

SPRING WASHER

B

PI-ASTIC

o

HINGE

10

SCREW

11 AFi/

12

ARM

OPEMTING

I/ICROSWITCH

14

ARM

IA

to

17

RETURN

MICROSWITCH

INSULATED

MICROSWITCH

200Hc,

PARTS NAME

BMCKET

WASHER

BRACKET

BMCKET

ADJUSTING

SPRING

BMCKET

PLqTE

SCREW

300Hc,

lTElr,

17-1

MICROSWITCH

18 MICROSWITCH

19 MICROSWITCH

20 HINGE

400HC,

PARTS

PIN

NAME

SPRING PUTE

ASSEMBTED

FIXED

21 WIRECONNECTOR

EARIH

22

23

24 BASE

25 EARTH

WIRE

EARTH WIRE

NUT

PI.ATE

WIRE

SCREW

WASHER

26 BUSHING

POWER

CORD

28 RUBBER

29 RUBBER

30

JI HEATING

32

33 TEFLON

34

FOOT

FOOTSCRM

LOWER

IEFLON

ELEMENT

UPPER

TEFLON

PI.ATE

TEFLON

PTATE

(ADHESIVE)

SCREW

_10_

SCHEW

SCBEW

500HC

ITEM

35

TEFLON

36

TEFION

37

SEAUNG

38

SEALING

39

SEALING

40

SEAUNG

41

SEALING

42

SILICON

43

HANDLE

44

HANDLE

AF

BI.ADE

46

CUTTER

47

BLADE

48

BI-ADE

49

HEATING

50

HEATING

PARTS

FIXED

NAME

PI.ATE

FIXED PI.ATE

BAR

BAR

FIXED

BMCKET

BAR

FIXED

BRACKET

BAR

RETURN

BAR

RETURN

(SEALING

RUBBER

KNOB

KNOB

WASHER

HOLDER

BI.ADE

FIXED

PLATE

FIXED

SCREW.

ELEMENT

COVER

ELEI\,IENI

COVER

SCREW

SCREW

SPRING

SPRING

SCREW

PAD)

NUT

SCREW

Page 13

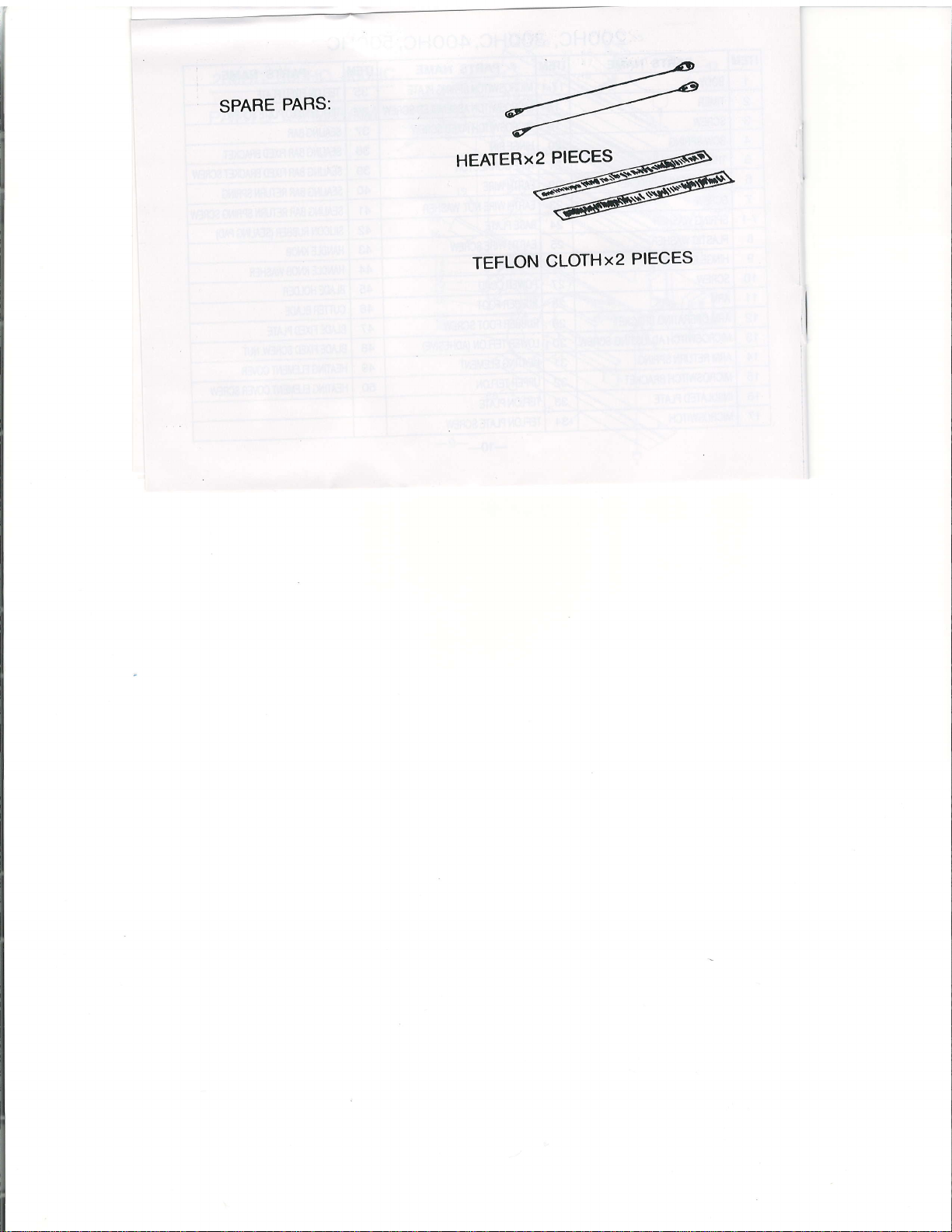

SPARE

PARS:

TEFLON

GLOTHx2

PIECES

Loading...

Loading...