Page 1

Continuous Band Sealer Instruction Manual

Distributed By:

Version 3.5

Last Updated: December 11, 2019

Sealer Sales | www.sealersales.com | Tel: 818-718-8818 | E-mail: contact@sealersales.com

Page 2

Copyright © 2014 by Stephanie Hwang

All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any form or by any means, including photocopying,

recording, or other electronic or mechanical methods, without the prior written permission of the publisher, except in the case of brief quotations embodied in

critical reviews and certain other noncommercial uses permitted by copyright law. For permission requests, write to the publisher, addressed “Attention:

Permissions Coordinator,” at the address below.

Sealer Sales, Inc.

8820 Baird Avenue

Northridge, Ca 91324

www.sealersales.com

Printed in the United States of America

Page 3

General Information

E Q U I P M E N T I N F O R M A T I O N

Model #

Serial #

Purchase Date:

Reference # (found on packing slip)

Owner:

Thank you for purchasing our continuous band sealer.

This owner’s manual contains information relating to your band sealer machine. The manual will

provide you with basic information concerning both operation and maintenance of your new machine.

Please read it carefully as failure to do so may result in bodily injury and/or damage to the equipment.

Please fill in the information below. You will find the information on the machine identification plate.

You will need this information when ordering replacement parts or making technical inquiries.

No part of this manual may be duplicated, reproduced, stored in a retrieval system, translated, transcribed, or

transmitted in any form without the express prior written permission of Sealer Sales.

ii

Page 4

Page 5

Table of Contents

Safety Instructions ........................................................................................... 1

Introduction ...................................................................................................... 3

Installation ......................................................................................................... 8

Operating your Band Sealer .......................................................................... 10

Maintenance .................................................................................................... 23

FRM-1120C Parts Diagram .......................................................................... 26

FRS-1120W Parts Diagram ........................................................................... 39

Troubleshooting ............................................................................................. 48

Spare Parts List ............................................................................................... 54

Quality Control Testing ................................................................................. 55

Page 6

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

Safety Instructions

WARNING!

Below are general safety precautions and warnings that should be

understood prior to setting up or operating your equipment. Read and fully understand all instructions and

warnings prior to using this unit. Your safety is most important! Failure to comply with procedures may

result in serious injury or property damage. Remember:

responsibility.

Unsafe practices or unauthorized modifications could result in accidents or property damage. Failure to follow these

safety rules and take necessary precautions can result in serious injury as well as damage to equipment.

Never operate or service your band sealer until you have read this manual completely and understand it

fully.

Plug the band sealer into a standard 120 Volt, 60Hz wall outlet or surge protector. We highly suggest using a

surge protector. Some special order units are 220 Volt, 50Hz. Make adjustments as necessary.

Do not use the band sealer if the power cord, plug or any other parts are damaged. Be sure not to allow the

power cord to drape into your work area. Check that all parts are operating properly and perform the

intended functions. Check for all other conditions that may affect the operation.

Reduce risk of unintentional starting. Make sure the power switch is in the "OFF" position before attaching

to the power source.

Always disconnect sealer from power source before servicing, changing accessories or cleaning the unit.

Your personal safety is your

To provide protection against the risk of electrical shock, the power connection must be properly grounded

at all times.

Do not leave the sealer unattended when in use. Disconnect the sealer from the power source before

leaving the work area.

Band sealer is used solely for sealing thermoplastic materials. Using the machine for any other purpose can

cause damage to the machine and operator.

Always operate machine on a flat stable surface.

While operating machinery, wear close-fitting clothing and tie back long hair to prevent any external items

from getting caught in the machine. Do not wear jewelry when operating the band sealer.

1

Page 7

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

2

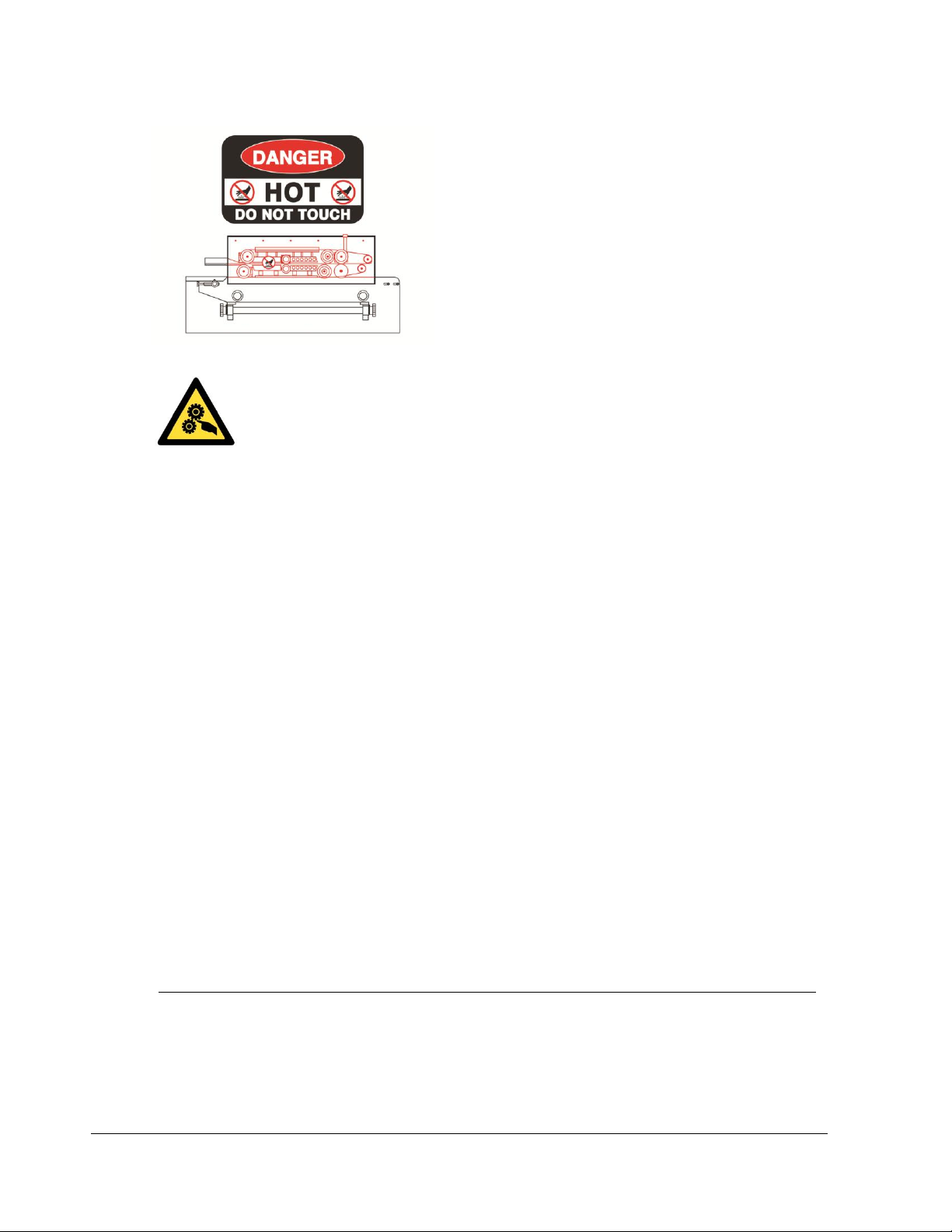

While machine is operating do not touch the heating and/or

cooling blocks. Blocks will be extremely hot and may burn your hands.

While machine is in operation, do not place fingers, tools, or other foreign objects on or into

the machine. Do not touch any moving parts while machine is operating. Fingers may get caught in

between the gears /pinch points and cause significant injury.

Thermoplastic bags and material are hand fed into the machine. Place bag on the guide and carefully feed

the bag through the band sealer. Fingers may be placed on the guide but do not allow fingers to touch any

of the moving parts on the band sealer.

Use emergency stop to turn off machine should material/bags get jammed into the machine. Carefully pull

material out of the band sealer. Do NOT use fingers to touch any part of the machine.

The band sealer is not water resistant or water proof. Spraying down the machine will damage machine or

cause electrical shock. Do not submerge the band sealer into water or liquid.

Do not operate band sealer in a corrosive or humid environment.

Always keep the machine clean, lubricated and in good working condition. Follow any maintenance and

lubrication procedures outlined in this manual. Make sure unit is disconnected from power source before

cleaning.

NEVER use any accessories or parts from other manufacturers. Machine should not be altered or modified

using parts that are not genuine authorized parts. Doing so will VOID YOUR WARRANTY.

Never leave the band sealer unattended. Be safe, disconnect the band sealer from power source before

leaving work area.

Close supervision is necessary when any appliance is near children or persons with reduced physical, sensory

or mental capabilities or lack of experience and knowledge . This sealer is NOT to be used by children or

by persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge.

DO NOT use the band sealer outdoors.

DO NOT use the band sealer while under the influence of drugs, medications or alcohol.

SAVE THESE INSTRUCTIONS - REFER TO THEM OFTEN AND USE THEM TO INSTRUCT OTHERS.

Page 8

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

3

Introduction

Our band sealers are equipped with electronic temperature controllers and variable speed conveyors to

seal all types of thermoplastic materials (PP, PE, stand up pouches, gusseted bags, moisture barrier bags,

etc.). Seals are created using PTFE bands which maintain high seal quality and produce consistently

strong, clean seals on all heat sealable bags. Because bags are placed on a conveyor system, the width of

the bag does not matter. These versatile machines offer several adjustments which allow them to be used

for a wide range of applications. These machines are used extensively in the food, medical, chemical,

cosmetic, and electronic industries.

The FRM-1120C band sealer adopts dry ink coding designed to print date and lot codes at the seal line.

Ink dries instantly upon contact with packaging materials and produces clear and legible characters. For

FRM-1120C, the standard font size is 18PT which allows for two-line printing. An optional 10.5PT font

size which allows for three-line printing can be purchased separately. Please ask your distributor for more

information.

The FRS-1120W band sealer adopts hot stamp printing to print date and lot codes at the seal line. Hot

stamp printing is similar to an analog printing press. Color ribbon printing provides a stronger adhesion

print than dry ink coding and works best for humid environments.

The FRM-1120C / FRS-1120W are stand alone units with casters providing easy mobility for the band

sealer. In addition, the sealer is equipped with a tilting mechanism which allows the conveyor to tilt up

to 30 degrees, ideal for packaging liquids and grains.

Features of our Band Sealer

Your band sealer is equipped with a wide range of standard features and capabilities.

Simple to use – minimal operator training

Fast warm up time

Unit feeds right to left

Rust inhibiting stainless steel construction

Equipped with bag entry guide for easy bag feeding and straight seals

Industrial grade safety emergency stop switch

10amp protection power surge breaker

Equipped with photo sensor for optimal printing precision

Dry ink coder for printing characters at the seal line (FRM-1120C)

Hot stamp printing coder for printing characters at the seal line (FRS-1120W)

Wide seal (8mm) to assure airtight seal

PTFE sealing belts

Extended forced-air cooling system with extra wide cooling bars and 6 heat transfer orifices

One pair of brass sealing bars

Sealing method – constant heat

Adjustable 2-way pulley system for optimal stability and embossing clarity

Page 9

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

4

FRM-1120C

FRS-1120W

Dry Ink Coding

Hot Stamp Printing

Power

110V/60Hz

Motor Power

100W

Sealing Speed

0-394 inches/minutes

Sealing Width

8mm

Temperature Range

0-300˚C (572˚F)

Conveyor Size

43” x 8”

Max Conveyor Load

16.5lbs

Printing Heating Power

40 x 2 (W)

50 x 2 (W)

Character Size

3x5x7mm / 18PT – 2 lines

2x3x7mm / 10.5PT – 3 lines

(additional option available)

2x4x15mm

Printing Colors

Black, Blue, Green, Red,

White, Yellow

Black, Blue, Red, White

Dimensions

43” x 24” x 41”

Weight

187lbs (n.w.) / 275lbs (g.w.)

Basic

Principles

FRM-1120C is easy to

use. To seal, adjust

temperature and place

bag on conveyor

Knurled pressure rolls with variable pressure adjustment

PID digital temperature controller 0-300˚C (572˚F) with dual alphanumeric displays (target & current

temperature)

Motorized rubber conveyor with speed control

Capable of speeds up to 394 inches/minute

How Does the Band Sealer Work?

Our band sealers are comprised of a stainless steel frame, speed adjusting

mechanism, sealing temperature control system and transmission system. Turning

on the heat for the band sealer will cause a rapid rise in the temperature of the

heating blocks. Required temperature and speed can be adjusted via the

temperature controller and speed adjusting device. Plastic material to be sealed is

placed on the guide and conveyor. Conveyor will then take the material between the two heating blocks

to fuse the material together. Material will then pass through the cooling blocks to allow the material to

congeal. Finally, a photoelectric sensor will direct the dry ink coder to print a clear and legible print at the

seal line.

The motor drives the sealing belts, drive belts and conveyor simultaneously.

Specifications

Page 10

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

5

Band Sealer Diagram

Figure 1. FRM-1120C (1) Pedestal, (2) Lock Handle, (3) Slide Block for Bracket, (4) Guide Belt, (5) Conveyor Belt, (6) Conveyor Table, (7) Silicone Wheel, (8)

Guiding Wheel (small), (9) Printing Wheel, (10) Solid Ink Roller, (11) Ink Roller Heat Block, (12) Housing Case (13) Embossing Wheel (14) Control Panel (15)

Driving Wheel, (16) Cooling Block, (17) Adjusting Knob, (18) Pressing Wheel, (19) Heating Block, (20) Sealing Belt, (21) Driven Wheel, (22) Cam Shaft, (23)

Guide, (24) Work Table, (25) Adjusting Knob for Conveyor, (26) Lifting Hand Wheel of Conveyor Table, (27) Lifting Hand Wheel of Complete Unit, (28) Casters

Figure 2. FRS-1120W Band Sealer (29) Hot Stamp Imprinter

Page 11

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

6

Getting to Know your Band Sealer

Page 12

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

7

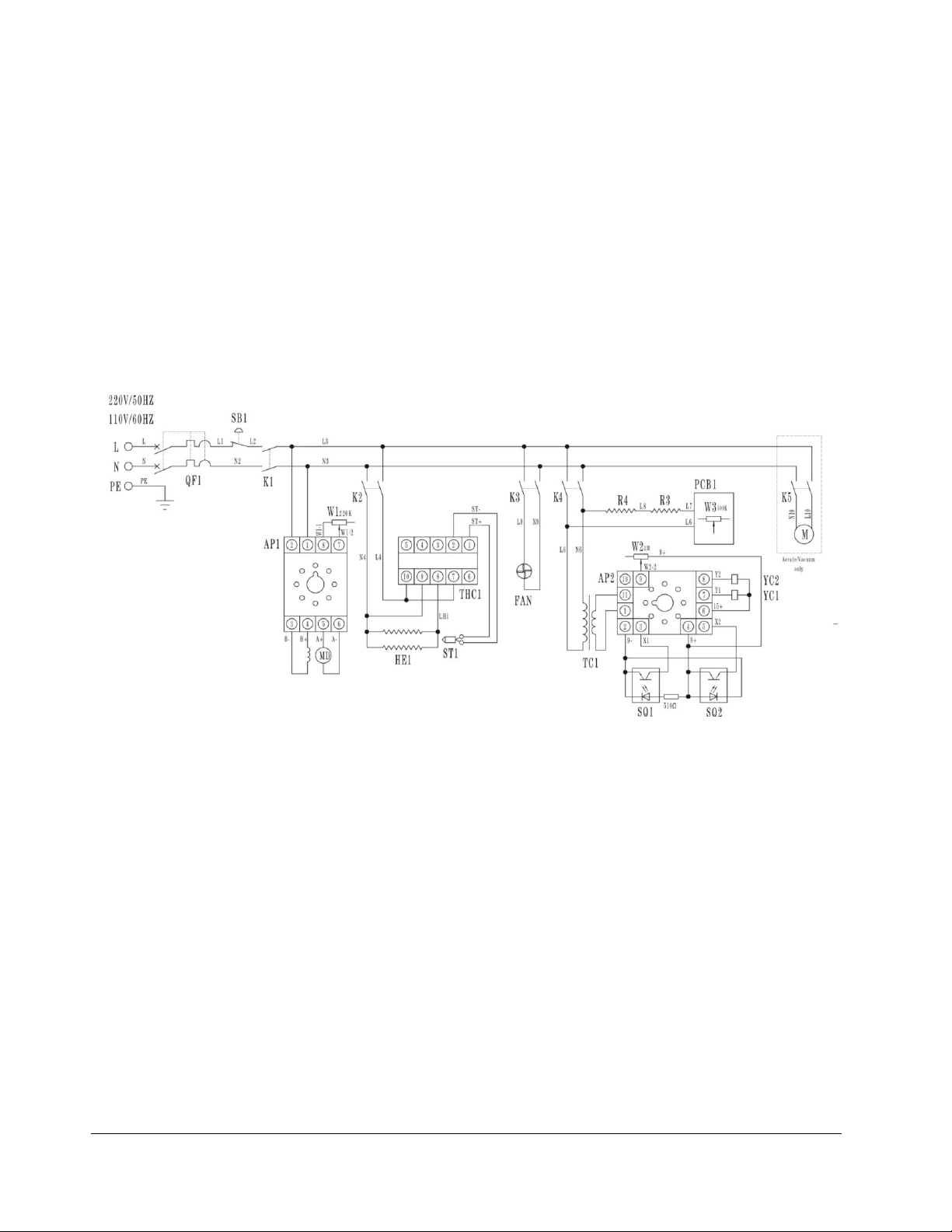

Electrical Circuit Diagram

Figure 3. Electrical Circuit Diagram. (QF1) High Rupture Switch, (SB1) Emergency Stop Switch, (K1) Switch/Power, (K2) Switch/Heat, (K3) Switch/Fan,

(K4) Switch/Printer, (K5) Switch/Aerating-Vacuum (W1) Speed-Regulating Potentiometer; (W2) Coding Position Potentiometer, (W3) Temperature-Regulating

Potentiometer; (HE1) Heating Element of Sealing, (R3/R4) Heating Element of Ink Roller; (MD), Speed adjusting Motor; (M) Aerating/Vacuum, (FAN) Fan,

(TC1) Transformer, (YC1) Electromagnetic Clutch, (YC2) Electromagnetic Brake, (SQ1) Groove Sensor, (SQ2) Photoelectric Sensor, (THC1) Temperature

Controller, (ST1) Thermocouple, (AP1) Speed Adjusting PC Board, (AP2) Main Control PC Board, (PCB1) Temperature Adjusting PC Board

Page 13

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

8

Installation

Important

Read this manual carefully, and make it available to everyone connected with the supervision, maintenance,

or operation of this machine. Additional copies are available at your request. (Contact your distributor for

this information.) Be very careful when operating, adjusting, or servicing this equipment. If in doubt, stop

and obtain qualified help before proceeding.

Installation

Place the band sealer in the desired location with the required electrical power source available. (See power

requirements.) Make certain that proper electrical wiring is provided to guard against low voltage. If the

voltage is too low, the equipment will not function properly.

Finding the proper location is a most important function of the initial set-up. One must take several factors

into consideration:

Adequate power source

Relationship to source of product

Relationship to band sealer

Relationship to any conveyors necessary to transport finished product

Convenience of operator

1. Your new HL-M1120LD band sealer comes packaged in a heavy duty crate to protect it. If your

machine does not arrive in this condition, write on shipping paperwork that outside of box is

damaged. Concealed damage may have occurred.

2. Remove the nails.

Page 14

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

9

Figure 4. FRM-1120C Crate

Figure 5. Bolts locking FRM-1120C to crate.

3. Remove the protective plastic covering the machine.

4. Remove bolts holding machine to crate.

5. Carefully check the contents against the spare parts list in the toolbox (see Spare Parts List on page

Error! Bookmark not defined.). Once you have determined that all of the parts have arrived in

good order set up can proceed. If any parts are missing or appear to be damaged, please notify your

distributor or Sealer Sales AND your freight company at once.

Page 15

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

10

Operating your Band Sealer

Operation Set-up

1. Our machines are equipped with a three-prong grounded plug. Make sure the plug is well-

connected in the socket to ensure safe operation.

2. Make sure the circuit breaker is in the “ON” position. (Levers pointing up)

3. First time operation. Allow the machine to pre-heat by running at a low temperature for a few

minutes. This would apply if the machine has not been in operation for a long time. The

machine can sometimes be damp from storage or shipment and running at a low temperature

will dry out any residual moisture.

4. Adjust the conveyor position forwards or backwards. Loosen the two screws at the bottom of

the conveyor table. Move out the conveyor table to the suitable position, then fasten the screws.

Refer to Figure 6.

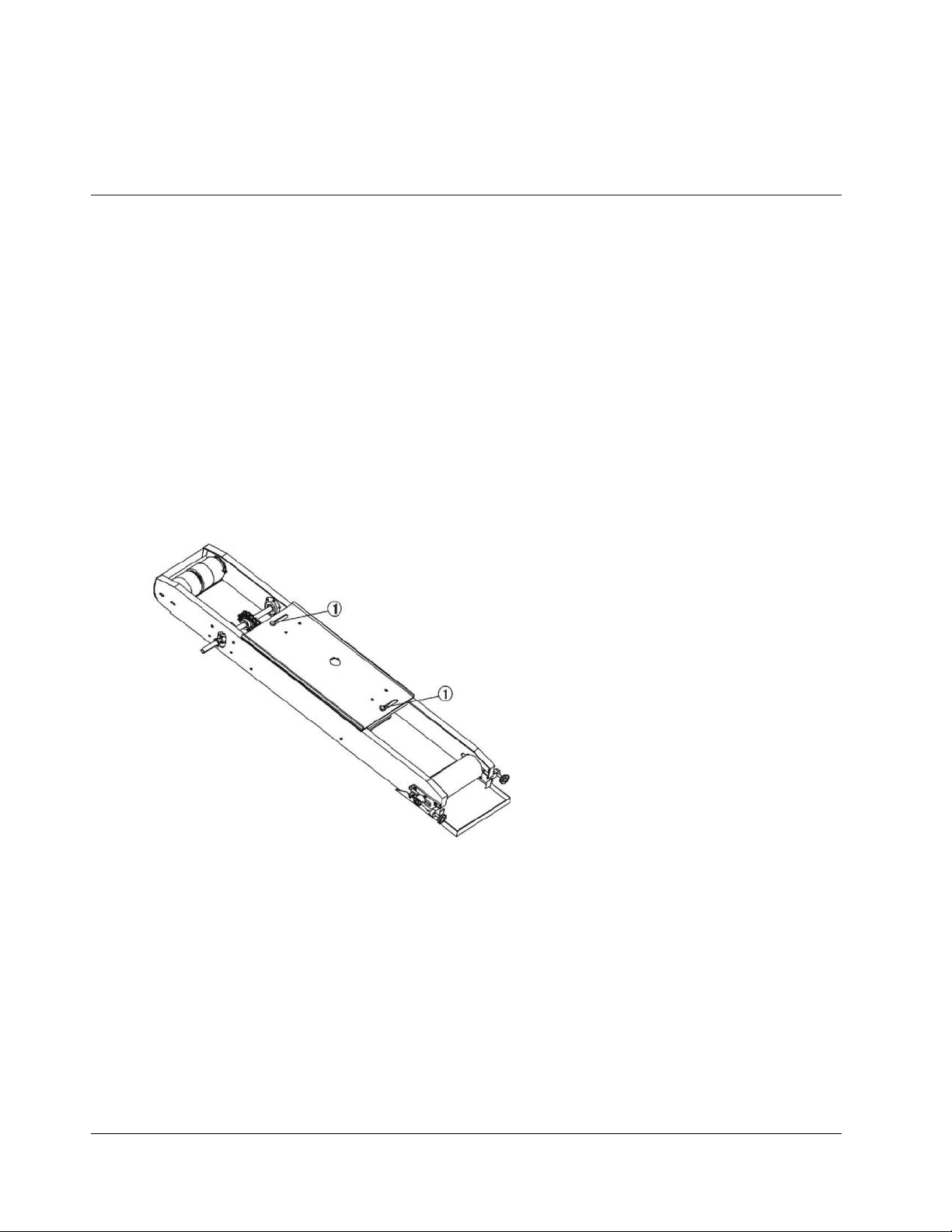

Figure 6.

5. Adjust the guide to adjust seal width and position of seal line on your material.

Page 16

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

11

Operation

Figure 7. Control Panel of FRM-1120C

1. Our machines are equipped with a three-prong grounded plug. Make sure the plug is well-

connected in the socket to ensure safe operation.

2. Make sure the circuit breaker is in the “ON” position. (Levers pointing up)

3. Turn Power, Heat (Seal), Fan, and Printer switches to the “On” position. Belts and conveyor

will begin to move simultaneously.

4. Adjust the conveyor speed.

5. Adjust the temperature controller to the temperature desired to seal your material. Temperature

settings will vary based on bag material and thickness. If you are unsure what temperature setting

to use, we recommend starting at a low temperature (150ºC) and gradually increase to a

temperature that will seal your material. We highly discourage sealing material at a temperature

above 200ºC. Please note: Temperature will be in Celsius, not Fahrenheit. The

temperature controller cannot be displayed in Fahrenheit.

The PV value is the actual temperature and the SV value is the desired temperature setting. The

SV value can be viewed by pressing the button.

Figure 8. FRM-1120C Temperature Controller

Page 17

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

12

a. To set the temperature, press the button. The SV temperature will be displayed.

The SP light will be on to show the SV temperature.

b. Press the and button to change temperature setting.

c. Press the button to save the temperature settings.

d. Wait until the PV temperature matches the SV temperature which should take

approximately 5-10 minutes.

e. Check our YouTube channel (https://www.youtube.com/user/sealersales) for a video

demo.

f. Please note: Temperature will be in Celsius, not Fahrenheit. Do not attempt to make

additional adjustments to the temperature controller besides the temperature. The

temperature controller CANNOT be displayed in Fahrenheit and is ALWAYS in Celsius.

Please do not set the temperature controller above 200ºC. Please contact your local

distributor if you need assistance.

6. Adjust the pressure knob (Figure 34 , Item #71) on your band sealer depending on the

thickness of your bag material.

7. Place material on the guide (Figure 36, Item #28) and allow the band sealer to pull your

material through. Make sure your material is flat on the guide. While the material is moving

through the band sealer, do not push or pull the material as this will cause irregular sealing.

8. If the sealing belt is running off the guide wheels, make adjustments to the screws that are found

on the driven wheel seat (Figure 9, Item #1 & 2)

Figure 9. (1) Driven Wheel Seat (Adjusting Block), (2) Driven Wheel Seat (Adjusting Block), (3)/(4) Adjusting Screws, (5) Springs

Page 18

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

13

9. Emergency Stop – Press the emergency stop to turn off the machine. In order to restart the

machine, you must release the emergency stop by turning the knob 120˚ clockwise.

10. To shut down, turn off the heater switch and allow the temperature of the machine to drop

before turning off the power and fan switches. Following this shut down procedure will significantly

prolong the life of machine and sealing belts.

Sealing Optimization

1. Sealing performance can be adjusted with the sealing temperature and sealing speed. The higher

the speed the less exposure the material to heating blocks and therefore a higher temperature will

be required to seal the material.

2. Try a variety of different sealing temperatures and conveyor speeds to get the optimal seal for

your material.

Page 19

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

14

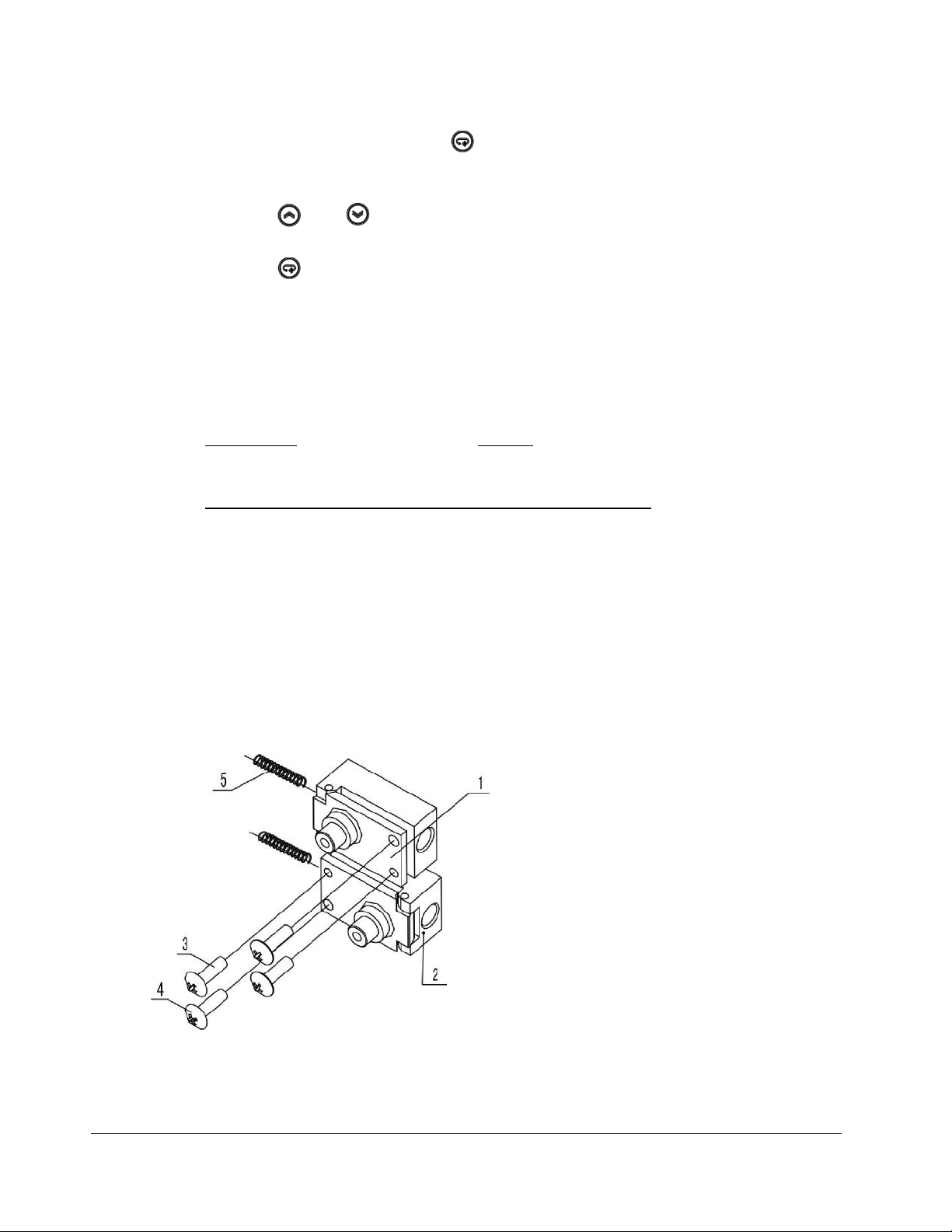

Figure 10. Standard font size - 18PT

Figure 11. Optional 10.5PT font size available for purchase

Figure 12. Locked Handle Position

Figure 13. Unlocked Handle Position

Printing Operation - FRM-1120C

FRM-1120C is equipped with a dry ink coding feature capable of printing characters at the seal line. Ink

dries instantly upon contact with packaging materials and produces clear and legible letters/numbers.

Standard font size is 18PT which allows for two-line printing up to 20 characters per line. Optional print

wheel which allows for 40 characters per line is available to be purchased separately. In addition, we also

carry 10.5PT font size which allows for three-line printing can also be purchased separately. Ask your

distributor for more details. Check our YouTube channel (https://www.youtube.com/user/sealersales) for

a video demo.

1. Removing Print Wheel. To remove the printing wheel from the base, push the red handle in and

turn clockwise until you feel the handle unlock. (See Figure 12 and Figure 13 for locked and

unlocked positions). You may need to turn the wheel a few times until the red handle unlocks and

pops out of its locked position.

Page 20

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

15

Figure 14. Place characters from right to left.

Figure 15. Place silicone pin to lock characters in place.

Figure 16. Ensure two holes and pins line up with the base

Figure 17. Ensure two holes and pins line up with the base

2. Installing Types/Characters on Print Wheel. Place selected characters in the grooves of the

printing wheel. Be sure to insert the characters from right to left to ensure actual imprint prints

correctly on your packaging material. Once completed, insert the silicone pin at the top of the

printing wheel to hold the characters in place.

3. Installing the Print Wheel. To insert the spring-loaded print wheel into the print wheel base,

ensure that the pin on the printing wheel is aligned with the notch of the print wheel base. Gently

insert the print wheel into the base. Lock the print wheel by pushing the red handle in until you

feel the handle lock into place.

Page 21

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

16

Figure 18. Remove metal wring found on the ink roller holder

Figure 19. Ink roller installed on ink roller holder

Figure 20. Correct Ink Roller Position

Figure 21. Incorrect Ink Roller Position

4. Install Ink Roller into the Ink Roller Holder. Remove the metal ring found on the ink roller

holder using an allen wrench. Place the ink roller onto the ink roller holder and place the metal

ring back on the ink roller holder to hold the ink roller in place. Please note that for 30mm wide

ink rollers, the metal ring will not be used.

5. Insert Ink Roller in the Ink Wheel Heating Block. When inserting the ink roller, ensure the

ink roller lines up with the type on the printing wheel. If the ink roller is pushed in too far, the

printing wheel will not print correctly. Note: Do not allow the ink roller to heat continuously when machine

is not in use as heating block may melt the ink roller.

Test the ink roller position relative to the printing wheel. Place your finger under the

photoelectric sensor. The sensor light will turn green and allow the printing wheel to rotate.

6. Make Adjustments to Ink Wheel Adjusting Device. As the print wheel rotates, check that

the printing wheel makes contact with the ink roller. Make adjustments using the ink wheel

adjusting device (Figure 22, Item #5) if necessary. Turning the adjusting screw clockwise will

move the ink roller away from the print wheel and turning the adjusting screw counterclockwise

will move the ink roller closer to the print wheel.

Page 22

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

17

Figure 22. (1) Ink Roller, (2) Ink Roller Heating Block, (3) Swing Pole, (4) Adjusting Strut, (5) Ink Wheel Adjusting Device

7. Make Adjustments Between Printing Wheel and Silicone Wheel. The typesets/characters

on the printwheel should only touch the silicone wheel during the printing process. The

characters should not touch the silicone wheel at any other time. If the band sealer is used to seal

relatively thicker materials, the screw (Figure 23, Item #4) should be loosened. Rotate the

eccentric sleeve (Figure 23, Item #3) to ensure the characters/typesets slightly tough the silicone

wheel's surface. Refasten the screw after making adjustments.

Figure 23. (1) Printing Wheel, (2) Silicone Wheel, (3) Eccentric Sleeve, (4) Screw

8. Setting Printing Temperature. We recommend setting the ink temperature on the higher end.

Allow 5-10 minutes for the ink heating block and ink roller to reach the correct temperature.

Note: If band sealer is not in use right away, do not leave ink roller in the unit while temperature is on. This may

result in the ink roller melting and producing messy print.

9. Adjust Printing Position. The coding seat knob determines printing position on your material.

For example, if you want to print on the left side of your bag, turn the coding seat to its lowest

Page 23

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

18

setting (or counterclockwise). If you want to print on the right side of the bag, turn the coding

seat to a higher setting (or clockwise).

Printing Optimization

1. Print quality will be determined by the degree of ink melting, distance between the ink roller and

printing wheel and distance between the silicone wheel and printing wheel.

2. Over time, decrease the gap between the ink roller and printing wheel.

3. A newer ink roller will require a lower temperature vs. an older ink roller. Make adjustments to

ink temperature as necessary.

4. Ensure there is adequate pressure on the silicone wheel (Part #BS-57A) by the printing wheel.

We suggest using factory default settings before making any adjustments. Adjustments may be

needed based on material thickness.

5. If the printing wheel rotates and there is no thermoplastic material running through the band

sealer, excess ink will rub off on the silicone wheel. Clean the silicone wheel with a shop cloth

and silicone spray to remove any excess ink.

6. Remove the ink roller from unit until sealer is ready for use. If ink roller is left in the

machine while not in use, this may result in melting of the ink roller and messy print. To

clean, wipe down belts, silicone wheel, and other parts with silicone spray and cloth.

Page 24

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

19

Figure 24. Type Example - FRS-1120W

Figure 25. FRS-1120W Control Panel

Each number dial turn moves the print

approximately 1” – 1½” to the right

Each number dial turn moves the

print approximately 1/8” to the right

Printing Operation - FRS-1120W

FRS-112W is equipped with a hot stamp ribbon printer. The printer works much like an analog printing

press. Types are loaded into the imprinter then heated. An inked printing ribbon sits between the type and

material to be printed. The heated type presses onto the ribbon, melting the ink onto the material. A spring

biased dancer assembly having a idler roller maintains a tension on the inked print ribbon as the inked print

ribbon is transferred from a supply reel to a rewind reel. To change the code of the hot stamp, types can be

easily replaced.

1. Determining the correct position for printing on your bag will require some trial and error.

Adjust the Speed, Coarse Tuning, and Fine Tuning knobs to determine the optimal printing

location on your bag.

2. To install the hot stamp ribbon, web the imprinter per diagram below (Figure 26). Be sure that

the dull side (pigment) of the tape faces away from printing head and toward the base of the

imprinter. To web the ribbon through the ribbon press wheel, pull the handle upwards to release

the ribbon press wheel. Lock the ribbon to the collect wheel by using a piece of scotch tape to

adhere the ribbon to the collect wheel.

Page 25

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

20

Figure 26. Ribbon Webbing Guide

3. Insert the printing head/type holder in the printing block. To lock the printing head, press the

handle on the printing head inward and turn clockwise about 90 degrees. When locked, you

should not be able to pull the printing head out of the printing block.

4. If temperature is left on while imprinter is not in use, we suggest turning the ribbon collect wheel

a few turns so that ribbon exposed to the heat of the printing block is moved into the ribbon

collect wheel. This will prevent ribbon breakage.

Imprinter Adjustments

Best results in hot stamp imprinting depends on correct temperature, pressure, and stroke speed. Different

materials may require adjusting any of these, as follows:

1. Temperature Adjustment. Turn the temperature knob to the appropriate temperature for the

material to be printed. Turning the knob clockwise will cause the temperature to rise and turning

the temperature counterclockwise will cause the temperature to lower. Wait approximately 15-20

minutes for imprinter to reach set temperature.

2. Pressure Adjustment. Normal printing pressures vary with the printing material. Pressure

should be kept just high enough to obtain good results. Too much pressure causes excessive

wear on type and silicone rubber pad. If pressure is too high, the ribbon may break and printed

materials may be melted through. If pressure is too low, the printed characters will be illegible.

The connection pole can be adjusted up or down to accommodate different types of material

and varying degrees of print darkness. To adjust the length of the connection pole, release either

of the two nuts located on the connection pole. Turning the nuts clockwise will cause the

Page 26

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

21

Figure 27. To adjust the length of the connection pole, release either of the two nuts located on the connection pole. Turning the nuts clockwise will

cause the connection pole to lengthen. Turning the nuts counterclockwise will cause the connection pole to shorten.

Figure 28. Ribbon Step Distance Adjustment. Loosen the butterfly-shaped nut found on the bolt. Moving the bolt upwards will reduce the step distance

and moving the bolt downwards will increase the step distance.

Adjust either of the two nuts located on the connection

pole.

Loosen butterfly-shaped nut and adjust the bolt up or

down.

connection pole to lengthen. Turning the nuts counterclockwise will cause the connection pole

to shorten.

3. Ribbon Step Distance Adjustment. The step distance is the amount of tape pulled through

by each printing stroke. If the step distance is higher, more ribbon will be consumed during

print. This distance is controlled by the bolt located at the back of the machine. Loosen the

butterfly-shaped nut found on the bolt. Moving the bolt upwards will reduce the step distance

and moving the bolt downwards will increase the step distance. Once the optimal step distance

is acquired, tighten the butterfly-shaped nut. The tape should advance just enough to present a

new surface on each impression.

Changing Type

Typesets are easily changed but

extremely hot when taken out of the imprinter.

280-58) to release the typesets. Insert new types into the printing head/typeset holder and tighten set screw

to ensure types do not fall out when inserted into the printing block. Additional types may be ordered as

needed. Please ask your distributor for more details.

please use caution as the printing head/typeset holder will be

Using an allen wrench, loosen the set screws (Part# HP-

Page 27

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

22

Figure 29. Printing Head / Typeset Holder with typesets

Page 28

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

23

Maintenance

The following maintenance procedures should be followed to ensure the longevity of your FRM-1120C

band sealer.

Inspection and Cleaning

1. Inspect your machine daily.

2. Check if there is any foreign matter or dirt adhering to the band sealer.

3. To clean your band sealer, wipe down your sealer with silicone spray and a shop cloth. Do not

apply silicone directly to your sealer. Definitely DO NOT wash down your machine with water.

Sealing and Drive Belts

1. Check and replace the belts as necessary. Both the sealing and drive belts are consumable items.

Replace sealing belts when there are burn marks or if the belts become hard and brittle. Replace

drive belts when the belts break or become badly cracked.

2. To change out the belts, make sure the machine is turned off.

3. Remove the safety cover.

4. Remove the two drive belts.

5. To remove the sealing belts, push on the adjustment blocks (Figure 34, Item #28/34) and the

sealing belts should easily slip off.

6. Put new sealing and/or drive belts back on the machine. Test the machine, making adjustments

as necessary.

7. Replace the safety cover.

8. Check our YouTube channel (https://www.youtube.com/user/sealersales) for a video demo.

Page 29

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

24

Cap on turbocase

Turbocase Maintenance

1. Remove dust and clean motor at regular intervals. Avoid contact with alcohol, gasoline and

benzene chemicals.

2. The turbocase should be oiled monthly with 50g 20# oil by:

a. Remove the back cover.

b. Locate the turbocase and unscrew the cap. Replenish any depleted gear oil with 50g 20#

oil.

3. The motor brush (Part #BS-29A) is designed to be used 2,500 hours continuously. Replace

carbon brush at regular intervals.

Figure 30. Turbocase cap

Page 30

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

25

Figure 31. Remove Ink Temperature Knob

Figure 32. Remove Washer Holding Ink Temperature Potentiometer

Figure 33. Unplug Ink Temperature Potentiometer w/ PC Board and Replace with a New Ink Temperature Potentiometer w/ PC Board

Printing Maintenance

FRM-1120C band sealers are equipped with an ink temperature potentiometer which is attached to a PC

Board. This part controls the temperature that is transmitted to both the ink heating block as well as the

printing wheel. The part is located behind the ink temperature knob. (Figure 40, Item #12) You should

change the ink temperature potentiometer w/ PC Board when both ink heating block and printing wheel

on your band sealer are not achieving optimal heat temperatures.

1. Turn off and unplug your band sealer.

2. Remove ink temperature knob from potentiometer and remove the washer that holds the ink

temperature potentiometer on the panel.

3. Remove the band sealer display panel. There should be six screws to remove.

4. Unplug the ink temperature potentiometer and plug in a new ink temperature potentiometer.

Make sure the part is plugged in properly and tight.

Page 31

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

26

FRM-1120C Parts Diagram

To order spare parts, please use diagram and part #s below:

Figure 34 – Spare Parts Diagram Overview

Figure 36 – Heating / Cooling Blocks and Dry Ink Coding

Figure 38 – Conveyor Table

Figure 40 – Controller Box

Figure 43 – Sealer Rack

Error! Reference source not found. – Sealer Rack II

Page 32

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

27

Figure 34. FRM-1120C Spare Parts Diagram Overview

Page 33

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

28

Item Part # Quantity Description Reference Comments

1 1

bottom board

106042

2 FRM-1120C-6A-2 2

small pulley shaft

106002

3 FRM-1120C-6A 2

small pulley

106003

Includes #3-5

4 FRM-1120C-6A 2

bearing (626)

GB/T276-1994

Includes #3-5

5 FRM-1120C-6A 2

circlip for hole

GB/T893.1-1986

Includes #3-5

6 Washer-M5x16 2

flat washer

GB/97.1-2002

7 Screw-M4x8 2

screw

GB/T818-2000

M4x8

8 FRM-1120C-26 1

guiding belt (678×4.5×3.5) (65°)

910803

9 FRM-1120C-26 1

guiding belt (678×4.5×3.5) (65°)

910803

10 1

embossing wheel shaft

106006

11 FRM-1120C-3A 1

bearing (6201)

GB/T276-1994

Includes #11-13

12 FRM-1120C-3A 1

embossing wheel

106007

Includes #11-13

13 FRM-1120C-3A 1

circlip for hole

GB/T893.1-1986

Includes #11-13

14 Washer-M5x16 1

flat washer

GB/T97.1-2002

M5x16

15 Screw-M4x8 1

screw

GB/T818-2000

M4x8

16 1

silicone wheel shaft

106011

17 FRM-1120C-2 1

silicone wheel assembly

106010

18 1

silicone wheel cover

19 FRM-1120C-6 2

driving wheel

106012

20 Washer-M5x28 2

flat washer

M5x28

21 Screw-M4x8 2

screw

GB/T818-2000

22 FRM-1120C-21-22-26 1

upper pressing wheel shaft

106023

Includes #22-25

23 FRM-1120C-21-22-26 2

bearing (16002)

GB/T276-1994

Includes #22-25

24 FRM-1120C-21-22-26 2

circlip for shaft

GB/T894.1-1986

Includes #22-25

25 FRM-1120C-21-22-26 2

pressing wheel

106025

Includes #22-25

26 FRM-1120C-21-22-26 2

circlip for hole

GB/T893.1-1986

27 FRM-1120C-21-27 1

lower pressing wheel shaft

106024

Includes #23-27

28 FRM-1120C-13 1

upper driven wheel seat (adjusting block)

106026

29 FRM-1120C-12a 2

driven wheel shaft

106030

30 FRM-1120C-12 2

driven wheel

106029

Includes #30-32

31 FRM-1120C-12 2

bearing (6005)

GB/T276-1991

Includes #30-32

32 FRM-1120C-12 2

circlip for hole

GB/T893.1-1986

Includes #30-32

33 Washer-M5x28 2

washer

M5x28

34 FRM-1120C-13 1

lower driven wheel seat (adjusting block)

106026

35 Screw-M4x8 4

screw

GB/T818-2000

36 FRM-1120C-13-36 2

cam shaft

11511011104

37 2

cam shaft seat

106033

Figure 35. FRM-120C Spare Parts Diagram Overview

Page 34

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

29

Item Part # Quantity Description Reference Comments

38 FRM-1120C-13-38 2 cam 11511011106

39 Screw-M4x8 2 screw GB/T818-2000

40 FRM-1120C-13-40 2 pressing plate for adjusting block 11511011107

41 FRM-1120C-13-41 4 spacing ring of pressing plate 11511011108

42 Screw-M4x8 4 screw GB/T818-2000

43 WasherM5x16 4 flat washer GB/T97.1-2002

44 Screw-M4x8 4 screw GB/T818-2000

45 FRM-1120C-13A 2 spring

46 1 spring seat 106034

47 Washer-M5x16 2 flat washer GB/97.1-2002

48 2 hexagonal nut GB/T41-2000

49 FRM-1120C-28-49 2 single slide block seat 106004

50 Washer-M5x16 8 flat washer GB/97.1-2002

51 Screw-M4x8 8 screw GB/T818-2000

52 FRM-1120C-6-50-56 3 circlip for hole GB/T893.1-1986 Includes #52-56

53 FRM-1120C-6-50-56 2 driving wheel shaft 106013 Includes #52-56

54 FRM-1120C-6-50-56 6 bearing (6201) GB/T276-1994 Includes #52-56

55 FRM-1120C-6-50-56 2 spacing ring of bearing 106009 Includes #52-56

56 FRM-1120C-6-50-56 3 bearing seat 106008 Includes #52-56

57 Screw-M4x8 9 screw GB/T818-2000

58 FRM-1120C-35B 5 gear 106014

59 FRM-1120C-29 1 motor 110V/100W

BS-29A 2 motor brush

Not shown

60 FRM-1120C-30 1 worm-gear case assembly 106084 determine gen 1.0 or 2.0

61 FRM-1120C-30-61 1 driving sprocket

62 Circlip-T894.1-1986 3 circlip for shaft GB/T894.1-1986

63 1 bearing seat for connecting shaft 105013

64 1 connecting shaft

65 FRM-1120C-28-65 2 slide block 106005

66 FRM-1120C-28-66 2 spring seat for slide block 106038

67 5 socket cap screw GB/T70.1-2000

68 BS-35-68 1 medium gear 106040

69 1 bearing (6101) GB/T276-1994

70 1 medium gear shaft 106041

71

FRM-1120C-28A, 28B,

or 28C

2 adjusting knob

A = 65mm, B = 77mm,

C = 92mm

72

FRM-1120C-28A, 28B,

or 28C

2 adjusting screw for slide block 106036

A = 65mm, B = 77mm,

C = 92mm

73 2 spring for slide block

74

FRM-1120C-28A, 28B,

or 28C

2

adjusting double-screw bolt for

slide block

106037

A = 65mm, B = 77mm,

C = 92mm

75 FRM-1120C-28D 2 adjusting seat for slide block 106035

Page 35

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

30

Page 36

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

31

Figure 36. FRM-1120C Heating / Cooling Blocks and Dry Ink Coding

Page 37

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

32

Item # Part # Quantity Description Reference Comments

1 1 bottom board 106042

2 BS-46 1 ink roller shaft 105036

3 BS-62E-FRM 1 swing pole of ink roll er 201007

4 FRM-1120C-47 1 heating block of ink roller 201002

5 BS-48C 1 heating pipe 110v/40w 921301

6 1 printing wheel shaft 106071

7 BS-48-7 1 spring of holding latch on printing wheel

8 BS-48-8 1 cov er for printing wheel shaft 201015

9 BS-48B 1 printi ng wheel 201013

10 BS-48A 1 printing wheel cover 201014 Includes #10, #11

11 BS-48A 1 holding latch for printing wheel 201016 Includes #10, #11

12 1 printing-silicone wheel shaft 201010

13 BS-57A 1 sili cone ring 910107

14 BS-57 1 circl ip for hole GB/T893.1-1986 Includes #14-17

15 BS-57 1 core of sil icone wheel 201011 I ncludes #14-17

16 BS-57 1 beari ng GB/T276-1994 Includes #14-17

17 BS-57 1 eccentric sleeve 201012 Includes #14-17

18 FRM-1120C-8-18 1 upper cooling block shaft 11511010502

19 FRM-1120C-8 2 upper cooling block 11511010503 /11511010601 Includes #19, #23, sold as pair

20 7 flat washer GB/97.1-2002

21 7 cap nut GB/923-1988

22 FRM-1120C-8-22 1 l ower cooling block shaft 11511010602

23 FRM-1120C-8 1 lower cooli ng block 11511010503 /11511010601 I ncludes #19, #23, sold as pair

24 FRM-1120C-9-24 2 upper heating block shaft 11511010902

25 FRM-1120C-9A-SS 1 upper heating block 11511010901 / 11511011002 Includes #25, #27, sold as pair

26 FRM-1120C-9-26 2 lower heating block shaft 11511011001

27 FRM-1120C-9A-SS 1 lower heating block 11511010901 / 11511011002 Includes #25, #27, sold as pair

28 FRM-1120C-44 1 feed opening 101035

29 1 wind catcher 106058

30 FRM-1120C-32 1 fan

31 BS-64B 1 support for brush 106073

32 BS-64A 1 carbon brush holder 920423

33 BS-64C 2 pressing plate of brush 201009

BS-64 2 carbon brush

34 BS-65 1 groove sensor

35 BS-139-FRM-1120C 1 electromagnetic clutch assembly A10501

36 BS-54B 1 middle pulley 105032

37 BS-54B-35 1 middle pulley shaft 105035

38 BS-54C-34 1 ink roller shaft pulley 105041

39 BS-54C 1 seat for ink roller swing pole shaft 201006

Figure 37. FRM-1120C Heating / Cooling Blocks and Dry Ink Coding

Page 38

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

33

Figure 38. FRM-1120C Conveyor Table

Page 39

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

34

Item # Part # Quantity Description Reference Comments

1 1 conveyor table

2 FRM-1120C-41 1 adjusting shaft Includes #2-5,#12-13

3 FRM-1120C-41 1 connecting ball Includes #2-5,#12-13

4 FRM-1120C-41 1 connecting sleeve Includes #2-5,#12-13

5 FRM-1120C-41 1 base plate for middle shaft 106025 Includes #2-5,#12-13

6 FRM-1120C-37 2 bearing (6201) GB/T276-1994 Includes #6-8, #10-11

7 FRM-1120C-37 2 bearing seat 106085 Includes #6-8, #10-11

8 FRM-1120C-37 2 front roller of conveyor table 106047 Includes #6-8, #10-11

9 1 outfeed plate 106090

10 FRM-1120C-37 2 sprocket of conveyor table 106089 Includes #6-8, #10-11

11 FRM-1120C-37 1 front shaft of conveyor table 106044 Includes #6-8, #10-11

12 FRM-1120C-41 1 middle shaft of conveyor table 106045 Includes #2-5,#12-13

13 FRM-1120C-41 2 bearing seat of conveyor table middle shaft 101003 Includes #2-5,#12-13

14 2 middle roller of conveyor table

15 2 middle roller shaft of conveyor table

16 4 bearing seat

17 4 bearing sleeve

18 FRM-1120C-36 1 rear roller of conveyor table 106048 Includes #18-20

19 FRM-1120C-36 1 rear shaft of conveyor table 106046 Includes #18-20

20 FRM-1120C-36 2 bearing (6201) GB/T276-1994 Includes #18-20

21 2 adjusting seat of conveyor table 106086

22 FRM-1120C-16 2 adjusting loop of conveyor table 106051 Includes #22-24

23 FRM-1120C-16 Includes #22-24

24 FRM-1120C-16 Includes #22-24

25 FRM-1120C-15 1 working table

Figure 39. FRM-1120C Conveyor Table

Page 40

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

35

Figure 40. FRM-1120C Controller Box

Page 41

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

36

Item # Part # Quantity Description Comments

1 1

rear cover of electric cabinet

2 BS-45B 1

PF113A relay holder

3 FRM-1120C-56 1

20 pin socket

4 BS-22A 1

emergency stop

5 BS-52C 1

main control PCB

6 BS-52A 1

speed regulating PCB

7 BS-66A 1

transformer BK-10/220-13.5V

8 BS-45A 1

PF083 relay holder

9 1

control panel

10 BS-22 1

control switch

specify large or small

11 TMC-XMTE-1000-2 1

temperature controller

determine version by taking temp controller out

TMC-XMTE -1000-2-O 1

temperature controller

determine version by taking temp controller out

TMC-E5CSL-QTC-FRM-1120 1

temperature controller

12 BS-25A 1

knob

13 BS-51 1

coding potentiometer 1.0M

14 BS-50A 1 ink temperature potenti ometer wih pc board

BS-25 1 potenti ometer 100K

15 BS-51 1 coding potentiometer 1.0M

19 R-JQX-13F 1

Relay

R-JG3NA 1

Relay

20 BS-74A 1

Seat for relay

Figure 41. FRM-1120C Controller Box

Figure 42. Controller Box

Page 42

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

37

Figure 43. FRM-1120C Sealer Rack

Page 43

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

38

Item # Part # Quantity Description Reference Comments

1 1

pedestal

2 4

caster

3 1

bearing seat of lifting screw rod

106064

4 1

bearing (6201) GB/T276-1994

5 1

bevel gear

106061

6 1

lifting slide block

7 4

lock handle

106063

8 1

bevel gear seat

106062

9 1

handle bevel gear

106060

10 1

bearing (6201) GB/T276-1994

11 1

lifting nut

106067

12 1

lifting screw rod

106065

13 1

rear cover of pedestal

14 1

rear cover of bracket

15 1

bracket

16 1

upper cover of bracket

17 FRM-1120C-20-17 1

connecting plate of bracket slide block

11511050009

18 FRM-1120C-20-18 1

connecting plate of conveyor table

11511050010

19 1

support plate of bracket

20 1

bearing (6201) GB/T276-1994

21 1

bearing seat for lifting screw rod

106064

22 1

bracket

23 1

screw rod of bracket

106066

24 1

lifting nut for bracket

106067

25 FRM-1120C-90 1

handwheel QB8251.2-98

26 1

slide block of bracket

27 1

stay bar for bracket

28 1

front cover of bracket

Figure 44. FRM-1120C Sealer Rack

Page 44

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

39

FRS-1120W Parts Diagram

To order spare parts, please use diagram and part #s below:

Figure 45. FRS-1120W Spare Parts Overview Diagram

Figure 47. FRS-1120W Heating / Cooling Blocks Parts Diagram

Figure 49. FRS-1120W Motor and Gears Parts Diagram

Figure 51. FRS-1120W Conveyor Parts Diagram

Figure 53. FRS-1120W Control Box Diagram

Figure 55. FRS-1120W Sealer Rack Parts Diagram

Page 45

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

40

Figure 45. FRS-1120W Spare Parts Overview Diagram

Page 46

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

41

Item Part # Quantity Description Reference Comments

1 FRM-1120C-28a, b or c 5 Adjusting Assembly for FRM-1120C, FRS-1120W 11511010203

2 FRM-1120C-28a, b or c 5 Adjusting Assembly for FRM-1120C, FRS-1120W 11511010204

3 FRM-1120C-28a, b or c 3 Adjusting Assembly for FRM-1120C, FRS-1120W 11511010205. 65

4 FRM-1120C-28a 5 Adjusting Assembly for FRM-1120C, FRS-1120W - 65mm 9100411120625

Includes #1-4

5 FRM-1120C-28c 1 Adjusting Assembly for FRM-1120C, FRS-1120W - 92mm 11511010205.92

Includes #1-3, 5

6 FRM-1120C-28b 1 Adjusting Assembly for FRM-1120C, FRS-1120W - 78mm 11511010205.78

Includes #1-3, 6

7 FRM-1120C-6-56 3 Bearing Seat 11511010303

8 3 E-clip 12mm 9746036400012

9 Bearing_6201Z 7 Bearing 6201 Z (12 x 32 x 10) 9105200602011

10 FRM-1120C-6-55 3 Spacing Ring of Bearing 11511010304

11 4 E-Cl ip 32mm 9746016400032

12 FRM-1120C-6-53 2 Driving Wheel Shaft 11511010402

13 FRM-1120C-6 2 Driving Wheel, Big 11511010401

14 Washer-M5x28 2 Washer M5 x 28 x 2 11511010403

15 1 Rubber Wheel Shaft 11511010302

16 FRM-1120C-2 1 Rubber Wheel 11511010301

17 CBS -880-2-33 1 Sil icone Wheel Cover 11111030018

18 FRM-1120C-3A-10 1 Emboss ing Wheel Shaft 11511010201

19 FRM-1120C-3A 1 Embossing Wheel, Meshed 11511010202

20 FRM-1120C-40A 1 Drive Shaft Connector, Gimbel Assembly A115110107

21 FRS-1120W-HP-241G 1 Imprinter for FRS-1120W A21312105

FRS-1120W-48A 1 Print Head for FRS-1120W

22 FRS-1120W-6B 2 Small Pulley Shaft 11513010101

23 2 Driving Wheel, Small 11311030001

24 Bearing_6062Z 2 Bearing 606-ZZ (17 x 6 x 6) 9105200600062

25 Circlip-17mm 2 E-Clip 17mm 9746016400017

26 FRS-1120W-26 2 Drive Belt (#830mm) 9425100020830

Figure 46. FRS-1120W Spare Parts Overview Parts List

Page 47

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

42

Figure 47. FRS-1120W Heating / Cooling Blocks Parts Diagram

Page 48

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

43

Item # Part # Quantity Description Reference Comments

1 2 Cam Shaft Seat 11511011105

2 FRM-1120C-13-36 2 Cam Shaft 11511011104

3 FRM-1120C-13-41 8 Spacing Ring of Pres sing Pl ate 11511011108

4 FRM-1120C-13 2 Adjustment Block Assembly 11511011111 Includes #4, 5

5 FRM-1120C-13 2 Adjustment Block Assembly 11511011112 Includes #4, 5

6 2 Driven Wheel Shaft 11511011102

7 FRM-1120C-12 2 Bearing 6005-2RS (25 x 47x x12) 9105200601052 Includes #7-9

8 FRM-1120C-12 2 Driven Wheel 11511011101 Includes #7-9

9 2 E-Clip 47mm 9746016400047 Includes #7-9

10 Washer-M5x28 2 Washer M5 x 28 x 2 11511010403

11 BS-9B 2 Heater sold as a pair

12 FRM-1120C-9-26 2 Lower Heating Block Shaft 11511011001

13 FRM-1120C-9A-SS 1 Heating Block 11511011002 Includes #13, 15 - sold as a set

14 FRM-1120C-9-24 2 Upper Heating Block Shaft 11511010902

15 FRM-1120C-9A-SS 1 Heating Block 11511010901 Includes #13, 15 - sold as a set

16 FRM-1120C-10 2 Sealing Belt (#1120mm) 9430113112015

17 FRM-1120C-34 1 Thermocouple 9241100021000

18 FRM-1120 C-21-27 1 Lower Pressing Wheel Shaft 11511010801 Includes #18-22

19 2 E-Clip 32mm 9746016400032 Includes #18-22

20 2 Pressing Wheel 9105200601022 Includes #18-22

21 2 E-Clip 15mm 9746036400015

22 2 Bearing 6002 ZZ (15 x 32 x 9) 11511010702

23 FRM-1120C-21-22-26 1 Upper Pressing Wheel Shaft 11511010701 Includes #18-21, 23

24 FRM-1120C-8-22 2 Lower Cooling Block Shaft 11511010602

25 FRM-1120C-8-SS 1 Cooling Block 11511010601 Includes #25, 27 - sold as set

26 FRM-1120C-8-18 1 Upper Cooling Block Shaft 11511010502

27 FRM-1120C-8-SS 1 Cooling Block 11511010503 Includes #25, 27 - sold as set

Figure 48. FRS-1120W Heating / Cooling Blocks Parts List

Page 49

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

44

Item # Part # Quantity Description Reference Comments

1 HL-M810-40C 1 Connecting Shaft Bearing Seat 11311030026 Includes #1, 2, 3

2 HL-M810-40C 2 E-Clip 28mm 9746016400028 Includes #1, 2, 3

3 HL-M810-40C 3 Bearing 6001 ZZ (12 x 28 x 8) 9105200601012 Includes #1, 2, 3

4 1 E-Clip 12mm 9746036400012

5 FRM-1120C-35b Wheel Gear (with out groove) 11511010305

FRM-1120C-35c Wheel Gear (with groove) 11511010305C

6 1 Wheel Shaft 11511011202

7 FRM-1120C-35-68 1 Medium Gear 11511011201

8 5 Slide Spring Seat 11511010207

9 FRM01129C-28-66 5 Spring Seat for Slide Block 11511010208

10 1 Slide Block Seat 11511010209A

11 FRM-1120C-29 1 Motor

FRM-1120C-30 Turbocase

12 FRM-1120C-28-49 4 Slide Block Seat 11511010209

13 1 Bottom Plate 11513011303

14 BS-33A 1 Connection Station (4P) 9201401110002

15 FRM-1120C-32 1 Fan 11511020011 Includes #15, 16

16 FRM-1120C-32 1 Fan 9230121000765 Includes #15, 16

17 FRM-1120C-13-46 1 Adjusting Block Seat 11511011110

18 FRM-1120C-13-40 2 Adjusting Pressing Plate 11511011107

19 FRM-1120C-13-38 2 Cam / Protruding Wheel 11511011106

Figure 49. FRS-1120W Motor and Gears Parts Diagram

Figure 50. FRS-1120W Motor and Gear Parts List

Page 50

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

45

Item # Part # Quantity Description Reference Comments

1 FRM-1120C-15 1 Working Table 11511030002

2 FRM-1120LD-16 2 Adjusting Knob 9100402140632 Includes #2, 3, 4

3 FRM-1120LD-16 2 Adjusting Screw 11511030403. 01 Includes #2, 3, 4

4 FRM-1120LD-16 2 Adjusting Loop 11511030403 Includes #2, 3, 4

5 FRM-1120LD-16-15 2 Adjusting Seat 11511030404

6 FRM-1120C-36 6 Bearing 6201-2RS 9105200602012 Includes #6-9

7 FRM-1120C-36 2 E-Clip 12mm 9746036400012 Includes #6-9

8 FRM-1120C-36 1 Conveyor Roller Shaft, Right 11511030402 Includes #6-9

9 FRM-1120C-36 1 Conveyor Roller, Right 11511030401 Includes #6-9

10 1 Conveyor Belt 2080 x 175 x 2 9422112208173

11 2 Intermediate Roller Shaft A115110304

12 1 Conveyor 11513030001

13 FRM-1120C-41 2 Middle Post 11111010014 Includes #6, #13-16

14 FRM-1120C-41 2 Gear 11511030104 Includes #6, #13-16

15 FRM-1120C-41 1 Shaft 11511030201 Includes #6, #13-16

16 FRM-1120C-41 1 Conveyor Middle Post with Gear 11511030203 Includes #6, #13-16

17 FRM-1120C-37 2 Front Roller Bearing 11511030102 Includes #6, #17-19

18 FRM-1120C-37 2 Conveyor Roller, Left 11511030103 Includes #6, #17-19

19 FRM-1120C-37 1 Shaft 11511030101 Includes #6, #17-19

20 1 Chain (06B-1 x 69L) 9104101106069

21 FRM-1120C-1-9 1 Outfeed Plate 11511030003

Figure 51. FRS-1120W Conveyor Parts Diagram

Figure 52. FRS-1120W Conveyor Parts List

Page 51

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

46

Item # Part # Quantity Description Reference Comments

1 BS-22A_G 1 Emergency Stop, Green / Green 9212232220640

BS-22A_O 1 Emergency Stop, Orange / Green

2 BS-25A 4 Knob 9210200100004

3 TMC-E5CSL-QTC 1 Temperature Controller 9241131305325

4 1 Font Panel Plate 9160103115412

5 BS-22-LARGE 4 Switch, Large 9212240130395

6 BS-25A 1 Speed Potentiometer 9300112520100

7 Relay-JG3NA 1 Relay JG3NA-2255B 9215301102252

8 FRM-1010-31 1 Speed PC Board 9310121115015

9 1 Guard 11513020005

10 1 Body 11513020001

11 FRM-1120C-44 1 Sealing Width Adjusting Guide 11511020101

12 BS-14 1 Socket for Power Cord 9201111031002

13 BS-27 1 Circuit Breaker 9212711602005

14 1 Back Cover 11513020004

15 2 Door Latch 1151102001381

Figure 53. FRS-1120W Control Box Diagram

Figure 54. FRS-1120W Control Box Parts List

Page 52

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

47

Item Part # Quantity Description Reference Comments

1 1 Conveyor Connecting Plate 11511050010

Compatible with FRM-1120C

2 1 Backet Slider Connecting Plate 11511050009

Compatible with FRM-1120C

3 BS-5_Gen2.0 6 Pressure Adjusting Knob 9450101111004

Includes #3, 4

4 BS-5_Gen2.0 6 Pressure Adjusting Knob 9450101111003

Includes #3, 4

5 1 Bracket Front Cover 11511050002

Compatible with FRM-1120C

6 2 Side Bracket 11511050003

Compatible with FRM-1120C

7 1 Mid Bracket Slider 11511050004

Compatible with FRM-1120C

8 1 Bracket Support 11511050008

Compatible with FRM-1120C

9 2 Upper Bracket Shafts 11511050001

Compatible with FRM-1120C

10 2 Lower Bracket Shafts 11511050001-D2

Compatible with FRM-1120C

11 Bearing_60 02Z 3 Bearing 6002 ZZ (15 x 32 x 9) 9105200601022

12 2 Lifting Bracket Bearing Housing 11511040007

Compatible with FRM-1120C

13 1 Lifting Bracket Shaft 11511050006

Compatible with FRM-1120C

14 2 Lifting Bracket Nut 11511040004

15 FRM-1120C-90 2 Handwheel 9100303112100

16 1 Top Bracket Cover 11511050011

Compatible with FRM-1120C

17 1 Back Bracket Cover 11511050012

Compatible with FRM-1120C

18 1 Base 11511040001

Compatible with FRM-1120C

19 4 Caster Support 11510000099

20 FRM-1120C-92B 2 Cas ters With Brake 9400102410403

21 FRM-1120C-92A 2 Casters Without Brake 9400102400403

22 1 Handle Bevel Gear 11511040009

Compatible with FRM-1120C

23 1 E-clip 32mm 9746016400032

24 1 E-clip 15mm 9746036400015

25 1 Bev el Gear 1151140005

Compatible with FRM-1120C

26 1 Base Back Cover 11511040006

Compatible with FRM-1120C

27 1 Lifting Slider 11511040002

Compatible with FRM-1120C

28 1 Lifting Slider Shaft 11511040003

Compatible with FRM-1120C

29 1 Bev el Gear 11511040008

Figure 55. FRS-1120W Sealer Rack Parts Diagram

Figure 56. FRS-1120W Sealer Rack Parts List

Page 53

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

48

Troubleshooting

Unable to Set Temperature Controller

If operator is unable to set the temperature or is finding the temperature settings inaccurate, we suggest

resetting the temperature controller to the default settings. Please follow the following steps:

Hold the for at least three seconds.

Press the or key at the display for the parameter for which the setting is to be changed.

The parameter setting display will appear. Use the or key to change the setting.

Example: Changing the Input Type from 0 to 1 is below:

Enter to move on to the next parameter display.

To save the settings, hold again for more than three seconds. The temperature controller will

automatically restart and save the settings.

Please note: This temperature controller can only be set to Celsius. If you try and change

the temperature unit to F, the temperature controller will not function properly.

Page 54

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

49

Figure 57. Default Setting Parameters

Figure 58. Parameter Displays

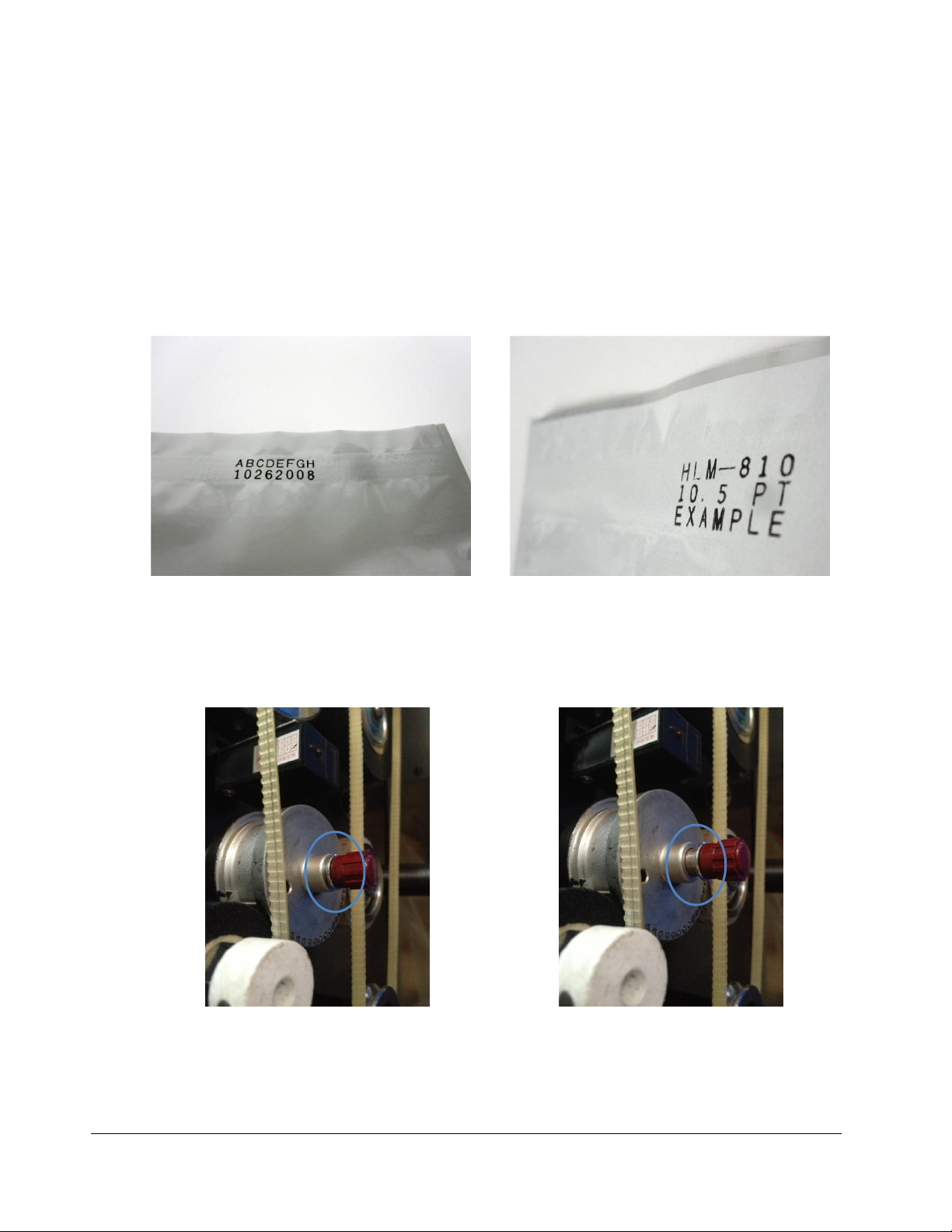

Printing Wheel Adjustments

Problem: Print wheel on the band sealer rotates more than once.

Possible Cause: Electromagnetic clutch on the back of the unit and groove sensor are not aligned properly.

The flat panel of the electromagnetic clutch signals the grove sensor to stop the print wheel rotation.

1. We suggest the following steps:

2. Loosen the nut as shown in Figure 59. This will allow the carbon brush holder and grove sensor

some movement.

3. Push the groove sensor closer to the electromagnetic clutch

4. Re-tighten the nut

Page 55

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

50

Figure 59. Incorrect position of groove sensor and electromagnetic clutch

Figure 60. Correct position of groove sensor and electromagnetic clutch

Loosen Nut in

order to move the

groove sensor

closer to

electromagnetic

clutch

Electromagnetic Clutch

Groove Sensor

Page 56

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

51

Problem Possible Causes Solution

Sealing belt is off tracking.

Driving wheel shaft is not parallel to

driven wheel shaft

Adjust two adjusting screws on the adjusting block

seat (Part# FRM-1120C-13)

Sealing belts are tearing

1. Too much tension on sealing belt

2. Sealing belt is off tracking

3. Creases on the sealing belt

4. Residual film or other debris

attached to the sealing belt

1. Adjust the vertical adjusting screw on driven

wheel seal to decrease tension on sealing belt

2. see above

3. When installing belt, make sure no creases are

found on belt

4. Clean surface of belt with cloth

Seal is crumpled and film sticks to

sealing belts

1. Temperature is too high

2. Guide belt is not correctly in place

3. Plastic melted on the sealing belt

1. Reduce temperature

2. Adjust guide belt

3. Clean or replace sealing belt

If any plastic melts on the sealing belt, your bags

will stick to the melted plastic

Embossing is not clear

1. Embossing roller is worn out

2. Pressure spring on embossing

roller needs to be tightened

1. Replace embossing roller

2. Adjust the embossing roller spring (Part# FRM1120C-28B)

Material will not pass through

sealing blocks

Clearance between heating blocks or

cooling blocks may be too small

Adjust the clearance between blocks by adjusting

the springs and stopping flakes found above the

blocks

Conveyor belt is off tracking

Driving roller shaft is not parallel to

the driven roller shaft

Adjust using the conveyor belt adjustment (Part#

FRM-1120C-16)

Conveyor and sealing belt are not

moving at same speed

Not enough tension on conveyor belt

1. Tighten the chain of driving roller shaft (front

shaft) and middle shaft. (Parts # FRM-1120C-37

and FRM-1120C-41)

2. Tighten the conveyor belt

Temperature doesn't rise or cannot

be controlled

1. Heat switch is damaged

2. Heater (BS-9B) is damaged

3. Temperature Controller

4. Coupling

Replace:

1. Heat switch (BS-22-Large)

2. Heater (BS-9B)

3. Temperature Controller

4. Thermocouple (FR-1120C-34)

Page 57

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

52

Problem Possible Causes Solution

Printing wheel does not rotate

1. Sensor is blocked

2. Sensor is not clean and eye is

blocked by dust

1. Make sure sensor is not blocked

2. Clean sensor

3. Replace PCB (BS-52C)

Printing wheel does not stop

rotating

1. Sensor (groove) is damaged or

dirty

2. Photoelectric sensor is damaged

or dirty

3. Main control PC Board is damaged

1. Replace or correct position of the groove

sensor or clean its surface (BS-65)

2. Replace or clean photoelectric sensor (BS-60)

3. Repalce PC Board (BS-52C)

No heat on the ink heating block

1. Heating element in heating block

is damaged

2. Heating PCB is damaged

3. Potentiometer w/ PC Board (BS50A) is damaged

4. Carbon brush is not in place

5. Carbon brush is damaged

1. Replace element (BS-48C) in heating block

2. Replace PCB (BS-50A)

3. Replace potentiometer with PC Board (BS-50A)

4. Adjust and tighten nut on carbon brush seat

5. Replace carbon brush

Temperature of heating block for

ink roller cannot be regulated

Relay for temperature control PCB is

damaged

Check and replace temperature control PCB (BS50A)

Printing position cannot be

regulated

1. Tighten screw on printing wheel

2. Coding seat potentiometer may be

damaged

1. Tighten screw on printing wheel.

2. Replace coding seat potentiomter (BS-51)

Motor runs at a high speed and

cannot be regulated

Speed controller has malfunctioned Replace the speed controller (BS-52A)

Power, heater, and or fan switches

do not light up

1. No AC Voltage

2. Open Fuse

3. Lamp is damaged

Check power source / power cord

Connect the power

Replace the fuse

Replace the lamp

Page 58

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

53

Problem Possible Causes Solution

Machine does not run

1. Board for speed regulation is

abnormal

2. Doesn't connect well

3. Brushes in the motor are too short

because of friction

1. Replace the speed board (BS-52A)

2. Tighten the connecting screws

3. Replace motor brushes (BS-29A)

If the temperature controller works and the power

lamp illuminates but the motor does not move,

start off by checking the motor and turbocase

connection. Remove the back of the machine and

you will see bushing where the motor connects to

the gear box. Ensure the bushing is not broken.

There is also a set screw that connects the bushing

to the gear box / motor shafts. Ensure that these

are tight so that when the motor turns, the

turbocase turns as well.

If the turbocase is noisy before it stopped

working, the gear box could be broken inside.

Lack of oil could cause this.

If the lamp illuminates and the motor does not

turn, the motor speed controller may need to be

replaced.

Page 59

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

54

Spare Parts List

Included with your band sealer are the following parts. Please note that spare parts included with your

band sealer are subject to change without notice.

Typeset Box which includes numbers (0-9), Letters – EXP, MFD, silicone pins (Part# BS-59),

tweezers, and allen wrench

Power Cord (Part# PWC-CBS)

PTFE Sealing Belts (Part# FRM-1120C-10)

Drive Belts (Part# FRM-1120C-26)

Speed Adjusting PC Board (Part# BS-52A)

Central Circuit PC Board (Part# BS-52C)

Ink Temperature Potentiometer with Heat PC Board (Part# BS-50A)

O-Rings (Part#s BS-53 and BS-54)

Silicone Ring (Part#BS-57A)

Ink Roller Holder (Part# BS-58)

Ink Rollers, 15mm (Part# IT-IR-15-BLK)

Groove (Trough) Sensor (BS#BS-65)

Carbon Brush for Printer (BS#64)

Philips Screwdriver

Flat Screwdriver

Allen Wrench (3mm and 5mm)

Wrench

Page 60

F R M - 1 1 2 0 C I N S T R U C T I O N M A N U A L

55

Steps

Description

Inspect all wiring on the unit, nothing is loosely attached.

Make sure all wires are connected correctly.

Make sure all connections are tight and properly mounted. (Ex: PC Board, Relay)

Check parts to ensure they are in proper working order (ex: wheels, belts, knobs, etc)

CBS-880 only - Attach the conveyor to the body via the drive shaft (Part #40). Detach

after testing.

Turn on machine - start, seal, fan, printer

Check all knobs to make sure they start and end in the correct position

Make adjustments as necessary if there is any unusual noise. Noise should be under

80db.

Check fan - There should be air coming out of the cooling blocks

Check motor - motor brushes should be held in tightly

Check conveyor belt to make sure the belt is running smoothly and evenly

Run machine for at least 20 minutes - after the seal temperature has been reached, seal

bag sample to ensure good quality seal

Band Sealers w/ Printing Option:

Printing - make sure ink heating block, ink printing wheel are at optimal heat

temperature

Sensor and Coding Seat - test the sensor and coding seat are working properly; make

adjustments as necessary

Clean machine

Enter serial # of the unit in the manual

Repackage sealer w/ QC form, sealed bag / printed sample and manual.

Quality Control Testing

Our band sealers are manufactured in a facility which is certified in accordance with ISO 9001:2008. In

addition, we quality test all of our band sealers in our facility following a rigorous and exacting standards to

ensure that the product you purchased is a high quality reliable machine.

Date:

Technician:

Page 61

Loading...

Loading...