. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist Pro Family

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist 2160N (ST52160N)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist 2160WC (ST52160WC)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

SCSI Interface Drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist Pro Family

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist 2160N (ST52160N)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist 2160WC (ST52160WC)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

SCSI Interface Drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

2 Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

© 1996 Seagate Technology, Inc. All rights reserved

Publication Number: 32650-001, Rev. A, December 1996

Seagate, Seagate Technology, the Seagate logo and Medalist are

registered trademarks of Seagate Technology, Inc. Ot her product names

are trademarks or registered trademarks of their owners.

Seagate reserves the right to change, without notic e, product offerings

or specifications. No part of this publication may be reproduced in any

form without written permission from Seagate Technology, Inc.

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A iii

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications summary table . . . . . . . . . . . . . . . . . . . 3

1.0 Specifications summary . . . . . . . . . . . . . . . . . . . . . 5

1.1 Formatted capacity . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Physical geometry . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Functional specifications . . . . . . . . . . . . . . . . . . . 5

1.4 Physical dimensions . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Seek time . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Read look-ahead and caching . . . . . . . . . . . . . . . . 7

1.7 Start/stop command . . . . . . . . . . . . . . . . . . . . . . 7

1.7.1 Power-up sequence . . . . . . . . . . . . . . . . . . . 7

1.7.2 Power-down sequence . . . . . . . . . . . . . . . . . . 8

1.7.3 Auto-park . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.8 Power management . . . . . . . . . . . . . . . . . . . . . . 8

1.8.1 Power consumption . . . . . . . . . . . . . . . . . . . . 9

1.8.2 Voltage tolerance . . . . . . . . . . . . . . . . . . . . . 9

1.8.3 Input noise . . . . . . . . . . . . . . . . . . . . . . . 10

1.9 Environmental . . . . . . . . . . . . . . . . . . . . . . . . 10

1.9.1 Ambient temperature (HDA case) . . . . . . . . . . . 10

1.9.2 Temperature gradient . . . . . . . . . . . . . . . . . . 10

1.9.3 Altitude . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.9.4 Relative humidity . . . . . . . . . . . . . . . . . . . . 11

1.10 Shock and vibration . . . . . . . . . . . . . . . . . . . . 11

1.11 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.12 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.13 Agency listings . . . . . . . . . . . . . . . . . . . . . . . 12

1.14 Electromagnetic Compliance for the European Union . . . 13

1.15 FCC verificatio n . . . . . . . . . . . . . . . . . . . . . . 13

2.0 Hardware and interface . . . . . . . . . . . . . . . . . . . . 17

iv Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

2.1 SCSI-3 compatibility . . . . . . . . . . . . . . . . . . . . . 17

2.2 Handling and static-discharge precautions . . . . . . . . . 17

2.3 Electrical interface . . . . . . . . . . . . . . . . . . . . . . 18

2.4 Interface and connector configuration . . . . . . . . . . . . 19

2.5 ST52160N interface connector . . . . . . . . . . . . . . . 20

2.5.1 ST52160N interface pin assignments . . . . . . . . . 21

2.5.2 ST52160WC interface connector . . . . . . . . . . . . 22

2.5.3 ST52160WC interface pin assignments . . . . . . . . 22

2.6 Interface cable requirements . . . . . . . . . . . . . . . . 25

2.6.1 Interface cable length for asynchronous operation . . . 25

2.6.2 Interface cable for Fast SCSI operation . . . . . . . . 25

2.6.3 Interface cable for UltraSCSI operation . . . . . . . . 25

2.7 Options jumper block . . . . . . . . . . . . . . . . . . . . 26

2.7.1 SCSI address . . . . . . . . . . . . . . . . . . . . . . 26

2.8 Active Termination . . . . . . . . . . . . . . . . . . . . . . 29

2.9 Parity enable option . . . . . . . . . . . . . . . . . . . . . 29

2.9.1 Motor Start option . . . . . . . . . . . . . . . . . . . . 29

2.9.2 Remote LED connection . . . . . . . . . . . . . . . . 29

2.10 Daisy chaining . . . . . . . . . . . . . . . . . . . . . . . 29

2.11 Hot-plugging . . . . . . . . . . . . . . . . . . . . . . . . 30

2.12 Mounting the drive . . . . . . . . . . . . . . . . . . . . . 30

3.0 Command set . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.1 Command descriptor block . . . . . . . . . . . . . . . . . 35

3.2 Status byte . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.3 Supported commands . . . . . . . . . . . . . . . . . . . . 36

3.4 Group 0 commands . . . . . . . . . . . . . . . . . . . . . 37

3.4.1 Test Unit Ready command (00

3.4.2 Rezero Unit command (01

3.4.3 Request Sense command (03

3.4.4 Format Unit command (04

3.4.5 Reassign Blocks command (07

) . . . . . . . . . . . . 37

H

) . . . . . . . . . . . . . . 38

H

) . . . . . . . . . . . . 38

H

) . . . . . . . . . . . . . . 39

H

) . . . . . . . . . . . 43

H

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A v

3.4.6 Read (6) command (08H) . . . . . . . . . . . . . . . . 45

3.4.7 Write (6) command (0A

3.4.8 Seek (6) command (0B

3.4.9 Inquiry command (12

3.4.10 Mode Select (6) command (15

3.4.11 Reserve (6) command (16

3.4.12 Release (6) command (17

3.4.13 Mode Sense (6) command (1A

3.4.14 Start/Stop Unit command (1B

3.4.15 Receive Diagnostic Results command (1C

) . . . . . . . . . . . . . . . . 46

H

) . . . . . . . . . . . . . . . . 47

H

) . . . . . . . . . . . . . . . . . 47

H

) . . . . . . . . . . . 48

H

) . . . . . . . . . . . . . 51

H

) . . . . . . . . . . . . . 52

H

) . . . . . . . . . . . 53

H

) . . . . . . . . . . . . 56

H

) . . . . . 57

H

3.4.16 Supported Diagnostic Pages . . . . . . . . . . . . . 58

3.4.17 Translate Address Page . . . . . . . . . . . . . . . 59

3.4.18 Send Diagnostic command (1D

) . . . . . . . . . . . 61

H

3.5 Supported Diagnostics Page—Send Diagnostics . . . . . . 62

3.6 Translate Address Page—Send Diagnostic . . . . . . . . . 62

3.6.1 Read Capacity command (25

3.6.2 Read (10) command (28

3.6.3 Write (10) command (2A

3.6.4 Seek (10) command (2B

3.6.5 Write and Verify command (2E

3.6.6 Verify command (2F

) . . . . . . . . . . . . . . . . . 68

H

3.6.7 Read Defect Data command (37

3.6.8 Write Data Buffer command (3B

3.6.9 Read Data Buffer command (3C

3.6.10 Read Long command (3E

3.6.11 Write Long command (3F

) . . . . . . . . . . . . 63

H

) . . . . . . . . . . . . . . . 64

H

) . . . . . . . . . . . . . . . 65

H

) . . . . . . . . . . . . . . . 66

H

) . . . . . . . . . . . . 67

H

) . . . . . . . . . . . 68

H

) . . . . . . . . . . . 70

H

) . . . . . . . . . . . 72

H

) . . . . . . . . . . . . . . 74

H

) . . . . . . . . . . . . . . 74

H

3.7 Group 2 commands . . . . . . . . . . . . . . . . . . . . . 75

3.7.1 Log Select command (4C

3.8 Log Sense command (4D

H

3.9 Reserve (10) command (56

3.10 Release (10) command (57

) . . . . . . . . . . . . . . 75

H

) . . . . . . . . . . . . . . . . . 82

) . . . . . . . . . . . . . . . . 83

H

)

. . . . . . . . . . . . . . .

H

84

vi Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

3.11 Group 3 and 4 commands . . . . . . . . . . . . . . . . . 85

3.12 Group 5 and 6 commands . . . . . . . . . . . . . . . . . 85

3.13 Group 7 commands . . . . . . . . . . . . . . . . . . . . 85

Appendix A. Supported messages . . . . . . . . . . . . . . . . 87

A.1 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 87

A.2 Synchronous Data Transfer Request message (01

) . . . . 88

H

A.2.1 Wide Data Transfer Request Message . . . . . . . . . 89

Appendix B. Sense data . . . . . . . . . . . . . . . . . . . . . . 91

B.1 Additional sense data . . . . . . . . . . . . . . . . . . . . 91

B.2 Sense key . . . . . . . . . . . . . . . . . . . . . . . . . . 93

B.3 Additional sense code and additional sense code qualifier . 94

Appendix C. Mode pages . . . . . . . . . . . . . . . . . . . . . 97

C.1 Read-Write Error Recovery page (01H) . . . . . . . . . . 98

C.2 Disconnect/Reconnect page (02

C.3 Format Device page (03

) . . . . . . . . . . . . . . . . 102

H

C.4 Rigid Disc Geometry page (04

C.5 Verify error recovery page (07

C.6 Caching page (08

) . . . . . . . . . . . . . . . . . . . . 108

H

) . . . . . . . . . . . . 100

H

) . . . . . . . . . . . . . 104

H

) . . . . . . . . . . . . . 107

H

C.6.1 Read look-ahead and caching . . . . . . . . . . . . 108

C.6.2 Write caching and write merging . . . . . . . . . . . 109

C.6.3 Caching page description . . . . . . . . . . . . . . 110

C.7 Control Mode page (0A

C.7.1 Unit Attention Parameters (00

) . . . . . . . . . . . . . . . . . 113

H

) . . . . . . . . . . . 114

H

Appendix D. Inquiry data . . . . . . . . . . . . . . . . . . . . 117

D.1 Inquiry data . . . . . . . . . . . . . . . . . . . . . . . . 117

D.2 Vital product data pages . . . . . . . . . . . . . . . . . 120

D.2.1 Unit Serial Number page (80

D.2.2 Implemented Operating Definition page (81

D.2.3 Firmware Numbers page (C0

D.2.4 Date Code page (C1

) . . . . . . . . . . . . . . . . 123

H

D.2.5 Jumper Settings page (C2

) . . . . . . . . . . . . 121

H

) . . . . 121

H

) . . . . . . . . . . . 122

H

) . . . . . . . . . . . . . 123

H

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A vii

Figures

Figur e 1. Ty p ical startu p current p r o fi l e . . . . . . . . . . . . . . . . 7

Figure 2. Single-ended transmitter and receiver . . . . . . . . . . .18

Figure 3. Connectors . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 4. ST52160N jumper settings . . . . . . . . . . . . . . . . 27

Figure 5. ST52160WC jumper settings . . . . . . . . . . . . . . . 28

Figure 6. ST52160N Mounting dimensions . . . . . . . . . . . . . 32

Figure 7. ST52160WC Mounting dimensions . . . . . . . . . . . 33

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A 1

Introduction

This manual describes the functional, mechanical and interface specifications for the Medalist

hard disc drives. The Medalist Pro 2160N is referred to in this manual by

its model number ST52160N. This drive comes with the standard 50-pin

interface connector. The Medalist Pro 2160WC is referred to in this

manual by its model number ST52160WC. This drive comes with the

80-pin blindmate single-connector attachment (SCA-2).

Seagate desktop products take a step into the future with the ST52160N

and ST52160WC. These drives feature MR heads and PRM L r ecording

technology.

The Medalist Pro drives uses an UltraSCSI interface. The ST52160N

supports a synchronous external transfer rate of up to 20 Mbytes per

second. The ST52160WC supports a synchronous external transfer rate

of up to 40 Mbytes per second.

These drives have other features that ensure fast data throughput. The

ST52160N uses a 128-Kbyte buffer. The ST52160WC uses a 256-Kbyte

buffer. The adaptable cache aids the flow of read and write data.

Embedded servo technology allows the drives to position the heads for

data retrieval efficiently and accurately while eliminating the periodic

thermal recalibration that can interrupt during data transfers. These

drives also use a 16-bit microprocessor and an intelligent controller that

provides data streaming: direct data transfers between the drive and the

host without microprocessor intervention. This feature allows for a sustained data rate that facilitates video playback and other multimedia

operations.

Pro 2160N and Medalist Pro 2160WC SCSI

The drives conform to the standard 3.5-inch footprint but have a 0.75-inch

(19 mm) height profile and a 5.380-inch depth profile. The lower height

and shorter depth gives the designer or integrator more room for air

circulation, other peripherals or a smaller drive bay.

The SCSI commands the drives support are listed in Section 3.3. on

page 36.

2 Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

The following is a summary of the drives’ features:

Capacity

• 2.17 Gbytes, guaranteed

Features

• SCSI-3 SPI and SCAM Plug and Play compliant

• 8-bit and 16-bit UltraSCSI

• Transfer rates up to 20 Mbytes and 40 Mbytes per second

• 11-msec average seek time

• 5,379-RPM rotational speed

• 5.56 average latency

• 128-Kbyte

1

and 256-Kbyte2 buffer

• Self-Monitoring, Analysis and Reporting Technology (S.M.A.R.T.)

• Rotational-position seek/sort

• On-the-fly EC C co rrect i on

• Embedded servo

• PRML channel

• MR heads

Acoustics

• 3.4-bel idle sound power level

• 27-dBA idle sound pressure level

Mini 3.5-inch form-factor

• 19-mm-height profile

• Fits standard 3.5-inch footprint

1. ST52160N

2. ST52160WC

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A 3

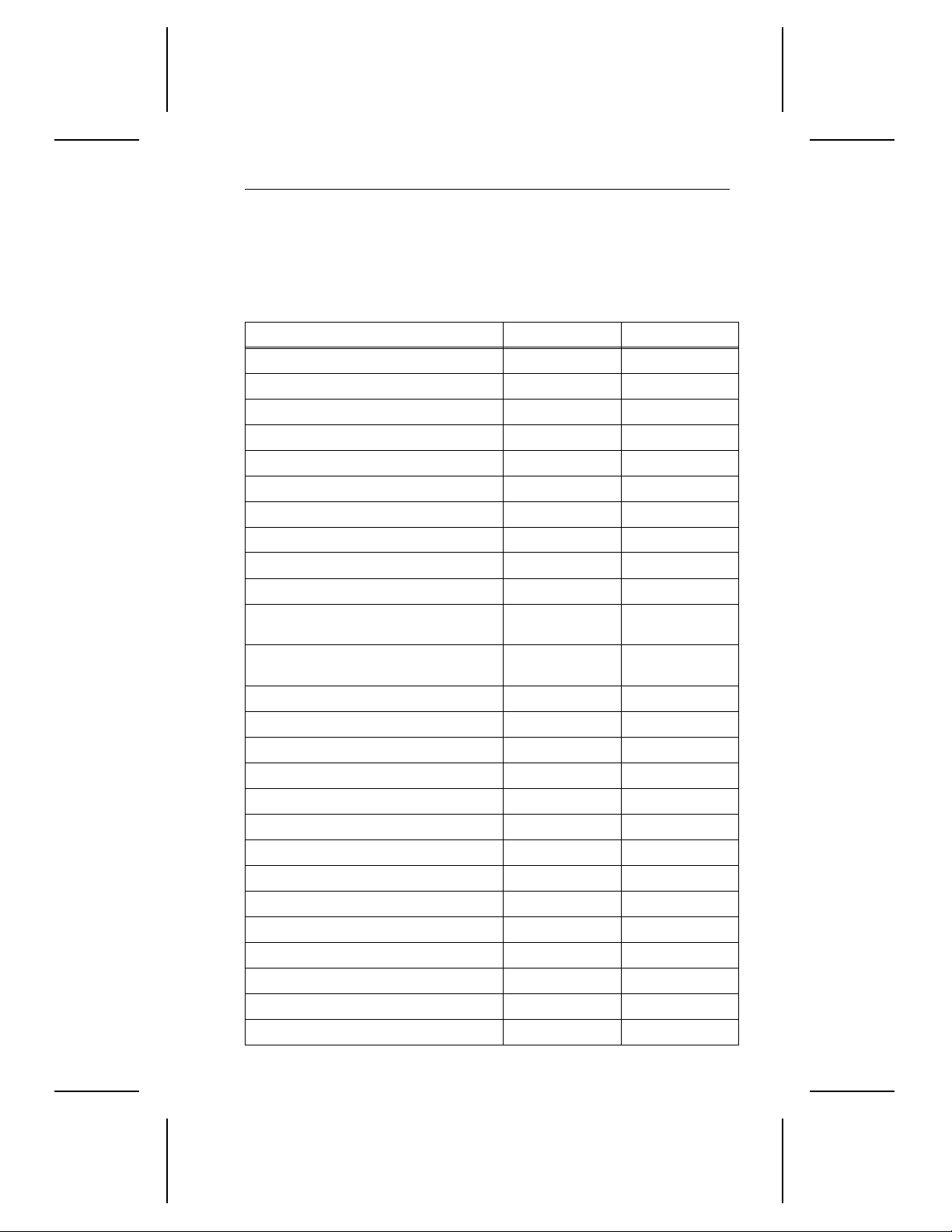

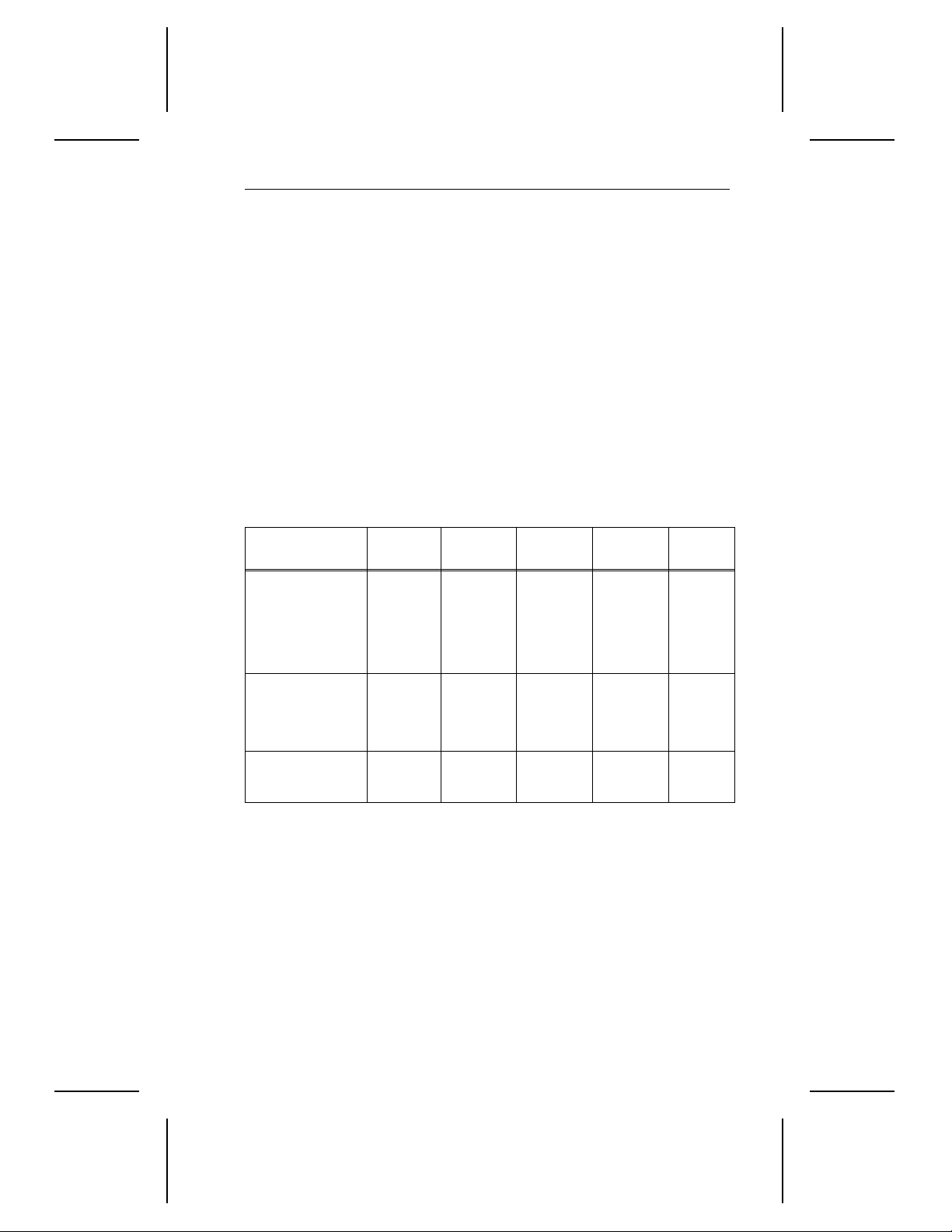

Specifications summary table

The following table serves as a quick reference for the drives’ performance specifications. These and other specifications are discussed in the

Specifications summary section following the table.

Drive specification ST52160N ST52160W C

Guaranteed capacity (Gbytes, 10

Guaranteed sect or s 4,238,282 4,238,282

Bytes per secto r 512 512

Sectors per track (average) 161 161

Physical cylind er s 6,536 6,536

Physical read /wr i t e heads 4 4

Discs 2 2

Recording density (bits per inch, max) 122,369 122,369

Track density (t r acks per inch) 6,731 6,731

Spindle speed (R PM) 5,397 ± 0.5% 5,397 ± 0.5%

Internal data-t ra nsfe r ra te

(Mbits per se cond max)

External tran sf er rate

(Mbytes per second, max)

Cache buffer (Kbytes) 128 256

Height, inches max (mm) 0.748 (19.0) 0.748 (19.0)

Width, inches max (mm) 4.01 (101.8) 4.01 (101.8)

Depth, inches max (mm) 5.38 (136.6) 5.38 (136.6)

Typical weight, l b. (Kg) 1.0 (0.45) 1.0. (0.45)

Track-to-t ra ck seek time (msec , typi cal) 3.5 3.5

Average seek tim e (msec, typical) 11.0 11.0

Average seek tim e re ad ( m sec, t ypi cal) 12.0 12.0

Average seek tim e writ e ( m sec, t ypi cal ) 13.0 13. 0

Full-stroke seek tim e (msec, typical) 25.0 25.0

Average laten cy (msec) 5.56 5.56

Power-on to re ady ( sec, typical) 20 20

Spinup curren t: +12V (max) 1.18A 1.18A

Seek power (typi cal) 6.4W 6.4W

9

)2.17 2.17

56.3 to 99.6 MHz 56.3 to 99.6 MHz

10.0 asynchro nus

20.0 synchron ous

20.0 asyn chr onus

40.0 synch r onous

4 Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

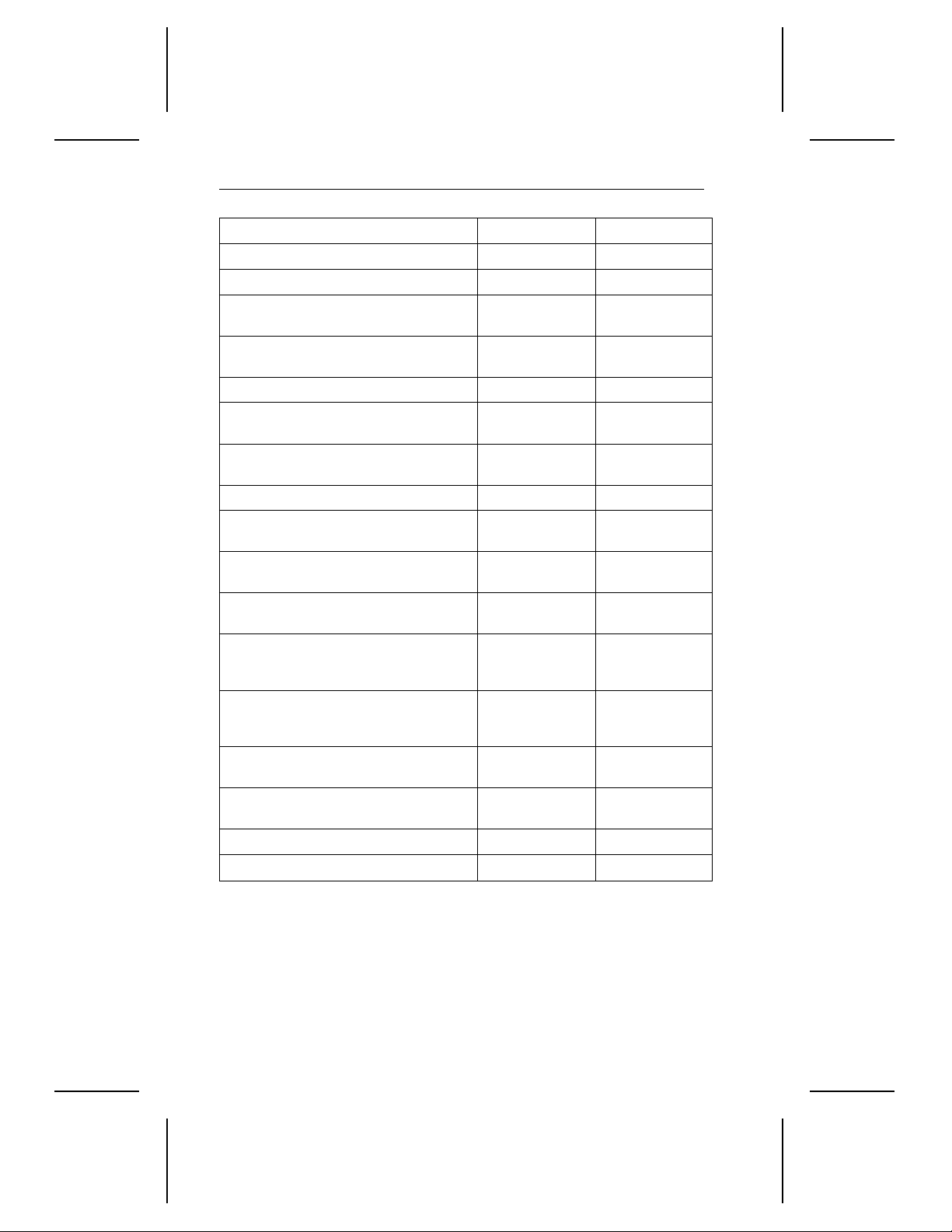

Drive specification ST52160N ST52160W C

Read/Write po w er (typi cal) 6.3W 6.3W

Idle power (typical) 6.2W 6.2W

Voltage tolerance (including noise) : +5V

Voltage toleran ce ( includ ing no ise): +12V

Ambient tem per at ur e, oper at i ng ( C °) 5° to 55°C 5° to 55°C

Temperature gr adient, operati ng

(°C per hour max) 20° C 20°C

Relative humidity,operating gradient

(max) 10% per hr. 10% per hr.

Relative humidi t y, oper at i ng 8% to 80% 8% to 80%

Wet bulb temperature

operating (non condensing) 29.4°C 29.4°C

Altitude, opera ting –1,000 to

Shock, norma l op er at in g

(Gs max for 11 msec) 2 Gs 2 Gs

Vibration, operating

(Gs max at 22–350 Hz without

nonrecoverable errors)

Vibration, no noperating

(Gs max at 22–350 Hz with no physical

damage incurr ed)

Nonrecoverable read errors

(bits transfer r ed)

Mean time betw een failures (MTBF)

(power-on hou rs )

Contact start -s top cycles 50,00 0 50,000

Service life (years) 5 5

±

5%

±

5%

±

±

5%

5%

–1,000 to

10,000 ft.

0.75 Gs

0 to Peak

4 Gs

0 to Peak

1 per 10

13

10,000 ft.

0.75 Gs

0 to Peak

4 Gs

0 to Peak

1 per 1013

500,000 500,000

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A 5

1.0 Specifications summary

1.1 Formatted cap acit y

The capacities specified here do not include spare sectors and cylinders.

The media contains 2,000 spare blocks at the end of the volume.

3

Guaranteed capacity (Gbytes

Guaranteed sectors 4,238,282

1.2 Physical geometry

Discs 2

Read/write heads 4

Cylinders 6,536

Sectors per track (average) 161

1.3 Functional specifications

)2.17

Interface SCSI-3 SPI Compliant

PRML recording method Code (0,4,4)

4

External data-transfer rate

(Mbytes per sec, max)

Internal data-transfer rate

10 asynchronous

synchronous

20

20 asynchronous

40 synchronous

56.3 - 99.6 MHz

4

5

5

(Mbits per sec)

Bytes per sector 512

Data zones 19

2

Areal density (Mbits/ in

) 823.7

Track density (TPI) 6,731

Recording density (BPI, max) 122,369

3. One Gbyte equals 1,000,000,000 b y tes.

4. ST52160N

5. ST52160WC

6 Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

1.4 Physical dimensions

Height (max) 0.748 inches (19 mm)

Width (max) 4.01 inches (101.8 mm)

Depth (max) 5.38 inches (136.6 mm)

Weight (max) 1.0 lb. (0.45 Kg)

1.5 Seek time

All seek time measurements are taken under nominal conditions of

temperature and voltage with the drive mounted horizontally. In the

following table:

•

Track-to-track

seek time is the average of all possible singl e-track

seeks in both directions.

•

Average/typical

seek time is a true statistical random average of at

least 5,000 measurements of seeks in both directions between random cylinders, less overhead.

•

Full-stroke

seek time is one-half the time needed to seek from logical

block address zero (LBA 0) to the maximum LBA and back to LBA 0.

Track-to-track

seek time typ

Average/typical

6

seek time

7

Full-stroke

seek time typ

8

Average

latency

3.5 msec typ 11.0 msec typ 25.0 msec typ 5.56 msec

4.5 msec max 12. 0 msec read 27.0 msec max

13.0 msec write

Note.

Host overhead varies between systems and cannot be specified.

Drive internal overhead is measured by issuing a no-motion

seek. Drive overhead is typically less than 1.0 msec.

____________________

6. All possib le on e- t r ac k seek s a r e d iv ide d i nt o the t i me req ui red t o p erf or m thes e se ek s.

Only the mechanism time is used; interface o verhead is excluded.

7. All possible seeks are divided into the time required to perform these seeks. Only the

mechan ism time i s used; interface overhead is excluded.

8. The average of 1,000 full-stroke seeks is used in this computation. Only the mechanism

time is used; interface overhe ad is excluded.

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A 7

1.6 Read lo ok-ahead and caching

The drives use algorithims that improve seek performance by storing

data in a buffer and processing it at a more convenient time. Three

methods are used: read look-ahead, read c aching and write caching.

These are described in Appendix C.6 on page 108.

1.7 Start/stop command

If the motor-start option is disabled, the drive is ready within 20 seconds

after power is appli ed. If the motor-start option is enabled, the drive is

ready within 20 seconds after it receives the Motor Start command. If the

drive receives a command to spin down or power is removed, the drive

stops within 15 seconds.

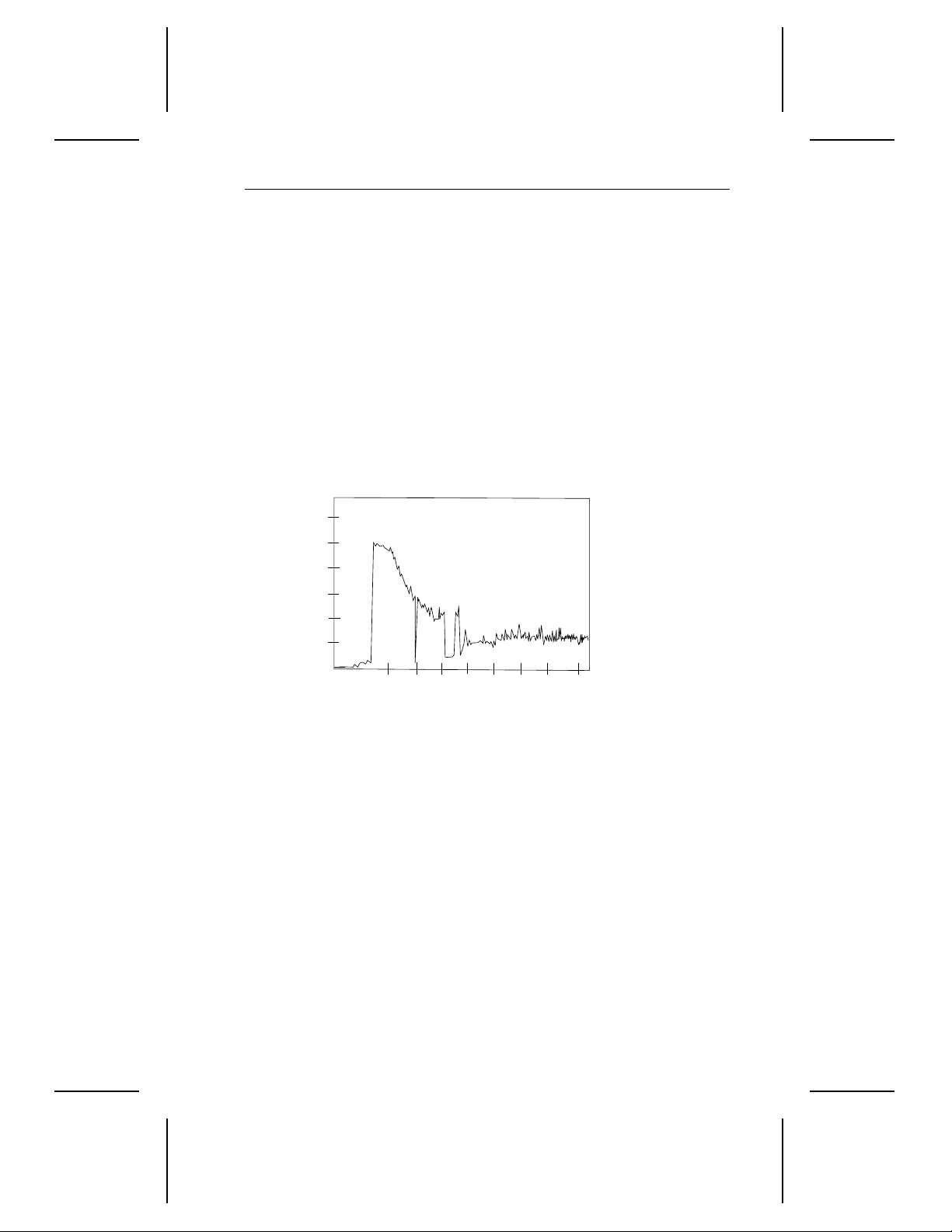

Current (mA)

1,200

1,000

800

600

400

200

2 4

8

6

Time (seconds)

12

10

16

14

Figure 1. Typical startu p cur rent profile

1.7.1 Power-up sequence

The following typical power-up sequence i s provided to assist you in

evaluating drive performance. This information does not constitute a

specification or a performance guarantee.

Power is applied to the disc drive.

1.

Depending on whether there is a jumper installed on pins 9 and 10 of

2.

the options jumper block (J5) shown in Figure 3 on page 19, either of

the following sequences occurs:

• If a jumper is not installed, the remote start option is not enabled, and

the drive begins to spin up as soon as power is applied.

• If a jumper is installed, the remote start option is enabled, and the drive

begins to spin up when the host sends a command for the motor to

start.

8 Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

Within 250 msec after power is applied, the drive responds to the Test

3.

Unit Ready, Request Sense, Mode Sense and Inquiry commands.

The drive begins to lock in speed-control circuits.

4.

The actuator lock releases the actuator.

6.

The spindle motor reaches operating speed in about 5 seconds. After

7.

5 seconds, there are no speed variations.

The drive performs velocity-adjustment seeks.

8.

The drive seeks track 0 and is then ready.

9.

1.7.2 Power-down sequence

Caution.

stop.

The power is turned off.

1.

Within 15 seconds, the drive spindle stops rotating.

2.

The read/write heads automatically move to the landing zone, which

3.

is inside the maximum data cylinder.

The magnetic acuator lock mechanism locks the arm. This completes

4.

the power-down sequence.

Do not move the drive until the motor has come to a complete

1.7.3 Auto-park

During power-down, the read/write heads automatically move to the

landing zone. The heads park inside the maximum data cylinder and the

magnetic actuator lock engages. When power is applied, the heads

recalibrate to track 0.

1.8 Power managemen t

The drive supports power-management modes that reduce its overall

power consumption. They automatically change from one mode to

another in response to interface activity. You do not need to change any

parameters or send any special commands to make the drive change

modes. The power-management modes are described as follows:

•

Spinup.

coming up to operating speed. The power consumed in t his m ode is

equivalent to the average power during the first 10 seconds after the

drive begins to spin up.

Spinup is defined as the period dur ing whic h the spindl e is

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A 9

•

•

•

The servo electronics are active, and the heads are moving to

Seek.

a specific location on the disc. The read/write electronics are powereddown. The power consumed in this mode is equivalent to the average

power measured while executing random seeks with a 2-revolution

(26.6 msec) dwell between seeks. The drive enters this mode from

the Idle mode.

Read/Write.

and the heads are on track.

The motor is up to speed and the drive is in track-follow mode.

Idle.

The drive is reading or writing. All electronics are active

1.8.1 Power consumption

Values in the table below were measured at the dr ive power c onnec tor

with an RMS DC ammeter. The terminating resistors are disabled, and

terminator power is supplied through the SCSI connector. All values are

measured 10 minutes after the drive spins up except as noted.

Spinup Seeking

Current at +12V

Amps peak 1.18 — — — —

RMS amps typ — 0.287 0.274 0.274 0.020

Watts typ — 3.444 3.288 3.288 0. 240

Current at +12V

RMS amps typ — 0.596 .0.590 0.581 0.625

Watts typ — 2.980 2.950 2.905 3. 125

Power

Total watts typ — 6.424W 6.238W 6.193W 3.365W

Read/

Write

Idle Standby

1.8.2 Voltage tolerance

Voltage tolerance

(including noise)

+5V +12V

± 5% ± 5%

10 Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

1.8.3 Input noise

+5V +12V

Voltage tolerance

(including noise)

Input noise frequency

(max)

Input noise

(max, peak-to-peak)

± 5% ± 5%

25 MHz 25 MHz

100 mV 240 mV

1.9 Environmental

This section specifies acceptable environmental conditions for the drives.

The operating specifications assume that the drive is powered up. The

nonoperating specifications assume that the drive is packaged as it was

shipped from the factory.

1.9.1 Ambient temperature (HDA case)

Operating 5°C to 55°C (41°F to 131°F)

Nonoperating –40°C to 70°C (–40°F to 158°F)

The system must provide sufficient airflow so that the

Note.

aluminum base surface temperature remains below 55°C.

1.9.2 Temperature gr ad ien t

Operating 20°C per hour (36°F per hour)

Nonoperating 30°C per hour (54°F per hour)

1.9.3 Altitude

Operating –1,000 ft. to 10,000 ft. (–305 m to 3,048 m)

Nonoperating –1,000 ft. to 40,000 ft. (–305 m to 12,192 m)

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A 11

1.9.4 Relative humidity

Operating 8% to 80% noncondensing

Maximum wet bulb 29.4°C (84.9° F )

Operating gradient, max 10% per hour

Nonoperating 5% to 95% noncondensing

Maximum wet bulb 35°C (95.0°F)

1.10 Shock and vibration

All shock and vibration specifications assume that the inputs are measured

at the drive mounting screws. Shock measurements are based on an

11-msec, half sine wave shock pulse, not to be repeated m or e than twic e

per second.

During normal operating shock and vibration, there is no phys ic al damage to the drive or performance degradation.

During abnormal operating shock and vibration, there is no physical

damage to the drive, although performance may be degraded during the

shock or vibration episode. When normal operating shock levels resume,

the drive meets its performance specifications.

During nonoperating shock and vibration, the read/write heads are

positioned in the shipping zone.

Normal

operating

Shock 2 Gs 10 Gs 75 Gs

5–22 Hz vibration 0.020-i nch

displacement

22–350 Hz vibration 0.50 Gs 0.75 Gs 4.00 Gs

Abnormal

operating

0.030-inch

displacement

Nonoperating

0.160-inch

displacement

12 Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

1.11 Acoustics

This table shows the overall A-weighted sound power and sound pressure levels for the drives. All measurements are generally consistent with

ISO document 7779. Acoustic measurements are taken under essentially free-field conditions over a reflecting plane. The drive is oriented

with the top cover up for all tests.

Overall A-weighted Value

Sound power, typ (bels) 3.4 4.0

Sound power, max (bels) 3.7 4.3

Sound pressure, typ (dBA) 27 30

Sound pressure, max (dBA) 30 33

Idle

Seek

1.12 Reliability

Read error rates are measured with automatic retries and data correction

with ECC enabled and all flaws reallocated. The mean time between

failures (MTBF) is measured at nominal power at sea level and an

ambient temperature of 35°C.

13

Nonrecoverable read errors 1 per 10

Seek errors 1 per 10

Contact stops and starts 50,000

MTBF 500,000 power-on hours

Service life 5 years

bits transferred

7

physical seeks

1.13 Agency listings

These drives are listed by agencies as follows:

• Recognized in accordance with UL 478 and UL 1950

• Certified to CSA C22.2 No. 220-M1986 and CSA C22.2 No. 950-

M1989

• Certified to VDE 0806/05.90 and EN 60950/1.88 as tested by VDE

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A 13

1.14 Electromagnetic Compliance for the European

Union

This model has the CE Marking, signifying that it complies with the

European Union requirements of the Electromagnetic Compatibility Directive 89/336/EEC of 03 May 1989 as amended by Directive 92/31/EEC

of 28 April 1992 and Directive 93/68/EEC of 22 July 1993.

®

Seagate

above directives. The drive was tested in a representative system for

typical applications. T he selected system r epresents the most popular

characteristi cs for tes t plat for ms.

The system configurations include:

• 486, Pentium, and PowerPC microprocessors

• 3.5-inch floppy disc drive

• Keyboard

• Monitor/display

Although the test system with this Seagate model complies to the

directives, we cannot guarantee that al l systems will comply. The computer manufacturer or system integrator will confirm EMC compliance

and provide CE Marking for their product. The drive is not meant for

external uses (without properly designed enclosure, shielded I/O cable,

etc.), and a terminator should be used on all unused I/O ports.

uses an independent laboratory to confirm compliance to the

1.15 FCC verification

The Medalist Pro SCSI interface drives are intended to be contained

solely within a personal computer or s imilar enclosure (not at tached to

an external device). As such, a drive is c onsidered to be a subassembly

even when individually marketed to the customer. As a subassembly, no

Federal Communications Commission authorization, verification or certification of the device is required.

Seagate Technology, Inc. has tested the drive in an enclosure as

described above to ensure that the total assembly (enclosure, disc drive,

motherboard, power supply, etc.) does comply with the limits for a

Class B computing device, pursuant to Subpart J of Part 15 of the FCC

rules. Operation with noncertified assemblies is likely to result in interference to radio and television reception.

14 Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

Radio and television interference.

radio frequency energy and, if not installed and used in strict accordance

with the manufacturer’s instructions, may cause interference to radio and

television reception.

This equipment is designed to provide reasonable protection against

such interference in a residential installation. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause interference to radio or television, which c an be

determined by turning the equipment on and off, you are encouraged to

try one or more of the following corrective measures:

• Reorient the receiving antenna.

• Move the device to one side or the other of the radio or TV.

• Move the device farther away from the radio or TV.

• Plug the equipment into a diff erent outlet so that the receiver and

computer are on different branch outlets.

If necessary, you should consult your dealer or an experienced radio/television technician for additional suggesti ons. You may find helpful the

following booklet prepared by the Federal Communications Commission:

This equipment generates and uses

How to Identify and Resolve Radio-Television Interference Problems.

This booklet is available from the Superintendent of Documents, US

Government Printing Office, Washington, DC 20402. Refer to publication

number 004-000-00345-4.

Note.

This digital apparatus does not exceed the Class B limits for

radio noise emissions from computer equipment as set out in the

radio interference regulations of the Canadian Department of

communications.

Le présent appareil numérique n′émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de Classe B prescrites dans le règlement sur le brouillage

radioélectrique édicté par le Ministère des Communications du

Canada.

Medalist Pro 2160N/ 2160WC Product Manual, Rev. A 15

Sicherheitsanleitung

Das Gerrät ist ein Einbaugerät, das für eine maximale Umgebung-

1.

stemperatur von 55°C vorgesehen ist.

Zur Befestigung des Laufwerks werden 4 Schrauben 6-32 UNC-2A

2.

benötigt. Bei seitlicher Befestigung darf die maximale Länge der

Schrauben im Chassis nicht mehr als 5,08 mm und bei Befestigung

an der Unterseite nicht mehr als 5,08 mm betragen.

Als Versorgungsspannugen werden benötigt:

3.

+5V æ 5% 0.55A

+12V æ 5% 0.35A (1,9A fur ca. 10 Sek. fur ± 10%)

Die Versorgungsspannung muss SELV entsprechen.

4.

Alle Arbeiten an der Festplatte dürf en nur von ausgebildetem Serv-

5.

icepersonal durchgeführt werden. Bitte entfernen Sie nicht die Aufschriftenschilder des Laufwerkes.

Der Einbau des Laufwerkes muss den Anforderungen gemäss DIN

6.

IEC 950 VDE 0805/05.90 entsprechen.

16 Medalist Pro 2160N/ 2160WC Product Manual, Rev. A

Medalist Pro 2160N/2160WC Product Manual, Rev. A 17

2.0 Hardware and interface

The Medalist Pro drives use an UltraSCSI interface. The ST52160N

consists of an 8-bit bidirectional data bus. The ST52160WC consists of

a 16-bit bidirectional data bus. The interface supports multiple initiators,

disconnect and reconnect, self-configuring host software and logical

block addressing.

The UltraSCSI interface uses a singled-ended driver/receiver configuration that uses asynchronous or synchronous communication protocols.

The ST52160N supports asynchronous transfer rates up to 10 Mbytes

per second and synchronous transfer rates up to 20.0 Mbytes per

second. The ST52160WC supports asynchronous transfer rates up to

20 Mbytes per second and synchronous transfer rates up to 40 Mbytes

per second.

2.1 SCSI-3 compati bil ity

The drive interface is described in the Seagate SCSI-2 /SCSI-3 Interface

Manual, publication number 77738479. The drives comply with the

mandatory subset of the ANSI SCSI-2 Interface. The Fast SCSI-3

interface is based on the ANSI Small Computer System Interface-2

(SCSI-2), document number ANSI X3.131-1994.

2.2 Handling and static-discharge precautions

The drive has static-sensitive devices. Avoid damaging the drive and

these devices by observing t he following standard handl ing and stati cdischarge precautions:

• Keep the drive in its static-shielded bag until you are ready to complete

the installation. Do not attach any cables to the drive while it is in its

static-shielded bag.

• Before handling the drive, put on a grounded wrist strap, or ground

yourself frequently by touching the metal chassis of a computer that

is plugged into a grounded outlet. Wear a grounded wrist strap

throughout the entire installation procedure.

Wool and synthetic clothes, carpets, plastics and Styrofoam contributes to electrostatic buildup. Static discharge may damage sensitive

components in your drive and computer.

• Handle the drive by its edges or frame only.

• The drive is extremely fragile—handle it with care. Do not press down

on the drive’s top cover.

18 Medalist Pro 2160N/2160WC Product Manual, Rev. A

• Always rest the drive on a padded, antistatic surface until you mount

it in the host system.

• Do not touch the connector pins or the printed circuit board.

• Do not remove the factory-installed labels from the drive or cover them

with additional labels. If you do, you void the warranty. Some factoryinstalled labels contain information needed to service the drive. Others

are used to seal out dirt and contamination.

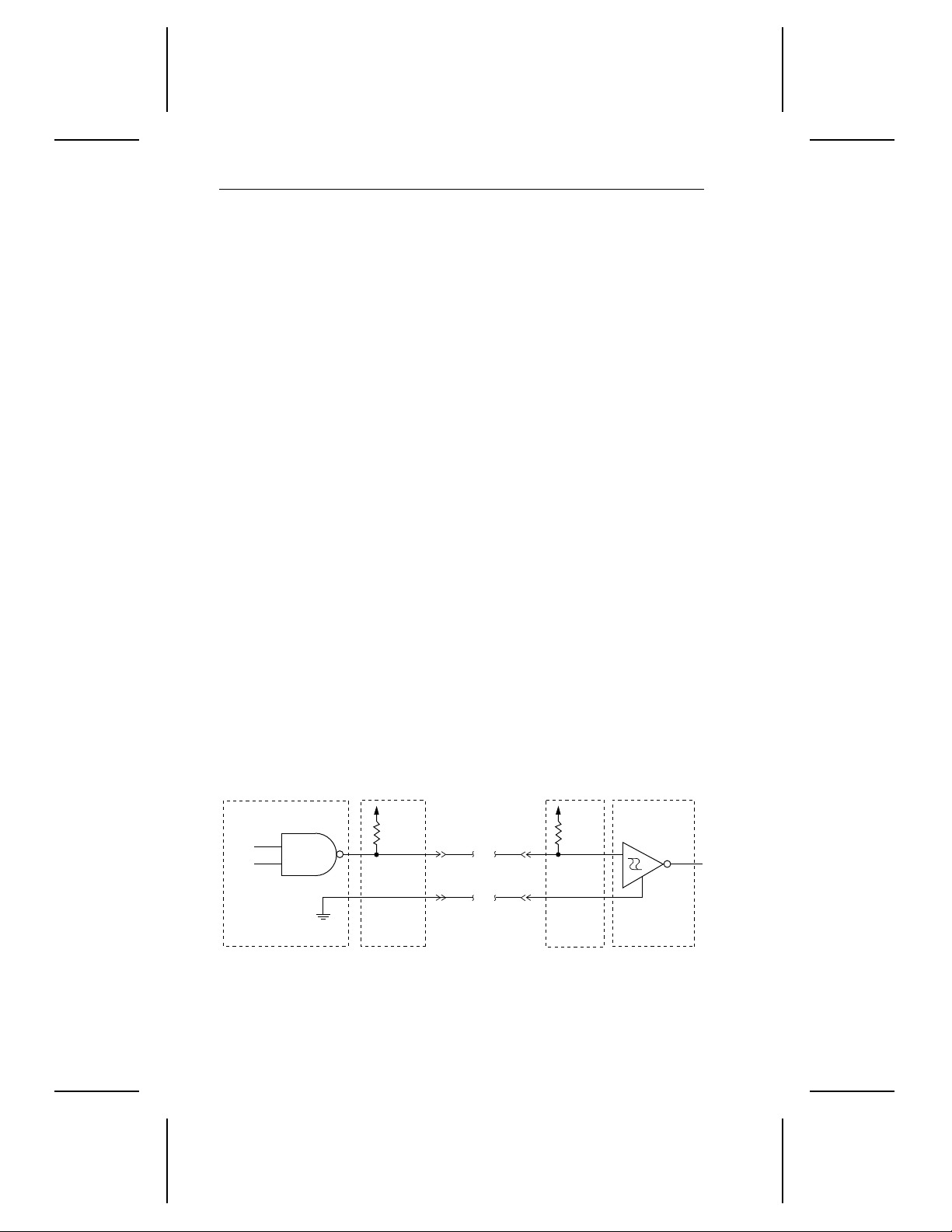

2.3 Electrical interface

The drives are designed to use single-ended interface signals. They use

single-ended drivers and receivers and active terminator circuitry. Figure

2 shows a single-ended transmitter and receiver without the active

terminator circuitry.

•

Transmitter characteristics.

The drives use an ANSI SCSI-compatible, open-collector, single-ended driver. This driver is capable of

sinking a current of 48 mA with a low-level output voltage of 0.4 volts.

•

Receiver characteristics.

The drives use an ANSI SCSI single-

ended receiver with hysteresis gate or equivalent as a line receiver.

The loss in the cable is defined as the difference between the voltages

of the input and output signals, as shown below:

Logic level Driver output (x) Receiver input (x)

Asserted (1)

Negated (0)

Line driver

(transmitter or transceiver)

ANSI SCSI

compatible circuit

≤

x ≤ 0.4V 0.0V ≤ x ≤ 0.8V

0.0V

≤

2.5V

x ≤ 5.25V 2.0V ≤ x ≤ 5.25V

+2.85V

110

ohms

Flat cable pair

+2.85V

110

ohms

Line receiver

ANSI SCSI

compatible

circuit

Figure 2. Single-ended transmitter and receiver

Medalist Pro 2160N/2160WC Product Manual, Rev. A 19

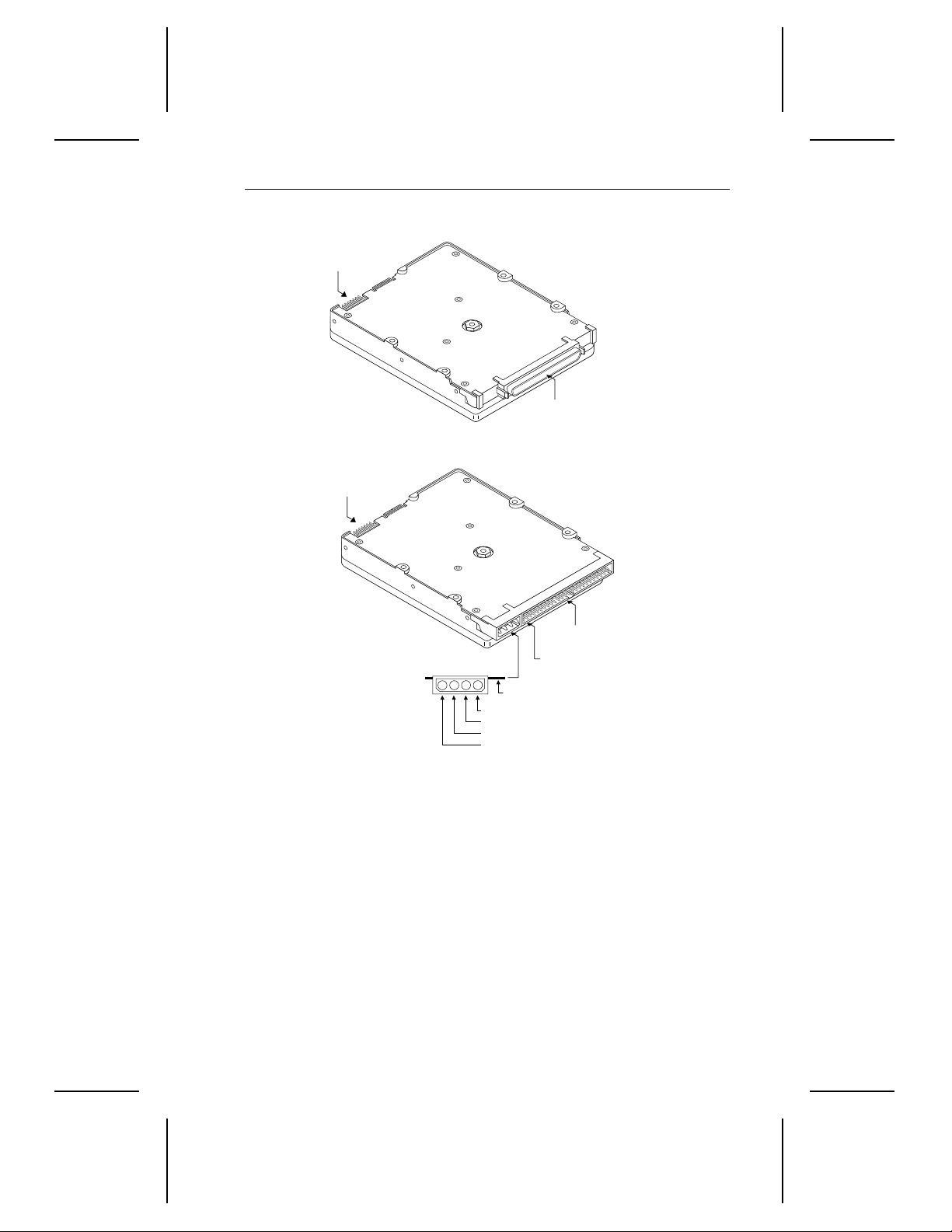

ST52160WC

Options Jumper

Block (J5)

SCA-2 Interface

connector

ST52160N

Options Jumper

Block (J5)

50-Pin Interface

Standard

power connector

4

3

2

1

+5V

+

+12V return

+12V

Circuit

board

5V return

connector

Pin 1

Figure 3. Connectors

2.4 Interface and connector configuration

The ST52160N and ST52160WC drives are differentiated by their connectors. The ST52160N comes with a standard 50-pin interface connec tor and a standard 4-pin power connector. The ST52160WC comes with

an 80-pin blindmate single-connector attachment (SCA-2) . The power is

supplied to the driv e through the bus. To minimize noise, us e shielded

mating connectors.

20 Medalist Pro 2160N/2160WC Product Manual, Rev. A

2.5 ST52160N inter fa ce connec to r

The ST52160N uses a standard 50-pin, nonshielded, keyed connector.

The connector consists of two rows of 25 male contacts 0.100 inches

apart. Pin 1 on the connector is shown in Figure 3 on page 19. Recommended mating connectors and their part numbers are

listed below.

Part numbers for mating 3M connectors that are compatible with the

drives are listed below. These connectors do not have a center key and

are available with or without strain relief.

Without strain relief

No center key

Closed end

(for cable ends)

Open end

(for daisy chain)

Part numbers for mating Molex connectors compatible with the drives

are listed below. These connectors have a center key.

Closed end

(for cable ends)

Open end

(for daisy chain)

Below are part numbers for strain reliefs that can be used with the M olex

connectors.

Molex strain relief,

preferred version

in Europe

Molex strain relief,

preferred version

in Japan

3M

3425-7000

3M

3425-6000

Molex

39-51-2504

Molex

39-51-2501

Molex 90170-0050

Molex 15-25-1503

With strain relief

No center key

3M

3425-7050

3M

3425-6050

Loading...

Loading...