User and maintenance manual

for generating sets

R44

C

3

33504024301NE_0_1

1. Preface .................................................................................................................................................................................................. 3

1.1. General recommendations ....................................................................................................................................................... 3

1.2. Pictograms and their meanings ................................................................................................................................................ 4

1.3. Instructions and safety regulations ........................................................................................................................................... 6

1.3.1 General advice ......................................................................................................................................................................... 6

1.3.2 Risks related to exhaust gases and fuels ................................................................................................................................. 7

1.3.3 Risks related to toxic products .................................................................................................................................................. 7

1.3.4 Risk of fire, burns and explosion ............................................................................................................................................... 8

1.3.5 Risks related to electrical networks .......................................................................................................................................... 8

1.3.6 Dangers presented by electric currents (first aid) ..................................................................................................................... 9

1.3.7 Risks related to moving the set ................................................................................................................................................. 9

1.3.8 Risks related to noise .............................................................................................................................................................. 9

2. General description .............................................................................................................................................................................. 10

2.1. Technical specifications ......................................................................................................................................................... 13

2.2. Identifying sets ....................................................................................................................................................................... 15

2.3. Fluid retention ........................................................................................................................................................................ 16

2.4. Fuel and consumables ........................................................................................................................................................... 16

2.4.1 Specifications ......................................................................................................................................................................... 17

2.4.1.1. Oil grades ................................................................................................................................................................. 17

2.4.1.2. Specifications of coolants ......................................................................................................................................... 18

3. Installation-Connections ...................................................................................................................................................................... 19

3.1. Unloading ............................................................................................................................................................................... 19

3.1.1 Safety during unloading .......................................................................................................................................................... 19

3.1.2 Instructions for unloading ....................................................................................................................................................... 20

3.2. Choice of location .................................................................................................................................................................. 21

3.3. Moving the genset .................................................................................................................................................................. 21

3.4. Connections ........................................................................................................................................................................... 22

3.4.1 Connections - general information .......................................................................................................................................... 22

3.4.2 Power cables .......................................................................................................................................................................... 22

3.4.3 Power connections ................................................................................................................................................................. 23

3.4.4 Battery installation ................................................................................................................................................................. 24

3.5. Protection for individuals and equipment ............................................................................................................................... 24

3.5.1 Earth connection ..................................................................................................................................................................... 24

3.5.2 Earthing system principle ....................................................................................................................................................... 25

3.5.3 TT system ............................................................................................................................................................................... 26

3.5.4 Differential protection .............................................................................................................................................................. 26

3.5.5 Adjusting the genset differential protection ............................................................................................................................. 27

3.6. Connection summary ............................................................................................................................................................. 28

3.7. Special arrangements ............................................................................................................................................................ 29

4. Trailer .................................................................................................................................................................................................. 29

4.1. Trailer linkage ........................................................................................................................................................................ 29

4.2. Check before towing .............................................................................................................................................................. 29

4.3. Operation ............................................................................................................................................................................... 30

4.4. Unhitching the trailer .............................................................................................................................................................. 30

4.5. Implementation for installation ............................................................................................................................................... 31

4.6. Break transmission adjustment .............................................................................................................................................. 31

4.7. Faults and repairs .................................................................................................................................................................. 33

4.8. Electrical connection diagram ................................................................................................................................................ 34

4.9. Complete wheels technical information .................................................................................................................................. 34

5. Preparation before operating the set ................................................................................................................................................... 35

5.1. Installation checks .................................................................................................................................................................. 35

5.2. Checks after starting the generating set ................................................................................................................................ 35

1/202

6. Using the generator set ....................................................................................................................................................................... 36

6.1. Pre-Start Inspection ............................................................................................................................................................... 36

6.2. Generator set with NEXYS control panel ............................................................................................................................... 39

6.2.1 Control panel presentation ..................................................................................................................................................... 39

6.2.1.1. Introduction to pictograms ......................................................................................................................................... 40

6.2.2 Manual starting ....................................................................................................................................................................... 41

6.2.3 Switching off .......................................................................................................................................................................... 42

6.2.4 Alarms and faults ................................................................................................................................................................... 42

6.2.5 Faults and alarms - Details ..................................................................................................................................................... 42

6.3. Generator set with TELYS control panel ................................................................................................................................ 44

6.3.1 Control panel presentation ..................................................................................................................................................... 44

6.3.1.1. View of the front panel .............................................................................................................................................. 44

6.3.1.2. Description of the screen .......................................................................................................................................... 46

6.3.1.3. Description of the pictograms in zone 1 .................................................................................................................... 47

6.3.1.4. Description of the pictograms in zone 2 .................................................................................................................... 48

6.3.1.5. Description of the pictograms in zone 3 .................................................................................................................... 49

6.3.1.6. Display of messages in zone 4 ................................................................................................................................. 51

6.3.2 Starting ................................................................................................................................................................................... 55

6.3.3 Switching off .......................................................................................................................................................................... 56

6.3.4 Alarms and faults .................................................................................................................................................................... 56

6.3.4.1. Viewing alarms and faults ......................................................................................................................................... 56

6.3.4.2. Activation of an alarm or fault ................................................................................................................................... 57

6.3.4.3. Activation of an alarm and a fault .............................................................................................................................. 58

6.3.4.4. Engine fault codes display ........................................................................................................................................ 59

6.3.4.5. Horn reset ................................................................................................................................................................. 60

7. Maintenance schedule ......................................................................................................................................................................... 60

7.1. Reminder of use ..................................................................................................................................................................... 60

7.2. Maintenance safety instructions ............................................................................................................................................. 60

7.3. Table of maintenance operations ........................................................................................................................................... 61

7.4. Fault finding ........................................................................................................................................................................... 62

7.5. No load and under load tests ................................................................................................................................................. 62

8. Battery ................................................................................................................................................................................................. 63

8.1. Storage and transport ............................................................................................................................................................ 63

8.2. Battery setting into service ..................................................................................................................................................... 64

8.3. Check ..................................................................................................................................................................................... 64

8.4. Load preconization ................................................................................................................................................................. 65

8.5. Faults and remedies .............................................................................................................................................................. 66

9. Appendix .............................................................................................................................................................................................. 67

9.1. Appendix A – Engine user and maintenance manual ............................................................................................................ 67

9.2. Appendix B - Alternator user and maintenance manual .......................................................................................................165

2/202

1. Preface

1.1. General recommendations

Thank you for choosing an electrical generating set from our company.

This manual has been designed to help you operate and maintain your electrical generating set correctly.

The information contained in this manual is taken from technical data available at the time of print. In lin e with our policy of continually

improving the quality of our products, this information may be amended without warning.

Read the safety instructions attentively in order to prevent any accidents, faults or damage. These instructions must always be

followed.

You are likely to encounter several warning symbols in this manual.

This symbol indicates an immediate danger to human he alth and life in case of exposure. Fai lure to follow

the corresponding advice entails serious consequences for human health and life in case of exposure.

Danger

This symbol draws attention to the potential risks to human health and life in case of exposure. Failure to

follow the corresponding advice entails serious consequences for human health an d life in case of exposure.

Warning

This symbol indicates a dangerous situation if the warning is not heeded.

Failure to follow the corresponding advice risks resulting in minor injury of personnel or damage to any other

object in case of exposure.

Important

In order to obtain optimum efficiency and the longest poss ible life for the electrical generating sets, maintenance operations must be

carried out according to the periods indicated in the attached prevent ative maintenance tables. If the electrical generating set is us ed

under dusty or unfavourable conditions, some of these periods will be shorter.

Ensure that all repairs and adjustments are carried out by personnel who have received appropriate training. Dealers have this

qualification, and can answer all of your questions. They can also supply you with spare parts and other services.

The left and right sides can be seen from the back of the electrical generating set (the radiator is at the front).

Our electrical generating sets have been designed so that damaged or worn parts can be replaced by new or reconditioned parts

thereby reducing the out of action period to a minimum.

For any replacement of parts, contact your nearest dealer for our company who will have the necessary equipment and can offer

properly trained and informed staff to carry out maintenance, parts replacement and even total reconditioning of generating sets.

Contact your local dealer for the available repair manuals and to make the necessary arrangements for training personnel in

implementation and maintenance.

Some user and maintenance manuals for the engines fitted to generating sets cover control units and

include the start-up and shutdown procedures for the engines.

As the generating sets are fitted with control units that are specific to the generating sets, only the

information that appears in the documentation for the generating sets' control units should be taken into

consideration.

In addition, according to the manufacturing criteria of the generating sets , some engines may be fitted with

specific electrical wiring different to that described in the engine documentation.

Important

3/202

1.2. Pictograms and their meanings

Safety notices are clearly mounted on the equipment to draw the operator's or maintenance technician's attention to the potential

dangers and explain the action to be taken in the interest of safety. These notices are reproduced in this publication for ease of

identification by the operator.

Replace any notice that is missing or illegible.

Warning: danger

Publications delivered

with the generating set

must be referred to

Warning: risk of explosion

Warning: risk of

electric shock

Protective clothing

must be worn

Naked flames and

unprotected lights

prohibited.

No smoking

Warning: toxic

materials

Your eyes and ears

must be protected

Entry prohibited to nonauthorised persons

Warning:

pressurised fluids

Periodic maintenance

must be carried out

Jet washing prohibited

Warning: high

temperature, risk

of burns

Battery level must be

checked

Earth

Warning: rotating

or moving parts

(risk of getting

caught in the

machinery)

Lifting point required

Warning: corrosive product

Figure 1.1: Pictograms and their meanings

4/202

Battery isolating

switch

Fuel

External fuel connections

Inspection hatch

Retention container

drainage

Fuel drainage

Oil drainage

Oil filling

Coolant filling

Coolant drainage

Forklift required for

lifting

Bulk tank level high

Fuel supply selection valves

During any operation on the

batteries, wear protective

glasses and protective clothing

Rinse any splashes of acid on the

skin or in the eyes using clean water.

Consult a doctor immediately.

Contaminated clothes must be

washed with water

Important: refer to the docum entatio n accompanying the generating set.

Warning: emission of toxic exhaust gases. Do not use in a confined or badly

ventilated area.

Figure 1.1 ( continued ) : Pictograms and their meanings

5/202

1.3. Instructions and safety regulations

THESE SAFETY GUIDELINES ARE IMPORTANT

If you do not understand or have any questions about any point in this manua l, contact your de al er who will expla in it t o you o r give you

a demonstration. A list of risks and precautionary measures to take follows. You should also refer to any local and nationa l regulations

that apply in accordance with your own jurisdiction.

KEEP THIS MANUAL

This manual contains important instructions which must be followed when installing or carrying out maintenance on a generating set or

batteries.

1.3.1 General advice

Use

The operating and safety instructions must be made known to operating personnel. They will be regularly up dated.

Read and understand the manuals provided with the generating set, pump unit or li ghting column properly. The manufacturer's

instructions must remain at the disposal of technicians, if possible in situ.

The facility must be operated under the direct or indirect supervision of a person appoi nted by the operator, who is familiar wit h th e

operation of the facility, and the dangers and drawbacks of the products used or stored in the facility.

Do not wear loose clothing, or get close to machines in operation. Note that the fans are not clear ly visible when the engine is

running.

Warn personnel present to keep their distance during operation.

Do not run the generating set, pump unit or lighting column without refitting the protective covers and closing all the access doors.

Never let a child touch the generating set, pump unit or lighting column, even when shut down.

Avoid operating the generating set, pump unit or lighting tower in the presence of animals (disturbance, scares, etc.).

Enga ge the parking brake when the generating set or lighti ng tower on its trailer is installed on the operating site. When chocking

the trailer on a slope; ensure that there is nobody in the path of the trailer.

Never start the engine without an air filter or exhaust.

Engine with turbocharger: never start the engine without fitting the air filter. The compres sor wheel rotating inside the t urbocharger

may cause serious bodily injury. Foreign objects in the inlet pipe may cause mechanical damag e.

Engi ne with air preheating (starting components): never use a startin g spray or any other similar starter assistance product. Upon

contact with the starting component, an explosion may occur in the inlet tube, causing bodily injury.

Do not touch the lighting column lights when they are switched on.

Maintenance

Follow the maintenance table and its instructions.

Always use tools in goo d condition which are suited to the work to be done. Ensure you have understood the instr uctions before

beginning any operation.

Goggles should be worn when carrying out maintenance operations and watches, bracelets etc. should be removed.

Fit only original parts.

Disconnect the battery and the pneumatic starter (if fitted) before undertaking any repairs, to prevent the engine from starting

accidentally. Fit a panel over the controls to prevent any attempt to start.

Only use the correct crankshaft turning techniques for turning the crankshaft manually. Do not try to turn the crankshaft by pulling it

or levering the fan. This method may cause serious bodily or material damage, or damage the vanes of the fan, reducing the

service life of the fan.

Clean off any trace of oil, fuel or coolant using a clean cloth.

Do not use a soapy solution containing either chlorine or ammonia, as these two chemicals prevent bu bble formation.

Never use petrol or other inflammable substances to clean the parts. Use only approved cleaning solvents.

Do not use a high pressure cleaner for cleaning the engine and equipment. The radiator, hoses, electric al components, etc. may be

damaged.

Avoid accidental contact with parts at high temperatures (exhaust manifold, exhaust).

Before any maintenance operation on a lighting column light, cut the electrical power supply and wait for the bulbs to cool down.

Consumables

Observe regulations in force concerning use of fuel before using your generating set, pump unit or lighting tower.

Under no circumstances use seawater or any other corrosive or electrolytic product in the cooling circuit.

Environment

The operator must take the necessary measures to comply with the aesthetics of the site of use. The whole site must be maintained

in a good state of cleanliness.

The premises must be kept clean, and be regularly cleaned so as t o avoid accumulation of dangerous materials or pollutants and

dust, which could ignite or cause an explosion. The cleaning equipment must be suited to the risks posed b y the products and dust.

The presence of dangerous or combustible materials inside premises ho using combustion devices shall b e limited to the operating

requirements.

Facilities must be operated under the constant supervision of a qualified person, who must regularly check that th e safety devices

are operating correctly and ensure that the combustion devices have the correct fuel supply.

Apart from the combustion devices, it is prohibited to use fire in any form. This restriction must be clearly displayed.

6/202

Spreading of waste water, sludge and waste is prohibited.

The fuels to be used must correspond to those featured in the declaration file and the specifications recommended by the

combustion device manufacturer.

The fuel is considered to remain in the same physical state as when it is introduced into the combustion chamber.

Burning of waste in the open air is prohibited.

Always protect your hands when checking f or leaks. Pressurised liquids may penetrate body tissue and cause serious damage.

Risk of blood contamination.

Drain and dispose of engine oil in a specially provided container (fuel distributors can collect your used oil).

Exce pt by special agreement, once closed, the gas supply main un it must only be re-opened by the g as distributor. However, the

user may access it under certain conditions. Check these for each site.

1.3.2 Risks related to exhaust gases and fuels

The carbon monoxide present in exhaust gases may cause death if the concentration levels in the air

breathed are too high.

Always use generating sets, pump units or lighting towers in a well-ventilated place where gases cannot

accumulate.

In case of indoor use:

Be sure to evacuate exhaust gases outdoors.

Provide appropriate ventilation so that personnel present are not affected.

Danger

Observe the local regulations in force for generating sets, pump units or lighting towers, as well as local regulations for us e of fuel

(petrol, diesel fuel and gas) before using your generating set, pump unit or lighting tower.

Fuel filling should be carried out when the engine is off (except for generating sets with an automatic filling system).

Engine exhaust gases are toxic: do not run the generating set, pump unit or lighting column in unventi lated premises. If insta lled in

a ventilated room, additional requirements for fire and explosion protection must be observed.

A leaking burnt gas exhaust may increase the sound level of the generating set, pump unit or li ghting column. To check on its

efficiency, regularly examine the burnt gas exhaust.

Pipes must be replaced as soon as their condition demands it.

1.3.3 Risks related to toxic products

The corrosion inhibitor contains alkali.

Do not swallow it.

This substance should not come into contact with the

eyes. In the event of contact with the eyes, rinse

immediately with plenty of water for at least 15

minutes.

Avoid prolonged or repeated contact with the skin. In

the event of contact with the skin, wash thoroughly

with water and soap. CONSULT A DOCTOR

IMMEDIATELY. KEEP THE PRODUCT OUT OF

THE REACH OF CHILDREN.

The anti-rust product is toxic and dangerous if

absorbed. Avoid all contact with the skin and eyes.

Read the instructions on the packaging.

Glycol is a toxic product and dangerous if absorbed.

Avoid all contact with the skin and eyes. Read the

instructions on the packaging.

Warning

Caution: fuels and oils are dangerous to inhale. Ensure proper ventilation, and use a protective mask.

Never expose the equipment to liquid splashes or rainfall, and do not place it on wet ground.

The battery electrolyte is harmful to skin and especially eyes. If splashes get into eyes, rinse immed iately with running water and/or

a 10% diluted boric acid solution.

Wear protective eyewear and strong base resistant gloves for handling the electrolyte.

7/202

1.3.4 Risk of fire, burns and explosion

The engine should not be operated in environments containing explosive products. As not all of the

electrical and mechanical components are shielded, there is a risk of sparks forming.

Danger

Make sure not to create sparks or flames, and not to smoke near the batteries, as the electrolyte gases are highly flammable

(especially if the battery is charging). Their acid also poses a risk to the skin, and in particular to the eyes.

Never cover the generating s et, pump unit or lighting tower with any material during operation or just after shutdown (wait for the

engine to cool).

Do not touch hot parts such as the exhaust pipe, or put combustible materials on it.

Keep all flammable or explosive materials (e.g. petrol, oil, cloth, etc.) out of the way when the set is running.

Proper ventilation is required for your generating set, pump unit or l ighting column to work properly. Without this ventilation, the

engine would very quickly rise to an excessively high temperature, causing accidents or damage to the equipment and to

surrounding property.

Do not remove the radiator cap if the engine is hot and the coolant is pressurised, due to risks of burns.

Depressurise the air, oil and cooling circuits before removing or disconnecting all the fittings, pipes or connected components.

Watch out for the possible presence of pressure when disconnecting a device from a pressurised system. Do not try to find

pressure leaks by hand. Oil at high pressure can cause bodily damage.

Some preservative oils are flammable. Also, some are dangerous to inhale. Ensure proper ventilation. Use a protective mask.

Hot oil causes burns. Avoid contact with hot oil. Check that the s ystem is no l onger pr ess urised before c arrying o ut an y proc edures.

Never start or run the engine with the oil filler cap off (oil may splash out).

Never coat the generating set, pump unit or lighting column with a thin layer of oil to protect it from rust.

Never top up the oil or coolant if the generating set, pump unit or lighting column is running, or if the engine is hot.

A generating set can only operate when stationary, and cannot be installed on a vehicle or other mobile equipment, without a prior

study taking into account the various specific features of using the generating set.

1.3.5 Risks related to electrical networks

The electrical equipment supplied with the generating set complies with standard NF C15.100 (Franc e), or with the standards of the

countries in question.

The earth connection must be installed in accordance with the standards in force in each country in qu estion, and with the neutral

system sold.

Read the manufacturer's identification plate carefully. The values for voltage, power, current and frequency are shown. Ch eck that

these values match the supply use.

Never accidentally touch stripped cables or loose connections.

Never handle a generating set with wet hands or feet.

Maintain electrical wires and connections in good condition. Using equipment in poor condition can lead to electrocution and

damage to equipment.

Al ways disconnect the power to the equipment or faci lity (generating set voltage, battery v oltage and network voltage) before any

operation.

The electrical connections must be made in accordance with current standards and regulations in the country of use.

Do not use faulty, poorly insulated or provisionally connected wires.

Never reverse the positive and negative terminals on batteries when connecting them. This could ca use severe damage to the

electrical equipment. Follow the wiring diagram supplied by the manufacturer.

The generating set should not be connected to any other power sources, such as the mains s upply network. In specific cases

where there is to be a connection to existing electrical networks, this must only be install ed by a qualified electrician, who should

take the operating differences of the equipment into account, according to whether the mains supply net work or generating set is

being used.

8/202

Protection against electric shocks is ensured by an assembly of specific equipment. If this needs to be replac ed, it should be by

components with identical nominal values and specifications.

If the protective plates (blanking covers) need to be removed to route cables, the protector (blanking cover) must be refitted when

the operations are finished.

Due to high mechanical stresses, use only strong flexible wiring with rubber sheathing, compliant with IEC 245-4, or equivalent

wiring.

1.3.6 Dangers presented by electric currents (first aid)

First aid

In the event of an electric shock, shut off the power immediately and activate the

emergency stop on the generating set or lighting colum n. If the voltage has not yet

been cut off, move the victim out of contact with the live conductor as quickly as

possible. Avoid direct contact both with the live conductor and the victim's body. Use

a dry plank of wood, dry clothes or other non-conductive materials to move the victim

away. The live wire may be cut with an axe. T ake great care to avoid the electric arc

that will be generated by this.

Begin emergency procedures

Resuscitation

If breathing has stopped, begin artificial respiration at once i n the same pla ce the acci dent took plac e u nless the victim or operator's lif e

could be endangered by this.

In the event of cardiac arrest, carry out cardiac massage.

1.3.7 Risks related to moving the set

To unload the generating sets, pump units or lighting columns from their transport support brackets under optimum safety and

efficiency conditions, you must ensure that the following points are observed:

The lifting machinery or equipment is suited to the work required, in good condition and with sufficient lifting capacity.

The slings are positioned in the rings provided for this operation, the forklift arms are resting fully underneath all of the base frame

cross-beams, or the lifting bars are inserted in the apertures provided for this purpose in the base to l ift the entire generating set

(according to models).

For completely safe working conditions and to prevent damage to the components fitted on the upper edge of the set, pump u nit or

lighting column, the generating set, pump unit or lighting column m ust be lifted up with an adjustable boom. All the chains and

cables must be parallel with each other, and as perpendicular as possible with the upper edge of the gen erating set, pump unit or

lighting column.

If other equipment fitted on the generating set, pump unit or lighting column alters its centre of gravity, special lifting devices may be

necessary to maintain correct balance and completely safe working conditions.

The ground must be able to withstand the load of the generating set, pump unit or lighting column and its lifting mac hinery without

stress (otherwise, put down beams of sufficient strength in a stable configuration).

Position the generating set, pump unit or lighting column as close as possible to its plac e of use or transport, in a clear space with

free access.

Never perform work on a generating set, pump unit or lighting tower just hanging from a lifting device.

1.3.8 Risks related to noise

Dangerous noise

Risk of hearing loss

Important

Prolonged exposure to a noise level above 80dB (A) can lead to permanent hearing damage.

Therefore, it is recommended that ear defenders are used when working in close proximity to a generating set which is in oper ation.

9/202

2. General description

Overview

Figure 2.1.1 : General description of the generating set

1 Acces to maintenance area 4 Acces to control unit

2 Lifting ring 5 Acces to power connections

3 Forklift grooves 6 Drawbar

6

2

4

1

3

5

10/202

Figure 2.1.2 : General description of the generating set

1 Protective grille 4 Alternator

2 Battery isolating switch 5

External fuel supply combined tap

(optional)

3 Starter battery 6 Charging alternator

3

1

2

4

6

5

11/202

Control

Figure 2.1.3 : General description of the generating set

Note : Photo presented with the Nexys control unit.

1 Control unit 4 Working hours counter

2 Emergency stop 5 Power circuit breaker

3 Socket control panel 6 Connection terminal block

6

5

2

3

1

4

12/202

2.1. Technical specifications

Range / Generating set type RENTAL POWER / R44C3

Weights and Dimensions

Dimensions with high autonomy tank

Dimensions l x w x h

2200 mm x 1000 mm x 1528 mm

Weight:

1150 kg dry weight / 1350 kg in operating configuration

Hood:

M3127

Sound pressure level:

at 1 m: 73 dB(A)

measurement uncertainty : 0.70

Output

Voltage Hz Phase Load factor

Max current (A)

Emergency

power

1

kW / kVA

Prime power

2

kW / kVA

400/230 50 3 0.8 58 32 / 40 29 / 36

(1) ESP: Stand-by output available for emergency use under variable charge up to 200hrs per year as per lSO 8528-1, no overload availabl

e

under these service conditions.

(2) PRP: Main output available continuously under variable load f or an unlimited time period p er year as per ISO 8528-1, an overload of 10

%

one hour every 12 hours is available, as per ISO 3046-1.

- Term of use :

Standard reference conditions ESP/PRP 40° / 40°, Air Intlet Temp, 1000m / 1000m mA.S.L. 60 % relative humidity.

Engine data

Manufacturer / model MITSUBISHI S4S-Z3DT61SD

Type 4 Cycles Naturally aspirated

Cylinder configuration 4 XL

Cubic capacity 3.33 L

Rotation speed 1500 Rpm

prime power at nominal speed 36 kW

Adjustment type Mechanical

Fuel consumption

100 % main power 10.4 L/h

Fuel

Fuel type Diesel

High autonomy fuel tank 220 L

Lubrication

Oil capacity 10 L

Min. Oil pressure 1 bar

Nominal oil pressure 3.9 bar

Oil consumption (100 % load) 0.11 L/h

Oil sump capacity 9 L

Type of lubricant Genlub

Cooling

Engine capacity with radiator 9.5 L

Max coolant temperature 102 °C

Fan power 0.8 kW

Refrigerant type Gencool

Thermostat 76.5 – 90 °C

13/202

Alternator data

● Compliant with NEMA MG21 standards, UTE NF C51 111,

VDE 0530, BS 4999, IEC 34.1, CSA

● The alternator is protected against short circuits

● Vacuum impregnation, epoxy winding, IP23 protection rating

Type LEROY SOMER LSA43.2S159

Number of phases 3

Power factor (cos Phi) 0.8

Number of poles 4

Excitation type AREP

Insulation classe H

Number of bearings 1

Coupling Direct

Control unit(s)

NEXYS

Standard specifications:

Frequency meter, Voltmeter, Ammeter

Alarms and faults

:

Oil pressure, Coolant temperature, Fail to start, Overspeed,

Alternator min/max, Fuel level low, Emergency shutdown

Engine parameters

:

Working hours counter, Engine speed, Battery voltage, Fuel

Level, Air Preheating

TELYS

Standard specifications:

Voltmeter, Ammeter, Frequency meter

Alarms and faults:

Oil pressure, Water temperature, Start failure, Overspeed,

Alternator min/max, Battery voltage min/max, Emergency stop

Engine parameters

:

Timer, Oil pressure, Water temperature, Fuel level, Engine

speed, Battery voltage

14/202

2.2. Identifying sets

Generating sets and their components are identified by means of identification plates.

The precise rules for identifying each major comp onent (engine, alternator etc.) are set out in each manufacturer's documentation

contained in the appendices of this manual.

1 - Generating set

2 - Manufacturer name

3 - Model

4 - Serial number

5 - Year of manufacture

6 - Rated output (kVA and kW) according to the ISO

8528-1 standard

PRP: main power

ESP: emergency power

7 - Rated power factor

8 - Maximum altitude of the site above sea level (m)

for the rated power

9 - Maximum ambient temperature for the rated power

(°C)

10 - Rated frequency (Hz)

11 - Generating set rotation speed (RPM)

12- Rated voltage (V)

13 - Rated current (A)

14 - Weight (kg)

15 - CE marking

16 - Non CE standard marking e.g.: GOSSTANDART)

17 - Sound pressure

18 - Sound power

Figure 2.2: Example of generating set identification plate

15/202

2.3. Fluid retention

Any outflow of the fluids contained in the generating sets (fuel , oil and coolant, or rainwater or condensation) will be collected in a

retention container.

The containers have a capacity which allows 110% of the fluids contained in the generating set fitted with this option to be collected.

Diagram 2.3: Fluid retention container

The generating sets are fitted with a visual alarm warning when the upper limit of the retention container has been reached.

In all cases, the retention containers must be regularly checked to ensure they contain no fluid (fuel, oil and coo lant, or rainwater or

condensation). If necessary, drain the containers via the drain port.

Note: Never allow these fluids to drain onto the ground; ensure they are collected in a designated container.

2.4. Fuel and consumables

All specifications (product features) are given in the engine maintenance manuals attached to this manual.

Fuels:

The specifications refer to European or international standards. Fuels complying with the standards indicated in the engine

maintenance manuals can be used without any contraindications. Only these fuels may be used.

Consumables:

In addition to the specifications indicated in the engine maintenance manuals, the consumables mentioned in the section entitled

"Specifications" are recommended.

16/202

2.4.1 Specifications

2.4.1.1. Oil grades

Engine Oil

Make Type Make Type

John Deere All

John Deere John Deere PLUS-50

GenPARTS GENLUB TDX 15W40

MITSUBISHI All GenPARTS GENLUB TDX 15W40

Volvo All GenPARTS GENLUB TDX 15W40

GENLUB TDX 15W-40

Top-of-the-range lubricant recommended for diesel engines: for generating sets used under severe conditions.

USES:

Particularly suited to more modern engines with or without turbochargers, intercoolers, or sophisticated injection systems (e.g.

HEUI, injector-pumps).

All types of use: can cope with the most demanding applications.

Depolluted engines: complies with EURO 2 and EURO 3 technology and can be used with all types of diesel fuel, especially

ecological diesel with low sulphur content.

PERFORMANCE:

ACEA E3

API CH-4

Meets level E3 of the specifications defined by European manufacturers in the ACEA standards 98 edition.

ADVANTAGES:

Less frequent oil services: this product has been put to the test during thousands of hours of use on worksites under varying

conditions, demonstrating its high quality.

Conformity with new environmental legislation: adherence to new anti-pollution standards required for new EURO 2 and

EURO 3 engines.

SPECIFICATIONS:

SAE Grade

15W-40

Density at 15°C 0.883

Cinematic viscosity at 40 °C

Cinematic viscosity at 100 °C

105

14.1

mm2/s (cSt)

mm2/s (cSt)

Viscosity index 140

Dynamic viscosity at -15 °C 3000 mPa.s(cP)

Pour point - 30 °C

Flash point 220 °C

Sulphated ash content 1.4 % weight

(Values given as examples only)

17/202

2.4.1.2. Specifications of coolants

Engine Coolants

Make Type Make Type

John Deere All GenPARTS GENCOOL PC -26°C

MITSUBISHI All

Mitsubishi LLC

GenPARTS GENCOOL PC -26°C

Volvo All GenPARTS GENCOOL PC -26°C

GenCOOL PC -26

High-protection coolant, approved by manufacturers.

GenCOOL PC -26 is a ready-to-use, highly protective coolant which is pr oduced from an antifreeze recommended by the majority of

European manufacturers.

It is made from antifreeze and G 48 inhibitors.

It protects up to -26°C.

It is free from nitrates, amines and phosphates.

It is a clear, fluorescent orange liquid.

REFERENCES/APPROVALS (for the antifreeze):

HEAVY GOODS VEHICLE LIGHTER VEHICLES

Approved by MTU, MERCEDES BENZ, MAN, KHD,

GENERAL MOTORS

Conforms with VOLVO, IVECO, VAN HOOL and STAYR

TRUCK specifications

Approved by BMW, VOLKSWAGEN, MERCEDES, PORSCHE

Conforms with VOLVO, OPEL, SEAT and SKODA

specifications

Conforms with the NF R 15.601 standard

REINFORCED ANTI-CORROSION FEATURES:

Protects against high-temperature corrosion by oxidisation of ethylene (cylinder head protection).

Protects against high-temperature cavitation (top of cylinder and coolant pump protection).

Non-corrosive for seals and hoses.

Improves the efficiency and longevity of the cooling system.

GenCOOL PC -26 is especially recommended for engines fitted with aluminium or light alloy radiators.

HIGH TEMPERATURE SUITABILITY:

Provides good conditions for thermal exchange.

Perfect stability at high temperatures.

GenCOOL PC -26 is specially adapted for engines with high power densities.

LONG LASTING PROTECTION:

High alkaline reserve/stability and longevity of corrosion inhibitors.

Maintains its technical properties during prolonged use at high temperatures (neutralisation of acids).

Ensures maximum heat transfer without the build up of deposits in the cooling system.

GenCOOL PC -26 ensures optimum protection against overheating and corrosion in extreme conditions of vehicle use.

18/202

PACKAGING/STORAGE:

GenCOOL PC -26 is supplied in 210 l metallic barrels with smooth interior linings.

It can be stored for 2 years in its original container and packaging.

Avoid zinc coated containers.

RECOMMENDATIONS FOR USE:

Compatible with the original fluid.

It is recommended that the cooling system is completely drained when replacing the fluid.

SPECIFICATIONS UNITS SPECIFIED VALUES

TRIAL

METHODS

Density at 20°C

kg/m3

1,059 +/- 3

R 15-602-1

pH

pH

7.5 to 8.5

NF T 78-103

Alkalinity reserve

ml

>=10

NF T 78-101

Boiling point

°C

105 +/- 2

R 15-602-4

Freezing point:

°C

-26 +/- 2

NF T 78-102

Glassware corrosion :

(test with antifreeze)

mg/test piece

R 15-602-7

- Copper

+/- 2.6

- Weld

+/- 0.5

- Brass

+/- 2.3

- Steel

+/- 1.6

- Cast iron

+/- 0.8

- Cast aluminium

+/- 1.0

Corrosion on warm plate

(test with antifreeze)

mg/(cm²week)

+/- 0.17

R 15-602-8

3. Installation-Connections

3.1. Unloading

3.1.1 Safety during unloading

To unload electrical generating sets from their transport supports with optimum safety and efficiency, you must ensure that the

following points are observed:

- The lifting machinery or equipment is suitable for the work required.

- The sling is correctly position ed in the central lifting eye or the lifting arms are correctly positioned in the fork-lift poc kets intended

for this purpose.

- The ground is able to bear the load of the generating set and its lifting machinery without stress (otherwise lay do wn stabilising

beams of sufficient strength).

- The generating set is put down as close as possible to its place of use or transport, in a clear space with free access.

Example of equipment to be used:

crane, slings, lifting beam, safety hook, shackles.

Forklift truck.

19/202

3.1.2 Instructions for unloading

Hoisting

Attach the sling on the lifting equipment to the ring on the generating set (no. 1) provided for this purpose. Tension the slings

slightly.

Check that the sling is correctly attached and the equipment is steady.

Lift the generating set carefully.

Direct the generating set towards the chosen location and stabilise it.

Carefully set down the equipment while continuing to position it.

Release the sling, then detach it.

Forklift truck:

Position the arms of the forklift truck in the forklift pockets (no. 2).

Lift the equipment, handling it gently.

Set down the generating set in its unloading position.

1

2

20/202

3.2. Choice of location

This shall be determined according to the application. There are no strict rules governing the choice of location, other than the proximity

of the electrical supply panel and the disturbance cause d by the no ise. Ho wever, it is important to take i nto account the f uel suppl y, the

evacuation of burnt gases, the direction of these gases and evacuation noises.

The choice of location will therefore be the result of a carefully considered compromise!

Examples of problems that may be encountered:

Incorrect ventilation and exhaust Building or terrain too rough.

Generating set incorrectly seated

Reduced access

Impossible to fill with fuel Impossible to open enclosure doors

Figure 3.1: Examples of problems that may be encountered

Ensure that the generating set is placed on a flat surface.

Warning

3.3. Moving the genset

Whenever the generating set is moved, the appropriate equipm ent must be used (sling, forklift, etc.) and you must know the parts of

the generating set which enable it to be moved ( see below).

Central lifting ring

Forklift pockets

Drawbars

21/202

3.4. Connections

3.4.1 Connections - general information

As with low voltage electrical installations, use and maintenance is governed by standard NFC 15. 100 (France) or by the standards in

the relevant country, based on international standard IEC 60364-6-61.

They must also adhere to the regulations in the NFC 15.401 application guide (France) or to the regulations and standards in th e

relevant country.

3.4.2 Power cables

These can be unipolar or multipolar according to the power of the generating set.

Power cables should preferably be installed in ducts or on a cable tray for this purpose.

The cable cross-section and number of cables should be determined according to th e cable type and the current standards to be

observed in the country of installation. The choice of conductors must comply with international standard IEC 30364-5-52.

Three phase - Calculation hypothesis

Fitting method = wiring in cable runs or non perforated trays.

Permissible voltage drop = 5%

Multiconductors or single conductor joined when precision 4X…(1)

Cable type PVC 70°C (e.g. H07RNF).

Ambient temperature = 30°C.

Circuit breaker

calibre

(A)

Cable sizes

0 - 50m 51 - 100m 101 - 150m

mm²/AWG mm²/AWG mm²/AWG

10 1.5 / 14 2.5 / 12 4 / 10

16 2.5 / 12 4 / 10 6 / 9

20 2.5 / 12 4 / 10 6 / 9

25 4 / 10 6 / 9 10 / 7

32 6 / 9 6 / 9 10 / 7

40 10 / 7 10 / 7 16 / 5

50 10 / 7 10 / 7 16 / 5

63 16 / 5 16 / 5 25 / 3

80 25 / 3 25 / 3 35 / 2

100 35 / 2 35 / 2 4X(1X50) / 0

125 (1) 4X(1X50) / 0 4X(1X50) / 0 4X(1X70) / 2/0

160 (1) 4X(1X70) / 2/0 4X(1X70) / 2/0 4X(1X95) / 4/0

250 (1) 4X(1X95) / 4/0 4X(1X150) / 2350MCM 4X(1X150) / 2350MCM

400 (1) 4X(1X185) / 0400MCM 4X(1X185) / 0400MCM 4X(1X185) / 0400MCM

630 (1) 4X(2X1X150) / 2x 2350MCM 4X(2X1X150) / 2x 2350MCM 4X(2X1X150) / 2x 2350MCM

Single phase - Calculation hypothesis

Fitting method = wiring in cable runs or non perforated trays.

Permissible voltage drop = 5%

Multiconductors.

Cable type PVC 70°C (e.g. H07RNF).

Ambient temperature = 30°C.

Circuit breaker

rating (A)

Cable sizes

0 - 50m 51 - 100m 101 - 150m

mm²/AWG mm²/AWG mm²/AWG

10 4 / 10 10 / 7 10 / 7

16 6 / 9 10 / 7 16 / 5

20 10 / 7 16 / 5 25 / 3

25 10 / 7 16 / 5 25 / 3

32 10 / 7 25 / 3 35 / 2

40 16 / 5 35 / 2 50 / 0

50 16 / 5 35 / 2 50 / 0

63 25 / 3 50 / 0 70 / 2/0

80 35 / 2 50 / 0 95 / 4/0

100 35 / 2 70 / 2/0 95 / 4/0

125 50 / 0 95 / 4/0 120 / 2250MCM

22/202

3.4.3 Power connections

Disconnect the battery leads or use the battery isolating switch before carrying out any operations

on the generating set.

(To disconnect the battery, disconnect the negative lead (-) first).

Warning

1. Open the access hatch to the power section.

2. Feed the power cables through the access hatch on the genset control unit.

3. Connect the power cables to the bars. (N/L0-L1-L2-L3 or N2-R2-S2-T2).

4. Connect the power cables to the installation ensuring the live and neutral wires are correctly connected.

Ensure that the direction of rotation of the phases is identical on the genset and the installation.

(Our gensets are factory-set with a conventional direction of phase rotation)

Warning

N/L0

or

N2

L

3

or

T2

L2

or

S2

L

1

or

R2

USE

Acces hatch

23/202

3.4.4 Battery installation

Install the battery or batteries in the immediate vicinity of the electric starter motor. The cables will be connecte d directly from the

battery terminals to the starter motor terminals.

The primary instruction to follow is to ensure that the polarities between the battery and starter motor match. Never reverse the positiv e

and negative battery terminals when connecting them. This could cause severe damage to the electrical equipment.

The minimum cross-section of the cables will be 70 mm

2

. It varies according to the power of the starter motor but also the distance

between the batteries and the set (voltage drops on the line).

3.5. Protection for individuals and equipment

3.5.1 Earth connection

For effective protection against electric shocks, the generating set needs to be earthed. To do this, use a copper wire, with a minimum

cross-section of 25 mm2 for a stripped cable and 16 mm2 for an insulated cable, connected to the generating set earth socket and a

galvanised steel earthing rod embedded vertically into the ground.

The earthing rod resistance value should comply with the values shown in the table below.

Note: use the highest differential setting from the installation as a guideline.

The resistance value is calculated in the following way:

R = Ul

I Δn

Maximum resistance value of the earth socket R (Ω) according to the diff erential unit operational

current (operation time should not be longer than 1 second).

I Δn

differential

Earth R

(Ω)

Ul: 50 V

Earth R

(Ω)

Ul: 25 V

≤ 30 mA 500 > 500

100 mA 500 250

300 mA 167 83

500 mA 100 50

1A 50 25

3A 17 8

5A 10 5

10A 5 2.5

The Ul value: 25 V is required for work site installations, and livestock buildings, etc.

generating set earth socket

24/202

For a default voltage of 25 V and a default current of 30 mA, this rod must be of a minimum length of: see table below

Nature of ground

Length of

rod in

metres

Thick arable land,

moist compact ballast

1

Lean arable land,

Gravel, coarse ballast

1

Bare stony soils, dry sand,

impermeable rock

3.6

To obtain an equivalent length, you can use several earthing rods

connected in parallel and set apart by at least their length.

Example: 4 interconnected 1 metre rods separated by 1 metre.

Note: For the United States (National Electrical Code reference NFPA-70).

The generating set must be earthed. To do this, use a copper wire with a minimum cross-section of 13.3 mm² (or AWG 6, at most)

connected to the generating set earth socket and a galvanised steel earthing rod fully embedded into the ground vertically.

This earthing rod embedded fully in the ground must have a minimum length of 2.5 m.

3.5.2 Earthing system principle

The Earthing system, or SLT (formerly Neutral system) of the electrical facility defines the situation of the generating s et neutral in

relation to earth and the grounds of the electrical facility at the user end.

The purpose of the earthing systems is to protect personnel and equipment by managing risks posed by insulation defects. For safety

reasons, any live conducting part of a facility must be insulated from the earth. This insulation may be achieved by distance, or by using

insulating materials. But with time, insulation may deteriorate (due to vibrations, mechanical impacts, dust, etc.), and therefore generate

an earth with dangerous potential. This defect poses risks for personnel and property, but also continuity of service.

Earthing systems are codified by two letters that define the connections:

The first letter defines the neutral connection:

I Insulated or earthed via an impedance device

T Connected to earth

The second letter defines the grounding situation of the electrical facility:

T Connected to earth

N Connected to neutral

E.g.: IT = Isolated Neutral + Ground earthed

Speed

Number of

conductors

Detection Note

TT 4 poles Measurement of residual current Triggering of 1

s

t

fault by RCD

TN

C 3 poles

No measurement of residual current

Triggered by overcurrent protection

upon 1

st

fault

S 4 poles

IT SN 3 poles Insulation resistance measurement

Triggered upon 2

n

d

fault by

overcurrent protection

25/202

3.5.3 TT system

R

Ph 1

Ph 2

Ph 3

N

PE

R

R

Neutral connected

to earth T

Ground connected

to earth T

Neutral

earth

Ground

earth

R

Ph 1

Ph 2

Ph 3

N

PE

R

id

id

id

Figure 3.2: TT neutral system.

The alternator neutral is earthed, and the grounds of the user equipment have their own earth connection.

In the TT system, automatic power cut-off via a Residual Current Device (RCD) is obligatory at the upstream part of the facility, t o

ensure protection of personnel (with a maximum 30 mA device on outlet circuits).

3.5.4 Differential protection

In order to ensure that people are protected from electric shocks from the TT system, the generating set is equipped with a residual

current device: this can be fixed or adjustable depending on the option chosen.

• If the generating set's residual current device is not adjustable and the activation threshold has been set at 30 mA, all terminal

circuits in use are protected.

• If the generating set's residual current device is not adjustable and the activation threshold has been set at 300 mA, a 30mA

residual current device must be added to each of the circuit outlets in use.

• If the generating set's residual current device is adjustable, (located upstream) this must be above those devices located

downstream (terminal circuits); this means that continuity on clean circuits will be maintained in the event of a fault on one of

the terminal circuits.

Example:

Any change to the setting on the generating set's resid ual curren t device could pose a risk to personal safety.

The user will be held liable - any changes must only be made by trained, qualified engineers.

When the generating set is disconnected from an inst allation after use, the general residual current device

must be restored to factory settings by a qualified engineer who can then check this.

Important

Generating set's residual

current device

Residual current device

Terminal circuit 1

Residual current device

Terminal circuit 2

Residual current device

Terminal circuit 3

300mA

30mA

30mA

30mA

Generating set

26/202

3.5.5 Adjusting the genset differential protection

Before adjusting the settings on the generating set's residual c urrent device, the f ollowing two parameters must be taken into account:

the sensitivity of the current threshold and the activation time.

The generating set's residual current device must have, in relation to the downstream device (terminal circuit):

- a sensitivity three times greater.

- a longer cut-off time.

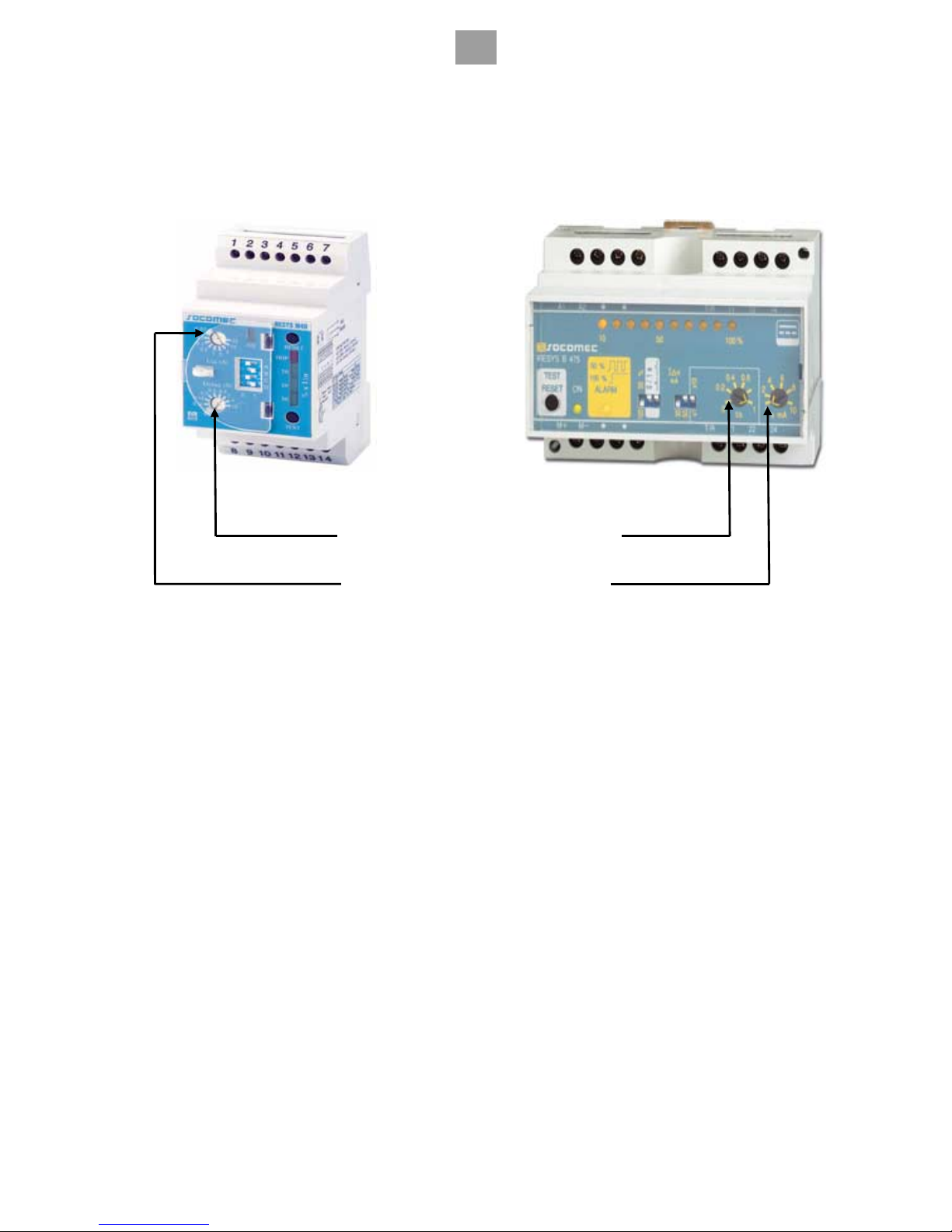

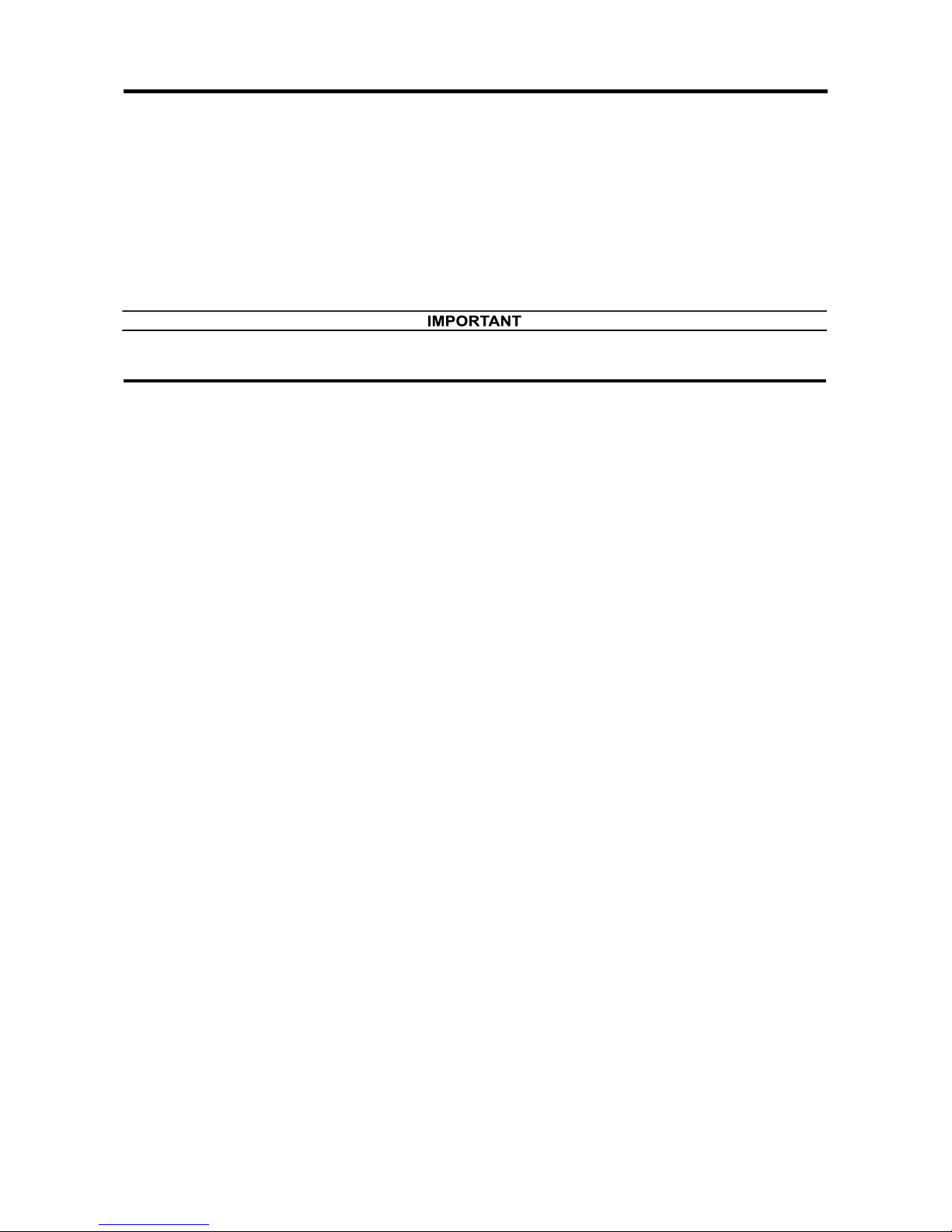

Type A/AC

Type B

Two types of differential relay are fitted on the generating sets:

Type A:

Differential device for which operation is guaranteed:

for residual sinusoidal alternating currents,

for continuous pulsed residual currents,

for continuous pulsed residual currents with a continuous component of 0.006 A with or without phase check, independent of

the polarity.

Type B:

Device for which operation is guaranteed:

as in the case of type A,

for residual sinusoidal currents up to 1000 Hz,

for residual sinusoidal currents superimposed on a pure continuous current,

for continuous pulsed currents superimposed on a pure continuous current,

for residual currents which could come from rectifier circuits i.e.:- three phase half-wave rectifier or a three-phase full-wave

bridge rectifier, full-wave bridge rectifier between phases, with or without phase angle check, independen t of the polarity.

Our residual current devices are factory-set with an activation threshold of 30 mA and with automatic cut-off. Depending on the use, if

the residual current device is modified, it is recommended to fit a seal to prevent any tampering when the generating set is being use d.

Time setting potentiometer

Current threshold adjustment potentiomete

r

27/202

3.6. Connection summary

Identify its earthing system

TT

Option « Application EDF »

France uniquement

Mark the type of differential protection

Fixed genset differential protection

Adjustable genset differential protection

30 mA 30 mA 300 mA 300 mA

No operation required:

terminal circuits protected

No operation required:

terminal circuits protected

Add differential protection

set to 30 mA to the terminal

circuit output(s)

Add differential protection

set to

30 mA to the terminal circuit

output(s)

Earth the generating set

Connect to the power supply

28/202

3.7. Special arrangements

Generating sets are not fitted with protection against power surges caused by drops in atmospheric pressure or manoeuvring.

The company does not accept any responsibility regarding damage caused b y these occurrences.

However, lightning conductors can be installed, on the understanding that this does not give total protection.

4. Trailer

4.1. Trailer linkage

Before attaching the trailer, check the trailer hook on the tow vehicle; it should fit the trailer ring perfectly.

Trying to tow a trailer with a non-matching device (bar, wires, cords, etc.) could lead to serious

accidents.

Also check:

- no incipient fractures or excessive wear on the hitching system.

- locking system is operating properly.

Warning

To hitch the trailer, proceed as follows:

Lock the wheels to stop the trailer from moving

Lift up the rear trailer supports and lock them

Release the parking brake

Release the locking levers for the draw bar arms and adjust the ring to the same height as the vehicle hook

Hitch the trailer, remove the locks on each side of the wheels then lift up the front wheel fully using its handle

Connect the electrical circuit of the trailer to that of the tow vehicle

Hook the handbrake safety wire onto the hook on the tow vehicle.

Diagram 4.1 : Coupling a trailer

4.2. Check before towing

Before towing, check the following:

Tightness of the generating set enclosure bolts.

Wheel tightness.

Hitching hook locked.

Tyre pressure.

Signalling lights working, for "on-road" trailers.

Enclosure doors closed.

Parking brake released, for "on-road" trailers.

Guide wheels (jockey wheels) and stands lifted (if fitted).

Towbar arm locking levers tightened and pinned (if fitted with an adjustable towbar).

Brake test, for "on-road" trailers.

Safety cable fitted, for "on-road" trailers.

Tow vehicle

Trailer

CORRECT

Tow vehicle

Trailer

CORRECT

Tow vehicle

Trailer

INCORRECT

Tow vehicle

Trailer

INCORRECT

29/202

4.3. Operation

"On-site" trailer

These trailers are not fitted with a main brake, and so cannot be braked in motion; t he tyr es allo w for a maximum speed of 27 km/h. So

it is absolutely prohibited to exceed this speed.

Nor are these trailers fitted with signalling lights. On-road use is prohibited.

"On-road" trailer

The driving speed must be suited to the condition of the road and the handling of the trailer.

Driving at high speed causes heating of the tyres; so it is important to stop from time to time, and check them. Excessive heating may

cause a puncture, and therefore a serious accident. For reversing manoeuvres, remember to lock the inertia brake.

Particular attention must be paid to the tightness of the wheels on new vehicles.

In the first few miles' driving, heating of the brake hubs a nd drums will ac tually reduce the wheel tightne ss. It

is therefore essential to check the tightness every 6 miles (10 kilometres) until no further loosening is noted.

Nonetheless the tightness must be checked whenever you are about to tow the trailer.

Warning

Lights/signalling (only for "on-road" trailers)

Warning lights are obligatory for on-road driving. Signalling must comply with regulations in force in the country of use.

Figure 4.2: Example of French signalling

4.4. Unhitching the trailer

This operation should be carried out on horizontal, flat, stable ground.

Lock the wheels

Lower the front wheel

Disconnect the road signals wire

Refit the hitch using the wheel to release the hook ring from the tow vehicle,

Release the tow vehicle

Engage the handbrake.

Red rear lights + direction indicators+ stop lights

Front reflective devices (white)

Side reflective devices (orange)

Rear reflective devices (red triangle)

30/202

4.5. Implementation for installation

Operations to be carried out:

Ensure that the ground is strong enough for the assembly not to sink into it.

Unhitch the trailer.

Immobilise the trailer by placing chocks under the wheels.

Fully engage the parking brake (if fitted).

Using the front wheel, position the generating set as close to horizontal as possible.

Lower the stands (if fitted), and lock them.

4.6. Break transmission adjustment

- The handbrake is used only as a parking brake.

- Setting is carried out starting with the brakes moving to the brake control.

Important

After fitting the wheels on the axle, turn the wheels in the FORWARD direction (on all R A 2 type brake s, check that the adjustm ent

screw 8 reaches the “FORWARD” stop on the brake backing plate).

Adjust the brake setting using screw 8, with the cables not connected to the cross bar(s). The shoes should rub the drum slightly.

Connect the brake cables to the cross bars(s) and tighten the nuts and lock nuts, leaving the end of the threaded en d protruding

by around 10 mm (Fig. 4.4).

IMPORTANT: Wherever possible, cables must cross over to achieve the highest possible gain curve (Fig. 4.5).

Check that the parking lever 1 is in the ‘REST” position and that the compensating spring 4 is completely free on its rod (unscrew

the nuts 5 fully).

Check that the hook slide 2 is not compressed and the yoke 3 is in the pulled out position.

Fit the transmission and adjust the assembly using the tensioner 6 until a gap (J1) of 1 mm max is obtained bet ween the linkage 9

and slide 2.

Adjust the compensating spring 4 at one end pressing it against the anchorage plate, and at the other end leaving a 2 mm gap (J2)

max between the spring and nuts 5.

Tighten all the lock nuts.

Checking the setting (trailer on axle stands):

Pull the parking lever 2 notches - the wheels cannot turn in a FORWARD direction.

The wheels can turn in REVERSE (adjustment screw 8 switches to the REAR position).

Pull the parking lever fully.

The wheels will not turn either in FORWARD or REVERSE and the cross bar(s) must remain parallel with the axle body.

Check the transmission setting after 180 miles (300 km) (running in period) and if necessary adjust the gap (J1) using the

tensioner.

Parking

The lever must be fully pulled up, so that the compensating spring is fully compressed.

Every 900 miles (1500 km), check the braking settings and distribution on all the wheels.

Important

The brake controls are designed to draw trailers behind flexible suspension touring vehicles. If used behin d an HGV, be sure

to provide the fitted ball joint with a shock absorber to prevent premature wear.

During any manoeuvres with the trailer coupled, do not turn more than 90° or force reverse.

The specifications of our brake controls are indicated on a manufacturer's plate, and the items on this should be su pplied to us

when requesting replacement parts, in particular for the shock absorber, of a special type, approved by the Service des Mines

to correspond to European standards (it is advisable to have a spare shock absorber to enable instant repairs).

31/202

Figure 4.3: Braking transmission

Figure 4.4: Cross bar fitting Figure 4.5: Tandem bearing fitting

32/202

4.7. Faults and repairs

Fault observed Origin Solutions

Erratic braking of trailer - Faulty shock absorber Replace the shock absorber

Braking too weak

- Jaws worn Replace the jaws

- Jaws not run in Fault will disappear only after running in

- Incorrect linkage setting Adjust the setting

- Significant friction on the slide Grease the sliding parts

- Slide corrosion Remove the corrosion and grease

- Coupling height does not match that of

the towing vehicle

Adjust the height so that the two parts

are in the same horizontal plane

Drum temperature abnormally high

- Incorrect linkage setting Adjust the settings

- Incorrect brake setting Adjust the settings

- High levels of dust in the drums Remove the dust

- Jaws, springs, drums damaged Replace the damaged parts

- Brake cables or link rod damaged Replace the damaged parts

Jerky braking

- Incorrect linkage setting Adjust the settings

- Interfering parts on the slide Remove, clean and grease

- Corroded slide Remove the corrosion and grease

- Damage to slide guide rings

Replace the rings (and possibly the

slide) and grease

- Faulty shock absorber Replace the shock absor ber

Trailer tending to swerve upon braking

- Cross-bar(s) not balanced Adjust the cross-bar(s)

- Different brake setting on the two sides Adjust the brake settings

- Cables damaged or incorrectly fitted

Replace the damaged parts

Refit the cables

- Poor load distribution Check the load distribution

When starting the trailer holds back the

towing vehicle

- Damage to slide or to guide rings Replace the faulty parts and grease

- Slide corrosion Remove the corrosion and grease

- Tie rod damaged

Replace the tie rod and adjust the

settings

- Linkage damaged or incorrectly set

Replace the damaged parts and adjust

the settings

- Brake on Loosen the brake

Play in the coupling head

- Head worn (see wear indicator) Replace the head

- Ball joint worn Replace the ball joint

Parking braking too weak

- Compensating spring incorrectly set Adjust the setting

- Braking system incorrectly set Adjust the setting

- Notched sector damaged

Replace the sector and adjust the

setting

- Lever ratchet worn Replace the lever and adjust the setting

- Cable ruptured Replace the cable and adjust the setting

33/202

4.8. Electrical connection diagram

Figure 4.6 : Electrical connection diagram

4.9. Complete wheels technical information

TYRES COMPLETE

WHEELS

Dimensions Indices Diameter (mm) Cross section

(mm)

Radius under

load

(mm)

Load

(Kg)

Pressure

(bar)

135 R 13 70 T 550 134 265 335 2.4

145 R 13 75 T 566 145 272 387 2.4

155 R 13 79 T 578 150 277 437 2.4

145/70 R 13 71 T 534 150 259 345 2.5

155/70 R 13 75 T 548 147 263 387 2.5

185/70 R 13 86 T 594 185 285 530 2.5

165 R 14 C 98 N 622 172 284 650 3.8

155/70 R12 100 N 525 155 244 650

(1)

800

(2)

6.25

185 R 14 C 102 P 650 188 316 675

(1)

850

(2)

4.5