User and maintenance manual

for generating sets

R34

0

U

33504081101NE_0_1

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth

defects, and other reproductive harm.

If this product contains a gasoline engine

WARNING

The engine from this product contains

chemicals known to the State of California to

cause cancer, birth defects or other

reproductive harm

The state of California requires the above two warnings.

1. Preface ............................................................................................................................................................................................ 3

1.1. General recommendations ................................................................................................................................................. 3

1.2. Pictograms and their meanings .......................................................................................................................................... 4

1.3. Instructions and safety regulations ..................................................................................................................................... 8

1.3.1 General advice ................................................................................................................................................................... 8

1.3.2 Risks related to exhaust gases and fuels ........................................................................................................................... 9

1.3.3 Risks related to toxic products ......................................................................................................................................... 10

1.3.4 Risk of fire, burns and explosion ...................................................................................................................................... 10

1.3.5 Risks related to electrical networks .................................................................................................................................. 11

1.3.6 Dangers presented by electric currents (first aid) ............................................................................................................. 11

1.3.7 Risks related to moving the set ........................................................................................................................................ 11

1.4. Identifying sets ................................................................................................................................................................. 12

2. General description ........................................................................................................................................................................ 14

2.1. Description ....................................................................................................................................................................... 14

2.2. Technical specifications ................................................................................................................................................... 17

2.3. Fuel and consumables ..................................................................................................................................................... 19

2.3.1 Specifications ................................................................................................................................................................... 19

2.3.1.1. Oil grades ............................................................................................................................................................ 19

2.3.1.2. Specifications of coolants .................................................................................................................................... 20

3. Installation ...................................................................................................................................................................................... 21

3.1. Unloading ......................................................................................................................................................................... 21

3.1.1 Safety during unloading ................................................................................................................................................... 21

3.1.2 Instructions for unloading ................................................................................................................................................. 21

3.1.2.1. Slings .................................................................................................................................................................. 21

3.1.2.2. Fork lift truck ........................................................................................................................................................ 22

3.2. Fluid retention ................................................................................................................................................................... 22

3.3. Choice of location ............................................................................................................................................................. 24

3.4. Electricity .......................................................................................................................................................................... 25

3.5. Special arrangements ...................................................................................................................................................... 26

4. Trailer ............................................................................................................................................................................................. 27

4.1. Trailer linkage ................................................................................................................................................................... 27

4.2. Check before towing ......................................................................................................................................................... 27

4.3. Operation ......................................................................................................................................................................... 28

4.4. Unhitching the trailer ........................................................................................................................................................ 28

4.5. Implementation for installation .......................................................................................................................................... 29

4.6. Break transmission adjustment ........................................................................................................................................ 29

4.7. Faults and repairs ............................................................................................................................................................. 31

4.8. Electrical connection diagram ........................................................................................................................................... 32

4.9. Complete wheels technical information ............................................................................................................................ 32

5. Preparation before operating the set ............................................................................................................................................. 33

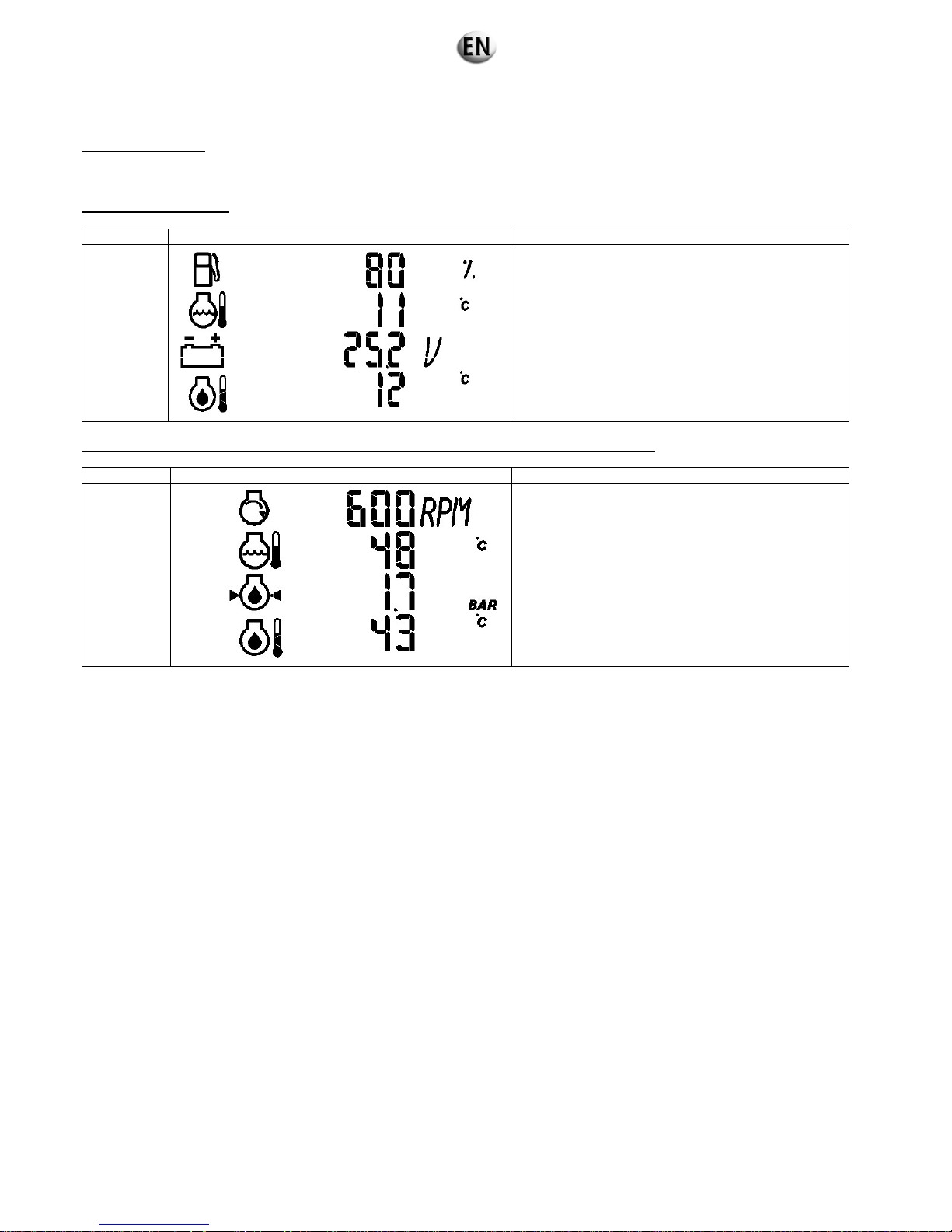

5.1. Installation checks ............................................................................................................................................................ 33

5.2. Checks after starting the generating set ........................................................................................................................... 33

6. Using the generator set .................................................................................................................................................................. 33

6.1. Pre-Start Inspection .......................................................................................................................................................... 33

6.2. Generator set with TELYS control panel .......................................................................................................................... 35

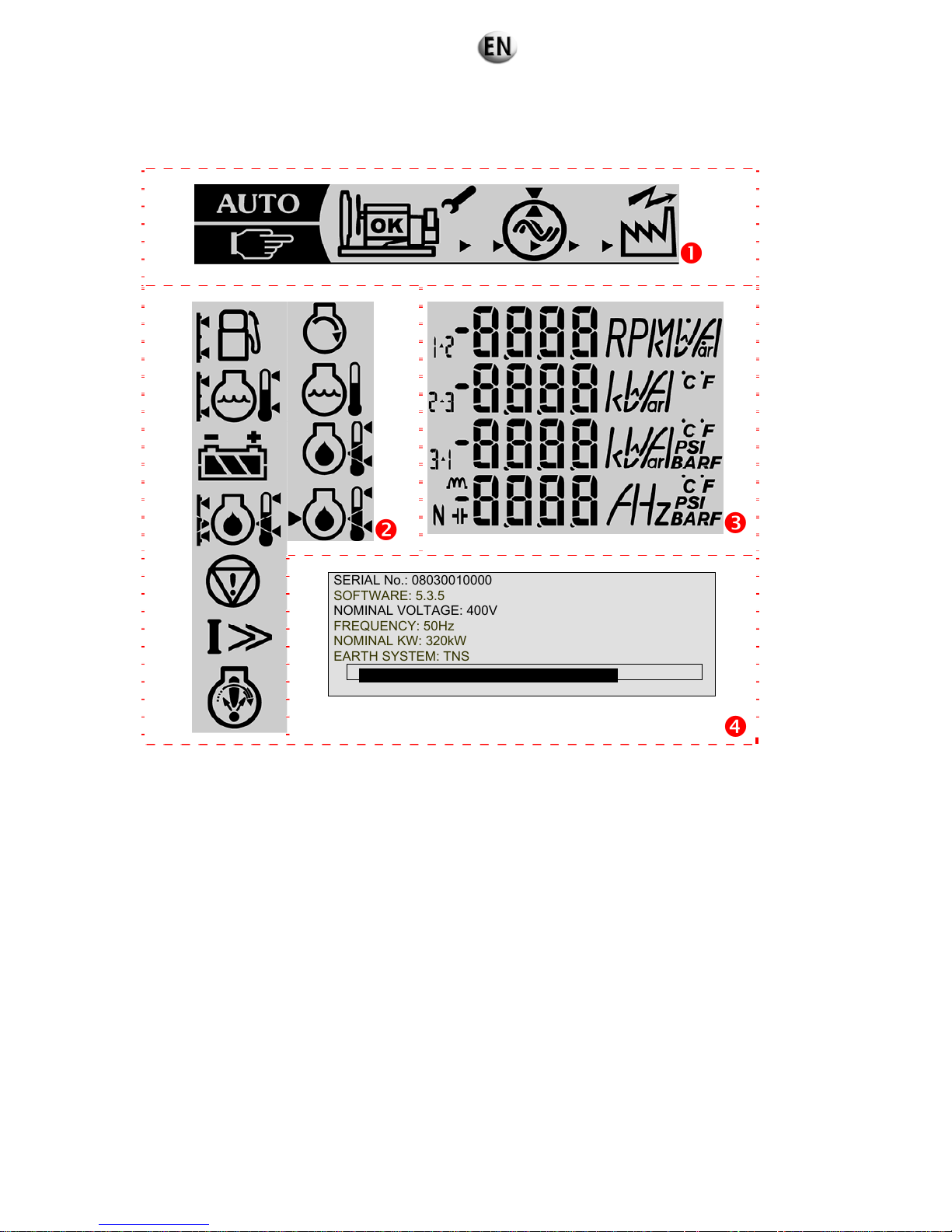

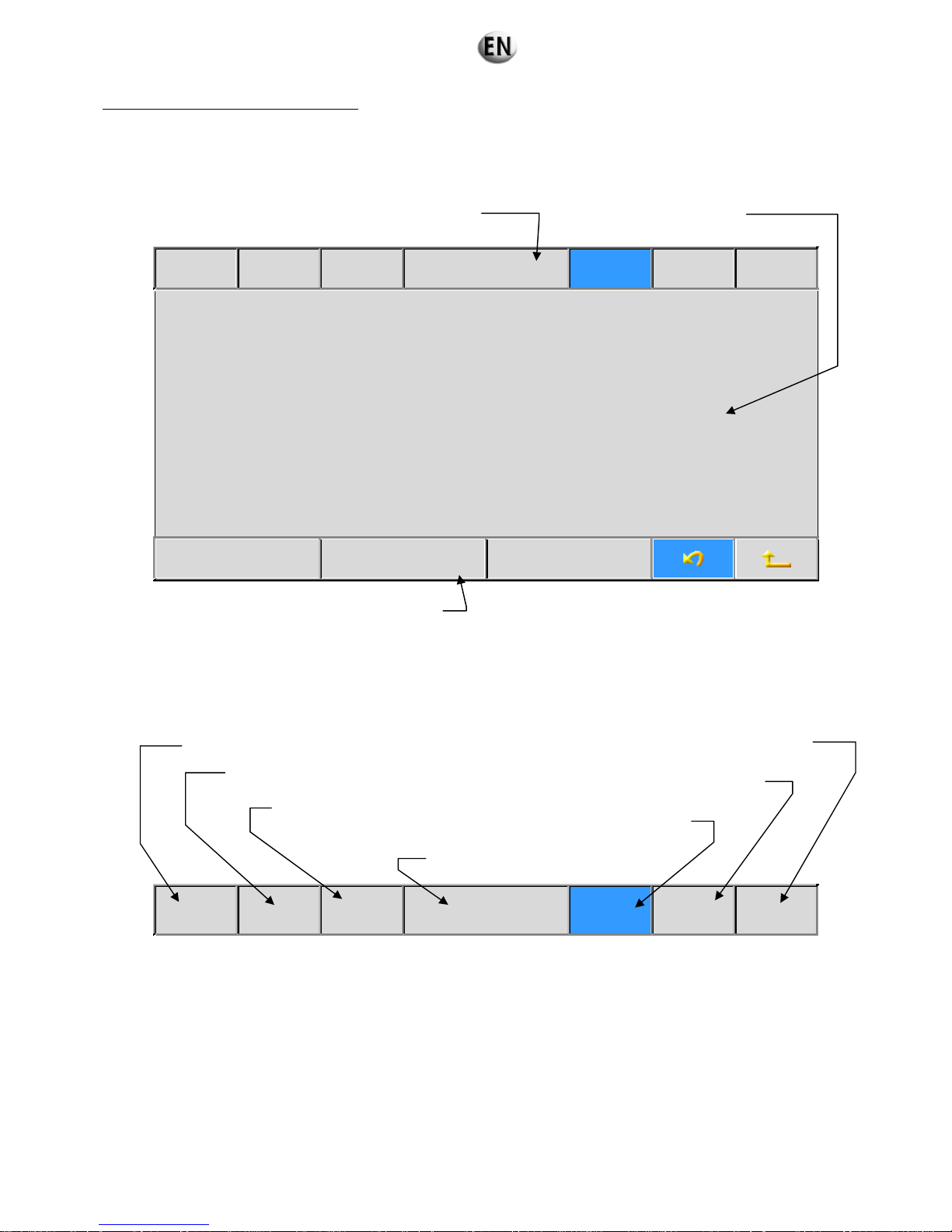

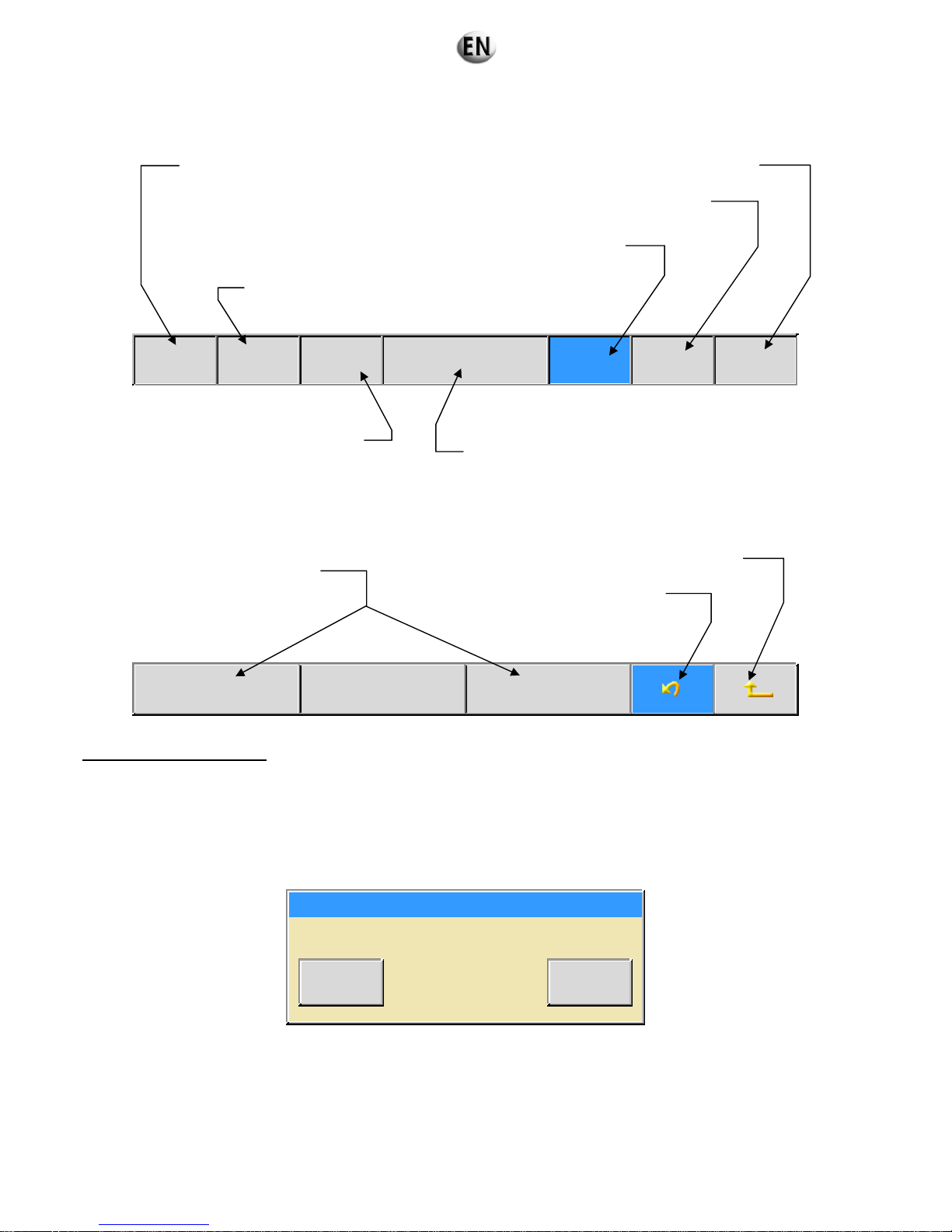

6.2.1 Control panel presentation ............................................................................................................................................... 35

6.2.1.1. View of the front panel ......................................................................................................................................... 35

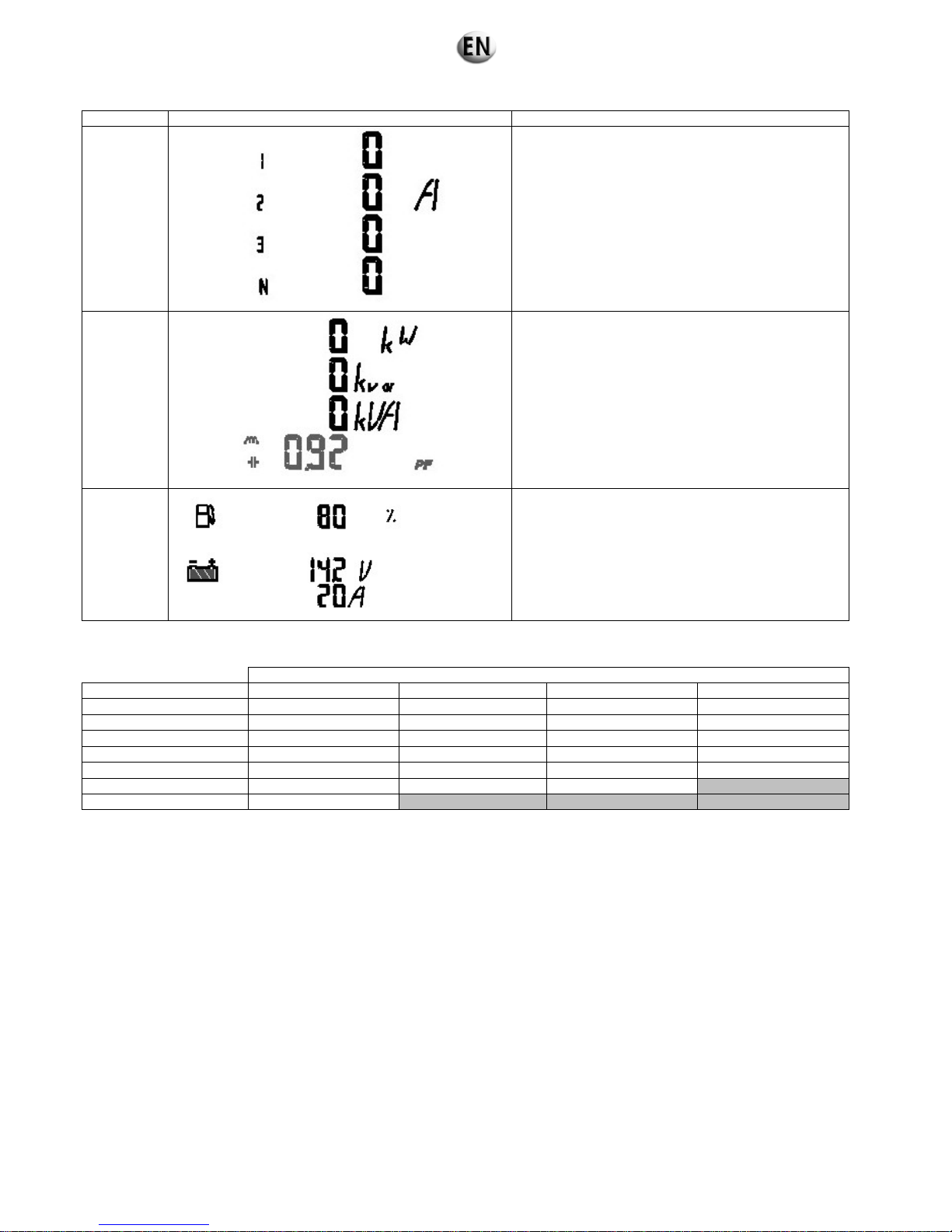

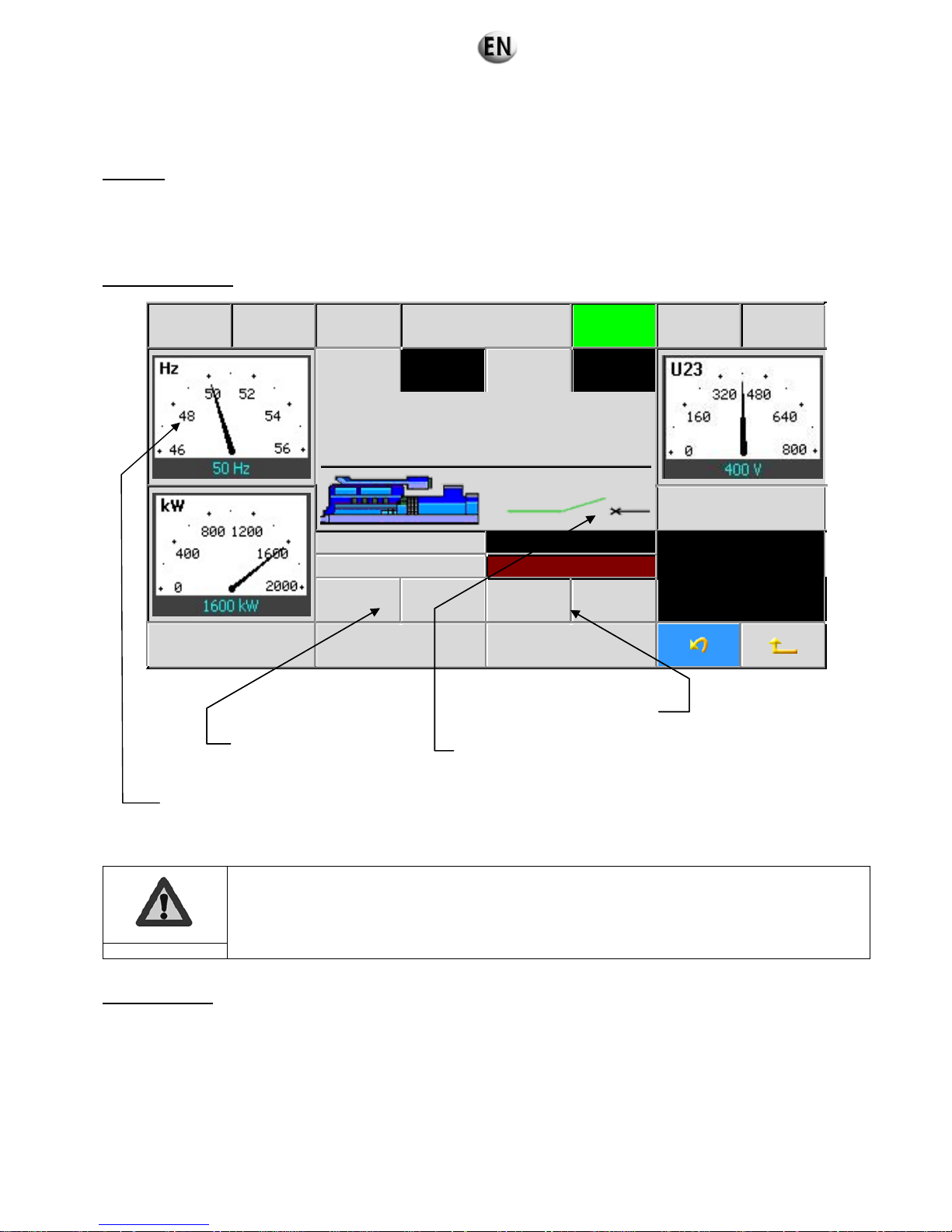

6.2.1.2. Description of the screen ..................................................................................................................................... 37

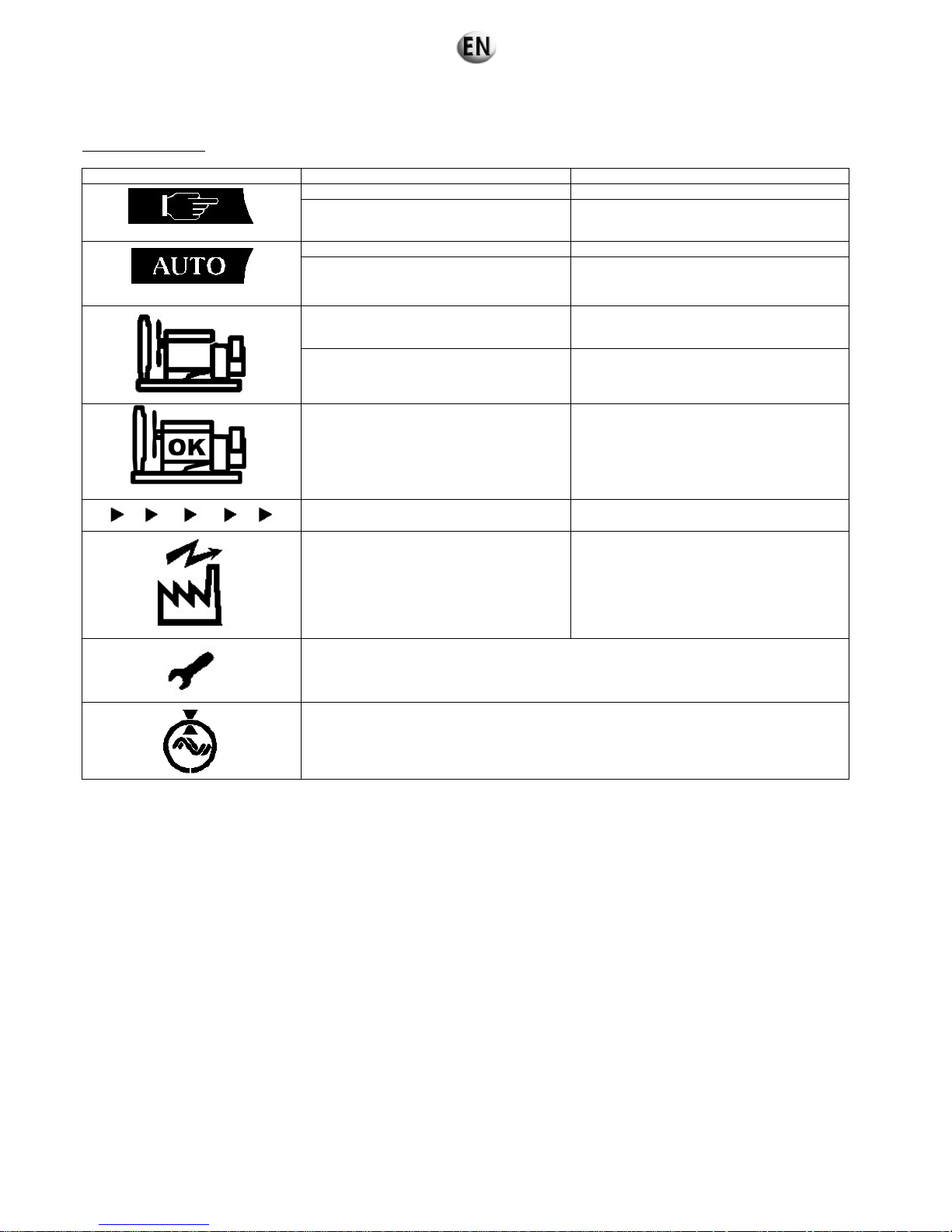

6.2.1.3. Description of the pictograms in zone 1 .............................................................................................................. 38

6.2.1.4. Description of the pictograms in zone 2 .............................................................................................................. 39

6.2.1.5. Description of the pictograms in zone 3 .............................................................................................................. 40

6.2.1.6. Display of messages in zone 4 ............................................................................................................................ 43

6.2.2 Starting ............................................................................................................................................................................. 47

6.2.3 Switching off ..................................................................................................................................................................... 48

6.2.4 Alarms and faults ............................................................................................................................................................. 48

6.2.4.1. Viewing alarms and faults ................................................................................................................................... 48

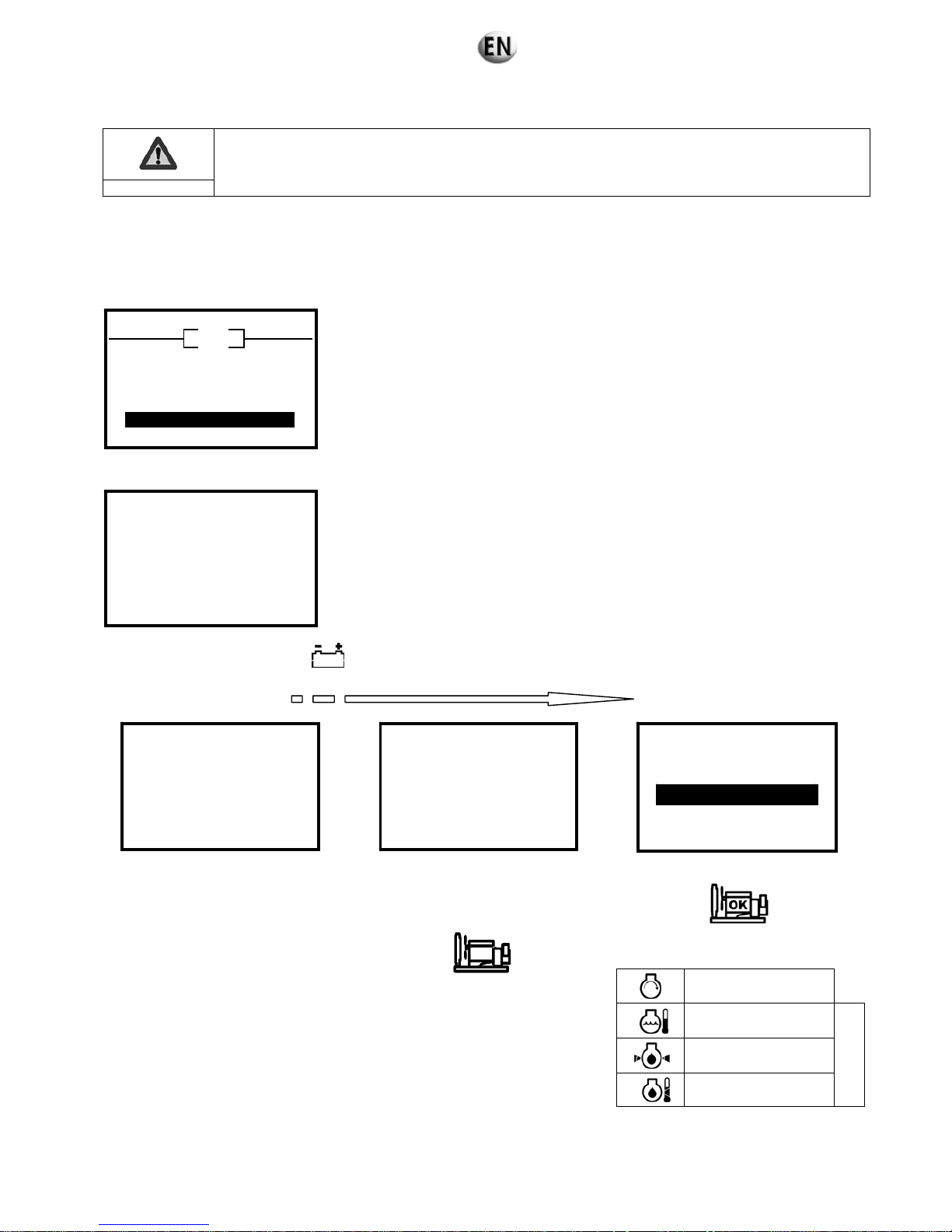

6.2.4.2. Activation of an alarm or fault .............................................................................................................................. 49

6.2.4.3. Activation of an alarm and a fault ........................................................................................................................ 50

6.2.4.4. Engine fault codes display ................................................................................................................................... 51

6.2.4.5. Horn reset ........................................................................................................................................................... 52

1/285

6.3.

Generator set with KERYS control panel .......................................................................................................................... 53

6.3.1 Presentation of the KERYS............................................................................................................................................... 53

6.3.1.1. Operating conditions ............................................................................................................................................ 53

6.3.1.2. Conformity to legal and regulatory requirements ................................................................................................. 54

6.3.2 Description of the KERYS ................................................................................................................................................. 55

6.3.2.1. Identification of the hardware components .......................................................................................................... 55

6.3.2.2. Identification of the software components ............................................................................................................ 58

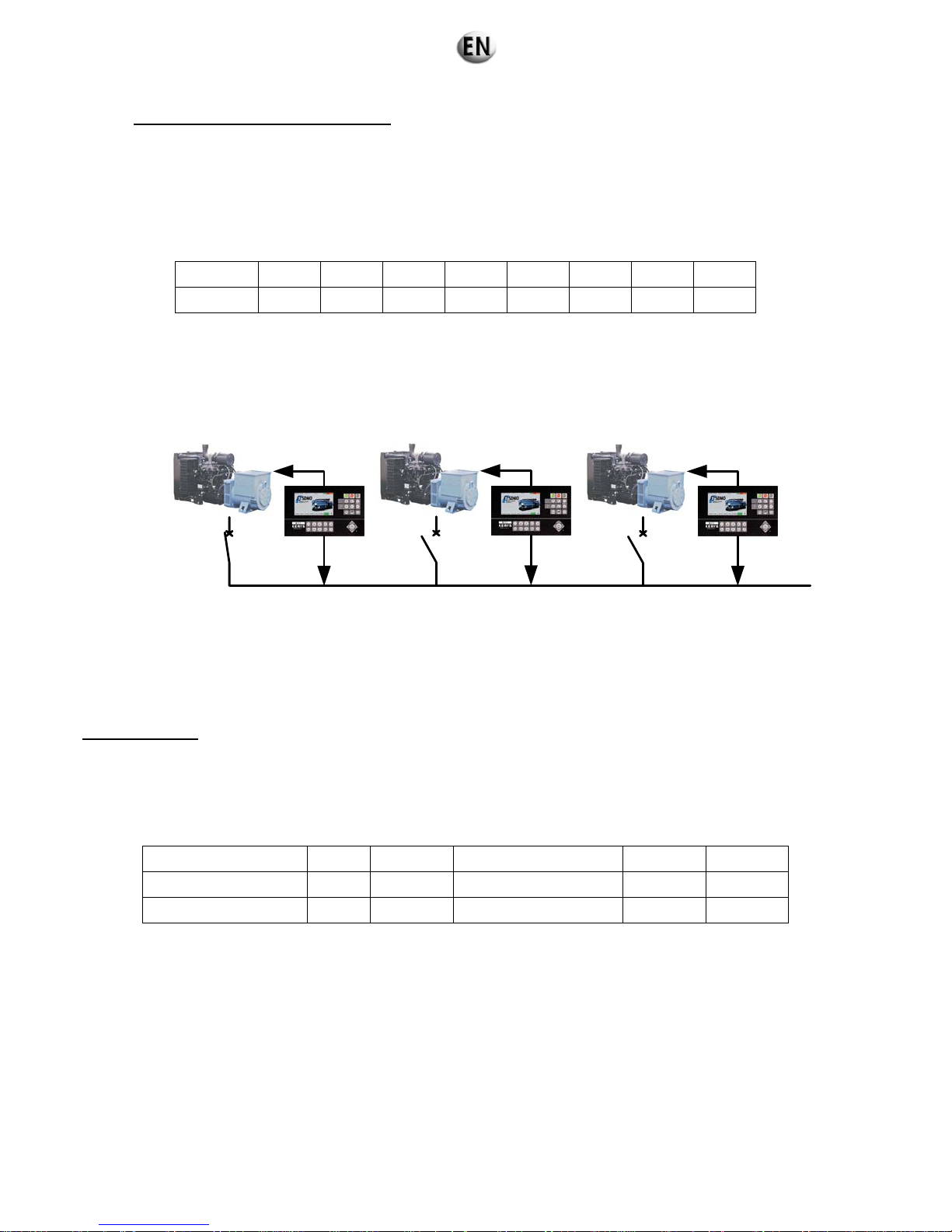

6.3.3 Description of the Man Machine Interface (IHM / MMI) ..................................................................................................... 59

6.3.3.1. The Man Machine Interface ................................................................................................................................. 59

6.3.3.2. Navigation in the screens ..................................................................................................................................... 62

6.3.4 Configurations ................................................................................................................................................................... 67

6.3.4.1. Operating principle ............................................................................................................................................... 67

6.3.4.2. Legends ............................................................................................................................................................... 68

6.3.4.3. Configuration in solo generating set..................................................................................................................... 68

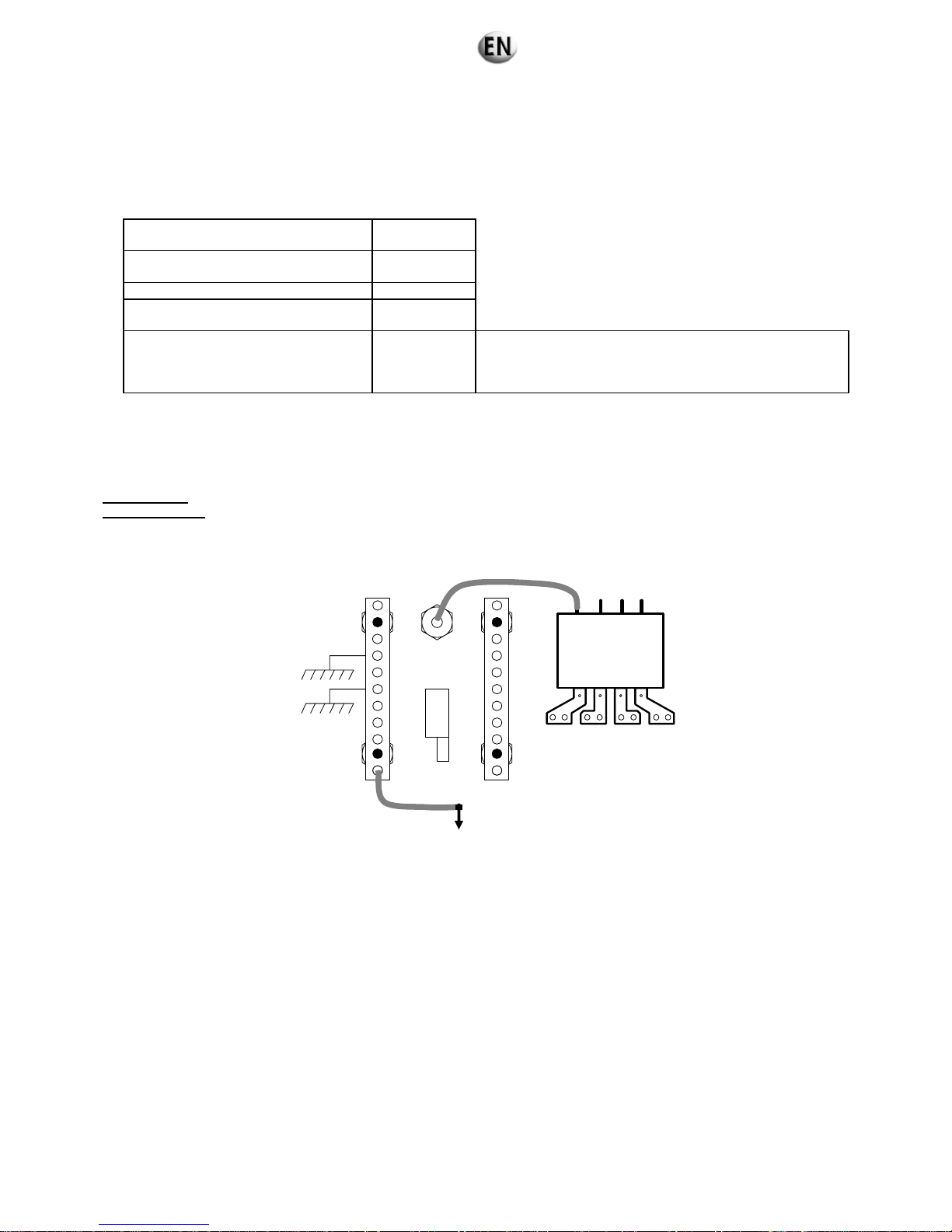

6.3.4.4. Power plant configuration (Several generating sets in parallel) ........................................................................... 71

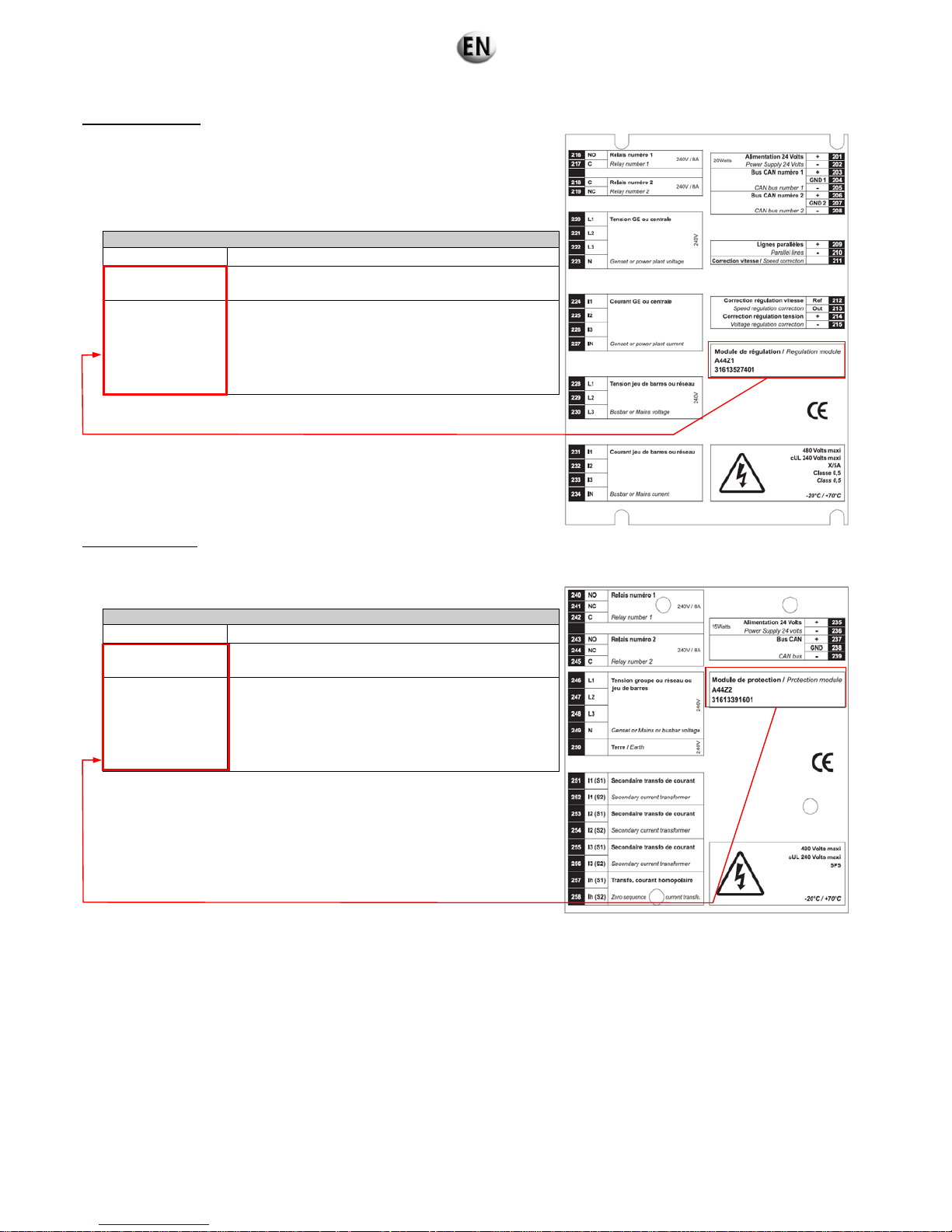

6.3.5 Connections of the generating sets .................................................................................................................................. 78

6.3.5.1. Recommendations before the connections .......................................................................................................... 78

6.3.5.2. Connections according to the configurations ....................................................................................................... 78

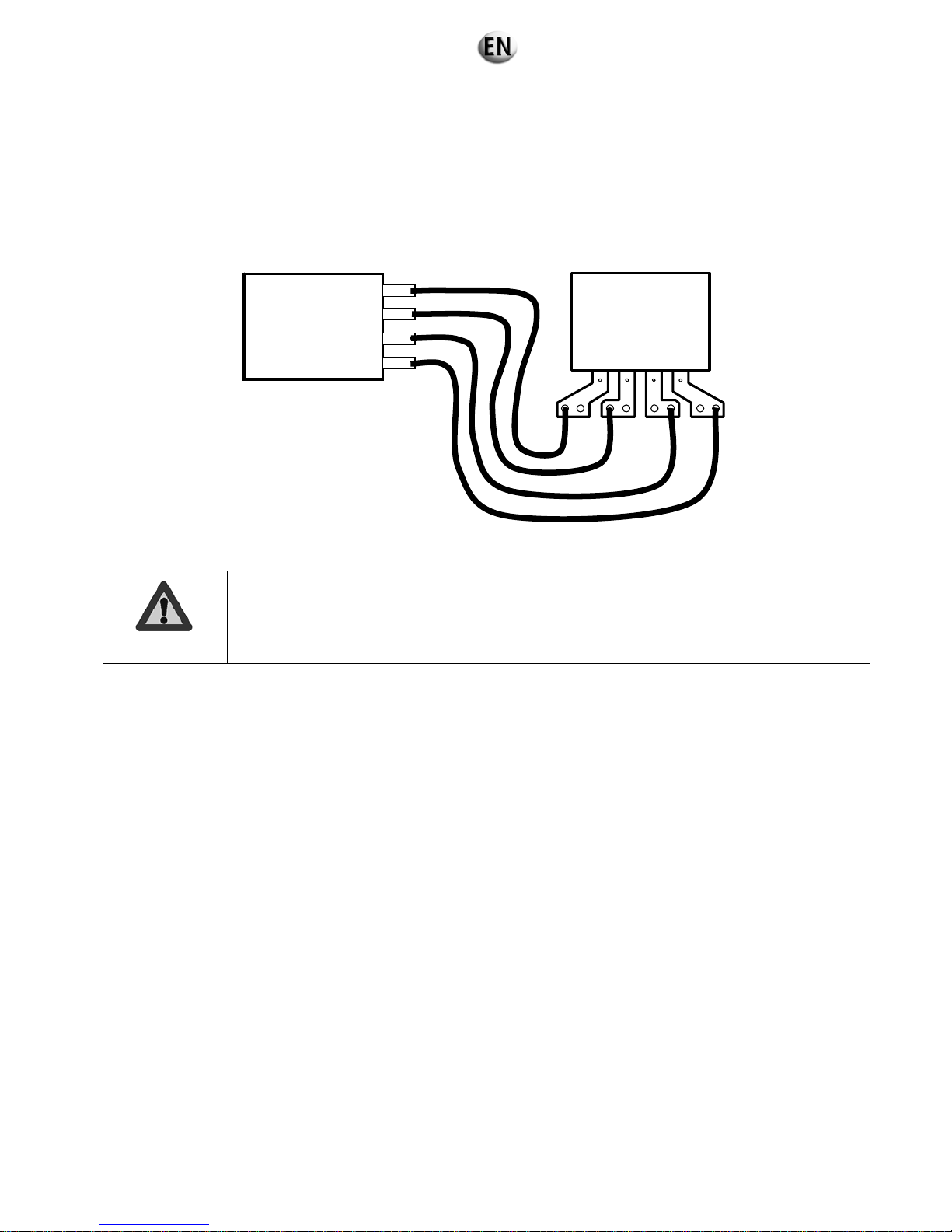

6.3.5.3. Earthing system (Standard only) .......................................................................................................................... 79

6.3.5.4. Facility power outlet ............................................................................................................................................. 83

6.3.5.5. Connecting cable between the generating sets (power plant) ............................................................................. 84

6.3.5.6. Power ................................................................................................................................................................... 85

6.3.5.7. Client terminal block ............................................................................................................................................. 85

6.3.6 Operation and setting menus ............................................................................................................................................ 86

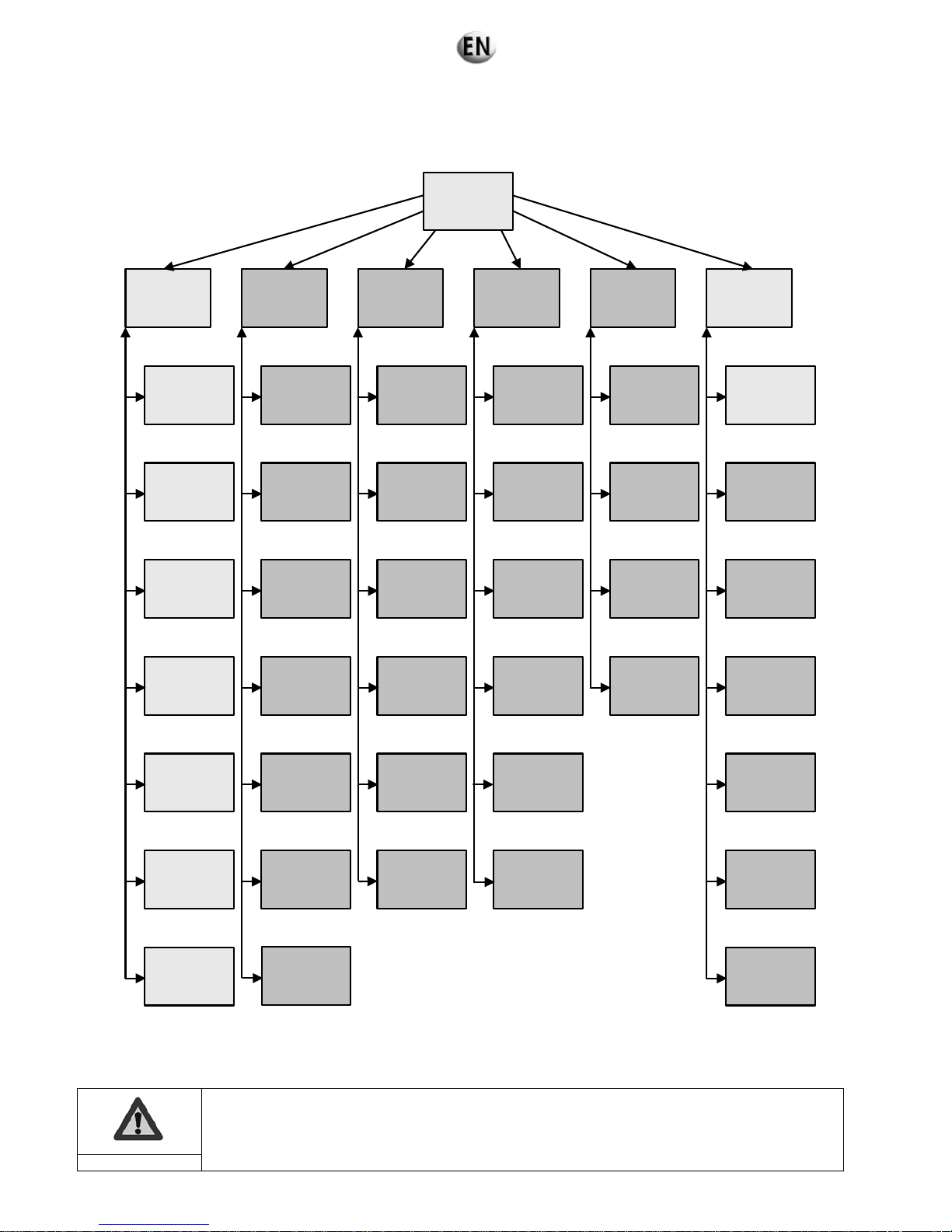

6.3.6.1. Layout of the menus ............................................................................................................................................ 86

6.3.6.2. Setting of regional parameters ............................................................................................................................. 87

6.3.6.3. Information on the KERYS ................................................................................................................................... 89

6.3.6.4. Operating menus ................................................................................................................................................. 91

6.3.7 Rental configurations ........................................................................................................................................................ 93

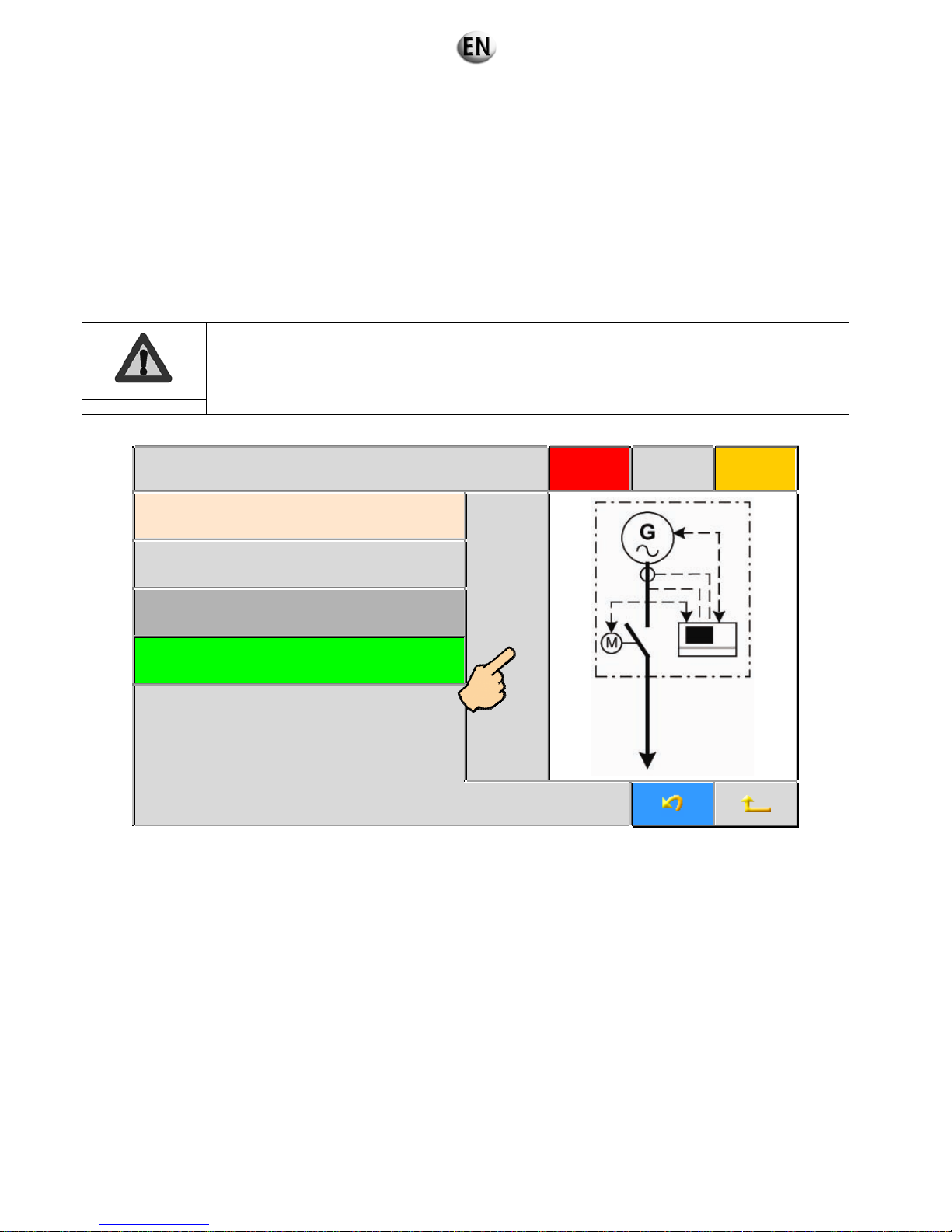

6.3.7.1. Choice of application configuration ...................................................................................................................... 93

6.3.8 Use ................................................................................................................................................................................. 102

6.3.8.1. Choice of priority generating set in power plant (if equipped) ............................................................................ 102

6.3.8.2. Starting, tests and stop ...................................................................................................................................... 108

6.3.8.3. Rental options .................................................................................................................................................... 115

7. Maintenance schedule .................................................................................................................................................................. 117

7.1. Reminder of use .............................................................................................................................................................. 117

7.2. Engine ............................................................................................................................................................................. 117

7.3. Alternator ........................................................................................................................................................................ 118

8. Battery .......................................................................................................................................................................................... 119

8.1. Storage and transport ..................................................................................................................................................... 119

8.2. Battery setting into service .............................................................................................................................................. 120

8.3. Check .............................................................................................................................................................................. 120

8.4. Load preconization .......................................................................................................................................................... 121

8.5. Faults and remedies ....................................................................................................................................................... 122

9. Appendix ...................................................................................................................................................................................... 123

9.1. Appendix A – Engine user and maintenance manual ..................................................................................................... 123

9.2. Appendix B - Alternator user and maintenance manual .................................................................................................. 209

9.3. Appendix C - Common spare parts ................................................................................................................................. 269

9.4. Appendix D - List of John Deere - Volvo and Perkins fault codes ................................................................................... 271

2/285

1. Preface

1.1. General recommendations

Thank you for choosing an electrical generating set from our company.

This manual has been designed to help you operate and maintain your electrical generating set correctly.

The information contained in this manual is taken from technical data available at the time of print. In line with our policy of

continually improving the quality of our products, this information may be amended without warning.

Read the safety instructions attentively in order to prevent any accidents, faults or damage. These instructions must always be

followed.

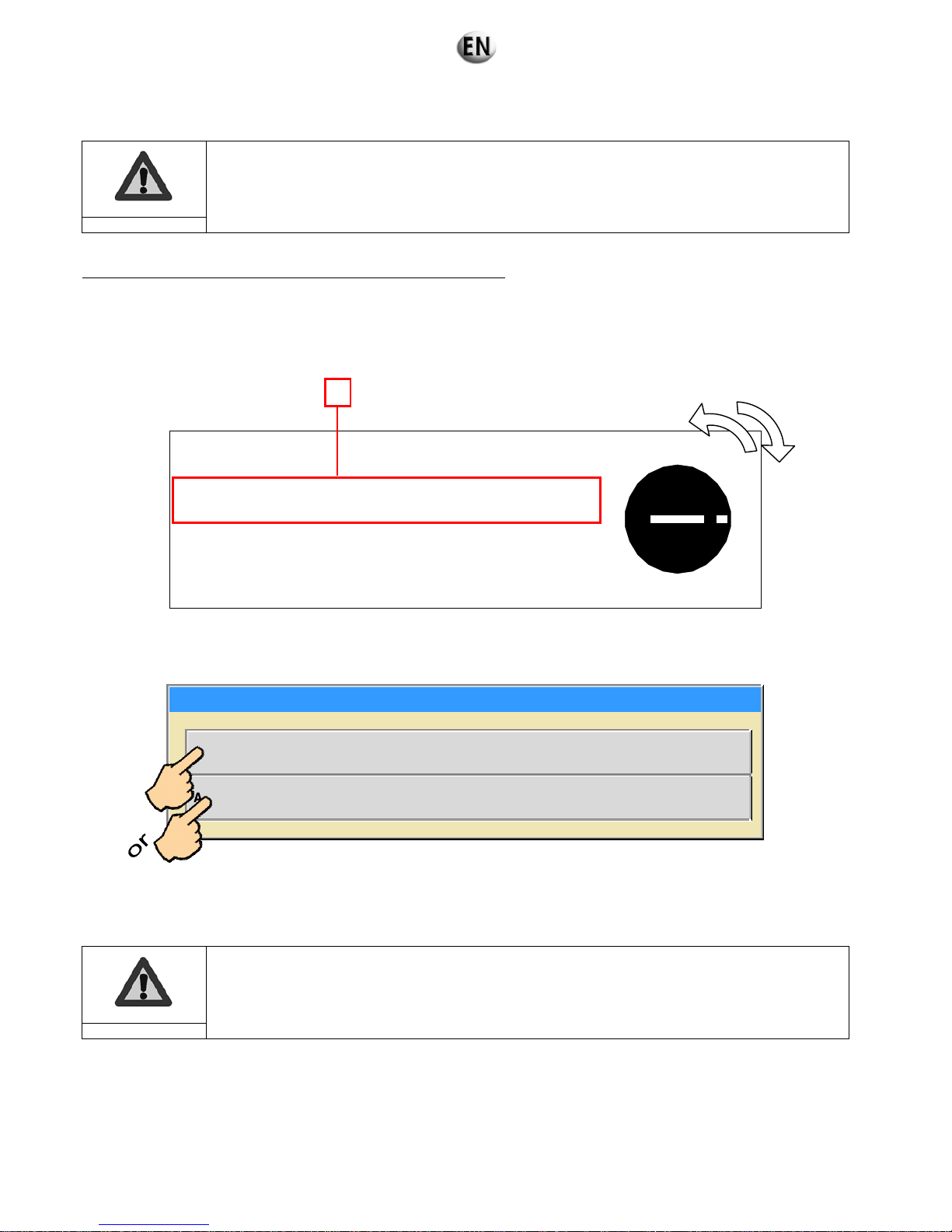

You are likely to encounter several warning symbols in this manual.

This symbol indicates an immediate danger to human health and life in case of exposure. Failure to follow

the corresponding advice entails serious consequences for human health and life in case of exposure.

Danger

This symbol draws attention to the potential risks to human health and life in case of exposure. Failure to

follow the corresponding advice entails serious consequences for human health and life in case of exposure.

Warning

This symbol indicates a dangerous situation if the warning is not heeded.

Failure to follow the corresponding advice risks resulting in minor injury of personnel or damage to any other

object in case of exposure.

Important

In order to obtain optimum efficiency and the longest possible life for the electrical generating sets, maintenance operations must be

carried out according to the periods indicated in the attached preventative maintenance tables. If the electrical generating set is

used under dusty or unfavourable conditions, some of these periods will be shorter.

Ensure that all repairs and adjustments are carried out by personnel who have received appropriate training. Dealers have this

qualification, and can answer all of your questions. They can also supply you with spare parts and other services.

The left and right sides can be seen from the back of the electrical generating set (the radiator is at the front).

Our electrical generating sets have been designed so that damaged or worn parts can be replaced by new or reconditioned parts

thereby reducing the out of action period to a minimum.

For any replacement of parts, contact your nearest dealer for our company who will have the necessary equipment and can offer

properly trained and informed staff to carry out maintenance, parts replacement and even total reconditioning of generating sets.

Contact your local dealer for the available repair manuals and to make the necessary arrangements for training personnel in

implementation and maintenance.

Some user and maintenance manuals for the engines fitted to generating sets cover control units and

include the start-up and shutdown procedures for the engines.

As the generating sets are fitted with control units that are specific to the generating sets, only the

information that appears in the documentation for the generating sets' control units should be taken into

consideration.

In addition, according to the manufacturing criteria of the generating sets, some engines may be fitted with

specific electrical wiring different to that described in the engine documentation.

Important

3/285

1.2. Pictograms and their meanings

Safety notices are clearly mounted on the equipment to draw the operator's or maintenance technician's attention to the potential

dangers and explain the action to be taken in the interest of safety. These notices are reproduced in this publication for ease of

identification by the operator.

Replace any notice that is missing or illegible.

Caution: danger

Publications delivered

with the generating set

must be referred to

Caution: risk of explosion

Caution: risk of

electric shock

Protective clothing

must be worn

Naked flames and

unprotected lights

prohibited.

No smoking

Caution: toxic

materials

Eyes and ears must be

protected

Entry prohibited to nonauthorised persons

Caution:

pressurised fluids

Periodic maintenance

must be carried out

Jet washing prohibited

Caution: high

temperature, risk

of burns

Battery level must be

checked

Earth

Caution: rotating

or moving parts

(risk of getting

caught in the

machinery)

Lifting point must be

used

Caution: corrosive

product

Fork pockets for

lifting

Retention tank level

high

Important: refer to the documentation accompanying the generating set.

Important: emission of toxic exhaust gases. Do not use in a confined or badly

ventilated area.

Figure 1.1 : Pictograms and their meanings

4/285

WARNING: DANGER

This symbol warns of a safety hazard. The presence of this symbol indicates a risk

of injury.

Observe the safety instructions and precautions for use.

Important:

Carefully read the instructions supplied with the generating set before using or

servicing the equipment.

WARNING: DANGER

Risk of electrocution

Do not touch the cables or connections when the generating set is in

operation.

Switch off the generating set for maintenance operations.

DANGER

Use diesel fuel only.

The fuel is highly flammable, handle with care. Do not smoke near the

generating set or expose it to a naked flame or sparks.

Shut down the generating set engine before filling the fuel tank. Fill with fuel

outside.

To prevent fire risks, clean the generating set regularly. Wipe away any dirt

and traces of grease or fuel.

WARNING: DANGER

The exhaust gases from the engine are toxic and can affect health or even

cause death.

Use the generating set outdoors only, in well ventilated areas, or fit an exhaust

extension to discharge the exhaust gases outside.

Figure 1.2 : Pictograms and their meanings

5/285

WARNING: DANGER

Hot coolant can cause serious burns.

Switch off the engine. Do not remove the filler cap until it is completely cold.

Do not open the radiator when it is hot.

DANGER

Rotating parts can cause serious injury.

Do not operate the generating set with the doors open.

Do not remove the enclosures.

Shut down the generating set before any maintenance or servicing

operation.

DANGER

Avoid any contact with the exhaust pipes, turbochargers and silencers.

Keep flammable materials away from hot parts.

Wait for the machine to cool down completely before touching it.

WARNING: DANGER

The gas from the battery electrolyte is explosive. Keep the batteries away

from any flames.

The battery electrolyte (sulphuric acid) is toxic. Risk of poisoning.

Figure 1.2 (continued) : Pictograms and their meanings

6/285

WARNING: DANGER

A poor earth connection can lead to serious injuries or death.

Always connect the earth terminal of the generating set to an external earth

terminal.

WARNING

Voltage selector

This function should be used by qualified persons only.

WARNING

Adjust the output voltage correctly before connecting a load.

WARNING

The voltage selector must not be used when the generating set is operating.

Figure 1.2 (continued) : Pictograms and their meanings

7/285

1.3. Instructions and safety regulations

THESE SAFETY GUIDELINES ARE IMPORTANT

If you do not understand or have any questions about any point in this manual, contact your dealer who will explain it to you or give

you a demonstration. A list of risks and precautionary measures to take follows. You should also refer to any local and national

regulations that apply in accordance with your own jurisdiction.

KEEP THIS MANUAL

This manual contains important instructions which must be followed when installing or carrying out maintenance on a generating set

or batteries.

1.3.1 General advice

Use

The operating and safety instructions must be made known to operating personnel. They will be regularly updated.

Read and understand the manuals provided with the generating set, pump unit or lighting column properly. The manufacturer's

instructions must remain at the disposal of technicians, if possible in situ.

The facility must be operated under the direct or indirect supervision of a person appointed by the operator, who is familiar with

the operation of the facility, and the dangers and drawbacks of the products used or stored in the facility.

Do not wear loose clothing, or get close to machines in operation. Note that the fans are not clearly visible when the engine is

running.

Warn personnel present to keep their distance during operation.

Do not run the generating set, pump unit or lighting column without refitting the protective covers and closing all the access

doors.

Never let a child touch the generating set, pump unit or lighting column, even when shut down.

Avoid operating the generating set, pump unit or lighting tower in the presence of animals (disturbance, scares, etc.).

Engage the parking brake when the generating set or lighting tower on its trailer is installed on the operating site. When

chocking the trailer on a slope; ensure that there is nobody in the path of the trailer.

Never start the engine without an air filter or exhaust.

Engine with turbocharger: never start the engine without fitting the air filter. The compressor wheel rotating inside the

turbocharger may cause serious bodily injury. Foreign objects in the inlet pipe may cause mechanical damage.

Engine with air preheating (starting components): never use a starting spray or any other similar starter assistance product.

Upon contact with the starting component, an explosion may occur in the inlet tube, causing bodily injury.

Do not touch the lighting column lights when they are switched on.

Maintenance

Follow the maintenance table and its instructions.

Always use tools in good condition which are suited to the work to be done. Ensure you have understood the instructions before

beginning any operation.

Goggles should be worn when carrying out maintenance operations and watches, bracelets etc. should be removed.

Fit only original parts.

Disconnect the battery and the pneumatic starter (if fitted) before undertaking any repairs, to prevent the engine from starting

accidentally. Fit a panel over the controls to prevent any attempt to start.

Only use the correct crankshaft turning techniques for turning the crankshaft manually. Do not try to turn the crankshaft by

pulling it or levering the fan. This method may cause serious bodily or material damage, or damage the vanes of the fan,

reducing the service life of the fan.

Clean off any trace of oil, fuel or coolant using a clean cloth.

Do not use a soapy solution containing either chlorine or ammonia, as these two chemicals prevent bubble formation.

Never use petrol or other inflammable substances to clean the parts. Use only approved cleaning solvents.

Do not use a high pressure cleaner for cleaning the engine and equipment. The radiator, hoses, electrical components, etc. may

be damaged.

Avoid accidental contact with parts at high temperatures (exhaust manifold, exhaust).

Before any maintenance operation on a lighting column light, cut the electrical power supply and wait for the bulbs to cool down.

Consumables

Observe regulations in force concerning use of fuel before using your generating set, pump unit or lighting tower.

Under no circumstances use seawater or any other corrosive or electrolytic product in the cooling circuit.

8/285

Environment

The operator must take the necessary measures to comply with the aesthetics of the site of use. The whole site must be

maintained in a good state of cleanliness.

The premises must be kept clean, and be regularly cleaned so as to avoid accumulation of dangerous materials or pollutants

and dust, which could ignite or cause an explosion. The cleaning equipment must be suited to the risks posed by the products

and dust.

The presence of dangerous or combustible materials inside premises housing combustion devices shall be limited to the

operating requirements.

Facilities must be operated under the constant supervision of a qualified person, who must regularly check that the safety

devices are operating correctly and ensure that the combustion devices have the correct fuel supply.

Apart from the combustion devices, it is prohibited to use fire in any form. This restriction must be clearly displayed.

Spreading of waste water, sludge and waste is prohibited.

The fuels to be used must correspond to those featured in the declaration file and the specifications recommended by the

combustion device manufacturer.

The fuel is considered to remain in the same physical state as when it is introduced into the combustion chamber.

Burning of waste in the open air is prohibited.

Always protect your hands when checking for leaks. Pressurised liquids may penetrate body tissue and cause serious damage.

Risk of blood contamination.

Drain and dispose of engine oil in a specially provided container (fuel distributors can collect your used oil).

Except by special agreement, once closed, the gas supply main unit must only be re-opened by the gas distributor. However,

the user may access it under certain conditions. Check these for each site.

1.3.2 Risks related to exhaust gases and fuels

The carbon monoxide present in exhaust gases may cause death if the concentration levels in the air

breathed are too high.

Always use generating sets, pump units or lighting towers in a well-ventilated place where gases cannot

accumulate.

In case of indoor use:

Be sure to evacuate exhaust gases outdoors.

Provide appropriate ventilation so that personnel present are not affected.

Danger

Observe the local regulations in force for generating sets, pump units or lighting towers, as well as local regulations for use of

fuel (petrol, diesel fuel and gas) before using your generating set, pump unit or lighting tower.

Fuel filling should be carried out when the engine is off (except for generating sets with an automatic filling system).

Engine exhaust gases are toxic: do not run the generating set, pump unit or lighting column in unventilated premises. If installed

in a ventilated room, additional requirements for fire and explosion protection must be observed.

A leaking burnt gas exhaust may increase the sound level of the generating set, pump unit or lighting column. To check on its

efficiency, regularly examine the burnt gas exhaust.

Pipes must be replaced as soon as their condition demands it.

9/285

1.3.3 Risks related to toxic products

The corrosion inhibitor contains alkali.

Do not swallow it.

This substance should not come into contact with the

eyes. In the event of contact with the eyes, rinse

immediately with plenty of water for at least 15

minutes.

Avoid prolonged or repeated contact with the skin. In

the event of contact with the skin, wash thoroughly

with water and soap. CONSULT A DOCTOR

IMMEDIATELY. KEEP THE PRODUCT OUT OF

THE REACH OF CHILDREN.

The anti-rust product is toxic and dangerous if

absorbed. Avoid all contact with the skin and eyes.

Read the instructions on the packaging.

Glycol is a toxic product and dangerous if absorbed.

Avoid all contact with the skin and eyes. Read the

instructions on the packaging.

Warning

Caution: fuels and oils are dangerous to inhale. Ensure proper ventilation, and use a protective mask.

Never expose the equipment to liquid splashes or rainfall, and do not place it on wet ground.

The battery electrolyte is harmful to skin and especially eyes. If splashes get into eyes, rinse immediately with running water

and/or a 10% diluted boric acid solution.

Wear protective eyewear and strong base resistant gloves for handling the electrolyte.

1.3.4 Risk of fire, burns and explosion

The engine should not be operated in environments containing explosive products. As not all of the

electrical and mechanical components are shielded, there is a risk of sparks forming.

Danger

Make sure not to create sparks or flames, and not to smoke near the batteries, as the electrolyte gases are highly flammable

(especially if the battery is charging). Their acid also poses a risk to the skin, and in particular to the eyes.

Never cover the generating set, pump unit or lighting tower with any material during operation or just after shutdown (wait for the

engine to cool).

Do not touch hot parts such as the exhaust pipe, or put combustible materials on it.

Keep all flammable or explosive materials (e.g. petrol, oil, cloth, etc.) out of the way when the set is running.

Proper ventilation is required for your generating set, pump unit or lighting column to work properly. Without this ventilation, the

engine would very quickly rise to an excessively high temperature, causing accidents or damage to the equipment and to

surrounding property.

Do not remove the radiator cap if the engine is hot and the coolant is pressurised, due to risks of burns.

Depressurise the air, oil and cooling circuits before removing or disconnecting all the fittings, pipes or connected components.

Watch out for the possible presence of pressure when disconnecting a device from a pressurised system. Do not try to find

pressure leaks by hand. Oil at high pressure can cause bodily damage.

Some preservative oils are flammable. Also, some are dangerous to inhale. Ensure proper ventilation. Use a protective mask.

Hot oil causes burns. Avoid contact with hot oil. Check that the system is no longer pressurised before carrying out any

procedures. Never start or run the engine with the oil filler cap off (oil may splash out).

Never coat the generating set, pump unit or lighting column with a thin layer of oil to protect it from rust.

Never top up the oil or coolant if the generating set, pump unit or lighting column is running, or if the engine is hot.

A generating set can only operate when stationary, and cannot be installed on a vehicle or other mobile equipment, without a

prior study taking into account the various specific features of using the generating set.

10/285

1.3.5 Risks related to electrical networks

The electrical equipment supplied with the generating set complies with standard NF C15.100 (France), or with the standards of

the countries in question.

The earth connection must be installed in accordance with the standards in force in each country in question, and with the

neutral system sold.

Read the manufacturer's identification plate carefully. The values for voltage, power, current and frequency are shown. Check

that these values match the supply use.

Never accidentally touch stripped cables or loose connections.

Never handle a generating set with wet hands or feet.

Maintain electrical wires and connections in good condition. Using equipment in poor condition can lead to electrocution and

damage to equipment.

Always disconnect the power to the equipment or facility (generating set voltage, battery voltage and network voltage) before

any operation.

The electrical connections must be made in accordance with current standards and regulations in the country of use.

Do not use faulty, poorly insulated or provisionally connected wires.

Never reverse the positive and negative terminals on batteries when connecting them. This could cause severe damage to the

electrical equipment. Follow the wiring diagram supplied by the manufacturer.

The generating set should not be connected to any other power sources, such as the mains supply network. In specific cases

where there is to be a connection to existing electrical networks, this must only be installed by a qualified electrician, who should

take the operating differences of the equipment into account, according to whether the mains supply network or generating set

is being used.

Protection against electric shocks is ensured by an assembly of specific equipment. If this needs to be replaced, it should be by

components with identical nominal values and specifications.

If the protective plates (blanking covers) need to be removed to route cables, the protector (blanking cover) must be refitted

when the operations are finished.

Due to high mechanical stresses, use only strong flexible wiring with rubber sheathing, compliant with IEC 245-4, or equivalent

wiring.

1.3.6 Dangers presented by electric currents (first aid)

First aid

In the event of an electric shock, shut off the power immediately and activate the

emergency stop on the generating set or lighting column. If the voltage has not yet

been cut off, move the victim out of contact with the live conductor as quickly as

possible. Avoid direct contact both with the live conductor and the victim's body. Use

a dry plank of wood, dry clothes or other non-conductive materials to move the victim

away. The live wire may be cut with an axe. Take great care to avoid the electric arc

that will be generated by this.

Begin emergency procedures

Resuscitation

If breathing has stopped, begin artificial respiration at once in the same place the accident took place unless the victim or operator's

life could be endangered by this.

In the event of cardiac arrest, carry out cardiac massage.

1.3.7 Risks related to moving the set

To unload the generating sets, pump units or lighting columns from their transport support brackets under optimum safety and

efficiency conditions, you must ensure that the following points are observed:

The lifting machinery or equipment is suited to the work required, in good condition and with sufficient lifting capacity.

The slings are positioned in the rings provided for this operation, the forklift arms are resting fully underneath all of the base

frame cross-beams, or the lifting bars are inserted in the apertures provided for this purpose in the base to lift the entire

generating set (according to models).

For completely safe working conditions and to prevent damage to the components fitted on the upper edge of the set, pump unit

or lighting column, the generating set, pump unit or lighting column must be lifted up with an adjustable boom. All the chains and

cables must be parallel with each other, and as perpendicular as possible with the upper edge of the generating set, pump unit

or lighting column.

If other equipment fitted on the generating set, pump unit or lighting column alters its centre of gravity, special lifting devices

may be necessary to maintain correct balance and completely safe working conditions.

The ground must be able to withstand the load of the generating set, pump unit or lighting column and its lifting machinery

without stress (otherwise, put down beams of sufficient strength in a stable configuration).

Position the generating set, pump unit or lighting column as close as possible to its place of use or transport, in a clear space

with free access.

Never perform work on a generating set, pump unit or lighting tower just hanging from a lifting device.

11/285

1.4. Identifying sets

Generating sets and their components are identified by means of identification plates.

The precise rules for identifying each major component (engine, alternator etc.) are set out in each manufacturer's documents

contained in this manual.

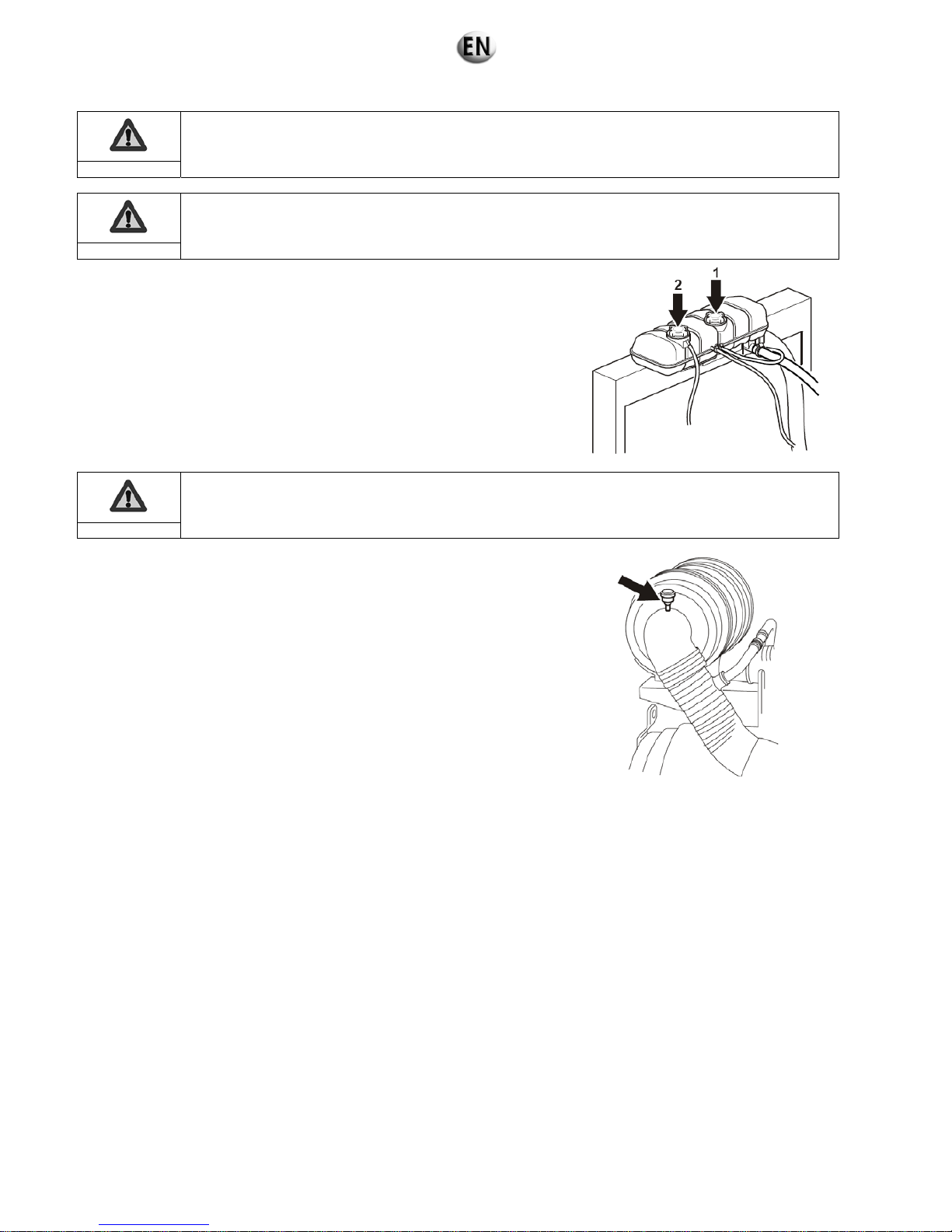

Examples of identification plates

Generating set

Engines

Figure 1.2 : Examples of identification plates

12/285

Alternator

Cabinet

Figure 1.3 : Examples of identification plates

13/285

2. General description

2.1. Description

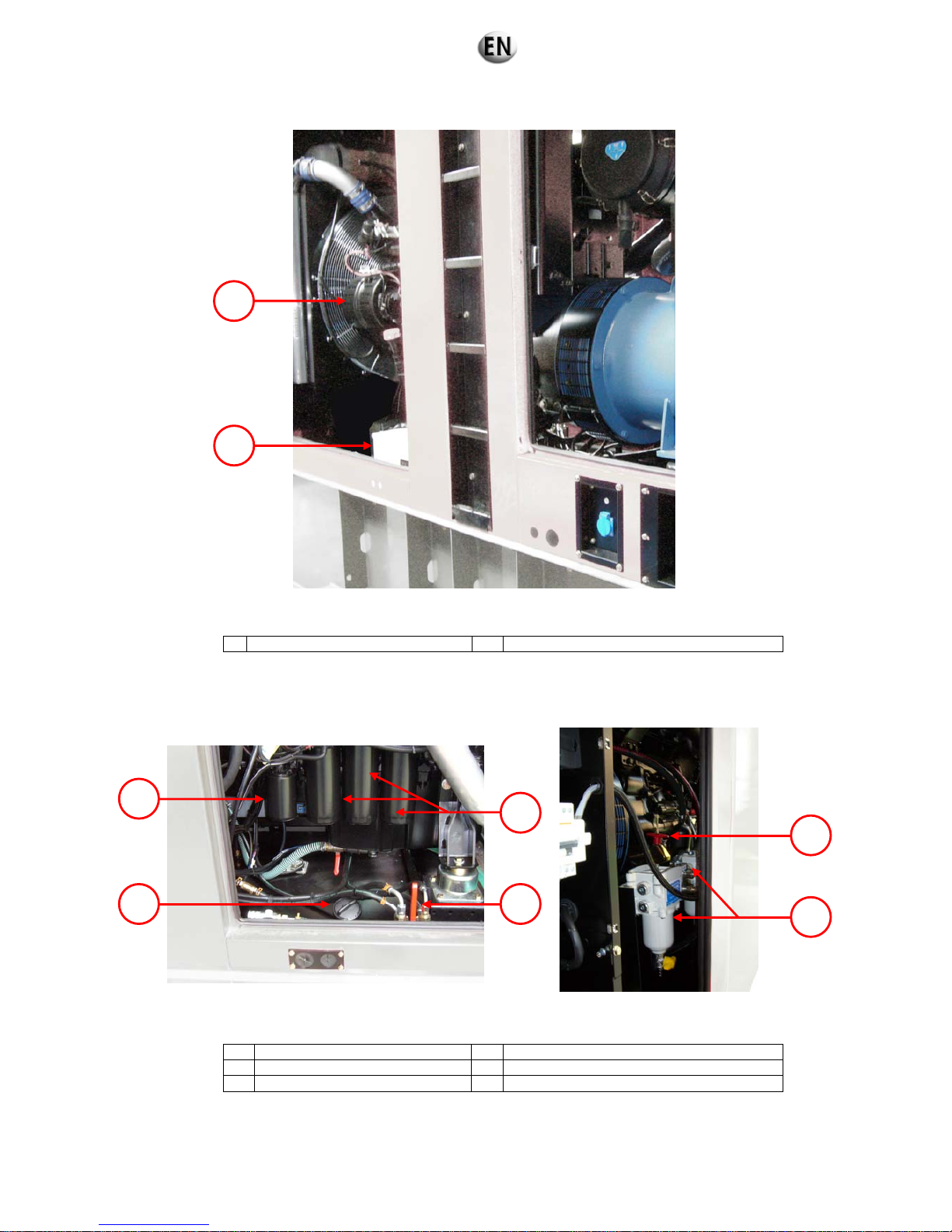

Overview

1 Control unit 4 Protective grilles

2 External emergency stop 5 Chassis

3 Expansion bottle 6 Circuit breakers

Figure 2.1 : General description of the generating set

3

4

2 1

5

6

14/285

7 Battery charge alternator 8 Starter batteries

Figure 2.1 (continued): General description of the generating set

9 Coolant filter 12 External fuel supply combined tap (optional)

10 Filling with fuel 13 Circuit breaker

11 Oil filters 14 Interchangeable fuel pre-filters

Figure 2.1 (continued) : General description of the generating set

9

10

11

12

14

13

7

8

15/285

Sockets ( voltage 208/120V )

16/285

2.2. Technical specifications

Range / Generating set type RENTAL POWER / R340U

Weights and Dimensions

Dimensions with standard tank

Dimensions l x w x h:

4475 mm x 1410 mm x 2690 mm

Weight:

3830 kg dry weight 4300 kg in operating configuration

Hood:

M228C

Noise level:

80 dB à 1 m (0.70)

70 dB à 7 m (0.70)

Dimensions with high autonomy tank

Dimensions l x w x h:

4527 mm x 1410 mm x 2780 mm

Weight:

4520 kg dry weight 5888 kg in operating configuration

Hood:

M228C-DW

Noise level

:

80 dB à 1 m (0.70)

70 dB à 7 m (0.70)

Output

Voltage Hz Phase Load factor

Max current (A)

Emergency

Emergency power

1

kW / kVA

Prime power

2

kW / kVA

480/277 V 60 3 0.8 453 301.6 / 377 274.2 / 342.7

380/220 V 60 3 0.8 573 301.6 / 377 274.2 / 342.7

220/127 V 60 3 0.8 989 301.6 / 377 274.2 / 342.7

208/120 V 60 3 0.8 1046 301.6 / 377 274.2 / 342.7

(1) ESP: Stand-by output available for emergency use under variable charge up to 200hrs per year as per lSO 8528-1, no

overload available under these service conditions.

(2) PRP: Main output available continuously under variable load for an unlimited time period per year as per ISO 8528-1, an

overload of 10% one hour every 12 hours is available, as per ISO3046-1.

Engine data

Manufacturer / model VOLVO TAD941GE

Type Turbo

Cylinder configuration 6 L

Cubic capacity 9.36 L

Rotation speed 1800 Rpm

Max emergency/prime power at nominal speed 344 / 313 kW

Adjustment type Electrical

Fuel consumption

110 % (emergency power) 79.2 L/h

100 % main power 70.8 L/h

75 % main power 52.8 L/h

50 % main power 37.0 L/h

17/285

Fuel

Fuel type Diesel

Standard fuel tank 470 L

High autonomy fuel tank 1368 L

Lubrication

Oil capacity with filter 35 L

Min. Oil pressure 0.7 bar

Nominal oil pressure 6 bar

Oil consumption (100 % load) 0,06 L/h

Oil sump capacity 28 L

Type of lubricant Genlub

Cooling

Engine capacity with radiator 41 L

Max coolant temperature 103 °C

Fan power 17.8 kW

Ventilator air flow 7.2 m3/s

Refrigerant type Gencool

Thermostat 82-92°C

Alternator data

● Compliant with NEMA MG21 standards, UTE NF C51.111,

VDE 0530, BS 4999, IEC 34.1, CSA

● The alternator is protected against short circuits

● Vacuum impregnation, epoxy winding, IP23 protection rating

Type LEROY SOMER LSA462VL12

Number of phases 3

Power factor (cos Phi) 0.8

Number of poles 4

Excitation type AREP

Voltage regulator R450

Short-circuit current 3 IN

Number of bearings 1

Coupling Direct

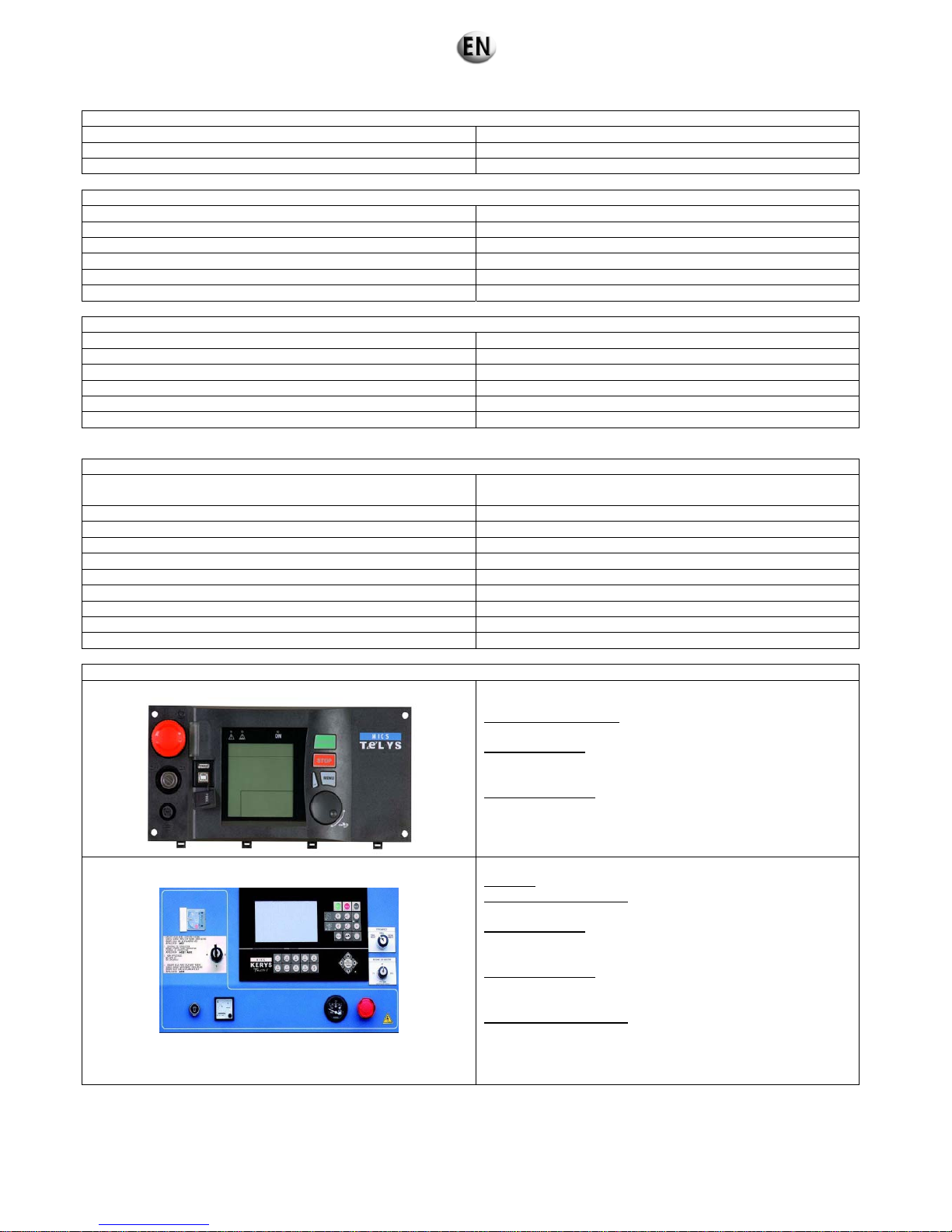

Control unit(s)

TELYS

Standard specifications:

Voltmeter, Ammeter, Frequency meter

Alarms and faults

:

Oil pressure, Water temperature, Start failure, Overspeed,

Alternator min/max, Battery voltage min/max, Emergency stop

Engine parameters

:

Timer, Oil pressure, Water temperature, Fuel level, Engine

speed, Battery voltage

KERYS

Coupling

: pre-programmed coupling mode selector.

Electrical measurements

:

Voltmeter, Ammeter, Frequency meter

Alarms and faults:

Oil pressure, Water temperature, Start failure, Overspeed,

Alternator min/max, Battery voltage min/max, Emergency stop

Engine parameters

:

Timer, Oil pressure, Water temperature, Fuel level, Engine

speed, Battery voltage

Additional specifications

:Coupling Website, Troubleshooting,

Assistance and maintenance, plotting and logging, load

impact, 8 configurations available, Compliance with

international standards…

18/285

2.3. Fuel and consumables

All specifications (product features) are given in the motor and alternator maintenance manuals attached to this manual.

In addition, we recommend the consumables to be used in the "specifications" section.

2.3.1 Specifications

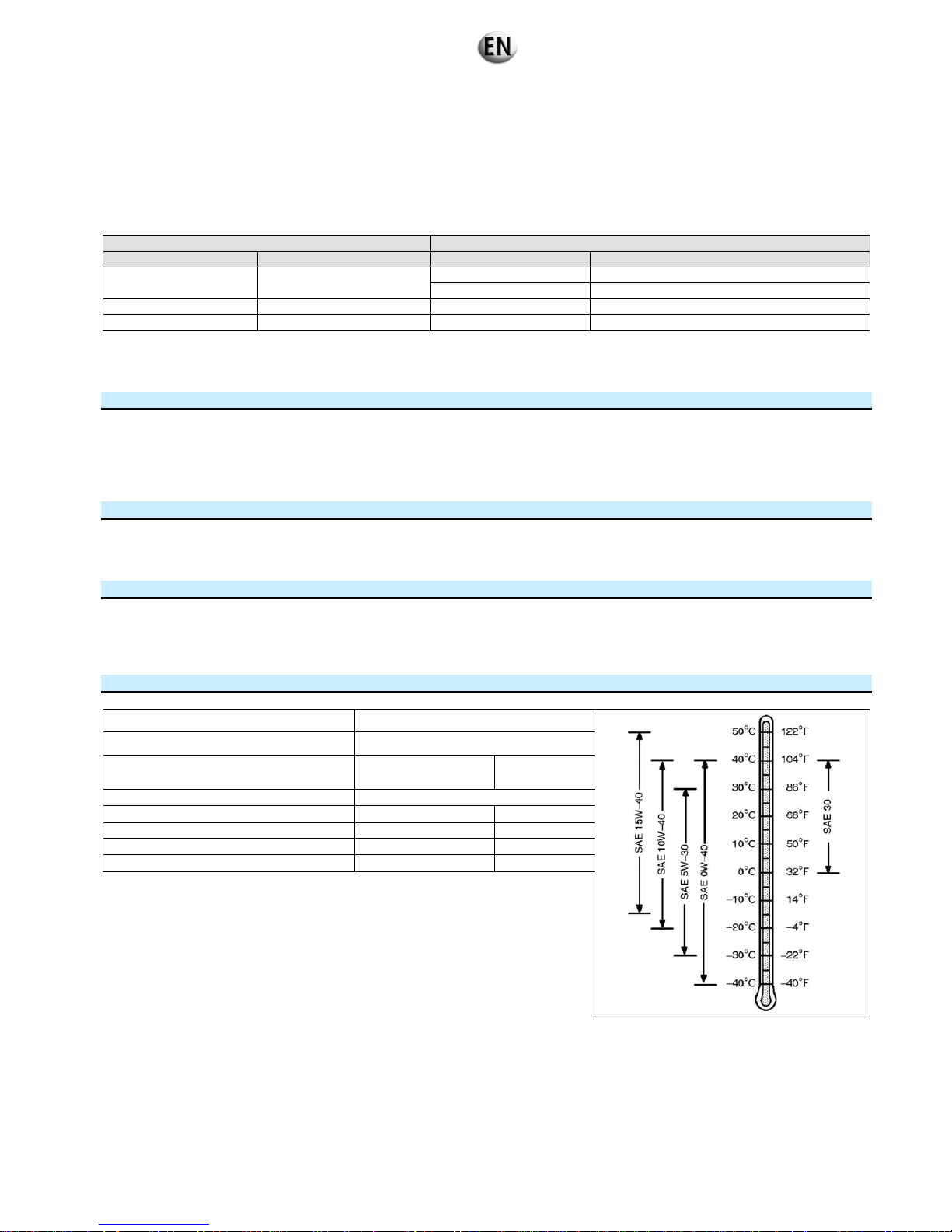

2.3.1.1. Oil grades

Engine Oil

Make Type Make Type

John Deere All

John Deere John Deere PLUS-50

GenPARTS GENLUB TDX 15W40

MITSUBISHI All GenPARTS GENLUB TDX 15W40

Volvo All GenPARTS GENLUB TDX 15W40

GENLUB TDX 15W-40

Top-of-the-range lubricant recommended for diesel engines: for generating sets used under severe conditions.

USES:

Particularly suited to more modern engines with or without turbochargers, intercoolers, or sophisticated injection systems

(e.g. HEUI, injector-pumps).

All types of use: can cope with the most demanding applications.

Depolluted engines: complies with EURO 2 and EURO 3 technology and can be used with all types of diesel fuel,

especially ecological diesel with low sulphur content.

PERFORMANCE:

ACEA E3

API CH-4

Meets level E3 of the specifications defined by European manufacturers in the ACEA standards 98 edition.

ADVANTAGES:

Less frequent oil services: this product has been put to the test during thousands of hours of use on worksites under

varying conditions, demonstrating its high quality.

Conformity with new environmental legislation: adherence to new anti-pollution standards required for new EURO 2

and EURO 3 engines.

SPECIFICATIONS:

SAE Grade 15W-40

Density at 15°C 0.883

Cinematic viscosity at 40 °C

Cinematic viscosity at 100 °C

105

14.1

mm2/s (cSt)

mm2/s (cSt)

Viscosity index 140

Dynamic viscosity at -15 °C 3000 mPa.s(cP)

Pour point - 30 °C

Flash point 220 °C

Sulphated ash content 1.4 % weight

(Values given as examples only)

19/285

2.3.1.2. Specifications of coolants

Engine Coolants

Make Type Make Type

John Deere All GenPARTS GENCOOL PC -26°C

MITSUBISHI All

Mitsubishi LLC

GenPARTS GENCOOL PC -26°C

Volvo All GenPARTS GENCOOL PC -26°C

GenCOOL PC -26

High-protection coolant, approved by manufacturers.

GenCOOL PC -26 is a ready-to-use, highly protective coolant which is produced from an antifreeze recommended by the majority

of European manufacturers.

It is made from antifreeze and G 48 inhibitors.

It protects up to -26°C.

It is free from nitrates, amines and phosphates.

It is a clear, fluorescent orange liquid.

REFERENCES/APPROVALS (for the antifreeze):

HEAVY GOODS VEHICLE LIGHTER VEHICLES

Approved by MTU, MERCEDES BENZ, MAN, KHD, GENERAL

MOTORS

Conforms with VOLVO, IVECO, VAN HOOL and STAYR

TRUCK specifications

Approved by BMW, VOLKSWAGEN, MERCEDES, PORSCHE

Conforms with VOLVO, OPEL, SEAT and SKODA specifications

Conforms with the NF R 15.601 standard

REINFORCED ANTI-CORROSION FEATURES:

Protects against high-temperature corrosion by oxidisation of ethylene (cylinder head protection).

Protects against high-temperature cavitation (top of cylinder and coolant pump protection).

Non-corrosive for seals and hoses.

Improves the efficiency and longevity of the cooling system.

GenCOOL PC -26 is especially recommended for engines fitted with aluminium or light alloy radiators.

HIGH TEMPERATURE SUITABILITY:

Provides good conditions for thermal exchange.

Perfect stability at high temperatures.

GenCOOL PC -26 is specially adapted for engines with high power densities.

LONG LASTING PROTECTION:

High alkaline reserve/stability and longevity of corrosion inhibitors.

Maintains its technical properties during prolonged use at high temperatures (neutralisation of acids).

Ensures maximum heat transfer without the build up of deposits in the cooling system.

GenCOOL PC -26 ensures optimum protection against overheating and corrosion in extreme conditions of vehicle use.

PACKAGING/STORAGE:

GenCOOL PC -26 is supplied in 210 l metallic barrels with smooth interior linings.

It can be stored for 2 years in its original container and packaging.

Avoid zinc coated containers.

20/285

RECOMMENDATIONS FOR USE:

Compatible with the original fluid.

It is recommended that the cooling system is completely drained when replacing the fluid.

SPECIFICATIONS UNITS SPECIFIED VALUES

TRIAL

METHODS

Density at 20°C

kg/m3

1,059 +/- 3

R 15-602-1

pH

pH

7.5 to 8.5

NF T 78-103

Alkalinity reserve

ml

>=10

NF T 78-101

Boiling point

°C

105 +/- 2

R 15-602-4

Freezing point:

°C

-26 +/- 2

NF T 78-102

Glassware corrosion :

(test with antifreeze)

mg/test piece

R 15-602-7

- Copper

+/- 2.6

- Weld

+/- 0.5

- Brass

+/- 2.3

- Steel

+/- 1.6

- Cast iron

+/- 0.8

- Cast aluminium

+/- 1.0

Corrosion on warm plate

(test with antifreeze)

mg/(cm²week)

+/- 0.17

R 15-602-8

3. Installation

3.1. Unloading

3.1.1 Safety during unloading

To unload electrical generating sets from their transport supports under optimum safety and efficiency conditions, you need to

ensure that the following points are observed:

- Lifting machinery or equipment appropriate to the work required.

- Slings positioned in the eyes provided for this operation or lifting arms resting fully underneath the chassis cross members.

- Ground able to take the load of the set and the lifting machinery without stress (otherwise lay down beams of sufficient strength

and stability).

- Set put down as close as possible to its point of use or transportation, in a clear area with free access.

Example of equipment to be used:

crane, slings, cross bar, safety catch, shackles.

Fork lift truck.

3.1.2 Instructions for unloading

3.1.2.1. Slings

Attach the lifting vehicle slings to the rings on the generating set designed for this procedure. Hang the slings carefully.

Check that the slings are correctly attached and the equipment is solid.

Lift the generating set carefully.

Direct and stabilise the set towards the chosen position.

Carefully set down the equipment while continuing to position it.

Release the slings, then detach and remove the lifting rings.

21/285

3.1.2.2. Fork lift truck

Position the forklift arms under the base frame (except with generating sets fitted with "forklift pockets", in which case position

the forklift arms in these pockets), making sure that only its cross-members are resting on the arms.

Lift the equipment, handling it gently.

Set down the generating set in its unloading position.

Figure 3.1: Transporting a generating set using a forklift truck

3.2. Fluid retention

Any outflow of the fluids contained in the generating sets (fuel, oil and coolant, or rainwater or condensation) will be collected in a

retention container if the generating set is fitted with this option.

The containers have a capacity which allows 110% of the fluids contained in the generating set fitted with this option to be collected.

Three different fittings are available.

Figure 3.2: Fluid retention container integrated into the tank chassis.

22/285

Figure 3.3: Offset fluid retention container underneath the generating set chassis.

Figure 3.4: Offset fluid retention container integrated into the chassis and tank.

Generating sets fitted with the offset tank option (DW) above also have a high level indicator in the retention container.

In all cases, the retention containers must be regularly checked to ensure they contain no fluid (fuel, oil and coolant, or rainwater or

condensation). If necessary, drain the containers either via the drain port or by using the drain pump (for containers fitted with this

pump).

Note: Never allow these fluids to drain onto the ground; ensure they are collected in a designated container.

23/285

3.3. Choice of location

It should be determined on the basis of use. There are no specific rules governing the choice of location, other than proximity to the

electric distribution panel and disturbances caused by the noise. However, fuel supply, burnt gas evacuation, and the direction of

these gases and the noises emitted should be taken into account.

The choice of its position will be based on carefully considered compromise!

Examples of problems that may be encountered:

Incorrect exhaust and ventilation Ground too uneven or soft.

Set incorrectly positioned

Reduced access

Fuel filling impossible Opening cover doors impossible

Figure 3.5: Examples of problems that may be encountered

24/285

3.4. Electricity

a) Connections - general information

As with low voltage electrical installations, use and maintenance is governed by standard NFC 15.100 (France) or by the standards

in the relevant country, based on international standard IEC 60364-6-61.

They must also adhere to the regulations in the NFC 15.401 application guide (France) or to the regulations and standards in the

relevant country.

b) Power cables

These can be unipolar or multipolar according to the power of the generating set.

Power cables should preferably be installed in ducts or on a cable tray for this purpose.

The cable cross-section and number of cables should be determined according to the cable type and the current standards to be

observed in the country of installation. The choice of conductors must comply with international standard

IEC 30364-5-52.

Three phase - Calculation hypothesis

Fitting method = wiring in cable runs or non perforated trays.

Permissible voltage drop = 5%

Multiconductors or single conductor joined when precision 4X…(1)

Cable type PVC 70°C (e.g. H07RNF).

Ambient temperature = 30°C.

Circuit breaker

calibre

(A)

Cable sizes

0 - 50m 51 - 100m 101 - 150m

mm²/AWG mm²/AWG mm²/AWG

10 1.5 / 14 2.5 / 12 4 / 10

16 2.5 / 12 4 / 10 6 / 9

20 2.5 / 12 4 / 10 6 / 9

25 4 / 10 6 / 9 10 / 7

32 6 / 9 6 / 9 10 / 7

40 10 / 7 10 / 7 16 / 5

50 10 / 7 10 / 7 16 / 5

63 16 / 5 16 / 5 25 / 3

80 25 / 3 25 / 3 35 / 2

100 35 / 2 35 / 2 4X(1X50) / 0

125 (1) 4X(1X50) / 0 4X(1X50) / 0 4X(1X70) / 2/0

160 (1) 4X(1X70) / 2/0 4X(1X70) / 2/0 4X(1X95) / 4/0

250 (1) 4X(1X95) / 4/0 4X(1X150) / 2350MCM 4X(1X150) / 2350MCM

400 (1) 4X(1X185) / 0400MCM 4X(1X185) / 0400MCM 4X(1X185) / 0400MCM

630 (1) 4X(2X1X150) / 2x 2350MCM 4X(2X1X150) / 2x 2350MCM 4X(2X1X150) / 2x 2350MCM

Single phase - Calculation hypothesis

Fitting method = wiring in cable runs or non perforated trays.

Permissible voltage drop = 5%

Multiconductors.

Cable type PVC 70°C (e.g. H07RNF).

Ambient temperature = 30°C.

Circuit breaker

rating (A)

Cable sizes

0 - 50m 51 - 100m 101 - 150m

mm²/AWG mm²/AWG mm²/AWG

10 4 / 10 10 / 7 10 / 7

16 6 / 9 10 / 7 16 / 5

20 10 / 7 16 / 5 25 / 3

25 10 / 7 16 / 5 25 / 3

32 10 / 7 25 / 3 35 / 2

40 16 / 5 35 / 2 50 / 0

50 16 / 5 35 / 2 50 / 0

63 25 / 3 50 / 0 70 / 2/0

80 35 / 2 50 / 0 95 / 4/0

100 35 / 2 70 / 2/0 95 / 4/0

125 50 / 0 95 / 4/0 120 / 2250MCM

c) Battery cables

Install the battery or batteries in the immediate vicinity of the electric starter motor. The cables will be connected directly from the

battery terminals to the starter motor terminals.

The primary instruction to follow is to ensure that the polarities between the battery and starter motor match. Never reverse the

positive and negative battery terminals when connecting them. This could cause severe damage to the electrical equipment.

The minimum cross-section of the cables will be 70 mm2. It varies according to the power of the starter motor but also the distance

between the batteries and the set (voltage drops on the line).

25/285

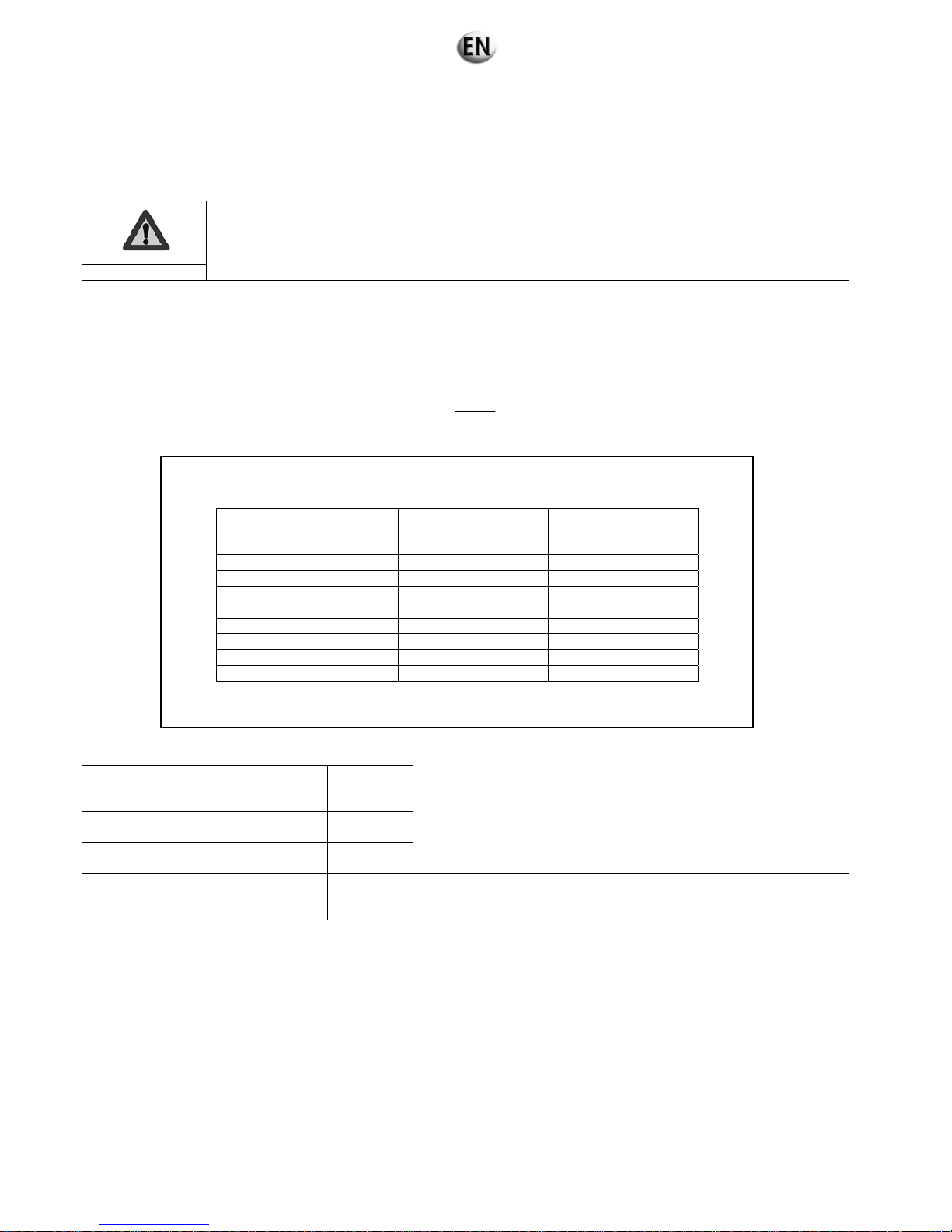

d) Safety guidelines

References: NFC 15-100:2002 (France) - IEC: 60364-5-54

In order to protect personnel against electric shocks, this generating set is equipped with a differential residual current protector

"factory" set to trigger instantly, with a sensitivity of 30 mA.

Any modification to this setting could endanger personnel. Any modification would render the user liable, and

must only be performed by qualified and authorised personnel.

When the generating set is disconnected from a facility after use, the master differential protector must be

returned to its "factory" settings, and this must be checked by trained personnel.

Important

For effective protection against electric shocks, the generating set needs to be earthed. To do this, use a copper wire, with a

minimum cross-section of 25 mm2 for a stripped cable and 16 mm2 for an insulated cable, connected to the generating set earth

socket and a galvanised steel earthing rod embedded vertically into the ground.

The earthing rod resistance value should comply with the values shown in the table below.

Note: use the highest differential setting from the installation as a guideline.

The resistance value is calculated in the following way:

For a default voltage of 25 V and a default current of 30 mA, this rod must be of a minimum length of: see table below:

Nature of ground

Length of

rod in

metres

Thick arable land,

moist compact ballast

1

Lean arable land,

Gravel, coarse ballast

1

Bare stony soils, dry sand,

impermeable rock

3.6

To obtain an equivalent length, you can use several earthing rods

connected in parallel and set apart by at least their length.

Example: 4 interconnected 1 metre rods separated by 1 metre.

Note: For the United States (National Electrical Code reference NFPA-70).

The generating set must be earthed. To do this, use a copper wire with a minimum cross-section of 13.3 mm² (or AWG 6, at most)

connected to the generating set earth socket and a galvanised steel earthing rod fully embedded into the ground vertically.

This earthing rod embedded fully in the ground must have a minimum length of 2.5 m.

3.5. Special arrangements

Generating sets are not fitted with protection against power surges caused by drops in atmospheric pressure or manoeuvring.

The company does not accept any responsibility regarding damage caused by these occurrences.

However, lightning conductors can be installed, on the understanding that this does not give total protection.

R = Ul

I Δn

Maximum resistance value of the earth socket R (Ω) according to the differential unit operational

current (operation time should not be longer than 1 second).

I Δn

differential

Earth R

(Ω)

Ul: 50 V

Earth R

(Ω)

Ul: 25 V

≤ 30 mA 500 > 500

100 mA 500 250

300 mA 167 83

500 mA 100 50

1A 50 25

3A 17 8

5A 10 5

10A 5 2.5

The Ul value: 25 V is required for work site installations, and livestock buildings, etc.

26/285

4. Trailer

4.1. Trailer linkage

Before attaching the trailer, check the trailer hook on the tow vehicle; it should fit the trailer ring perfectly.

Trying to tow a trailer with a non-matching device (bar, wires, cords, etc.) could lead to serious

accidents.

Also check:

- no incipient fractures or excessive wear on the hitching system.

- locking system is operating properly.

Warning

To hitch the trailer, proceed as follows:

Lock the wheels to stop the trailer from moving

Lift up the rear trailer supports and lock them

Release the parking brake

Release the locking levers for the draw bar arms and adjust the ring to the same height as the vehicle hook

Hitch the trailer, remove the locks on each side of the wheels then lift up the front wheel fully using its handle

Connect the electrical circuit of the trailer to that of the tow vehicle

Hook the handbrake safety wire onto the hook on the tow vehicle.

Figure 4.1 : Coupling a trailer

4.2. Check before towing

Before towing, check the following:

Tightness of the generating set enclosure bolts.

Wheel tightness.

Hitching hook locked.

Tyre pressure.

Signalling lights working, for "on-road" trailers.

Enclosure doors closed.

Parking brake released, for "on-road" trailers.

Guide wheels (jockey wheels) and stands lifted (if fitted).

Towbar arm locking levers tightened and pinned (if fitted with an adjustable towbar).

Brake test, for "on-road" trailers.

Safety cable fitted, for "on-road" trailers.

Tow vehicl e

Trailer

CORRECT

To w ve h icle

Trai ler

CORRECT

To w ve h icle

Trailer

INCORRECT

To w ve h icle

Trai ler

INCORRECT

27/285

4.3. Operation

"On-site" trailer

These trailers are not fitted with a main brake, and so cannot be braked in motion; the tyres allow for a maximum speed of 27 km/h.

So it is absolutely prohibited to exceed this speed.

Nor are these trailers fitted with signalling lights. On-road use is prohibited.

"On-road" trailer

The driving speed must be suited to the condition of the road and the handling of the trailer.

Driving at high speed causes heating of the tyres; so it is important to stop from time to time, and check them. Excessive heating

may cause a puncture, and therefore a serious accident. For reversing manoeuvres, remember to lock the inertia brake.

Particular attention must be paid to the tightness of the wheels on new vehicles.

In the first few miles' driving, heating of the brake hubs and drums will actually reduce the wheel tightness. It

is therefore essential to check the tightness every 6 miles (10 kilometres) until no further loosening is noted.

Nonetheless the tightness must be checked whenever you are about to tow the trailer.

Warning

Lights/signalling (only for "on-road" trailers)

Warning lights are obligatory for on-road driving. Signalling must comply with regulations in force in the country of use.

Figure 4.2: Example of French signalling

4.4. Unhitching the trailer

This operation should be carried out on horizontal, flat, stable ground.

Lock the wheels

Lower the front wheel

Disconnect the road signals wire

Refit the hitch using the wheel to release the hook ring from the tow vehicle,

Release the tow vehicle

Engage the handbrake.

Red rear lights

+ direction indicators

+ stop lights

Front reflective devices (white)

Side reflective devices (orange)

Rear reflective devices

(

red triangle)

28/285

4.5. Implementation for installation

Operations to be carried out:

Ensure that the ground is strong enough for the assembly not to sink into it.

Unhitch the trailer.

Immobilise the trailer by placing chocks under the wheels.

Fully engage the parking brake (if fitted).

Using the front wheel, position the generating set as close to horizontal as possible.

Lower the stands (if fitted), and lock them.

4.6. Break transmission adjustment

- The handbrake is used only as a parking brake.

- Setting is carried out starting with the brakes moving to the brake control.

Important

After fitting the wheels on the axle, turn the wheels in the FORWARD direction (on all RA 2 type brakes, check that the

adjustment screw 8 reaches the “FORWARD” stop on the brake backing plate).

Adjust the brake setting using screw 8, with the cables not connected to the cross bar(s). The shoes should rub the drum

slightly.

Connect the brake cables to the cross bars(s) and tighten the nuts and lock nuts, leaving the end of the threaded end

protruding by around 10 mm (Fig. 4.4).

IMPORTANT: Wherever possible, cables must cross over to achieve the highest possible gain curve (Fig. 4.5).

Check that the parking lever 1 is in the ‘REST” position and that the compensating spring 4 is completely free on its rod

(unscrew the nuts 5 fully).

Check that the hook slide 2 is not compressed and the yoke 3 is in the pulled out position.

Fit the transmission and adjust the assembly using the tensioner 6 until a gap (J1) of 1 mm max is obtained between the

linkage 9 and slide 2.

Adjust the compensating spring 4 at one end pressing it against the anchorage plate, and at the other end leaving a 2 mm gap

(J2) max between the spring and nuts 5.

Tighten all the lock nuts.

Checking the setting (trailer on axle stands):

Pull the parking lever 2 notches - the wheels cannot turn in a FORWARD direction.

The wheels can turn in REVERSE (adjustment screw 8 switches to the REAR position).

Pull the parking lever fully.

The wheels will not turn either in FORWARD or REVERSE and the cross bar(s) must remain parallel with the axle body.

Check the transmission setting after 180 miles (300 km) (running in period) and if necessary adjust the gap (J1) using the

tensioner.

Parking

The lever must be fully pulled up, so that the compensating spring is fully compressed.

Every 900 miles (1500 km), check the braking settings and distribution on all the wheels.

Important

The brake controls are designed to draw trailers behind flexible suspension touring vehicles. If used behind an HGV, be

sure to provide the fitted ball joint with a shock absorber to prevent premature wear.

During any manoeuvres with the trailer coupled, do not turn more than 90° or force reverse.

The specifications of our brake controls are indicated on a manufacturer's plate, and the items on this should be supplied

to us when requesting replacement parts, in particular for the shock absorber, of a special type, approved by the Service

des Mines to correspond to European standards (it is advisable to have a spare shock absorber to enable instant repairs).

29/285

Figure 4.3: Braking transmission

Figure 4.4: Cross bar fitting Figure 4.5: Tandem bearing fitting

30/285

4.7. Faults and repairs

Fault observed Origin Solutions

Erratic braking of trailer - Faulty shock absorber Replace the shock absorber

Braking too weak

- Jaws worn Replace the jaws

- Jaws not run in Fault will disappear only after running in

- Incorrect linkage setting Adjust the setting

- Significant friction on the slide Grease the sliding parts

- Slide corrosion Remove the corrosion and grease

- Coupling height does not match that of

the towing vehicle

Adjust the height so that the two parts

are in the same horizontal plane

Drum temperature abnormally high

- Incorrect linkage setting Adjust the settings

- Incorrect brake setting Adjust the settings

- High levels of dust in the drums Remove the dust

- Jaws, springs, drums damaged Replace the damaged parts

- Brake cables or link rod damaged Replace the damaged parts

Jerky braking

- Incorrect linkage setting Adjust the settings

- Interfering parts on the slide Remove, clean and grease

- Corroded slide Remove the corrosion and grease

- Damage to slide guide rings

Replace the rings (and possibly the

slide) and grease

- Faulty shock absorber Replace the shock absorber

Trailer tending to swerve upon braking

- Cross-bar(s) not balanced Adjust the cross-bar(s)

- Different brake setting on the two sides Adjust the brake settings

- Cables damaged or incorrectly fitted

Replace the damaged parts

Refit the cables

- Poor load distribution Check the load distribution

When starting the trailer holds back the

towing vehicle

- Damage to slide or to guide rings Replace the faulty parts and grease

- Slide corrosion Remove the corrosion and grease

- Tie rod damaged

Replace the tie rod and adjust the

settings

- Linkage damaged or incorrectly set

Replace the damaged parts and adjust

the settings

- Brake on Loosen the brake

Play in the coupling head

- Head worn (see wear indicator) Replace the head

- Ball joint worn Replace the ball joint

Parking braking too weak

- Compensating spring incorrectly set Adjust the setting

- Braking system incorrectly set Adjust the setting

- Notched sector damaged Replace the sector and adjust the setting

- Lever ratchet worn Replace the lever and adjust the setting

- Cable ruptured Replace the cable and adjust the setting

31/285

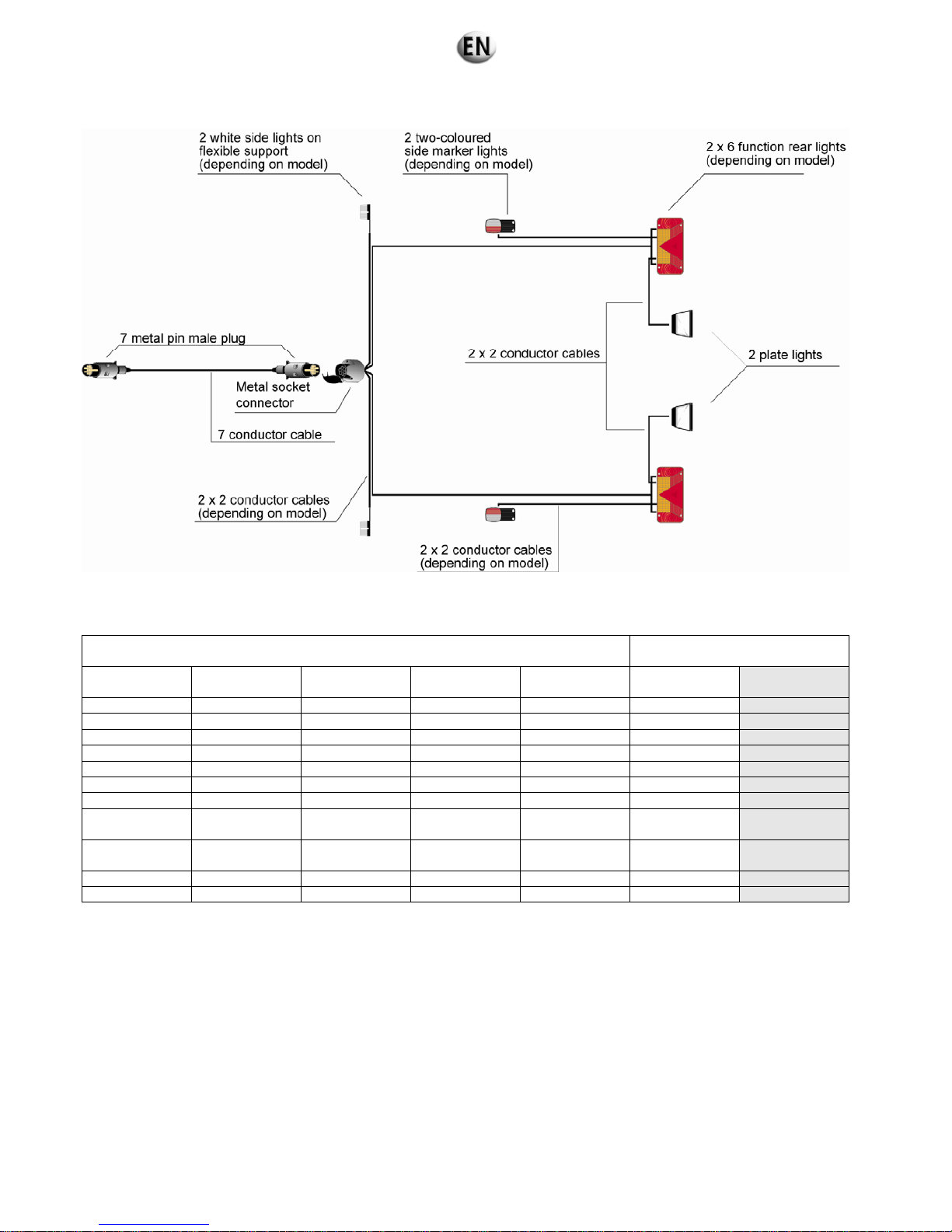

4.8. Electrical connection diagram

Figure 4.6 : Electrical connection diagram

4.9. Complete wheels technical information

TYRES

COMPLETE

WHEELS

Dimensions Indices Diameter (mm)

Cross section

(mm)

Radius under

load (mm)

Load

(Kg)

Pressure

(bar)

135 R 13 70 T 550 134 265 335 2.4

145 R 13 75 T 566 145 272 387 2.4

155 R 13 79 T 578 150 277 437 2.4

145/70 R 13 71 T 534 150 259 345 2.5

155/70 R 13 75 T 548 147 263 387 2.5

185/70 R 13 86 T 594 185 285 530 2.5

165 R 14 C 98 N 622 172 284 650 3.8

155/70 R12 100 N 525 155 244

650

(1)

800

(2)

6.25

185 R 14 C 102 P 650 188 316

675

(1)

850

(2)

4.5

195 R 14 C 106 P 666 198 32 950 4.5

195/50 x 10 98 N 450 190 - 750 6.0

(1)

Wheel with 4 holes

(2)

Wheel with 5 holes

32/285

5. Preparation before operating the set

The inspections referred to in this section enable the electrical generator set to operate.

Specific skills are required to carry out these operations.

They must only be entrusted to personnel with the necessary skills.

Failure to follow these instructions in any way could result in malfunction or very serious accidents.

Danger

5.1. Installation checks

Check that the general recommendations given in the installation section (ventilation, exhaust, fluids, etc.) are observed.

Carry out the level checks (oil, water, diesel fuel, battery).

Check the generating set earth connection is earthed.

Check that the electrical connections are in order.

5.2. Checks after starting the generating set

Carry out the mechanical checks (oil pressure, water temperature, absence of noise etc.)

Carry out the electrical checks (voltage and frequency)

Carry out the safety checks (emergency stop, oil pressure, water temperature etc.)

6. Using the generator set

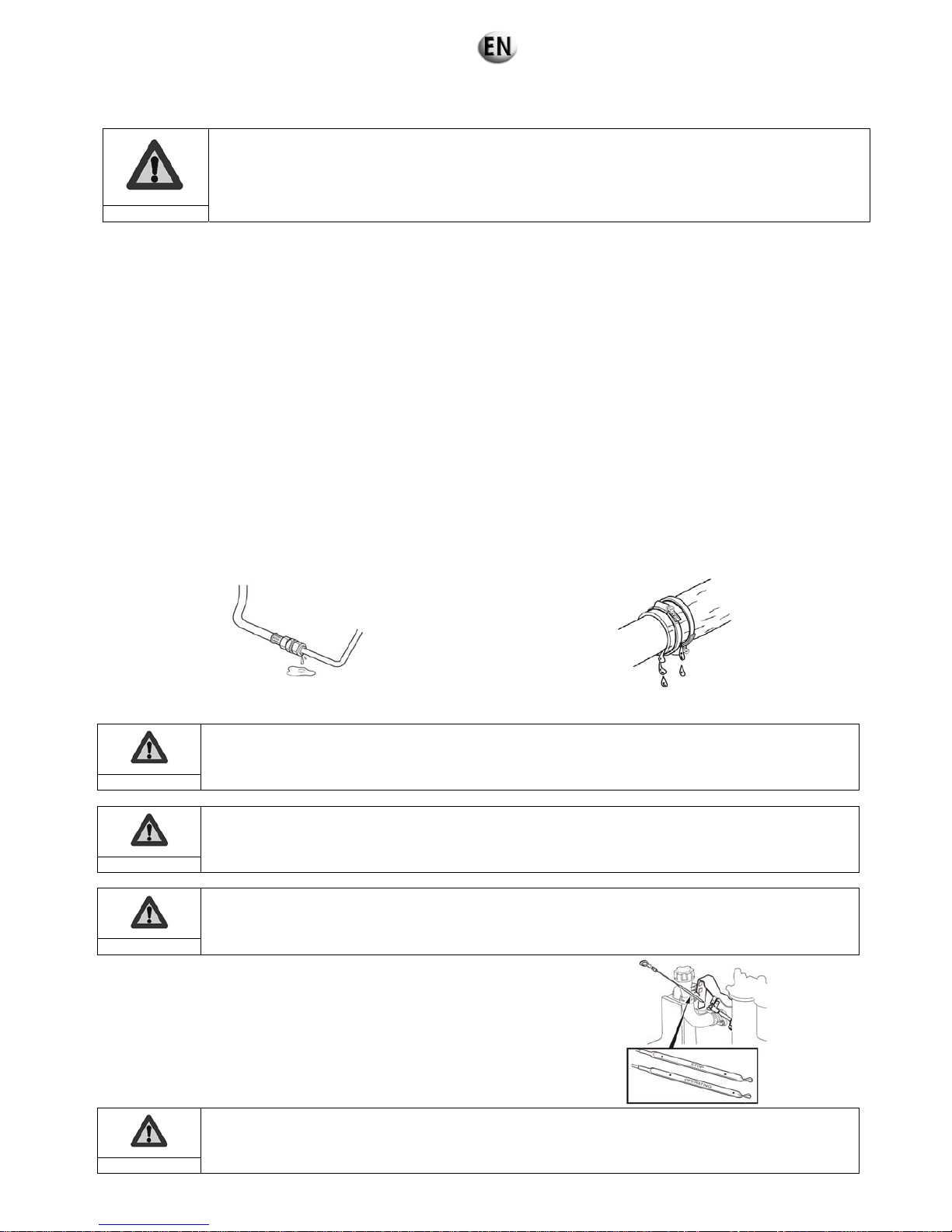

6.1. Pre-Start Inspection

• Engine and engine compartment, general check

Visually check the engine and engine compartment before starting the engine and after stopping the engine.

Check:

there are no oil, fuel or coolant leaks,

the screws are tightened,

the condition of the belts (wear, tension).

Fuel, oil and grease deposits on the engine or in the engine compartment are always a fire hazard and must be

removed as soon as they are noticed.

Warning

If there are any oil, fuel or coolant leaks, locate the origin of the fault and repair it immediately before starting

the engine.

Important

Never use a high pressure cleaner for cleaning the engine and equipment.

Important

• Oil level, check and top up

Check the oil level every day before the first start-up.

Check that it is between the MAX and MIN marks on the oil dipstick.

If necessary, top up the oil through the filler opening, on the left-hand side of

the engine.

Before checking the level again, wait a few minutes for the oil to drain into the

sump.

Never fill oil past the maximum level.

Only use oil of the recommended grade.

Important

33/285

• Coolant level, check

Do not open the filler cap when the engine is hot, except in an emergency. Boiling liquid or vapour may be

ejected.

Warning