33

C

3

User and maintenance manual

for generating sets

33504023701NE_2_1

Translation of the original instructions

R

1/242

CONTENTS

1. Preface .................................................................................................................................................................................................. 4

1.1. General recommendations ....................................................................................................................................................... 4

1.2. Warnings .................................................................................................................................................................................. 4

1.3. Pictograms and their meanings ................................................................................................................................................ 5

1.4. Safety instructions .................................................................................................................................................................... 8

1.4.1 General guidelines .................................................................................................................................................................... 8

1.4.2 Electrical safety precautions ................................................................................................................................................... 10

1.4.3 Safety precautions in case of electrical shock ........................................................................................................................ 11

1.4.4 Safety precautions relating to fire, burns and explosions ....................................................................................................... 11

1.4.5 Toxic risk safety precautions .................................................................................................................................................. 13

1.4.6 Precautions for risks relating to handling phases ................................................................................................................... 14

1.4.7 Precautions for risks relating to noise ..................................................................................................................................... 14

2. General description .............................................................................................................................................................................. 15

2.1. Description ............................................................................................................................................................................. 15

2.2. Technical specifications ......................................................................................................................................................... 18

2.3. Identifying sets ....................................................................................................................................................................... 20

2.4. Fluid retention ........................................................................................................................................................................ 21

2.5. Fuels, lubricants and coolants ................................................................................................................................................ 22

2.5.1 Fuel specifications .................................................................................................................................................................. 22

2.5.2 Lubricant specifications .......................................................................................................................................................... 24

2.5.3 Coolant specifications ............................................................................................................................................................. 25

3. Transporting the equipment ................................................................................................................................................................. 27

3.1. Warnings concerning transport .............................................................................................................................................. 27

3.2. Preparing for transport ........................................................................................................................................................... 27

3.3. Road transport ....................................................................................................................................................................... 27

3.3.1 Generating sets with and without an enclosure ...................................................................................................................... 27

3.3.2 Generating sets on trailers...................................................................................................................................................... 28

3.3.2.1. Hitching and unhitching the trailer ............................................................................................................................. 28

3.3.2.2. Check before towing ................................................................................................................................................. 32

3.3.2.3. Operation .................................................................................................................................................................. 32

3.4. Rail transport .......................................................................................................................................................................... 33

3.4.1 Generating sets with and without an enclosure ...................................................................................................................... 33

3.5. Shipping ................................................................................................................................................................................. 34

3.5.1 Generating sets with and without an enclosure ...................................................................................................................... 34

3.6. Air transport ........................................................................................................................................................................... 34

4. Installation - Connections .................................................................................................................................................................... 35

4.1. Unloading the generating set ................................................................................................................................................. 35

4.1.1 Choosing the location ............................................................................................................................................................. 35

4.1.2 Safety during unloading .......................................................................................................................................................... 36

4.1.3 Unloading the generating set .................................................................................................................................................. 36

4.1.3.1. Slings ........................................................................................................................................................................ 36

4.1.3.2. Fork lift truck ............................................................................................................................................................. 37

4.1.4 Moving the generating set ...................................................................................................................................................... 37

4.2. Connecting the generating set ............................................................................................................................................... 38

4.2.1 Connection summary .............................................................................................................................................................. 38

4.2.2 Protecting people and equipment ........................................................................................................................................... 39

4.2.2.1. Earthing system principle .......................................................................................................................................... 39

4.2.2.2. TT system ................................................................................................................................................................. 39

4.2.2.3. Installing the differential protection ........................................................................................................................... 40

4.2.2.4. Setting the generating set differential protection ....................................................................................................... 41

4.2.2.5. Earthing the generating set ....................................................................................................................................... 43

4.2.3 Making the connections .......................................................................................................................................................... 44

4.2.3.1. Connections - general information ............................................................................................................................ 44

4.2.3.2. Selecting the power cables ....................................................................................................................................... 45

4.2.3.3. Connecting the generating set to the installation ...................................................................................................... 46

4.2.3.4. Connecting the battery or batteries to the generating set ......................................................................................... 48

4.2.4 Overvoltage ............................................................................................................................................................................ 48

5. Installation............................................................................................................................................................................................ 48

5.1. Warnings concerning commissioning ..................................................................................................................................... 48

5.2. Checking the generating set installation ................................................................................................................................ 48

5.3. Preparing for operation of the generating set ......................................................................................................................... 49

5.4. Checking the generating set before startup ........................................................................................................................... 49

5.5. Checking the generating set after startup .............................................................................................................................. 49

2/242

6. Using the generator set ....................................................................................................................................................................... 50

6.1. Pre-Start Inspection ............................................................................................................................................................... 50

6.2. Generator set with NEXYS control panel ............................................................................................................................... 53

6.2.1 Control panel presentation ..................................................................................................................................................... 53

6.2.1.1. Introduction to pictograms ......................................................................................................................................... 54

6.2.2 Manual starting ....................................................................................................................................................................... 55

6.2.3 Switching off ........................................................................................................................................................................... 56

6.2.4 Alarms and faults .................................................................................................................................................................... 56

6.2.5 Faults and alarms - Details ..................................................................................................................................................... 56

6.2.6 MURPHY diagnostic module .................................................................................................................................................. 58

6.3. Generator set with TELYS control panel ................................................................................................................................ 64

6.3.1 Control panel presentation ..................................................................................................................................................... 64

6.3.1.1. View of the front panel .............................................................................................................................................. 64

6.3.1.2. Description of the screen .......................................................................................................................................... 66

6.3.1.3. Description of the pictograms in zone 1 .................................................................................................................... 67

6.3.1.4. Description of the pictograms in zone 2 .................................................................................................................... 68

6.3.1.5. Description of the pictograms in zone 3 .................................................................................................................... 69

6.3.1.6. Display of messages in zone 4 ................................................................................................................................. 71

6.3.2 Starting ................................................................................................................................................................................... 76

6.3.3 Switching off ........................................................................................................................................................................... 77

6.3.4 Alarms and faults .................................................................................................................................................................... 77

6.3.4.1. Viewing alarms and faults ......................................................................................................................................... 77

6.3.4.2. Activation of an alarm or fault ................................................................................................................................... 78

6.3.4.3. Activation of an alarm and a fault .............................................................................................................................. 79

6.3.4.4. Engine fault codes display ........................................................................................................................................ 80

6.3.4.5. Horn reset ................................................................................................................................................................. 81

7. Maintenance schedule ......................................................................................................................................................................... 81

7.1. Reminder of use ..................................................................................................................................................................... 81

7.2. Maintenance safety instructions ............................................................................................................................................. 81

7.3. Table of maintenance operations ........................................................................................................................................... 82

7.4. Cover maintenance ................................................................................................................................................................ 83

7.5. Trailer maintenance ............................................................................................................................................................... 83

7.6. Fault finding ........................................................................................................................................................................... 84

7.7. No load and under load tests ................................................................................................................................................. 84

8. Starter batteries ................................................................................................................................................................................... 85

8.1. Checking the electrolyte level ................................................................................................................................................ 85

8.2. Checking the voltage/acid density .......................................................................................................................................... 85

8.3. Charging the battery .............................................................................................................................................................. 86

8.4. Cleaning the battery ............................................................................................................................................................... 86

8.5. Fault finding ........................................................................................................................................................................... 87

9. Options ................................................................................................................................................................................................ 88

9.1. Dual frequency ....................................................................................................................................................................... 88

9.2. Neutral system ....................................................................................................................................................................... 91

9.3. Fuel supply valve ................................................................................................................................................................... 91

10. Appendix ............................................................................................................................................................................................ 93

10.1. Appendix A – Engine user and maintenance manual ............................................................................................................ 93

10.2. Appendix B - Alternator user and maintenance manual ........................................................................................................191

3/242

TABLE OF ILLUSTRATIONS

Figure 1 : Warning pictograms .................................................................................................................................................................. 5

Figure 2 : Pictograms indicating prohibited activities ................................................................................................................................. 5

Figure 3 : Pictograms indicating compulsory operations ........................................................................................................................... 6

Figure 4 : Information pictograms .............................................................................................................................................................. 6

Figure 5 : Specific pictograms ................................................................................................................................................................... 7

Figure 6 : Pictograms relating to battery operations .................................................................................................................................. 7

Figure 7 : General description of the generating set ................................................................................................................................ 15

Figure 8 : General description of the generating set (Continuation) ........................................................................................................ 16

Figure 9 : General description of the generating set (control) .................................................................................................................. 17

Figure 10 : Example of a generating set identification plate .................................................................................................................... 20

Figure 11 : Fluid retention container ........................................................................................................................................................ 21

Figure 12 : Example of French signalling ................................................................................................................................................ 33

Figure 13 : Examples of problems that may be encountered .................................................................................................................. 35

Figure 14 : Points used for lifting and moving .......................................................................................................................................... 37

Figure 15 : TT earthing system ................................................................................................................................................................ 39

Figure 16 : View of the front side ............................................................................................................................................................. 53

Figure 17 : Description of the LEDs ......................................................................................................................................................... 54

Figure 18 : View of pictograms ................................................................................................................................................................ 54

Figure 19 : View of the front panel ........................................................................................................................................................... 64

Figure 20 : Description of the LEDs ......................................................................................................................................................... 65

Figure 21 : Close-up of USB ports ........................................................................................................................................................... 65

Figure 22 : Description of the screen (example) ...................................................................................................................................... 66

Figure 23 : Trailer lubrication/greasing points .......................................................................................................................................... 83

4/242

1. Preface

1.1. General recommendations

The information contained in this manual is taken from technical data available at the time of print. In line with our policy of continually

improving the quality of our products, this information may be amended without warning.

Read the safety instructions attentively in order to prevent any accident, incident or damage. These instructions must be adhered to

constantly.

In order to obtain optimum efficiency and the longest possible service life for the generating sets, maintenance operations must be

carried out according to the periods indicated in the attached maintenance tables. If the generating set is used under dusty or

unfavourable conditions, some of these periods will be shorter.

Ensure that all adjustments and repairs are carried out by personnel who have received appropriate training. Our agents possess this

qualification, and can answer all of your questions. They can also supply you with spare parts and other services and they have

qualified staff to carry out preventive and corrective maintenance or even total reconditioning of generating sets.

The left and right sides can be seen from the back of the generating set (the radiator is at the front).

: some user and maintenance manuals for engines fitted to gener ating sets cover control units and include the start-up and sh ut

Note

down procedures for the engines.

As our generating sets are fitted with control units that are specific to the generating sets; only the i nformation that appears in the

documentation for the generating set control units should be taken into consideration.

In addition, depending on the manufacturing criteria of the generating sets, some engines may be fitted with specific electrical wiring

different to that described in the engine documentation.

1.2. Warnings

In this manual, the warning messages are used as follows:

Immediate danger.

Indicates an imminent danger which may result in death or serious injury. Failure to follow the instruction

shown may pose serious risks to the health and life of those concerned.

DANGER

Potential danger.

IMPORTANT

Indicates a dangerous situation if the warning is not heeded. Failure to follow the instruction indicated may

cause minor injuries to those concerned or damage to equipment.

5/242

1.3. Pictograms and their meanings

The aim of the pictograms is as follows:

- To draw the attention of the operator or maintenance technician to the potential dangers.

- To explain how to act in the interest of personal safety and to avoid damaging the equipment.

The safety pictograms present on the equipment are explained below.

Warning: danger

Important,

toxic materials

Important,

high temperature

Important,

Electrical risk

Important,

rotating or moving

parts

Important,

corrosive product

Important,

risk of explosion

Important,

pressurised fluids

Danger: automatic

start-up

Figure 1 : Warning pictograms

Entry prohibited to

unauthorised

persons

Figure 2 : Pictograms indicating prohibited activities

Jet washing

prohibited

6/242

Reading the

manual for the

equipment is

compulsory

Lifting point

required

Periodic

maintenance

compulsory

Figure 3 : Pictograms indicating compulsory operations

Earth

Wearing suitable

protective clothing

is compulsory

Forklift required for

lifting

Battery isolating

switch

Wearing suitable

protective goggles

and ear defenders

is compulsory

Battery charge

must be checked

External fuel

connections

Diesel fuel

Fill the coolant

Fill the oil

Retention container

high level

Drain the fuel

Drain the coolant

Drain the oil

Drain the retention

container

Figure 4 : Information pictograms

Inspection flap

Mains supply

connection

prohibited before

filling with water

7/242

Flammable product,

Do not smoke or create sparks or flames

Fuel supply

- Selection valve -

Figure 5 : Specific pictograms

Reading the manual for the equipment is

compulsory

Securing straps routing point

Rinse any splashes of acid on the skin or

in the eyes using clean water.

Wearing suitable protective clothing and

goggles is compulsory

Consult a doctor immediately.

Wash contaminated clothing with water.

Figure 6 : Pictograms relating to battery operations

8/242

1.4. Safety instructions

RETAIN THIS MANUAL

This manual contains important instructions which must be followed when installing or carrying out maintenance on a generating set

and batteries.

IMPORTANT - SAFETY ADVICE

If any parts of this manual are not understood, or in case of doubt, contact your nearest agent in order to receive an explanation or

demonstration to allow the equipment to be used correctly. The guidelines listed below must always be respected to ensure the safety

of personnel and equipment. In addition to this information, it is essential to refer to the local and national regulations applicable

according to the jurisdiction.

1.4.1 General guidelines

Installing the equipment

The installer of the equipment must create a document describing any modifications made to the equipment during installation.

Using the equipment

- Before starting any operations on the equipment:

Nominate an operations manager.

The role of the operations manager is to monitor, either directly or indirectly, any operations performed on the equipment

and to ensure that the safety and operating instructions are respected.

The operations manager should read and understand all the documentation supplied with the equipment.

- Information for personnel:

Regularly reiterate the safety and operating instructions to the operating personnel.

Contact your dealer if you have any questions regarding the equipment and any training requests for personnel.

Make the manufacturer's instructions available to the users (if possible on site).

- Protection for individuals and equipment:

Wear suitable clothing.

Move away from equipment in operation.

Ensure that persons who are not authorised to intervene as well as animals are kept away from the equipment. Observe

this guideline regardless of whether the equipment is in operation or stopped.

Protect the equipment from any fluid splashes and bad weather.

Before starting the equipment, refit the enclosures and close all the access doors.

Before starting the engine, check that the air filter is present and the correct extraction circuit for the exhaust gas.

Respect the current regulations relating to fuel use.

Under no circumstances use seawater or any other corrosive or electrolytic product in the cooling circuit.

Adjust the equipment according to the manufacturer's prescriptions.

Check that the equipment operates correctly.

Engage the parking brake when the equipment is installed on the operating site on its trailer. When chocking the trailer on

a slope, ensure that there is nobody in the path of the trailer.

9/242

Maintaining the equipment

- Personnel skills:

Ensure that the maintenance operations are performed on the equipment by appropriately trained personnel.

- Personnel protection:

Wear suitable clothing and protective goggles.

Remove any personal belongings that may hinder the operation: watch, bracelet, etc.

Fit a panel over the controls of the equipment to prevent any attempt to start.

Disconnect the battery (and pneumatic starter if fitted) before beginning any maintenance operation.

Handle the equipment according to best practices, using techniques which do not endanger the personnel.

It is essential to wear gloves when detecting leaks.

Regularly check that the safety devices are operating correctly.

- Equipment protection:

Use tools in good condition and suited to the work to be done. Ensure you have understood the instructions before

beginning any operation.

Respect the maintenance table and its recommendations. In dusty or unfavourable conditions, certain maintenance

intervals will need to be reduced.

Check that the spare parts fitted on the equipment are supplied only by the dealer.

Handle the equipment according to best practices, using techniques which do not risk damaging the equipment.

Replace any safety pictograms that are missing or illegible on the equipment.

Note

: the mounting bolts on the protective devices of t he rotating parts are captive bolts equipped with retaining washers.

Also, in order to ensure the integrity of this assembly, it is prohibited to use elec tric or pneumatic screwdrivers to undo these

mounting bolts.

- Cleaning the equipment:

Clean off any trace of oil, fuel or coolant using a clean cloth.

Use only approved cleaning solvents.

Cleaning products and methods that are strictly prohibited:

• petrol or other flammable substances;

• soapy solution containing chlorine or ammonia;

• high pressure cleaner.

- Additional instruction:

If necessary, contact the dealer for the following reasons:

• answers to any questions relating to the equipment;

• training requests for personnel;

• supplying the relevant documentation for maintenance operations;

• supplying spare parts;

• corrective or preventive maintenance operations.

10/242

Operating site

- Maintenance:

Clean the entire operating site regularly with suitable cleaning materials.

The presence of dangerous or combustible materials inside premises must be limited to the operating requirements.

- Access:

Prohibit free access to persons who are not part of the establishment, except for those designated by the user.

- Respecting the environment:

Drain and dispose of engine oil in a specially provided container (fuel distributors can collect your used oil).

Burning of waste in the open air is prohibited.

Remove waste water, sludge and other waste in a specialised processing centre.

1.4.2 Electrical safety precautions

DANGER

- Read the manufacturer's identification plate carefully. The values for voltage, power, current and frequency are shown. Check

that these values match the installation being supplied.

- The electrical connections must be made in accordance with current standards and regulations in the country of use and the

neutral system sold.

- Ask a qualified electrician to intervene when there are specific cases requiring equipment to be connected to an existing

electrical network.

- Disconnect the power to the equipment (equipment voltage, battery voltage and network voltage) before any installation or

maintenance operation is performed.

- Connect the equipment wires by respecting the wiring diagram supplied by the manufacturer.

- Always handle the equipment with dry hands and feet.

- Take all the necessary precautions to avoid touching stripped cables or disconnected connectors.

- Use and maintain the cables in good condition, well insulated and connected correctly and securely.

- Only replace equipment that provides protection against electric shock with identical equipment (specifications and nominal

values).

- Only use flexible durable cables with a rubber covering, which conform to ECI 245-4, or equivalent cables.

- Refit the protective plates (blanking covers) after each maintenance operation.

ELECTRICAL EQUIPMENT - RISK OF ELECTRIC SHOCKS

Note

: The electrical equipment supplied with the equipment co mplies with standard NF C15.100 (F rance), or with the standards of th e

countries in question.

11/242

1.4.3 Safety precautions in case of electrical shock

In the event of an electric shock, observe the following instructions:

1. Avoid direct contact both with the live conductor and the victim's body.

2. Shut off the power immediately and activate the emergency stop for the

equipment concerned. Note

care to avoid the electric arc that will be generated by this.

3. If it is impossible to access the equipment: move the victim away from the live

conductor using a dry piece of wood, dry clothing or other non-conducting

material.

4. Move the victim away from any situations where there is a danger of death.

5. Contact the emergency services.

6. If breathing has stopped, begin artificial respiration at once.

7. In the event of cardiac arrest, carry out cardiac massage.

1.4.4 Safety precautions relating to fire, burns and explosions

: the live wire may be cut with an axe. Take extreme

DANGER

FUELS / FLAMMABLE PRODUCTS / PRESSURISED FLUID

- RISK OF BURNS -

- RISK OF FIRE -

- RISK OF EXPLOSION -

1. Before starting the equipment, move any flammable or explosive products away (petrol, oil, cloth, etc.).

2. It is prohibited to put combustible materials on the hot parts of the equipment (for example: exhaust pipe).

3. Avoid any contact with the hot parts of the equipment (for example: exhaust pipe).

4. Use appropriate ventilation to allow the equipment to cool correctly.

5. Wait for the engine to stop and cool down completely before removing the radiator cap.

6. Wait for the equipment to stop and cool down completely before covering the equipment (if necessary).

7. Depressurise the air, oil and cooling circuits before removing or disconnecting all the fittings, pipes or connected components.

8. Ensure that the equipment in operation is fixed (in a stationary position).

When installing the equipment on a vehicle or other mobile equipment, a study must be conducted

beforehand in order to take into account the various specific uses of the generating set.

IMPORTANT

12/242

Fuels

- Respect current local regulations regarding the equipment and fuel used

(petrol, diesel and gas).

- Top up the engine with fuel when the engine has stopped (except for

equipment with an automatic filling system).

- Smoking, using a flame or producing sparks are forbidden while the fuel

tank is being filled.

- Use protection suitable against fires and explosions.

- Pipes must be replaced as soon as their condition demands it.

Oils

1. Check that the system is no longer pressurised before carrying out any procedures.

2. Avoid contact with hot oil.

3. Wait for the engine to stop and cool down completely before topping up the oil.

4. Before starting the engine, refit the oil filler cap.

5. It is prohibited to cover the generating set with a fine layer of oil for anti-rust protection.

Battery

- Smoking, using a flame or producing sparks are forbidden close to batteries (particularly when the batteries are being

charged).

Supply gas

(concerns generating sets running on gas)

- Request the user technical notes and LPG or NG safety data sheets from your gas supplier.

- For any operation on a gas installation, ask a recognised specialist to intervene.

- Gas supply procedures must be carried out in the open air (outside) in accordance with local regulations, in an area well away

from fires, people or animals.

- Check the sealing of the gas supply circuit using soapy water with the circuit pressurised, or using a leak detector.

- It is forbidden to smoke, bring flames near or create sparks when the tank is being filled, and near to the generating set.

13/242

1.4.5 Toxic risk safety precautions

DANGER

EXHAUST GAS - TOXIC PRODUCTS

- TOXIC RISK -

Exhaust gas

- Use suitable ventilation to release the exhaust gas outside and prevent it from

accumulating.

- Respect current local regulations regarding the equipment and fuel used (petrol, diesel

and gas).

- Periodically examine the burnt gas exhaust.

- Pipes must be replaced as soon as their condition demands it.

Note

: the carbon monoxide present in the exhaust gas may lead to death by inhalation if the concentration l evels i n the atmosphere are

too high.

Corrosion inhibitor in the coolant

(contains alkali)

- Read the instructions on the packaging.

- Keep the product out of the reach of children.

- Do not swallow it.

- Avoid prolonged or repeated contact with the skin.

- Never allow contact with the eyes.

In the event of contact with the eyes:

1. Rinse immediately with plenty of water for at least 15 minutes.

2. Consult a doctor immediately.

In the event of contact with the skin:

1. Wash thoroughly with water and soap.

2. Consult a doctor immediately.

Fuels and oils

- Do not swallow it.

- Ensure proper ventilation.

- Use a suitable protective mask.

14/242

Battery electrolyte

- Avoid all contact with the skin and eyes.

- Wear suitable protective goggles and clothing and strong alkali-resistant

gloves for handling the electrolyte .

If splashes get into the eyes:

1. Rinse immediately with running water and/or a 10% diluted boric acid solution.

2. Consult a doctor immediately.

1.4.6 Precautions for risks relating to handling phases

DANGER

HANDLING PHASES - RISK OF DROPPING

1. Select the appropriate handling equipment and apparatus according to the type of equipment being handled. Check that there

is sufficient handling capacity.

2. Check that the handling equipment and apparatus are in good operating condition.

3. Respect the handling instructions described in the present documentation and the pictograms displayed on the equipment to

be handled.

4. Be sure never to stand under the load being handled.

Note

: the lifting rings provided on the equipment are designed to handle the generating set alone. If additional equipment is fitted to the

generating set, a study should be conducted in order to define the centre of gravity of the assembly and to check the correct

mechanical performance of the structure and its lifting rings.

1.4.7 Precautions for risks relating to noise

HIGH SOUND LEVEL - RISK OF HEARING LOSS

DANGER

- Always use suitable ear defenders when working in close proximity to a generating set which is in operation.

Note

: for generating sets used inside, for which the ambient noise levels are dependent upon the installation conditions, it is not

possible to specify these ambient noise levels in the oper ating instructions. As prolonged exposure to high sound pressure leve ls can

cause permanent damage to hearing, it is necessary to measure the acoustics after installation in order to determine the sound

pressure level and, if necessary, to implement the appropriate preventive measures.

15/242

2. General description

2.1. Description

Overview

1

2

4

5

3

6

Figure 7 : General description of the generating set

1 Acces to maintenance area 4 Acces to control unit

2 Lifting ring 5 Acces to power connections

3 Forklift grooves 6 Drawbar

16/242

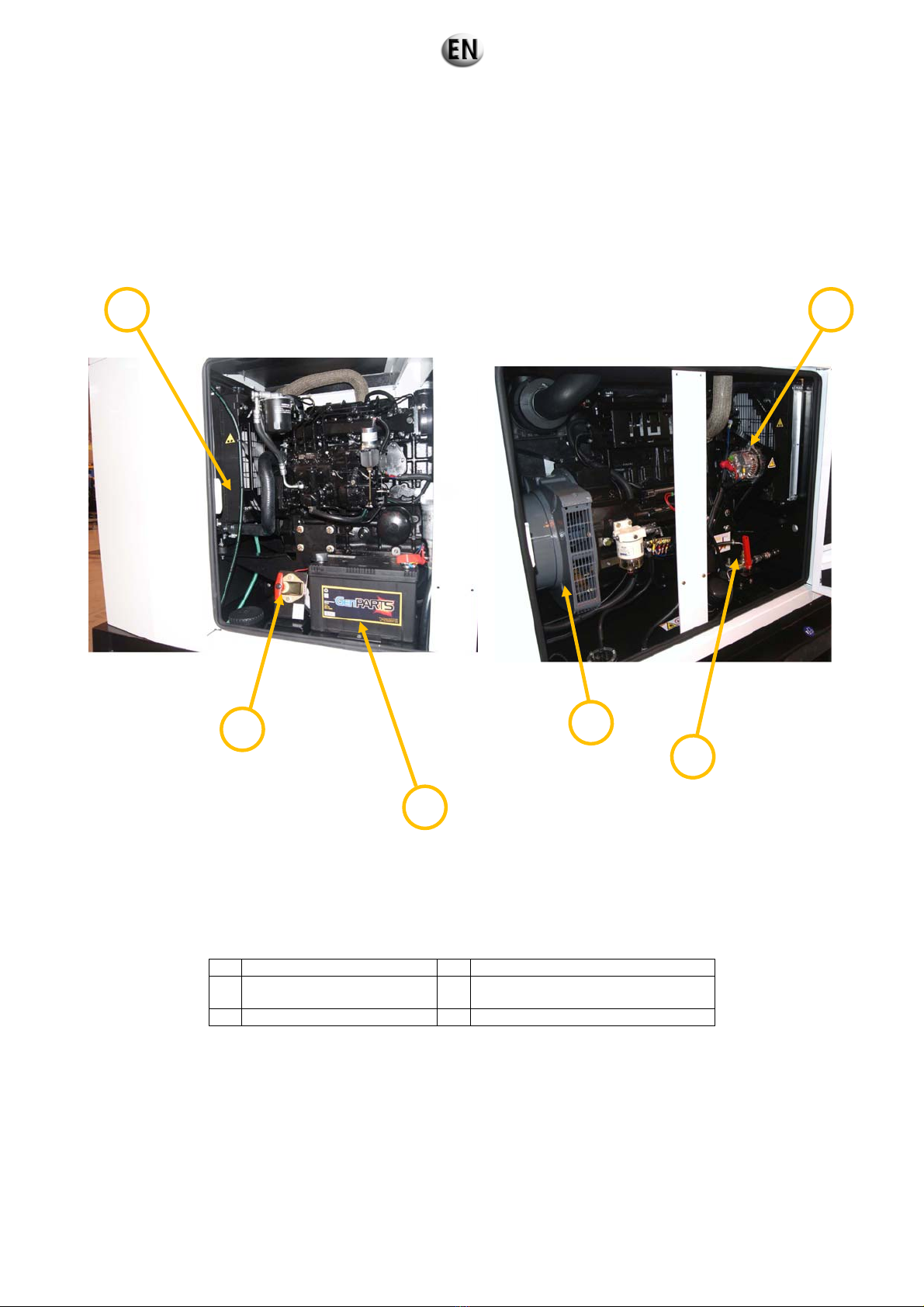

1

6

2

4

5

3

Figure 8 : General description of the generating set (Continuation)

1 Protective grille 4 Alternator

2 Battery isolating switch 5

External fuel supply combined tap

(optional)

3 Starter battery 6 Charging alternator

17/242

Control

4

1

2

3

Figure 9 : General description of the generating set (control)

1 Control unit 4 Working hours counter

2 Emergency stop 5 Power circuit breaker

3 Socket control panel 6 Connection terminal block

Note : Photo presented with the Nexys control unit.

5

6

e

%

18/242

2.2. Technical specifications

Range / Generating set type RENTAL POWER / R33C3

Weights and Dimensions

Dimensions with high autonomy tank

Dimensions l x w x h

2200 mm x 1000 mm x 1528 mm

Weight:

1100 kg à vide / 1300 kg en ordre de marche

Hood:

M3127

Sound pressure level at 1 m

Measurement uncertainty : 0.66

Output

Voltage Hz Phase Load factor Max current (A)

400/230 50 3 0.8 48 26.4 / 33 24 / 30

(1) ESP: Stand-by output available for emergency use under variable charge up to 200hrs per year as per lSO 8528-1, no overload availabl

under these service conditions.

(2) PRP: Main output available continuously under variable load for an unlimited time peri od per year as per ISO 8528-1, an overload of 10

one hour every 12 hours is available, as per ISO 3046-1.

Term of use :

Standard reference conditions ESP/PRP 40° / 40°, Air Intlet Temp, 1000m / 1000m mA.S.L. 60 % relative humidity.

Engine data

Manufacturer / model MITSUBISHI S4S-Z361SD

Type 4 Cycles Naturally aspirated

Cylinder configuration 4 XL

Cubic capacity 3.33 L

Rotation speed 1500 Rpm

Max emergency/prime power at nominal speed 31.3 / 28.3 kW

Adjustment type Mechanical

Fuel consumption

100 % main power 8.60 L/h

Fuel

Fuel type Diesel

High autonomy fuel tank 220 L

Lubrication

Oil capacity 10 L

Min. Oil pressure 1 bar

Nominal oil pressure 3.9 bar

Oil consumption (100 % load) 0.08 L/h

Oil sump capacity 9 L

Type of lubricant Genlub

Cooling

Engine capacity with radiator 8.5 L

Max coolant temperature 105 °C

Fan power 0.8 kW

Refrigerant type Gencool

Thermostat 76.5 – 90 °C

: 72 dB(A)

Emergency

power

kW / kVA

1

Prime power

2

kW / kVA

19/242

Alternator data

● Compliant with NEMA MG21 standards, UTE NF C51 111,

VDE 0530, BS 4999, IEC 34.1, CSA

Type LEROY SOMER LSA42.2L9

Number of phases 3

Power factor (cos Phi) 0.8

Number of poles 4

Excitation type AREP

Regulation R438

Number of bearings 1

Coupling Direct

Control unit(s)

NEXYS

● The alternator is protected against short circuits

● Vacuum impregnation, epoxy winding, IP23 protection rating

TELYS

Standard specifications

:

Frequency meter, Voltmeter, Ammeter

Alarms and faults

:

Oil pressure, Coolant temperature, Fail to start, Overspeed,

Alternator min/max, Fuel level low, Emergency shutdown

Engine parameters

:

Working hours counter, Engine speed, Battery voltage, Fuel

Level, Air Preheating

Standard specifications:

Voltmeter, Ammeter, Frequency meter

Alarms and faults:

Oil pressure, Water temperature, Start failure, Overspeed,

Alternator min/max, Battery voltage min/max, Emergency stop

Engine parameters

:

Timer, Oil pressure, Water temperature, Fuel level, Engine

speed, Battery voltage

20/242

2.3. Identifying sets

Generating sets and their components are identified by means of identification plates.

The precise rules for identifying each major component (engine, alternator, etc.) are set out in each manufacturer's documentation

contained in the appendices of this manual.

1 - Generating set

2 - Manufacturer name

3 - Model

4 - Serial number

5 - Year of manufacture

6 - Rated output (kVA and kW) according to the ISO

8528-1 standard

PRP: main power

ESP: emergency power

7 - Rated power factor

8 - Maximum altitude of the site above sea level (m)

for the rated power

Figure 10 : Example of a generating set identification plate

9 - Maximum ambient temperature for the rated

power (°C)

10 - Rated frequency (Hz)

11 - Generating set rotation speed (RPM)

12- Rated voltage (V)

13 - Rated current (A)

14 - Weight (kg)

15 - CE marking

16 - Non CE standard marking

(e.g.: GOSSTANDART)

17 - Sound pressure

18 - Sound power

21/242

2.4. Fluid retention

Any outflow of the fluids contained in the generating sets (fuel, oil and coolant, or rainwater or condensation) will be collected in a

retention container.

The containers have a capacity which allows 110% of the fluids contained in the generating set fitted with this option to be collected.

Figure 11 : Fluid retention container

The generating sets are fitted with a visual alarm warning when the upper limit of the retention container has been reached.

In all cases, the retention containers must be regularly checked to ensure they contain no fluid (fuel, oil and coolant, or rainwater or

condensation). If necessary, drain the containers via the drain port.

Note: Never allow these fluids to drain onto the ground; ensure they are collected in a designated container.

22/242

2.5. Fuels, lubricants and coolants

All specifications (product features) are given in the engine and alternator maintenance manuals attached to this manual.

In addition to these, we recommend the fuels, lubricants and coolants mentioned in the "Specifications" section.

2.5.1 Fuel specifications

General quality requirements

The quality of the fuel is essential for engine performance. It affects the technical performances such as the service life, power supplied

and fuel consumption as well as the ability to respect the requirements issued by authorities relating to pollutant emissions. Only fuels

which conform to the current legal requirements and national and international standards should be used. Consult the local

fuel distributor to find out the characteristics of the diesel fuel available in the area.

Examples of standards and requirements:

EN 590

ASTM D 975 1-D and 2-D

European standard (CEN) for vehicle fuel - fuels for diesel engines (diesel fuel) requirements and test methods

American Society for Testing and Materials: basic requirement in the United States and

Canada

JIS KK 2204 Japanese Industrial Standards: Japanese industrial standards

Respecting pollutant emissions

The certification measures confirming that the legal emission value limits are respected are performed with certified fuels which

conform to the standards and requirements stated above.

Resistance to low temperatures

When the external temperature is low, the fluidity of diesel fuel may no longer be sufficient due to paraffin deposits. Also, in the winter

in order to avoid malfunctions (for example, clogged filters), use diesel fuels which are fluid enough in cold weather.

The requirements to respect for the various geographical regions and various seasons (winter/summer) are specified in the standards

and/or national regulations. Petrol companies should always supply fuels with the correct flow properties regardless of the time of year.

In general, diesel fuel is treated with additives so that the fuel can be used at low temperatures in the region where it is marketed.

Treating fuel with additives must respect the engine manufacturer's recommendations and maintain a suitable lubricity for the injection

systems. It is recommended to favour fuels whose additives have been added in a refinery over those modified in the storage tank.

23/242

General specifications for diesel fuel

The fuel used must have the following characteristics (non-exhaustive list):

The sulphur content must meet the current emissions regulations in the region where the

generating set is used.

For the United States and countries respecting the EPA regulation

Only use Ultra Low Sulphur Diesel (ULSD) fuel with a maximum sulphur content of 15 mg/kg

for Interim Tier 4 and Tier 4 certified engines.

Sulphur content

For the European Union

Directive 2009/30/CE whose aim is to limit atmospheric pollution, imposes the use of a diesel

fuel with a very low sulphur content of 10 mg/kg, for non road mobile machinery

In France, this obligation has resulted in the development of a diesel fuel called "off road diesel

fuel" or "GNR". The maximum admissible sulphur content is 10 mg/kg. However, member

states allow these diesel fuels to contain up to 20 mg/kg of sulphur when they are distributed

to the final users. It is recommendable to avoid storing off road diesel fuel for long periods of

time (over 6 months).

The viscosity and density directly affect the performance (power and fuel consumption),

emissions and service life of the engine. A low level of viscosity and density reduces engine

power and increases fuel consumption. Too high a level of viscosity and density seriously

Viscosity and

reduces the service life and operation of the fuel injection system.

density

In order to maintain adequate technical and environmental performance, the viscosity and

density must conform to the specifications indicated in the manufacturer's instructions for the

engines fitted to our generating sets.

Lubricity (or

capacity for

lubrication or

oiliness)

In order to protect the fuel injection system against excessive wear, the fuel must have

satisfactory lubricity (refer to the manufacturer's instructions for the engines fitted to our

generating sets).

The ignition behaviour of diesel fuels is described by the cetane index. The cetane index is

Cetane index

important for emissions, the ability to start in cold weather and engine noises. The minimum

technical requirements are 45.

.

The fuel and tank must not contain any water. Water causes the engine parts to corrode and

wear more rapidly, particularly the injection system parts. In addition, water promotes the

Water and

contaminants

growth of bacteria and fungi in the tank, which can clog the fuel filter. The fuel must not contain

any type of residue. Organic contaminants (bacteria, fungi, etc.) can block the fuel filters;

inorganic material in the fuel (dust, sand) can cause serious damage to the injection

equipment.

24/242

2.5.2 Lubricant specifications

Essential for the correct operation of the engine. The oil should be selected according to its use. Besides the lubrication function, oil

should also:

- cool certain parts;

- protect metal parts against corrosion;

- improve the sealing, in particular between pistons, piston rings and cylinders;

- remove impurities (to the filter).

It is recommendable to use a top of the range lubricant for diesel engines. The table below lists the oils recommended for each engine

manufacturer.

Engine

Make Type Make Type

Cummins All GenPARTS GENLUB TDX 15W40

John Deere All

MTU All GenPARTS GENLUB TDX 15W40

Mitsubishi All GenPARTS GENLUB TDX 15W40

Fuel GenPARTS GENLUB TDX 15W40

Perkins

Gas MOBIL PEGASUS 705

Volvo All GenPARTS GENLUB TDX 15W40

Doosan All GenPARTS GENLUB TDX 15W40

Lombardini

All

Kohler

John Deere John Deere PLUS-50

GenPARTS GENLUB TDX 15W40

GenPARTS

or Kohler

GENLUB TDX 15W40 or Kohler 5W40,

according to the model of the engine

Viscosity

Viscosity is a measure of the flow resistance of a fluid. The viscosity of an engine oil is expressed by 2 SAE (Society of Automotive

Engineers) grades. One grade for cold weather and one grade for hot weather. The grade for cold weather appears before the letter W.

The 1st grade represents dynamic viscosity in cold weather, namely the ability to start the engine and to prime the oil pump (and

therefore to lubricate the various components quickly). The lower the number, the more fluid the oil.

The 2nd grade represents the kinematic viscosity in hot weather. The higher the number, the thicker the film of oil when hot (which aids

protection and sealing). The lower the number, the less friction there will be in hot weather (it helps to save fuel).

In order to ensure immediate protection when starting the engine, the choice of viscosity grade when cold is essential. More fluid oil is

quicker to flow when oil begins to circulate through the engine. It should be selected according to the ambient temperature. See the

table below.

25/242

Characteristics of GENLUB TDX 15W40 oil

Performance

GENLUB TDX oil is a 15W40 multigrade mineral oil which meets the following specifications: ACEA E3 and API CG-4.

ACEA E3: oil with superior viscosity stability, suited to extended oil change intervals and severe conditions of use.

API CG-4: oil particularly effective to meet the emissions requirements.

ACEA = European Automobile Manufacturers' Association

API = American Petroleum Institute

Specifications

Specifications Units Grade SAE 15W-40

Density at 15°C kg/m3 883

Kinematic viscosity at 100°C mm2/s (cSt) 14

Viscosity index – 130

Flow point °C - 27°

Flash point °C >200

TBN* mgKOH/g 9.7

Typical values given for information purposes

* TBN (Total Base Number – degree of alkalinity): a measure of a lubricant's reserve alkalinity according to standard ASTMD 2896.

This check makes it possible to assess the ability of the product to remain in service and to check the ’capacity of the lubricant to

neutralise the acidity contained in the oil, which may corrode the metallic elements of the lubricated component.

2.5.3 Coolant specifications

The engine's internal cooling system allows the engine to operate at a precise temperature.

The table below lists the coolants recommended for each engine manufacturer.

Engine

Make Type Make Type

Mitsubishi LLC

Mitsubishi All

GenPARTS GENCOOL PC -26

MTU All GenPARTS GENCOOL PC -26

John Deere All GenPARTS GENCOOL PC -26

Volvo All GenPARTS GENCOOL PC -26

Doosan All GenPARTS GENCOOL PC -26

26/242

Specifications of GENCOOL PC -26 coolant

Performance

GENCOOL PC -26 coolant is a ready-to-use cooling fluid which provides a high level of protection and is produced from an antifreeze

approved by the majority of manufacturers (Power Cooling concentrated antifreeze).

It offers the following:

- Improved anticorrosion: improves the effectiveness and service life of the cooling system.

- High temperature feature: promotes heat exchange.

- Long-term protection: against overheating and corrosion under extreme conditions of use.

- Compatible with the original fluid (however, it is recommended to drain the entire cooling system when replacing the fluid).

Specifications

Specifications Units Characteristics

Density at 20°C kg/m3 1053 ± 3

pH pH 7.5 to 8.5

Alkalinity reserve ML ≥ 10

Boiling temperature °C 105 ± 2

Freezing temperature °C -26 ± 2

Typical values given for information purposes

27/242

3. Transporting the equipment

3.1. Warnings concerning transport

It is prohibited to operate generating sets whilst they are being transported.

IMPORTANT

3.2. Preparing for transport

Before the equipment is transported, perform the following operations:

1. Close the tap on the oil top up tank outlet.

2. Fill up the oil top up tank with oil.

3. Fill up the crankcase with oil.

4. Fill up the on-board tank with fuel.

5. Check that the batteries are fitted and filled with electrolyte.

3.3. Road transport

3.3.1 Generating sets with and without an enclosure

Generating sets must be transported by road in accordance with the regulations of the countries concerned.

When transporting generating sets in containers by road, the following steps must be observed:

1. Put a plastic cover over non-enclosed generating sets during transportation.

2. Select transport equipment (trailer, semi-trailer, etc.) suitable for this usage and having all the safety guarantees in terms of

load bearing capacity and of the securing devices.

3. Chock and fix the generating sets to the floor of the transport equipment.

4. Strap the generating sets to the transport equipment.

5. Select a transport route which makes it possible to travel on roads suitable for vehicles, and whose quality will not damage the

on-board generating sets.

28/242

3.3.2 Generating sets on trailers

3.3.2.1. Hitching and unhitching the trailer

Jockey wheel for

M3126

and M3127

type trailers

Before hitching the trailer, check the hitching system on the towing vehicle; this must be perfectly compatible with the trailer.

Jockey wheel for

M3128

and M3129

type trailers

Towing a trailer with a non-compliant device (bar, cables, lashing, etc.) runs the risk of serious accidents.

IMPORTANT

Also check:

- That there are no incipient ruptures or significant wear on the hitching system.

- That the locking system is working properly.

29/242

Hitching a trailer fitted with a hitching ring

1. Drive the towing vehicle or bring the trailer up to the hitching point, then:

- With the jockey wheel touching the ground, place the stabiliser (1) in the top position:

Loosen the jaw of the stabiliser (2) with its lever;

Raise the stabiliser fully;

Tighten the jaw of the stabiliser (2) with its lever.

- Remove the wheel chocks if necessary and store them.

2. Position the trailer parallel to the ground using the guide wheel handle (jockey wheel).

3. Place the hitching ring above the towing vehicle's hitching system:

After this adjustment, the trailer must remain parallel to the ground.

Make any necessary height adjustments to the towbar using the jockey wheel to enable hitching.

IMPORTANT

2

1

- Remove the safety pin from the towbar (3);

- Undo the nut with the lever (4);

- Use the adjustable towbar handle to place the ring above the hitching system;

- Tighten the nut to lock the towbar;

- Fit the towbar safety pin.

4. Attach the ring to the hitching system:

- Lower the trailer by moving the jockey wheel away from the ground using

its handle (5).

5. Lock the jockey wheel in the towing position:

When in the towing position, the jockey wheel must not:

- obstruct the unlocking cable's movement;

- trap any electrical cables.

IMPORTANT

M3126/M3127 type trailers

- Position the jockey wheel at the rear.

- Raise the jockey wheel with its handle (5) into the

notches on its tube (6).

- Loosen the jaw of the tube (7) with its lever.

- Raise the tube fully.

- Tighten the jaw of the tube (7) with its lever.

6

5

7

4

3

5

M3128/M3129 type trailers

- Remove the safety pin from the position lock (8).

- Remove the position lock (8).

- Place the jockey wheel in the towing position.

- Fit the position lock (8).

- Fit the safety pin in the position lock (8).

- Raise the jockey wheel with its handle fully and at right

angles to the towbar.

8

30/242

6. Attach the unlocking cable to the hitching plate on the towing vehicle.

Examples of how to attach the hitching cable

If the hitching ring is not correctly connected to the hitching hook, the trailer will become separated from the

IMPORTANT

towing vehicle. In this case the unlocking cable actuates the parking brake (which then becomes an emergency

brake).

To ensure that the device fulfils its function correctly, the unlocking cable:

- MUST NOT be wound around the jockey wheel, as this will disable emergency braking;

- MUST NOT be taut or obstructed, as this could activate emergency braking during towing;

- MUST be routed as straight as possible and not be obstructed at any point;

- MUST be sufficiently long to allow cornering.

7. Connect the electrical cable plug controlling the lamps, indicators, etc. to the socket on the towing vehicle.

8. Remove the parking brake:

- Remove the wheel chocks if necessary and store them;

- Perform the following operations simultaneously on the parking brake:

Press the unlocking button (9);

Lower the handle (10) fully.

9

10

31/242

Unhitching a trailer fitted with a hitching ring

1. Immobilise the trailer:

- Chock the wheels;

- Apply the parking brake:

Raise the parking brake lever (10) fully.

2. Disconnect the electrical cable plug controlling the lights, indicators, etc. from the socket on the towing vehicle.

3. Remove the unlocking cable on the towing vehicle.

4. Release the hitching ring:

M3126/M3127 type trailers

- Disengage the jockey wheel from the notches in the

tube (6) with its handle (5).

- Loosen the jaw of the tube (7) with its lever.

- Lower the tube until the jockey wheel touches the

ground.

- Tighten the jaw of the tube (7) with its lever.

6

5

7

- Support the load on the jockey wheel:

Lower the jockey wheel with its handle;

When you are sure that the wheel can bear the load (the towbar rises), unhitch the trailer from the vehicle.

5. Fit the stabiliser (1):

- Loosen the jaw of the stabiliser (2) with its lever;

- Place the stabiliser in contact with the ground;

- Tighten the jaw of the stabiliser (2) with its lever.

- Remove the safety pin from the position lock (8) on the

jockey wheel.

- Remove the position lock (8).

- Place the jockey wheel in the bottom position.

- Fit the position lock (8).

- Fit the position lock pin.

- Lower the jockey wheel to the ground with its handle.

M3128/M3129 type trailers

8

1

2

32/242

3.3.2.2. Check before towing

Before first use, it is essential to check the tightness of the wheel bolts.

IMPORTANT

Before towing, check the following:

- Wheel tightness.

- Hitching hook locked.

- Tyre pressure.

- Signalling lights working.

- Enclosure doors closed.

- Parking brake released.

- Guide wheels (jockey wheels) and stands lifted and locked.

- Safety cable fitted.

INFLATION PRESSURE (BAR)

145R13 2.2 185R14C 4.5

155 / 70R13 2.5 195R14C 4.5

185 / 70R13 2.5 215R14C 4.5

175R14C 4.5 215 / 75R14C 4.5

TIGHTENING TORQUE WHEELS

Axis of 10 60 Nm

Axis of 14 and 16 120 Nm

3.3.2.3. Operation

The driving speed must be suited to the condition of the road and the handling of the trailer.

Maximal speed on road: 140km/h.

Driving at high speed causes the tyres to heat; it is therefore important to stop from time to time and check them. Excessive heating

may cause a puncture, and therefore a serious accident. For reversing manoeuvres, remember to lock the inertia brake.

Particular attention must be paid to the tightness of the wheels on new vehicles.

IMPORTANT

In the first few miles' driving, heating of the brake hubs and drums will actually reduce the wheel tightness. It

is therefore essential to check the tightness every 6 miles (10 kilometres) until no further loosening is noted.

The tightness check must nonetheless be carried out whenever you have towed the trailer.

(

33/242

Lights / signalling

Warning lights are obligatory for on-road driving. Signalling must comply with regulations in force in the country of use.

Red rear lights

+ direction indicators

+ stop lights

Rear reflective devices

red triangle)

Front reflective devices (white)

Side reflective devices (orange)

Figure 12 : Example of French signalling

3.4. Rail transport

3.4.1 Generating sets with and without an enclosure

Generating sets must be transported by rail in accordance with the specific rules governing rail transport.

When transporting generating sets in containers by rail, the following steps must be observed:

1. Put a plastic cover over non-enclosed generating sets during transportation.

2. Choose transport equipment appropriate for this usage, and having all the safety guarantees both in terms of load-bearing

capacity and securing devices.

34/242

3.5. Shipping

3.5.1 Generating sets with and without an enclosure

Transportation must be carried out in accordance with the rules of shipping. Generating sets must be transported in a shipping

container.

When shipping generating sets in containers, the following steps must be observed:

1. Choose transport equipment appropriate for this usage, and having all the safety guarantees both in terms of load-bearing

capacity and securing devices.

2. In the case of a grouped load container, SEI cases must be used for packing.

3.6. Air transport

Containers must be transported by air in accordance with the specific rules governing air transport.

The UN has classified generating sets as "dangerous goods" listed under UN code 3166 - class 9 - "Engine, internal combustion

(flammable liquid powered)".

Any air shipment of generating sets must be subject to prior declaration to the air freight company, in accordance with form MOD3909.

For air transport, observe the following steps:

1. Choose transport equipment appropriate for this usage, and having all the safety guarantees both in terms of load-bearing

capacity and securing devices.

2. For control boxes, packing in an SEI 4 C case (solid case with waterproof cover) is obligatory.

35/242

4. Installation - Connections

4.1. Unloading the generating set

4.1.1 Choosing the location

When choosing where to site the generating set, bear in mind the:

- proximity to the electrical distribution panel;

- nuisance caused by the noise;

- fuel supply;

- burnt gas evacuation;

- direction of these gases and the noise generated.

1 m min.

Incorrect ventilation and exhaust Building or terrain too rough

Generating set incorrectly seated

Impossible to open enclosure doors Impossible to fill with fuel

Figure 13 : Examples of problems that may be encountered

36/242

4.1.2 Safety during unloading

Always follow the safety instructions before unloading

IMPORTANT

- The lifting machinery or equipment is suitable for the work required and the weight of the generating set. This is indicated on the

generating set's identification plate.

- The sling is correctly positioned in the central lifting eye or the lifting arms are correctly positioned in the fork-lift pockets intended

for this purpose.

- The ground is able to bear the load of the generating set and its lifting machinery without stress (otherwise lay down stabilising

beams of sufficient strength).

- The generating set is put down as close as possible to its place of use or transport, in a clear space with free access.

Example of equipment to be used:

crane;

slings;

lifting beam;

safety hook;

shackles;

Forklift truck.

4.1.3 Unloading the generating set

Before unloading or moving generating set, check that the handling equipment used is able to bear the weight of

IMPORTANT

the generating set (shown on the generating set's identification plate.

4.1.3.1. Slings

1. Attach the sling on the lifting equipment to the ring on the generating set (no. 1) provided for this purpose. Tension the slings

slightly.

2. Check that the sling is correctly attached and the equipment is steady.

3. Lift the generating set carefully.

4. Direct the generating set towards the chosen location and stabilise it.

5. Carefully set down the equipment while continuing to position it.

6. Release the sling, then detach it.

37/242

4.1.3.2. Fork lift truck

1. Position the arms of the forklift truck in the forklift pockets (no. 2).

2. Lift the equipment, handling it gently.

3. Set down the generating set in its unloading position.

3

1

2

3

Figure 14 : Points used for lifting and moving

4.1.4 Moving the generating set

Whenever moving the generating set, ensure suitable equipment is used (e.g. sling, forklift, etc.) and identify those parts on the

generating set which can be used to move it:

- lifting eye (no.1);

- forklift grooves (no.2);

- tow bar (no.3).

y)

38/242

4.2. Connecting the generating set

4.2.1 Connection summary

This diagram can be used to retrace the different steps enabling the generating set to be correctly connected.

Identify the type of differential protection

TT earthing system

TT

fitted on the generating set

"EDF application" option (France

onl

Fixed differential protection Adjustable differential protection

30 mA 30 mA 300 mA 300 mA

No operation required:

terminal circuits protected

Add differential protection

set to 30 mA to the terminal

circuit output(s)

Set the differential protection

of the generating set

No operation required:

terminal circuits protected

Add differential protection

set to 30 mA to the terminal

circuit output(s)

Earth the generating set

Connect the generating set to the installation

39/242

4.2.2 Protecting people and equipment

4.2.2.1. Earthing system principle

The Earthing system, or SLT (formerly Neutral system) of the electrical installation defines the situation of the generating set neutral

in relation to earth and the grounds of the electrical installation at the user end.

Our generating sets are designed to operate with the TT system (or EDF application depending on the option, for France only).

4.2.2.2. TT system

In the TT earthing system, automatic power cut-off via a Residual Current Device (RCD) is obligatory at the upstream part of the

installation, to ensure that personnel are protected (additionally, a maximum 30 mA device must be installed on outlet circuits).

R

id

id

R

Ph 1

Ph 2

Ph 3

N

PE

R

Neutral connected

to earth

T

Ground connected

to earth

T

R

Ph 1

Ph 2

Ph 3

N

PE

R

Neutral earth

Ground earth

id

Equipment

Figure 15 : TT earthing system

The alternator neutral is earthed, the grounds of the user equipment have their own earth connection.

40/242

4.2.2.3. Installing the differential protection

The generating set is equipped with a residual current device in order to guarantee individuals are protected from electric shocks with

the TT system. This may be fixed ("vigi" unit) or adjustable (Resys) depending on the option chosen.

• If the generating set's residual current device is fixed and the activation threshold is set to 30 mA, it is guaranteed to protect people.

• If the generating set's residual current device is fixed and the activation threshold has been set at 300 mA, a 30mA residual current

device must be added to each of the circuit outlets in use.

• If the generating set's residual current device is adjustable, (located upstream) this must be above those devices located

downstream (terminal circuits); this means that continuity on clean circuits will be maintained in the event of a fault on one of the

terminal circuits (see the following point on setting the residual current device).

Example:

0.03A

30mA

0.3A

(300mA)

Residual current device

Terminal circuit 1

0.03A

30mA

Risk of electric shock.

The generating set's differential relay is factory-set with a current threshold of 0.03 A (30 mA) and with an

automatic time delay (0 s).

Any change to the setting on the residual current device could pose a risk to personal safety. The user will be held

liable - any changes must only be made by trained, qualified engineers.

If the setting is modified, it is essential to restore the original settings after use.

Generating set

Generating set's residual