GENERATING SET USER

AND

MAINTENANCE MANUAL

BOOSTER 1000 U

K

33522120801_1_1

2/4

A

B

C

18

16

5

1

7

6

17

3

2

4

8

9

10

11

12

14

15

3

13

3/4

E

2

1

1

2

3

D

F

3

2

3

1

H

4/4

I

1

2

0.6 -0.7 mm

K1

1

G

2

2

K2

1

2

2

1/10

Contents

1. Preface

2. General description

3. Preparation before starting

4. Using the generator set

5. Safety features (if fitted, see specifications

table)

6. Maintenance schedule

7. Maintenance procedures

8. Storing the generating set

9. Fault finding

10. Specifications

11. Cable sizes

12. Conditions of warranty

13. EC Declaration of conformity

1. Preface

1.1. Recommendations

Thank you for buying one of our generating sets. We recommend that you read this manual carefully and follow the safety and

maintenance advice and user instructions for your generating set very closely.

The information contained in this manual is taken from technical data available at the time of print. In the intention of permanently

improving the quality of our products, this information may be amended without warning.

1.2. Pictograms and plates on the generating sets and what they mean

Danger

Warning: risk of electric

shock

Earth

Danger, risk of burns

Warning: oil is not supplied with the generating set. Always check the oil level before starting the generating set.

1 2 3

1 - Important, refer to the documentation accompanying the generating set

2 - Warning, emission of toxic exhaust gases. Do not use in a confined or poorly ventilated area.

3 - Stop the motor before filling with fuel

A = Generating set model

B = Generating set output

C = Voltage

D = Amperage

E = Current frequency

F = Power factor

Example of an identification plate

G = Fuse rating

H = Generating set noise output

I = Generating set earth

J = Reference Standard

K = Serial number

2/10

1.3. Instructions and safety regulations

1.3.1 Warnings

You are likely to encounter several warning symbols in this manual.

Danger

This symbol indicates a definite risk to the health and life of people. Not following this instruction may seriously

affect the health of people or prove fatal.

Warning

This symbol draws attention to the potential risk to the health and life of people. Not following this instruction may

seriously affect the health of people or prove fatal.

Warning

This symbol indicates a dangerous situation if the warning is not heeded.

Not following this instruction could result in non-serious injury or damage.

1.3.2 General advice

One of the fundamental safety considerations is observation of the interval between maintenance procedures (see maintenance

schedule). Furthermore, never attempt to carry out repairs or maintenance procedures without the necessary experience and/or tools.

When you take delivery of your generating set, check that it is complete and not damaged in any way. A generating set should be

handled gently, avoiding brusque movements, and the place where it is to be stored or used should be carefully prepared beforehand.

Warning

Before use, it is essential that you know how to stop the generating set immediately and that you thoroughly

understand all the controls and operations.

Never let other people use the generating set without giving them all necessary instructions beforehand.

Never let children touch the generating set, even when it is not in operation. Do not operate the generating set near animals (as it

could cause them to panic).

Never start the motor without an air filter or exhaust.

Never invert the positive and negative battery terminals (if fitted) when connecting them. Such an inversion can lead to severe damage

to the electrical equipment.

Never cover the generating set with any type of material while it is in operation or just after it has been turned off. Wait until the

motor is cold.

Never coat the generating set with oil in an attempt to protect it from corrosion. Some preservative oils are flammable. Also, some are

dangerous to inhale.

In all cases, respect the local regulations currently in place concerning the use of generating sets.

1.3.3 Safety guidelines to prevent electrocution

Danger

While they are in operation, generating sets produce electric current.

Connect the generating set to earth each time you use it, in order to prevent electrocution.

Never touch stripped cables or disconnected connectors. Never handle a generating set with wet hands or feet.

Never expose the equipment to liquid splashes or rainfall, and do not place it on wet ground. Always keep the electrical cables and the

connections in good condition. Do not use equipment in a poor state of repair which could lead to electrocution or damage to the

equipment. Use a differential protection device between the generating set and the appliances if the cable or cables used are more than

1 metre in length.

Use flexible, durable cables, with rubber sheathing, conforming to the IEC 60245-4 standard or equivalent cables.

Do not connect the generating set to other power sources, such as the mains. In specific cases where there is provision for a reserve

connection to existing electrical networks, this must only be carried out by a qualified electrician, who should take the operating

differences of the equipment into account, according to whether the mains or generating set is being used.

Special circuit breakers designed for use with generating sets are used to prevent electrocution. If these circuit breakers need to be

replaced, circuit breakers with identical nominal ratings and specifications must be used.

3/10

1.3.4 Safety guidelines to prevent fire

Danger

Keep all inflammable materials (e.g.: petrol, oil, fabric etc.) out of the way when the generating set is in operation.

The motor should not be operated in areas containing explosive products. There is a risk of sparks forming where

all electrical and mechanical components are not shielded. Never cover the generating set with any materials while

it is operating or just after it has been switched off (wait for the motor cool down).

1.3.5 Safety guidelines for exhaust gases

Danger

Exhaust gases contain carbon monoxide, which is a highly toxic substance. This substance can cause death if it is

present in excessive concentrations in the air inhaled.

For this reason, always use the generating set in a well ventilated area, where gases will not be able to accumulate.

Good ventilation is required for your generating set to work properly. Without this, the motor would very quickly run at too high a

temperature, which could lead to accidents or damage to the equipment and to surrounding items. However, if it is necessary to

operate it inside a building, adequate ventilation must be provided, so that people and animals are not affected. It is imperative that

exhaust gases are discharged outside.

1.3.6 Filling with fuel

Danger

The fuel is highly flammable and its vapours are combustible.

Smoking, using a naked flame or producing sparks are forbidden while the fuel tank is being filled.

Filling should be carried out with the motor turned off. All traces of fuel should be wiped off with a clean cloth.

Always place the generating set on a flat, level and horizontal surface to avoid fuel spillage from the tank onto the motor. Storage and

handling of petroleum products must be carried out in accordance with the law. Close the fuel tap (if fitted) each time the tank has

been filled. Fill the tank using a funnel, taking care not to spill any fuel. Then screw the petrol cap back on to the fuel tank as soon as

filling is complete. Never top up fuel when the generating set is in operation or hot.

1.3.7 Safety guidelines against burns

Warning

Never touch the motor or the silencer while the generating set is in operation, or when it has just stopped.

Hot oil burns, avoid contact with the skin. Check that the system is no longer pressurised before carrying out any procedures. Never

start or run the motor when the oil filler cap is off as oil may splash out.

1.3.8 Safety guidelines for handling batteries

Danger

Never place the battery close to a flame or fire

Use only insulated tools

Never use sulphuric acid or acid water to top up the electrolyte level.

1.3.9 Protecting the environment

Never drain or discard used oil onto the ground, but put it into a designated container. As far as possible, try to avoid sound

reverberating through walls and buildings, as the noise will be amplified. If the exhaust silencer of your generating set is not fitted

with a spark arrester and you need to use it in wooded, bushy or uncultivated areas, be extremely careful and make sure that sparks do

not cause a fire (clear vegetation from a fairly large area where you wish to place your generating set).

1.3.10 Danger of moving parts

Warning

Never go near a moving part that is in operation if you have loose clothing or long hair that is not enclosed in a

protective hair net. Do not try to stop, slow down or impede a moving part when it is in operation.

1.3.11 Capacity of the generating set (overload)

Never exceed the rated load of the generating set (in Amps and/or Watts) when it is running continuously.

Before connecting and operating the generating set, calculate the electrical power required by the electric appliances (in Watts). This

electrical power rating is usually found on the manufacturer's plate on bulbs, electrical appliances, motors etc. The sum total of power

required by these appliances should not exceed the nominal power rating of the generating set.

4/10

1.3.12 Operating conditions

The stated outputs of the generating sets are obtained in example conditions according to ISO 3046-1:

+27° C, 100 m above sea-level, humidity level equal to 60 % or

+20° C, 300 m above sea-level, humidity level equal to 60 %.

Performance is reduced by approximately 4 % for every additional 10°C and/or approximately 1 % for every additional 100 m in

altitude.

2. General description

2.1. Description of the generating set (diagram A)

Starter (No. 1) Starter – recoil reel (No. 2) Earth connection (no. 3)

Fuel tank cap

(No. 4)

Starter key (No. 5) Access enclosure for maintenance points

(No. 6)

Exhaust silencer (No. 7)

Operating light (No. 8)

680 W operating light (No. 9) 900 W operating light (No. 10)

Alternating current socket (No. 13) Overload warning light (No. 11) Oil level fault warning light

(No. 12)

Direct current sockets (No. 14)

Direct current circuit breaker (No. 15) Control lever (16) Spark plug enclosure (18)

Access enclosure for oil drain port (No. 17)

3. Preparation before starting

3.1. Checking the oil level (diagrams A and B)

Warning

Always check the engine oil level before starting.

Checking and topping up should be carried out with the generating set on a horizontal surface.

❶ Open the enclosure (No. 6, diag. A) with a screwdriver

❷ Unscrew and take off the oil filler cap (diag. B) and wipe the dipstick, then, insert the dipstick into the filler neck without

tightening it

❸ Remove the dipstick and check the oil level

❹ If it requires topping up, top up with new approved oil to the top of filler tube. Wipe off excess oil with a clean cloth.

❺ Refit the oil filler cap and screw in place.

3.2. Checking the fuel level (diagram C)

Danger

Stop the motor before filling up with fuel and fill up in a well-ventilated area.

Do not smoke, or bring naked flames or sparks near to the area where you are filling up with fuel or where the

fuel is stored. Only use clean fuel without any water.

Do not overfill the tank (there should not be any fuel in the filler neck).

When you have filled up, ensure that the tank cap is closed correctly. Take care not to spill any fuel when filling

the tank. Before starting up the generating set, and if any fuel has been spilt, make sure that it has dried and that

the vapours have cleared away.

Check the fuel level and fill it up to the maximum level, if necessary (diag. C).

3.3. Earthing the generating set

To earth the generating set, use a 10 mm2 copper wire attached to the generating set earth connection and to an earthing rod of

galvanised steel set in the ground to a depth of 1 metre. This also dissipates the static electricity that builds up in the electrical

machines.

3.4. Positioning the generating set for operation

Place the generating set on a flat, horizontal surface which is firm enough to prevent the set sinking down (under no circumstances

should the set tilt any direction by more than 10°).

Choose a site that is clean, well-ventilated and sheltered from bad weather, and store the additional supplies of oil and fuel within

close proximity, although respecting a certain distance for safety.

5/10

4. Using the generator set

Danger

Never run the generating set without an air filter. Do not run the generating set if the enclosure is not in place.

Never take the enclosure off, if the generating set is running

4.1. Fuel cap (diagrams K1 and K2)

BEFORE STARTING THE ENGINE

Turn the fuel cap lever (No. 1, Diag K1) fully clockwise to the ON position (No. 2, Diag K1).

NOTE: Turn the fuel cap vent lever to the OFF position (No. 2, Diag K2) when transporting the generator.

AFTER STOPPING THE ENGINE

Turn the fuel cap vent lever (No. 1, Diag K2) fully counterclockwise to the "OFF" position (No.2, Diag K2).

Warning

Be sure the fuel cap vent lever (No. 1, Diag K1) and the engine switch (No. 1, Diag D) are on "OFF" positions

when stopping, transporting and/or storing the generator.

4.2. Starting procedure (diagrams A and D)

❶ Check that the earth wire is properly connected to the bolt (No. 3, diag. A)

❷ Move the starter switch (No. 1, diag. D) to contact position "I"

❸ Move the choke (No. 2, diag. D) to position

❹Hold the recoil starter handle (No. 3, diag. D) then pull it slowly until some resistance is felt, then slowly return the handle to the

recoil starter. Hold the starter handle again, then quickly pull it firmly (with both hands if necessary). By hand, the motor starts.

Slowly return the starter handle back against the starter.

❺ Once the motor has started, wait until the motor temperature starts to rise then gradually push the choke back to its original

position.

4.3. Operation

4.3.1 Alternating current operation (diagram E)

When the running speed of the generating set has stabilised (approximately 3 minutes):

❶ Check that the operating light (No. 1) is lit

❷ Connect the plug(s) to the generating set socket(s).

Note 1 : If the load is greater than 680 W and the control lever is in position

, the 680 W operating light (No. 2) lights up. In

this event, the load needs to be removed, then move the control lever to position

Note 2 : If the load is above 1000 W the overload warning light (No. 3) lights up, and after operating for 20 seconds, the production of

electric current stops. In this event, stop the motor, wait 30 seconds then restart the motor.

4.3.2 Direct current operation (diagram F)

The 12 V direct current is only used for charging car batteries.

Warning

The generating set should be stopped before connecting the electric cables.

Do not try to start a car engine, if the generating set is connected to the battery.

❶ Connect the cables to the battery terminals then to the generating set current socket observing the polarities (the generating set +

cable to the battery + cable and the generating set – cable to the battery – cable)

❷ Start the generating set to charge the battery.

Note 1: load capacities

9 control lever in position

: 4.2 A

9 control lever in position

: 8.3 A

Note 2 : combined operation

It is possible to produce both alternative current and direct current at the same time. However, in this scenario, performance will be

reduced and fuel consumption will increase.

The performances in this operation mode are:

9 Alternating current: 800 W

9 Direct current: 8.3 A.

6/10

4.4. Switching off (diagram A)

Warning

When the generating set is turned off, the motor continues to give off heat.

Suitable ventilation should be provided after the generating set is turned off.

To stop the generating set quickly, turn the On/Off switch to stop "О".

❶ Disconnect the sockets and allow the motor to run without any load for 1 to 2 minutes.

❷ Turn the On/Off switch (No. 5, Diag. A) to off "О", the generating set switches off

5. Safety features (if fitted, see specifications table)

5.1. Oil cut-out

This mechanism is designed to prevent any damage to the motor resulting from lack of oil in the motor sump. It automatically cuts out

the motor. If the motor stops and will not restart, check the motor oil level before looking for any other cause of the problem.

5.2. Circuit breaker

The electrical circuit of the set is protected by several magnetothermal, differential or thermal cut-out switches. Any overload and/or

short circuits cause the supply of electrical energy to be cut.

5.3. Overload

When there is electrical overload, the overload indicator turns on and electrical current production cuts out in less than 20 seconds.

6. Maintenance schedule

6.1. Reminder of use

The maintenance interval frequency and the operations to be carried out are outlined in the maintenance programme.

However, it should be added that it is the environment in which the generating set is operating which determines this programme.

Accordingly, if the set is used in extreme conditions, shorter intervals between maintenance procedures should be adopted.

These maintenance schedules apply only to generating sets running on fuel and oil, that conform to the specifications given in this

booklet.

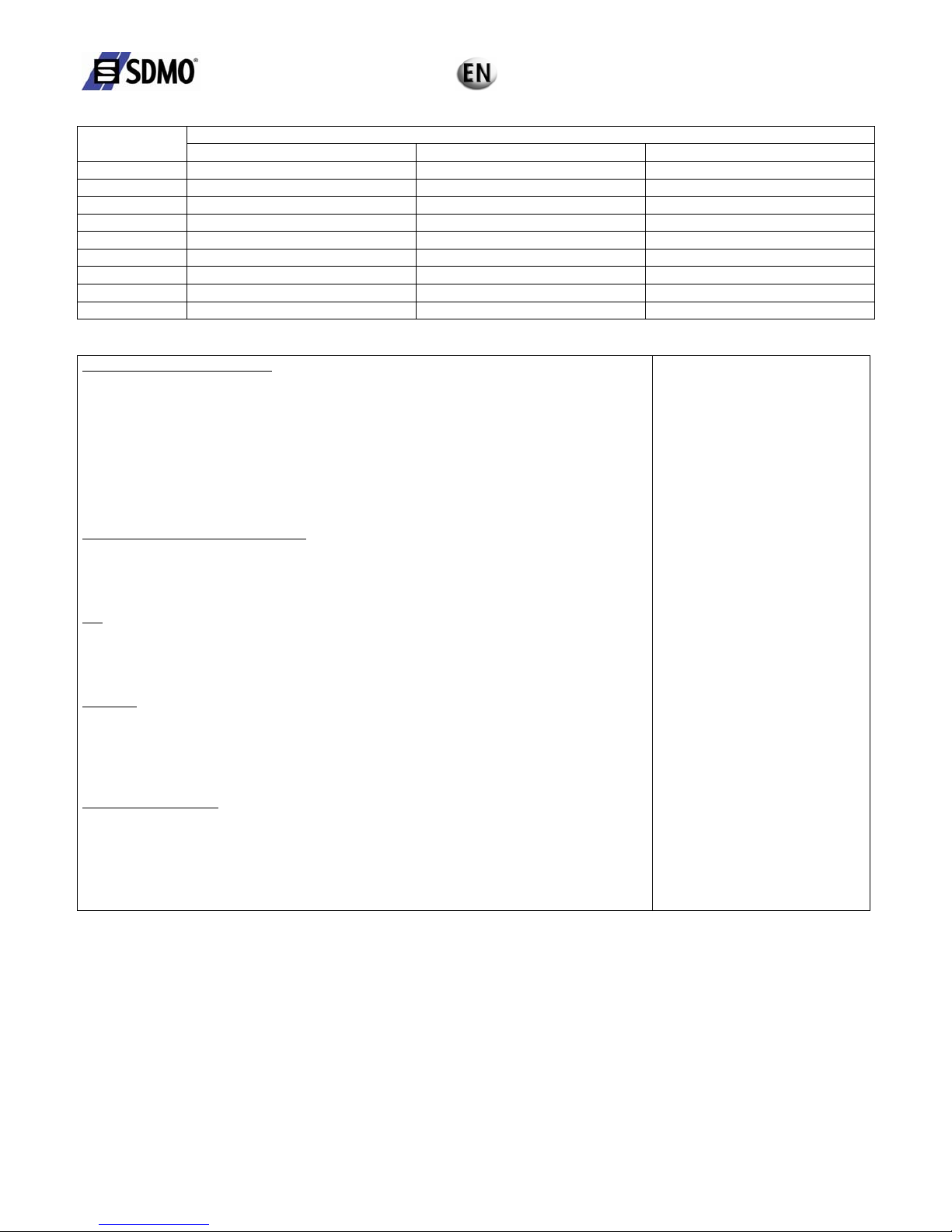

6.2. Maintenance table

carry out the maintenance

procedures

at whichever

deadline is reached

first

first

Each time

it is used

first month

or first ten

months

hours

Every 3

months or

25 hours

Every 6

months or

50 hours

1 year or

100 hours

2 years or

300 hours

Check the level

•

Motor oil

Change

•

•

Check

•

Air filter

Clean

• (1)

Check / clean

•

Spark

plug

Replace

•

Cleaning the generating set

•

Valves (2) Check / adjust Once per year

Fuel filter (2) Clean Once per year

(1) more frequently if the operating conditions are difficult

(2) these operations must be carried out by one of our agents

7/10

7. Maintenance procedures

Warning

Stop the motor before carrying out any maintenance procedure.

To make allowances for any accidental spillage, switch off the motor ignition and disconnect the spark plug cap(s).

Only use original parts or equivalent. The use of spare parts of a different quality can damage the generating set.

7.1. Cleaning the air filter (diagrams A and G)

Danger

Never use petrol or flammable solvents for cleaning the air filter element as this could result in a fire or

explosion.

❶ Open and remove the maintenance enclosure (No. 6, Diag A) using a screwdriver

❷ Remove the air filter cover (No. 1, Diag G), then remove the filter. Check to see if the filter is not torn or has holes, replace it if it

is damaged.

❸ Wash the foam element (No. 2, Diag G) with cleaning detergent diluted in warm water. Leave to dry fully.

❹ Reinsert the air filter element and refit the cover in the opposite order to removal.

❺ Close the enclosure.

7.2. Renewing the motor oil (diagrams A and H)

Change the oil when the engine is still warm, to ensure that drainage is rapid and complete.

❶ Open and remove the maintenance enclosures (No. 6, Diag A) and the drain port access cover (No. 17, Diag. A or No. 1,

Diag. H)

❷ Remove the oil filler cap (No. 2, Diag. H) and the drain plug (No. 3, Diag. H) and drain the oil into a suitable container.

❸ When this is done, screw the drain plug back in tightly and then fill, with recommended oil, to the upper limit on the dipstick. (see

paragraph 3.1).

❹ Check that there are no leaks

❺ Close the enclosures.

7.3. Checking the spark plug (diagrams A and I)

❶ Remove the spark plug enclosure (No. 18, Diag A) then the spark plug cap and use a spark plug spanner to remove the spark plug.

❷ Inspect each spark plug and discard any that have worn electrodes or melted or cracked insulation. If they are to be re-used, clean

the spark plugs with a metallic brush.

❸ Measure the space between the electrodes with a thickness gauge. The electrode gap should be 0.6 to 0.7 mm. Check that the

washer for each spark plug is in good condition and screw in the spark plugs by hand to avoid damaging the threads.

❹ After inserting the spark plug, tighten it with a spark plug spanner to compress the washer.

Note: when fitting a new spark plug, tighten it by 1/2 turn after it is in place, in order to compress the washers tightly. When fitting an

old spark plug, tighten it by a 1/8 –1/4 turn when in position, in order to compress the washer.

7.4. Checking bolts, nuts and screws

Daily, detailed checks of all nuts, bolts and screws are essential in order to prevent any accidents or breakdowns.

n Inspect the generating set as a whole before and after each use.

o Tighten any loose nuts or screws.

NB: the tightening of cylinder head bolts should be carried out by a specialist. Contact your local agent.

7.5. Cleaning the generating set

n Remove all dust and debris from around the exhaust and clean the generating set using a cloth and a brush (cleaning with a water

jet is not recommended, and cleaning with high-pressure cleaning equipment is forbidden).

o Carefully clean the motor air inlets and outlets and the alternator.

p Check the general condition of the generating set and, if necessary, replace any faulty parts.

8/10

8. Storing the generating set

Generating sets, which are to remain unused during a long period of time must undergo certain procedures, in order to keep them in

good condition. Check that the storage area is not dusty or humid. Clean the outside of the generating set and apply a rustproofing

product

8.1. Oil and fuel (diagram A)

❶ While the motor is still warm, drain the oil from the sump and top up with new oil of a suitable grade.

❷ Open and remove the maintenance enclosures (No. 6) and the spark plug access enclosures (No. 18)

❸ Remove the spark plug cap then remove the spark plug

❹ Pour approximately one clean spoonful of oil n the spark plug orifice

❺ Drain the fuel reservoir into a suitable container moving the starter switch (No. 5) to "I", then unscrewing the carburettor drain

plug

s Hold the starter recoil reel then pull the handle 3 to 4 times to drain completely and distribute the oil around the cylinder

❼ Move the starter switch (No. 5) to the "O" position and retighten the carburettor drain screw, refit it, and tighten the spark plug,

put the cap back on the spark plug then close the enclosures.

❽ Hold and pull the starter recoil reel until you feel resistance (inlet and exhaust vales close) then release the handle and store the

generating set in a clean and dry place.

9. Fault finding

Probable causes Remedial action

The generating set is being charged during start-up Stop charging

Fuel level too low Fill up with fuel

Control at ""О"

Move the control to "I"

Fuel supply blocked or leaking Have the system repaired

The motor will

not start

Clogged air filter Clean the air filter

Probable causes Remedial action

Blocked ventilation inlets Clean the air inlet and outlet guards

The motor cuts

out

Probable overload (overcharge indicator turned on) Check the load, wait 30 seconds and start again

Probable causes Remedial action

Circuit breaker disconnected (direct current) Reset the circuit breaker

Circuit breaker faulty (direct current) Have it checked, repaired or replaced

Faulty plug socket Have it checked, repaired or replaced

Faulty appliance supply lead Replace the leads

No electric

current

Faulty alternator Have it checked, repaired or replaced

Probable causes Remedial action

Circuit breaker

trips out

Faulty equipment or lead Have it checked, repaired or replaced

10. Specifications

Model BOOSTER 1000 UK

Motor type Honda GXH 50

50 Hz (Watt) output position

680

Maximum 50 Hz output (Watt) position

900

Alternating current (voltage and amperage) 230 V / 2.95 A 230 V / 3.9 A

Direct current (voltage and amperage)

Position

12 V / 4.2 A

maximum

Position

12 V / 8.3 A

maximum

Circuit breaker ● 12 V

Oil cut-out ●

E.E.C. sound level (Lwa) 89

Weight in kg (without fuel) 14

Dimensions l x w x h in cm 46.5 x 26.5 x 38

Recommended oil SAE 10W-30

Oil sump capacity in L 0.25

Recommended fuel Unleaded petrol

Fuel tank capacity in L 3.8

Spark plug « NGK »CR4HSB – « DENSO »U14FSR-UB

●: standard ○: option X: not possible

9/10

11. Cable sizes

Cable lengths Rated current

(A)

0 – 50 metres 51 – 100 metres 101 – 150 metres

6 1.5 mm

2

1.5 mm2 2.5 mm2

8 1.5 mm2 2.5 mm2 4.0 mm2

10 2.5 mm2 4.0 mm2 6.0 mm2

12 2.5 mm2 6.0 mm2 10.0 mm2

16 2.5 mm2 10.0 mm2 10.0 mm2

18 4.0 mm2 10.0 mm2 10.0 mm2

24 4.0 mm2 10.0 mm2 16.0 mm2

26 6.0 mm2 16.0 mm2 16.0 mm2

28 6.0 mm2 16.0 mm2 16.0 mm2

12. Conditions of warranty

Faults covered by the guarantee.

The supplier undertakes to rectify all operating problems resulting from defects in design,

materials and workmanship. This obligation does not apply to damage resulting from materials

supplied by, or adjustments made by the buyer. The guarantee excludes incidents resulting from

accident or force majeure, and also excludes replacements or repairs necessary as a result of

normal usage of the equipment, or from deteriorations or accidents arising from negligence, lack

of supervision or maintenance or from improper use of the equipment.

The guarantee is strictly limited to the free replacement or repair in our factory workshops of

parts showing defects in materials or manufacture. The supplier cannot be held responsible for

consequences arising directly or indirectly from the defectiveness of a part.

Length of guarantee and when it starts

.

Unless otherwise stipulated, this clause only applies to faults occuring within a period of:

- 24 months or 150 operating hours (whichever is reached first) for private use (applies

to the OPEN and SILENT ranges).

- 12 months or 1,000 operating hours (whichever is reached first) for professional use.

NB

Private use refers to occasional operation by the consumer for their own personal use for the

sole purpose of DIY.

The guarantee period runs from the day on which the buyer is advised in writing by the supplier

that the equipment is at his disposal.

If dispatch is delayed, the guarantee period will be extended by the length of the delay.

Damages

Responsibility is strictly limited to the obligations outlined herein, and it is expressly

understood that the supplier will not be accountable to the buyer for any wrong or damage

suffered such as personal injury, damage to goods (other than that mentioned in the guarantee)

or loss of income. The clauses of the guarantee are applicable only to the first-hand buyer, and

cannot be transferred to a second buyer.

Insurance of workforce

In the case of accidents arising at any time and for any reason whatsoever, the responsibility of

the supplier is strictly limited to his own staff and their equipment.

NB All written or verbally communicated orders, as well as acceptance of our offers, imply the

formal acceptance of our conditions of sale.

In the case of a claim under guarantee, carriage costs outward will be borne by the buyer.

GENERATING SET

The generating set detailed below

Generating set serial no:

Motor serial no:

is guaranteed from that date.

AGENT:

Stamp and signature

10/10

13. EC Declaration of conformity

Name and address of manufacturer

SDMO, 12 bis rue de la Villeneuve, CS 92848, 29228 BREST CEDEX 2

Description of the equipment

Product Generating set

Make SDMO

Type BOOSTER 1000 UK

G. Le Gall, the manufacturer's authorised representative, confirms that the product conforms to the following EC Directives:

98/37/EC / Machinery Directive.

73/23/EC / Low Voltage Directive.

89/336/EC / Electro Magnetic Compatibility (EMC) Directive.

2000/14/EC / Noise Emission of Outdoor Equipment Directive

References to harmonized standards used

o EN12601/EN1679-1/EN 60204-1

o IEC 34.1/EN 60034-1

o EN 50081-2 / EN 50082-2

09/2004

G. Le Gall

Loading...

Loading...