MINI-SA PORTABLE

GAS DETECTION

INSTRUMENT

1

INTRINSICALLY SAFE GAS

LEVEL DETECTOR

R

USC

39NO

CERTIFIED BY UNDERWRITERS LABORATORIES INC.

ONLY AS TO INTRINSIC SAFETY

FOR USE IN HAZARDOUS LOCATIONS

CLASS I, DIV, 1, GROUPS A, B, C, & D.

CERTIFIED TO CANADIAN CSA STANDARD C22.2 NO. 157-92

WARNING:

SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRINSIC SAFETY.

USE ONLY WITH APPROVED BATTERIES.

TEMPERATURE CODE T3C.

CAUTION:

FOR SAFETY REASONS, THIS EQUIPMENT MUST BE

OPERATED AND SERVICED BY QUALIFIED PERSONNEL ONLY.

READ AND UNDERSTAND MANUAL BEFORE OPERATING AND SERVICING

CHANGE BATTERIES IN NON-HAZARDOUS AREA

SCOTT INSTRUMENTS

EXTON, PA 19341

2

SCOTT INSTRUMENTS

MINI-SA PORTABLE GAS

DETECTION INSTRUMENT

Contents

1.0 INTRODUCTION ................................................................. 4

2.0 OPERATIONAL ENVIRONMENT ........................................ 4

3.0 GENERAL INSTRUCTIONS ............................................... 5

3.1 UNPACKING .......................................................... 5

3.2 REGISTRATION ..................................................... 5

3.3 BATTERY INSTALLATION ..................................... 5

4.0 INSTRUMENT DESCRIPTION ............................................ 6

4.1 ALARM LEGENDS ................................................. 7

4.2 AUDIBLE ALARMS ................................................ 8

4.3 VIBRATION ALARM ............................................... 9

4.4 ALARM LED LIGHTS ............................................. 9

4.5 STATUS LIGHT ...................................................... 9

5.0 SWITCH FUNCTIONS AND DISPLAYS ........................... 10

6.0 OPERATING INSTRUCTIONS ........................................... 11

6.1 INSTRUMENT TURN ON / OFF............................ 12

6.2 MENU SELECTION .............................................. 14

6.3 ZERO CALIBRATION MENU ................................ 17

6.4 SPAN CALIBRATION MENU ................................ 18

6.5 SENSOR REPLACEMENT MESSAGE ................. 22

6.6 PEAK / HOLD MENU............................................ 23

6.6.1 PEAK ............................................................. 23

6.6.2 HOLD ............................................................. 25

6.7 ALARM SETPOINT MENU ................................... 26

6.8 TWA / STEL MENU .............................................. 29

6.9 CONFIGURATION MENU ..................................... 32

6.9.1 BATTERY SAVER MODE ............................... 32

6.9.2 PASSWORD PROTECTION .......................... 33

7.0 ERROR MESSAGES ........................................................ 37

8.0 CALIBRATION GASES .................................................... 38

9.0 SPECIFICATIONS ............................................................ 39

3

SCOTT INSTRUMENTS MINI-SA PORTABLE GAS DETECTOR

1.0 INTRODUCTION

The SCOTT INSTRUMENTS MINI-SA Portable Gas Detector is a self contained

instrument designed to detect and provide audible, visual, and tactile indication

of the presence of oxygen or toxic gas in the air. The toxic gas concentration is

monitored and shown in the graphic display in parts per million (ppm) of the

atmosphere. The oxygen concentration is shown in the graphic display as a

percent (%). When the gas level exceeds the preset level, alarms actuate

including a pulsing audible alarm tone, flashing LED, and a vibration alarm.

The alarm functions for toxic gases include a Time Weighted Average (TWA)

Alarm and a Short Term Exposure Level (STEL) Alarm.

Other features include AUTO CALIBRATION and self diagnostic capabilities, a HOLD function that displays the lowest level detected, and user

adjustable high and low ALARM SETPOINTS. A battery life indicator constantly monitors remaining battery capacity and a backlight provides visibility in low light situations.

Additional features include a PASSWORD PROTECT menu and a BATTERY SAVER mode.

2.0 OPERATIONAL ENVIRONMENT

The SCOTT INSTRUMENTS MINI-SA Portable Gas Detector is designed to

be “INTRINSICALLY SAFE” suitable for operation in Class I, Division 1, Groups

A, B, C & D Hazardous Locations.

4

3.0 GENERAL INSTRUCTIONS

3.1 UNPACKING

Remove the SCOTT INSTRUMENTS MINI-SA instrument from its packaging

and examine it for external damage. If any damage is found, notify your

SCOTT INSTRUMENTS distributor, sales representative, or the SCOTT INSTRUMENTS Service Department.

3.2 REGISTRATION

Fill out and mail the postage paid Registration Card provided. Registering

your SCOTT INSTRUMENTS MINI-SA instrument assures that you will receive notification of any future enhancements and/or upgrades that become

available. You may also register your instrument on SCOTT INSTRUMENTS

web site “www.scottinstruments.com”.

3.3 BATTERY INSTALLATION

The SCOTT INSTRUMENTS MINI-SA instrument is powered by two “AAA”

Alkaline batteries. Use only alkaline (Eveready Energizer Industrial EN 92,

Duracell PC2400, or Ray-O-Vac AL-AAA) batteries. Use of any other batteries except those listed will void the intrinsic safety listing of the SCOTT

INSTRUMENTS MINI-SA Portable Gas Detector. Use of rechargeable batteries is prohibited. Two of the specified “AAA” Alkaline batteries will provide

approximately one hundred (100) hours of continuous non-alarming operation before requiring replacement.

Install the batteries as follows:

1) Remove the battery cover by loosening the #1-phillips-head captive cover

screw counterclockwise, then lifting the cover out of the housing. Then

lift the two batteries from the housing, using a small coin or tool.

2) Install two (2) AAA Alkaline batteries of the specified type. Note polarity

orientation (+/-) as shown inside the battery box and push the batteries

securely in between the contacts.

3) Replace the battery cover by pushing it into the bottom detents and

secure by tightening the cover screw.

NOTE

The metal belt clip is designed to be removed from the instrument. After

removing the battery cover, remove the cover screw completely and slide

the clip out of the cover. Store the clip for future use. Replace the cover

screw and reattach battery cover to the instrument.

5

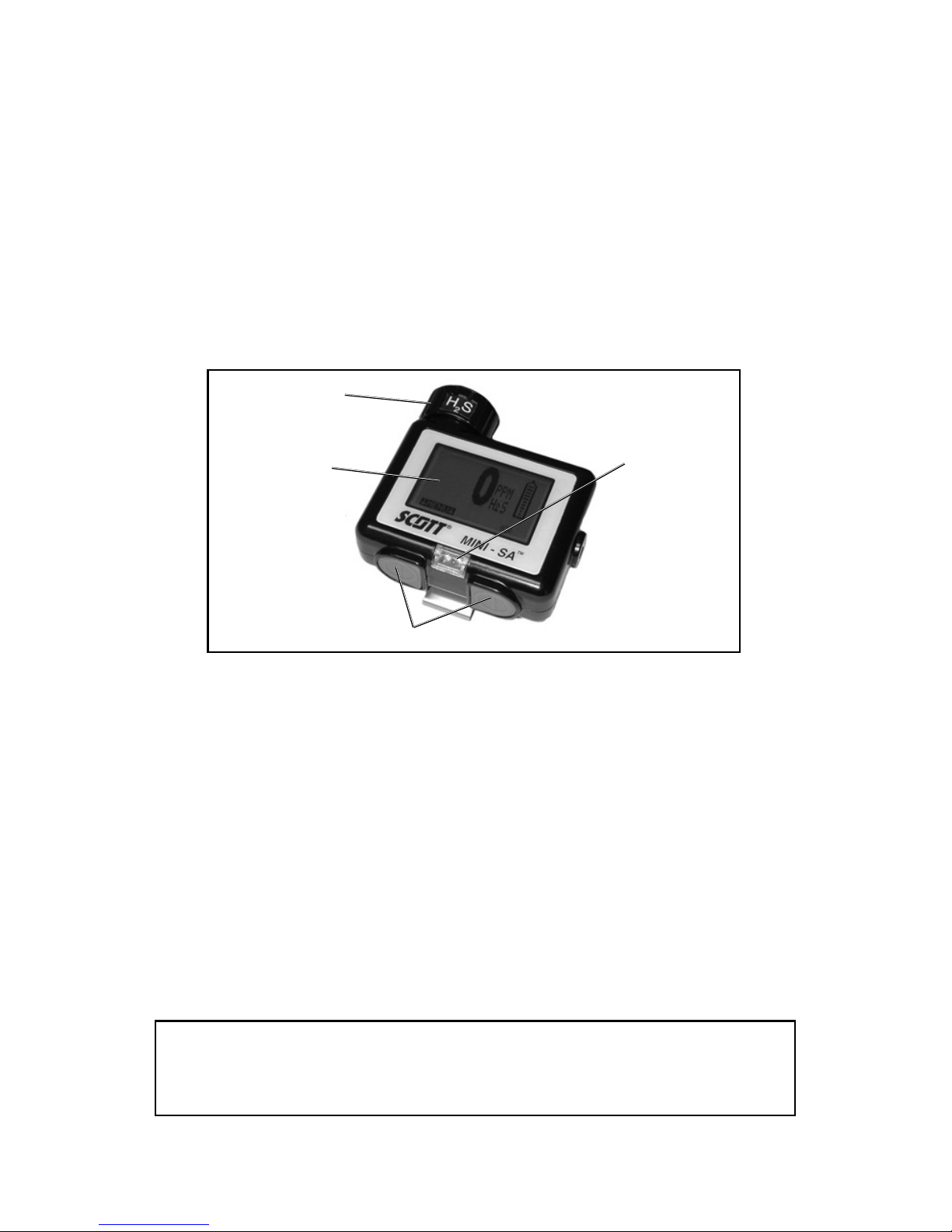

4.0 INSTRUMENT DESCRIPTION

THE SCOTT INSTRUMENTS MINI-SA INSTRUMENT is designed for use as

a personal monitor. The MINI-SA is equipped with a snap mounting clip for

ease of use. A break-away neck strap and rubber boot are also available.

All operations of the instrument are controlled by two push-button actuators

which are large enough to accommodate use with gloved hands. In each

menu screen, “PROMPTS” over each push-button define their use.

The SCOTT INSTRUMENTS MINI-SA INSTRUMENT case is constructed of

high impact resistant, flame retardant plastic. The push-button actuators

and the graphic display overlay are UV and chemical resistant.

The Graphic Liquid Crystal Display (LCD) provides continuous readings of

gas concentration as well as battery life remaining and other information.

Alarm conditions are signaled by an alarm legend on the graphic display, an

audible tone, a flashing light, and an internal vibration. Audible tones for

certain alarms can be suspended for thirty (30) second intervals while others will continue until the unit is reset in an atmosphere that corresponds to

the preset safe values. Alarms can also be configured to be latching or

nonlatching. Latching alarms operate until acknowledged. Nonlatching

alarms clear automatically when the detected gas is on the safe side of the

alarm setting.

SENSOR

GRAPHIC

PUSHBUTTONS

(w/ H2S Sensor shown for reference)

BATTERY

MENU

LED

(GREEN OR RED

DEPENDING

FIGURE 1

MINI-SA INSTRUMENT

6

4.1 ALARM LEGENDS

The following alarm legends appear in the graphic display:

“ALARM” flashing legend indicates one of the following:

a) Gas concentration which exceeds the preset level

b) A Time Weighted Average (TWA) Alarm

c) A Short Term Exposure Level (STEL) Alarm.

For toxic gas, the ppm, TWA, or STEL level detected and the “ALARM”

legend will flash alternately.

A graphic battery level indicator appears continuously on the display screen.

The indicator shows battery capacity as ten (10) lines inside a picture of a

battery. Each line represents approximately 10% of battery time remaining.

The battery level indicator flashes when the batteries are low. This will occur

when approximately 10% of battery life remains.

EACH LINE REPRESENTS

APPROXIMATELY 10%

OF BATTERY TIME REMAINING

FIGURE 2

BATTERY LEVEL INDICATOR

An exhausted battery alarm will occur after the last bar disappears. See

Figure 2.

“HOLD ACTIVATED” flashing legend indicates that the HOLD feature has

been selected. The instrument will display the highest reading of a toxic gas

or the lowest oxygen reading. This reading will continue to be displayed until

the HOLD function is reset.

7

4.2 AUDIBLE ALARMS

The SCOTT INSTRUMENTS MINI-SA has an audible alarm which is activated when any of the following conditions occurs:

- The preset gas alarm level is exceeded (ALARM)

- The Time Weighted Average (TWA) is exceeded

- The Short Term Exposure Limit (STEL) is exceeded

- The battery is exhausted

- The sensor is missing or incompatible

In addition, each time the instrument is turned ON, the audible alarm will

pulse three times.

The following describes the function of the Audible Alarm during the alarm

conditions listed above:

GAS ALARM – The Audible Alarm sounds when a gas concentration is detected that exceeds the chosen alarm level, or when a TWA or STEL alarm

value is exceeded. A repetitive pulsing tone will occur at one (1) second

intervals while the alarm condition exists.

In the LATCHING alarm mode, selected in the Alarm Setpoint Menu, after an

alarm condition has cleared, the alarm indication will continue until the alarm

is acknowledged by depressing a pushbutton. In the NON-LATCHING alarm

mode, all alarm indications clear when the alarm condition clears. In either

mode, the instrument gives an “all clear” signal with three audible beeps,

three flashes of the Red Alarm Light, and three vibration pulses when the

alarm indication is cleared.

When an Audible Alarm sounds, depressing either pushbutton on the instrument will silence the Audible Alarm for thirty (30) seconds. If the original

alarm condition still exists after the thirty (30) second silence period, the

Audible Alarm will sound again. The Audible Alarm can be silenced repeatedly by depressing a pushbutton.

LOW BATTERY – An Audible Alarm tone will pulse once every fifteen (15)

seconds to indicate when less than 10% of battery life remains.

MISSING SENSOR – The Audible Alarm for a missing or incompatible sensor is identical to the pulsing one (1) second tone that occurs during an

ALARM condition. Depressing a pushbutton to acknowledge the condition

turns the unit OFF.

8

4.3 VIBRATION ALARM

An internal vibrating motor activates whenever the Audible Alarm sounds. The

Vibration Alarm operates as a secondary alarm feature in high noise environments where the audible alarm may be difficult to hear.

The Vibration Alarm is reset the same as the Audible Alarm as described in

Section 4.2.

The Vibration Alarm will also pulse briefly whenever the MINI-SA instrument

is turned ON or OFF.

WARNING

THE VIBRATION ALARM DOES NOT FUNCTION FOR THE LOW BATTERY INDICATION.

4.4 ALARM LIGHT

The SCOTT INSTRUMENTS MINI-SA instrument contains a Red Light Alarm

LED (Light Emitting Diode) which flashes whenever any Alarm Condition occurs. It will continue to flash when the Audible Alarm is silenced and will flash

as long as the alarm condition is present. In the LATCHING alarm mode,

selected in the Alarm Setpoint Menu, after an alarm condition has cleared,

the alarm indication will continue until the alarm is acknowledged by depressing a pushbutton. In the NON-LATCHING alarm mode, all alarm indications clear when the alarm condition clears. In either mode, the instrument

gives an “all clear” signal with three audible beeps, three flashes of the Red

Alarm Light, and three vibration pulses when the alarm indication is cleared.

4.5 STATUS LIGHT

The instrument also has a Green Status LED that flashes periodically, indicating continuing instrument operation.

9

5.0 SWITCH FUNCTIONS AND DISPLAYS

All operations on the MINI-SA Portable Detector are controlled by two pushbuttons located on the bottom of the unit. The operations vary depending on

the operating mode and the graphic display appearing above the two switches.

The unit sounds a brief audible “beep” whenever either pushbutton is depressed while the instrument is on. Whenever the instrument is turned ON or

OFF, three successive audible tones will sound and the Red Alarm LED will

flash. The Green Status LED will flash once every fifteen (15) seconds during

instrument operation. When in the BATTERY SAVER mode, the Green Status LED flash rate increases to once every five (5) seconds.

SENSOR

LED

(GREEN OR RED

DEPENDING

GRAPHIC

PUSHBUTTONS (2)

FIGURE 3

COMPONENT LOCATIONS

When the unit is in the operating mode, depressing the Display Backlight

Pushbutton will illuminate the graphic display for fifteen (15) seconds. A light

bulb icon for the Backlight is located above the pushbutton on the operating mode screen. Depressing the button again extinguishes the Backlight.

The Backlight is sustained ON or OFF while the MENU operations are in

progress, except for calibration. In an alarm condition, the Backlight flashes

for the duration of the alarm indication.

When in the BATTERY SAVER mode, the instrument graphic display will be

blank. Depressing either pushbutton will turn on the graphic display. The

display remains on for thirty (30) seconds after the last pushbutton operation.

USE OF THE DISPLAY BACKLIGHT FOR EXTENDED PERIODS OF TIME

WILL REDUCE BATTERY SERVICE LIFE.

WARNING

10

6.0 OPERATING INSTRUCTIONS

Before using this instrument, read and understand ALL instructions for ALL

operating modes described in this Section. Prior to use, the instrument should

be checked for proper calibration as described in this Section.

WARNING

BEFORE EACH DAY’S USAGE, THE SENSITIVITY OF THE GAS SENSOR

MUST BE TESTED ON A KNOWN CONCENTRATION OF CALIBRATION

GAS.

WARNING

ACTUAL CALIBRATION SHOULD ONLY BE PERFORMED BY QUALIFIED INSTRUMENT MAINTENANCE PERSONNEL.

WARNING

ANY INDICATION OR READING DENOTING A TOXIC GAS OR A LACK

OF OXYGEN SIGNIFIES THE NECESSITY TO FOLLOW ESTABLISHED COMPANY PROCEDURES FOR THE INDICATED CONCENTRATIONS OF THE PARTICULAR GAS.

WARNING

USE IN OXYGEN ENRICHED ATMOSPHERES (ABOVE 25% O2) MAY BE

HAZARDOUS.

WARNING

CONFIRM THE INSTRUMENT’S BASIC CALIBRATION IS APPROPRIATE FOR THE INTENDED USE.

11

6.1 INSTRUMENT TURN ON / OFF

To turn the instrument ON, depress either pushbutton. Three successive “beeps”

will sound. The Red LED will flash and the vibration alarm will pulse for each

“beep.” The graphic display will show one of the following screens while the

instrument initializes. The sensor installed in the unit defines which display is

shown:

SCOTT INSTRUMENTS

For Toxic Gases MINI-SA VERSION X.X

<gas> SENSOR

INITIALIZING

All toxic gas screens appear similar, therefore wherever the symbol <gas>

appears on any of the graphic display screens in this manual, it will be substituted with the applicable toxic sensor (either CO, Cl

NO2, NH

3, PH3

or SO2) installed in the instrument at the time. For some toxic

, ClO

2

HCN, H2S, NH3,

2,

gases, the screen display will show 0.0 or 0.00 resolution.

The following toxic gas sensors are available in the MINI-SA:

CO = Carbon Monoxide

Cl2 = Chlorine

ClO

= Chlorine Dioxide

2

HCN = Hydrogen Cyanide

H2S = Hydrogen Sulfide

NH3 = Ammonia

NO2 = Nitrogen Dioxide

PH3 = Phosphine

SO2 = Sulphur Dioxide

Refer to Section 9.0 for sensor specifications.

SCOTT INSTRUMENTS

For O2 MINI-SA VERSION X.X

O2 SENSOR

INITIALIZING

After a few seconds, the instrument will sound a single “beep” and go to the Operating Mode where the graphic display will show one of the following screens:

Note: If a new sensor is installed or if batteries have been removed for more

than a few minutes, the initialization sequence may take longer. If the

12

sensor type has been changed or if the previous calibration was not successful, the bottom line of the display will show “CALIBRATION REQUIRED”.

ppm

<gas>

For Toxic Gases 0

For O

MENU

2

20.9% O

MENU

2

In the normal Operating Mode, the following information is displayed:

- Gas concentration in either ppm (toxic Gas) or % (oxygen)

- Battery life indication

- Backlight prompt

- Menu prompt

To turn OFF the instrument, depress and hold both push-buttons. The unit

will sound three successive “beeps” accompanied by flashes of the Red

LED. The instrument will then display the following screen:

DO YOU WANT TO TURN

THE UNIT OFF?

YES NO

13

6.2 MENU SELECTION

From the Operating Mode screen, there are six menus that can be selected

by the user. They are “ZERO CALIBRATION,” “SPAN CALIBRATION,” “PEAK/

HOLD,” “ALARM SETPOINT,” “TWA/STEL,” and “CONFIGURATION.” Depress the pushbutton below the MENU prompt on the display and then one

of the following screens will appear:

ZERO CALIBRATION

For Toxic Gases

NEXT AUTO ZERO

AUTO CALIBRATION

For O

2

NEXT CALIBRATE

The AUTO ZERO or CALIBRATE command and “NEXT” command appear

above the pushbutton that activates that function.

To AUTO ZERO or CALIBRATE the sensor, depress the right pushbutton.

See Section 6.3 for details on calibration.

To go to the next menu, depress the left pushbutton below the “NEXT” command and the following screen will be displayed:

SPAN CALIBRATION

For toxic gases

NEXT SELECT

To Span a toxic gas sensor, depress the “SELECT” pushbutton. See Section 6.4 for details on span calibration.

NOTE: There is no span calibration screen when using the Mini-Sa

portable to detect oxygen. The screen will go directly to the next

menu.

To go to the next menu, depress the left pushbutton below the “NEXT” command and the following screen will be displayed:

14

PEAK / HOLD

NEXT SELECT

To go to the PEAK/HOLD menu, depress the “SELECT” pushbutton.

To go to the next menu, depress the left pushbutton below the “NEXT” command and one of the following screens will be displayed:

<gas> ALARM SETPOINT

For Toxic Gases

NEXT SELECT

O2 ALARM SETPOINT

For O

2

NEXT SELECT

To go to the ALARM SETPOINT menu, depress the “SELECT” pushbutton.

To go to the next menu, depress the left pushbutton below the “NEXT” command and one of the following screens will be displayed:

<gas> TWA/STEL

For Toxic Gases

NEXT SELECT

NOTE: There is no TWA/STEL menu displayed when an instrument is

used for oxygen detection.

To go to the TWA/STEL menu, depress the “SELECT” pushbutton. See

Section 6.8 for details.

To go to the next menu, depress the left pushbutton below the “NEXT” command and the following screen will be displayed:

15

CONFIGURATION

NEXT SELECT

To go to the CONFIGURATION menu, press the “SELECT” pushbutton.

To go to the next menu, depress the left pushbutton below the “NEXT” command and the ZERO CALIBRATION for toxic gas or AUTO CALIBRATION for

oxygen screen will again be displayed.

The MINI-SA will scroll repeatedly through these Menus each time the “NEXT”

pushbutton is depressed. Each time either pushbutton is depressed, the unit

will sound a single “beep”.

If no menu action is taken for fifteen (15) seconds while one of the menus is

displayed, the instrument will automatically return to the operating mode,

signified by a single “beep”.

16

6.3 ZERO CALIBRATION MENU

The MINI-SA instrument can be Auto Zeroed at any time. An Auto Zero should

only be performed in an area known to be free of toxic gas or any known

cross sensitive materials. See Section 8.0 for SCOTT INSTRUMENTS supplied calibration gas cylinders. When performing an auto-zero with an oxygen unit, be sure the area contains 20.9% oxygen.

To perform Zero Calibration of the sensor as described in Section 6.2, depress the “AUTO ZERO” pushbutton when the ZERO CALIBRATION menu

screen is displayed.

The instrument will display one of the following screens while it calibrates the

appropriate sensor.

<gas> SENSOR

For Toxic Gases ZERO CALIBRATION

2

O2 SENSOR

For O2 ZERO CALIBRATION

2

The instrument display will count down 2 seconds while the sensor is zeroed. After a successful “ZERO CALIBRATION”, the instrument will sound a

“beep” and automatically go back into the Operating Mode.

If, during the “ZERO CALIBRATION”, the unit detects that the sensor is out of

range, an error message will be displayed. See Section 7.0 for a description

of error messages.

17

6.4 SPAN CALIBRATION MENU FOR TOXIC GAS ONLY

Note: The MINI-SA software requires that an “AUTO ZERO” be performed as

described in Section 6.3 before the instrument will allow a “SPAN CALIBRATION”. Failure to do so will display the following screen when attempting a

“SPAN CALIBRATION” of the instrument:

AUTO ZERO REQUIRED

BEFORE

SPAN CALIBRATION

ACKNOWLEDGE

Depress both pushbuttons simultaneously to acknowledge this message

and “AUTO ZERO” the instrument per Section 6.3 to procede.

The MINI-SA instrument can be calibrated with span gas supplied by SCOTT

INSTRUMENTS or with a calibration gas supply certified to a concentration

within the following ranges:

CO = 25 to 120 ppm

Cl2 = 5 ppm only Cl

ClO2 = 5 ppm only Cl

2

2

HCN = 2.0 to 25.0

H2S = 10 to 110 ppm

NH3 = 10 to 40 ppm

NO2 = 2.0 to 15.0 ppm

PH3 = 0.5 to 4.5 ppm

SO2 = 2.0 to 18.0 ppm

See Section 8.0 for SCOTT INSTRUMENTS supplied calibration gas

cylinders.

To perform “SPAN CALIBRATION” of the sensor, depress the “SELECT”

pushbutton when the “SPAN CALIBRATION” screen is displayed as described in Section 6.2. The instrument will display the one of the following

screens:

For Toxic Gases SPAN CALIBRATION

<gas> SENSOR

USING <_> ppm <CALGAS>

CHANGE OK

18

Calibration cylinders supplied by SCOTT INSTRUMENTS contain 25 PPM

H2S or 50 PPM CO. To use another certified concentration, depress the left

pushbutton below the “CHANGE” command. The one of the following screens

will be displayed:

<gas> SENSOR

For Toxic Gases SPAN CALIBRATION

GAS = <_> ppm <CALGAS>

UP DOWN

Factory preset span calibration gas values:

CO = 50 ppm

Cl2 = 5.0 ppm

ClO2 = 5.0 ppm Cl

2

HCN = 10.0 ppm

H2S = 25 ppm

NH3 = 25 ppm

NO2 = 5.0 ppm

PH3 = 1.0 ppm

SO2 = 10 ppm

If you select the “UP” pushbutton, for example, one of the following screens

will display with the number value flashing:

<gas> SENSOR

For Toxic Gases SPAN CALIBRATION

GAS = <_> ppm <CALGAS>

UP SET

When the desired value has been reached depress the “SET” pushbutton

and the “CHANGE/OK” screen will appear again. Select the “OK” pushbutton

and one of the following screens will display:

For Toxic Gases SPAN CALIBRATION

<gas> SENSOR

INJECT <_> ppm <CALGAS>

EXIT

19

This screen will remain on until the instrument detects calibration gas. If no

calibration gas is detected after thirty (30) seconds, the instrument will sound

a single beep and return to the operating mode.

Depressing the “EXIT” pushbutton will also return the instrument to normal

operation with no calibration having occurred. The last successful calibration

will remain valid.

To continue “SPAN CALIBRATION”, attach the 40014936 Calibration Adapter over

the sensor cap as shown in Figure 4.

TO GAS

CYLINDER

FIGURE 4

CALIBRATION ADAPTER

20

Attach the hose of the Adapter to the calibration gas cylinder and begin flowing gas

to the cap at a flow rate of 500 cc/min. (300 cc/min. for Cl2 and ClO2). When the

instrument detects the gas, the display will change to one of the following screens:

<gas> SENSOR

For Toxic Gases SPAN CALIBRATION

<time> seconds

The display will count down <seconds> (See chart below for applicable sensor) after which the instrument will display the message “SPAN CALIBRATION PASSED ACKNOWLEDGE”. Press either button to return to the Operating Mode showing the gas concentration. If the user does not acknowledge within 2 minutes, the instrument returns to Operating Mode automatically. In either case, the calibration is accepted as valid. If the calibration

gas concentration exceeds the alarm setpoint, the alarm will operate. Turn

off the gas supply and remove the Calibration Adapter.

If, during “SPAN CALIBRATION”, the unit detects that the sensor is out of

range, an error message will be displayed. See Section 7.0 for a description

of error messages.

Max. Span

Cal Time

in Seconds

300

180

180

60

90

180

60

Ammonia (NH )

Chlorine(Cl )

Chlorine Dioxide (ClO )

Carbon Monoxide (CO 500)

Carbon Monoxide (CO 1000)

Hydrogen Cyanide (HCN)

Hydrogen Sulfide (H S 100)

Applicable

Toxic Sensor

3

2

Hydrogen Sulfide (H S 500)60

90 Nitrogen Dioxide (NO )

90

120

Phosphine (PH )

3

Sulfur Dioxide (SO )

2

2

2

2

2

21

Note: SCOTT INSTRUMENTS supplies Teflon®-lined tubing with all

chlorine and ammonia calibration kits. Sticky gases such as chlorine

and ammonia require this tubing be used for calibration. Using tubing of another type may inhibit the automatic calibration of a MINI-SA

and lead to improper readings or a false failed sensor message. All

other calibration kits are supplied with Tygon (R-3603) Tubing.

SCOTT INSTRUMENTS also recommends that the tubing and cylinder

regulator used with a specific toxic gas not be used with other gases.

6.5 SENSOR REPLACEMENT MESSAGE

If a successful “AUTO CALIBRATION” reveals that the gas sensor is near the

end of its service life, the MINI-SA will display one of the following REPLACEMENT MESSAGE:

WARNING <gas> SENSOR

For Toxic Gases APPROACHING FAILURE

REPLACE SOON!

ACKNOWLEDGE

WARNING OXYGEN SENSOR

For O2 APPROACHING FAILURE

REPLACE SOON!

ACKNOWLEDGE

The user must “ACKNOWLEDGE” this message by depressing either

pushbutton.

WARNING

THIS SCREEN IS FOR INFORMATION ONLY AND IS NOT INTENDED TO

BE AN EXACT DETERMINATION OF WHEN A SENSOR WILL FAIL AND

REQUIRE REPLACEMENT. THE TIME REMAINING UNTIL A SENSOR

FAILS AFTER A REPLACEMENT MESSAGE IS DISPLAYED IS BASED

ON MANY FACTORS SUCH AS FREQUENCY OF CALIBRATION, LAST

CALIBRATION, FREQUENCY OF USE AND LEVEL OF GAS TO WHICH

SENSOR IS EXPOSED. A SENSOR MAY FAIL PRIOR TO DISPLAY OF

THE REPLACEMENT MESSAGE.

22

6.6 PEAK / HOLD MENU

The MINI-SA can be set to display either the lowest and highest gas reading

(PEAK) or just the highest toxic gas or lowest oxygen reading (HOLD) during

use. To enter the PEAK/HOLD menu, depress the “SELECT” pushbutton

when the PEAK/HOLD menu is displayed as described in Section 6.2. The

following screen will appear:

SELECT MODE

PEAK HOLD

If neither pushbutton is depressed for fifteen (15) seconds after the above display appears, the unit will automatically return to the Operating Mode accompanied by a single “beep”.

6.6.1 PEAK

The PEAK feature allows the user to display both the lowest and highest

readings that were detected since the instrument was last turned on, or

since the readings were last reset.

In the SELECT MODE menu, depress the “PEAK” pushbutton. Then one of

the following screens will appear for fifteen (15) seconds displaying the highest reading since instrument turn on:

PEAK <gas> LEVEL

For Toxic Gases MAX = <_> ppm

RESET SHOW

PEAK PEAK

PEAK O2 LEVEL

For O

2

MAX = 20.9%

MIN = 20.2%

RESET SHOW

PEAK PEAK

If neither the “RESET PEAK” or “SHOW PEAK” pushbutton is depressed,

the unit will return to the Operating Mode accompanied by a single “beep”.

If the “SHOW PEAK” pushbutton is depressed, the instrument will return to the

Operating Mode and display the peak values as follows on the appropriate screen:

23

ppm

4

<gas>

For Toxic Gases

MAX = <_> ppm

MENU

%

20

O

2

For O2 MAX = 21.5 %

MIN = 20.9 %

MENU

Current and peak readings update continuously while this screen is displayed.

If the PEAK menu is accessed from a peak reading display, the option “SHOW

PEAK” will read “HIDE PEAK” instead, as follows:

PEAK <gas> LEVEL

For Toxic Gases MAX =<_> ppm

RESET HIDE

PEAK PEAK

PEAK O

For O

2

MAX =20.9 %

LEVEL

2

MIN = 20.2%

RESET HIDE

PEAK PEAK

Selecting “HIDE PEAK” will return the display to the standard Operating Mode

screen with only the current reading displayed. The “SHOW PEAK” function is

latching and will not change by turning the instrument OFF.

To reset the peak value, depress the “RESET PEAK” pushbutton in the

PEAK menu. This will reset the MAX value to the current ambient reading.

Turning the instrument OFF will also RESET the PEAK value the next time

the unit is turned ON. The PEAK value will continue to be displayed until

“HIDE PEAK” is selected in the PEAK menu.

24

NOTE: After an Alarm Condition occurs and the Audible Alarm is silenced as instructed in Section 4.0, the instrument will automatically

change to the “SHOW PEAK” display to inform the user of the actual

level responsible for the alarm condition. To return to the standard

operating screen, depress the pushbutton under “HIDE PEAK,” which

appears in place of “MENU.”

6.6.2 HOLD

The HOLD feature displays the highest toxic gas or the lowest oxygen concentration detected while the MINI-SA instrument is in the “HOLD MODE”.

To activate the “HOLD MODE”, return to the “PEAK/HOLD” menu and select

the “HOLD” pushbutton. The following screen will be displayed:

HOLD MODE

ACTIVATE EXIT

Depress the “ACTIVATE” pushbutton to turn on the HOLD feature. The “EXIT”

pushbutton will return to the Operating Mode without activating the HOLD

feature.

In the “HOLD MODE”, the instrument will continually update and display the

highest toxic gas or lowest oxygen reading. One of the following screens will

appear with the words “HOLD ACTIVATED” flashing:

ppm

0

<gas>

For Toxic Gases HOLD ACTIVATED

RESET

%

O

2

For O

20.9

HOLD ACTIVATED

2

RESET

Depress the “RESET” pushbutton to turn off the HOLD feature and return the

unit to the standard Operating Mode.

Note: The HOLD and PEAK function automatically reset when the

calibration menu is entered.

25

6.7 ALARM SETPOINT MENU

The “ALARM SETPOINT” can be adjusted by the user in the ALARM

SETPOINT menu within the following ranges:

CO = 5 to 250 ppm

Cl2 = 0.1 to 10.0 ppm

ClO2 = 0.10 to 2.00 ppm

HCN = 0.1 to 50.0 ppm

H2S = 5 to 100 ppm

NH3 = 5 to 100 ppm

NO2 = 0.2 to 5.0 ppm

O2 LO = 0.0 to 21.0%

O2 HI = 21.0 to 25.0%

PH3 = 0.10 to 5.00 ppm

SO2 = 0.5 to 20.0 ppm

Very low oxygen alarm settings are useful when the instrument is used to

verify nitrogen purging. On leaving the setpoint function or on subsequent

power on, the user will be prompted to verify the safety of abnormally low

settings

To enter the ALARM SETPOINT menu, depress the “SELECT” pushbutton in

the menu selection screen as described in Section 6.2 above. One of the

following ALARM SETPOINT menu screens will appear:

<gas> ALARM SETPOINT

For Toxic Gases HI ALARM = <_> ppm

CHANGE OK

ALARM SETPOINT

For O

2

HI ALARM = 23.5%

LO ALARM = 19.5%

CHANGE OK

The setpoint shown is the factory default setting. If acceptable, depress

26

the “OK” pushbutton to return to the Operating Mode.

To change the setpoint, depress the “CHANGE” pushbutton. One of the

following screens will be displayed:

<gas> ALARM SETPOINT

For Toxic Gases HI ALARM = <_ >ppm

UP DOWN

CHANGE O2 ALARM

For O

2

HI ALARM = 23.5%

LO ALARM = 19.5%

LO HI

For toxic gases, choose “UP” or “DOWN” to change the corresponding

“ALARM SETPOINT”. For example, choose “UP” and one of the following

screens will appear:

<gas> ALARM SETPOINT

For Toxic Gases HI ALARM = <_ >ppm

UP SET

Choose “DOWN” and one of the following screens will appear:

<gas> ALARM SETPOINT

For Toxic Gases HI ALARM = <_ >ppm

The ppm value will flash while either of these screens is displayed. Each

time the “UP” or “DOWN” pushbutton is depressed, the setpoint will be

changed by 1 ppm. Holding the pushbutton automatically repeats the action.

For oxygen, choose “LO” or “HI” to change the corresponding “ALARM

SETPOINT”. For example, choose “LO” and the following screen will appear:

DOWN SET

27

CHANGE O2 ALARM

For O

2

LO ALARM = 19.5 %

UP DOWN

To raise or lower this setpoint, select the “UP” or “DOWN” command. For

example, choose “DOWN” and the following screen will appear:

CHANGE O2 ALARM

For O

2

LO ALARM = 19.5 %

DOWN SET

The % value will flash while this screen is displayed. Each time the “DOWN”

pushbutton is depressed, the setpoint will be decreased by 0.1%. If the

“UP” pushbutton had been chosen, the value would be increased by 0.1%

each time the pushbutton was depressed.

The operation of the “HI” setpoint is exactly the same as for the “LO”. Remember the “Oxygen LOW ALARM SETPOINT” is adjustable in increments

of 0.1% from 0% to 21.0%, and the “Oxygen HIGH ALARM SETPOINT” is

adjustable in increments of 0.1% from 21.0% to 25.0%.

For all sensors, when the desired setpoint is reached, depress the “SET”

pushbutton. If the “SET” pushbutton is not depressed while in this screen,

after fifteen (15) seconds the unit will automatically revert back to the previous setpoint.

If the “SET” pushbutton is depressed, the “ALARM SETPOINT” screen will

reappear and display the new setpoints in one of the following screens:

<gas> ALARM SETPOINT

For Toxic Gases HI ALARM = <_> ppm

CHANGE OK

O

ALARM SETPOINT

2

For O

2

HI ALARM = 22.0%

LO ALARM = 18.5%

CHANGE OK

28

Depressing the “OK” pushbutton will display one of the following screens:

<gas> ALARM

For Toxic Gases

NON-LATCHING

LATCH OK

O2 ALARM

For O

2

NON-LATCHING

LATCH OK

The status of the alarms will be displayed as “NON-LATCHING” or

“LATCHING”. Status can be changed by depressing the left pushbutton.

Depress the “OK” pushbutton to leave the status as indicated. If neither

pushbutton is selected, after fifteen (15) seconds the unit will automatically return to the Operating Mode with the new alarm setpoints in effect

and the alarms at the status indicated.

Note: The instrument will not operate using any new setpoint for

determining an alarm condition until it returns to the operating

mode after a setpoint has been changed.

While in the setpoint menu the instrument remains operational. If

an alarm condition occurs, the instrument will override the setpoint

menu and display the alarm as appropriate. The changed setpoint

will not take effect and the previous settings will be reestablished.

No user menu’s can be accessed when a instrument is in an alarm

condition until the unit is turned “OFF”. When turned back “ON”, if

an alarm state occurs during the first minute of operation, all user

menu’s are accessible.

6.8 TWA / STEL MENU (TOXIC GASES ONLY)

The SCOTT INSTRUMENTS MINI-SA has factory preset “TWA/STEL” alarms.

When the values for these alarms are exceeded, the instrument alarm will

activate as described in Section 4.0. The TWA (Time Weighted Average)

function of the instrument averages the level of toxic gas over an eight (8)

hour period and alarms when the preset TWA value of in parts per million is

exceeded.

29

The STEL (Short Term Exposure Level) function measures the level of toxic

gas during a fifteen (15) minute interval and alarms when the preset STEL

value in parts per million is exceeded. The alarm levels are as follows:

STEL TWA

Ammonia 35 ppm 25 ppm

Carbon monoxide 100 ppm 25 ppm

Chlorine 1 ppm 0.5 ppm

Chlorine Dioxide 0.3 ppm 0.1 ppm

Hydrogen Cyanide 4.0 ppm 2.0 ppm

Hydrogen sulfide 15 ppm 10 ppm

Nitrogen Dioxide 5.0 ppm 3.0 ppm

Phosphine 1 ppm 0.3 ppm

Suphur Dioxide 5 ppm 2 ppm

To enter the TWA/STEL Menu, depress the “SELECT” pushbutton as described in Section 6.2 when the TWA/STEL Menu screen is displayed. The

instrument will display one of the following screens:

<gas> TWA/STEL MENU

For Toxic Gases STEL = 0 ppm

TWA = 0 ppm @ 0:05

RESET SHOW

DISABLE TWA/STEL

STEL and TWA values are calculated. STEL averages exposure for the

latest fifteen (15) minutes. TWA shows the eight-hour average exposure.

Both measures start from zero when the instrument is turned on. The TWA

reading accumulates total exposure since turn-on or “RESET” and is calculated as if the total exposure occurred in a standard eight-hour shift.

The “RESET/DISABLE” pushbuttons allows the user to reset the values and

time on the display to “0”. One of following screens will be displayed when

the “RESET/DISABLE” pushbuttons are depressed:

<gas> TWA/STEL MENU

TIME AVERAGE VALUES

For Toxic Gases

RESET DISABLE

30

Depressing the “RESET” pushbutton will reset the TWA value, the STEL

value, and time all to “0”. The instrument will automatically go back into the

Operating Mode and begin collecting measurement data.

The “DISABLE” pushbutton turns off the TWA/STEL functions. If the TWA/

STEL functions are off, one of the following screens will be displayed:

<gas> TWA/STEL MENU

TIME AVERAGE VALUES

For Toxic Gases

RESET ENABLE

Depress the “RESET” pushbutton to go back to the Operating Mode. Depress the “ENABLE” pushbutton to turn on the TWA/STEL functions.

When the TWA/STEL functions are enabled, selecting the TWA/STEL Menu

as described in Section 6.2 will display one of the following screens:

<gas> TWA/STEL MENU

STEL = 0 ppm

For Toxic Gas TWA = 0 ppm @ 0:05

RESET SHOW

ON/OFF TWA/STEL

Depress the “SHOW TWA/STEL” pushbutton to display the STEL and TWA

values on the Operating Mode screen in real time in one of the following

screens:

ppm

0

<gas>

STEL = 1 ppm

For Toxic Gases TWA = 0 ppm @ 0:03

MENU

To turn off the TWA/STEL display, go back to the TWA/STEL MENU. The

screen will now show “HIDE TWA/STEL” over the right pushbutton. Select

this pushbutton and the standard Operating Mode screen will appear.

The TWA/STEL data measurement functions will be reset by turning off the

instrument whether the function is enabled or disabled.

31

6.9 CONFIGURATION MENU

The CONFIGURATION menu of the SCOTT INSTRUMENTS MINI-SA provides the user with the following two (2) optional features:

• BATTERY SAVER mode can extend operational battery life to several hundred hours by turning off the instrument graphic display during normal non-alarm operation.

• PASSWORD PROTECTION menu can be used to lock out all menus

except ZERO CALIBRATION for toxic gas sensors or AUTO CALIBRATION for an oxygen sensor, preventing unauthorized users from

changing instrument settings.

6.9.1 BATTERY SAVER MODE

The BATTERY SAVER mode extends the operational life of the batteries by

turning off the graphic display when it is not needed. To use this feature,

depress the “SELECT” pushbutton when the CONFIGURATION menu screen

is displayed as described in section 6.2. The following screen will appear:

CONFIGURATION

BATTERY PASSWORD

SAVER MENU

Depress the “BATTERY SAVER” pushbutton and the following screen will

appear:

CONFIGURATION

ENABLE BATTERY

SAVER MODE?

YES NO

Depress the “YES” pushbutton to enable the BATTERY SAVER mode. When

the BATTERY SAVER mode is enabled, the MINI-SA will beep once and the

Operating Mode screen will appear. To the right of the the battery level

indicator three (3) vertical plus signs (+) will appear, which signify that the

BATTERY SAVER mode is enabled. After thirty (30) seconds, the instrument

will beep once and the graphic display will go blank. While the graphic display is blank, the Green Status LED will flash at an increased rate of once

every five (5) seconds.

While the BATTERY SAVER mode is on, depressing either pushbutton will

turn on the graphic display for thirty (30) seconds.

32

If an alarm condition occurs while in the BATTERY SAVER mode, the graphic

display will come on automatically and remain on until the alarm is reset.

After the alarm indication clears, the graphic display will remain on for

thirty (30) seconds and then the display will go blank as described above.

If the BATTERY SAVER mode had already been enabled , the graphic display

will show the following:

DISABLE BATTERY

SAVER MODE?

YES NO

Depressing the “YES” pushbutton will turn off the BATTERY SAVER mode.

6.9.2 PASSWORD PROTECTION

The PASSWORD PROTECTION menu is intended to be used by authorized personnel for the purpose of locking out the menus to prevent changes to the instrument

settings. A four digit numeric password can be set up to restrict access to all menus

except AUTO CALIBRATION or ZERO CALIBRATION. To use this feature, depress the “SELECT” pushbutton when the CONFIGURATION MENU screen is displayed as described in section 6.2. The following screen will appear:

CONFIGURATION

BATTERY PASSWORD

SAVER MENU

Depress the “PASSWORD MENU” pushbutton and the following screen will

appear:

ENTER PASSWORD

0000

UP SET

Use the “UP” and “SET” push-buttons to enter the correct password. (The

MINI-SA comes from the factory with the default password: 1234.) Entering

an incorrect password will display an INCORRECT PASSWORD message

and allow the user to enter the password again. When the correct password

33

has been entered, the instrument will display the following screen:

PASSWORD PROTECTION

FOR ADVANCED MENUS

TURN CHANGE

ON PASSWORD

The MINI-SA is shipped from the factory with password protection off.

The “TURN ON” pushbutton will bring up the following display:

PASSWORD PROTECTION

LOCK OUT ACCESS TO

ADVANCED MENUS?

YES NO

Pressing “NO” returns the instrument to normal operation with no password

required to use all menu functions. Pressing “YES” returns the instrument to

normal operation with the password required to access any menu except

ZERO CALIBRATION for toxic gas sensors or AUTO CALIBRATION for an

oxygen sensor. Until the instrument is turned off and then on, all menus will

remain accessible.

After the instrument is turned off and then on, when scrolling through the

menus as described in section 6.2, the following screen will appear after the

AUTO CALIBRATION or ZERO CALIBRATION menu:

PASSWORD REQUIRED

FOR ADVANCED MENUS

ENTER

EXIT PASSWORD

To disable the PASSWORD PROTECTION choose the “ENTER PASSWORD”

pushbutton when the above screen appears. The instrument will display the

following screen:

ENTER PASSWORD

0000

UP SET

34

Use the “UP” and “SET” push-buttons to enter the correct password. Entering the incorrect password will display an INCORRECT PASSWORD message and allow the user to enter the password again. When the correct

password has been entered, the instrument will display the following screen:

PASSWORD PROTECTION

FOR ADVANCED MENUS

TURN CHANGE

OFF PASSWORD

Depress the “TURN OFF” pushbutton and the instrument will display the

menus as described in section 6.2.

The PASSWORD menu in the CONFIGURATION menu will still require that

the password be properly entered to change the password and/or turn on the

PASSWORD PROTECTION feature after it has been turned off.

To change a password, navigate through the CONFIGURATION menu to the

PASSWORD menu:

PASSWORD PROTECTION

FOR ADVANCED MENUS

TURN CHANGE

ON PASSWORD

Depress the “CHANGE PASSWORD” pushbutton. The following display will

appear with the first digit flashing:

ENTER NEW PASSWORD

0000

UP SET

Depressing the “UP” pushbutton will increase the value of the flashing digit

from 0 through 9. Depressing the “SET” pushbutton will set the digit and

advance to the next digit. For example, we will set the password to “5678”.

When the fourth digit (number 8) has been set by depressing the “SET”

pushbutton, the display will change to the following screen:

35

VERIFY NEW PASSWORD

5678

UP SET

Note: If the pushbutton is not depressed within fifteen (15) seconds,

the instrument will beep once and automatically go back to the operating mode and the password will be unchanged.

If you wish to change the password shown in the VERIFY NEW PASSWORD screen, depress the “CHANGE” pushbutton. The previous ENTER

NEW PASSWORD screen will appear and changes can be made. Be sure

to record the password in a safe pace for future use.

NOTES:

1. The MINI-SA comes from the factory with the default password

“1234”.

2. To insure the integrity of the PASSWORD PROTECTION feature

of the MINI-SA, only SCOTT INSTRUMENTS Sales Representatives

and Service Departments will be authorized to enter a master password to access the MINI-SA menus in the event the password entered by the user is lost. If assistance is required, contact your

SCOTT INSTRUMENTS Sales Representative or Service Department

with the serial number of the instrument in question.

36

7.0 ERROR MESSAGES

WARNING

A SCOTT INSTRUMENTS MINI-SA INSTRUMENT THAT DISPLAYS

ANY ERROR MESSAGE MUST BE REMOVED FROM SERVICE IMMEDIATELY AND THE FAILURE DIAGNOSED AND REPAIRED BY

AUTHORIZED PERSONNEL. DO NOT ASSUME THAT A PROBLEM

HAS CORRECTED ITSELF IF A PREVIOUSLY DISPLAYED ERROR

MESSAGE DOES NOT APPEAR A SECOND TIME.

During calibration, if the SCOTT INSTRUMENTS MINI-SA detects a sensor

with insufficient output to be calibrated, the following screen will appear:

<gas> SENSOR

For Toxic Gases SPAN CALIBRATION

FAILURE

TURN OFF RECAL

OXYGEN SENSOR

For O2 SPAN CALIBRATION

FAILURE

TURN OFF RECAL

If one of these screens appears, verify that the proper gas is flowing to the

instrument and all fittings are properly connected. Then press “RECAL” to

attempt the calibration again. If calibration is not successful, press “TURN

OFF” and service the instrument as needed.

On subsequent power on, the INITIALIZING line on the first screen

displayed (SCOTT INSTRUMENTS MINI-SA...) will be replaced with

CALIBRATION REQUIRED, until the instrument is successfully

recalibrated. This may require replacing the sensor.

37

8.0 CALIBRATION GASES

Contact your SSCOTT INSTRUMENTS distributor, sales representative, or

the SCOTT INSTRUMENTS Service Center for information regarding availability of Calibration Gases and accessories for the SCOTT INSTRUMENTS

MINI-SA Portable Gas Detection Instrument.

Calibration eguipment from SCOTT INSTRUMENTS:

Calibration Kits ( Including gas cylinder, regulator, cal adapter and tubing)

P/N 096-2389 25 ppm H2S

P/N 096-2390 50 ppm CO

P/N 096-2391 18.5% O

P/N 096-2656 5 ppm Cl

P/N 096-2658 1 ppm PH

P/N 096-2660 25 ppm NH

P/N 096-2662 10 ppm SO

2

2

3

3

2

P/N 096-2893 10 ppm HCN

P/N 096-2894 5 ppm NO

2

Replacement Cylinders

P/N 077-0272 25 ppm H2S

P/N 077-0273 50 ppm CO

P/N 077-0274 18.5% O

P/N 077-0276 10 ppm SO

P/N 077-0277 25 ppm NH

2

2

3

P/N 077-0278 10 ppm HCN

P/N 077-0279 5 ppm Cl

P/N 077-0280 5 ppm NO

P/N 077-1239 1 ppm PH

2

2

3

38

9.0 SPECIFICATIONS

HYDROGEN SULFIDE SPECIFICATIONS

Range:

0 to 100 ppm (for H2S 100)

0 to 500 ppm (for H2S 500)

Response Time:

T90 < 30 seconds

Operating Temperature Range:

-40 to +50 oC

(-40 to +122 o F)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 o F)

Operating Humidity:

15 to 90% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±3% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Sensor Cross Sensitivity:

Carbon Monoxide at 300 ppm: < 2 ppm

Sulfur Dioxide, 5 ppm: ≈ - 1 ppm

Nitric Oxide, 35 ppm: < 0.7 ppm

Hydrogen, 10000 ppm: < 10 ppm

Nitrogen Dioxide, 5 ppm: ≈ - 1 ppm

Consult Factory for additional information.

39

CARBON MONOXIDE SPECIFICATIONS

Range:

0 to 500 ppm (for CO 500)

0 to 999 ppm (for CO 999)

Response Time:

T90 < 25 seconds

Operating Temperature Range:

-20 to +50 oC

(-4 to +122 o F)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 oF)

Operating Humidity:

15 to 90% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±3% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Sensor Cross Sensitivity:

Filtered against H2S, 15 ppm: < 0.5 ppm

Filtered against SO2, 5 ppm ≈ 0 ppm

Nitric Oxide, 35 ppm: < 3 ppm

Nitrogen Dioxide, 5 ppm: ≈ - 1 ppm

Chlorine, 1 ppm ≈ 0 ppm

Hydrogen, 100 ppm: < 40 ppm

Ethylene, 100 ppm: < 50 ppm

Ethanol, 200 ppm: ≈ 0 ppm

Consult Factory for additional information.

40

SULPHUR DIOXIDE SPECIFICATION

Range:

0.0 to 99.9 ppm

Response Time:

T90 < 35 seconds

Operating Temperature Range:

-20 to +50 oC

(-4 to +122 o F)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 o F)

Operating Humidity:

15 to 90% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±3% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Sensor Cross Sensitivity:

Carbon Monoxide at 300 ppm: < 3 ppm

Hydrogen Sulfide, 15 ppm: 0 ppm

Nitric Oxide, 35 ppm: 0 ppm

Nitrogen Dioxide, 5 ppm: ≈ - 5 ppm

Consult Factory for additional information.

41

PHOSPHINE SPECIFICATIONS

Range:

0.00 to 9.99 ppm

Response Time:

T90 < 30 seconds

Operating Temperature Range:

-20 to +50 oC

(-4 to +122 o F)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 oF)

Operating Humidity:

15 to 90% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±3% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Sensor Cross Sensitivity:

Arsine at 150 ppb: 100 ppb

Silane, 1000 ppb: 900 ppb

Diborane, 300 ppb: 105 ppb

Germane Dioxide, 600 ppb: 550 ppb

Sulphur Dioxide, 5 ppm: 1 ppm

Hydrogen, 1000 ppm: 1 ppm

Ethylene, 100 ppm: 1 ppm

Carbon Monoxide, 1000 ppm: 5 ppm

Consult Factory for additional information.

42

CHLORINE SPECIFICATION

Range:

0.0 to 99.9 ppm

Response Time:

T80 < 60 seconds

Operating Temperature Range:

-20 to +50 oC

(-4 to +122 o F)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 o F)

Operating Humidity:

15 to 90% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±3% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Sensor Cross Sensitivity:

Carbon Monoxide at 300 ppm: 0 ppm

Hydrogen Sulfide, 15 ppm: -3 to 0 ppm

Sulphur Dioxide, 5 ppm: 0 ppm

Nitric Oxide, 35 ppm: 0 ppm

Consult Factory for additional information.

43

AMMONIA SPECIFICATIONS

Range:

0 to 200 ppm

Response Time:

T90 < 150 seconds

Operating Temperature Range:

-25 to +30 oC

(-13 to +86 o F)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 oF)

Operating Humidity:

15 to 90% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±3% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Sensor Cross Sensitivity:

Carbon Monoxide at 300 ppm: 0 ppm

Hydrogen Sulfide, 15 ppm: ≈ 15 ppm

Sulpher Dioxide, 5 ppm: ≈ 4 ppm

Nitric Oxide, 35 ppm: ≈ 7 ppm

Nitrogen Dioxide, 5 ppm: 0 ppm

Chlorine, 1 ppm ≈ -0.5 ppm

Hydrogen, 200 ppm: 0 ppm

Hydrogen Cyanide, 10 ppm: ≈ 0.5 ppm

Hydrogen Chloride, 5 ppm: 0 ppm

Ethylene, 100 ppm: 0 ppm

Consult Factory for additional information.

44

CHLORINE DIOXIDE SPECIFICATION

Range:

0.00 to 2.00 ppm

Response Time:

T80 < 60 seconds

Operating Temperature Range:

-20o to +50 oC

(-4o to +122o F)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 o F)

Operating Humidity:

15 to 90% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±3% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Sensor Cross Sensitivity:

Chlorine at 3 ppm: 1 ppm

Carbon Monoxide at 300 ppm: 0 ppm

Hydrogen Sulfide, 15 ppm: -3 to 0 ppm

Sulphur Dioxide, 5 ppm: 0 ppm

Nitric Oxide, 35 ppm: 0 ppm

Consult Factory for additional information.

45

OXYGEN SPECIFICATIONS

Range:

0.0 to 25.0%

Response Time:

T95 = 15 seconds

Operating Temperature Range:

-20 to +50 oC

(-4 to +122 oF)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 oF)

Operating Humidity:

0 to 99% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±2% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Consult Factory for additional information.

46

HYDROGEN CYANIDE SPECIFICATION

Range:

100 ppm

Response Time:

T90 < 200 seconds

Operating Temperature Range:

-20o to +50 oC

(-4o to +122o F)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 o F)

Operating Humidity:

15 to 90% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±3% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Sensor Cross Sensitivity:

Carbon Monoxide at 300 ppm: <15 ppm

Hydrogen Sulfide, 15 ppm: ≈ 90 ppm

Sulpher Dioxide, 20 ppm: <75 ppm

Nitric Oxide, 35 ppm: <0 ppm

Nitrogen Dioxide, 5 ppm: < -10 ppm

Ethylene, 100 ppm: <25 ppm

Consult Factory for additional information.

47

NITROGEN DIOXIDE SPECIFICATIONS

Range:

150 ppm

Response Time:

T90 < 25 seconds

Operating Temperature Range:

-20 to +50 oC

(-4 to +122 oF)

Graphic Display Temperature Range:

-10 to +60 oC

(+14 to +140 oF)

Operating Humidity:

0 to 90% RH, Non-Condensing

Recommended Storage Temperature:

0 to 20 oC

(32 to 68 oF)

Sensor Accuracy:

±3% of Applied Gas

Linearity:

±3% of Full Scale

Battery Life:

About 100 Hours - Non-Alarming

About 800 Hours in Battery Save Mode

Sensor Cross Sensitivity:

Carbon Monoxide at 300 ppm: <15 ppm

Hydrogen Sulfide, ≈ -1.2 ppm

Sulpher Dioxide, 5 ppm: 0 ppm

Nitric Oxide, 35 ppm: 0 ppm

Nitrogen Dioxide, 5 ppm: 0 ppm

Chlorine, 1 ppm: ≈ -1 ppm

Consult Factory for additional information.

48

NOTES

49

Telephone: (610)363-5450 • Fax: (610)363-0167

40014802 Rev. D 08/21/03

CN #3181

®

251 Welsh Pool Road

EXTON, PA 19341

50

Loading...

Loading...