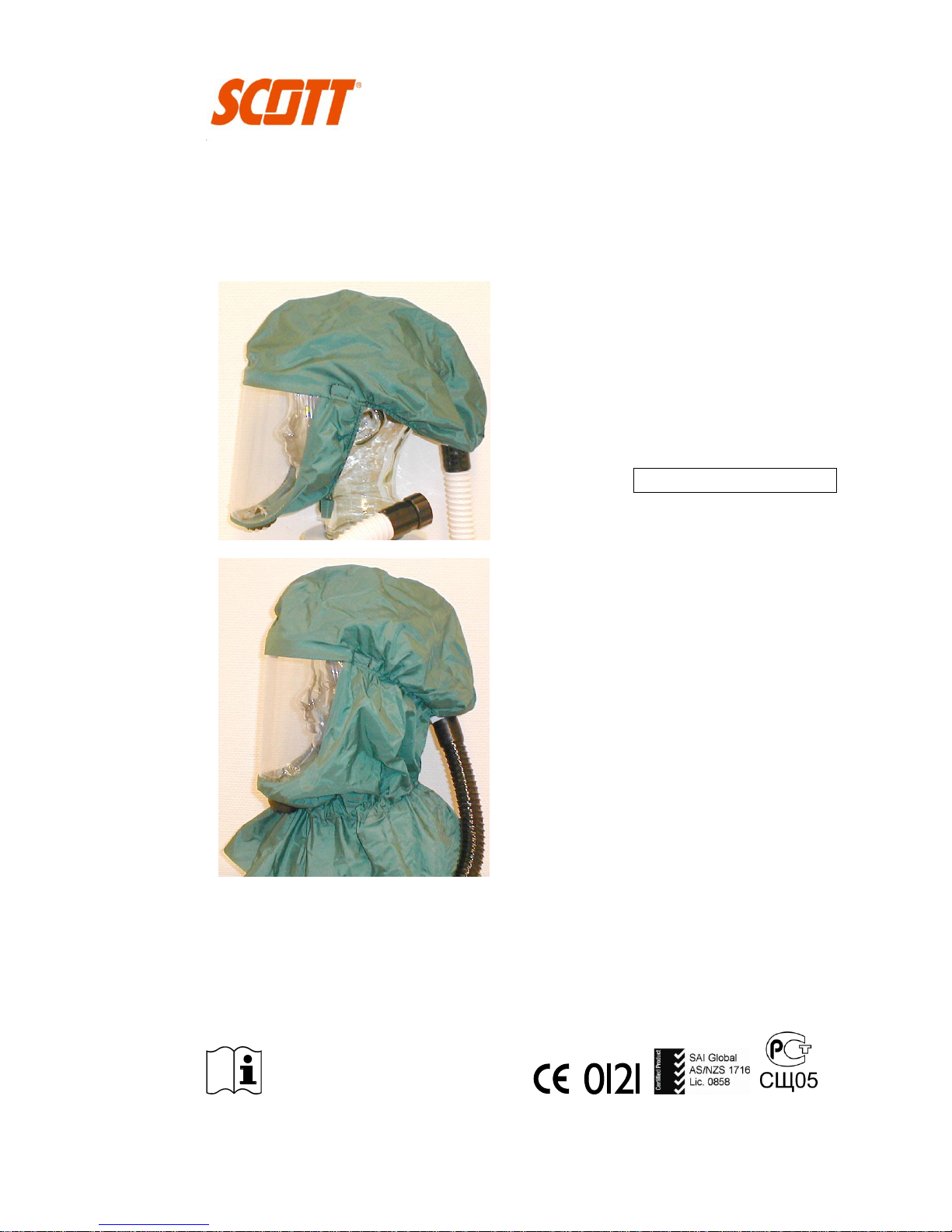

Flowhood 1 & 2

Instructions for Use

ENGLISH

009738-E 05/2010

2

FL 1 ML 064280 FL 2 064282 FL 2 A/S 064283 FL2 SU 064670

FL 1 SM 064281 (antistatic) (single use)

BGIA, DE-53754 Sankt Augustin, Germany Australia Russia

(excluding FL2 SU)

2

1

3

4

6

7

5

3

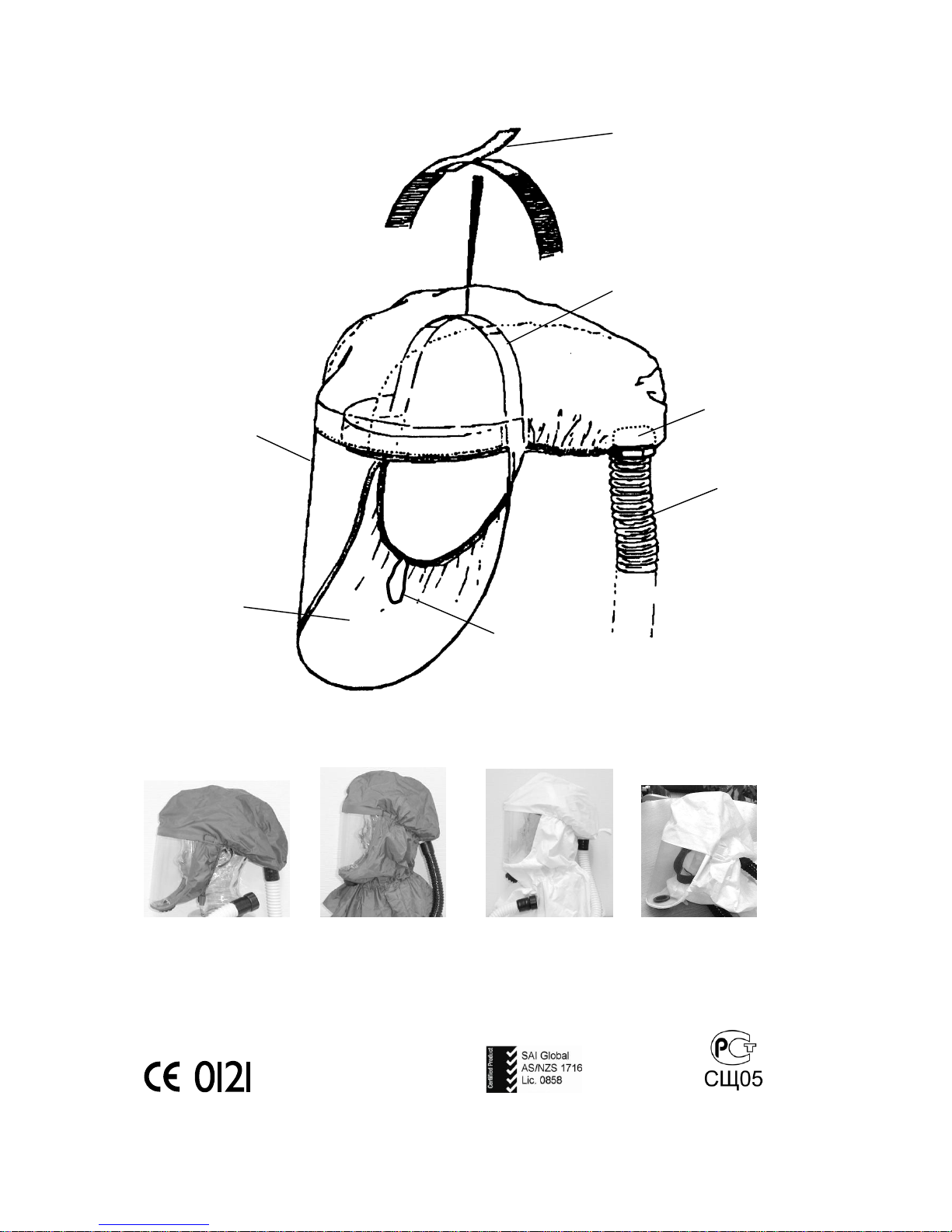

Components

1-2

- -

velcro / crown strap

3

- -

nut (+ washer)

4

064297

breathing hose FL PU (3)

5

- -

loop

6

- -

064296

exhalation valve

valve disc FL (2 pcs)

7

- -

face seal

8

- -

visor

064295

visor cover FL (10 pcs)

064291

hood FL1 ML

064292

hood FL1 SM

064293

hood FL2

064294

hood FL2 A/S (anti-static)

064540

hood FL2 SU (5)

Approved combinations

Pro2000

Pro2000

Hood

Blower device

Combined filter

Particle filter

Flowhood 2

Flowhood 2 A/S

Flowhood 2 SU

064024

Proflow2 SC 120

CF22 A P R

CF22 B P R

CF22 AB P R

CF22 ABE P R

CF32 ABEK P R

CF32 ABEKHg P R

PF 10 P R

063781

Proflow2 Ex 120

063581

Proflow3 120

063582

Proflow3 180

062976

Autoflow 120

Flowhood 1

064024

Proflow2 SC 120

CF22 A P R

CF22 B P R

CF22 AB P R

CF22 ABE P R

CF32 ABEK P R

PF 10 P R

063781

Proflow2 Ex 120

063581

Proflow3 120

063582

Proflow3 180

062976

Autoflow 120

Year of manufacture: inside the hood, over the visor (month+year).

Symbolit

-10 ºC

+50 ºC

< 75 %

See Instructions for Use!

Recommended storage conditions (temperature and humidity).

WARRANTY

The products manufactured at our factories in Skelmersdale and Vaasa carry a warranty of 12 months (unless stated

otherwise) for parts, labour and return to site. The warranty period runs from the date of purchase by the end user.

These products are warranted to be free from defects in materials and workmanship at the time of delivery. Scott will be

under no liability for any defect arising from wilful damage, negligence, abnormal working conditions, failure to follow

the original manufacturers instructions, misuse or unauthorised alteration or repair.

Evidence of purchase date will need to be provided for any claims arising during the warranty period. All warranty

claims must be directed through Scott Customer Services and in accordance with our sales return procedure.

4

Hood Flowhood 1 & 2

064280 Flowhood 1 ML (half hood)

064281 Flowhood 1 SM (half hood, small)

064282 Flowhood 2 (full hood)

064283 Flowhood 2 A/S (full hood, antistatic)

064670 Flowhood 2 SU (full hood, single use)

1. General

The Flowhood 1 and Flowhood 2 is designed to protect the respiratory system and face against

hazardous gases and particles.

o Use with a blower device, with the filters fitted to the blower device.

o Consists of a hood and a breathing hose.

o Air is drawn through particle filters connected to the blower, by an electronically-controlled

fan and led through the breathing hose into the facepiece (airduct). Exhaled air exits

through an exhalation valve found in the lower part of the hood.

2. Limitations of use

2.1 The filtering device must not be used if the environment and contamination is unknown. In

case of doubt, isolating respirators (air supply) which function independently of the

atmosphere must be used.

2.2 The filtering device must not be used in confined spaces (e.g. cisterns, tanks) because of

the risk of oxygen deficiency or presence of heavy oxygen-displacing gases (e.g. carbon

dioxide).

2.3 The filtering device may be used only if the oxygen content of the air is 18–23 vol.%.

2.4 Gas filters do not protect against particles. Similarly, particle filters do not provide

protection against gases or vapours. In case of doubt, use combined filters.

2.5 Normal filtering devices do not protect against certain gases such as CO (carbon

monoxide), CO2 (carbon dioxide) and N2 (nitrogen).

2.6 Particle filters are only allowed for single use if they are applied against radioactive agents or

micro-organisms (virus, bacteria, fungi and spores).

2.7 It is likely that adequate protection cannot be guaranteed if the user’s beard, hair,

spectacle frames or clothing intrude into the faceseal.

2.8 When a breathing protector is used in explosive atmospheres, please follow the

instructions given for such areas. The use of Flowhood 1 & 2 is permitted when

connected to an intrinsically safe (ex) blower device.

2.9 The blower must be running while using the respirator. If the blower turns off by accident,

the device ceases to function as a respirator, and carbon dioxide levels may instantly rise.

This is considered an abnormal situation.

2.10 At a very intense working pace, the pressure in the facepiece can change into negative

pressure at peak inhalation.

2.11 Protection levels may be reduced if wind speed exceeds 2 m/s.

2.12 Recommended operation conditions -10 C...+50 C, relative humidity (RH) under 75 %.

2.13 Filters must not be fitted directly to the the face shield or breathing hose.

3. Use

See Instructions for Use of the filter and blower device to be used.

Check intactness of hood and breathing hose.

Fix the breathing hose of the hood tightly to the blower device.

Screw the filters tightly to the blower device.

Remove the protective film from both surfaces of the visor.

Adjust the headband (velcro).

5

Don the blower unit according to its instructions.

Switch on the blower device, then check adequate air flow (see Instructions for Use of the

blower unit).

Don the hood so that the visor comes in front of the face and the breathing hose trails

freely down the back and is not kinked.

Flowhood 1 (half hood): Tighten by arranging the faceseal under the chin (draw at the loop).

Flowhood 2 (full hood): Tighten by adjusting the drawstring around the neck.

Check that hair or clothing is not trapped in the seal.

4. Maintenance and storage

Store protected from direct sunlight, at -10 °C...+50 °C and relative humidity (RH) under 75 %.

Clean with a damp cloth or sponge, using lukewarm water and mild detergent (neutral, pH

6-8) (e.g. washing-up liquid) (be careful not to scratch the visor). Allow to dry.

TriGene

TM

wipes may be used for disinfecion.

Do not use solvents (e.g. acetone, turpentine), hot water or bleaching agents (perborate,

percarbonate). Never clean with compressed air or compressed water.

Check that the hood and breathing hose are undamaged and replace damaged items.

Only use original spare parts.

Replacing the breathing hose

Undo the nut found on the rear innerhood (with Flowhood 2, also remove the plastic

washer) and remove the hose.

Insert the new hose into the hood (with Flowhood 2, also fit the washer) and tighten the nut.

Check that both layers of hood fabric are trapped under the nut.

Replacing the exhalation valve

Pull the valve cover from the valve and remove the disc.

Insert a new disc making sure that it lies flat on the seat.

Align the valve cover with the slots and snap it into place.

5. Disposal

A very contaminated hood as well as used filters are special refuse and shall be disposed

of according to the filtered substances (gases or particles).

6. Australia and New Zealand

For complete national requirements, please refer to the standard AS/NZS1715:2009,

Use & Maintenance of Respiratory Products.

7. Selection of blower-assisted breathing protector equipped with filter

See Instructions for Use of the blower device to be used.

Type of protective device

Multiples of threshold concentration **)

Remarks, limitations

APF (Assigned protection factor)

BS 4275 (GB)

BGR 190-ZH1/701 (DE)

Power-assisted face shield with particle

filter

TH1P

TH2P (Flowhood 1

TH3P (Flowhood 2)

10

20

40

5

20

100

“Open” facepieces, such as helmets or hoods,

do not provide sufficient protection in case of

breakdown or inferior output of the blower.

Therefore, devices of class TH1 must never

be used against carcinogenic, very poisonous

or radioactive gases and vapours.

Power-assisted face shield with

gas filter *)

TH1 gas filter class 1 or 2

TH2 gas filter class 1 or 2

TH3 gas filter class 1 or 2

10

20

40

5

20

100

For devices with combined filter apply the

relevant limitations of gas and particle filters.

Device with combined filter

The specified multiples of threshold value for the gas or particle filters are

given separately, but in all cases the lowest value applies.

*) Provided that the maximum permissible detrimental gas concentration for the gas filter is not exceeded. For

power-assisted filtering devices with gas filter, concentration must not exceed 0.05 vol.% in gas filter class 1 and 0.1

vol.% in gas filter class 2 and 0.5 vol.% in gas filter class 3.

**) If national guidelines exist: in all cases the lowest value applies.

6

Scott Health & Safety Oy

P.O.BOX 501

FI-65101 Vaasa, Finland

TECHNICAL SUPPORT & SALES

Tel. +358 (0)6 3244 543 or 544 or 535

TEKNINEN TUKI JA MYYNTI

Puh. (06) 3244 536 tai 537

Fax +358 (0)6 3244 591

scott.sales.fin@tycoint.com

www.scotthealthsafety.com

Loading...

Loading...