Page 1

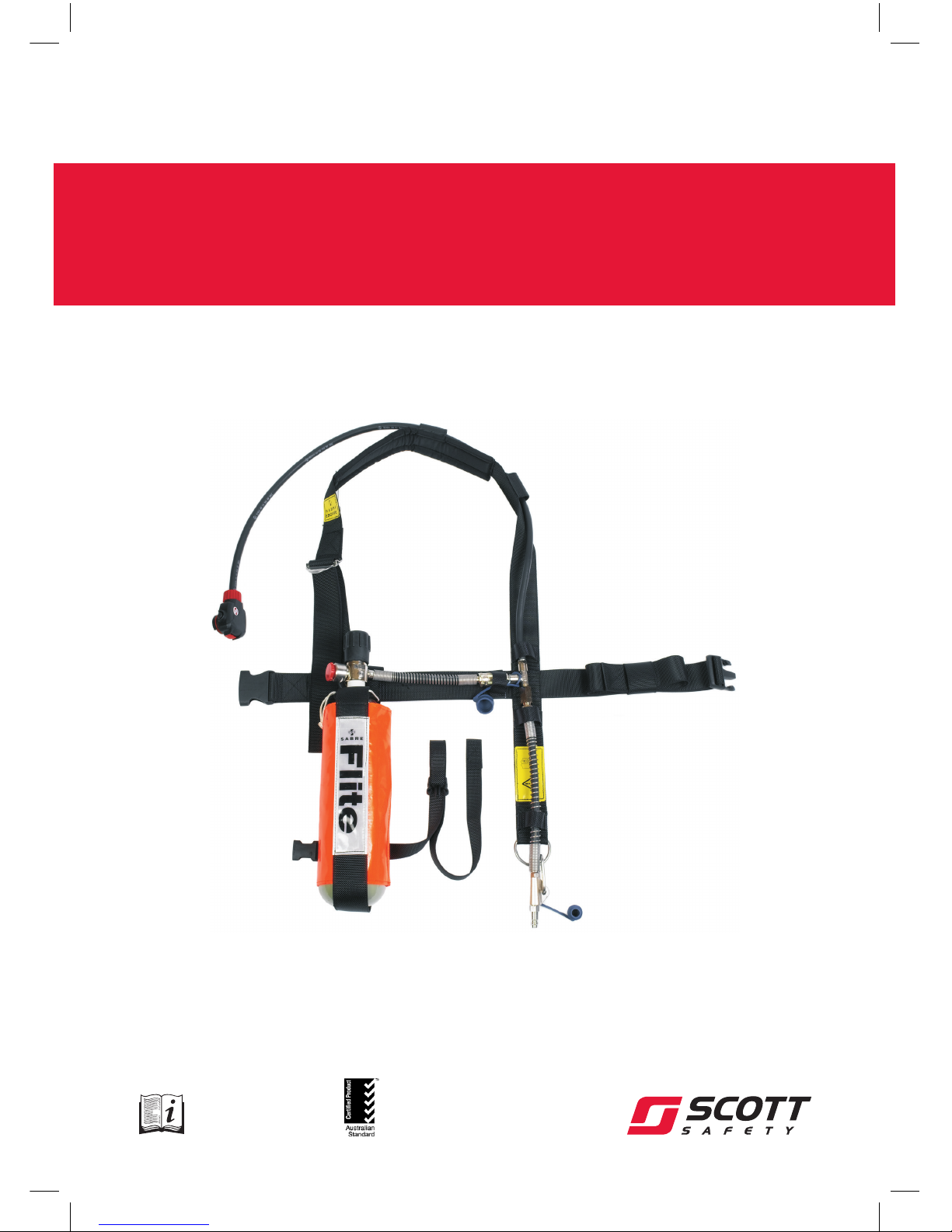

FLITE

COMPRESSED AIR BREATHING APPARATUS

1034988 J

02.2013

CE0086

AS/NZS1716 : 2012

Lic. 1214 SAI Global

Page 2

Page 3

i

Contents

WARNINGS ...................................................................................................................................................... II

1. INTRODUCTION .................................................................................................................................... 1

1.1 ABBREVIATIONS USED IN THIS MANUAL ................................................................................ 1

1.2 LIMITATIONS OF USE ................................................................................................................. 1

1.3 BREATHABLE AIR ....................................................................................................................... 1

1.4 COMPRESSED AIR AIRLINE SUPPLIES ................................................................................... 2

1.5 TRAINING .................................................................................................................................... 2

1.6 SERVICING .................................................................................................................................. 2

1.7 PARTS IDENTIFICATION ............................................................................................................ 2

1.8 ORDERING PARTS AND ACCESSORIES ................................................................................. 3

1.9 WARRANTY ................................................................................................................................. 3

1.10 SELECTING APPARATUS FOR RESPIRATORY PROTECTION .............................................. 3

2. TECHNICAL DESCRIPTION ................................................................................................................. 4

2.1 GENERAL .................................................................................................................................... 4

2.2 FILTERS ....................................................................................................................................... 4

2.3 DEMAND VALVE ......................................................................................................................... 5

2.4 FACEMASKS ............................................................................................................................... 5

2.5 REDUCER/CYLINDER VALVE .................................................................................................... 5

2.6 CYLINDERS ................................................................................................................................. 5

2.7 QUALITY ATTRIBUTES............................................................................................................... 6

2.8 NOTIFIED BODIES ...................................................................................................................... 6

3. PRE-USE CHECKS................................................................................................................................ 7

3.1 FACEMASK .................................................................................................................................. 7

3.2 BANDOLIER................................................................................................................................. 8

4. DONNING AND OPERATING PROCEDURES ..................................................................................... 8

4.1 BANDOLIER................................................................................................................................. 8

4.2 FACEMASK .................................................................................................................................. 9

4.3 POSITIVE PRESSURE TEST ...................................................................................................... 9

4.4 FACE SEAL TEST ........................................................................................................................ 9

4.5 NEGATIVE PRESSURE TEST (FLITE WITH FILTER) .............................................................. 10

4.6 CHANGING FROM FILTER CANISTER TO AIRLINE ............................................................... 10

4.7 CHANGING FROM AIRLINE TO FILTER CANISTER ............................................................... 10

4.8 CHANGING FROM AIRLINE TO CYLINDER ............................................................................ 11

4.9 CHANGING FROM CYLINDER TO AIRLINE ............................................................................ 11

5. DOFFING THE APPARATUS .............................................................................................................. 11

6. CLEANING AND SCHEDULED MAINTENANCE............................................................................... 12

6.1 FACEMASK ................................................................................................................................ 12

6.2 DEMAND VALVE ....................................................................................................................... 13

6.3 BANDOLIER............................................................................................................................... 13

6.4 REDUCER, GAUGE AND CYLINDER ....................................................................................... 13

6.5 CHECK APPARATUS ................................................................................................................ 13

6.6 DEMAND VALVE ....................................................................................................................... 13

6.7 RECORD DETAILS OF CHECKS .............................................................................................. 14

6.8 STORAGE .................................................................................................................................. 14

6.9 MONTHLY MAINTENANCE....................................................................................................... 14

6.10 ANNUAL MAINTENANCE.......................................................................................................... 14

Registered Office: Scott Safety, Pimbo Road, West Pimbo,

Skelmersdale, Lancashire, WN8 9RA, United Kingdom.

Page 4

ii

WARNINGS

Please Read Carefully and Fully Understand

This manual is for use by personnel trained in the use and care of compressed air

breathing apparatus (BA) and MUST NOT be used as a self-teaching guide by untrained

users. Failure to understand or adhere to these instructions may result in injury or death.

Scott Safety have taken great care to ensure that the information contained within this

manual is accurate, complete and clear. However, Training and Technical Support

Services will be pleased to clarify any points in the manual and answer any questions on

Scott Safety breathing apparatus.

The following warnings are in accordance with certifying authority requirements and

apply to the use of breathing apparatus in general:

Breathing apparatus users must be fully trained in the use and care of airline and self-contained,

compressed air breathing apparatus.

Ensure that the selection of the apparatus type is sufficient for the tasks being undertaken and the

hazards likely to be encountered. Please refer to National Regulations for guidance.

Adequate protection may not be provided in certain highly hazardous atmospheres.

The wearer must be aware of the length of time of the duration of the apparatus to ensure that they

have sufficient time to escape in the event of airline failure.

For potentially flammable or explosive atmospheres, anti-static hoses MUST be used.

Prior to use, check that the facemask is a good fit and that a good face seal can be achieved by the

wearer. The wearing of beards, side-burns or spectacles may adversely affect the sealing of a

facemask to the wearer's face.

If the apparatus fails any of the pre-use checks it must be withdrawn from service and returned for

repair.

The quality of air used to supply and charge breathing apparatus must meet the requirements of EN

12021 : 1999 or AS/NZS1715 : 1994.

In Australia and New Zealand, ensure that your selection of respiratory protective devices conform

to the requirements of AS/NZS1715 : 1994.

The apparatus is not designed for use underwater.

Where FLITE has been contaminated by anything that may pose a threat to life or health, local

statutes, health and safety guidance, site operating procedures or specialist advice for: doffing, decontamination, cleaning or disposal of FLITE or its filters must be obtained and adhered to.

The harness must not be used as a vehicle seat restraint.

FLITE can be used at temperatures down to -6°C and stored between -30°C and +60°C.

Compressed air for use with BA must have a dew-point sufficiently low to prevent internal freezing.

DISCLAIMER

Failure to comply with these instructions or misuse of the apparatus may result in

death, injury or material damage and invalidate any resulting warranty or insurance

claims.

COPYRIGHT

This manual must not be copied in part or in whole, or used for purposes other than its

intended purpose without the written permission of Scott Safety.

Page 5

FLITE

1

1. INTRODUCTION

1.1 ABBREVIATIONS USED

IN THIS MANUAL

BA Breathing Apparatus

DV Demand Valve

kg Kilograms

HP High-pressure

mg Milligrams

ml Millilitres

m Metres

NRV Non Return Valve

ppm Parts per million

psi Pounds per Square Inch

1.2 LIMITATIONS OF USE

FLITE must only be used with Scott

Safety breathing apparatus facemasks.

FLITE must only be used by competent

personnel trained by Scott Safety or their

approved agents.

FLITE must not be used with spectacle

side arms, beards (or other facial hair), or

clothing that may prevent the facemask

forming a good seal with the face.

1.3 BREATHABLE AIR

Air for compressed air BA may be natural

or synthetic. The composition of

breathable air is given in EN 12021 :

1999 or AS/NZS1715 : 1994. The data

given or required in EN 12021 are valid

for normal atmospheric pressure (one bar

absolute, 20oC). All percentage

requirements are given in % by volume.

The composition of natural air is shown in

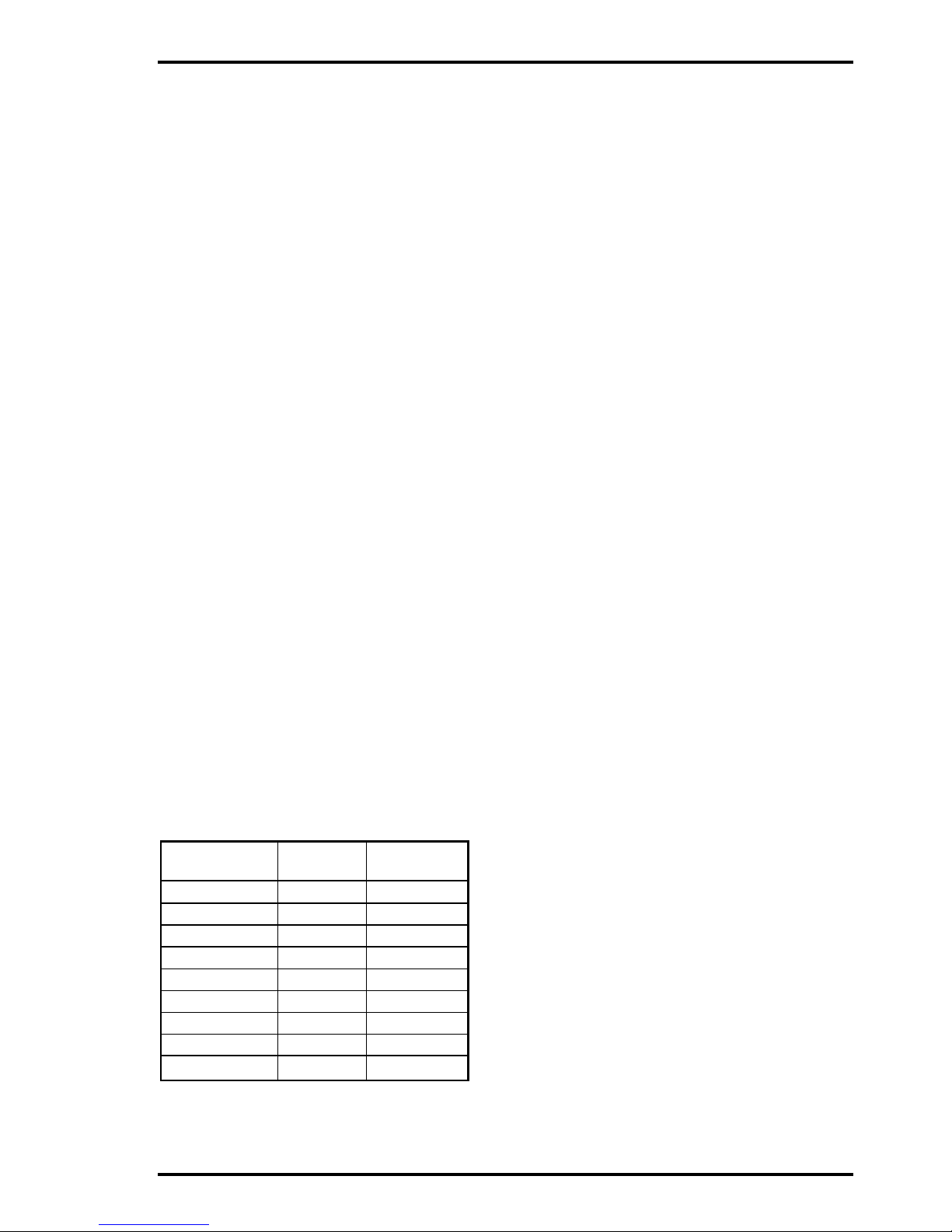

Table 1.

Element

Mass %

(Dry Air)

Volume %

(Dry Air)

Oxygen

23.14

20.948

Nitrogen

75.52

78.08

Argon

1.29

0.93

Carbon Dioxide

0.05

0.031 4

Hydrogen

0.000 003

0.000 05

Neon

0.001 270

0.001 818

Helium

0.000 037

0.000 524

Krypton

0.000 330

0.000 114

Xenon

0.000 039

0.000 009

Table 1: Breathable Air - EN 12021

(NOT applicable for Australia or New

Zealand)

The oxygen content must be in the range

of 21% (1%) by volume (dry air). There

is an increased fire risk when oxygen or

oxygen-enriched air is used to supply

breathing apparatus.

The purity/quality of air used to supply

and charge breathing apparatus should

be tested periodically in accordance with

national regulations. Compressed air for

breathing apparatus shall not contain any

contaminants at concentrations that can

cause toxic or harmful effects.

Contaminant levels must be kept as low

as possible and must be far below the

national exposure limit. Combination

effects of more than one contaminant

must be taken into account.

Note:

The limit of concentration for any

contaminant should be derived from

national exposure levels, taking into

account, as far as is reasonably practical;

the effects of pressure and exposure

time.

In the absence of more stringent national

regulations the following values shall

apply:

Lubricant content (droplets or mist)

shall not exceed 0.5 mg/m3. Where

synthetic lubricants are present

limits for toxic or harmful

contaminants apply (as defined

above).

Air shall be without significant

odour or taste.

Carbon monoxide content must not

exceed 15 ml/m3 (15 ppm).

Carbon dioxide content must not

exceed 500 ml/m3 (500 ppm).

There must be no free liquid water.

Where the apparatus is used and

stored at a known temperature, the

pressure dew-point shall be at least

5C below the likely lowest

temperature.

Where conditions of usage and

storage of the compressed air

supply are not known the pressure

dew-point shall not exceed -11C.

The maximum water content of air at

atmospheric pressure shall not exceed:

Page 6

FLITE

2

50 mg/m3 for 207 bar apparatus

35 mg/m3 for 300 bar apparatus

Note:

The water content of air supplied by a

compressor must not exceed 35 mg/m3.

Contaminants must be kept to a minimum

and must not exceed permissible

exposure levels. Air filters must be

suitable for the quality of air used and the

air must be tested periodically to ensure

that the supply reaches these standards.

The air must be free from the odour of oil

(odour threshold is 0.3 mg/m3).

The dew-point of air for compressed

airline BA must be sufficiently low to

prevent internal freezing.

National regulations for compressed

airline BA must be observed.

1.4 COMPRESSED AIR

AIRLINE SUPPLIES

Air for use with compressed air airlines

must conform to EN 12021 : 1999 or

AS/NZS1715 : 1994.

Airline pressure must be between 5.0 and

9.0 bar (70 - 130psi). Airflow supply

capacity for a single airline is given in

Table 2. Generally, each additional

wearer requires an extra 150 L/min, each

additional pair of wearers requires 300

L/min for one wearer and 450 L/min for

two wearers (see Table 2). All

measurements must be taken at the

wearer end of the airline. An Airline Flow

Tester (Article Number 1035978) is

available from Scott Safety for this

purpose.

Example: for 8 users (4 pairs) the

recommended flow is 4 x (300 + 150) =

1800 litres per minute.

External air supplies must conform to the

Supply Pressures and Flow Rates listed

in Table 2 when measured at the extreme

end of the supply hose.

Number of

Wearers

Supply Pressure bar

(psi)

Airflow

L/min

1

5.5 - 9.5 (70 - 130)

300

2 (1 pair)

5.5 - 9.5 (70 - 130)

450

Table 2: Wearer Air Consumption

1.5 TRAINING

Personnel who use breathing apparatus

must be fully trained in accordance with

these instructions and national

regulations.

These instructions cannot replace an

accredited training course run by fully

qualified instructors in the proper and

safe use of Scott Safety breathing

apparatus.

Please contact Training and Technical

Support Services or your Scott Safety

distributor for training course details.

Training and Technical Support

Services:

Scott Safety

Pimbo Road, West Pimbo,

Skelmersdale, Lancashire,

WN8 9RA, England.

Tel: +44 (0) 1695 711711

Fax: +44 (0) 1695 711775

1.6 SERVICING

FLITE must be serviced at scheduled

intervals by personnel who have

completed a formal training course and

hold a current certificate for servicing and

repairing Scott Safety breathing

apparatus. Details of the servicing

schedule are contained within the Scott

Safety FLITE Service Manual, copies of

which may only be obtained by registered

holders of a current certificate. Your

Scott Safety distributor or Training and

Technical Support Services at Scott

Safety will be pleased to provide training

course details and quotes for service

contracts. Please see above for contact

details.

1.7 PARTS IDENTIFICATION

All safety-related parts accessible to

wearers are clearly marked with a part

number and a serial number. Other parts

must only be removed or adjusted by

personnel qualified to service the

apparatus.

Page 7

FLITE

3

1.8 ORDERING PARTS AND

ACCESSORIES

Customer Services provide an efficient,

friendly customer contact point for

ordering new apparatus, spare parts and

accessories.

Customer Services:

Scott Safety

Pimbo Road, West Pimbo,

Skelmersdale, Lancashire,

WN8 9RA, England.

Tel: +44 (0) 1695 711711

Fax: +44 (0) 1695 711775

1.9 WARRANTY

The products manufactured at our

factories in Skelmersdale and Vaasa

carry a warranty of 12 months (unless

stated otherwise) for parts, labour and

return to site. The warranty period runs

from the date of purchase by the end

user.

These products are warranted to be free

from defects in materials and

workmanship at the time of delivery.

Scott Safety will be under no liability for

any defect arising from wilful damage,

negligence, abnormal working conditions,

failure to follow the original

manufacturer’s instructions, misuse or

unauthorised alteration or repair.

Evidence of purchase date will need to be

provided for any claims arising during the

warranty period. All warranty claims must

be directed through Scott Safety

Customer Services and in accordance

with our sales return procedure.

1.10 SELECTING

APPARATUS FOR

RESPIRATORY

PROTECTION

When selecting respiratory protective

equipment the following factors must be

considered:

Hazards likely to be encountered

and their effect on the wearer.

Physical and emotional stress and

their effect on wearer breathing

rate.

The type of respiratory protection

required.

The oxygen level may fall below

19%.

There are high levels of toxic

hazard.

Where any of the above are present, a

higher level of respiratory protection

should be selected.

When selecting respiratory protective

apparatus, refer to EN 529 : 2005 or

AS/NZS1715 : 1994.

Page 8

FLITE

4

2. TECHNICAL

DESCRIPTION

2.1 GENERAL

FLITE is a positive pressure compressed

air, airline, breathing apparatus (BA). It

can be used with either:

(a) A compressed air cylinder to

enable wearers to leave hazardous

areas safely in the event of airline

failure, or

(b) A facemask that can be fitted with a

suitable Scott Safety particulate

filter, to be used when entering or

leaving the hazard area with the

airline disconnected.

In the latter mode the facemask functions

as a negative pressure device.

The supply airline hose connects to a

CEN connector that supplies the

facemask-mounted demand valve via a

length of medium pressure air hose.

WARNING:

FLITE must not be used in oxygen

deficient atmospheres whilst

disconnected from the airline supply

and with the cylinder not in use.

Non Return Valves (NRV) in the

pneumatics seal the air inlet from the

airline and the cylinder when either are

not in use. The apparatus MUST be used

with a cylinder, or an airline, or both.

The apparatus comprises a full facemask,

a Demand Valve (DV), and a pigtail with

CEN coupling for attaching the supply

airline.

There are three cylinder options that can

be provided with the apparatus.

The air supply specification for FLITE is

detailed below:

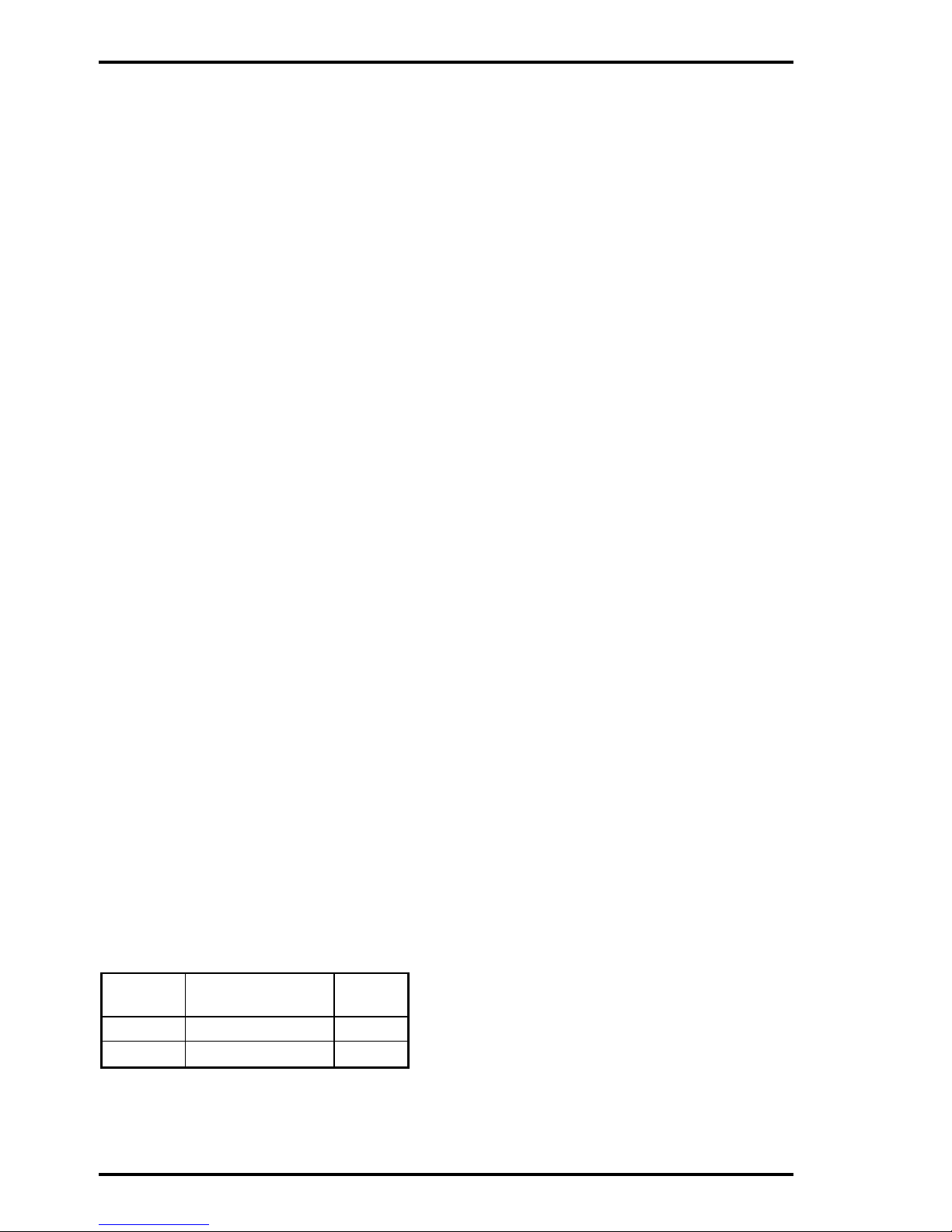

Maximum Cylinder Duration

10, 13 or 15 minutes

Maximum Airline Length

90 metres

Air Supply Specification

The flame-resistant bandolier relieves the

pull of the airline hose and when a

compressed air cylinder is fitted, supports

the cylinder bag.

FLITE is marked in accordance with EN

139 and AS/NZS1716 : 2012. An

explanation of those markings is given

below:

Key

Meaning

A =

Product brand name

B =

Serial number of apparatus

C =

Product model/designation

D =

Apparatus description

E =

Working Pressure

F =

Symbol - refer to User Instructions

G =

Number of Approval Body

H =

Date of manufacture

I =

Contact details of manufacturer

2.2 FILTERS

The service life of the filters is dependent

upon the environment and the use-bydate marked on the filter. DO NOT use

damaged, wet, clogged, or time expired

filters.

The filter screws directly into a threaded

connector on the facemask. A filter cover

is provided to preserve the filter when an

airline is in use. A blanking plug is

provided to seal the mask when a filter is

not fitted. Filters must conform to EN 141

or EN 143 with an EN 148-1 standard

thread and must be appropriate for the

known workplace hazards.

Page 9

FLITE

5

2.3 DEMAND VALVE

Airflow into the facemask is controlled by

the DV, which is attached to the

facemask by a quick-fit connection. The

DV can be closed by a reset button to

enable the facemask to be removed

without loss of air to the atmosphere.

When the DV is next used the first breath

taken by the wearer opens the DV

automatically.

The bypass knob enables the wearer to

open an unregulated flow of air into the

facemask.

2.4 FACEMASKS

FLITE is approved for use with

PanaSeal, PanaVisor, Vision 3 and

Promask PP full facemasks.

All of which have the following features:

Conformance with EN 136 and

AS/NZS1716 : 2012.

Speech diaphragm.

Ori-nasal inner mask to minimise

the carbon dioxide dead space and

prevent visor misting.

Polycarbonate visor.

Fully adjustable, five-point web, or

net head harness options.

Left quick fit DV connector.

Reflex face seal.

PanaSeal is the standard facemask. It is

available in non-dermatitic silicone or

neoprene and may be fitted with a

microphone for a personal radio.

PanaVisor is similar to PanaSeal, but its

larger size makes it more suitable for

larger face sizes.

Vision 3 is available in non-dermatitic

silicone. It has a large visor, which

provides the wearer with a wider range of

vision.

Promask PP is moulded in hypoallergenic, black ProcompTM with a soft

silicone inner mask.

2.5 REDUCER/CYLINDER

VALVE

The reducer/cylinder valve is a combined

cylinder valve and pressure reducer.

When the handwheel is opened, air flows

from the cylinder, through the reducer to

the facemask demand valve.

The reducer is a spring and piston device

with an integral Pressure Relief Valve

(PRV) that protects the medium pressure

circuit from over-pressurisation.

The pressure gauge indicates the current

cylinder pressure.

2.6 CYLINDERS

When cylinders are provided they may

be:

10 minute cylinder (CYL-FLITE-10):

Free air capacity:

400 litres

Charging pressure:

207 bar

Material:

Alloy Steel

Specification:

CE

Duration at 40 L/min:

10 minutes

Weight (charged):

3.8Kg

10 minute cylinder (CYL-FLITE-10-AUS/NZ):

Free air capacity:

440 litres

Charging pressure:

207 bar

Material:

Alloy Steel

Specification:

Work Cover

Duration at 40 L/min:

10 minutes

Weight (charged):

4.2Kg

10 minute cylinder (CYL-FLITE-SL):

Free air capacity:

540 litres

Charging pressure:

300 bar

Material:

Carbon Fibre / Aluminium

Specification:

HSE-AL-FW2 & TUV

Duration at 40 L/min:

13 minutes

Weight (charged):

4.3Kg

Page 10

FLITE

6

15 minute cylinder (CYL-FLITE-15):

Free air capacity:

600 litres

Charging pressure:

207 bar

Material:

Alloy Steel

Specification:

CE

Duration at 40 L/min:

15 minutes

Weight (charged):

4.7Kg

15 minute cylinder (CYL-FLITE-15-AUS/NZ):

Free air capacity:

660 litres

Charging pressure:

207 bar

Material:

Alloy Steel

Specification:

Work Cover

Duration at 40 L/min:

15 minutes

Weight (charged):

5.1Kg

Carbon fibre/aluminium cylinders should

be used with apparatus that is to be used

for full shift periods. Steel cylinders

should NOT be used for full shift working.

When changing from airline to cylinder

supply, the non-return valve in the supply

airline protects the airline from

contamination, while a second, in the

FLITE air hose prevents cylinder air loss.

2.7 QUALITY ATTRIBUTES

FLITE is 'CE' marked in accordance with

EEC Directive EC/686/1986.

It is approved to European Standard EN

139 : 1993 (Respiratory Protective

Devices - Compressed Airline Breathing

Apparatus). AS/NZS 1716 : 2012

(Respiratory Protective Devices).

Facemasks are approved to EN 136 and

AS/NZS1716 : 2012.

Scott Safety is quality assurance

approved to ISO 9001 : 2000.

2.8 NOTIFIED BODIES

Inspec International Limited (No. 0194)

56 Leslie Hough Way,

Salford,

Greater Manchester,

M6 6AJ,

England.

BSI (0086)

Kitemark Court,

Davy Ave,

Knowlhill,

Milton Keynes,

MK5 8PP.

England.

SAI Global

286 Sussex Street,

Sydney,

NSW 2000,

Australia.

Lic. No 1214.

Page 11

FLITE

7

3. PRE-USE CHECKS

3.1 FACEMASK

1. Remove the Visorguard and store

carefully for re-use later. Check that the

mask is clean and that visor is clear and

undamaged.

2. Slacken the facemask head

harness fully and check for damage.

3. Withdraw the DV locking catch, turn

the DV through 90o clockwise and

withdraw the DV from the facemask.

4. Check O-ring on the demand valve

is in good condition and attach the DV to

the facemask.

5. Twist the DV to check that the

locking catch has locked the DV to the

facemask.

6. Check that the bypass knob is in

the OFF position.

7. Reset the DV first breath

mechanism by pressing the black rubber

reset button.

WARNING:

When using with a facemask fitted

with a filter and breathing from an

airline, a filter cover or blanking plug

must be place to ensure that the first

breath mechanism will activate.

8. Check that the O-ring on the

blanking plug is in good condition.

9. Screw the blanking plug to the

facemask.

10. If using the facemask fitted with a

filter, check that the filter is suitable for

the workplace hazard and within its useby date (see filter label).

11. Check that the cord from the filter

cover is around the filter connector.

Page 12

FLITE

8

12. Check that the filter O-ring is in

place and in good condition. Screw the

filter to the facemask.

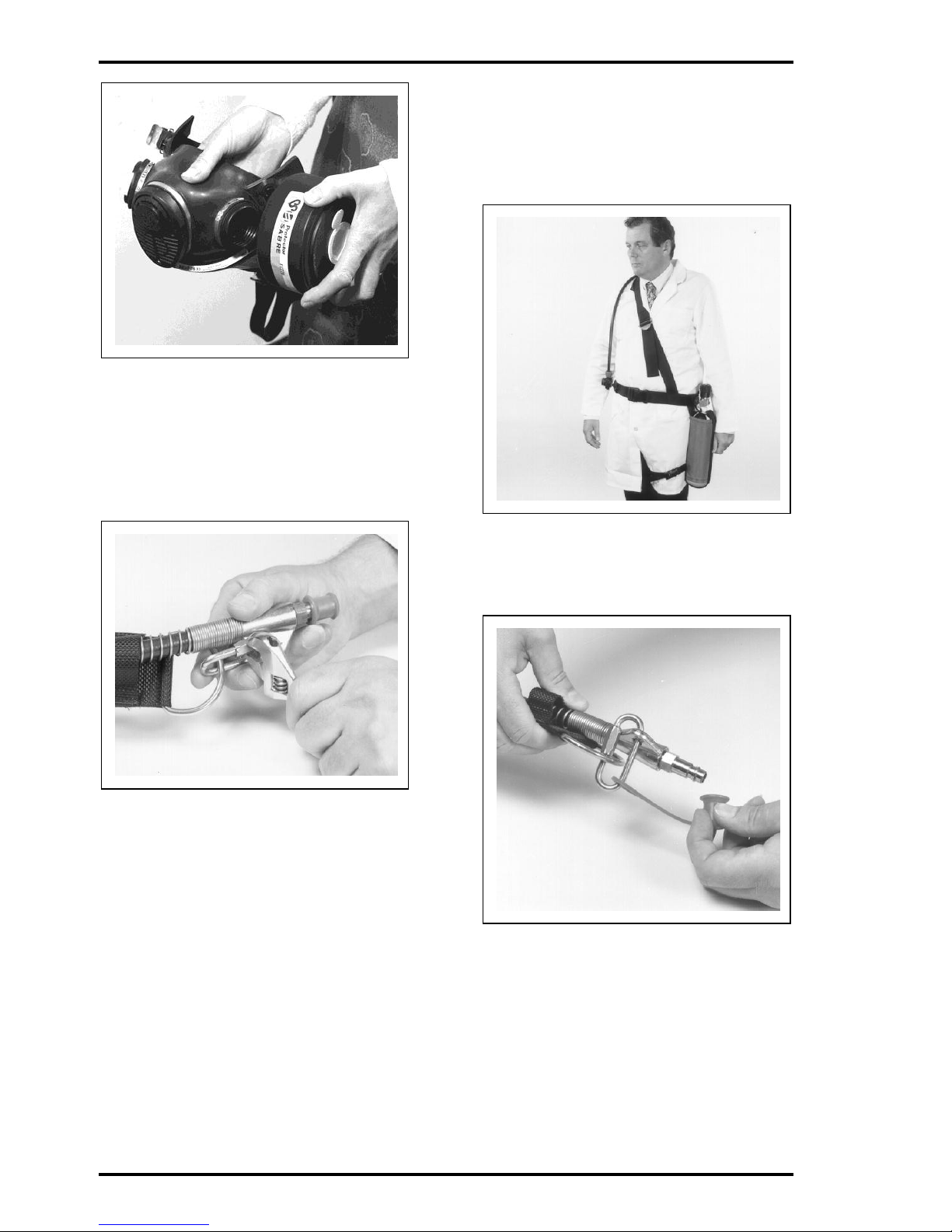

3.2 BANDOLIER

1. Fully slacken the bandolier

waistbelt and leg strap.

2. Check that the shackle is attached

to the pigtail and the shackle nut is fully

tightened.

3. Check that the cylinder is full and

securely held in its bag.

4. Check that the pigtail CEN

connector is clean and in good condition.

5. Check that there is no damage or

excess wear in the bandolier.

6. Replace any items that are

damaged or show signs of excessive

wear.

7. DO NOT use the equipment if it

fails any of the above checks.

8. Check the airline supply pressure.

4. DONNING AND

OPERATING

PROCEDURES

4.1 BANDOLIER

1. Don the bandolier so that the DV

hose is over the right shoulder and the

cylinder is on the left hip. Fasten the

waistbelt and leg strap.

2. Remove the coupling dust-cap,

connect the pigtail to the airline and pull

the airline to ensure that the coupling is

firmly connected.

Page 13

FLITE

9

4.2 FACEMASK

1. Hang the facemask from the

neckstrap.

2. Position the facemask so that the

chin fits into the chin-cup.

3. Pull the head harness over the

back of the head, ensuring that no hair is

trapped under the face seal.

4. Tighten the head harness straps in

sequence: bottom, middle, top. DO NOT

OVER-TIGHTEN.

5. Take a sharp breath to actuate the

first breath mechanism.

4.3 POSITIVE PRESSURE

TEST

1. Gently insert fingers into the mask

seal and check that there is a good flow

of air from the facemask.

2. Remove the fingers from the seal

and allow the mask to re-seal to the face.

4.4 FACE SEAL TEST

1. Hold your breath and listen

carefully for leaks.

2. If a leak is detected adjust the

facemask and head harness. Repeat the

test. If the leak is still present the

apparatus must be returned for repair.

WARNING:

DO NOT use the apparatus if there is a

leak.

3. If there are no leaks, the apparatus

is ready for use.

Page 14

FLITE

10

4.5 NEGATIVE PRESSURE

TEST (FLITE WITH

FILTER)

1. Disconnect the airline supply.

2. Attach the filter seal cord to the

neckstrap and fit the sealing cap to the

filter canister inlet.

3. Use a thumb to seal the airline

coupling.

4. Press the filter seal with the palm of

the hand to seal the filter inlet and inhale.

Hold your breath for 10 seconds. Check

that the facemask pulls onto the face and

does not pull away during the 10

seconds.

4.6 CHANGING FROM

FILTER CANISTER TO

AIRLINE

1. Connect the airline to the pigtail

and pull the couplings firmly to check that

the hose is secure.

2. Fit the sealing cap to the filter

canister inlet.

3. Take a sharp breath to activate the

DV and then breathe normally.

4.7 CHANGING FROM

AIRLINE TO FILTER

CANISTER

1. Remove the sealing cap from the

filter canister inlet.

2. Push the CEN coupling together,

pull back the airline collar and disconnect

the airline.

3. Depress the black reset button on

the DV, breathe normally and leave the

hazard area.

Note:

There will be a noticeable increase in

breathing resistance after the reset button

has been pressed.

Page 15

FLITE

11

4.8 CHANGING FROM

AIRLINE TO CYLINDER

1. Check the cylinder gauge to ensure

that there is sufficient air and open the

cylinder valve.

2. Push the CEN coupling together,

pull back the airline collar, disconnect the

airline and leave the hazard area.

4.9 CHANGING FROM

CYLINDER TO AIRLINE

1. Connect the airline to the pigtail

and close the cylinder valve.

2. Take a sharp breath to activate the

DV and then breathe normally.

DV Failure: Open the DV bypass if there

is a problem with the DV.

WARNING:

If the cylinder valve is not closed, the

cylinder will empty.

5. DOFFING THE

APPARATUS

WARNING:

DO NOT remove the apparatus until

well clear of the hazard area.

1. Take a deep breath then press the

DV reset button.

2. Release the head harness by

pulling the buckles forward in sequence:

bottom, middle, top. Remove the

facemask.

3. If you have been breathing from the

cylinder, close the cylinder valve.

Page 16

FLITE

12

4. Push the airline couplings together

and pull back the CEN collar to

disconnect the hose from the pigtail.

5. Open the DV bypass to vent any

compressed air from the facemask.

6. Fit the dust cap on the pigtail CEN

coupling.

7. Release the waistbelt and leg strap

and remove the apparatus.

8. Clean and check the apparatus in

accordance with Section 6: Cleaning and

Scheduled Maintenance before returning

it to service.

6. CLEANING AND

SCHEDULED

MAINTENANCE

6.1 FACEMASK

CAUTION:

DO NOT allow water to enter the

Demand Valve. Fit the yellow DV

dust cap.

Use ONLY specified substances

and methods to clean the

apparatus.

DRY thoroughly before storage.

1. Pull the DV red release catch and

disconnect the DV.

2. Wash the facemask in a hand-hot

solution of DistelTM and water.

3. Rinse the mask thoroughly in clean

running water, paying particular attention

to the exhale valve.

4. Dry the mask thoroughly at room

temperature. DO NOT expose to high

temperatures or direct sunlight.

5. When dry, wipe the facemask seal

with DistelTM disinfectant wipes.

6. Check that the inhale valve flaps

are not damaged or distorted.

7. Replace Visorguard (Article

Number 1031836).

8. When the mask is dry: polish the

visor with a soft, clean, lint-free cloth and

replace the Visorguard. Slacken the

head harness ready for use.

Page 17

FLITE

13

6.2 DEMAND VALVE

1. Fit the yellow DV dustcap (Article

Number 1033545) over the DV inlet,

immerse the bypass knob in running

water and operate the bypass knob

several times.

2. Clean the outer surfaces with a

clean, lint-free cloth. Persistent marks can

be removed with a clean, lint-free cloth

moistened with a solution of DistelTM and

warm water.

3. Check that both the locking catch

and bypass knob move freely. If either

does not move freely, the DV must be

serviced.

6.3 BANDOLIER

1. Brush dirt from the bandolier using

a stiff brush.

2. If heavily soiled, the bandolier can

be soaked in a solution of DistelTM and

warm water for one hour and then

scrubbed with a stiff brush.

3. Dry the bandolier thoroughly in a

well-ventilated room away from direct

heat and sunlight.

6.4 REDUCER, GAUGE AND

CYLINDER

1. Dust the exterior of the equipment

with a clean lint-free cloth.

2. Use a lint-free cloth moistened in

DistelTM to clean off persistent marks.

Note:

DistelTM cleansing and disinfecting

solution is available from Scott Safety in

both 1 litre and 5 litre containers under

Article Numbers 2008247 and 2008248

respectively.

Suitable pump dispensers are also

available under Article Numbers 1017672

(1 litre) and 1017670 (5 litres).

DistelTM disinfecting wipes are available

from Scott Safety in packs of 20 sachets,

(Article Number 2004225), or drums of

100 wipes, (Article Number 1017652).

6.5 CHECK APPARATUS

1. Check the apparatus thoroughly for

signs of damage and wear. If any of the

components are damaged, the apparatus

must be returned, with an explanatory

note, for servicing.

2. Check that the cylinder valve

handwheel turns smoothly and does not

stick.

3. Check that the cylinder is full. If it is

not, withdraw FLITE from service and

recharge the cylinder.

6.6 DEMAND VALVE

1. Operate the locking catch several

times to check that it does not stick. The

locking catch should spring back to its

original position without sticking.

Page 18

FLITE

14

2. Operate the bypass knob several

times and check that it does not stick and

when it is released, always rests in the

ON or OFF position.

3. Check that the DV O-ring is in good

condition.

4. Perform the pre-use tests to ensure

that the apparatus is fully operational.

Should an apparatus fail the pre-use

tests, it must only be serviced by trained

personnel who hold a current certificate

for servicing FLITE.

5. The apparatus can now be returned

for use or storage.

6.7 RECORD DETAILS OF

CHECKS

In the United Kingdom it is a statutory

requirement of both the Control of

Substances Hazardous to Health

(CoSHH) regulations and the Personal

Protective Equipment (PPE) directive,

that a Logbook is maintained for each

apparatus. The Logbook should record

the results of Apparatus Checks (as

described above) and all other service

procedures or repairs. The Logbook must

be available for examination at all times.

A Breathing Apparatus Logbook, (Article

Number 1034745), is available from

Scott Safety for this purpose.

The logbook should contain:

Name and address of the employer

responsible for the apparatus.

Name and signature, or unique

authentication, of the person

conducting the test.

Manufacturer, model and serial

number of the equipment, together

with details of any other

distinguishing features or markings

that aid identification.

Condition of the equipment and

details of any faults found during

the tests, including details of any

remedial action taken.

Air pressure within the cylinder.

The quantity of flow and quality of

air supplied by any airline system

or systems used with the

apparatus.

Types of test conducted.

Date of the test.

6.8 STORAGE

Device must be protected from damage

during transportation.

After use, store in a cool, clean, dry

environment away from excessive heat or

sunlight.

6.9 MONTHLY MAINTENANCE

1. The apparatus must be checked

monthly in accordance with the

instructions in this manual for Pre-use

Checks.

2. Details of these tests must be

recorded in the appropriate register and

retained for future reference.

In the United Kingdom, monthly testing is

a statutory requirement of the Control of

Substances Hazardous to Health

(CoSHH) regulations and the Personal

Protective Equipment (PPE) directive.

6.10 ANNUAL MAINTENANCE

1. The apparatus must be tested and

serviced in accordance with the FLITE

Service Schedule within a maximum

period of one year.

2. Full details of this testing and

servicing can be found in the FLITE

Service Manual, which may only be

obtained from Training and Technical

Support Services at Scott Safety upon

completion of formal apparatus

maintenance training.

3. If the apparatus is used frequently it

may be necessary to replace components

on a more frequent basis than stipulated.

Page 19

Page 20

www.scottsafety.com

scott.sales.uk@tycoint.com

Tel: +44 (0) 1695 711711

Fax: +44 (0) 1695 711775

Scott Safety

Pimbo Road, West Pimbo,

Skelmersdale, Lancashire,

WN8 9RA, England

© 2011 Scott Safety. All

rights reserved. SCOTT,

the SCOTT SAFETY Logo,

Scott Health and Safety,

Flite are registered and/or

unregistered marks of Scott

Technologies, Inc. or its

afliates.

English (GB)

Loading...

Loading...