Page 1

SCOTT EAGLE ATTACK

THERMAL IMAGING CAMERA

AND CHARGING SYSTEM

OPERATING AND MAINTENANCE INSTRUCTIONS

WARNING

USE OF THIS THERMAL IMAGING CAMERA MUST BE PART OF A COMPLETE

TRAINING PROGRAM. INTERPRETATION OF THE THERMAL IMAGE REQUIRES

TRAINING AND EXPERIENCE. DO NOT USE THE EAGLE ATTACK THERMAL

IMAGING CAMERA IF YOU HAVE NOT BEEN THOROUGHLY TRAINED IN ITS

USE AND OPERATION. USE OF THIS DEVICE WITHOUT PROPER TRAINING AND

UNDERSTANDING OF ITS OPERATION MAY CAUSE ERRORS IN JUDGEMENT

BASED ON MISINTERPRETATION OF THERMAL IMAGING INFORMATION

WHICH MAY RESULT IN SERIOUS INJURY OR DEATH.

© 2012 Scott Safety.

SCOTT, the SCOTT SAFETY Logo, Scott Health and Safety, and EAGLE ATTACK are registered

and/or unregistered marks of Scott Technologies, Inc. or its afliates.

Page 2

Page 3

P/N 595224-01 Rev E 7/12Page 1 of 32

CONTENTS

DESCRIPTION ..................................................................................... 2

OPTIONS / ACCESSORIES ................................................................ 4

OPERATIONAL ENVIRONMENT ........................................................ 4

PERFORMANCE PARAMETERS ........................................................ 4

RADIO FREQUENCY INTERFERENCE (RFI) ....................................5

THEORY OF OPERATION ................................................................... 6

BATTERY CHARGING SYSTEM ......................................................... 8

BATTERY SAFETY WITH THE LITHIUM-ION BATTERY PACK ........ 9

USE OF THE CHARGING SYSTEM ..................................................10

BATTERY INSTALLATION ...............................................................12

USING THE EAGLE ATTACK THERMAL IMAGING CAMERA ........14

THE DISPLAY SCREEN ....................................................................17

TEMPERATURE INDICATOR ............................................................ 18

THERMAL VIDEO RECORDER OPTION ..........................................20

RECORDING VIDEO .....................................................................21

SAVING THE VIDEO FILES ........................................................... 22

VIEWING OR EDITING VIDEO FILES ...........................................23

FLASHLIGHT ACCESSORY ............................................................. 24

LANYARD ACCESSORY ................................................................... 24

INSTALLATION OF THE CHARGING SYSTEM

IN A VEHICLE ....................................................................................25

REGULAR INSPECTION ................................................................... 26

MAINTENANCE ................................................................................. 27

CLEANING ......................................................................................... 27

STORAGE .......................................................................................... 27

REPLACEMENT PARTS ................................................................... 28

BATTERY BRACKET AND CLIP ................................................... 28

LENS BOOT ...................................................................................29

DISPLAY BOOT ............................................................................. 29

LENS REPLACEMENT ..................................................................30

LIMITED WARRANTY ........................................................................32

EAGLE ATTACK THERMAL IMAGING CAMERA

OPERATING AND MAINTENANCE INSTRUCTIONS

Page 4

P/N 595224-01 Rev E 7/12Page 2 of 32

DESCRIPTION

The SCOTT EAGLE ATTACK Thermal Imaging Camera is a lightweight, highly durable

infrared imaging device that can provide vision enhancement in re ghting and similar

emergency response activities. It is a rugged hand held unit with simple controls that

uses highly sensitive technology capable of recognizing small differences in temperature.

The EAGLE ATTACK Thermal Imaging Camera “sees” temperature differences (infrared

radiation) rather than visible light. The camera is available in two versions:

– The GRAYSCALE mode display version shows only shades of gray from black to

white. Warmer objects appear on the display screen as lighter gray to white images

while cooler objects appear darker gray to black. The EAGLE ATTACK Thermal

Imaging Camera operates in two temperature ranges, a Lower and an Upper range.

When viewing hotter objects at temperatures above approximately 200 °F / 93 °C,

the EI icon will appear in the display indicating that the Upper range is in operation.

– The TAC (Temperature Awareness Colorization) mode version displays shades

of gray the same as the GRAYSCALE mode, but objects or areas at elevated

temperatures appear as colors. This version may be an aid in helping re ghters

nd sources of extreme heat. The approximate temperatures at which the colors

appear are as follows:

200 °F to 500 °F (93 °C to 260 °C) – shades of Yellow

501 °F to 800 °F (261 °C to 426 °C) – shades of Orange

801 °F to 1200 °F (427 °C to 649 °C) – shades of Red

The power controls consist of one glove accessible POWER button just below the display

screen which controls power ON/OFF. The display provides information including battery status and over temperature warning. A digital temperature indicator on the display

screen gives the approximate temperature of the target area at the center of the display.

The temperature is determined by an average of points within the target area. The temperature indicator is available from the factory as either degrees Fahrenheit or Celsius.

The Lithium-ion (Li-Ion) battery is capable of powering the unit approximately 5 hours

(3.5 hours with TVR). A battery power gauge appearing in the display is standard. The

EAGLE ATTACK Charging System holds the camera and charges both the battery

installed in the camera as well as a second spare battery. The battery charger may be

used on a desk top or may be mounted on the wall or in a vehicle. For vehicle mounting,

the charger may be powered by a 12 volt adapter or may be hard wired into the vehicle

with either 12 or 24 volt supply. In addition, two charging stations may be wired together

and powered from a single AC adapter or up to three units may be wired together if using

the 12 VDC adapter or 12 or 24 VDC source power from a vehicle.

The EAGLE ATTACK Thermal Imaging Camera is available with a black housing with

a choice of outer boots in bright RED, BLACK, YELLOW, or ORANGE.

WARNING

THERMAL IMAGING CAMERAS HAVE UNIQUE OPERATING CHARACTERISTICS.

THEY ARE NOT NIGHT VISION CAMERAS. THE THERMAL IMAGE REPRESENTS

THE RELATIVE TEMPERATURES OF OBJECTS AND DOES NOT DEPICT WHAT

THE HUMAN EYE NORMALLY SEES. INTERPRETATION OF THE THERMAL IMAGE

REQUIRES TRAINING AND EXPERIENCE. DO NOT USE THE EAGLE ATTACK

THERMAL IMAGING CAMERA IF YOU HAVE NOT BEEN THOROUGHLY TRAINED IN

ITS USE AND OPERATION. DO NOT USE THE EAGLE ATTACK THERMAL IMAGING

CAMERA IF IT STOPS OPERATING OR OPERATES INCORRECTLY. USE OF THIS

DEVICE WITHOUT PROPER TRAINING AND UNDERSTANDING OF ITS OPERATION

MAY CAUSE ERRORS IN JUDGMENT BASED ON MISINTERPRETATION OF THERMAL

IMAGING INFORMATION WHICH MAY RESULT IN SERIOUS INJURY OR DEATH.

Page 5

P/N 595224-01 Rev E 7/12Page 3 of 32

WARNING

READ AND UNDERSTAND THIS ENTIRE MANUAL. TRAINING IS REQUIRED BEFORE

USE OF THIS EQUIPMENT IN A HAZARDOUS SITUATION. THE TRAINING MUST

INCLUDE EXTENSIVE PRACTICE WITH THE THERMAL IMAGING CAMERA IN A

VARIETY OF ENVIRONMENTS AND A COMPLETE UNDERSTANDING OF HOW TO

INTERPRET THE THERMAL IMAGE. BECAUSE DIFFERENT BRANDS AND MODELS

OF THERMAL IMAGING CAMERAS MAY OPERATE DIFFERENTLY, ALWAYS UPDATE

TRAINING WITH EACH NEW PIECE OF EQUIPMENT. USE OF A THERMAL IMAGING

CAMERA WITHOUT PROPER TRAINING MAY PLACE THE USER AT HIGHER RISK IN

DANGEROUS SITUATIONS WHICH COULD RESULT IN SERIOUS INJURY OR DEATH.

WARNING

NEVER BECOME WHOLLY DEPENDENT ON THE EAGLE ATTACK THERMAL IMAGING

CAMERA FOR PERSONAL NAVIGATION. IT IS NOT A NIGHT VISION CAMERA. ALWAYS

MAINTAIN AWARENESS OF LOCATION AND ESCAPE ROUTES WHEN USING THIS

DEVICE. FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY OR DEATH.

The EAGLE ATTACK Thermal Imaging Camera may be equipped with an optional built-

in Thermal Video Recorder that records up to 250 minutes of continuous video from the

camera display. This video can be downloaded to a standard Personal Computer (PC)

using a USB 2.0 cable, SCOTT P/N 31002216, and Power Supply, SCOTT P/N 31002284.

An optional heavy duty three foot long retractable lanyard is available. An optional glare

shield and rail-mount ash light are also available.

The lens is covered by a replaceable high impact cover that is chemical, water, and

heat resistant.

An optional Glare Shield version of the Display Boot is available.

Instructions for all optional features are contained in this manual.

Use and maintenance of this instrument must be part of a complete thermal imaging

camera training program. The following procedures shall be used to operate and maintain

the unit prepared for emergency use. The unit shall be inspected after each use. There

are no user serviceable parts inside the camera except as outlined in this instruction. If

any malfunction is noted, remove the unit from service and return to SCOTT Safety or

an authorized SCOTT Safety Service Center for repair.

The EAGLE ATTACK Thermal Imaging Camera is not a night vision camera. Although

this device can signicantly enhance vision in certain situations, the user must never

become wholly dependent on the unit for personal navigation. Always maintain awareness of location and escape routes when using this device.

Do not use the EAGLE ATTACK Thermal Imaging Camera in situations where a

dedicated infrared thermometer, a pyrometer, or a radiometer is required.

QUESTIONS OR CONCERNS

If you have any questions or concerns regarding use of this equipment, contact your

authorized SCOTT distributor, or contact SCOTT at 1-800-247-7257 (or 704-291-8300

outside the continental United States) or visit our web site at www.scottsafety.com.

EXPORT AND IMPORT

The international transport of this equipment and portions thereof is regulated under

United States export regulations and may be regulated by the import regulations of other

countries. If you have any questions or concerns regarding these regulations, contact

SCOTT at 1-800-247-7257 (or 704-291-8300 outside the continental United States).

Page 6

P/N 595224-01 Rev E 7/12Page 4 of 32

OPERATIONAL ENVIRONMENT

The EAGLE ATTACK Thermal Imaging Camera is designed to operate within an internal

core temperature range of -40 °F to +158 °F / -40 °C to +70 °C. The camera housing

is water resistant. The housing is made of impact resistant thermoplastic. The internal

electronics are isolated to withstand vibration and impact.

PERFORMANCE PARAMETERS

Sensitivity Distance

The EAGLE ATTACK Thermal Imaging Camera will focus on objects from three feet

to innity.

Environmental Conditions

The EAGLE ATTACK Thermal Imaging Camera enclosure is tested to the applicable

international standards and complies with the requirements of protection IP66/IP67 for

dust and water ingress.

Over Temperature Protection

If the core temperature of the camera reaches 160 °F / 71 °C, the EAGLE ATTACK

Thermal Imaging Camera will alert the user with a OVER TEMP warning in the upper

middle of the display screen. This warning indicates that camera performance will

begin to degrade and the unit may shut down until the core temperature drops below

158 °F / 70 °C.

Battery Life

A battery gauge in the display is standard. When the battery has at least ten minutes

of its life remaining, LOW BAT will appear below the battery level symbol in the display.

The camera will continue to operate while battery life remains, however replacing the

battery with a fully charged one when the LOW BAT appears assures continued operation

of the camera.

OPTIONS

TEMPERATURE INDICATOR AS EITHER F° or C°

The TEMPERATURE INDICATOR provides a small target area in the center of the

display screen and a digital readout of the approximate temperature of the object

contained by the target area. The temperature is determined by an average of points

within the target area. The digital readout is available from the factory as either degrees

Fahrenheit (F°) or degrees Celsius (C°).

EXTENDED WARRANTY

Additional Extended Warranty Plans are available at time of camera purchase.

ACCESSORIES

FLASHLIGHT ACCESSORY

An external ashlight accessory is available. The STREAMLIGHT TLR-11 ashlight

mounts on a Picatinny rail (MIL-STD-1913) on the top of the camera housing.

1

STREAMLIGHT and TLR-1 are registered trademarks of Streamlight, Inc., Eaglesville, PA.

Page 7

P/N 595224-01 Rev E 7/12Page 5 of 32

RADIO FREQUENCY INTERFERENCE (RFI)

The EAGLE ATTACK Thermal Imaging Camera may be susceptible to Radio Frequency

Interference (RFI) from a two-way radio or other radio frequency source. If the image in

the display screen appears distorted or unclear, it may be caused by a nearby powerful

source of radio frequency or by a two-way radio in close proximity. Move away from any

nearby powerful source of radio frequency. Please hold your hand-held two-way radio

away from the camera when transmitting.

WARNING

THE EAGLE ATTACK THERMAL IMAGING CAMERA IS A BATTERY OPERATED

ELECTRICAL DEVICE THAT HAS NOT BEEN EVALUATED FOR INTRINSIC SAFETY

AS AN IGNITION SOURCE. THIS DEVICE IS NOT TO BE USED IN A POTENTIALLY

EXPLOSIVE ATMOSPHERE. USE OF THE EAGLE ATTACK THERMAL IMAGING

CAMERA IN A FLAMMABLE OR EXPLOSIVE ATMOSPHERE MAY RESULT IN IGNITION

OF THE ATMOSPHERE RESULTING IN SERIOUS INJURY OR DEATH.

Page 8

P/N 595224-01 Rev E 7/12Page 6 of 32

THEORY OF OPERATION

Thermal imaging cameras only show temperature differences between objects and

not an optical image of the objects. Experience and training are required to correctly

interpret the thermal image.

WARNING

THIS IS NOT, NOR IS IT INTENDED TO BE, AN EXHAUSTIVE LIST OF THE

BEHAVIORS OF INFRARED ENERGY THAT DIFFER FROM VISIBLE LIGHT. USE OF

THIS THERMAL IMAGING CAMERA MUST BE PART OF A COMPLETE TRAINING

PROGRAM. INTERPRETATION OF THE THERMAL IMAGE REQUIRES TRAINING

AND EXPERIENCE. DO NOT USE THERMAL IMAGING CAMERA IF YOU HAVE NOT

BEEN THOROUGHLY TRAINED IN ITS USE AND OPERATION. USE OF THIS DEVICE

WITHOUT PROPER TRAINING AND UNDERSTANDING OF ITS OPERATION MAY

CAUSE ERRORS IN JUDGEMENT BASED ON MISINTERPRETATION OF THERMAL

IMAGING INFORMATION WHICH MAY RESULT IN SERIOUS INJURY OR DEATH.

Interpretation of the thermal image depends on a variety of issues including, but not

limited to the following:

• The thermal imaging camera cannot see through walls. A source of heat behind a

wall will not be evident if it does not heat the wall itself.

• The heat from some high temperature objects or sources of high heat may be

blocked, obscured, or made less distinct in the thermal image display by any of the

following:

– Water mist, spray, or highly saturated fog

– Some chemical substances in a concentrated cloud or vapor

– Extremely dense smoke

– Heated smoke or a layer of heated gases

These are some other circumstances which could result in misinterpretation:

• If a concrete oor and a hole in that oor have the same temperature, there will be

no apparent difference in the thermal image display to indicate the presence of the

hole.

• Visually transparent or reective materials such as glass, shiny plastic, or water

can reect infrared radiation from an actual source of high temperature. The user

must be able to distinguish and identify when the image in the display could be a

reection and not the actual source of high temperature. For example:

– When viewing a window or other shiny surface at an angle, a source of high

temperature reected in the surface will be at some angle opposite and away

from the apparent location.

– When viewing a source of high temperature through a clear window with a ther-

mal imaging camera, the camera display will only show a reection of the user

holding the camera and not the source of high temperature behind the window.

– When viewing a hole lled with water, the thermal imaging camera display will

show a reection of any heat sources above and away from the water surface.

• Molten or boiling substances will appear hot in the thermal image display, but it may

be difcult to identify their physical nature and the hazards they present based on

the thermal image alone.

Page 9

P/N 595224-01 Rev E 7/12Page 7 of 32

Keep the lens clean while operating the thermal imaging camera.

• Dirt or soot build up on the lens will obscure or reduce the clarity of the thermal

image. Wipe the lens with a glove or cloth as needed. Clean the lens thoroughly

after use.

• Condensation on the lens of the thermal imaging camera will also block the thermal

image and make entire display appear blank. Wipe the lens regularly to remove

accumulated condensation. Use an approved anti-fog preparation on the lens

to reduce the possibility of condensation on the lens.

SEE THE WARNINGS ON PAGES TWO AND THREE OF THIS INSTRUCTION

Page 10

P/N 595224-01 Rev E 7/12Page 8 of 32

WARNING

THE BATTERY CAN EXPLODE, LEAK, OR CATCH ON FIRE IF DIRECTLY EXPOSED

TO HIGH TEMPERATURE, WATER, OR FIRE, OF IF OPENED, DISASSEMBLED, OR

TAMPERED WITH. FAILURE TO HANDLE THE BATTERY PROPERLY MAY RESULT

IN SERIOUS INJURY.

BATTERY CHARGING SYSTEM

The EAGLE ATTACK Charging System provides a secure camera storage and recharging station for the SCOTT EAGLE ATTACK Thermal Imaging Camera. The Charging

System consists of a camera charger assembly which holds a camera with battery and

has an additional bay to charge a spare battery. Reversible hold down straps hold the

camera and battery in place while charging. The charger assembly can be placed at

on a desk or may be mounted horizontally or vertically. When properly installed in a

vehicle, the Charging System will securely hold an EAGLE ATTACK Thermal Imaging

Camera and spare battery to withstand the forces required of such installations. Refer

to the INSTALLATION OF THE EAGLE ATTACK CHARGING SYSTEM IN A VEHICLE

section of this instruction for details.

The Charging System can be powered only with one of the following:

• 100–240 VAC Power Converter (SCOTT P/N 31000366)

• 12 VDC Adapter Cable (SCOTT P/N 40014635)

• 12 or 24 VDC wired directly into the base of the charger.

When using the Power Converter or Adapter Cable, always connect to the charger rst

before plugging into the power source.

WARNING

THE CHARGING SYSTEM FOR THE EAGLE ATTACK THERMAL IMAGING CAMERA

IS AN ELECTRICAL DEVICE THAT HAS NOT BEEN EVALUATED FOR INTRINSIC

SAFETY AS AN IGNITION SOURCE. THIS DEVICE IS NOT TO BE USED IN A

POTENTIALLY EXPLOSIVE ATMOSPHERE. USE OF THE CHARGING SYSTEM FOR

THE EAGLE ATTACK THERMAL IMAGING CAMERA IN A FLAMMABLE OR EXPLOSIVE

ATMOSPHERE MAY RESULT IN IGNITION OF THE ATMOSPHERE RESULTING IN

SERIOUS INJURY OR DEATH.

CAUTION

SOME POWER SOURCES ON VEHICLES ARE NOT ACTIVE ALL THE TIME. BE SURE

THAT THE POWER SOURCE CHOSEN WILL PROVIDE THE NECESSARY POWER

FOR THE TIME REQUIRED TO RECHARGE A BATTERY. THE CHARGING SYSTEM

WILL NOT RECHARGE A BATTERY IF THE POWER SOURCE TO THE CHARGER

IS NOT ACTIVE. CONSULT THE BUILDER OF YOUR VEHICLE IF YOU HAVE ANY

QUESTIONS ABOUT ITS AVAILABLE POWER SOURCES BEFORE INSTALLING THE

CHARGING SYSTEM.

Page 11

P/N 595224-01 Rev E 7/12Page 9 of 32

BATTERY SAFETY WITH THE LI-ION BATTERY PACK

HANDLING

• Use care when handling the lithium-ion battery pack used with the EAGLE ATTACK

Thermal Imaging Camera.

• Always inspect batteries before use. The electrolyte contained within the lithium-ion

cells can cause severe irritation to the respiratory tract, eyes and skin. A ruptured

battery cell can vent hazardous air contaminants, including corrosive or ammable

vapors. All precautions should be taken to limit exposure to the electrolyte vapor.

If the battery has a damaged or broken battery housing, remove the battery from

service and tag for proper disposal and replacement.

• Never try to open or service a battery pack. There are no user serviceable parts

in the battery pack.

• Dispose of depleted or damaged batteries in accordance with federal, state, and

local environmental regulations.

• If the contacts of the battery are ever shorted by contact with something metal, an

internal circuit breaker will open making the battery inoperative. Simply place the

battery in the charger and charge to reset the circuit breaker and return the battery

to service.

CAUTION

IF THE CONTACTS OF THE BATTERY ARE EVER SHORTED BY CONTACT WITH

SOMETHING METAL, AN INTERNAL CIRCUIT BREAKER WILL OPEN MAKING THE

BATTERY INOPERATIVE. SIMPLY PLACE THE BATTERY IN THE CHARGER AND

CHARGE TO RESET THE CIRCUIT BREAKER AND RETURN THE BATTERY TO

SERVICE.

SHIPPING

• Shipping restrictions may apply to the lithium-ion batteries used with the EAGLE

ATTACK Thermal Imaging Camera. For DOT purposes, the battery pack used is

considered a Small size secondary (rechargeable) battery.

• Follow the appropriate regulations for shipment. Package batteries securely. Weight

limits apply to batteries and to batteries with equipment for passenger and/or cargo

aircraft. Pursuant to 49 CFR 173.185, all shipments of hazardous materials must

comply with packaging regulations based on the recommendations made by the

United Nations. There can be substantial nes and penalties for non-compliance.

CHARGING

• Before using the EAGLE ATTACK Thermal Imaging Camera, charge the battery

according to the USE OF THE CHARGING SYSTEM section of this instruction. A

battery may be charged either attached to the camera, or in the extra battery bay

on the charger.

• Leaving a battery in the charger after it is fully charged will not harm the battery.

• Although the camera is intended to operate in potentially severe environments, avoid

storing or charging the battery in extremes of temperature, hot or cold. Charge and/

or store the battery pack in a dry location at normal room temperature (no more than

77°F/ 25°C). It takes a longer time to charge the battery in cold temperatures. And

storing or charging the battery in high temperatures can degrade the battery.

• Through repeated use and recharging, a battery will eventually break down and

may not provide the duration of service it did when it was new.

Page 12

P/N 595224-01 Rev E 7/12Page 10 of 32

USE OF THE CHARGING SYSTEM

The EAGLE ATTACK Thermal Imaging Camera may be used only with the approved Li-Ion

Battery, SCOTT P/N 200848-01). The battery charger for the EAGLE ATTACK Thermal

Imaging Camera can charge two batteries at once: one installed on a camera and a second

battery in the additional charging bay. The charger may be placed on a table, mounted on a

wall, or mounted in a vehicle (see the INSTALLATION OF THE EAGLE ATTACK CHARGER

SYSTEM IN A VEHICLE section of this instruction for details). The hold down straps are

reversible to attach on either the left or the right to accommodate most mounting situations.

Always connect the power converter cable to the charger rst before plugging the converter

into the power source.

Before attempting to charge a battery, verify that the charger is connected to a suitable

power supply (see FIGURE 2):

• the 100–240 VAC Power Converter or

• the 12 VDC Adapter Cable or

• hard wired into a vehicle 12 or 24 VDC system (see the INSTALLATION OF THE

EAGLE ATTACK CHARGER SYSTEM IN A VEHICLE section of this instruction for

details).

FIGURE 1

LENS

CRADLE

To charge the battery installed on an EAGLE

ATTACK Thermal Imaging Camera, proceed

as follows:

1. Inspect the three battery charging contacts

on the charger assembly. The contacts

must be clean, straight, and undamaged.

2. Inspect the three external battery terminals

on the camera battery. The terminals must

be clean and undamaged.

3. Verify that the camera is OFF before plac-

ing the camera in the charger.

6. The charger light will ash GREEN to in-

dicate that the Battery Pack in the camera

is charging. See FIGURE 2.

7. When the battery is charged, the charger

light will change to solid GREEN. A battery

will require approximately 2 hours for a

FULL charge. After each use of the camera,

the battery should be recharged.

8. To release the hold down strap, pull the

strap end DOWN and AWAY from the base

to unhook the pin from the two strap hooks.

9. If the light on the charger base FLASHES

RED as soon as a EAGLE ATTACK Ther-

mal Imaging Camera is placed in the charger assembly, it indicates a defect in the

battery. REMOVE THE BATTERY FROM SERVICE AND DISPOSE OF ACCORDING

TO FEDERAL, STATE, AND LOCAL REGULATIONS.

4. Hold the camera as shown in FIGURE 1, with the display toward you, and slide the lens

boot into the lens cradle. When the lens boot is fully seated in the cradle, the battery ter-

minals will align with the charging contacts in the charger assembly.

5. Push the camera handle down fully into the charger assembly until the battery terminals

t against the charging contacts on the charger assembly. Secure with the hold down

strap by stretching the strap over the battery and tting the pin in the strap under the two

strap hooks.

FIGURE 2

CHARGING

LIGHT

12 VDC SUPPLY

FROM THE POWER

CONVERTER OR

ADAPTER CABLE

Page 13

P/N 595224-01 Rev E 7/12Page 11 of 32

Regularly inspect the EAGLE ATTACK CHARGING SYSTEM for worn or

damaged components.

– Verify that all fasteners and mounting hardware are present and tight.

– Check all battery contacts. The contacts must be clean and straight

– Check housing cradle and base for cracks or other damage

– Check the two (2) hold down straps or tears or cracks in the buckle which might

cause a failure of the strap.

If any loose, worn, or damaged components are found, remove the EAGLE ATTACK

CHARGING SYSTEM from service and tag for repair by authorized personnel.

REGULAR INSPECTION

4. Hold the battery in place and secure with the hold down strap by stretching the strap over

the battery and tting the pin in the strap under the two strap hooks.

5. The charger light will ash GREEN to indicate that the spare battery is charging. See

FIGURE 4.

6. When the battery is charged, the charger light will change to solid GREEN. A battery will

require approximately 2 hours for a FULL charge. After each use of the camera, the battery

should be recharged.

7. To release the hold down strap, pull the strap end DOWN and AWAY from the base to

unhook the pin from the two strap hooks.

8. If the light on the charger base FLASHES RED as soon as a EAGLE ATTACK Thermal

Imaging Camera is placed in the charger assembly, it indicates a defect in the battery.

REMOVE THE BATTERY FROM SERVICE AND DISPOSE OF ACCORDING TO

FEDERAL, STATE, AND LOCAL REGULATIONS.

To charge a spare battery, proceed as follows:

1. Inspect the three battery charging contacts on the charger assembly. The contacts must

be clean, straight, and undamaged.

2. Inspect the three external battery terminals on the spare battery. The terminals must be

clean and undamaged.

3. Hold the battery as shown in FIGURE 3, with the battery terminals aligned with the

charging contacts.

CHARGING

LIGHT

BATTERY FITS ONLY ONE WAY

FIGURE 3 FIGURE 4

CAUTION

REGULARLY INSPECT THE EAGLE ATTACK CHARGING SYSTEM FOR LOOSE,

WORN, OR DAMAGED COMPONENTS. IF ANY DAMAGE IS FOUND, REMOVE THE

UNIT FROM SERVICE AND TAG FOR REPAIR BY AUTHORIZED PERSONNEL.

Page 14

P/N 595224-01 Rev E 7/12Page 12 of 32

BATTERY INSTALLATION

A single specially designed Rechargeable Battery Pack is used for operation of the

EAGLE ATTACK Thermal Imaging Camera. Install the battery as follows:

1. Loosen the nger screw on the bottom of the camera handle by turning it counter-

clockwise.

2. When the screw is loose, angle the battery away from the handle and disengage

the clip on the battery from the slotted bracket on the handle.

3. Verify that Rechargeable Battery Pack is fully charged. See USE OF THE BATTERY

CHARGER section of this instruction.

4. The Rechargeable Battery Pack will only t into the camera handle one way.

Hook the Clip on the battery into the slotted Bracket on the camera handle and

seat the battery against the handle as shown in FIGURE 5. DO NOT FORCE THE

BATTERY IN. If improperly oriented, the battery will not t onto the camera.

FIGURE 5

SLOTTED

BRACKET ON

CAMERA

HANDLE

CLIP ON

BATTERY

Page 15

P/N 595224-01 Rev E 7/12Page 13 of 32

5. Thread the nger screw clockwise onto the top of the battery. Turn the screw

until it is snug. DO NOT OVER TIGHTEN. DO NOT USE ANY TOOL TO TIGHTEN

THE FINGER SCREW. Over tightening may damage the threads or make battery

changing more difcult. See FIGURE 6.

6. Test the operation of the camera according to the USE OF CAMERA section of this

instruction.

NOTE

THE CAMERA WILL NOT OPERATE IF THE BATTERY IS NOT PROPERLY INSTALLED.

IF THE CAMERA WILL NOT OPERATE OR IF THE BATTERY WILL NOT FIT AS

DESCRIBED, VERIFY THAT THE BATTERY IS PROPERLY ORIENTED AND IS NOT

DAMAGED.

FIGURE 6

FINGER TIGHT

ONLY

Page 16

P/N 595224-01 Rev E 7/12Page 14 of 32

USING THE EAGLE ATTACK THERMAL IMAGING CAMERA

1. Hold the EAGLE ATTACK Thermal Imaging Camera by the handle with the display

side toward you.

2. To turn ON the EAGLE ATTACK Thermal Imaging Camera, press and release the

POWER button below the display. The initialization screen will appear followed by

the thermal image. See FIGURE 7.

3. The EAGLE ATTACK Thermal Imaging Camera “sees” temperature differences

(infrared radiation) rather than visible light. The display screen shows shades of

gray from black to white. Warmer objects appear on the display screen as lighter

gray to white images while cooler objects appear darker gray to black. Compare

FIGURES 8 and 9.

NOTE

WHEN NOT IN USE, POSITION THE CAMERA WITH THE LENS POINTED DOWN

TO REDUCE RISK OF DIRECT EXPOSURE TO THE SUN.

CAUTION

DO NOT POINT THE EAGLE ATTACK THERMAL IMAGING CAMERA DIRECTLY AT THE

SUN. DO NOT POINT THE CAMERA AT HEAT SOURCES IN EXCESS OF 2700 °F / 1500

°C FOR EXTENDED PERIODS OF TIME. DOING SO MAY RESULT IN AN AFTER IMAGE

ON THE DISPLAY THAT COULD CAUSE TEMPORARY REDUCTION IN PERFORMANCE

OF THE CAMERA. IF THIS OCCURS, DO NOT USE UNTIL PERFORMANCE HAS

RETURNED TO NORMAL.

WARNING

BEFORE ENTERING A POTENTIALLY HAZARDOUS SITUATION, TURN ON AND TEST

THE THERMAL IMAGING CAMERA TO CONFIRM IT IS OPERATING PROPERLY.

FAILURE TO CONFIRM THE THERMAL IMAGING CAMERA IS OPERATING PROPERLY

MAY PLACE THE USER AT HIGHER RISK IN DANGEROUS SITUATIONS WHICH COULD

RESULT IN SERIOUS INJURY OR DEATH.

The appearance of the initialization screen will vary depending on the camera ver-

sion and the options installed:

– If the camera is the TAC (Temperature Awareness Colorization) version, a yellow

to orange color bar will appear in the lower left of the display.

– If the camera is equipped with the TVR Thermal Video Recorder option, “WITH

TVR” will appear in the lower right of the display.

Always turn ON and test the EAGLE ATTACK Thermal Imaging Camera before

entering a potentially hazardous situation to conrm it is operating properly.

FIGURE 7

POWER

BUTTON

INITIATION SCREEN SHOWN

WITH BOTH TAC VERSION

AND TVR OPTION

Page 17

P/N 595224-01 Rev E 7/12Page 15 of 32

NOTE

THE IMAGES IN THE DISPLAY SCREEN WILL APPEAR SHARPER WHEN

VIEWING A SCENE WHERE THE OBJECTS HAVE A GREATER TEMPERATURE

DIFFERENTIAL.

FIGURE 8

WHAT THE HUMAN EYE SEES

FIGURE 9

WHAT THE EAGLE ATTACK THERMAL IMAGING CAMERA

SEES

Page 18

P/N 595224-01 Rev E 7/12Page 16 of 32

CAUTION

TURN OFF THE CAMERA WHEN USE IS COMPLETE. DO NOT LEAVE THE EAGLE

ATTACK THERMAL IMAGING CAMERA ON FOR EXTENDED PERIODS WHEN NOT IN

USE. THE BATTERY LIFE WILL CONTINUE TO BE CONSUMED AND WILL REQUIRE

RECHARGING WHEN NEEDED FOR USE.

4. The EAGLE ATTACK Thermal Imaging Camera is available in two versions:

– The GRAYSCALE version display screen shows only shades of gray from black

to white. Warmer objects appear on the display screen as lighter gray to white

images while cooler objects appear darker gray to black. The EAGLE ATTACK

Thermal Imaging Camera operates in two temperature ranges, a Lower and an

Upper range. When viewing hotter objects at temperatures above approximately

200 °F / 93 °C, the EI icon will appear in the display indicating that the Upper

range is in operation.

– The TAC (Temperature Awareness Colorization) mode version displays shades

of gray the same as the GRAYSCALE mode, but objects or areas at elevated

temperatures appear as colors. The approximate temperatures at which the colors

appear are as follows:

200 °F to 500 °F (93 °C to 260 °C) – shades of Yellow

501 °F to 800 °F (261 °C to 426 °C) – shades of Orange

801 °F to 1200 °F (427 °C to 649 °C) – shades of Red

This version may be an aid in helping re ghters nd sources of extreme heat.

In the TAC mode version, as with the GRAYSCALE version, the EI icon will appear

in the upper left corner of the display indicating that the camera has switched into

the Upper temperature range. Refer to the TEMPERATURE INDICATOR section

of this instruction for details.

5. The Display Screen will periodically update the image to assure that the image

remains clear. This will momentarily freeze the image in the display.

6. To turn OFF the EAGLE ATTACK Thermal Imaging Camera, press and hold the

POWER Button for three (3) seconds. The EAGLE ATTACK Thermal Imaging

Camera will turn OFF.

Page 19

P/N 595224-01 Rev E 7/12Page 17 of 32

THE DISPLAY SCREEN

The Display Screen on the EAGLE ATTACK Thermal Imaging Camera provides infor-

mation on the scene being viewed as well as the status of the camera.

• EI ICON (INDICATES TEMPERATURES ABOVE

APPROXIMATELY 200 °F / 93 °C)

• TEMPERATURE INDICATOR

• TEMPERATURE TARGET AREA

• BATTERY STATUS / LOW BATTERY

• CORE OVER TEMPERATURE INDICATOR

FIGURE 10

TEMPERATURE INDICATOR

(DIGITAL °F SHOWN)

BATTERY

STATUS

TEMPERATURE

TARGET AREA

E I ICON

(UPPER TEMP RANGE)

CORE OVER TEMP

INDICATOR

Page 20

P/N 595224-01 Rev E 7/12Page 18 of 32

TEMPERATURE INDICATOR

The TEMPERATURE INDICATOR provides a small target area in the center of the

display screen and a readout of the approximate temperature of the object contained

by the target area. The temperature is determined by an average of points within the

target area. The temperature of the target area appears as numbers in the lower right

of the display screen. The TEMPERATURE INDICATOR is available from the factory

as degrees Fahrenheit or degrees Celsius.

TRAINING IS REQUIRED BEFORE USE. DO NOT use the TEMPERATURE INDICATOR readings as exact measurements. Be aware that different materials and different

surface textures will not register temperature readings in the same way. Use the readings

from the TEMPERATURE INDICATOR only to determine relative temperature differences. Training for this feature must include experience using the TEMPERATURE

INDICATOR in actual incident situations. DO NOT make a critical decision based

solely on a temperature reading.

WARNING

DO NOT USE THE TEMPERATURE INDICATOR READINGS AS EXACT MEASUREMENTS.

DIFFERENT MATERIALS AND SURFACE TEXTURES DO NOT REGISTER

TEMPERATURE READINGS IN THE SAME WAY. USE THE TEMPERATURE READINGS

ONLY TO DETERMINE RELATIVE TEMPERATURE DIFFERENCES. TRAINING FOR

THIS FEATURE MUST INCLUDE EXPERIENCE USING THE TEMPERATURE INDICATOR

IN ACTUAL INCIDENT SITUATIONS. DO NOT MAKE A CRITICAL DECISION BASED

SOLELY ON A TEMPERATURE READING. FAILURE TO CONSIDER ALL FACTORS

WHEN MAKING DECISIONS BASED ON INFORMATION FROM THE THERMAL

IMAGING CAMERA MAY RESULT IN SERIOUS INJURY OR DEATH.

NOTE

WHEN THE EAGLE ATTACK THERMAL IMAGING CAMERA IS POWERED UP, THE

SCREEN WILL DISPLAY THE TEMPERATURE INDICATOR ALL THE TIME.

Positioning the cross-hair target over an object seen in the display will register an

approximate temperature of that object on the display. See FIGURE 11.

Page 21

P/N 595224-01 Rev E 7/12Page 19 of 32

DIGITAL TEMPERATURE INDICATOR

IS SHOWING APPROXIMATELY 211 °F

TRAINING IS REQUIRED BEFORE USE

FIGURE 11

DIGITAL

TEMPERATURE

INDICATOR

Page 22

P/N 595224-01 Rev E 7/12Page 20 of 32

THERMAL VIDEO RECORDER OPTION

The SCOTT EAGLE ATTACK Thermal Camera may be equipped with an optional built

in Thermal Video Recorder (TVR). On TVR equipped cameras, the connector in the

handle base next to the battery connectors is used for TVR output. See FIGURE 12.

FIGURE 12

THERMAL VIDEO RECORDER OUTPUT CONNECTOR

HANDLE

BASE

OUTPUT

CONNECTOR

The TVR feature provides a continuous recording of the thermal images displayed

on the camera display screen while the camera is in use. The MP4 video les can be

downloaded from the camera onto any personal computer USB 2.0 port and viewed

with standard media player software. The video les are date and time stamped as

yymmdd_hhmmss. To download, you must have a Video Adapter Cable, SCOTT P/N

31002216, and AC power Power Supply, SCOTT P/N 31002284, which operates on

100 – 240 VAC, 60 Hz and comes with a set of international plug adapters.

NOTE

THE DATE AND TIME ARE MAINTAINED BY AN INTERNAL BACK-UP BATTERY THAT

IS RECHARGED BY THE MAIN BATTERY. IF THE CAMERA IS LEFT WITH NO MAIN

BATTERY INSTALLED OR WITH A DEAD BATTERY FOR APPROXIMATELY ONE

MONTH, THE INTERNAL BACK-UP BATTERY WILL BECOME DEPLETED. WHEN

THE INTERNAL BATTERY BECOMES DEPLETED, THE DATE AND TIME WILL HAVE

TO BE RESET. CONTACT SCOTT TECHNICAL SUPPORT AT ScottTechSupport@

tycoint.com FOR DETAILS.

Page 23

P/N 595224-01 Rev E 7/12Page 21 of 32

RECORDING VIDEO

The Thermal Video Recorder records up to a maximum of four (4) hours of continuous

video from the camera display. The camera memory stores the video in individual les.

Each le can be a maximum of fteen (15) minutes of video. When the total amount of

recorded video reaches the maximum, the camera will begin recording over the oldest

le, replacing the entire le with the new content.

The camera begins recording automatically approximately 30 seconds after it is turned

ON and continues recording as long as the camera is ON. After the camera is turned

OFF, the unit will continue operating up to one (1) minute to complete writing the current

video le to memory. DO NOT REMOVE THE BATTERY DURING THIS TIME OR THE

FINAL FILE WILL BE LOST.

THERMAL VIDEO RECORDER OPTION

CONTINUED ON NEXT PAGE...

CAUTION

FOLLOW THESE INSTRUCTIONS CAREFULLY TO ASSURE PROPER PROCESSING

OF THE VIDEO FILES. THE CAMERA BEGINS RECORDING AUTOMATICALLY AS

SOON AS IT IS TURNED ON AND CONTINUES RECORDING AS LONG AS THE

CAMERA IS ON AND FOR APPROXIMATELY ONE MINUTE AFTER THE CAMERA IS

TURNED OFF. DO NOT REMOVE THE BATTERY DURING THIS TIME OR THE FINAL

FILE WILL BE LOST.

THERE IS NO WAY TO STOP THE RECORDING EXCEPT TO TURN THE CAMERA

OFF. ALWAYS TURN THE CAMERA OFF WHEN NOT IN USE. THIS WILL CONSERVE

BATTERY LIFE AS WELL AS PREVENT FILLING THE VIDEO MEMORY WITH USELESS

CONTENT AND/OR RECORDING OVER POTENTIALLY VALUABLE CONTENT.

There is no way to stop the recording except to turn the camera OFF. Always turn the

camera OFF when not in use. This will conserve battery life as well as prevent lling

the video memory with useless content and/or recording over potentially valuable

content.

CAUTION

ALWAYS TURN OFF THE CAMERA PROPERLY BEFORE REMOVING THE BATTERY.

FAILURE TO DO SO MAY RESULT IN DAMAGE TO THE INFRARED SENSOR.

SCOTT recommends that the recorded video be downloaded to a computer after each

incident to assure that a back-up copy of recorded events is secured before the camera

begins to record over the oldest le. SCOTT also recommends deleting the les from

the camera after they have been saved to the computer so that the full capacity of video

memory is available the next time the camera is used.

Page 24

P/N 595224-01 Rev E 7/12Page 22 of 32

SAVING THE VIDEO FILES

SCOTT recommends that the recorded video be downloaded after each incident to

assure that a back-up copy of recorded events is secured before the camera begins to

record over the oldest le.

1. Remove the battery according to the BATTERY INSTALLATION section of this

instruction.

2. The Video Adapter Cable, SCOTT P/N 31002216, has three connectors:

a) Connect the Output Connector on

the Camera to the mating connector

on the cable. See FIGURE 13. The

connector ts only one way. Be sure

the six (6) pins and the connector

key align. Thread in nger tight. Use

no tools.

THERMAL VIDEO RECORDER OPTION CONTINUED...

FIGURE 13

VIDEO ADAPTER

CABLE

OUTPUT

CONNECTOR

b) Connect the USB Cable Power sup-

ply, SCOTT P/N 31002284, to the

Adapter Cable. See FIGURE 14.

c) Plug in the power supply into a

suitable AC power (100 – 240

VAC, 60 Hz). The 100–240 VAC

Power Converter comes with a set

of international plug adapters.

THERMAL VIDEO RECORDER

CABLE CONNECTION

FIGURE 14

USB CABLE

POWER SUPPLY

CONNECTION

POWER

CONNECTION

ON ADAPTER CABLE

d) Connect the USB connector to a USB port on your PC.

3. Turn the Camera ON using the POWER button. The initialization screen will appear

followed by the thermal image.

4. It may take up to thirty seconds for the PC to recognize the camera as a device. The

camera will appear as a mass storage device (like another hard drive or a “thumb”

drive) with a drive letter on your PC.

5. Open the drive, “Removable Disk (drive letter:)”, usually by selecting it in the “My

Computer” screen. A window similar to the one shown in FIGURE 15 will appear.

6. Video les will appear on the drive as a list of MP4 les (MPEG-4 Movie) with a

numerical name such as “100510_164533.mp4.” The le name represents the

date and time the le was created. The rst part of the number will be the DATE in

the format YYMMDD. For example, 100510 is May 10, 2010. That is followed by a

six digit number that represents the TIME in the format HHMMSS, as a twenty-four

hour clock. For example, 164533 is 4:45 (PM) and 33 seconds.

Page 25

P/N 595224-01 Rev E 7/12Page 23 of 32

VIEWING OR EDITING VIDEO FILES

1. Files will play with whatever media player is installed on your computer that is set

to play MP4 les. If you do not have a media player installed on your PC, several

free downloads are available including:

a) Microsoft Media Player (www.microsoft.com)

b) Nero (www.nero.com)

c) QuickTime (www.apple.com)

d) Real Player (www.real.com)

2. Individual still pictures can be captured either by using the “Print Screen” function

on your PC (which saves an image of the current screen to your Clipboard), or using a purchased screen capture software.

3. Video les may be edited using any commercially available software for editing

MP4 type video les.

FIGURE 15

VIDEO FILES ON THE CAMERA

NOTE

THE DATE AND TIME ARE FACTORY SET BUT MAY BE ADJUSTED BY THE END

USER. CONTACT SCOTT TECHNICAL SUPPORT AT ScottTechSupport@tycoint.com

FOR DETAILS.

7. Copy the les into a folder on your PC. This can be done by copying the les and

pasting them in the new folder or selecting the les and dragging them into the folder.

8. After saving, the les on the camera may be erased (deleted) from the camera just

as any unlocked les on a computer disk drive. SCOTT recommends deleting the

les from the camera after they have been saved to the computer so that the full

capacity of video memory is available the next time the camera is used.

9. Press and hold the POWER Button for three (3) seconds to turn OFF the EAGLE

ATTACK Thermal Imaging Camera. This should disconnect the removable disk drive,

but follow the procedures for your computer to safely disconnect a removable disk drive.

10. Reinstall a fully charged battery according to the BATTERY INSTALLATION section of

this instruction.

Page 26

P/N 595224-01 Rev E 7/12Page 24 of 32

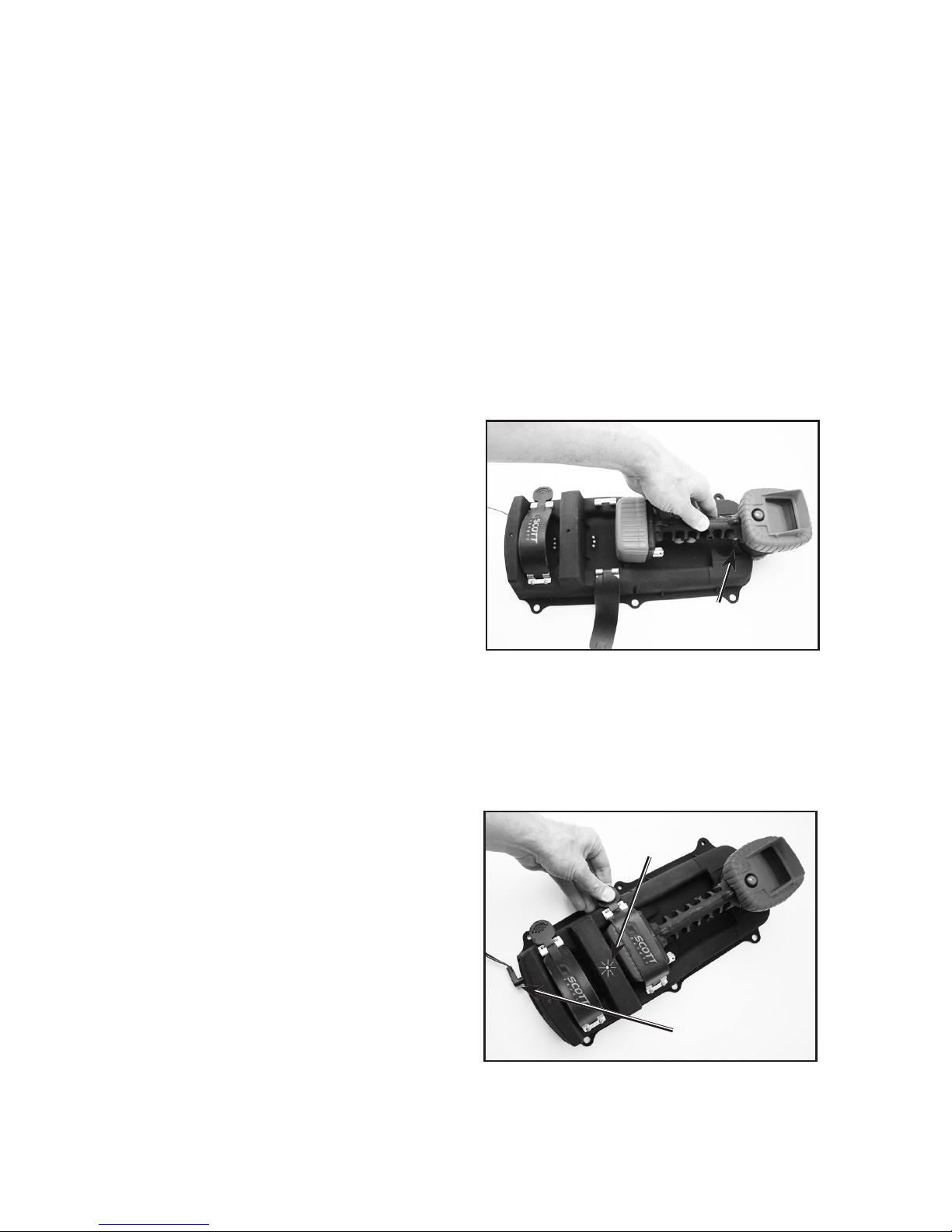

FLASHLIGHT ACCESSORY

An external ashlight accessory is available. The STREAMLIGHT TLR-1 ashlight

mounts on a rail on the top of the camera housing. The ashlight projects a beam of

light in whatever direction the camera is pointed. The ashlight can be removed for

independent operation. The ashlight uses its own battery and is not recharged along

with the camera. The Picatinny mounting rail (MIL-STD-1913) will also accommodate

other accessories. Refer to the User Instructions provided with the ashlight for details

of mounting, use, and maintenance. See FIGURE 16.

LANYARD ACCESSORY

An optional heavy duty three foot long retractable lanyard (P/N 201021-01) is equipped

with a clip on one end. The split ring attachment point may be installed in any of the

three ring loops on the handle. See FIGURE 17.

FIGURE 16

FIGURE 17

SPLIT

RING

RING

LOOPS

Page 27

P/N 595224-01 Rev E 7/12Page 25 of 32

2. Place the charger assembly in the desired position and mark the six mounting holes

through the six (6) mounting tabs on the housing. Use Template P/N 595247-01 provided

with the charger assembly to facilitate proper location of the holes.

3. When installed in a vehicle, the Charging System assembly must be securely mounted

in either a vertical or horizontal position using all six (6) mounting holes provided. Use

six (6) #10 at head machine screws. Recommended torque is 2.5 ft-lbs. or 30 inch-lbs.

NOTE

WHEN MOUNTING TWO OR MORE CHARGERS SIDE-BY-SIDE, THE MOUNTING HOLES

ARE DESIGNED TO OVERLAP AND NEST SO THAT TWO CHARGERS MAY BE MOUNTED

USING NINE (9) SCREWS INSTEAD OF TWELVE (12).

4. The hold down straps are reversible to attach on either the left or the right to accommodate most mounting situations.

5. Power supply considerations:

a) For use with the 100–240 VAC power converter, choose a location for mounting the

assembly where the power source necessary can be reached within the length of the

power supply cord which is approximately six (6) feet. Two chargers can be installed

in series (“daisy-chained”) using the supplied 4 amp power supply. Use only stranded

wire no smaller than AWG 18 gauge and no larger than AWG 14 gauge to connect

the two chargers.

b) When powered by either 12 VDC or 24 VDC supplied from the vehicle, use only stranded

wire no smaller than AWG 18 gauge and no larger than AWG 14 gauge. Use larger

wire for longer runs (over twenty feet). Multiple chargers can be installed in series

(“daisy-chained”) provided the vehicle circuit can support the required electrical draw.

Use the following guidelines to determine the maximum number of chargers that can

be connected in this way:

1 charger Maximum draw of 2 amps at 12 VDC

2 chargers Maximum draw of 4 amps at 12 VDC

3 chargers Maximum draw of 6 amps at 12 VDC

6. All wiring must be secured and must not provide a hazard to tripping or entanglement in

the chosen location. All wiring must be protected to prevent abrasion or other damage.

WARNING

WHEN MOUNTING THE CHARGER ASSEMBLY, SECURE THE ENTIRE LENGTH OF

THE POWER SUPPLY CORD OR WIRING SO IT DOES NOT CAUSE A TRIPPING OR

ENTANGLEMENT HAZARD. PROTECT THE CORD OR WIRING FROM EDGES OR

CORNERS THAT MAY CAUSE IT TO FRAY OVER TIME. FAILURE TO PROPERLY SECURE

THE POWER SUPPLY CORD OR WIRING MAY RESULT IN SERIOUS INJURY OR DEATH.

If you have any questions about installing the Charger assembly, consult a qualied electrician

before proceeding.

1. Choose a suitable location for the Charger Assembly where the assembly will be readily

accessible but will not pose a hazard to occupants of the vehicle. Also, choose a location

where the Charger Assembly will not be exposed to excess moisture.

INSTALLATION OF THE CHARGER SYSTEM IN A VEHICLE

WARNING

WHEN INSTALLING WITHIN A VEHICLE, DO NOT MOUNT THE CHARGER ASSEMBLY

IN A LOCATION WHERE IT MAY PRESENT A HAZARD TO OCCUPANTS OF THE

VEHICLE. TO PREVENT POSSIBLE INJURY IN THE EVENT OF AN ACCIDENT,

MOUNT THE CHARGER ASSEMBLY WITHIN A CLOSED COMPARTMENT ON THE

VEHICLE. FAILURE TO PROPERLY LOCATE AND PROPERLY MOUNT THE CHARGER

ASSEMBLY MAY RESULT IN SERIOUS INJURY.

7. When the charger assembly is connected to power, the light on the charger base will

light in sequence RED-YELLOW-GREEN and then go out.

Page 28

P/N 595224-01 Rev E 7/12Page 26 of 32

CAUTION

REGULARLY INSPECT THE EAGLE ATTACK THERMAL CAMERA AND CHARGING

SYSTEM FOR LOOSE, WORN, OR DAMAGED COMPONENTS. IF ANY DAMAGE IS

FOUND, REMOVE THE UNIT FROM SERVICE AND TAG FOR REPAIR BY AUTHORIZED

PERSONNEL.

REGULAR INSPECTION

Routinely inspect the EAGLE ATTACK Thermal Imaging Camera and Charging System

for signs of wear or damage.

– Check the camera housing, handle, display, and lens for cracks, scratches or other

damage that interferes with the performance of the camera.

– Verify that all fasteners and mounting hardware are present and tight.

– Verify that all rubber boots are present and in good condition with no cuts, tears,

or loose pieces. Verify that the boots are fully installed and properly seated.

– Verify that the battery is undamaged and shows no signs of leakage.

– Check the optional ashlight assembly and bracket for damage.

– Check the optional camera lanyard for weakness or damage.

– Check all battery contacts. The contacts must be clean and undamaged. Spring

loaded contacts must be straight and move without sticking.

If any loose, worn, or damaged components are found, remove the EAGLE ATTACK

Thermal Camera from service and tag for repair by authorized personnel.

Regularly inspect the EAGLE ATTACK CHARGING SYSTEM for worn or damaged

components.

– Verify that all fasteners and mounting hardware are present and tight.

– Check all battery contacts. The contacts must be clean and straight. Spring loaded

contacts must be straight and move without sticking.

– Check housing cradle and base for cracks or other damage

– Check the two (2) hold down straps for tears or cracks which might cause a failure

of the strap.

– Verify that all electrical connections are secure and properly protected.

If any loose, worn, or damaged components are found, remove the EAGLE ATTACK

CHARGING SYSTEM from service and tag for repair by authorized personnel.

If any damage is found that is beyond the scope of these instructions, contact an

authorized SCOTT Safety service center for assistance.

Page 29

P/N 595224-01 Rev E 7/12Page 27 of 32

MAINTENANCE

NOTE

THE EAGLE ATTACK THERMAL IMAGING CAMERA HAS NO USER SERVICEABLE

PARTS EXCEPT AS INSTRUCTED IN THIS MANUAL. ANY OPERATIONAL PROBLEMS

SHOULD BE REFERRED TO AN AUTHORIZED SCOTT SAFETY SERVICE CENTER

FOR REPAIR.

If the Lens is damaged, it must be replaced using Replacement Lens, SCOTT P/N

31000409. See the LENS REPLACEMENT section of this instruction for details.

STORAGE

Store the EAGLE ATTACK Thermal Imaging Camera in its carrying case or in the

charger when not in use.

When storing the EAGLE ATTACK Thermal Imaging Camera for an extended period

of time, the battery pack should be removed to prevent damage to the battery terminals.

CLEANING

The EAGLE ATTACK Thermal Imaging Camera is factory sealed to protect the optics

and electronics from dirt and moisture. The camera should be cleaned when necessary

using a cloth dampened with a solution of mild detergent and water. DO NOT IMMERSE

THE CAMERA.

CAUTION

DO NOT IMMERSE THE CAMERA TO CLEAN. THE CAMERA HOUSING IS MOISTURE

RESISTANT BUT IS NOT SUBMERSIBLE. USE A DAMP CLOTH AS DESCRIBED

ABOVE TO CLEAN THE OUTSIDE OF THE CAMERA. IMMERSION MAY AFFECT THE

OPERATION OF THE CAMERA.

CAUTION

IF THE LENS IS DAMAGED OR MISSING, DO NOT TOUCH THE INTERNAL LENS.

REPLACE THE LENS AS SOON AS POSSIBLE. DO NOT PERMIT ANY DIRT OR

FOREIGN MATERIAL INTO THE LENS AREA. DIRT OR DAMAGE IN THIS AREA MAY

AFFECT THE OPERATION OF THE CAMERA.

WARNING

DISPOSE OF DAMAGED BATTERIES IN ACCORDANCE WITH FEDERAL, STATE,

AND LOCAL ENVIRONMENTAL REGULATIONS. DO NOT THROW AWAY DAMAGED

BATTERIES AS ORDINARY TRASH. FAILURE TO HANDLE BATTERY PROPERLY MAY

RESULT IN SERIOUS INJURY.

Dispose of damaged batteries in accordance with federal, state and local environmental

regulations for the Li-Ion battery. Do not throw away damaged batteries as ordinary trash.

If any damage is found that is beyond the scope of these instructions, contact an authorized SCOTT Safety service center for assistance.

Page 30

P/N 595224-01 Rev E 7/12Page 28 of 32

REPLACEMENT PARTS

3. To install a new bracket, align the two screws and tighten rmly. DO NOT OVER

TIGHTEN.

BATTERY BRACKET AND CLIP

Both the clip on the battery and the mating battery retainer bracket on the camera

handle can be replaced.

BATTERY RETAINER BRACKET (P/N 31001912)

The Battery Retainer Bracket, P/N 31001912, can be replaced as follows:

1. Remove the battery and set aside.

2. Install the new Clip and tighten the screw rmly. DO NOT OVER TIGHTEN. Stretch

the battery boot back up over the edge of the battery and around the battery clip.

BRACKET

ON HANDLE

FIGURE 18

CLIP ON

BATTERY

FIGURE 19

BATTERY CLIP (P/N 31001913)

1. To remove the Battery Clip P/N 31001913, gently lift one edge of the Battery Boot

P/N 31001916, and push the boot down to expose the screw holding the battery clip.

2. To remove the slotted Battery Retainer

Bracket on the camera handle, use a

at blade screwdriver to remove the

two screws holding the bracket. See

FIGURE 18.

Use a Phillips screw driver to remove

the screw. See FIGURE 19.

These replacements must be performed in a clean work area. Clean the EAGLE ATTACK

Thermal Imaging Camera according to the MAINTENANCE section of this instruction.

Be sure the camera is OFF before beginning any work. After performing any service

as described in these instructions, check the operation of the camera according to the

USING THE EAGLE ATTACK THERMAL IMAGING CAMERA section of this instruction

to verify the operation before returning the camera to service.

Page 31

P/N 595224-01 Rev E 7/12Page 29 of 32

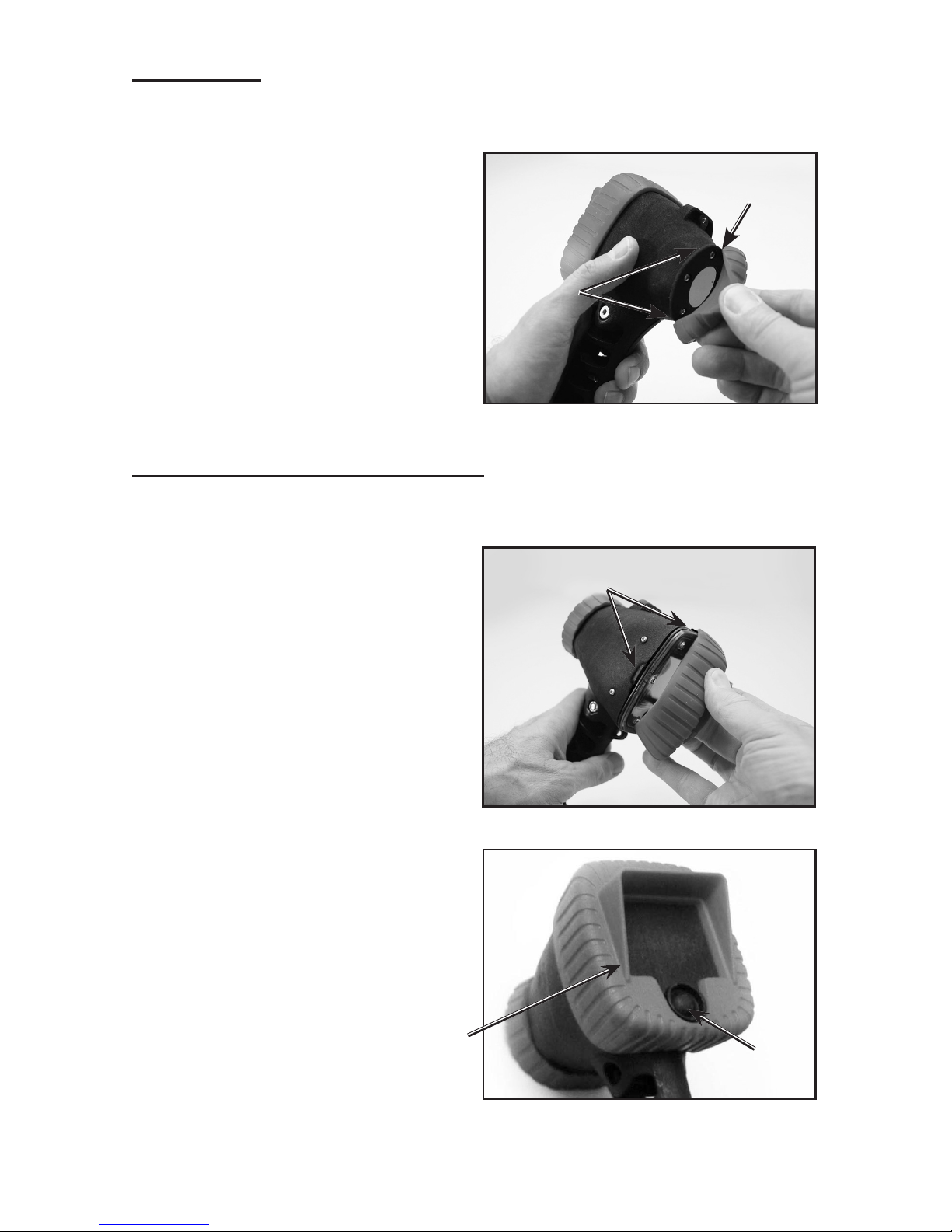

DISPLAY BOOT / GLARE SHIELD

The DISPLAY Boot, P/N 31001915-XX, (-XX extension number indicates color of

boot and/or Glare Shield version) stretches to fit around the display side of the

main housing.

POWER

SWITCH

SEATED AGAINST

DISPLAY SCREEN

1. To remove the DISPLAY Boot, gently

lift one edge of the boot until the boot

is released from the housing body.

Notice that there are four tabs around

the perimeter of the housing which

must line up with the four indentations

on the inside of the DISPLAY Boot.

2. To reinstall the DISPLAY Boot, orient

the DISPLAY Boot so that the notch

for the Power Switch aligns with the

Power Switch. See FIGURE 21.

FIGURE 22

3. Stretch the back edge of the DISPLAY

Boot around the display until it seats

with the display opening in the boot

rmly against the display screen. See

FIGURE 22.

LENS BOOT

The LENS Boot, P/N 31001914-XX, (-XX extension number indicates color of boot)

stretches to fit around the lens side of the main housing.

FIGURE 21

FOUR TABS

(ONE ON EACH SIDE)

FIGURE 20

FLATS ON

TOP AND

BOTTOM

“TOP” ON INSIDE

OF BOOT

1. To remove the LENS Boot, gently lift

one edge of the boot until the boot is

released from the lens ange.

2. To reinstall, orient the LENS Boot

with the word “TOP” toward the top

of the camera housing and the two

ats above and below the lens. See

FIGURE 20.

Page 32

P/N 595224-01 Rev E 7/12Page 30 of 32

LENS REPLACEMENT

The Germanium Lens on the front of camera is essential to protect the inner workings

of the camera from moisture and dirt. If the lens is broken, it must be replaced as soon

as possible.

If the Lens Assembly becomes damaged, it can be replaced with replacement Lens,

P/N 31000409. This replacement must be performed in a clean work area. Be sure the

camera is OFF before beginning any work. Clean the EAGLE ATTACK Thermal Imaging

Camera according to the MAINTENANCE section of this instruction.

CAUTION

WHILE THE LENS IS OFF, DO NOT TOUCH THE INTERNAL LENS. DO NOT PERMIT

ANY DIRT OR FOREIGN MATERIAL INTO THE LENS AREA. DIRT OR DAMAGE IN

THIS AREA MAY AFFECT THE OPERATION OF THE CAMERA.

CAUTION

USE OF A CAMERA WITH A BROKEN LENS MAY PERMIT MOISTURE, DIRT, OR

FOREIGN MATTER INTO THE INTERNAL LENS, OR THE CAMERA ELECTRONICS.

MOISTURE, DIRT, OR DAMAGE IN THIS AREA MAY AFFECT THE OPERATION OF

THE CAMERA.

Replace the Lens Assembly as follows:

1. To remove the LENS Boot, gently lift one edge of the boot until the boot is released

from the lens cover.

2. Using a #1 Phillips screw driver, remove the six (6) screws holding the lens cover

P/N 31001890. See FIGURE 23. Lift off the lens cover.

3. Lift off the old lens and lens seal, P/N 31001891. Do not touch the internal

lens.

FIGURE 23

LENS

COVER

LENS

Page 33

P/N 595224-01 Rev E 7/12Page 31 of 32

FIGURE 25

PIN ALIGNMENT

HOLE

ALIGNMENT

PIN

4. Fit the lens seal around the new

lens P/N 31000409 as shown in

FIGURE 24.

5. Place the new lens and lens seal on the front of the camera with the lens side in

rst. Align the six holes in the gasket with the holes in the housing. Make sure the

seal lays at with no kinks or wrinkles. Also make sure the pin alignment hole is

properly located. See FIGURE 25.

6. Place the lens cover on the lens seal with the alignment pin in the pin alignment hole

and align the six holes in the cover with the holes in the seal and the housing.

7. Replace the six (6) screws. Tighten screws to a torque of 6 to 8 Inch pounds. Use an

alternating pattern to assure even pressure on the seal. DO NOT OVER TIGHTEN.

Overtightening may damage the housing, lens cover, or seal.

8. Reinstall the LENS Boot with the two ats oriented above and below the lens. See

FIGURE 18.

9. Check the operation of the camera according to the USING THE EAGLE ATTACK

THERMAL IMAGING CAMERA section of this instruction to verify the operation

before returning the camera to service.

FIGURE 24

LENS

SEAL

LENS

CAMERA

CORE

ADDITIONAL REPLACEMENT PARTS

If you have any questions regarding other replacement parts or accessories, contact your

authorized SCOTT distributor, or contact SCOTT at 1-800-247-7257 (or 704-291-8300

outside the continental United States) or visit our web site at www.scottsafety.com.

Page 34

P/N 595224-01 Rev E 7/12Page 32 of 32

SCOTT SAFETY

LIMITED WARRANTY

ON THE EAGLE ATTACK THERMAL IMAGING CAMERA

SCOTT Safety (SCOTT) warrants the EAGLE ATTACK Thermal Imaging Camera to

be free from defects in workmanship and material for a period of two (2) years from

the date of shipment by SCOTT. SCOTT’s obligation under this warranty is limited

to replacing or repairing (at SCOTT’s option) THE PRODUCT or components shown

to be defective in either workmanship or materials.

Only SCOTT or, when directed by SCOTT, authorized SCOTT agents are authorized

to perform warranty obligations. This Warranty does not apply to defects or damage

caused by any repairs of or alterations to THE PRODUCT made by the owner or

any third party unless expressly permitted by SCOTT product manuals or by written authorization from SCOTT. To obtain performance under this warranty, and as a

condition precedent to any duty of SCOTT, the purchaser must return such products

to SCOTT, a SCOTT authorized distributor, or a SCOTT authorized service center.

Any product returned to SCOTT shall be sent to:

“SCOTT Safety”

(Attn: Warranty Claim Dept.)

4320 Goldmine Road

Monroe, NC 28110

This warranty does not apply to any malfunction of or damage to THE PRODUCT

resulting from accident, alteration, misuse, or abuse.

THIS WARRANTY IS MADE IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN ADDITION,

SCOTT EXPRESSLY DISCLAIMS ANY LIABILITY FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES IN ANY WAY CONNECTED WITH THE SALE OR

USE OF SCOTT PRODUCTS, AND NO OTHER FIRM OR PERSONS IS AUTHORIZED TO ASSUME ANY SUCH LIABILITY.

Page 35

Page 36

P/N 595224-01 Rev E 7/12 Printed in USA

SCOTT Safety

Monroe Corporate Center

PO Box 569

Monroe, NC 28111

Telephone 1-800-247-7257

Fax (704) 291-8330

www.scottsafety.com

Europe: United Kingdom

SCOTT Safety

Pimbo Road, West Pimbo

Skelmersdale, Lancashire

WN8 9RA, England

Tel: +44 (0)1695 711711

Fax: + 44 (0)1695 711772

Email:scottintuk@tycoint.com

www.scottint.com

Loading...

Loading...