Page 1

CONTOUR

Self-contained Breathing Apparatus

User Instructions

Article No. 1034994 Issue H 05. 2010

AS/NZS1716 : 2003

Lic. 1214 SAI Global

Page 2

Self-contained Breathing Apparatus

Contents

WARNINGS ............................................................................................................................................................................... ii

1. INTRODUCTION .......................................................................................................................................................... 1

1.1 ABBREVIATIONS............................................................................................................................................... 1

1.2 BREATHABLE AIR ............................................................................................................................................. 1

1.3 COMPRESSED AIR AIRLINE SUPPLIES .......................................................................................................... 1

1.4 APPARATUS DURATION .................................................................................................................................. 2

1.5 TRAINING .......................................................................................................................................................... 2

1.6 SERVICING ........................................................................................................................................................ 2

1.7 SPARE PARTS AND ACCESSORIES ............................................................................................................... 2

1.8 WARRANTY ....................................................................................................................................................... 3

1.9 NOTIFIED BODIES ............................................................................................................................................ 3

2. APPARATUS DESCRIPTION ...................................................................................................................................... 3

2.1 GENERAL .......................................................................................................................................................... 3

2.2 HARNESS .......................................................................................................................................................... 4

2.3 CYLINDER BAND ............................................................................................................................................... 4

2.4 THE PNEUMATIC SYSTEM ............................................................................................................................... 6

2.5 REDUCER .......................................................................................................................................................... 6

2.6 GAUGE AND WHISTLE ..................................................................................................................................... 6

2.7 DEMAND VALVE ................................................................................................................................................ 6

2.8 OPTIONAL ATTACHMENTS .............................................................................................................................. 7

2.9 FACEMASKS ..................................................................................................................................................... 7

3. PRE-USE AND MONTHLY CHECKS .......................................................................................................................... 8

3.1 CHECK APPARATUS ........................................................................................................................................ 8

3.2 REPLACING CYLINDERS ................................................................................................................................. 8

3.3 DUO CYLINDER BAND ...................................................................................................................................... 9

3.4 RESET DEMAND VALVE ................................................................................................................................. 10

3.5 CYLINDER PRESSURE/LEAK TEST ............................................................................................................... 10

3.6 DV AND FACEMASK ........................................................................................................................................ 10

3.6.1 All Facemasks ......................................................................................................................................... 10

3.6.2 Facemasks with a Web Harness ............................................................................................................ 11

3.6.3 Facemasks with a Net Harness .............................................................................................................. 11

3.7 POSITIVE PRESSURE TEST .......................................................................................................................... 12

3.8 WHISTLE TEST ............................................................................................................................................... 12

3.9 AIRLINE AND DECONTAMINATION ATTACHMENTS .................................................................................... 12

3.10 RSM ATTACHMENTS ...................................................................................................................................... 13

3.11 HOSES ............................................................................................................................................................. 13

4. DONNING PROCEDURE .......................................................................................................................................... 13

4.1 DON APPARATUS ........................................................................................................................................... 13

4.2 CHECK DV/OPEN CYLINDER VALVE ............................................................................................................. 14

4.3 DON FACEMASK ............................................................................................................................................. 14

4.3.1 Facemasks with a Web Harness ............................................................................................................ 14

4.3.2 Facemasks with a Net Harness .............................................................................................................. 14

4.4 POSITIVE PRESSURE TEST .......................................................................................................................... 15

4.5 FACEMASK SEAL TEST .................................................................................................................................. 15

4.6 WHISTLE TEST ............................................................................................................................................... 15

4.7 FINAL CHECKS ................................................................................................................................................ 15

4.8 ATTACHING AN AIRLINE ................................................................................................................................ 16

5. DOFFING INSTRUCTIONS ....................................................................................................................................... 16

5.1 DOFFING THE APPARATUS ........................................................................................................................... 16

5.2 REMOVE CYLINDER(S) .................................................................................................................................. 17

6. AFTER USE ............................................................................................................................................................... 17

6.1 CLEANING ....................................................................................................................................................... 17

6.2 CHECK APPARATUS ...................................................................................................................................... 18

6.3 RECORD TEST DETAILS ................................................................................................................................ 18

6.4 STORAGE ........................................................................................................................................................ 19

7. SCHEDULED MAINTENANCE .................................................................................................................................. 19

7.1 MONTHLY ........................................................................................................................................................ 19

7.2 ANNUALLY ....................................................................................................................................................... 19

Registered Office: Scott Health and Safety Limited, Pimbo Road, West Pimbo,

Skelmersdale, Lancashire, WN8 9RA, England.

i

Page 3

WARNINGS

Please Read Carefully and Fully Understand

This manual is for use by personnel trained in the use and care of compressed air

breathing apparatus, and MUST NOT be used as a self-teaching guide by untrained users.

Failure to understand or adhere to the Contour user instructions may result in injury or

death.

Scott Health and Safety Limited has taken great care to ensure that the information in

this manual is accurate, complete and clear. However, Training and Technical Support

Services will be pleased to clarify any points in the manual and answer questions on

SCOTT breathing apparatus.

The following warnings are in accordance with certifying authority requirements and

apply to the use of breathing apparatus in general:

Breathing apparatus users must be fully trained in the use and care of selfcontained, compressed air breathing apparatus.

Ensure that the selection of the apparatus type is sufficient for the tasks

being undertaken and the hazards likely to be encountered. Please refer to

National Regulations for guidance.

Adequate protection may not be provided in certain highly toxic

atmospheres.

The apparatus must be tested and serviced in accordance with Section 7 -

Scheduled Maintenance and the notes in Section 1 under Training and

Servicing.

The quality of air used to supply and charge breathing apparatus must meet

the requirements of EN 12021 : 1999 or AS/NZS1715 : 1994. See Section 1 for

details.

In Australia and New Zealand, ensure that your selection of respiratory

protective devices conform to the requirements of AS/NZS1715 : 1994.

Ensure that a good seal can be obtained between the face and facemask.

The wearing of beards, side-burns or spectacles may adversely affect the

sealing of a facemask to the wearer's face.

The apparatus is not designed for use underwater.

The harness must not be used as a vehicle seat restraint.

DISCLAIMER

Failure to comply with these instructions or misuse of the apparatus may result in:

death, injury or material damage, and invalidate any warranty or insurance claims.

COPYRIGHT

This manual must not be copied in part or whole, or used for purposes other than its intended

purpose without the written permission of Scott Health and Safety Limited.

ii

Page 4

CONTOUR

1. INTRODUCTION

1.1 ABBREVIATIONS

The following abbreviations are used in

this manual:

AL Airline Attachment

BA Breathing Apparatus

CVR Cylinder Valve Retainer

DCC Decontamination Attachment

DV Demand Valve

HP High Pressure

IRIS Integrated Radio Information

System

m Metres

min Minutes

mg Milligrams

mm Millimetres

MP Medium Pressure

NRV Non Return Valve

PRV Pressure Relief Valve

psi Pounds per Square Inch

RSM Rescue Mask Attachment

1.2 BREATHABLE AIR

Air used to supply or charge breathing air

may be natural or synthetic and must

comply with EN 12021 : 1999 or

AS/NZS1715 : 1994. The composition of

breathable air in accordance with EN

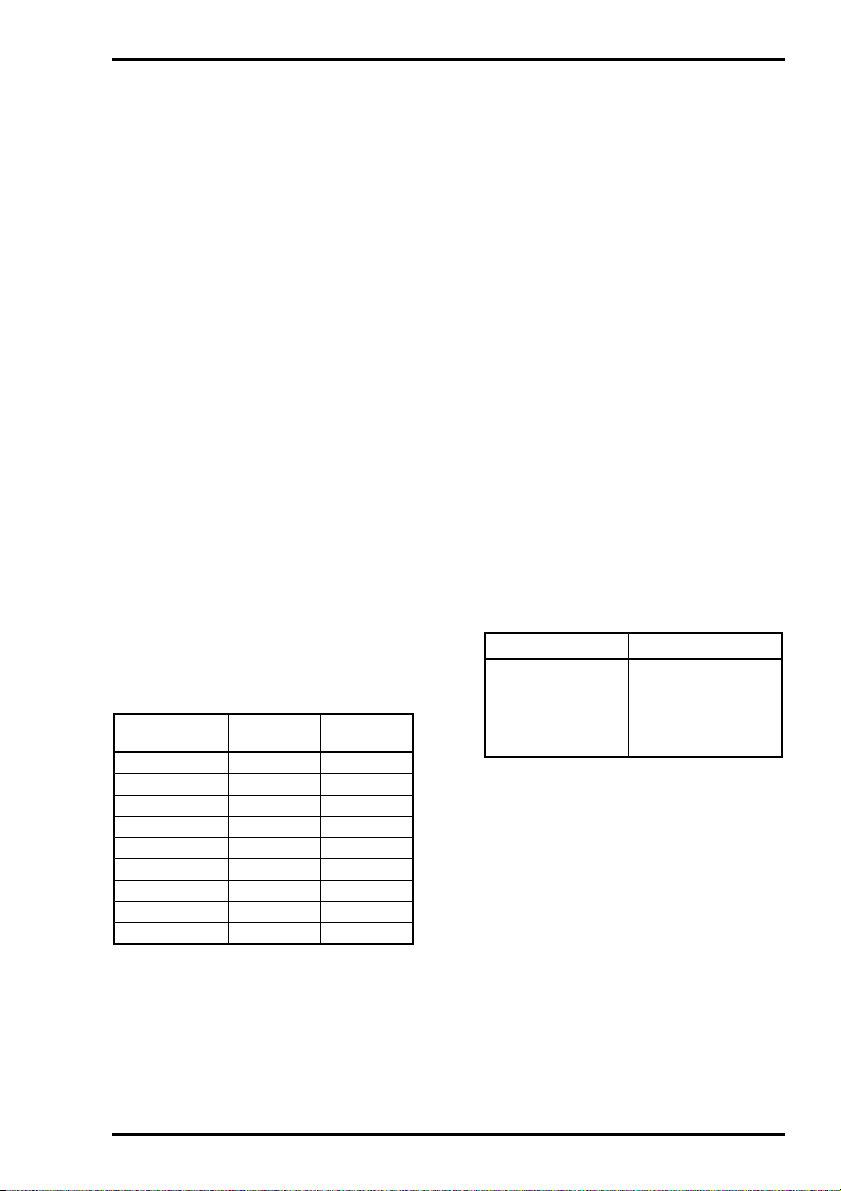

12021 is given in Table 1.

Component Mass %

(Dry Air)

Oxygen 23.14 20.948

Nitrogen 75.52 78.08

Argon 1.29 0.93

Carbon Dioxide 0.05 0.031 4

Hydrogen 0.000 003 0.000 05

Neon 0.001 270 0.001 818

Helium 0.000 037 0.000 524

Krypton 0.000 330 0.000 114

Xenon 0.000 039 0.000 009

Table 1: Breathable Air - EN 12021

(NOT applicable for Australia or

New Zealand)

There is an increased fire risk when the

oxygen content is above the value shown

above.

Volume%

(Dry Air)

The purity/quality of air used to supply

and charge breathing apparatus should

be tested periodically in accordance with

national regulations.

Unless otherwise specified, the

contaminants shall not exceed the

permissible exposure level.

National regulations must be observed.

The mineral oil content shall be such that

the air is without the odour of oil. The

odour threshold is in the region of 0.3

3

mg/m

.

The water content shall not exceed 50

3

for 200 and 207 bar apparatus and

mg/m

30 mg/m

3

for 300 bar apparatus.

For airline apparatus, air must be used

with a dew-point sufficiently low to

prevent internal freezing.

1.3 COMPRESSED AIR

AIRLINE SUPPLIES

Air for use with compressed air airlines

must conform to EN 12021 : 1999 or

AS/NZS1715 : 1994 and must have a

dew point sufficiently low to prevent

internal freezing when apparatus is used

in temperatures below 4°C.

No. of Wearers Airflow (L/min.)

1

2

3

4

Table 2

Airline pressure must be between 5.0 and

9.0 bar (70 and 130 psi). Airflow supply

capacity for a single airline is given in

Table 2.

Generally; each additional wearer

requires an extra 150 litres per minute,

each additional pair of wearers requires

300 L/min for one wearer and 450 L/min

for two wearers. All measurements must

be taken at the wearer end of the airline.

Example: for 8 users (4 pairs) the

recommended flow is 4 x (300 + 150) =

1800 litres/minute.

300

450

750

900

1

Page 5

CONTOUR

An airline flow tester is available from

Scott Health and Safety Limited under

Article Number 1035978.

Compressed air airlines used with

Contour must be SCOTT products,

approved to EN 139 or AS/NZS1716 :

2003.

Ensure that hoses used in an explosive or

flammable atmosphere are marked:

ANTI-STATIC

EN 139

AS/NZS1716

BREATHING AIR

Cost effective PVC hoses may be used in

other atmospheres.

Scott Health and Safety Limited

manufacture a range of anti-static and

PVC hoses, in lengths ranging from 15m

to 60m. Our Customer Services

Department will be pleased to provide

details on price and delivery.

1.4 APPARATUS DURATION

All durations quoted are nominal, based

on an Average Wearer Consumption

Rate of 40 L/min and FULLY CHARGED

cylinders. Actual Wearer Consumption

rates vary due to many factors, such as:

• Workload: high work rates increase

consumption rates.

• Weight of apparatus and use of

heavy or restrictive clothing.

• Work environments with extremes

of heat or cold.

• Physical fitness of the wearer.

• Other factors include emotional

stress and fatigue.

• Supplying cylinder air to a

resuscitator or rescue second mask

(RSM).

It is important that all wearers are aware

of these factors and take account of them

when assessing cylinder duration.

1.5 TRAINING

Personnel who use self-contained,

compressed air breathing apparatus must

be fully trained in accordance with these

instructions and national regulations.

These instructions cannot replace an

accredited training course run by fully

qualified instructors in the proper and

safe use of SCOTT breathing apparatus.

Please contact Training and Technical

Support Services or your distributor for

training course details.

1.6 SERVICING

Contour must be serviced at scheduled

intervals by personnel who have

completed a formal training course and

hold a current certificate for the servicing

and repair of SCOTT breathing

apparatus. Details of the servicing

schedule are contained in the SCOTT

Contour Service Manual, copies of which

can only be obtained by registered

holders of a current certificate.

Your distributor or Training and

Technical Support Services will be

pleased to provide training course details

and quotes for service contracts. Please

see above for contact details.

1.7 SPARE PARTS AND

ACCESSORIES

Customer Services provide an efficient,

friendly, customer contact point for

ordering new apparatus, spare parts and

accessories. The team can also provide

general information on SCOTT products.

2

Page 6

CONTOUR

1.8 WARRANTY

The products manufactured at our

factories in Skelmersdale and Vaasa

carry a warranty of 12 months (unless

stated otherwise) for parts, labour and

return to site. The warranty period runs

from the date of purchase by the end

user.

These products are warranted to be free

from defects in materials and

workmanship at the time of delivery.

SCOTT will be under no liability for any

defect arising from wilful damage,

negligence, abnormal working conditions,

failure to follow the original

manufacturer’s instructions, misuse or

unauthorised alteration or repair.

Evidence of purchase date will need to be

provided for any claims arising during the

warranty period. All warranty claims must

be directed through SCOTT Customer

Services and in accordance with our

sales return procedure.

1.9 NOTIFIED BODIES

Inspec International Limited (0194)

56 Leslie Hough Way,

Salford,

Greater Manchester,

M6 6AJ,

England.

BSI Product Services (0086)

Kitemark House,

Maylands Avenue,

Hemel Hempstead,

HP2 4SQ,

England.

SAI Global

286 Sussex Street,

Sydney,

NSW 2000,

Australia.

Lic. No 1214.

2. APPARATUS

DESCRIPTION

2.1 GENERAL

Contour is an open circuit, self-contained

compressed air Breathing Apparatus (BA)

for use by fire-fighters and in industrial

applications, where a high level of

respiratory protection is required.

Standard versions of Contour feature a

mechanical pressure gauge and whistle

mounted on the left-hand shoulder strap.

Versions specifically intended for use by

fire-fighters are available which

incorporate the IRIS data-

communications system.

All safety-critical components on the

Contour Set, (for example the reducer

valve and demand valve etc), are

individually identified by a unique serial

number and date of manufacture.

Contour is approved to European

Standards EN 137 : 1993, EN 137 : 2006

Class 1 (self-contained breathing

apparatus) and EN 139 : 1995 (selfcontained breathing apparatus with airline

attachment). Contour is 'CE' marked in

accordance with EC Directive

EC/686/1986.

Contour is approved to Australian/New

Zealand Standard AS/NZS1716 : 2003.

Contour is also approved for use at sea

by:

Lloyds Inspectorate, in accordance with

SOLAS regulation 17 and the 1980

Merchant Shipping Act.

Please call Scott Health and Safety

Limited for further apparatus approval

details.

This manual contains user instructions for

single cylinder, twin cylinder (Duo)

versions, and versions for use with

compressed air airlines. Duo models are

not normally provided with airline

attachments.

3

Page 7

CONTOUR

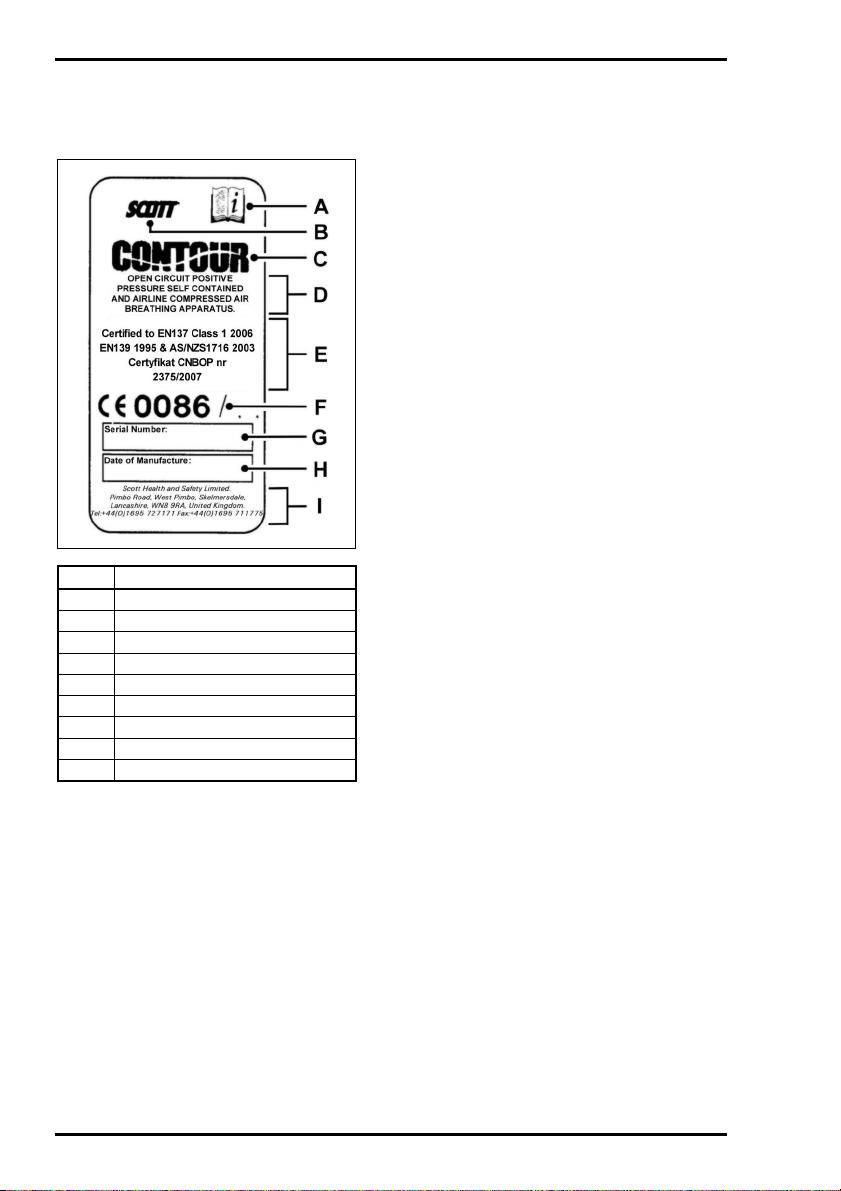

Contour is marked in accordance with

EN 137 : 2003 and AS/NZS1716 : 2003.

An explanation of those markings is given

below:

Key Meaning

A =

Symbol - refer to User Instructions

B =

Product brand name

C =

Product model/designation

D =

Apparatus description

E =

Standards to which apparatus is certified

F =

Number of Approval Body

G =

Serial number of apparatus

H =

Date of manufacture

I =

Contact details of manufacturer

2.2 HARNESS

Contour is available with a flame-

retardant polyamide/ polyester or a

TM

Kevlar

/NomexTM harness (identified by

a -K in the unit part number). Buckles are

of black nylon or stainless steel. Pressstuds are of brass or nickel plated brass.

On Kevlar

TM

versions the pneumatics and

hoses are attached to the harness by

loops closed by press-studs. On EN

versions the loops do not open.

For wearer comfort, a lumbar pad (fitted

as standard), or a full back pad (fitted as

an option) is provided. Both are fabricated

from flame-retardant material and packed

with flame retardant, closed cell foam.

The lumbar pad is held in place by four

press-studs. The full length pad is held by

press studs and the harness straps.

A chest-strap is available as an option.

2.3 CYLINDER BAND

Contour can be configured for use with

one or two (Duo), 200, 207 or 300 bar,

steel or fully wrapped aluminium carbon

fibre composite cylinders (see Table 3).

Cylinders are secured to the light-weight

back-plate by a webbing cylinder band

and a cylinder valve retainer (CVR). A

conversion kit is available for converting

single cylinder apparatus to Duo.

The webbing cylinder band is closed by a

cam lock buckle with a latch that prevents

accidental opening. The band can be

adjusted to accept the range of cylinders

listed in Table 3. The cam-lock buckle

facilitates replacement of similar size

cylinders without cylinder band

adjustment.

Contour Duo cylinder bands can be

easily altered by the wearer (no tools

required) to mount a single cylinder,

centrally on the back-plate.

4

Page 8

CONTOUR

(litres)

Nominal

Duration

(mins)

Cylinders Water

CYL-1200 6.0 200 1200 22 8 30 8.8 11.8 CYL-HWG-

1200

CYL-FWC1300

CYL-1640

CYL-HWG1640

CYL-FWC1640

CYL-1800 9.0 200 1800 33 12 45 13.0 16.0 CYL-HWG-

1800

CYL-FWC1800

CYL-FWC1860

CYL-FWC2460

Capacity

(litres)

Charging

Pressure

(bar)

6.0 207 1200 22 8 30 7.2 10.2 -

4.7 300 1300 25 7 32 5.0 8.0 -

6.0 300 1640 33 8 41 12.5 15.5 -

6.0 300 1640 33 8 41 10.0 13.0 -

6.0 300 1640 33 8 41 6.3 9.3 15.6

9.0 207 1800 33 12 45 11.2 14.2 -

9.0 207 1800 33 12 45 6.75 9.75 16.5

6.8 300 1860 37 9 46 6.75 9.75 16.5

9.0 300 2460 50 12 62 8.8 11.8 -

Free air

Volume

Note:

Only cylinders in shaded areas are suitable for use with Contour Duo in twin cylinder

configuration. The total apparatus weight must not exceed 18 kg when fully-charged; (ref: EN

137, Clause 5.4 and AS/NZS1716 : 2003).

Table 3: Cylinders approved for use with Contour apparatus

Table 4 identifies the cylinder material code and the cylinder specification.

Warning

Period

(mins)

Total

Duration

(mins)

Cylinder

Charged

Weight

(kg)

Weight of

Contour with

Cylinder (kg)

Single Duo

Code Material Specification

No Code Steel (e.g.: CYL-1200)

HWG Hoop Wrapped Glass Fibre (e.g.: CYL-HWG-1200)

FWC Fully Wrapped Carbon (e.g.: CYL-FWC-1300)

CE Marked (EU)

Work Cover (Australia & New Zealand)

HSE-AL-HW1 (EU)

Work Cover (Australia & New Zealand)

CE Marked (EU)

Work Cover (Australia & New Zealand)

Table 4: Cylinder Codes and Specifications

Durations are nominal and based on an Average Wearer Consumption Rate of 40 L/min and

are for fully charged cylinders.

Total Duration =

Cylinder Free Air Capacity

Average Wearer Consumption Rate

Nominal Duration = Total Duration minus the Warning Period.

Warning Period =

Whistle Operating Pressure

Average Wearer Consumption Rate

5

Page 9

CONTOUR

2.4 THE PNEUMATIC

SYSTEM

The pneumatic system has two pressure

reduction stages: air from the cylinder is

reduced to a medium-pressure (MP) of

between 5.5 and 11 bar by the reducer.

The second pressure reduction is

performed in the facemask Demand

Valve (DV).

Air from the cylinder passes through a

sintered bronze particle filter in the

cylinder connector, which protects the

pneumatic system, then through a short

length of High Pressure (HP) braided

hose to the reducer inlet manifold.

2.5 REDUCER

The reducer is a simple, self-regulating,

spring and piston device, which requires

no adjustment. It has a pressure relief

valve (PRV) that protects the MP system

from over-pressurisation.

On versions fitted with the IRIS data-

communications system, the warning

whistle and pressure gauge are

incorporated within the IRIS unit.

The warning whistle sounds when

pressure in the cylinder falls to 55 bar (±5

bar).

The duration of the air remaining in the

cylinder, from the start of the warning

whistle, is listed for each cylinder type

under Warning Period in Table 3.

The pressure gauge dial is photo

luminescent to aid use in low light levels.

The lens is impact resistant

polycarbonate. A rubber shroud protects

the gauge.

Should the gauge, whistle or hose

become damaged, a restrictor in the

reducer limits air-loss to less than 25

litres per minute.

2.7 DEMAND VALVE

The DV operates in conjunction with the

facemask spring-loaded exhale valve to

maintain a positive pressure within the

facemask.

The DV has a servo-assisted tilting

diaphragm mechanism that responds to

pressure changes within the facemask to

regulate the flow of air to the mask,

ensuring that pressure within the mask

remains safely above ambient.

Air from the reducer is connected through

a reinforced chlorinated polyethylene

hose to the facemask-mounted DV, which

regulates the air supplied to the wearer.

2.6 GAUGE AND WHISTLE

A high-pressure hose from the reducer

inlet manifold connects air, at cylinder

pressure, to a warning whistle and

pressure gauge mounted on the Contour

shoulder strap.

On standard versions, the warning whistle

and pressure gauge are mounted on the

left-hand shoulder strap.

The DV has a reset button that enables

wearers to close the air-flow through the

DV, allowing the facemask to be removed

during test procedures and at the end of a

task without loss of cylinder air.

6

Page 10

CONTOUR

When the apparatus is donned the DV is

normally “reset” (closed), and is opened

(activated) when the wearer takes a first

breath.

The DV has a supplementary flow device

(bypass), that the wearer can open using

the bypass knob.

When the bypass is used the unregulated

flow of air through the DV reduces

cylinder duration.

The DV is connected to the facemask by

a Quick-Fit (QF) bayonet fitting with a

spring-loaded locking catch to prevent

accidental disconnection.

2.8 OPTIONAL

ATTACHMENTS

The options available are:

• Decontamination attachment (DCC)

- facilitates airline connection into a

gas-tight chemical suit, permitting

the wearer to breathe from an

airline during extended

decontamination procedures.

• Rescue mask attachment (RSM) -

permits the wearer to supply a

rescue mask or an air powered

resuscitator from own cylinder air.

This reduces the duration of the

cylinder supply.

• Airline attachment (AL) - permits

Contour to be used with an airline.

The cylinder provides emergency

backup.

Note:

Air for use with airlines must conform to

Breathable Air as detailed in Section 1.

PanaSeal is suitable for medium and

smaller face sizes; PanaVisor is suitable

for medium to larger face sizes. Vision 3

is available in three sizes: small, medium

and medium/large which cover most face

sizes. Promask PP is available in two

sizes: small/medium and medium/large.

Vision 3 is moulded in grey silicone,

while PanaSeal and PanaVisor are of

non-dermatitic, black neoprene or blue

silicone. Promask PP is moulded in

hypo-allergenic, black Procomp

soft silicone inner mask.

The polycarbonate visors conform to EN

166 Grade B for medium impactresistance and AS/NZS 1337 : 1992 for

high-impact resistance.

Versions of the above masks are also

available with helmet attachment clamps

fitted. Please contact Customer Services

for further information.

Vision 3 Facemask with Web Harness

TM

with a

2.9 FACEMASKS

Contour is approved for use with: Vision

3, PanaSeal, PanaVisor and Promask

PP full facemasks, all of which conform to

EN 136, Class 3 and AS/NZS1716 :

2003.

All are available with five point, fully

adjustable web or net head-harnesses

and neck-straps.

An inner mask minimises CO

space and visor misting. A speech

diaphragm is fitted.

dead

2

PanaSeal/PanaVisor Facemask with

Net Harness

7

Page 11

CONTOUR

Promask PP Facemask

3. PRE-USE AND

MONTHLY CHECKS

3.1 CHECK APPARATUS

Contour must be clean and in good

condition. Check that all hose retaining

press-studs (if fitted) are closed. Fully

slacken the waist-belt and shoulder

straps ready for use.

3.2 REPLACING CYLINDERS

WARNING:

On Duo models, always fit matching,

fully-charged cylinders.

1. Close the cylinder valve (on Duo

Sets, close both cylinder valves).

2. Open the facemask bypass to vent

the system.

3. Undo the cylinder connector(s).

8

Page 12

CONTOUR

4. Grasp and pull the edges of the

cam-lock buckle with index finger and

thumb of the left hand and use the right

index finger to slide the ribbed, release

catch. Pull the cam-lock fully open.

5. Open the buckle and remove the

cylinder(s).

6. Place fully charged cylinder(s) on

the back-plate with the cylinder outlet(s)

through the cylinder valve retainer(s).

7. On Duo, ensure that the dividing

loop is between the cylinders.

firmly onto the cylinder valve (onto the

Duo manifold).

Note:

In some instances it may be necessary to

adjust the size of the cylinder band. To do

this:

i) Engage the buckle hinge, but do

not close the cam-lock.

ii) Tighten the cylinder band using the

slide buckle, until the band holds the

cylinder securely.

iii) Close the cam-lock buckle.

When Contour is used with an airline

check that:

i) The airline is in good condition, free

from splits, bulges and abrasions.

ii) The airline connector is in good

condition and that it connects securely to

the Contour pigtail.

iii) The air supply conforms to EN

12021 or AS/NZS1715 : 1994 (see

Section 1.3 - Compressed Airline

Supplies).

iv) The Contour airline coupling is in

good condition.

3.3 DUO CYLINDER BAND

The Duo cylinder band can be adapted to

hold two or one cylinder.

In normal use, the dividing loop passes

between the two cylinders, to separate

and secure them. By flattening the

dividing loop against the cylinder band

wearers can configure Duo for single

cylinder operation.

To alter the Duo cylinder band to hold

only one cylinder:

1. Slide the dividing loop so that it is

next to the back-plate and lying flat on the

cylinder band.

8. Check that the cylinder hand-wheel

connector O-ring(s) is (are) clean and in

good condition and screw the connector

9

Page 13

CONTOUR

2. Shorten the cylinder band by

feeding the excess length through the

buckles on the band.

3.4 RESET DEMAND VALVE

1. Press the black rubber reset button

on the side of the DV and check that the

red bypass knob is turned so that the flat

on the bypass knob aligns with the DV

outlet.

2. Check that the orange O-ring on

the DV outlet is clean and in good

condition.

3.5 CYLINDER PRESSURE/

LEAK TEST

3. Close the cylinder valve and

monitor the pressure gauge for one

minute. If the reading falls by more than

10 bar during this time there is an

unacceptable leak.

4. On Duo Sets, close the first

cylinder valve, vent the apparatus by

opening the DV bypass and repeat the

test using the second cylinder.

5. If the system fails the leak test:

close the cylinder valve, vent air from the

system by opening the DV bypass. Check

all pneumatic connections and repeat the

leak test.

6. DO NOT USE apparatus that leaks

excessively. Attach an explanatory note

and return the apparatus for service.

3.6 DV AND FACEMASK

3.6.1 All Facemasks

1. Check that the facemask is clean

and undamaged.

1. Slowly open cylinder valve fully (on

Duo Sets open only one cylinder valve)

and allow 10 seconds for the apparatus to

pressurise.

2. Check that the pressure gauge

shows the cylinder is at least 80% FULL

(240 bar for 300 bar cylinders, 170 bar for

200 and 207 bar cylinders). Listen for

leaks.

2. Check that the orange O-ring on

the DV outlet is clean and in good

condition.

10

Page 14

CONTOUR

3. Fit the DV to the facemask and

check that the red locking catch engages

fully. Twist the DV gently to confirm that it

has.

4. Open the cylinder valve(s) fully.

3.6.2 Facemasks with a Web

Harness

1. Hold the head-harness lower

straps, place chin in chin-cup and pull

straps over back of head, brushing back

hair from under face-seal.

3.6.3 Facemasks with a Net

Harness

1. Hold the mask by the side of the

net harness, place the chin into the chincup and pull the mask onto the face.

Grasp the pull-strap at the rear of the net

harness and pull the net over the head.

2. Tighten harness straps in

sequence: Bottom, Middle, Top. DO

NOT over-tighten.

3. Inhale deeply and check that the

DV first breath mechanism operates.

2. Tighten harness side straps. DO

NOT over-tighten.

3. Inhale deeply and check that the

DV first breath mechanism operates.

11

Page 15

CONTOUR

3.7 POSITIVE PRESSURE

TEST

1. With the cylinder valve open, insert

a finger under face-seal and check for a

steady outward flow of air. Remove finger

and allow mask to re-seal.

2. Hold breath for ten seconds and

listen for leaks. If there are leaks, loosen

the head-harness and adjust the mask for

a comfortable leak tight fit and repeat

test. DO NOT over-tighten the headharness.

3. DO NOT USE apparatus that leaks.

Attach an explanatory note and return for

servicing.

4. When satisfied with the apparatus,

press the DV reset knob, remove the

facemask and close the cylinder valve.

3.8 WHISTLE TEST

1. With the cylinder valve(s) closed,

open the bypass knob briefly to vent air

from the system.

2. Check that the whistle sounds

clearly as the pressure gauge falls below

55 bar (±5 bar).

3. The apparatus is now fully tested

and may be stored prior to use.

Note:

Other warning whistle pressures may be

selected at purchase: 55 bar whistles

(green spot), 44 bar (red) and 68 bar

(yellow).

3.9 AIRLINE AND

DECONTAMINATION

ATTACHMENTS

1. Check the supply airline flow and

pressure. Remove connector dust caps

and check for wear and damage.

2. Make connection to an appropriate

connector capable of supplying

breathable compressed air (see Section

1.3 - Compressed Air Airline Supplies).

3. Check that the connection is secure

and that the connector releases easily,

without sticking.

4. Press the DV reset button.

5. Pressurise the attachment and

check all connections for leaks. On airline

attachments, check that the female

connector does not leak.

6. DO NOT use attachments that

show signs of excessive wear or damage,

or that leak excessively.

7. Replace dust caps.

12

Page 16

CONTOUR

3.10 RSM ATTACHMENTS

1. Remove RSM dust caps and attach

a rescue mask to the RSM attachment.

2. Press the DV reset buttons on the

wearer facemask and rescue mask.

3. Open the Contour cylinder valve

and check that the RSM connection does

not leak.

4. Don the rescue mask, inhale

sharply to activate the first breath

mechanism and check that there is a

plentiful supply of air.

5. Disconnect the rescue mask and

check once again that the RSM connector

does not leak.

6. Replace dust caps.

7. DO NOT use attachments that

show signs of excessive wear or damage,

or that leak excessively.

3.11 HOSES

1. Check all hoses for damage and

excess wear. Flex hoses to reveal any

splits, cracks or crazing (minor crazing is

acceptable).

2. Check couplings for damage and

excess wear; and ensure that they can be

opened.

3. When closed, check that they form

a secure coupling.

4. Replace damaged or worn hoses.

4. DONNING

PROCEDURE

4.1 DON APPARATUS

Note:

Specialist Users, (such as Emergency

Services) may operate alternative

donning procedures, which conform to

the relevant statutory regulations and

have been approved by Scott Health and

Safety Limited.

1. Check that the Contour and

facemask harnesses are fully slackened

and that the DV is connected to the

facemask.

2. Hang the facemask round the neck

by its neck-strap.

3. Pass the right arm through the

shoulder strap and swing the harness

across the back and slip the left arm

through the shoulder strap.

4. Pull down on the shoulder strap

ends until the apparatus fits comfortably

then close the waist-belt.

Note:

If the waist-belt is closed first, tightening

the shoulder straps will pull up the waistbelt, causing discomfort.

13

Page 17

CONTOUR

4.2 CHECK DV/OPEN

CYLINDER VALVE

1. Check that the flat on the DV

bypass knob aligns with the DV outlet and

press the black reset button.

2. Open the cylinder valve slowly with

your right hand, whilst holding the

pressure gauge in your left (on Duo Sets

open only one cylinder valve) and check

that the pressure gauge reads 80% FULL

(170 bar for 200 and 207 bar cylinders

and 240 bar for 300 bar cylinders).

WARNING:

When opening cylinder valve, DO NOT

use the high-pressure hose as

leverage.

1. Hold the head-harness lower

straps, place chin in chin-cup and pull

straps over back of head, brushing hair

away from face-seal.

2. Adjust the facemask top strap so

that the mask is at the correct level with

the face and the head-harness pad is in

the centre of the back of the head and

then tighten harness straps in sequence:

Bottom, Middle, Top. DO NOT overtighten.

3. Inhale deeply to activate the DV

then breathe normally.

4.3.2 Facemasks with a Net

Harness

4.3 DON FACEMASK

4.3.1 Facemasks with a Web

Harness

1. Hold the mask by the side of the

net harness, place the chin into the chincup and pull the mask onto the face.

Grasp the pull-strap at the rear of the net

harness and pull the net over the head.

14

Page 18

CONTOUR

4.6 WHISTLE TEST

2. Tighten harness side straps. DO

NOT over-tighten.

3. Inhale deeply to activate the DV

then breathe normally.

4.4 POSITIVE PRESSURE

TEST

With the cylinder valve open, insert a

finger under face-seal and check for a

steady outward flow of air. Remove finger

and allow mask to re-seal.

4.5 FACEMASK SEAL TEST

1. Close the cylinder valve and keep

hold of the hand-wheel. Hold breath for

10 seconds and listen carefully for leaks.

A leak will cause the pressure gauge

reading to fall.

2. If the facemask fails the leak test:

open the cylinder valve, loosen the headharness, adjust the facemask and repeat

the test.

1. With cylinder valve still closed,

slowly breathe down the air from the

system. Check that the whistle sounds

clearly as the pressure gauge falls to 55

bar (±5 bar).

2. Once the whistle has sounded,

open the cylinder valve fully.

3. DO NOT USE apparatus that fails

this test. Attach an explanatory note and

return for service.

4.7 FINAL CHECKS

1. Check that the cylinder valve(s)

is/are fully open and that the pressure

gauge shows that there is sufficient air.

WARNING:

On Duo models, BOTH cylinder valves

MUST be fully open immediately prior

to and during use.

2. Turn on the DV bypass knob and

check for a steady flow of air into the

mask. Close the bypass knob.

15

Page 19

CONTOUR

4.8 ATTACHING AN AIRLINE

WARNING:

• Airlines should be at least 15

metres long.

• Use anti-static hoses in

flammable or explosive

atmospheres.

1. Push the airline onto the Contour

attachment connector.

WARNING:

Close cylinder valve while breathing

from the airline.

2. Give the supply airline a firm tug to

ensure that it is securely connected.

3. Proceed with tasks to be

performed.

5. DOFFING

INSTRUCTIONS

5.1 DOFFING THE

APPARATUS

WARNING:

• DO NOT remove apparatus until

well clear of the hazardous area.

• If wearing a gas-tight chemical

suit, DO NOT remove until

decontamination procedures are

complete.

• During extended decontamination procedures,

connect an airline to the DCC

attachment.

1. Hold breath and press the DV reset

button.

2. Release the head-harness by

pulling the harness buckles forwards.

Remove mask and let it hang from the

neck strap.

16

Page 20

3. Release the hand-wheel locking

mechanism and close the cylinder

valve(s).

4. Open the DV bypass knob to

depressurise the system, then turn the

bypass to OFF.

CONTOUR

6. AFTER USE

Contour must be cleaned and tested as

detailed in the following instructions.

6.1 CLEANING

CAUTION:

• DO NOT immerse the DV or

warning whistle in water.

• USE ONLY the specified methods

and materials. DO NOT use

bleach, solvent, detergent or

abrasive cleaners.

• Dry thoroughly, away from direct

heat and sunlight, prior to

storage.

5. Release the waist-belt buckle,

slacken shoulder straps by pulling up

metal buckles and doff the apparatus.

5.2 REMOVE CYLINDER(S)

1. Close the cylinder valve(s) and vent

the pneumatics by opening the bypass.

Unscrew cylinder valve connector handwheel(s).

CAUTION:

Ensure air is completely evacuated

from the Set before removing the highpressure hose.

2. Release cylinder band cam-lock

and remove cylinder(s) - (see Section 3 of

this Manual). Mark cylinders as empty,

store separately from charged cylinders

and return for charging.

1. Disconnect DV from the facemask.

2. Wash and disinfect the mask

thoroughly in a solution of TriGene

warm water. See following Note.

3. Rinse the mask thoroughly in clean

running water. Pay particular attention to

flushing out the exhale valve.

4. Hang mask by its neck-strap and

allow it to dry thoroughly away from direct

heat or sunlight.

5. When dry, wipe facemask seals

with TriGene

6. Polish the visor inside and out with

a clean, lint-free cloth and slacken the

head-harness, ready for use.

Note:

TriGene

and Safety Limited in 1 litre and 5 litre

containers under Article Numbers

2008247 and 2008248 respectively.

TM

disinfectant wipes.

TM

is available from Scott Health

17

TM

and

Page 21

CONTOUR

Pump dispensers are available for the

above under Article Numbers 1017672 (1

litre) and 1017670 (5 litres).

TM

TriGene

from Scott Health and Safety Limited

under Article Number 2004225 (pack of

20).

7. The harness can be sponged clean

with a mild solution of soap and warm

water. Rinse thoroughly and dry in a well

ventilated room away from direct heat and

sunlight.

8. Fully slacken cylinder band,

shoulder straps and waist-belt; and

detach the lumbar pad. Release the hose

retaining press-studs (if fitted) and

separate the pneumatics from the

harness.

9. In extreme cases, remove the

pneumatics from the harness to gain full

access for cleaning. The lumbar pad

filling is closed-cell foam that will not

absorb water. DO NOT store until

completely dry.

CAUTION:

DO NOT immerse the DV.

10. Fit the yellow cap on the DV outlet.

11. If required use a small brush (e.g.

toothbrush) and a mild solution of soap

and warm water to clean around the

locking catch and bypass knob.

12. Clean the valve body using a lint

free cloth moistened in a mild solution of

soap and warm water. DO NOT store until

completely dry.

disinfecting wipes are available

6.2 CHECK APPARATUS

1. Operate the DV locking catch and

bypass knob several times and check that

they do not stick. If either is not free

moving, attach explanatory note and

return for servicing.

2. Check that the harness webbing

and fittings are not worn or damaged; and

that buckles and fastenings are fully

operational. Apparatus with major defects

must be returned for servicing, with an

explanatory label attached.

3. Check Contour in accordance with

Section 3 - Pre-Use and Monthly Checks.

6.3 RECORD TEST DETAILS

Record test details in accordance with

local regulations within a Breathing

Apparatus Logbook (available from Scott

Health and Safety Limited under Article

Number 1034745).

Information recorded usually includes:

• Name and address of employer

responsible for the apparatus.

• Make, model number or mark

description of any distinguishing

features, sufficient to enable clear

identification.

• The date of the examination

together with the name, signature

or unique authentication mark of

the examiner.

• The condition of the apparatus and

details of any defects found and

any remedial action taken, including

any airline supply equipment used

with the apparatus.

• Cylinder air pressure.

18

Page 22

CONTOUR

6.4 STORAGE

The apparatus must be stored in a clean,

dry environment away from direct heat

and sunlight. Storage temperature should

not exceed -10°C to +40°C.

7. SCHEDULED

MAINTENANCE

7.1 MONTHLY

Test Contour in accordance with Section

3 - Pre-Use and Monthly Checks.

Record test details in the apparatus’ BA

Logbook. This record is mandatory in the

UK and most EC countries; and must be

kept up to date and available for

inspection. Please see Section 6.3 for

details.

7.2 ANNUALLY

Contour must be returned for a workshop

service annually and for a major

workshop service at six-yearly intervals.

After each workshop service, perform the

user checks detailed in Section 3 - Pre-

Use and Monthly Checks prior to

returning Contour to service.

Check that workshop service details have

been recorded in the apparatus’ BA Log.

19

Page 23

Thank you for reading this data sheet.

For pricing or for further information, please contact us at our UK Office, using the details

below.

UK Office

Keison Products,

P.O. Box 2124, Chelmsford, Essex, CM1 3UP, England.

Tel: +44 (0)330 088 0560

Fax: +44 (0)1245 808399

Email: sales@keison.co.uk

Please note - Product designs and specifications are subject to change without notice. The user is responsible for determining the

suitability of this product.

Loading...

Loading...